Abstract

The Malaysian palm oil industry is the second largest global producer of palm oil products in the world after Indonesia. However, oil palm plantation activities are typically very labour-intensive and inefficient. The rapid development of technologies, especially Industry Revolution 4.0 technologies, has brought forward a variety of advanced smart technologies and systems that can be adapted in the palm oil industry to improve the efficiency and yields in the industry as well as create better economic performance. This work aims to explore and quantify the potential of adaption and implementations of smart irrigation system in oil palm plantations. The proposed approach considers economic performance (return of investment, ROI) and water footprint (additional water usage) of smart irrigation. In addition, the analysis also includes the consideration of different server setup options and plantation sizes. The results show that smart irrigation is a feasible method to be implemented in oil palm plantations with positive economic performance for plantation with land size more than 1.5 ha. The findings also show a significant reduction in water footprint and costs in the smart irrigation system to achieve optimal moisture conditions in a plantation. This paper provides insight for oil palm stakeholders to understand the feasibility and performance of smart irrigation systems as a feasible option to transform oil palm plantations with Industrial Revolution 4.0 technologies.

1. Introduction

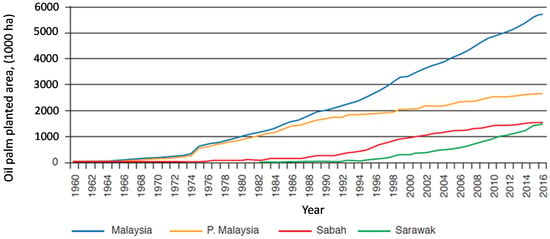

The palm oil industry has existed in Malaysia since the early British colonial era; oil palms were originally a decorative plant, but they soon grew to be a major export of the country [1]. Malaysia is currently ranked as the second largest global producer of palm oil products, and Indonesia is the leading producer. In the post-independence decade (1960s), palm oil plantations took up around 55,000 hectares (ha) of agriculture land, and the area expanded to 5.74 million ha in 2016, as shown in Figure 1. In year 2021, the plantation area has further expended to more than 5.9 million ha [2]. This shows that the palm oil industry has seen steady growth in the last decades to meet the increasing global vegetable oil demands. Palm oil products have variety use in both non-edible and edible sectors. In the non-edible sector, palm oil is used for products such as soaps, cosmetics, and biofuels. As for edible, the most common are margarine, cooking oil, and other foods [3]. The drastic increment in palm oil products demand has imposed stress on the development of the industry towards more effective and sustainable production. Due to the recent international pressure on the sustainable production of palm oil products, there are a number of initiatives being launched in Malaysia in the past decade, for example, a no burning policy, evacuation from peat soil, etc. In addition, the Malaysian government also launched a mandatory scheme of Malaysia Sustainable Palm Oil (MSPO) certification to ensure all stakeholders are fulfilling their role and responsibility in the responsible production of palm oil products. With such an initiative, the plantation which is planted in the high risk area has been evacuated. Therefore, the overall planted area decreased to 5.67 million ha in 2022 [4].

Figure 1.

Growth of Malaysian oil palm planted area [2].

Despite the huge usage of palm oil products, there are still lots of improvement potential for the industry, especially in the cultivation of oil palm, which is highly dependent on manual labour. The rapid development of technologies through the latest industrial revolution may be the key to change conventional practice in oil palm plantations. Historically, the first Industrial Revolution adapted the use of steam and water powered technologies in the 1760s, the second Industrial Revolution improved the process with the use of electrical energy in the 1870s, and the third Industrial Revolution introduced computational-aided process control and automation systems in the 1970s. Recently, many industries have been moving toward the fourth Industrial Revolution (IR 4.0), developing processes integrated with smart technologies including machine learning, artificial intelligence (AI), and internet-of-things (IoT) devices to improve overall operations efficiency [5]. The incorporation of IR 4.0 technologies could potentially reduce wastage and improve sustainability in agriculture industries. For example, a smart system using AI to make optimum decisions and robotic equipment on framing practices could improve crop yields and reduce labour dependency. Studies have shown that smart farming can improve the overall production yield by controlling water requirements and other resources [6,7]. Other studies discussed the implementation of IR 4.0 technologies such as utilising drones in plantations for monitoring and fertiliser dispersal and robotic harvesting. Table 1 summarises recent studies of IR 4.0 technology adaptation in agriculture industries.

Table 1.

Adaptation of Industry 4.0 technologies in agriculture.

Though IR 4.0 has shown much promise in improving the yield of crops, there has been little implementation of such systems in the context of the Malaysian palm oil industry, particularly in the upstream processes in oil palm plantations. Currently, many of the plantation’s activities are highly dependent on physical labour to maintain and harvest crops. The maintenance and harvesting of oil palm is a yearlong process, with the yields varying based on seasonal conditions [6]. The optimal growth and maintenance of oil palm plantations requires specific conditions. Understanding the optimum condition for an oil palm plantation and having the ability to systematically monitor and manage the site is critical for yield improvement. One study shows that each oil palm tree requires 120–150 mm of rain water monthly to maintain maximum functionality [7]. Oil palm farmers often do not have the ability to determine soil conditions such as moisture and nutrient content. In the typical plantation practices, it depends on the natural rainfall and a fixed fertiliser application cycle, which is not optimal for oil palm yield. The adaptation of a smart irrigation system would be evaluate the requirement of water and its distribution optimally. While there is evidence of improved yields and utility savings, the analysis of the economic feasibility of smart irrigation system implementation has not been well addressed. As such, implementing new state-of-the-art technology is a big risk for oil palm stakeholders, especially small and medium enterprises (SMEs). This could potentially be a barrier and result in research gaps in the transformation of the oil palm industry toward IR 4.0. Economic analysis for implementation includes estimation of investment cost, operating cost, and return on investment (ROI) analyses, which are essential to assist investors in having better understanding of the requirements of IR 4.0 technology adaptation in plantations and help them set a logical expectation for profit return. For instance, the implementation cost and performance of a cognitive radio model for agriculture to improve information transmission was evaluated to determine the effectiveness and feasibility of implementing the new technology [18]. This study presents a systematic economy feasibility analysis for comparison of alternative smart irrigation systems implementation in oil palm plantations. The economic feasibility of smart irrigation is analysed as compared to the existing oil palm agriculture irrigation practice. Due to the diverse size of oil palm plantation ranging from small-sized farmers to established plantation organisations, the study includes an analysis of the economic performance with respect to different plantation sizes. The water footprint for the smart irrigation system is also evaluated to identify the water requirement and cost. Ultimately, the aim of the paper is to evaluate the economic performance and water footprint of implementing smart irrigation systems in oil palm plantations to understand the feasibility of the technology.

2. Proposed Evaluation Methodology of Smart Irrigation Systems for Oil Palm Plantations

Based on the current best management practice in oil palm plantations, most of the activities are normally carried out through manual labour, while irrigation and fertilisation activities are usually set to a fixed period or volume. This process disregards the water and nutrient content present within the soil, which has led to wastage due to overirrigation (or underirrigation) and imbalanced nutrient content for the trees. On most occasions, the overfertilisation will eventually cause nutrients to leach to the ground water and cause environment pollution. The implementation of a smart irrigation system could potentially monitor the soil condition and control the level of irrigation for optimum water and fertiliser usage. The system may consist of various options of implementation in terms instrumentation, computational facilities, size, and coverage. Thus, a systematic evaluation of the economic feasibility of the implementation of smart irrigation should be conducted, especially for oil palm plantations which operate in various sizes and are located in tropical countries with an abundance of water resources.

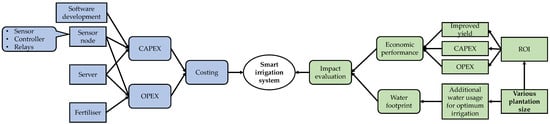

To determine the feasibility of implementing smart irrigation systems in oil palm plantations, several key data must be established before the economic assessments can be conducted. Figure 2 shows the cost calculation, economic performance, and water footprint model used to evaluate smart irrigation systems for oil palm plantations. On the left, the cost calculation for the smart irrigation system is considered as capital expenditure (CAPEX) (software development and equipment cost for sensor and server), while the operating expenditure (OPEX) includes the annual operating cost of the installed equipment and fertiliser cost. On the right, the impact of implementing the smart irrigation system is captured based on economic performance and water footprint. ROI is determined based on the estimated yield improvement of crude palm oil (CPO) due to optimal irrigation, CAPEX, and OPEX. Equation (1) shows the ROI calculation based on the gross profit per hectare of plantation, ; yield improvement, ; plantation land size, ; total OPEX, ; and total CAPEX, . Equation (2) shows the total OPEX calculation depending on the OPEX of the sensor, server, and fertiliser per hectare of land, which are , , and , respectively, and the additional OPEX due to the additional CAPEX to the upgrade server, . The additional OPEX is estimated to be at 2% of the CAPEX. Equation (3) shows the total CAPEX calculation based on the sensor and server CAPEX per hectare of land, and , and . Both Equations (1) and (2) account for a server upgrade in every third hectare of the plantation to accommodate a higher data-processing capability. ROI is calculated based on a 5-operating-year cycle for the expected life cycle of the major repair and upgrading of smart technologies [19,20,21].

Figure 2.

Cost and impact evaluation model for smart irrigation and fertilisation system.

The majority of oil palm farmers, especially SMEs, do not actively practice irrigation in the plantation, where they are highly dependent on rainfall as the primary water source for oil palms. Nonetheless, one study has shown variation of up to 24% in CPO production due to the fluctuation of rainfall in Malaysia [22]. A more recent study has also shown that changes in rainfall would have a higher impact to oil palm production as compared to other parameters, such as temperature [23]. The rainfall for optimum oil palm growth is found to be 150 mm of water [7]. Hence, the water footprint to determine the additional water requirement during a low rainfall period to achieve the optimum irrigation is calculated as shown in Equation (4), where is the monthly water requirement per hectare for optimum oil palm growth, and is the water collected from rainfall in month. The calculation would only account for the water footprint in a month in which rainfall is below the optimum water requirement.

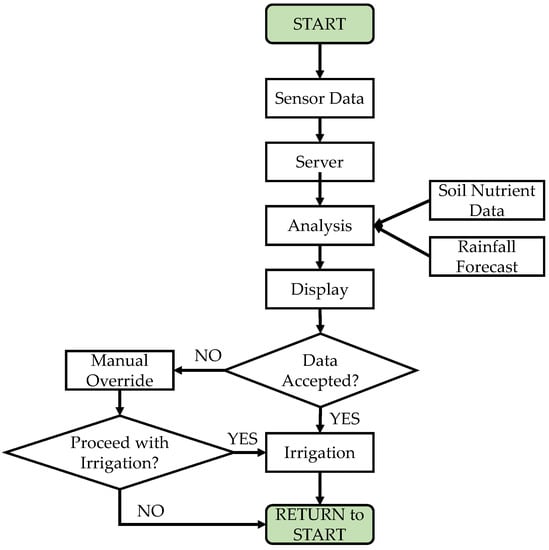

The utilisation of a smart system aims to reduce issues caused manual irrigation and fertilisation. This is achieved by using a network of sensors, controllers, and servers to determine the required amount of irrigation and fertilisation. The system works by analysing the moisture content in the soil and relaying the information to the server. Section 3 discusses the details of the smart irrigation system setup. The data are compared with forecast data and soil nutrient content data (for fertiliser application) to determine the best course of action, and the output is logged. Typically, the system consists of a digital display on a control board which allows users to see the required irrigation. If it requires fertiliser application, the system will mix the required amount of liquid N, P, and K fertiliser with the irrigation water to be distributed. A variable-rate application of NPK fertiliser on mature oil palm trees was established and designed to achieve the optimum nutrient level [24]. The flowchart below is a simplification of the smart process (see Figure 3).

Figure 3.

Smart irrigation system flow diagram.

3. Smart Irrigation System Setup

Prior to the economic estimation of a smart irrigation system, understanding of the components within the smart irrigation system and the available options is essential. In general, the system requires several components to be functional, including sensors, a transmitter, a server, and software for data analysis. Each of the components are discussed in the following section.

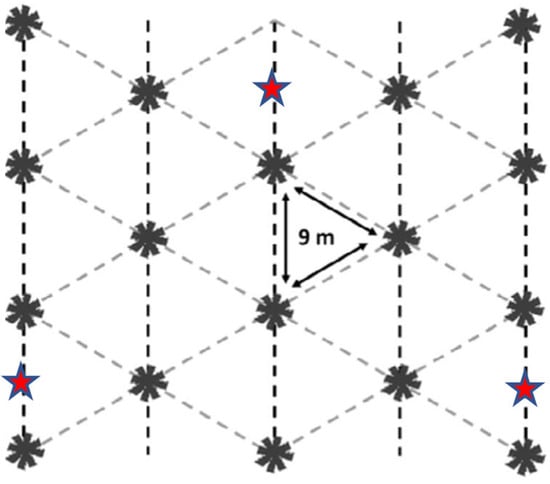

Based on the previous studies, the most common sensors for irrigation systems are moisture and temperature sensors with a controller (Raspberry Pi) to form a smart sensor node for a water irrigation system [12,14]. A total of 10 moisture sensors should be distributed evenly across 1 ha of plantation to ensure the better accuracy of the data to capture the soil condition. The system can be configured to be activated at any given time when the system detects a low moisture level or forecasted low rainfall. In contrast to soil nutrient sensors, fertiliser application has a relatively long cycle. Hence, it is recommended to have a separate setup of up to two nutrient (NPK) sensors per hectare of plantation. The measurement of soil nutrient level would be conducted prior to each fertiliser application cycle to establish the average nutrient level of the region. The position of the sensors should be placed in a zig-zag pattern to ensure optimal coverage, as shown in Figure 4.

Figure 4.

Illustration of sensor nodes’ (represented by the “red star”) positioning in oil palm plantation.

In terms of communication between the sensors and server, wireless transmission is the most economically feasible method. Wired transmission is not feasible for the huge coverage of a plantation area and may be exposed to additional risk from the plantation activities and weather. Wi-Fi and LoRa are two of the commonly available technologies for wireless transmission. Table 2 summaries the differences in the communication technologies. According to an expert in smart systems, LoRa is the preferred option for most companies that deal with large-scale smart systems as it has longer coverage and the transmission speed is sufficient for the low-bandwidth requirement of smart sensors. In addition, LoRa does not require a licensed data provider to relay the data which can be used for private servers among SMEs in the palm oil industry.

Table 2.

Comparison of Wi-Fi and LoRa [25].

A server is the facility for the data storage of the signals from all the sensors distributed across the plantation. A typical server facility consists of two types: a local server and cloud-based server. Investment into a local server requires additional costs in the installation and maintenance of the facility. A cloud-based server eliminates the requirement of additional CAPEX in the installation but would be imposed with subscription fees. In addition, a stable internet connection is required for a cloud-based server system to process the data. Despite the fact that both types of servers can be a standalone system, an industrial expert recommends that both types of servers can be employed at the same time to provide a safety net for the system to enhance the system reliability. Table 3 shows the comparison of different server setups. The server system would be configured to store the data for a set period before being overwritten to conserve storage space.

Table 3.

Comparison of different server setups.

For data analysis and display, in this work, three programmes have been identified for the smart irrigation system in oil palm plantations, namely Node-RED v3.0.2 (computation of the data), ThingsBoard v3.4.3 (data display and control), and a domain (for online access). Node-RED is a free, open-source, flow-based programming tool that was created by the IBM and is now run by the OpenJS Foundation. The programme acts as a network to connect different ‘nodes’ (the sensor relays or irrigation controls) and manage the incoming and outgoing data [26]. This is effectively the ‘brain’ of the system that executes the commands as required. ThingsBoard is a subscription-based, open-source software primarily focused on the visualisation of data. This provides an interactive display interface that shows data such as moisture content and forecast data. This display also acts as a control board in which users can access past data and input new commands for irrigation if an overwrite of the current irrigation parameters is required [27]. A domain is a network under a company or group. The function of the domain is to allow for remote access and monitoring of the plantation server. Additionally, a single domain can host multiple plantations under the same company that utilises the smart system. The data can be shared and compared by the parent company as well as other sites to improve outputs and solve any problems.

4. Cost Estimation for Smart Irrigation System

As discussed above, the implementation of a smart irrigation system involves various components with multiple choices, ranging from sensors, transmitters, servers, and software development. Detailed economic analysis is critical for stakeholders to understand the impact of the investment. This section summaries the estimated cost to set up and operate a smart irrigation system in an oil palm plantation. Table 4 and Table 5 show the breakdown of the cost estimation for the sensor and server components of the system. The cost estimation and economic performance evaluation were conducted based on two scenarios: (i) local-based server setup and (ii) a hybrid of local- and cloud-based setups. A local-based server setup is a more likely option for small- and medium-size stakeholders, especially for oil palm plantations located in rural areas. The hybrid server setup was considered in this work for established oil palm plantation organisations, which appreciate the characteristic of a hybrid server in higher security, redundancy design, and remote access capability.

Table 4.

CAPEX and OPEX for smart irrigation sensor node and fertiliser cost.

Table 5.

CAPEX and OPEX for servers.

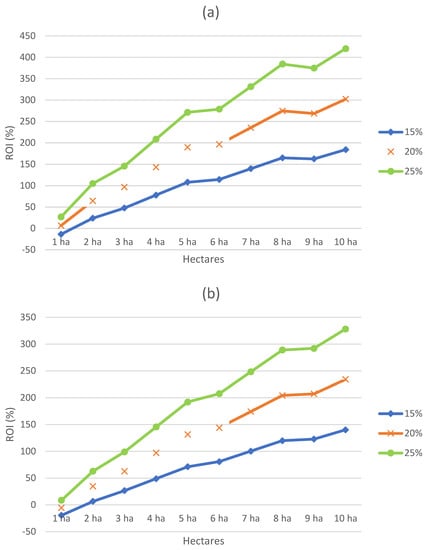

5. Investigation of Economic Performance

The implementation of smart irrigation systems is relatively new in the oil palm industry. Hence, the detailed evaluation of the economic performance of the technology is crucial prior to the adaptation. The evaluation was conducted based on the proposed Equations (1)–(3) and the tabulated information from Table 4 and Table 5. Due to the production from an oil palm plantation being highly dependent on the plantation land size, this study evaluated the economy performance with respect to ranging from 1 ha to 10 ha. The additional cost for server upgrade, , was estimated to be USD 1355.93. Previous studies show that the application of smart irrigation on various crops could result in an increase in production yield of between 15 and 25% [18,28]. Hence, sensitivity analyses based on the assumption of 15%, 20%, and 25% of yield improvement, , of CPO were considered in this study. The prices of CPO were taken to be 919 USD/t, and the baseline of CPO production was set to be at 5 t/ha/year [29]. Figure 5 shows the calculated ROI for smart irrigation systems for various sizes of oil palm plantations with different server options.

Figure 5.

ROI for smart irrigation based on 15%, 20%, and 25% yield improvement for (a) a local server and (b) a hybrid server.

For the smart irrigation system with a local server setup, the results show that it is not practical for stakeholders with small plantation sizes below 1.5 ha to invest into the technology. In the event that the oil crop production yield is at 15%, farmers with production land less than 1.5 ha in size would have a negative ROI. The minimum production yield improvement to obtain a positive ROI for 1 ha of plantation was estimated to be at approximately 18.4%. For stakeholders with larger plantation sizes, investment into smart irrigation systems was found to be economically beneficial to the production. The calculation of the CAPEX and OPEX was based on the baseline prices, which are generally for a single unit of equipment. The bulk purchase of equipment such as sensors may incur discounts which could further improve the ROI.

For a hybrid server setup, a similar result was observed where it was not found to be practical for stakeholders with small plantation sizes to adopt the smart irrigation system. In this case, approximately 1.75 ha of active production land is required to have a positive ROI if the production yield is increased by 15%. Alternatively, a minimum of 22% of yield improvement is required for a 1 ha oil palm plantation to have a positive ROI for the smart irrigation system in 5 years. Nonetheless, it is very unlikely for small stakeholders (less than 2 ha) to adopt a hybrid server setup because their limited budget and small-scale production typically does not require a high-level security system or remote monitoring and access features.

Despite the concerning economic performance of smart irrigation systems in small-size oil palm plantations, the typical small oil palm farmer in Malaysia has between 4 and 40 ha of active production land. The adaptation of a smart irrigation system would be feasible and practical to improve the production efficiency and reduce the dependency on labour. At the plantation size of 4 ha, improvement in the production yield of as low as 8.9% for a local server system and 9.8% for a hybrid server system is required to achieve a positive ROI by the end of the fifth operating year. The return would be more significant considering some of the smart irrigation system could be used for more than 5 years.

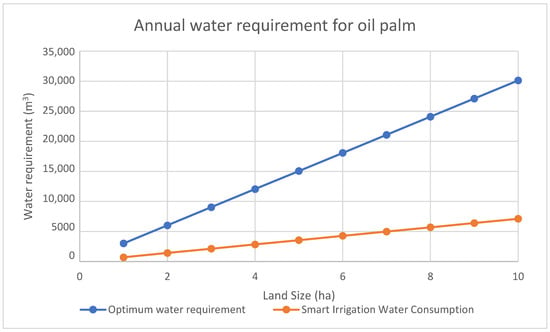

6. Impact of Smart Irrigation System on Water Footprint and Costing

Despite the positive economic evaluation as discussed in the previous section, operating a smart irrigation system would impose the additional usage of water. This translates to a larger water footprint and higher costs for those oil palm farmers who depend on rainwater for irrigation purposes. Hence, understanding of the impact of the additional water footprint and cost is essential to transform the industry practices. One study shows that an oil palm tree requires up to 150 mm of water for optimal growth, which is equivalent to approximately 251 m3/month/ha of water [7]. This translates to an additional water cost of 56.57 USD/month, based on the estate water tariff in Selangor, Malaysia of 0.23 USD/m3 or a minimum charge of 2.71 USD/month, if the water requirement is solely supported by irrigation [30]. However, the water usage footprint is typically offset by rainwater due to the strategic location of Malaysia in a tropical region. Table 6 shows the estimated water footprint and cost based on the average precipitation in Malaysia in 2021 [31].

Table 6.

Monthly water bill using rainwater savings [31].

Despite the relatively high rainfall, the data show that the majority of the months (10 out of 12) would still require irrigation to achieve an optimum condition for oil palm growth. The additional water footprint for irrigation was found to be approximately 680 m3/ha/y, with an estimated cost of 160.95 USD/ha/y. In comparison with the various plantation sizes, the amount of water used for irrigation can be significantly reduced to minimise the environmental footprint and cost, as shown in Figure 6.

Figure 6.

Annual water requirement for smart irrigation system for various plantation sizes.

7. Conclusions and Future Works

This study investigated the feasibility of smart irrigation in the palm oil industry. The results show that smart irrigation is a feasible investment despite the high CAPEX. An analysis was conducted to show that a minimum 1.5 ha and 1.75 ha plantation size is required to achieve a positive ROI in 5 years for a local server and hybrid server setup, respectively. Achieving optimum water usage for an oil palm plantation via a smart irrigation system, with an ROI exceeding 400% (as compared to current oil palm agriculture practice), may be possible for stakeholders with more than 9.5 ha of plantation land. The analysis of water footprint and the impact on cost caused by utilising smart irrigation system shows that oil palm plantations in Malaysia require 680 m3/ha/y of water at the estimated cost of 160.95 USD/ha/y to achieve the optimal soil moisture content.

Note that there are various assumptions in the presented work due to the limited information and uncertainties of the scenarios. For instance, the calculation of CAPEX and OPEX can be further refined through the consideration of bulk purchase costs based on the plantation size. More accurate data on the impact of smart irrigation to the production yield could also enhance the accuracy of the results. Currently, there are not sufficient data to accurately quantify the impact of smart irrigation in the oil palm industry due to the limited implementation. Nonetheless, this work provides a baseline of economic performance and water footprint for smart irrigation system implementation in oil palm plantation sites. In terms of the sustainability aspect, the current work could be further developed to consider other environmental impact aspects, including carbon footprint, organic and inorganic fertiliser options, and the integration of sustainable energy generation.

Author Contributions

Conceptualisation, A.C. and C.H.L.; data curation, A.C.; formal analysis, A.C. and C.H.L.; funding acquisition, C.H.L.; methodology, A.C. and C.H.L.; project administration, C.H.L.; resources, A.C.; supervision, C.H.L. and D.K.S.N.; validation, C.H.L. and D.K.S.N.; visualisation, A.C.; writing—original draft, A.C.; writing—review and editing, C.H.L. and D.K.S.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| additional CAPEX to upgrade server (USD) | |

| AI | artificial intelligence |

| CAPEX | capital expenditure (USD) |

| CAPEX of sensor (USD) | |

| CAPEX of server (USD) | |

| CPO | crude palm oil |

| gross profit per hectare of plantation | |

| Industry 4.0 | the fourth Industrial Revolution |

| IoT | internet of things |

| LoRa | long-range radio |

| OPEX | operating expenditure (USD) |

| OPEX of fertiliser (USD) | |

| OPEX of sensor (USD) | |

| OPEX of server (USD) | |

| monthly water requirement per hectare for optimum oil palm growth (m3) | |

| plantation land size, ha | |

| water collected from rainfall in month (m3) | |

| ROI | return on investment |

| SME | small and medium enterprises |

| total CAPEX (USD) | |

| total OPEX (USD) | |

| yield improvement |

References

- Wardhani, R.; Rahadian, Y. Sustainability strategy of Indonesian and Malaysian palm oil industry: A qualitative analysis. Sustain. Account. Manag. Policy J. 2021, 12, 1077–1107. [Google Scholar] [CrossRef]

- Nambiappan, B.; Ismail, A.; Hashim, N.; Ismail, N.; Shahari, D.N.; Idris, N.A.N.; Omar, N.; Salleh, K.M.; Hassan, N.A.; Kushairi, A. Malaysia: 100 Years of Resilient Palm Oil Economic Performance. J. Oil Palm. Res. 2018, 30, 13–25. [Google Scholar] [CrossRef]

- Ramadhani, T.N.; Santoso, R.P. Competitiveness analyses of Indonesian and Malaysian palm oil exports. Econ. J. Emerg. Mark. 2019, 11, 46–58. [Google Scholar] [CrossRef]

- MPBO. Oil Palm Planted Area 2022. Malaysian Palm Oil Board. Available online: https://bepi.mpob.gov.my/images/area/2022/Area_summary2022.pdf (accessed on 20 April 2023).

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Virk, A.L.; Noor, M.A.; Fiaz, S.; Hussain, S.; Hussain, H.A.; Rehman, M.; Ahsan, M.; Ma, W. Smart Farming: An Overview. Smart Village Technol. 2020, 17, 191–201. [Google Scholar] [CrossRef]

- Saiz-Rubio, V.; Rovira-Más, F. From Smart Farming towards Agriculture 5.0: A Review on Crop Data Management. Agronomy 2020, 10, 207. [Google Scholar] [CrossRef]

- Xiong, Y.; Ge, Y.; Grimstad, L.; From, P.J. An autonomous strawberry-harvesting robot: Design, development, integration, and field evaluation. J. Field Robot. 2020, 23, 202–224. [Google Scholar] [CrossRef]

- Lehnert, C.; McCool, C.; Sa, I.; Perez, T. Performance improvements of a sweet pepper harvesting robot in protected cropping environments. J. Field Robot. 2020, 37, 1197–1223. [Google Scholar] [CrossRef]

- Ahirwar, S.; Swarnkar, R.; Bhukya, S.; Namwade, G. Application of Drone in Agriculture. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 2500–2505. [Google Scholar] [CrossRef]

- Mogili, U.M.R.; Deepak, B.B.V.L. Review on Application of Drone Systems in Precision Agriculture. Procedia Comput. Sci. 2018, 133, 502–509. [Google Scholar] [CrossRef]

- Froiz-Míguez, I.; Lopes-Iturri, P.; Fraga-Lamas, P.; Celaya-Echarri, M.; Blanco-Novoa, Ó.; Azpilicueta, L.; Falcone, F.; Fernández-Caramés, T.M. Design, Implementation, and Empirical Validation of an IoT Smart Irrigation System for Fog Computing Applications Based on LoRa and LoRaWAN Sensor Nodes. Sensors 2020, 20, 6865. [Google Scholar] [CrossRef] [PubMed]

- Mason, B.; Rufí-Salís, M.; Parada, F.; Gabarrell, X.; Gruden, C. Intelligent urban irrigation systems: Saving water and maintaining crop yields. Agric. Water Manag. 2019, 226, 105812. [Google Scholar] [CrossRef]

- Khan, R.; Ali, I.; Zakarya, M.; Ahmad, M.; Imran, M.; Shoaib, M. Technology-Assisted Decision Support System for Efficient Water Utilization: A Real-Time Testbed for Irrigation Using Wireless Sensor Networks. IEEE Access 2018, 6, 25686–25697. [Google Scholar] [CrossRef]

- Bhattacharjee, D.; Prakash, O.; Islam, H. Smart Fertilizer Dispensary System for Automated Drip irrigation. In Proceedings of the 2018 3rd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, India, 18–19 May 2018; pp. 1458–1462. [Google Scholar] [CrossRef]

- Prabha, R.; Sinitambirivoutin, E.; Passelaigue, F.; Ramesh, M.V. Design and Development of an IoT Based Smart Irrigation and Fertilization System for Chilli Farming. In Proceedings of the 2018 International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 22–24 March 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Mudliar, R.R.; Mamun, K.A.; Islam, F.R.; Cirrincione, M. An Approach of Reviving Papaya Production in Fiji using Renewable Energy Powered Optimised Smart Irrigation. In Proceedings of the 2017 4th Asia-Pacific World Congress on Computer Science and Engineering (APWC on CSE), Mana Island, Fiji, 11–13 December 2017; pp. 232–238. [Google Scholar] [CrossRef]

- Teekaraman, Y.; Manoharan, H. Implementation of Cognitive Radio Model for Agricultureal Application s using Hybrid Algorithms. Wirel. Pers. Commun. 2022, 127, 505–522. [Google Scholar] [CrossRef]

- Pratt, G. How Long will my Gas Sensor Last? Crowcon Detection Instrument Ltd. Available online: https://www.crowcon.com/blog/how-long-will-my-gas-sensor-last/ (accessed on 20 April 2023).

- BAPI. Humidity Transmitter Service Life. Available online: https://www.bapihvac.com/wp-content/uploads/Humidity_Transmitter_Service_Life.pdf (accessed on 20 April 2023).

- Repas, R. Sensor Sence: Humidity Sensors. MachineDesing. Available online: https://www.machinedesign.com/news/article/21814913/sensor-sense-humidity-sensors (accessed on 20 April 2023).

- Chow, C.S. The effects of season, rainfall and cycle on oil palm yield in Malaysia. ELAEIS Palm Oil Res. Inst. Malays. 1991, 4, 32–43. [Google Scholar]

- Ahmed, A.; Ishak, M.Y.; Uddin, M.K.; Samad, M.Y.A.; Muktar, S.; Danhassan, S.S. Effects of Some Weather Parameters on Oil Palm Production in the Peninsular Malaysia. Preprint. Org. 2021, 2021, 060456. [Google Scholar] [CrossRef]

- Yamin, M.; Ismail, W.I.W.; Aziz, S.A.; Kassim, M.S.M.; Akbar, F.N.; Ibrahim, M. Design consideration of variable rate liquid fertilizer applictor for mature oil palm trees. Precis. Agric. 2022, 23, 1413–1448. [Google Scholar] [CrossRef]

- Niya, S.R.; Jha, S.S.; Bocek, T.; Stiller, B. Design and implementation of an automated and decentralized pollution monitoring system with blockchains, smart contracts, and LoRaWAN. In Proceedings of the NOMS 2018–2018 IEEE/IFIP Network Operations and Management Symposium, Taipei, China, 23–27 April 2018; pp. 1–4. [Google Scholar] [CrossRef]

- OpenJS Foundation & Contributors. Node-RED. Available online: https://nodered.org/about/ (accessed on 1 August 2022).

- ThingsBoard. What is ThingsBoard? Available online: https://thingsboard.io/docs/getting-started-guides/what-is-thingsboard/ (accessed on 1 August 2022).

- Panigrahi, P.; Raychaudhuri, S.; Thakur, A.K.; Nayak, A.K.; Sahu, P.; Ambast, S.K. Automatic drip irrigation scheduling effects on yield and water productivity of banana. Sci. Hortic. 2019, 257, 108677. [Google Scholar] [CrossRef]

- MPOC. The Oil Palm Tree. Malaysian Palm Oil Council. Available online: https://mpoc.org.my/the-oil-palm-tree/ (accessed on 4 July 2022).

- Air Selangor. Water Tariff Information. Available online: https://www2.airselangor.com/my-water-smart/water-tariff-information (accessed on 4 August 2022).

- Weather & Climate. Average Monthly Rainfall and Snow in Kuala Lumpur (Kuala Lumpur Federal Territory), Malaysia (Millimeter); World Weather & Climate Information: Kuala-Lumpur, Malaysia; Available online: https://weather-and-climate.com/average-monthly-precipitation-Rainfall,Kuala-Lumpur,Malaysia (accessed on 4 August 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).