Numerical Parametric Study and Design of Pultruded GFRP Composite Channel Columns

Abstract

1. Introduction

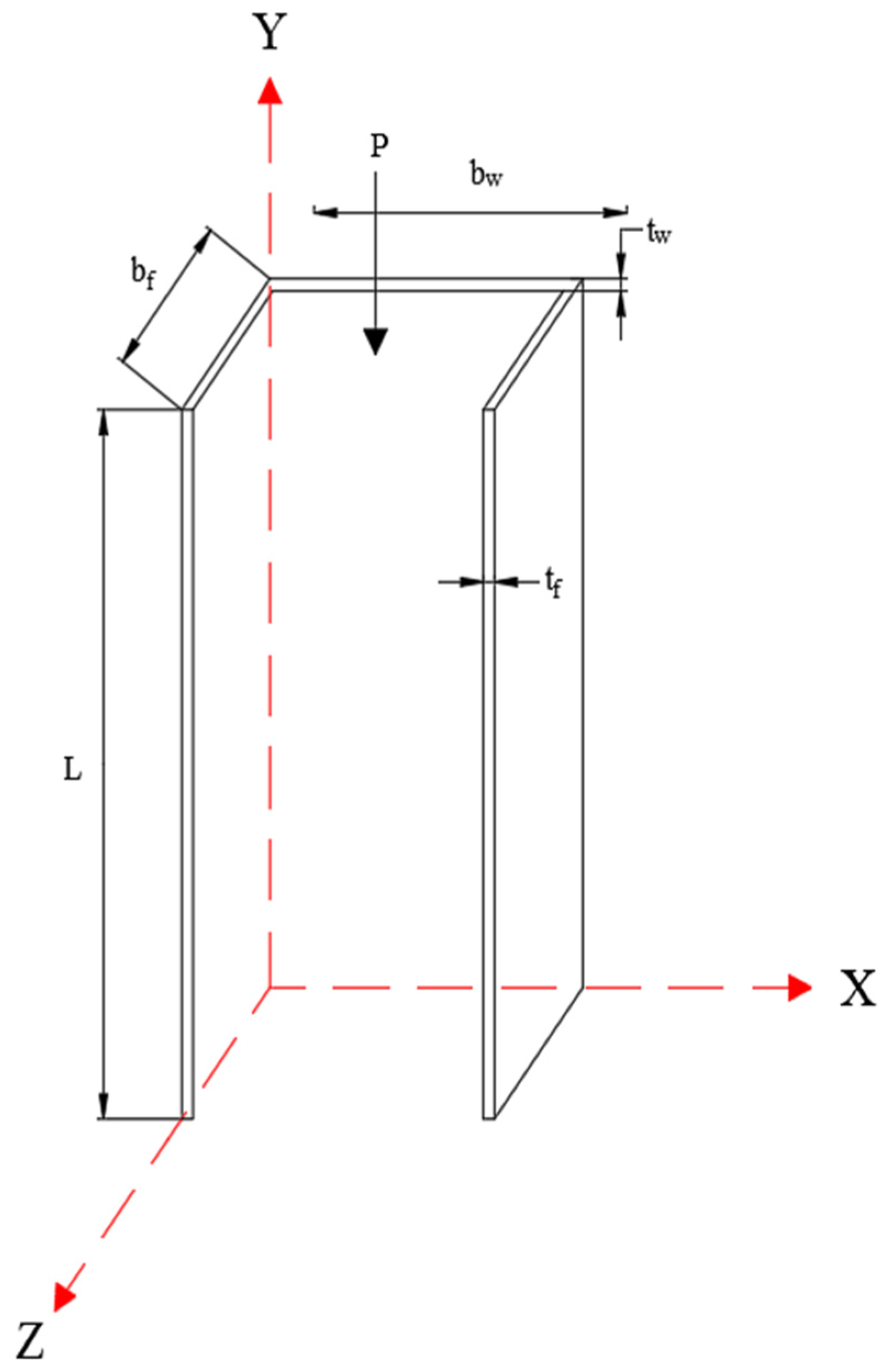

2. Geometry of Column

3. Numerical Analysis

3.1. General

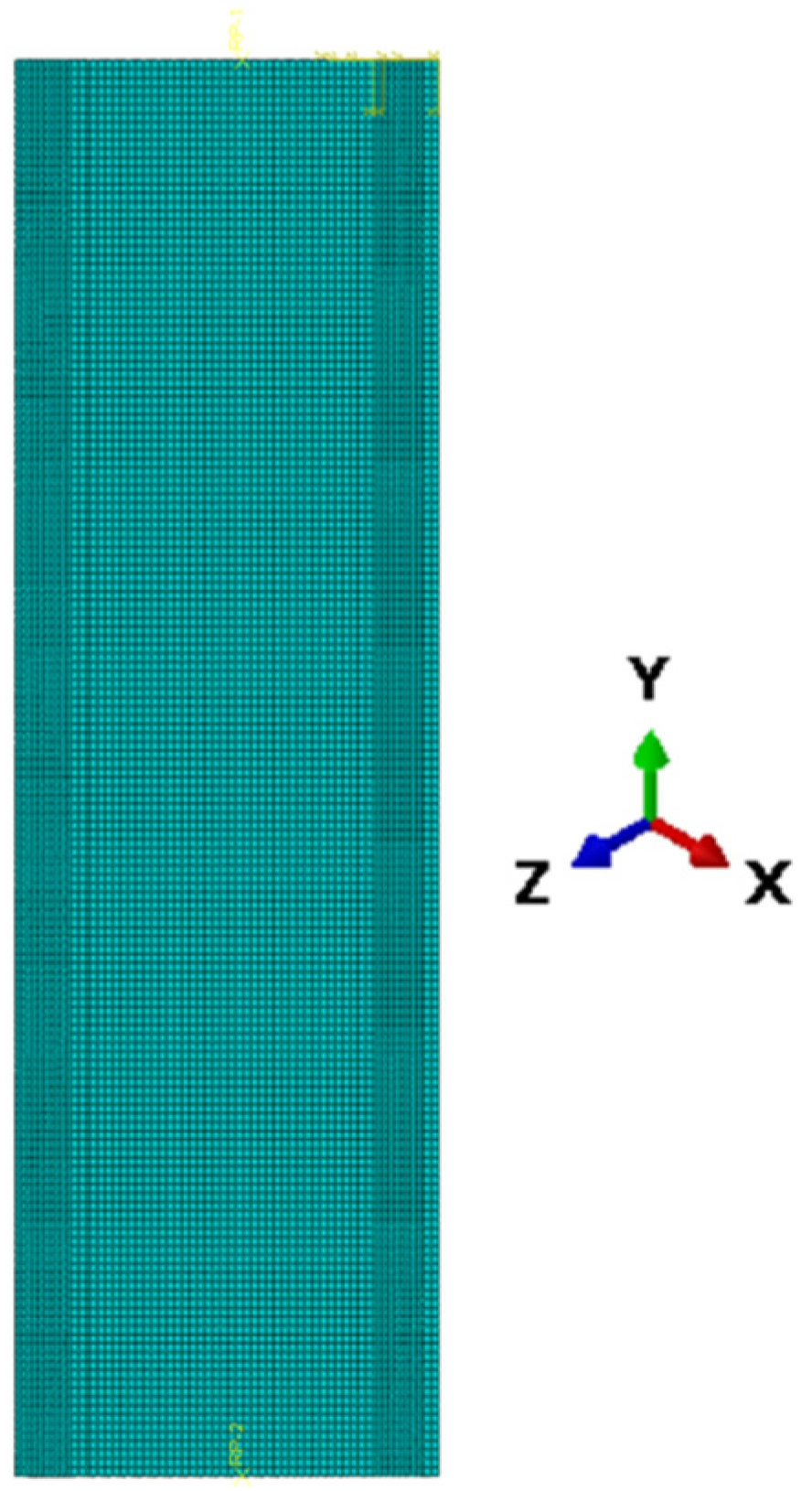

3.2. Element Type and Mesh

3.3. Material Properties

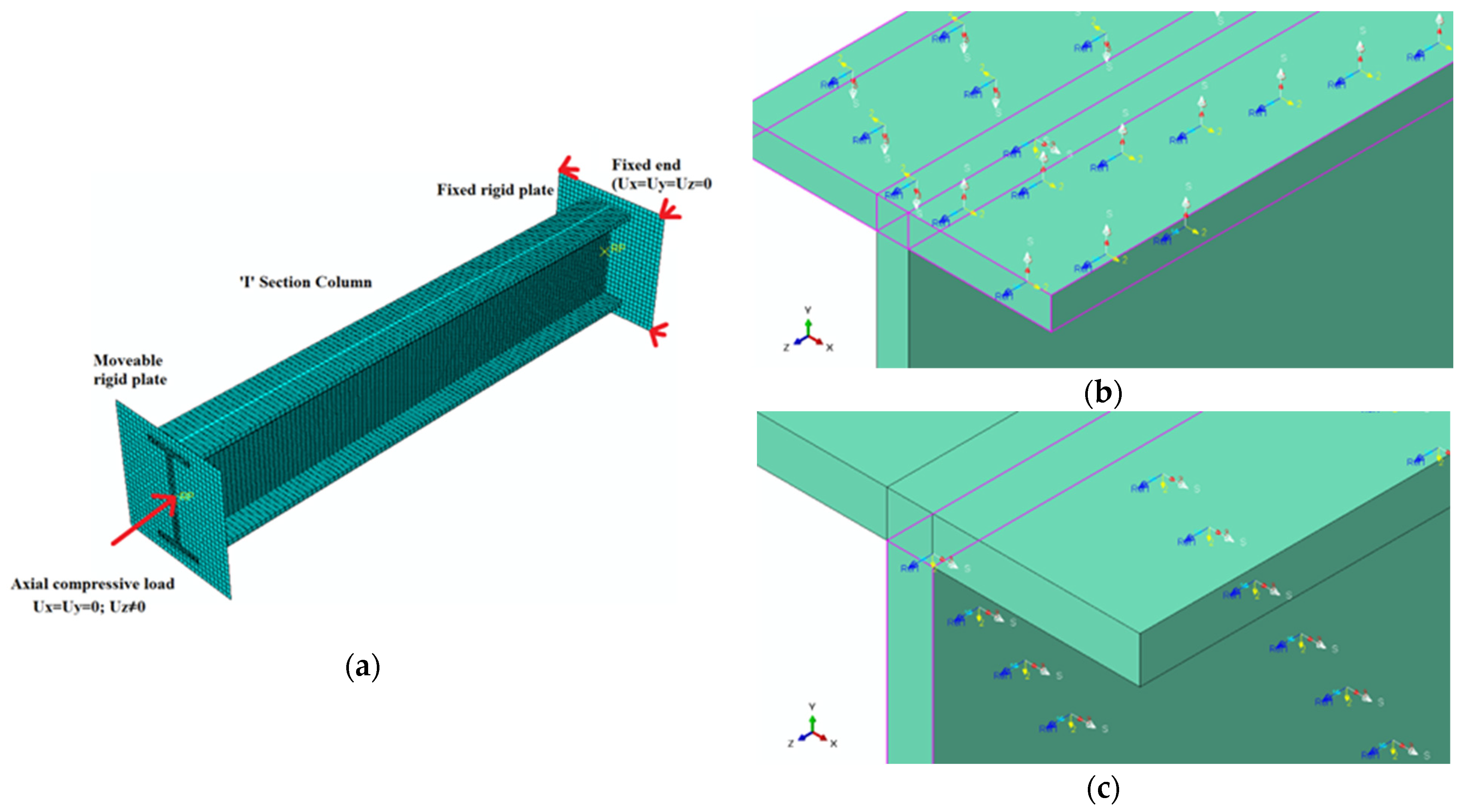

3.4. Loading and Boundary Conditions

3.5. Geometrical Imperfections

3.6. Elastic and Nonlinear Analysis

4. Parametric Study

5. Results and Discussion

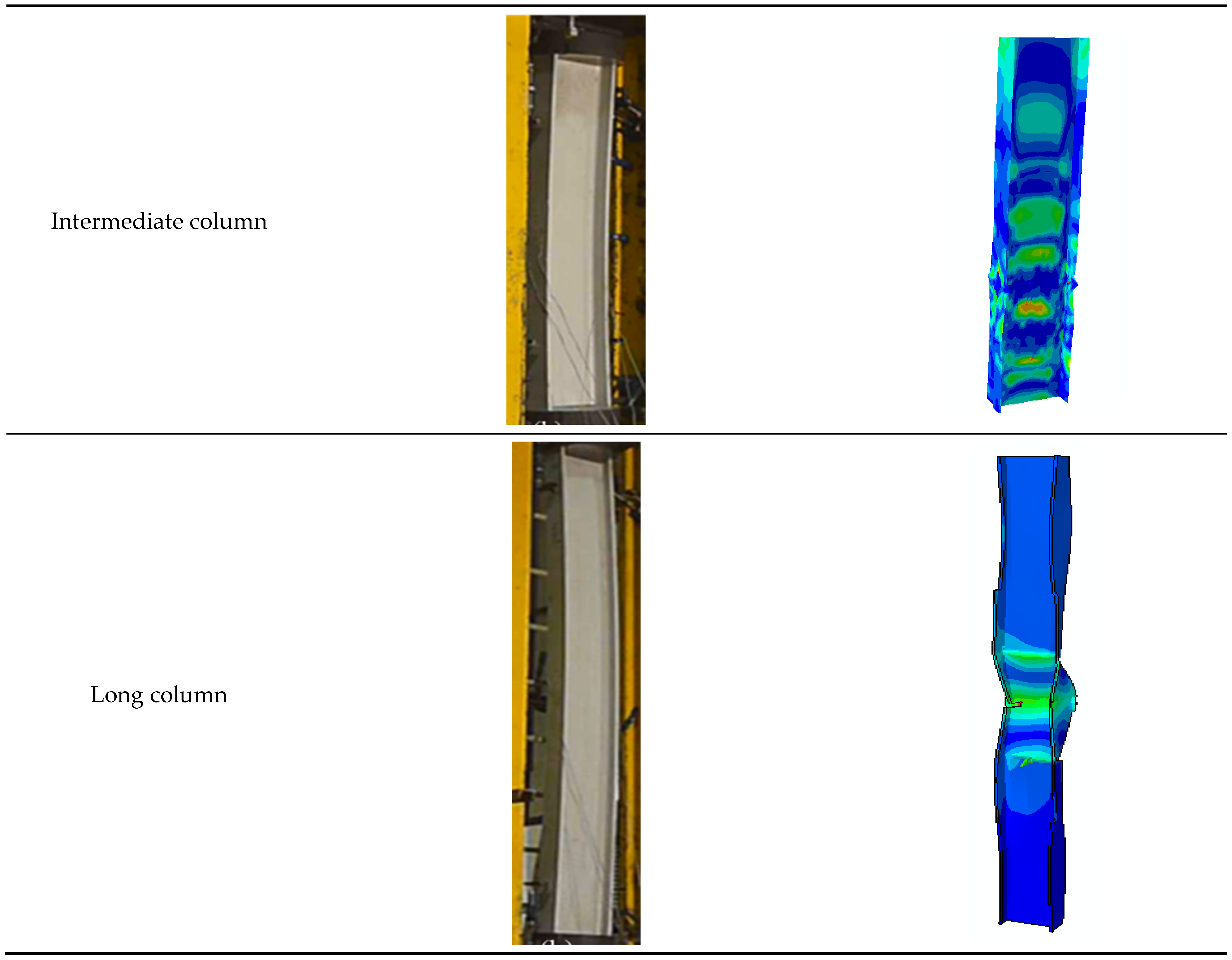

5.1. Validation of FEMs

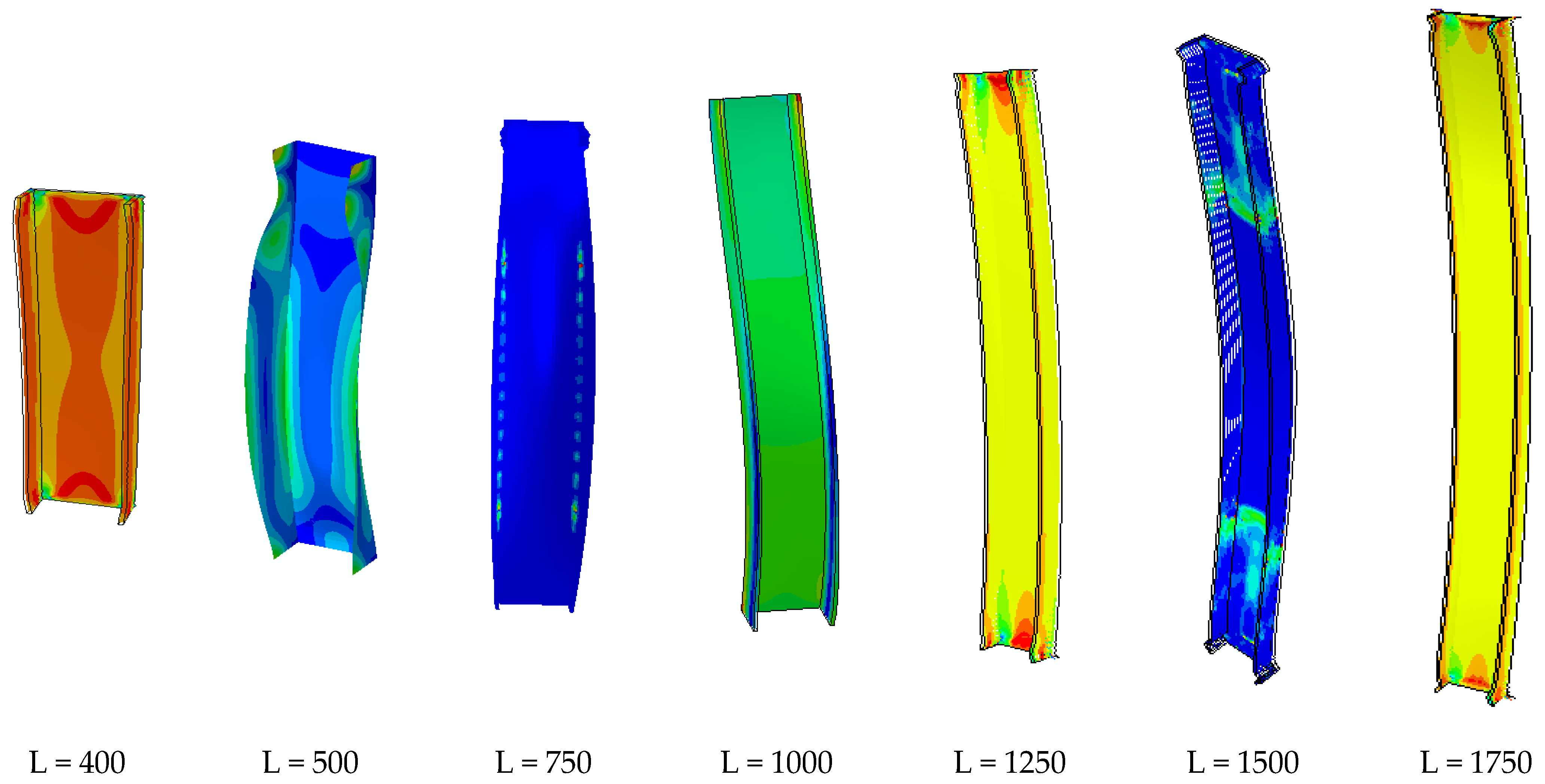

5.2. Behaviour and Deformed Shapes

5.3. Reliability Analysis

6. Strength Equations

6.1. DSM Method [42]

6.2. ASCE Pre-Standard [41]

6.3. Cardoso et al.’s [37] Design Procedure

6.4. Italian Code Approach [43]

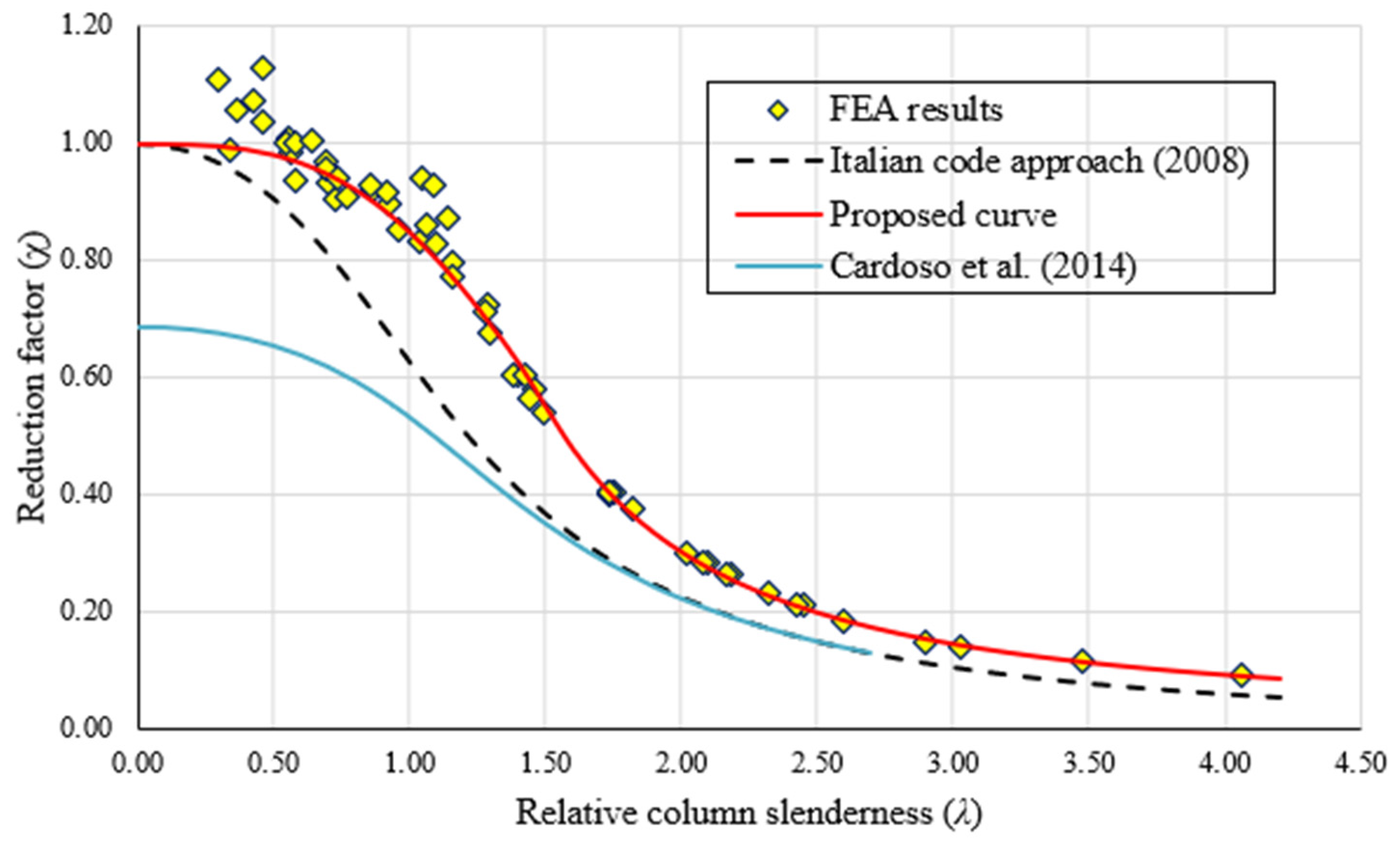

7. Assessment of Current Strength Predictions in the Literature

8. Assessment of Proposed Design Formulation

9. Conclusions

- The proposed FE modelling procedure replicates the experimental work to determine the critical buckling load and behavior of GFRP composite channel columns with high accuracy.

- As expected, all of the short GFRP composite channel columns are found to fail under local buckling with significant post-buckling strength. Similarly, all of the slender GFRP composite channel columns fail overall axial buckling.

- The axial compressive strength predicted by the DSM is conservative, with the mean and COV for predictions being 1.18 and 0.108, respectively. The conservatism is greater in the low slenderness range. Overall, the DSM predictions are reasonably accurate in estimating the compressive strength of the GFRP composite channel columns.

- The ASCE pre-standard axial compressive strength predictions provide a better average over the other methods, but marginally failed to reach the target reliability index of 3.50.

- The design strength equation proposed by Cardoso et al. for pultruded GFRP columns and by the Italian guidelines exhibits significantly conservative predictions for the low and medium relative column slenderness. Overall, they conservatively predicted the strength, with a mean of 1.36 and 1.33 and with a reliability index much greater than target reliability index of 3.5. However, it appeared to be incapable of reasonably predicting the strength of the pultruded GFRP channel columns which are precluded from crushing failure and interactive local–global buckling.

- A new design proposal was developed considering the geometric imperfections and the material failure criterion and performed better than existing design methods. The obtained predictions were in very good agreement by producing a mean of 1.05, with a COV. of 0.065. It is proved that the newly developed design equation is able to provide accurate and reliable predictions. Due to its relatively straightforward, simple, and familiar form, the proposed design equation is suited for the structural design applications of a wide range of FRP sections in the market.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| L | column length | ρp | plate reduction factor |

| bw | web width | η | flange-to-web width ratio |

| bf | flange width | kcr | local buckling coefficient |

| tf, tw | web and flange thickness | Nc,Rd | ultimate load |

| Fcrl | critical local buckling stress | Nc,Rd1 | compressive squash load (accounting for material strength) |

| Fcrg | critical global buckling stress | Nc,Rd2 | critical load (accounting for instability effects) |

| Fc | material crushing strength | fc | longitudinal compressive strength |

| Ee | Euler critical buckling stress | NLRd | local buckling load |

| ηs | shear form factor | Pcr-FEM | axial buckling load |

| Pn | nominal compressive strength | Pcr-Ita | axial load predicted according to Italian guidelines |

| χ | reduction factor | Pcr-ASCE | axial load predicted according to American pre-standard for load and resistance factor. |

| χp | plate strength reduction factor | Pcr-DSM | axial load predicted according to direct strength method |

| χc | column strength reduction factor | Pcr-ca | axial load predicted according to Cardoso |

| λ | column relative slenderness | Pcr-Prop. | axial load predicted according to proposed design equation |

| λp | plate relative slenderness | υLT, υTL | lamina major and minor Poisson’s ratio |

| αpL | plate imperfection factor in the longitudinal direction | EL, ET, GLT | longitudinal, transverse and shear modulus of elasticity |

| αc | column imperfection factor | Gft, Gfc | fracture energy associated to tensile and compressive failure mode |

References

- Dong, Z.; Sun, Y.; Zhu, H.; Wu, G.; Yan, Z.; Lu, F. Behavior and modeling of seawater sea-sand coral aggregate concrete-filled BFRP tubular columns under eccentric compression. Compos. Struct. 2022, 288, 115392. [Google Scholar] [CrossRef]

- Valsa Ipe, T.; Sharada Bai, H.; Manjula Vani, K.; Zafar Iqbal, M.M. Flexural Behavior of Cold-Formed Steel Concrete Composite Beams. Steel Compos. Struct. 2013, 14, 105–120. [Google Scholar] [CrossRef]

- Pajand, M.R.; Masoodi, A.R.; Alepaighambar, A. Lateral-torsional buckling of functionally graded tapered I-beams considering lateral bracing. Steel Compos. Struct. 2018, 4, 403–414. [Google Scholar]

- Bas, S. Lateral torsional buckling of steel I-beams: Effect of initial geometric imperfection. Steel Compos. Struct. 2019, 5, 483–492. [Google Scholar]

- Dar, M.A.; Subramanian, M.; Anbarasu, M.; Dar, A.R.; Lim, J.B.P. Structural performance of cold-formed steel composite beams. Steel Compos. Struct. 2018, 5, 545–554. [Google Scholar]

- Shahabi, R.; Narmashiri, K. Effects of deficiency location on CFRP strengthening of steel CHS short columns. Steel Compos. Struct. 2018, 3, 267–278. [Google Scholar]

- Russo, S. A Review on Buckling Collapses of Simple and Complex Columns Made from Pultruded FRP Material. Compos. Mech. Comput. Appl. Int. J. 2017, 8, 1–34. [Google Scholar] [CrossRef]

- European Structural Polymeric Composites Group. Structural Design of Polymer Composites EUROCOMP Design Code and Handbook; Clarke, J.L., Ed.; The European Structural Polymeric Composites Group: London, UK, 1996. [Google Scholar]

- EN 13706; Reinforced Plastics Composites—Specifications for Pultruded Profiles. European Committee for Standardisation: Brussels, Belgium, 2002.

- Bedford Reinforced Plastics Inc. Bedford Design Guide; Bedford Reinforced Plastics Inc.: Bedford, PA, USA, 2010. [Google Scholar]

- Creative Pultrusions Inc. The Pultex Pultrusion Global Design Manual of Standard and Custom Fiber Reinforced Polymer Structural Profiles; Creative Pultrusions Inc.: Pleasantville, PA, USA, 2004. [Google Scholar]

- Barbero, E.; Tomblin, J. A Phenomenological Design Equation for FRP Columns with Interaction between Local and Global Buckling. Thin-Wall. Struct. 1994, 18, 117–131. [Google Scholar] [CrossRef]

- Zureick, A.; Scott, D. Short-Term Behavior and Design of Fiber-Reinforced Polymeric Slender Members under Axial Compression. J. Compos. Cons. 1997, 1, 140–149. [Google Scholar] [CrossRef]

- Barbero, E.J. Prediction of Compression Strength of Unidirectional Polymer Matrix Composites. J. Compos. Mater. 1998, 32, 483–502. [Google Scholar] [CrossRef]

- Barbero, E.J. Prediction of Buckling-Mode Interaction in Composite Columns. Mech. Compos. Mater. Struct. 2000, 7, 269–284. [Google Scholar] [CrossRef]

- Hashem, Z.A.; Yuan, R.L. Short vs. Long Column Behavior of Pultruded Glass-Fiber Reinforced Polymer Composites. Const. Build. Mater. 2001, 15, 369–378. [Google Scholar] [CrossRef]

- Kollár, L.P. Local Buckling of Fiber Reinforced Plastic Composite Structural Members with Open and Closed Cross Sections. J. Struct. Eng. 2003, 129, 1503–1513. [Google Scholar] [CrossRef]

- Qiao, P.; Zou, G. Local Buckling of Composite Fiber-Reinforced Plastic Wide-Flange Sections. J. Struct. Eng. 2003, 129, 125–129. [Google Scholar] [CrossRef]

- Puente, I.; Insausti, A.; Azkune, M. Buckling of GFRP Columns: An Empirical Approach to Design. J. Compos. Constr. 2006, 10, 529–537. [Google Scholar] [CrossRef]

- Turvey, G.J.; Zhang, Y. A Computational and Experimental Analysis of the Buckling, Postbuckling and Initial Failure of Pultruded GRP Columns. Comput. Struct. 2006, 84, 1527–1537. [Google Scholar] [CrossRef]

- Bai, Y.; Keller, T. Shear Failure of Pultruded Fiber-Reinforced Polymer Composites under Axial Compression. J. Compos. Constr 2009, 13, 234–242. [Google Scholar] [CrossRef]

- Vanevenhoven, L.M.; Shield, C.K.; Bank, L.C. LRFD Factors for Pultruded Wide-Flange Columns. J. Struct. Eng. 2010, 136, 554–564. [Google Scholar] [CrossRef]

- Cardoso, D.C.T. Compressive Strength of Pultruded Glass-Fiber Reinforced Polymer (GFRP) Columns. Ph.D. Dissertation, University of Pittsburgh, Pittsburgh, PA, USA, 2014. [Google Scholar]

- Boscato, G.; Casalegno, C.; Russo, S. Performance of Built-up Columns Made by Pultruded FRP Material. Compos. Struct. 2015, 121, 46–63. [Google Scholar] [CrossRef]

- Russo, S. Shear and Local Effects in All-FRP Bolted Built-up Columns. Adv. Struct. Eng. 2015, 18, 1227–1240. [Google Scholar] [CrossRef]

- Russo, S. Bucklings Interactions in Columns Made by Built-up Thin, Open, Pultruded FRP Shapes. J. Reinf. Plast. Compos. 2015, 34, 972–988. [Google Scholar] [CrossRef]

- Minghini, F.; Tullini, N.; Ascione, F.; Feo, L. Numerical Failure Analysis of Built-up Columns Composed of Closely Spaced Pultruded FRP Channels. Compos. Struct. 2019, 207, 478–487. [Google Scholar] [CrossRef]

- Higgoda, T.M.; Elchalakani, M.; Kimiaei, M.; Wittek, A.; Yang, B. Experimental and Numerical Investigation of Pultruded GFRP Circular Hollow Tubular Columns under Concentric and Eccentric Loading. Compos. Struct. 2023, 304, 116427. [Google Scholar] [CrossRef]

- Kasiviswanathan, M.; Anbarasu, M. Numerical Study and Design Rule for Axial Capacities of Pultruded GFRP Hollow Columns. Structures 2022, 39, 253–265. [Google Scholar] [CrossRef]

- Zhan, Y.; Wu, G. Determination of Critical Loads for Global Buckling of Axially Loaded Pultruded Fiber-Reinforced Polymer Members with Doubly Symmetric Cross Sections. Adv. Struct. Eng. 2018, 21, 1911–1922. [Google Scholar] [CrossRef]

- Zhan, Y.; Wu, G. Prediction of Global Buckling Loads of Doubly Symmetric Pultruded FRP Columns Subjected to Concentric Compression. ZAMM—J. Appl. Math. Mech. 2019, 99, e201700277. [Google Scholar] [CrossRef]

- Kulkarni, V.; Jaiswal, M.; Ramtekkar, G. Numerical and Analytical Study on Axial Compression Behaviour of Pultruded GFRP Members. Adv. Mater. Lett. 2020, 11, 1–5. [Google Scholar] [CrossRef]

- ABAQUS. Standard User’s Manual; Version 6.11-1; Hibbitt, K.a.S., Inc.: Williston, VT, USA, 2011; Volumes 1–3. [Google Scholar]

- Nunes, F.; Silvestre, N.; Correia, J.R. Structural Behaviour of Hybrid FRP Pultruded Columns. Part 2: Numerical Study. Compos. Struct. 2016, 139, 304–319. [Google Scholar] [CrossRef]

- Czapski, P.; Kubiak, T. Numerical and Experimental Investigations of the Post-Buckling Behaviour of Square Cross-Section Composite Tubes. Compos. Struct. 2015, 132, 1160–1167. [Google Scholar] [CrossRef]

- Fierline Design Manual; Version 2.0, Denmark; Charlton & Jenrick Ltd.: Telford, UK, 2002.

- Cardoso, D.C.T.; Harries, K.A.; de Batista, E. Compressive Strength Equation for GFRP Square Tube Columns. Compos. Part B Eng. 2014, 59, 1–11. [Google Scholar] [CrossRef]

- Correia, M.M.; Nunes, F.; Correia, J.R.; Silvestre, N. Buckling Behavior and Failure of Hybrid Fiber-Reinforced Polymer Pultruded Short Columns. J. Compos. Constr. 2013, 17, 463–475. [Google Scholar] [CrossRef]

- SEI/ASCE 8-02; Specification for the Design of Cold-Formed Stainless Steel Structural Members. American Society of Civil Engineers: Reston, VA, USA, 2002.

- AISI-S100-07; North American Specification (NAS) for the Design of Cold-Formed Steel Structural Members. American Iron and Steel Institute (AISI): Washington, DC, USA, 2007.

- ASCE. Pre-Standard for Load and Resistance Factor Design (LRFD) of Pultruded Fiber Reinforced Polymer (FRP) Structures; ASCE: Reston, VA, USA, 2010. [Google Scholar]

- Monteiro, A.C.L.; Malite, M. Behavior and Design of Concentric and Eccentrically Loaded Pultruded GFRP Angle Columns. Thin-Wall. Struct. 2021, 161, 107428. [Google Scholar] [CrossRef]

- CNR-DT 205/2007. Guide for the Design and Construction of Structures Made of FRP Pultruded Elements. CNR-Advisory Committee on Technical Recommendations for Construction: Rome, Italy, 2008.

- Timoshenko, S.P.; Gere, J.M. Theory of Elastic Stability; McGraw-Hill Book: New York, NY, USA, 1961. [Google Scholar]

- Anbarasu, M.; Dar, M.A. Improved Design Procedure for Battened Cold-Formed Steel Built-up Columns Composed of Lipped Angles. J. Constr. Steel Res. 2020, 164, 105781. [Google Scholar] [CrossRef]

- Anbarasu, M.; Kasiviswanathan, M. A Simplified Design Method for Lateral–Torsional Buckling of GFRP Pultruded I-Beams. Arab. J. Sci. Eng. 2021, 46, 5047–5060. [Google Scholar] [CrossRef]

- Kasiviswanathan, M.; Anbarasu, M. Simplified approach to estimate the lateral torsional buckling of GFRP channel beams. Struct. Eng. Mech. 2021, 77, 523–533. [Google Scholar] [CrossRef]

| Column ID | Web Depth bw (mm) | Flange Width bf (mm) | Thickness of Web tw (mm) | Thickness of the Flange tf (mm) | Root Radius R (mm) |

|---|---|---|---|---|---|

| 120x36x6x6 | 120 | 36 | 6 | 6 | 7 |

| 120x50x6x6 | 120 | 50 | 6 | 6 | 7 |

| 140x40x5x5 | 140 | 40 | 5 | 5 | 5 |

| 160x48x8x8 | 160 | 48 | 8 | 8 | 8 |

| 200x60x10x10 | 200 | 60 | 10 | 10 | 10 |

| 240x72x8x8 | 240 | 72 | 8 | 8 | 8 |

| 240x72x12x12 | 240 | 72 | 12 | 12 | 12 |

| 300x90x15x15 | 300 | 90 | 15 | 15 | 15 |

| 120x50x5x5 | 120 | 50 | 5 | 5 | 15 |

| 360x108x15x10 | 360 | 108 | 15 | 10 | 10 |

| 304.8x76.2x12.7x12.7 | 304.8 | 76.2 | 12.7 | 12.7 | 12.7 |

| 355.6x38.9x19.05x19.05 | 355.6 | 38.9 | 19.05 | 19.05 | 19.05 |

| Property | Description | Value |

|---|---|---|

| ρ | Density (kg/m3) | 1900 |

| E11 | Young’s modulus in longitudinal (fiber) direction (MPa) | 36,633 |

| E22 | Young’s modulus in the transverse direction (MPa) | 10,754 |

| G12 | In-Plane shear modulus (MPa) | 3648 |

| G13 | In-Plane shear modulus (MPa) | 3648 |

| G23 | Out-of-Plane shear modulus (MPa) | 1601 |

| υ21 | Minor Poisson ratio | 0.266 |

| Xt | Longitudinal tensile strength (MPa) | 365 |

| Xc | Longitudinal compressive strength (MPa) | 465 |

| Yt | Transverse tensile strength (MPa) | 85.8 |

| Yc | Transverse compressive strength (MPa) | 110 |

| SX | Longitudinal Shear strength (MPa) | 30.6 |

| SY | Transverse Shear strength (MPa) | 30.6 |

| Property | Description | Value |

|---|---|---|

| Gft | Longitudinal tensile fracture energy (mJ) | 2.38 |

| Gfc | Longitudinal compressive fracture energy (mJ) | 5.28 |

| Gmt | Transverse tensile fracture energy (mJ) | 0.424 |

| Gmc | Transverse compressive fracture energy (mJ) | 0.948 |

| Column ID | H [mm] | tf = tw [mm] | Gft [N/mm] | Gfc [N/mm] | Gmt [N/mm] | Gmc [N/mm] | L [mm] | PU,EXP (kN) | PU,FEA (kN) | PU,EXP/ PU,FEA |

|---|---|---|---|---|---|---|---|---|---|---|

| S0 | 200 | 10 | 2.38 | 5.28 | 0.424 | 0.948 | 600 | 733.7 | 669.2 | 1.096 |

| S1 | 200 | 10 | 2.38 | 5.28 | 0.424 | 0.948 | 1000 | 511.4 | 462.54 | 1.105 |

| S3 | 200 | 10 | 2.38 | 5.28 | 0.424 | 0.948 | 2000 | 144.8 | 162.3 | 0.892 |

| Mean | 1.031 | |||||||||

| Standard deviation | 0.1204 | |||||||||

| Specimens ID | λ | χ | Pcr-FEM | Pcr-FEA/ Pcr-DSM | Pcr-FEA/ Pcr-ASCE | Pcr-FEA/ Pcr-Car | Pcr-FEA/ Pcr-Ita. | Pcr-FEA/ Pcr-Prop. |

|---|---|---|---|---|---|---|---|---|

| 120x36x6x6-L400 | 0.93 | 0.67 | 143.03 | 1.31 | 1.05 | 1.50 | 1.33 | 1.12 |

| 120x36x6x6-L500 | 1.16 | 0.53 | 127.53 | 1.29 | 0.94 | 1.51 | 1.50 | 1.16 |

| 120x36x6x6-L750 | 1.74 | 0.29 | 63.78 | 1.01 | 0.93 | 1.18 | 1.38 | 1.11 |

| 120x36x6x6-L1000 | 2.32 | 0.17 | 36.81 | 1.04 | 0.95 | 1.08 | 1.33 | 1.08 |

| 120x36x6x6-L1250 | 2.90 | 0.11 | 23.88 | 1.06 | 0.97 | 1.04 | 1.31 | 1.01 |

| 120x36x6x6-L1500 | 3.48 | 0.08 | 18.71 | 1.19 | 1.09 | 1.14 | 1.46 | 1.03 |

| 120x36x6x6-L1750 | 4.06 | 0.06 | 14.68 | 1.27 | 1.16 | 1.21 | 1.55 | 1.00 |

| 120x50x6x6-L400 | 0.56 | 0.88 | 149.23 | 1.24 | 0.95 | 1.46 | 1.12 | 1.05 |

| 120x50x6x6-L500 | 0.70 | 0.81 | 141.73 | 1.25 | 0.90 | 1.43 | 1.15 | 1.05 |

| 120x50x6x6-L750 | 1.05 | 0.60 | 142.53 | 1.45 | 0.91 | 1.66 | 1.57 | 1.26 |

| 120x50x6x6-L1000 | 1.40 | 0.41 | 91.87 | 1.08 | 0.91 | 1.35 | 1.48 | 1.09 |

| 120x50x6x6-L1250 | 1.75 | 0.29 | 61.35 | 1.04 | 0.95 | 1.20 | 1.41 | 1.14 |

| 120x50x6x6-L1500 | 2.10 | 0.21 | 43.16 | 1.05 | 0.96 | 1.12 | 1.37 | 1.13 |

| 120x50x6x6-L1750 | 2.45 | 0.16 | 31.95 | 1.06 | 0.97 | 1.08 | 1.35 | 1.09 |

| 140x40x5x5-L400 | 0.58 | 0.87 | 72.00 | 1.19 | 1.08 | 1.39 | 1.07 | 1.01 |

| 140x40x5x5-L500 | 0.73 | 0.80 | 69.61 | 1.22 | 1.04 | 1.39 | 1.14 | 1.02 |

| 140x40x5x5-L750 | 1.09 | 0.57 | 71.57 | 1.46 | 1.07 | 1.67 | 1.63 | 1.29 |

| 140x40x5x5-L1000 | 1.46 | 0.39 | 44.60 | 1.06 | 0.95 | 1.34 | 1.50 | 1.11 |

| 140x40x5x5-L1250 | 1.82 | 0.27 | 29.02 | 1.05 | 0.96 | 1.18 | 1.41 | 1.14 |

| 140x40x5x5-L1500 | 2.18 | 0.19 | 20.36 | 1.06 | 0.97 | 1.11 | 1.37 | 1.12 |

| 160x48x8x8-L400 | 0.69 | 0.82 | 273.45 | 1.29 | 1.14 | 1.49 | 1.19 | 1.08 |

| 160x48x8x8-L500 | 0.87 | 0.71 | 259.46 | 1.32 | 1.08 | 1.50 | 1.29 | 1.11 |

| 160x48x8x8-L750 | 1.30 | 0.46 | 190.96 | 1.16 | 0.88 | 1.41 | 1.48 | 1.11 |

| 160x48x8x8-L1000 | 1.73 | 0.29 | 114.00 | 1.02 | 0.93 | 1.19 | 1.39 | 1.11 |

| 160x48x8x8-L1250 | 2.17 | 0.20 | 74.23 | 1.04 | 0.95 | 1.09 | 1.34 | 1.10 |

| 160x48x8x8-L1500 | 2.60 | 0.14 | 52.15 | 1.05 | 0.96 | 1.06 | 1.32 | 1.05 |

| 160x48x8x8-L1750 | 3.03 | 0.10 | 39.10 | 1.07 | 0.98 | 1.05 | 1.33 | 1.00 |

| 200x60x10x10-L400 | 0.55 | 0.88 | 444.78 | 1.27 | 1.19 | 1.50 | 1.14 | 1.08 |

| 200x60x10x10-L500 | 0.69 | 0.82 | 421.24 | 1.27 | 1.12 | 1.47 | 1.17 | 1.07 |

| 200x60x10x10-L750 | 1.04 | 0.60 | 366.46 | 1.28 | 0.98 | 1.47 | 1.38 | 1.11 |

| 200x60x10x10-L1000 | 1.39 | 0.42 | 266.84 | 1.07 | 0.89 | 1.34 | 1.45 | 1.08 |

| 200x60x10x10-L1250 | 1.73 | 0.29 | 177.36 | 1.02 | 0.93 | 1.18 | 1.38 | 1.11 |

| 200x60x10x10-L1500 | 2.08 | 0.21 | 125.32 | 1.03 | 0.95 | 1.11 | 1.34 | 1.10 |

| 200x60x10x10-L1750 | 2.43 | 0.16 | 93.11 | 1.05 | 0.96 | 1.07 | 1.33 | 1.07 |

| 240x72x8x8-L400 | 0.29 | 0.97 | 203.98 | 1.25 | 1.25 | 1.58 | 1.14 | 1.13 |

| 240x72x8x8-L500 | 0.37 | 0.95 | 193.98 | 1.23 | 1.19 | 1.51 | 1.11 | 1.08 |

| 240x72x8x8-L750 | 0.55 | 0.89 | 184.17 | 1.26 | 1.13 | 1.48 | 1.13 | 1.07 |

| 240x72x8x8-L1000 | 0.73 | 0.79 | 172.85 | 1.27 | 1.06 | 1.45 | 1.19 | 1.07 |

| 240x72x8x8-L1250 | 0.92 | 0.68 | 168.12 | 1.34 | 1.03 | 1.50 | 1.34 | 1.13 |

| 240x72x8x8-L1500 | 1.10 | 0.57 | 152.03 | 1.30 | 0.93 | 1.49 | 1.46 | 1.15 |

| 240x72x8x8-L1750 | 1.29 | 0.46 | 133.21 | 1.23 | 0.92 | 1.47 | 1.56 | 1.17 |

| 240x72x12x12-L400 | 0.46 | 0.92 | 658.60 | 1.26 | 1.22 | 1.52 | 1.13 | 1.08 |

| 240x72x12x12-L500 | 0.58 | 0.87 | 633.59 | 1.27 | 1.17 | 1.49 | 1.14 | 1.07 |

| 240x72x12x12-L1000 | 1.15 | 0.53 | 490.10 | 1.25 | 0.91 | 1.46 | 1.44 | 1.12 |

| 240x72x12x12-L1250 | 1.44 | 0.39 | 357.99 | 1.03 | 0.90 | 1.31 | 1.44 | 1.06 |

| 240x72x12x12-L1500 | 1.73 | 0.29 | 255.54 | 1.02 | 0.93 | 1.18 | 1.38 | 1.11 |

| 240x72x12x12-L1750 | 2.02 | 0.22 | 190.50 | 1.03 | 0.94 | 1.11 | 1.35 | 1.11 |

| 300x120x15x15-L400 | 0.34 | 0.96 | 835.82 | 1.14 | 0.99 | 1.42 | 1.03 | 1.01 |

| 300x120x15x15-L500 | 0.43 | 0.93 | 904.11 | 1.28 | 1.07 | 1.55 | 1.15 | 1.11 |

| 300x120x15x15-L750 | 0.64 | 0.84 | 847.67 | 1.31 | 1.00 | 1.52 | 1.19 | 1.10 |

| 300x120x15x15-L1250 | 1.07 | 0.59 | 725.80 | 1.34 | 0.86 | 1.54 | 1.46 | 1.17 |

| 300x120x15x15-L1500 | 1.28 | 0.47 | 601.22 | 1.21 | 0.90 | 1.46 | 1.52 | 1.14 |

| 300x120x15x15-L1750 | 1.49 | 0.37 | 454.83 | 1.00 | 0.92 | 1.29 | 1.45 | 1.07 |

| 120x50x5x5-L400 | 0.46 | 0.92 | 97.22 | 1.36 | 1.07 | 1.64 | 1.22 | 1.17 |

| 120x50x5x5-L750 | 0.86 | 0.72 | 79.89 | 1.32 | 0.88 | 1.49 | 1.29 | 1.11 |

| 120x50x5x5-L1000 | 1.14 | 0.54 | 75.13 | 1.40 | 0.87 | 1.61 | 1.61 | 1.25 |

| 120x50x5x5-L1250 | 1.43 | 0.40 | 51.94 | 1.09 | 0.94 | 1.36 | 1.51 | 1.11 |

| 355.6x88.9x19.05x19.05-L1000 | 1.09 | 0.57 | 1206.70 | 1.14 | 1.20 | 1.32 | 1.26 | 1.20 |

| 355.6x88.9x19.05x19.05-L1500 | 1.63 | 0.32 | 717.19 | 0.96 | 0.88 | 1.17 | 1.34 | 1.05 |

| 360x108x18x18-L1000 | 0.77 | 0.77 | 1296.23 | 1.25 | 1.07 | 1.43 | 1.18 | 1.05 |

| 360x108x18x18-L1500 | 0.96 | 0.65 | 1214.16 | 1.27 | 1.00 | 1.45 | 1.30 | 1.08 |

| Average/Mean | 1.18 | 1.00 | 1.36 | 1.33 | 1.05 | |||

| COV | 0.108 | 0.100 | 0.132 | 0.111 | 0.065 | |||

| Reliability Index for resistance factor 0.7 | 3.94 | 3.36 | 4.30 | 4.38 | 3.72 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anbarasu, M.; Kasiviswanathan, M.; Kathiresan, M.; Mohan Ganesh, G. Numerical Parametric Study and Design of Pultruded GFRP Composite Channel Columns. Sustainability 2023, 15, 837. https://doi.org/10.3390/su15010837

Anbarasu M, Kasiviswanathan M, Kathiresan M, Mohan Ganesh G. Numerical Parametric Study and Design of Pultruded GFRP Composite Channel Columns. Sustainability. 2023; 15(1):837. https://doi.org/10.3390/su15010837

Chicago/Turabian StyleAnbarasu, M, M Kasiviswanathan, M Kathiresan, and G Mohan Ganesh. 2023. "Numerical Parametric Study and Design of Pultruded GFRP Composite Channel Columns" Sustainability 15, no. 1: 837. https://doi.org/10.3390/su15010837

APA StyleAnbarasu, M., Kasiviswanathan, M., Kathiresan, M., & Mohan Ganesh, G. (2023). Numerical Parametric Study and Design of Pultruded GFRP Composite Channel Columns. Sustainability, 15(1), 837. https://doi.org/10.3390/su15010837