1. Introduction

In recent years, China’s manufacturing industry has developed continuously and rapidly in the process of deepening supply-side reform and implementing the comprehensive innovation-driven strategy. However there is still a big gap between China’s manufacturing industry and the world’s advanced level in terms of independent innovation capability, resource utilization efficiency, production efficiency, etc. At present, the key to promote developing quality is to promote innovation of the manufacturing enterprises. Improving the sustainable innovation capacity is essential for the survival of manufacturing enterprises and is also necessary for fostering new growth drivers and achieving economic transformation.

With the rapid development of the digital economy, the digital transformation of enterprises has become the focus of attention from all sectors. Digital transformation has become an important strategy for traditional enterprises, which can ensure the enterprises remain competitive in the changing environment [

1]. Both the “Digital China Development Report” and “Manufacturing in China 2025” have clearly showed the important developing direction of China’s manufacturing industry in the future. The digital transformation in manufacturing enterprises can not only effectively solve the problems of high cost and low informationization degree, but also promote the innovation of the production mode and business model of enterprises, so as to enhance consumers’ consumption experience [

2], improve sustainable innovation capacity, and move towards the high end of technology and the value chain. On one hand, due to the popularization of digital technological means, enterprises can accelerate the innovation of products and processes through the analysis of large amounts of data [

3], which can better enhance the interaction between innovation subjects and customers in the process of marketization. On the other hand, the new generation of digital technology can effectively enhance the ability of collecting, mining, and analyzing various network data, and alleviate the information asymmetry in the market, improve financing efficiency through market-based means [

4], and create an environment conducive to innovation and, thus, enhance the innovation capability.

However, at present, only a small part of the small and medium-sized manufacturing enterprises in China have realized digital transformation, and a large number of manufacturing enterprises do not know how to transform [

5,

6]. Most manufacturing enterprises do not know how to improve their sustainable innovation capability, hence they also do not know how to allocate resources and capabilities in the process of digital transformation, and they cannot choose the appropriate digital transformation path according to their resources and capabilities [

7]. The purpose of this paper is to explore the mechanism of how digital transformation promotes the sustainable innovation capability of the manufacturing industry and opens the “black box” to identify the coupling relationships of various types of digital transformations and to explore the driving effects on enterprises’ sustainable innovation. The research is needed to help the manufacturing enterprises avoid failed digital transformation, which can also provide theoretical and policy support for the government to make industrial policies and innovation policies.

The research on digital transformation has roughly experienced three stages. In the early stage, digital technologies have unlimited potential in exploring enterprise governance and innovation. In the growth stage, the issues of product, service, and organizational digital transformation are discussed. In the rapid developing stage, the research explores the model and process of digital transformation and their impacts. This paper summarizes them into four main fields: types, antecedents, consequences, and dynamic evolution. The types of digital transformation include the digital transformation of products, services, processes, models, and organizations [

8]. The antecedents are mainly related to internal factors, such as digital technologies [

9]; digital transformation strategies [

10]; resources or capabilities [

11]; and external factors, such as user needs [

2]. The results are mainly expressed in terms of new products, new services, new processes and performance [

12], and stakeholder satisfaction at the ecosystem level [

13].

We further found that digital transformation has important impacts on firms’ innovation capabilities. Scholars have also conducted extensive research and found that digital transformation has a remarkable influence on green innovation [

14], the input of digital resources has a huge positive influence on service innovation, and the application of big data technologies has a positive influence on information service innovation [

15]. Abdalla S used a hierarchical, multiple regression approach to investigate Japanese manufacturing firms, and the results showed that collaborative innovation plays a catalytic role in digital transformation and supply chain adaptability [

16]. The application of the Internet by enterprises has an extremely important role in driving technological innovation [

17,

18,

19]. The research by using public listed companies showed that there is a positive correlation between the level of corporate digitization and innovation performance [

20]. However, some studies also found that digital transformation does not necessarily always affect innovation positively. For example, Feifei Yu conducted a questionnaire survey on companies, and the results showed that there is a U-shape relationship between the level of digitalization and innovation performance [

21].

In summary, the current academic research on digital transformation and the innovation capability of companies has the following shortcomings. Firstly, the previous literature does not directly link digital technology with the innovation capability of enterprises. There are only a few studies on their internal impact mechanisms, and the internal connection between the two has not been clarified. Secondly, the existing studies mainly concentrate on the impacts of digital technology on enterprise innovation and pay too much attention to the technical aspects of digital transformation, ignoring the changes in services, business processes, models, and even enterprise organization due to digital transformation. Thirdly, because of the complexity of digital transformation in enterprises and the many disciplines and fields involved [

22], the current research presents a high degree of fragmentation and ambiguity, especially on the concepts, types, antecedents, results, implementation processes, and dynamic evolution, which do not form a unified viewpoint and break the synergistic relationship between various types of digital transformation.

Based on the Complex System view, this paper uses a combination of fsQCA and NCA to explore the complex interaction between different types of digital transformation and sustainable innovation capability in manufacturing enterprises, and it is dedicated to answering the following questions: Can the different types of digital transformation of manufacturing enterprises work together to invigorate the “digital vitality”? Can the different types of digital transformation of manufacturing enterprises work together to stimulate the sustainable innovation capability? And to what extent are the various types of digital transformation necessary to generate highly sustainable innovation capability? What are the possible mechanisms of how the different types of digital transformation effectively drive sustainable innovation?

This paper makes the following theoretical contributions. First, the Complex System view holds that innovation is a combination of established knowledge and technology. Based on the Complex System view, this paper develops a comprehensive framework to analyze the driving mechanism of digital transformation on sustainable innovation capability in manufacturing enterprises. Furthermore, it considers five different types of digital transformation, offering another hypothetical viewpoint to empirical studies to analyze the connection between digital transformation and sustainable innovation capability, as well as expanding the research context (digitalization context) and research scope (innovation capability enhancement). Secondly, considering the interdependence of the five different types of digital transformation, we systematically analyze the complex mechanisms of how different types of digital transformation couple and synergistically drive the improvement of technological innovation capability in manufacturing enterprises based on the view of configuration. Additionally, the “multiple potential concurrent causalities” between different types of digital transformation and sustainable innovation capability are identified, and we explore the intrinsic influencing mechanism of digital transformation on the sustainable innovation capability in manufacturing enterprises to reveal multiple paths for improving sustainable innovation capability, which enriches the theory of sustainable innovation capability and digital transformation.

3. Model Framework

3.1. Theoretical Basis

The Complex System View argues that different market agents are interrelated, highly interactive, competitive, cooperative, and adaptable to each other. Many unclear problems appear in the economic system; hence, enterprises choose diversified solutions instead of optimal equilibrium. In the process of evolution, enterprises learn, adjust, and choose appropriate measures in the face of the new environment, thus evolving a variety of ecosystems [

53]. First, the Complex System View assumes that there is no optimal equilibrium. Instead, the Complex Systems View assumes the existence of a positive, forward feedback mechanism. Under the effect of positive feedback with increasing returns, small stochastic events can dynamically assume a multiplicative equilibrium. Consequently, the Complex Systems View argues that the economic system has complex characteristics, such as multiplicative equilibrium, path dependence, unpredictability, and asymmetry [

54]. Second, the Complex Systems View considers innovation a combination of existing knowledge or technologies [

53], and, therefore, it may be possible to develop highly sustainable innovation capabilities through different combinations of various types of digital transformations. Third, the Complex Systems View proposes that inductive reasoning is more effective than deductive reasoning in solving complex problems due to the dynamic, multi-causal, and multi-level interaction characteristics of complex systems [

55], and it points out the need for new methodologies, such as Mathematics of Combination.

Only through collaboration can various types of digital transformation fully play the role of enhancing enterprises’ sustainable innovation capability. The core of analyzing a complex problem is to find a cyclic pattern from diverse configurations [

55], while traditional linear analysis methods (for example, regression analysis focuses on the “net effect” of a variable.) are not suitable for complex system analysis. Therefore, a methodology that can rely on the “combination” effect among variables is needed [

56]. Thus, from the perspective of Complex Systems, various types of digital transformation can co-evolve different path mechanisms for the improvement of sustainable innovation capability through interdependence [

3], that is, enterprises’ sustainable innovation capability may be improved through the collaborative transformation of products, services, processes, models, and organizations, forming an equivalent multi-path of high sustainable innovation capability.

3.2. Model Construction

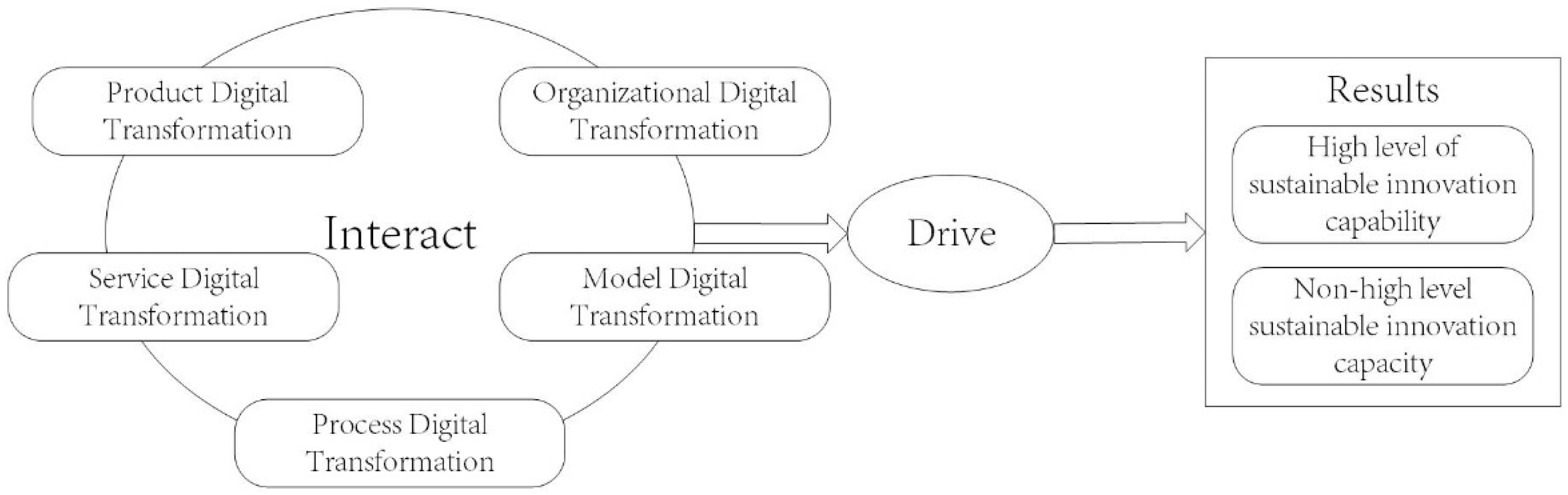

The existing studies rarely consider the collaborative coupling between different types of digital transformation, which not only restricts the implementation of digital transformation, but also greatly restricts the improvement of innovation capability. Due to the complex combination of paths for manufacturing enterprises to improve their sustainable innovation capability through digital transformation, it is difficult to use traditional methods [

57]. Therefore, we introduce a framework that argues that sustainable innovation capability does not depend on a single type of digital transformation, but rather on the interaction between multiple types of digital transformation (

Figure 1).

The five types of digital transformation of enterprises, including product digital transformation, service digital transformation, process digital transformation, model digital transformation, and organization digital transformation, are determined by referring to the research of Zhu Xiumei and Lin Xiaoyue [

8]. These five types all have a driving effect on sustainable innovation capability. In the process of product digital transformation, digital technology can provide users with intelligent products that are compatible with market demand. The application of digital technology in service digital transformation can improve service quality and product applicability, thus opening up new business models. Process digital transformation refers to the application of digital technology to business process optimization, R&D, and design, all while embedding new digital technology, thus improving the enterprise technology innovation ability. Model digital transformation can help enterprises introduce new MIS, optimize their business model, and accurately position products. Digital technology is an important guarantee for the digital transformation of enterprise organizations, and enterprise employees and leaders can transmit and obtain information at any time, thereby forming a new business model for users and stakeholders and finally promoting innovation.

In addition, the synergistic relationship between different types of digital transformation can also provide important support for manufacturing enterprises to enhance sustainable innovation capacity, mainly in the following aspects:

- (1)

The collaboration between model digital transformation and process, organization digital transformation

First, model digital transformation and process digital transformation. The model digitalization transformation can clarify the specific needs and tasks of process digitalization transformation, and promote enterprises to accelerate automation, intelligent response, and decision making. At the same time, process digital transformation can also effectively use the enterprise’s operational data, market environment data, business operation information, market information, enterprise information, and other data or information, which helps leaders to proactively improve their current business model and enhance commercialization capability.

Second, model digital transformation and organization digital transformation. Through the accelerated interaction of processes and resources, the enterprises can actively improve the existing business model, enhance the overall transformation practice and efficiency, and promote the sustainable innovation capability, so as to reduce the barriers of talent and knowledge in the industry and introduce new management information systems. At the same time, organization digital transformation stimulates the exploration and development of organizations and individuals in terms of data resources, and promotes the generation of new ideas and models, and finally improves the identification of opportunities in sustainable innovation capability.

Third, organization digital transformation and process digital transformation. The digital transformation of the enterprise provides talent and organizational security for the organization. At the same time, the organizational management structure of the enterprise will also change with the digital transformation in order to achieve cooperation and form new business models that can create value for the enterprise.

- (2)

The collaboration between process, organization digital transformation and product, service digital transformation

First, process digital transformation and product, service digital transformation. The process digital transformation supports the digital transformation of products and services, integrates resources on the data platform, supports flexible manufacturing and personalized customization through the construction of a flexible supply chain, and enables users to participate in the whole process of value creation, optimization, and product and service innovation. The wide use of digital technology facilitates the use and analysis of a large amount of data in the process of marketization, improves the interaction between innovation subjects and target customers, and accelerates product and process innovation for sustainable innovation [

3]. Therefore, the collaboration of digital transformation of processes and products and services can lead to an effective improvement of the sustainable innovation capability of enterprises.

Second, organization digital transformation and product, service digital transformation. “People” in an organization can provide knowledge needed for products and services. Knowledge needs to be understood, organized, and created in the process of information flow. Organizations that are alert and aware of opportunities tend to have the potential to anticipate new knowledge and to have a fast and flexible organizational structure that can adapt to rapidly changing products and services. Enterprises can identify and develop market opportunities through the collaborative development of the digital transformation of organizations and services to enhance their sustainable innovation capabilities.

Third, product digital transformation and service digital transformation. The product digital transformation drives the service digital transformation, as the value creation of services cannot be separated from products, and the service digital transformation will drive the product digital transformation, thus making the corresponding products more functional. Furthermore, these two types support each other and complement each other synergistically, which is conducive to new product development and enhances the sustainable innovation capability of enterprises [

58] (Luo, 2020).

- (3)

The collaboration between model digital transformation and product, service digital transformation

The efficient model digital transformation requires clearer and more rapid access to users’ needs, rapid updating of existing products and services, and flexible integration of them as well. The new model digital transformation requires companies to be able to effectively identify and process information resources and discover potential business opportunities, so that they can continuously develop new and unique products and services, thus maximizing the value of the company. The product and service digital transformation, on the other hand, prepares data for model digital transformation and the sustainable innovation of enterprise, analyzes data based on the actual demand of customers, and predicts market demand and potential markets.

In summary, the components of digital transformation in enterprises have been discussed in more depth in the literature, but the influence of enterprises’ digital transformation on sustainable innovation capability still needs to be further explored. At present, the relationship between digital transformation and the sustainable innovation capability of enterprises has not formed a complete system, and most of the literature starts from a single perspective, lacking a comprehensive analysis of its influencing factors. Moreover, with the continuous advancement of digitalization, it is difficult for a single factor to provide a more comprehensive explanation. Based on the characteristics of “multiple causes, one effect” and “all paths to the same destination” of configuration analysis, this paper constructs an integrated research framework in accordance with the “cause-and-effect” model, as shown in

Figure 1. Based on the perspective of configuration, this paper explores the multiple digital transformation paths and complex influence mechanisms to promote the improvement of enterprises’ sustainable innovation capability.

4. Data and Methods

4.1. Sample and Data

Dalian is one of the important cities of the old industrial base in northeast China. Since the founding of the People’s Republic of China, it has formed a strong manufacturing base. In particular, Dalian is also one of the country’s important petroleum refining and chemical industry bases. In recent years, Dalian’s petrochemical industry has developed rapidly, which has become an important pillar of the development of Dalian’s manufacturing industry. In 2020, petrochemical enterprises above a designated size in Dalian achieved an added value of CNY 52.62 billion, accounting for one third of the scale industry. Its crude oil processing capacity reaches 52.7 million tons. At present, it has formed a multi-industry system, including petroleum refining, petrochemicals, basic chemical materials, fertilizers, pesticides, tires, and fine chemicals, and has prominent features in the fields of catalysts and special gases. Based on this, this paper takes the manufacturing enterprises of chemical raw materials and chemical products in Dalian, China, as the main research object.

First, in the summer of 2022, we conducted a one-month online and offline survey on twenty chemical raw materials and chemical products manufacturing enterprises in Dalian (once a week on average), and we interviewed and communicated with the company’s general manager and other department heads to understand the current situation of digital transformation of the company’s products, services, processes, models, and organizations, which lays a practical foundation for this research. Subsequently, through in-depth visits to enterprises and interviews of senior executives, we learned about the current situation of the enterprises, their sustainable innovation capability, and the importance they attach to sustainable innovation development, which provides important practical support for this study. Finally, our questionnaires were distributed and collected in August 2022.

In order to ensure the authenticity and reliability of the obtained research data, as well as considering the convenience of the Internet, a combination of telephone communication, online research, and face-to-face research was used for data collection. The enterprises were asked to fill out the electronic questionnaires through wechat, mail, and other online channels, or through the face-to-face method, and, finally, the online and offline questionnaires were received and sorted out. Furthermore, we find that most of the enterprises in the sample are mainly petrochemical enterprises, of which 89.29% are private enterprises or other nature enterprises. Most of the enterprises are in the interval of 50–100 employees and less than 50 employees, which indicates that most of the researched enterprises are small and medium-sized enterprises and meet the requirements of sample size for the data analyzing method of this paper. The characteristics of the sample enterprises are shown in

Table 2.

4.2. Research Method: FsQCA Combined with NCA

QCA conducts sufficient and necessary research on causality on the basis of Set Theory, and it has the characteristics of combining qualitative and quantitative analysis. “Qualitative” is reflected in the case as the unit of analysis. QCA can analyze a large amount of case data and analyze it scientifically, as opposed to the qualitative approach of “rooting” and “case”. “Quantitative” is based on a Boolean algorithm, and the relevant causality index is modified in order to determine the necessary conditions and sufficient configuration, providing an equivalent path for the theoretical and practical “homogeneity” of the problem [

59]. There are three types of qualitative comparative analyses: csQCA, fsQCA, and mvQCA. FsQCA can better solve the related degree and affiliation problem than csQCA and mvQCA, and it is more focused on individual cases and can explain causality in a more detailed way [

60]. Therefore, we chose fsQCA for this study.

NCA is a novel analysis method of complex causality. Different from QCA, it can not only identify the necessary conditions of the result variables, but also can quantify the effect size and bottleneck level of the necessary conditions [

61]. QCA has been widely used in various fields, such as economics, management, public administration, medicine, communication, etc., and has been recognized by many authoritative journals. Under the advice of the chief editor of the

Journal of International Business Studies, the management field began to combine NCA and QCA to study the necessary and sufficient complex causal relationships [

62].

4.3. Variables

The result variables are mainly measured from three dimensions, including opportunity identification capability, innovation realization capability, and commercialization capability, which involve 15 questions. Based on the different types of digital transformation in enterprises, the conditional variables are measured from five dimensions, including product digital transformation, service digital transformation, process digital transformation, model digital transformation, and organization digital transformation, which involves a total of 16 questions. We designed a questionnaire entitled “A Survey on the Innovation Capability of Dalian Manufacturing Enterprises under Digital Transformation” and asked respondents to assign points according to their attitudes towards the questions. This study used a 5-point Likert scale, where a “1” means complete disagreement with the item and a “5” means complete agreement with the item. Below are the measurements for each variable in this study.

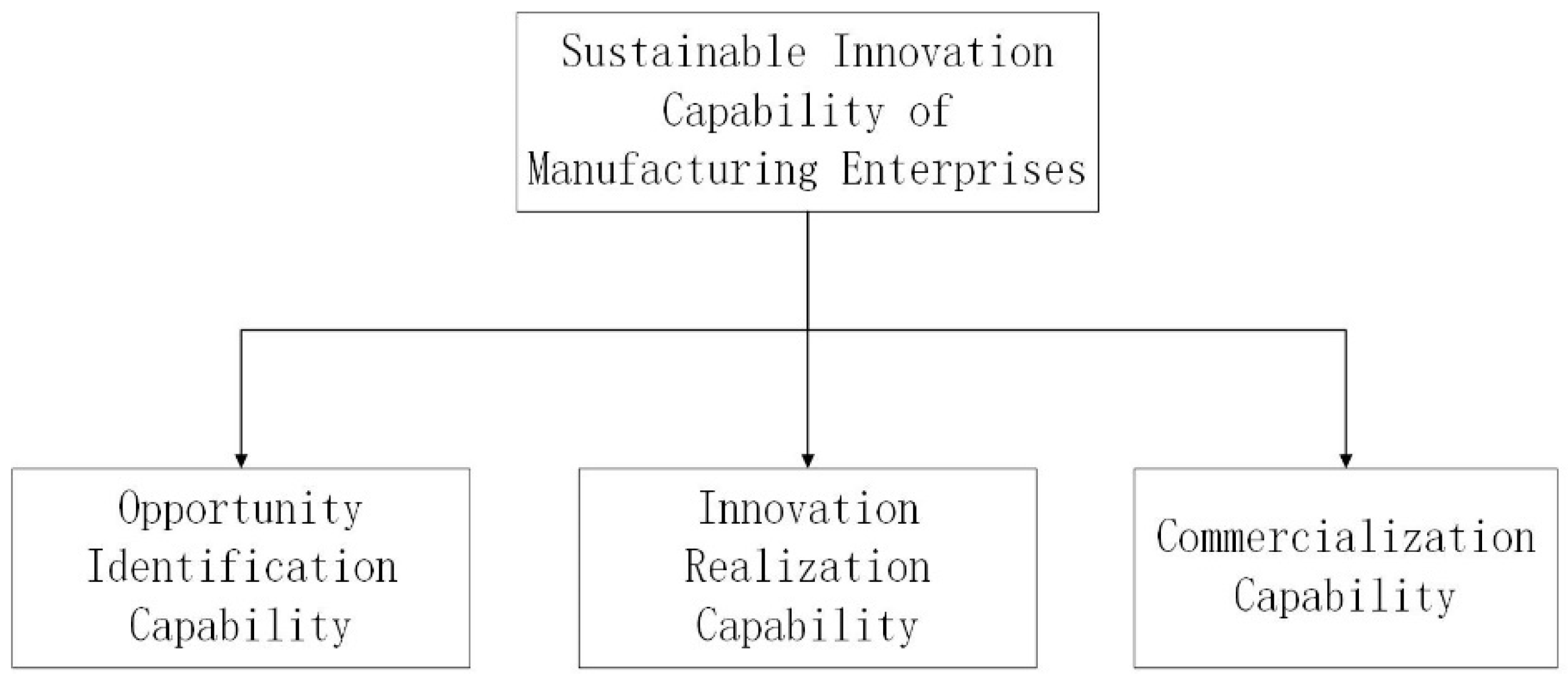

4.3.1. Result Variables

Sustainable innovation capability is a multifaceted concept, and the defined dimensions are divided differently; hence, the measurement approach is different. By referring to Sheng Weizhong and Chen Jin [

39], this study divides sustainable innovation capability into three dimensions, including opportunity identification capability, innovation realization capability, and commercialization capability. The measurement framework is shown in

Figure 2.

- (1)

Opportunity identification capability

This capability refers to the ability to actively explore and expand market development opportunities through various ways and means [

63]. It involves studying creativity and predicting whether the innovation of a product will adapt to the market prospect. This capability attaches great importance to creativity. Enterprise development opportunities cannot be effectively explored in all environments. Opportunity identification consists of three aspects, including analysis of market and technical opportunities, selection of innovative products and evaluation of ideas, and mastery and control of products and business plans [

64].

- (2)

Innovation realization capability

This capability refers to an enterprise’s ability to develop existing business opportunities. Developing business opportunities requires a willingness to invest in innovation, resources, and organizational management, as well as requiring a climate that supports innovation. The measurement focuses on the enterprise’s ability to continuously transform innovation opportunities from ideas to reality and turn them into long-term productivity, thus promoting the growth of the enterprise. This capability includes the enterprise’s strategic decision-making ability, the enterprise’s human and capital investment in the innovation project, and the management and regulation ability of the managers in all aspects of the enterprise’s operation.

- (3)

Commercialization capability

Commercialization refers to the fact that the idea has been brought to the market and requires market analysis and monitoring, contacting customers, marketing planning, and marketing in the target market [

65]. The commercialization capability is mainly manifested in the following aspects: the compatibility of the market test, customer preference, commercialization plan, innovative products, whether the market positioning of innovative products is accurate, whether convenient marketing channels can be found for well-positioned innovative products, and whether customers’ consumption demands can be satisfied through innovative products.

4.3.2. Condition Variables

- (1)

Product digital transformation

The product digital transformation is mainly reflected in the use of digital technology to improve product shape characteristics, optimize product functions, and so on. Companies use data collection technologies to determine the functionality of products and improve their usability. The product digitization can make the product have the function of monitoring, digitization, and intelligence. By using digital technologies, products can be produced more efficiently and accurately, development cycles can be shortened, and product quality can be further improved with the help of predictive tools.

- (2)

Service digital transformation

The service digital transformation refers to the transformation of services in commodity accessories, so that enterprises can obtain greater profits and improve the added value of products, including two major categories: digital services for user products and digital services for user behavior [

66]. In terms of supporting user products, enterprises use digital technology to carry out embedded services and support users to use digital service products. In terms of supporting user behavior, as the enterprise attaches great importance to customers’ satisfaction with the existing products and services, it constantly updates and upgrades the product functions according to customers’ needs, and provides customers with personalized functions and complete solutions.

- (3)

Process digital transformation

The process digital transformation refers to the process of creative generation, research and development, and production, whereby sales are redefined and integrated with the characteristics of digital transformation. Additionally, the digital technology is used to optimize business processes, mainly in the front-end business and back-end operations. In the front-end operation, the complete digital transformation of processes enables continuous interaction between companies and users before and after purchase, creating a new customer experience and making customers important participants in the whole value creation process [

51]. In the back-end operation, since the application of digital technology is very important for enterprises, it can realize the internal automation and intelligence in enterprises. Through the use of new digital technology for Internet collaborative operation, the operation cost of enterprises can be greatly reduced and the operation efficiency and operation quality of enterprises can be improved.

- (4)

Model digital transformation

The model digital transformation refers to the use of digital technology to create new value, new exchange mechanism, and transaction structure [

67], which is mainly divided into efficiency type and novel type model digital transformation [

68]. The former refers to the rapid and active improvement of the existing business model through communicating with multiple subjects, such as users, to improve the efficiency of interaction. The latter is to use new technologies, new subjects, new activities, new markets, new structures, and new management mechanisms to predict, evaluate, and utilize new opportunities to create added value, which is generally characterized by creativity and openness.

- (5)

Organization digital transformation

The organization digital transformation refers to the transformation in organizational structure, culture, leadership, roles, and skills of employees, etc. In terms of organizational structure, through restructuring the organizational form of enterprises, a new business model based on data asset-based operation is established to provide services for users and stakeholders. At the corporate culture level, the creativity of the enterprise is improved through the digital management of internal employees. In terms of leadership, leaders need to be aware and capable of new, dynamic, and continuous learning, as well as de-administration, flattening, and decentralization for R&D positions. In terms of employees’ roles and skills, electronic technology is used to replace simple and repetitive human labor; thus, the enterprises need to improve the employees’ digital quality, guide them to share their knowledge and creativity, and enhance their ability to handle complex business problems.

6. Conclusions, Implications, and Prospects

6.1. Conclusions

Taking 20 manufacturing enterprises as examples, this paper uses fsQCA and NCA methods to explore the configuration paths for manufacturing enterprises to use digital transformation to drive the improvement of sustainable innovation capability. The conclusions are:

(1) This paper finds that a single type of digital transformation is not a necessary condition to generate high sustainable innovation capability, and the digital transformation of service, model, and organization is a key bottleneck to improve the sustainable innovation capability of manufacturing enterprises.

(2) This paper finds that the combination of three different types of digital transformation can effectively drive manufacturing enterprises to improve their sustainable innovation capability, including pure product digital transformation driving path, model + organization digital transformation driving path, and comprehensive digital transformation driving path.

For the first type of enterprises, a higher level of product digital transformation is the leading factor to produce high sustainable innovation capability, which can make up for the disadvantages of manufacturing enterprises, such as low service level and incomplete digital process. This kind of manufacturing enterprise makes full use of digital technology to develop new products, use intelligent tools to improve the production efficiency and accuracy of products, and greatly improve the product quality and enterprise innovation level.

For the second type of enterprises, the model and organization digital transformation simultaneously serve as the core conditions to promote the improvement of sustainable innovation capability. At this time, manufacturing enterprises can postpone the process of digital transformation. Based on the digital transformation of the industrial Internet platform, such manufacturing enterprises carry out business model reform through digital technology. At the same time, at the organizational level, with the help of fine management and digital transformation, they can achieve “people-centered” management and improve management efficiency.

For the third type of comprehensive digital transformation, enterprises take the digital transformation of product and model as the core conditions, supplemented by the digital transformation of service and process, which can also promote the sustainable innovation capability of manufacturing enterprises. This kind of manufacturing enterprise chooses to focus on comprehensive and coordinated development and uses digital technology to transform core products and business models. At the same time, in terms of digital transformation of service and process, they build flexible production systems and make personalized customizations according to customer needs, so that customers can participate in the optimization and innovation of products and services in the production process.

There are four configuration paths of non-high sustainable innovation capability, which can be summarized as Process Digitalization Deficiency Type and Organization Digitalization Limitation Type. That is, the absence of high process digitalization transformation or high organization digitalization transformation, regardless of other conditions, may lead to the result of non-high sustainable innovation capability in manufacturing enterprises.

6.2. Implications

6.2.1. Theoretical Implications

From the perspective of Complex System, different types of digital transformation are interdependent, interrelated, and highly interactive, which can evolve multiple ecosystems and achieve diversified equilibrium. The selection of various digital transformation strategies may lead to different paths to improve the sustainable innovation capability of different enterprises [

53]. Therefore, based on the perspective of configuration, this paper systematically analyzes how different types of digital transformation can be coupled to achieve an effective combination of high sustainable innovation capability. The findings of this paper will have theoretical significance and implications for the current study of digital transformation and sustainable innovation capability.

First, based on the necessity causality and the combination of QCA and NCA, this paper finds that a single type of digital transformation is not a necessary condition for high sustainable innovation capability, indicating that a single factor does not constitute the bottleneck of high sustainable innovation capability. Previous literature indicated that product digital transformation [

68], service digital transformation [

65], process digital transformation [

50], model digital transformation [

67], and organization digital transformation [

66] have a positive impact on sustainable innovation capability. However, this study finds that a single type of digital transformation has a limited role in promoting the sustainable innovation capability of manufacturing enterprises. Though configuration Path 1 and Path 3 indicate that product digital transformation plays a key role in high sustainable innovation, configuration Path 2 indicates that in the absence of product digital transformation, model and organization digital transformation can promote high sustainable innovation capability.

Second, based on Configuration Theory, this paper systematically integrates different types of digital transformation and contributes to the analysis of the relationship between various types of digital transformation and the sustainable innovation capability of manufacturing enterprises. The configuration analysis of digital transformation provides a new idea for the research of digital transformation and sustainable innovation capability, and the conclusions provide rich and detailed evidence and implications for digital transformation and sustainable innovation in the context of the digital economy. Digital transformation is a complex and multi-dimensional phenomenon, not only a simple “quantitative change”, but also a comprehensive and multi-dimensional “qualitative change”. Therefore, the sustainable innovation capability is driven by digital transformation in multiple ways rather than a single optimal equilibrium [

52], and the interaction between various types of digital transformation makes it easier to achieve high sustainable innovation capability. According to the Complex System View, there may be a variety of equivalent and satisfactory equilibrium states for the influence of various factors on the result variables [

71]. Due to differences in enterprise size, resource endowment, and development stage of manufacturing enterprises, enterprises can promote the sustainable innovation capability through different combinations of product digital transformation, service digital transformation, process digital transformation, model digital transformation, and organization digital transformation, thereby forming a multi-path for sustainable innovation capability enhancement. Based on the Complex System View, this paper holds that the improvement of the sustainable innovation capability of manufacturing enterprises does not depend on a single type of digital transformation, but on the coupling and collaboration between various types of digital transformation, and builds a comprehensive model framework to discover the relationship between the digital transformation and sustainable innovation capability, as well as how to combine different types to lead to high/non-high sustainable innovation capability. These findings are of positive significance for research on the enhancement of sustainable innovation capability driven by digital transformation from the perspective of configuration.

Third, this paper adopts the method of combining NCA and QCA. On the one hand, QCA is suitable for analyzing sufficient conditions in complex causality. On the other hand, NCA can analyze the causal relationship of necessary conditions in a more detailed way, which is suitable for analyzing the relationship between various types of digital transformation and sustainable innovation capability. Combining NCA and QCA to explore the complex causal relationship between digital transformation and the sustainable innovation capability of manufacturing enterprises is helpful to develop the research on the necessary and sufficient relationship between digital transformation and sustainable innovation capability.

6.2.2. Practical Implications

This study has good practical value, which can help enterprises better solve the decision-making problems of whether to make digital transformations and how to make digital transformation to drive the improvement of sustainable innovation capability. Specifically, this paper identifies three paths of digital transformation to drive enterprises’ sustainable innovation capability. These paths can guide the manufacturing enterprises to foster sustainable innovation capability through digital transformation. For example, based on Path 2, some companies can achieve the goal of high levels of sustainable innovation by combining model and organization digital transformation. Alternatively, some manufacturing enterprises choose Path 3 to achieve a high level of sustainable innovation capability by simultaneously developing model and product digital transformation, combined with the use of digital technologies in service and process. In addition, “product-oriented enterprises” can be guided to choose the appropriate product digital transformation strategy by considering product characteristics to realize the goal of sustainable innovation.

- (1)

Focus on product digital transformation

Under the background of accelerating product updating and iteration, manufacturing enterprises can gradually improve their sustainable innovation capability by innovating independently of product digital transformation. The application of digital technology allows enterprises to quickly catch the changes of the market and make corresponding responses in order to quickly iterate and optimize products.

Therefore, in the context of digital transformation, manufacturing enterprises should adjust their development strategies in a timely manner to achieve continuous innovation through product digital transformation. Secondly, enterprises should actively use digital technology to develop and create digital products and improve product quality. Based on artificial intelligence, machine learning, and big data analysis, enterprises can process massive data and obtain knowledge and information to create new products, improve existing products, and improve product quality. Thirdly, enterprises can develop digital products and complementary products with the help of digital platforms to support and promote the digital transformation of enterprises, which will lead to multiple organizational and industrial changes.

- (2)

Focus on model digital transformation

Model digital transformation plays a guiding role in enhancing the sustainable innovation capability of manufacturing enterprises by using digital technology. The application of digital technology is conducive to developing new business models, improving customer experience, and changing the original rules and mechanisms of enterprises. The implementation of model digital transformation in manufacturing enterprises can change the way of communication and interaction between enterprises, users, and suppliers, which will increase the communication between enterprises, users, and suppliers, improve the flexibility, and also help enterprises to predict and make use of undeveloped value-creating opportunities in order to improve enterprises’ sustainable innovation capability.

Manufacturing enterprises should pay much attention to the economic and social environment when they use digital technology to change their business and management models. Through model digital transformation, the enterprises can establish cost control, resource sharing, and precise marketing processes, which can accelerate the pace of automation, intelligent response, and decision making. In addition, the manufacturing industry can also use the platform to build a new business model and turn the business model into a series of specific actions through digital technology in order to deliver the strategy of digital transformation and promote collaboration between departments.

- (3)

Focus on the comprehensive synergy between all types of digital transformation

The digital transformation of enterprises should not only focus on the promotion of a single type, but also involve the comprehensive synergy between multiple types. The synergistic coupling of various types of digital transformation is the optimal path to improve the sustainable innovation capability of manufacturing enterprises. The results of configuration analysis show that the enterprises should focus on the coordinated development of model, product, and organization digital transformation. For example, the enterprises can integrate product and organization digital transformation in the process of implementing the model digital transformation. If an enterprise is committed to carrying out efficiency model digital transformation, it must clearly and quickly obtain the needs of users and optimize the existing product structure. If an enterprise wants to carry out a novel type of model digitalization, it is necessary to discover and identify the potential demand of users from a wider range of information sources and develop new and unique products and organizational forms.

6.3. Limitations and Prospects

This paper explores the influencing mechanism of digital transformation on the sustainable innovation capability of manufacturing enterprises. However, there are still several shortcomings:

(1) With the change of the life cycle of manufacturing enterprises, the focus of digital transformation will change and the priority of transformation may be different. Future research can collect longitudinal data and adopt dynamic methods to explore the complex impacts of different types of digital transformation on sustainable innovation capability in the process of dynamic changes.

(2) This paper adopts the method of questionnaire survey to study the configuration paths of five types of digital transformation, but the measurement scale has not been unified. Therefore, in the future, the measurement scales of product, service, process, model, and organization digital transformation should be developed in order to further deepen the empirical analysis of complex collaborative paths and collaborative relationships and draw more universal conclusions.

Based on quantitative analysis, this paper makes a qualitative analysis of the case, which is conducive to revealing the mechanism. However, the qualitative research by QCA is hardly as deep and rich as the case study. Therefore, researchers can conduct further in-depth case studies on different driving modes of sustainable innovation capability in manufacturing enterprises in the future to reveal the process of digital transformation promoting sustainable innovation capability.

; the absence of the core condition is indicated by

; the absence of the core condition is indicated by  ; the presence of the edge condition is indicated by

; the presence of the edge condition is indicated by  ; the absence of the edge condition is indicated by

; the absence of the edge condition is indicated by  ; blank indicates that the condition is optional.

; blank indicates that the condition is optional.