Abstract

The supporting technology of retaining small coal pillars in a double roadway layout can effectively relieve the tension of mining and excavation replacement and improve the coal recovery rate. The critical difficulty is that the supporting structure on both sides of the small coal pillar has not established an effective mechanical connection, and the improvement of the bearing capacity of the coal pillar is limited, so it is difficult to achieve long-term stability control of the small coal pillar. Taking the 301 and 302 working faces of Gaojiapu Coal Mine as the engineering background, this paper first constructs the overburden structure model of the whole process of mining with small coal pillars in a double roadway layout, obtains the load calculation and strength calculation methods of small coal pillars through the analysis of the mechanism of small coal pillars surrounding rock mechanics, and gives the selection design of support parameters of anchor cables and concrete filled steel tubular piers; Secondly, the influence rules of physical and mechanical parameters such as axial load, elastic modulus and residual strength of anchor solid under different reinforcement methods and the lateral reinforcement coefficient of anchor cable are obtained through experiments. Finally, the support parameters and the coal pillar width are reasonably designed. The field monitoring data show that the reinforcement technology of a small coal pillar with anchor cable as the main body can effectively control the deformation of the small coal pillar, which has specific guiding significance and application value for solving the long-term stability control problem of small coal pillar under the influence of mining.

1. Introduction

At present, an increasing number of coal mines are beginning to use gob-side entry driving technology with narrow coal pillars. This technology arranges the roadway in the stress reduction area several meters away from the goaf and sets 3~5 m protective coal pillars, which not only improves the coal recovery rate but also effectively reduces the danger of coal pillar rock bursts [1,2,3]. In this regard, scholars worldwide have conducted a lot of research using theoretical analysis, numerical simulation, laboratory tests and other research methods. The research methods gradually show a trend of diversification and integration, and the research results are remarkable and useful for reference by other researchers. In terms of the movement law of roadway driving along goaf [4,5,6], Guanjun Li, to manage the unsymmetrical deformation due to dynamic loading from the hard main roof under gob-side entry driving, a combined strata control method was proposed. Tian Chen established the mechanical model of a hard roof and determined the critical stage of roadway stability control during the pressure relief roof cutting of the goaf side wall roadway. Zhu, D. studied the influence of roof-cutting technology on the movement law of overlying strata and the deformation characteristics of surrounding rock in gob-side entry. In terms of load on narrow coal pillars [7,8,9], Qi Fangkun, using a calculating and analytic program, calculated the top coal roof-sag values under the conditions of different supporting intensities, widths of narrow pillars and stiffness of top coal; Rajendra Singh discussed the measurement and analysis of the formation control parameters of the underground pillar and its surroundings in India. Yang Jiping According to the field conditions, the stress distribution in the coal pillar was quantified, and the surrounding rock deformation feature was studied with different widths of the pillars in gob-side entry driving; In terms of the reasonable size of the coal pillar [10,11], ZHANG KUN Based on the theory of coal pillar stress distribution, the reasonable retention width of the coal pillar in the deep buried thick coal seam is discussed. In terms of the mechanical properties of the coal pillar, Chunwang Zhang [12] studied the failure mechanism of the reinforced coal pillar and compared the bearing capacity before and after reinforcement. In addition, in the small coal pillar reinforcement technology aspect, combined support methods such as bolt cable support, grouting reinforcement, and bolt mesh steel belt shotcrete have also been widely studied and applied to perfect and enrich the theory and technology of roadway support [13]. However, there are still some shortcomings, as follows. To reduce the influence of dynamic pressure, the tunneling of the roadway in the next working face can only be started after the overburden movement in the goaf of the adjacent working face is stable. With the increase of mine mining intensity, the problem of tight mining replacement in the working face is becoming increasingly prominent, while the traditional double-roadway excavation causes wasted coal resources, and there is a contradiction between working face continuation and coal recovery rate. Second, at present, the reinforcement of small coal pillars is mainly a one-way bolt and cable support. There is no effective mechanical connection between the supporting structures on both sides of the coal pillar, which has a limited improvement of the bearing capacity of the coal pillar, which causes the small coal pillar to deform greatly under the influence of abutment pressure and mining activities. The small coal pillar is prone to plastic failure over its whole width [14]. Therefore, combining the traditional dual roadway layout with the gob-side entry driving technology is necessary. The double roadway layout can solve the problem of tight mining replacement while leaving small coal pillars can improve the coal extraction rate and reduce the loss of coal resources. At the same time, it can enhance the bearing capacity of small coal pillars and solve the long-term stability control problem of small coal pillars under the influence of mining by combining the two-way opposite anchor cable reinforcement support technology. The study on the reinforcement performance of small coal pillars in double roadway layout can create higher economic and social benefits for mines in China and other mining countries and have specific guiding significance and application value.

Based on this, this paper takes the 301 and 302 working faces of Gaojiapu Coal Mine in Shaanxi Province as the engineering background to research the reinforcement and support technology of small coal pillars arranged in the double roadway of the working face. First of all, through theoretical analysis, the layout method of double roadways and the stability of small coal pillars are summarized and analyzed, the load and strength calculation method of small coal pillars are obtained, and the type selection design of anchor cables and concrete filled steel tubular piers is given. Secondly, through laboratory tests, select the appropriate mix proportion of similar materials and similar anchor bolt material parameters; make similar simulation test pieces and study the influence laws of different anchor bolt density, different reinforcement methods and different layout methods on the physical and mechanical parameters of the anchor solid; compare the damage characteristics and influence laws of one-way reinforcement and two-way reinforcement and obtain the lateral reinforcement coefficient of the anchor cable. Finally, combined with theoretical analysis and test results, the width of the small coal pillar and support parameters are designed and calculated. The research results’ feasibility and application effect are further verified by monitoring the surrounding rock deformation of the roadway.

2. Study Area

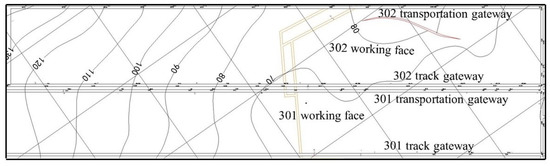

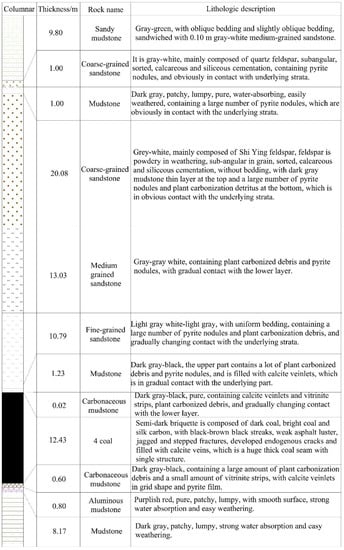

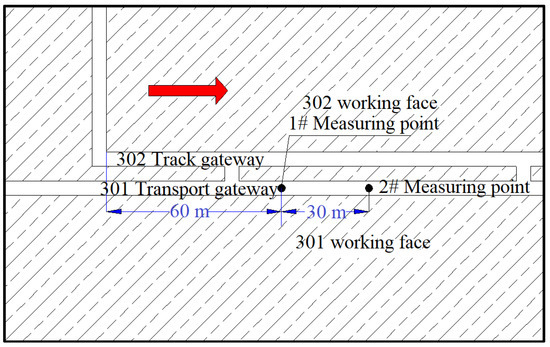

The 302 working face in Gaojiapu Coal Mine is the first mining face in three panels, and the 301 working face is east of the working face. The layout plan of the working face is shown in Figure 1. The coal seam in Sanpanqu is the No. 4 coal seam of the Yan’an Formation of the Middle Jurassic, and the burial depth of the coal seam is approximately 850~1100 m. The working face adopts the longwall fully mechanized top-coal caving backward mining method, and all caving methods manage the roof. The average thickness of the main coal seam in the 301 working face is approximately 12.43 m, the average thickness of the 302 working face is 12.2 m and the average dip angle of the coal seam is 3.4. Because the 301 working face and 302 working face are adjacent working faces, the characteristics of the roof and floor are basically the same. The main roof is fine sandstone with an average thickness of 10.79 m, and the immediate roof and old bottom are mudstone with average thicknesses of 1.25 m and 2.32 m, respectively. The comprehensive histogram of the working face is shown in Figure 2.

Figure 1.

Layout plan of the working face.

Figure 2.

Comprehensive histogram of the working face.

Due to the large mining depth and the influence of high ground stress, high ground temperature, high confined water and strong mining disturbance, coal and gas outbursts are serious, and the strata behavior is strong. The roadway layout of the working face adopts gob-side entry driving with a small coal pillar. The width of the narrow coal pillar is 7 m. During tunneling, long-distance tunneling makes it difficult for single roadway tunneling to meet the air volume requirements at the tunneling face, which seriously restricts the tunneling speed at the tunneling face. At the working face, under the superposition of mining stress and residual lateral abutment pressure, the coal side of the gob-sidewall is swollen and flaky, the coal body is broken severely and the roadway and coal pillars are deformed greatly [15,16].

3. Theoretical and Experimental Research Schemes

3.1. Theoretical Research

3.1.1. Construction of the Mechanical Structure Model

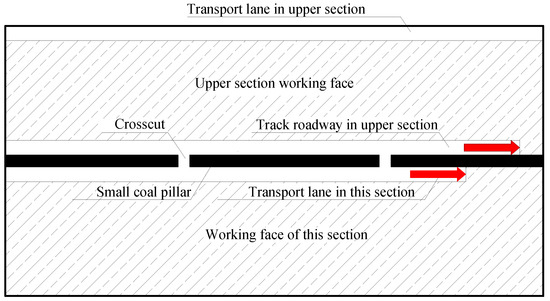

The double-lane layout mode combines the traditional double-lane layout with the characteristics of gob-side entry driving. The protective coal pillar with a large width in the original double-roadway excavation is replaced by a narrow coal pillar, and the roadway is arranged in a low-stress area, which improves the recovery rate and alleviates the problem of tight mining replacement. At the same time, the double-roadway arrangement is also beneficial to the ventilation of the working face during excavation and mining. The simultaneous excavation of double roadways is a kind of double-lane layout, that is, the simultaneous excavation of two roadways, the small coal pillar between the section roadways, the safe distance between the two driving faces during the excavation and the connection roadway between the two roadways for communication. After the roadway is connected, the working face in the upper section will be mined first. After the working face in the upper section is mined and the connecting roadway is sealed, the working face in the lower section will be mined until the mining is completed, as shown in Figure 3.

Figure 3.

Simultaneous excavation of double roadways.

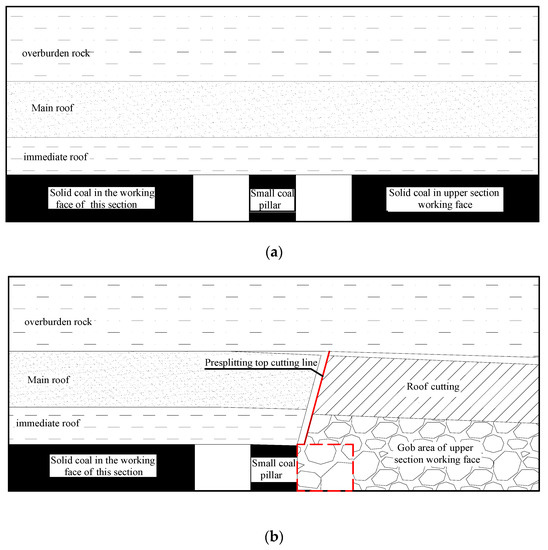

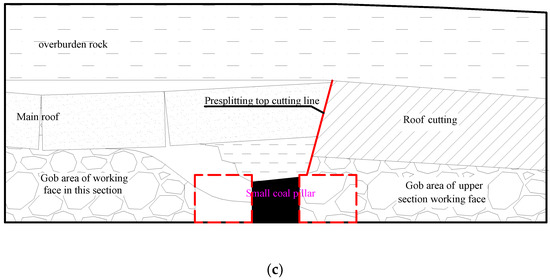

Using a double roadway layout with a small coal pillar, the small coal pillar and roadway have experienced the influence of two dynamic mining pressures from tunneling to mining completion. The structure state of overlying strata in the entire process of excavation and mining with small coal pillars arranged in double roadways can be divided into three stages: (a) the solid coal tunneling stage; (b) the mining stage of the upper section working face and (c) the mining stage of the working face in this section.

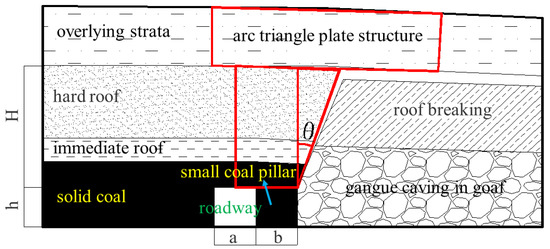

According to the analysis of the overlying strata structure in the entire process of excavation and mining with small coal pillars arranged in Figure 4, in the solid coal excavation stage, small coal pillars and roadways are only affected by excavation; the stress of the surrounding rock is redistributed, the stress disturbance of coal pillars and roadways is small, the internal integrity of small coal pillars is high and the overlying strata structure is relatively stable. In the upper section working face mining stage, the roof above the coal pillar is broken in advance. When the working face in the upper section is pushed, the rock beams of the direct roof and the main roof above the coal pillar side break and collapse along the roof cutting line under the action of rock weight and mine pressure. Moreover, the collapsed gangue in the goaf is not compacted, there is a gap between the cut roof rock stratum and the overlying rock stratum and the overlying rock stratum cannot be effectively supported and begins to sink slowly [17]. With the completion of mining of the working face in the upper section, the caving gangue in the goaf is gradually compacted, and the cut roof plays an effective supporting role in the overlying strata and tends to be stable [18]. In the mining stage of the working face in this section, one side of the small coal pillar is the goaf of the working face in the upper section; at this time, the cut roof and overlying strata tend to be stable. The other side is the goaf of the working face in this section, which is directly piled up by roof caving, and the basic roof rock beam bends, breaks, rotates and sinks, forming an arc triangle. At this time, the roadway and a small coal pillar have completed the mining task, and they are no longer supported. Therefore, a small coal pillar in the upper section of the working face pushes mining, cutting the roof along the top cutting line when the caving is affected the most, and it is necessary to strengthen the small coal pillar according to the coal pillar’s actual stress situation.

Figure 4.

Cross-section of overburden structure in the whole process of excavation and mining with small coal pillars arranged in double roadways. (a) Solid coal tunneling stage, (b) Mining stage of the upper section working face, (c) Mining stage of the working face in this section.

3.1.2. Mechanical Mechanism Analysis of Small Coal Pillar-Surrounding Rock

- (1)

- Load calculation of a small coal pillar

When the roof is cut back, the load and influence of the small coal pillar are the largest. By analyzing the overlying strata structure after cutting back, the load on the small coal pillar is obtained.

The old roof stratum was cut behind. The upper rock stratum bends and sinks, there are few cracks in the rock stratum, and the rock stratum structure is less damaged. A stable structure similar to an arc triangle is formed on the goaf side. This structure has good bearing capacity and has almost no influence on the load of the small coal pillar. The load borne by the small coal pillar under this structure can be simplified as the force of the immediate roof and main roof strata on the coal pillar at the upper part of the coal pillar. The mechanical model of the overburden structure is shown in Figure 5. Under the triangular structure support, the load on the coal pillar is shown in the figure. Assuming that half of the overlying load of the roadway is borne by the coal pillar, the coal pillar load consists of three parts: half of the overlying load of the roadway, the overlying rock load directly above the coal pillar and the inverted step overlying the rock load above the coal pillar side. The calculation formula of the small coal pillar load is obtained by:

where a is the width of the roadway, m; b is the width of the small coal pillar, m; θ1 is the top cutting angle; γ is the bulk density of the overlying strata; H is the top cutting height, m; , M is the mining height, m; and Kp is the expansion coefficient. a and b are the width of roadway and small coal pillar respectively.

Figure 5.

Mechanical model diagram of overburden structure.

Then, the overburden gravity borne by the small coal pillar is determined by Equation (2):

- (2)

- Strength calculation of small coal pillar

After cutting the roof strata with advanced precutting roof technology, the length of the lateral basic roof cantilever beam is reduced, and the influence caused by roof fracture and subsidence is weakened. However, in practical engineering applications, the cut roof will not collapse along the cutting line immediately after the working face advances, and the basic roof stratum will bend and separate from the layer. During the sinking period, the small coal pillar will be compressed and deformed, the coal body will change from an elastic state to a plastic state, and the strength of the coal pillar will also drop to residual strength. However, the geomechanical environment of coal pillars is complex, so it is necessary to consider the influence of joints, cracks, disturbances and other factors on their mechanical strength index [19]. The Hoek-Brown criterion and geological strength index (GSI) are used to modify the laboratory data, and the mechanical strength of coal pillars in engineering is obtained [20,21]. The Hoek-Brown strength estimation formula is expressed by Equation (3):

where is the uniaxial compressive strength of the rock mass, MPa, and s is the rock mass characteristic constant, which is determined by Equation (4):

where GSI is an index of geological strength, and the estimated value of GSI can be determined by the GSI quantitative table of the H-B criterion.

The residual strength of the small coal pillar is obtained by the Hoek-Brown criterion combined with the laboratory strength test, and the small coal pillar in the residual state is supported by the anchor cable. The lateral binding force produced by the anchor cable puts the small coal pillar in a bidirectional stress state, which limits the deformation and failure of the small coal pillar and then improves the residual strength and its bearing capacity. At this time, the residual ultimate bearing strength of a small coal pillar under the reinforcement of opposite anchor cables can be expressed by Equation (5):

where is the modified residual strength of the small coal pillar, MPa; is the lateral support strength of the anchor cable, MPa; and f1 is the lateral strengthening coefficient of the pair-through anchor cable, which can be obtained by laboratory testing.

Then, the ultimate bearing capacity of the small coal pillar under the support of opposite anchor cables is as follows:

Through the above analysis, the residual ultimate bearing capacity of a small coal pillar under the support of the opposite anchor cable can be obtained. If this value is far greater than the bearing capacity F of a small coal pillar, it is unnecessary to support the small coal pillar. If the value is less than or close to the bearing capacity F of a small coal pillar, then concrete-filled steel tubular piers can be erected on both sides of the small coal pillar as auxiliary supports beside the alley. On the one hand, concrete-filled steel tubular piers can bear the overlying rock pressure together with the coal pillar. On the other hand, they can exert extra lateral resistance to the small coal pillar, further strengthening its lateral confining pressure and improving the bearing capacity of the coal pillar. According to the study of the bearing capacity of concrete-filled steel tubular piers in the literature [22,23,24,25,26,27], the ultimate bearing capacity of the supporting structure of a single concrete-filled steel tubular pier beside the roadway can be obtained, and the specific quantity can be determined according to the actual bearing capacity of the supporting body beside the roadway. Finally, the ultimate strength of the small coal pillar under the joint support of the anchor cable and concrete-filled steel tubular pier can be obtained.

where n is the number of concrete-filled steel tubular piers, generally one or two.

At this time, only the ultimate bearing capacity of the small coal pillar under support is greater than the overburden gravity of the small coal pillar , and the safety factor is greater than 1.5, which can meet the engineering needs.

Based on the above analysis, a double-lane layout was adopted. The small coal pillar left between the roadways and the roadway of the working face in this section will be affected by the mining of the working face in the upper section. After the small coal pillar is pushed and mined in the working face in the upper section when the cutting roof falls along the cutting roof line, it will be most affected, and the small coal pillar will be deformed and destroyed. Therefore, it is necessary to reinforce the small coal pillar according to the actual stress. The two-way reinforcement technology through the anchor cable makes full use of the tensile capacity of the anchor cable bundle and the high compressive capacity of the coal structure. After the small coal pillar is reinforced by the anchor cable, the two free surfaces of the coal pillar in the roadway on both sides are compressed, which provides higher lateral confining pressure for the small coal pillar and changes the one-way stress state into a three-way stress state, thus providing two-way reinforcement of the small coal pillar. At the same time, the cement slurry material is injected into the anchor cable hole, and the anchor cable bundle and the surrounding rock of the borehole are bonded into a unified whole to form a common bearing structure, which reduces the damage from the anchor cable hole to the integrity of the small coal pillar and improves its integrity and mechanical bearing performance. At the same time, the problem of spalling and roof fall of the longwall working face is effectively solved [28].

3.2. Experimental Study on Mechanical Bearing Performance of Coal Pillar Anchorage

Based on the above theoretical analysis, when calculating and analyzing the strength of small coal pillars, it is necessary to obtain their residual strength and the lateral strengthening coefficient of opposite anchor cables through tests. This section passes indoor simulation tests. By comparing the deformation and failure characteristics of one-way reinforcement and two-way through–through reinforcement under different densities, different anchorage methods and different arrangement methods, the influence laws of different reinforcement methods on physical and mechanical parameters such as axial load, elastic modulus and residual strength of anchorage are obtained, which provides a theoretical basis for the selection and design of through–through anchorage cables.

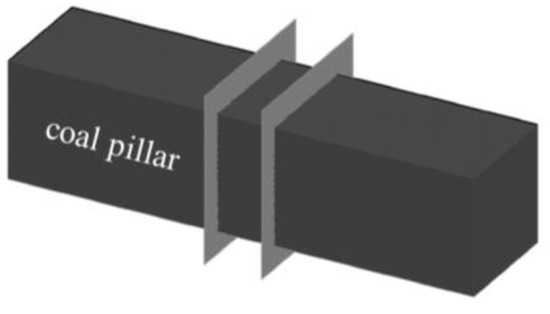

3.2.1. Test Model

According to the actual working conditions, a simplified model of small coal pillars is established. The prototype of the simulation test is equivalent to intercepting a section of coal from a small coal pillar in gob-side entry driving. The intercepted small coal pillar is subjected to the weight of overlying strata in the z-axis direction and the lateral anchoring force provided by bolt cables in the y-axis direction. The coal on both sides in the x-axis direction will provide a certain lateral supporting force. The simplified model is shown in Figure 6.

Figure 6.

Simplified model of a narrow coal pillar.

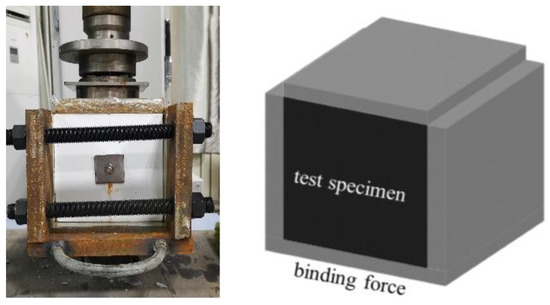

Based on the simplified model, the test fixture was designed. As shown in Figure 7, install the anchor solid test piece on the test instrument and then tighten the pull rod nut. By applying the load in the vertical direction, the test piece undergoes compression deformation, and the lateral expansion deformation of the test piece produces a force on the side plate. In contrast, the side plate transmits a reaction force to the test piece. The jack is located between the reaction plate and the front baffle plate. The reaction plate is used to apply a confining pressure to the front baffle plate to simulate the stress state of the original rock. Removing the confining pressure of the front baffle plate can affect the excavation process, and applying the anchor rod can simulate the anchoring effect of the anchor rod [29,30].

Figure 7.

Model comparison diagram.

3.2.2. Selection of Test Materials

- (1)

- Selection of similar materials

The materials used for the test are high-strength gypsum powder, water, retarder and water reducer. Two proportioning schemes were designed, the ratio of water to paste was 0.65:1 and 0.6:1, and three specimens were made in each group. After the specimen was manufactured, it was placed in a dry and ventilated environment for curing for seven days, and the uniaxial compression test was carried out on the specimen [31]. The test process is shown in Figure 8. The average value of the test results is calculated by removing the specimens with high discreteness. See Table 1 for the physical and mechanical parameters of each specimen.

Figure 8.

Uniaxial compression test of the specimen.

Table 1.

Physical and mechanical parameters of the specimens.

The uniaxial compressive strength of the simulated prototype coal in this test is 11 MPa, the density is 1.3 g/cm3, the internal friction angle is 30 and Poisson’s ratio is 0.3. After comparison, the first group of proportioning schemes that are closer to its physical and mechanical parameters was selected for the follow-up test.

- (2)

- Material selection of the bolt (cable)

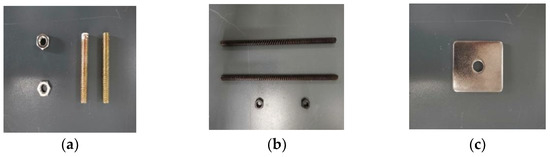

The anchor rod selected was a 304 stainless steel threaded rod with a strength grade of 4.8, and the nut selected was a 4.8-grade nut. The anchor cable was a 304 stainless steel threaded rod with a strength grade of 12.9, and the nut was a 12.9-grade nut. According to the geometric ratio, a 304 stainless steel gasket was selected for the tray, and the dimensions are 40 mm × 40 mm × 3 mm. The relevant test materials are shown in Figure 9.

Figure 9.

Anchor rod and matching nuts and gaskets. (a) Grade 4.8 screws and nuts, (b) Grade 12.9 screws and nuts, (c) 304 stainless steel gasket.

3.2.3. Test Scheme

By designing different bolt (cable) densities, different bolt (cable) reinforcement modes and different bolt (cable) arrangement modes, this test explored the influence of these variables on the physical and mechanical parameters of the anchorage and obtained the lateral strengthening coefficient of the anchor cable.

- (1)

- Different bolt (cable) densities

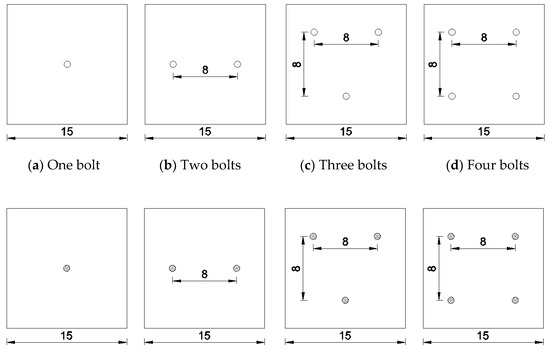

Five kinds of bolt (cable) densities were set in the test; that is, zero, one, two, three and four bolts (cables) were arranged on the test block of 150 × 150 × 150 mm. The layout plan is shown in Figure 10. The bolt length is 6 cm, and the anchor cable length is 20 cm.

Figure 10.

Layout position plan.

- (2)

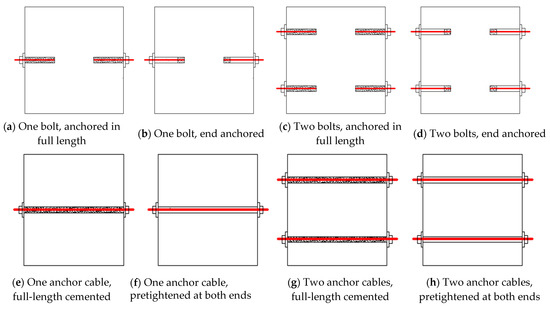

- Different anchoring methods

In the test, two kinds of anchoring methods were set up: end anchoring and full-length anchoring. The end anchoring length was 1 cm, and the full-length anchoring length was 4.5 cm. Two anchoring modes were set for the through anchor cable: full-length cementation and pretightening at both ends. The cross-sectional view of the specimen is shown in Figure 11.

Figure 11.

Sectional view of the specimen.

- (3)

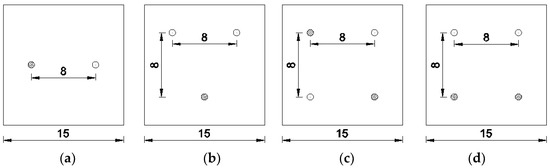

- Different arrangements

The combined arrangement of bolts (cables) was set in the test, and the anchorage mode of the bolts was full-length anchorage, while the reinforcement mode of the through anchorage cables was pretightening at both ends. Among these, the density of the four specimens can be divided into two arrangement combinations: parallel arrangement and cross arrangement. The layout of each specimen is shown in Figure 12.

Figure 12.

Plane layout of the specimen. (a) Combination arrangement of two roots, (b) Combination arrangement of three roots, (c) Combined cross arrangement, (d) Combined parallel arrangement.

4. Results Analysis and Discussion

4.1. Analysis of Anchorage Effect of Anchor Rod

To more intuitively analyze the strengthening effect of the bolt cable on the anchorage body, the concept of the strengthening coefficient is introduced, that is, the ratio of a certain mechanical parameter of the anchorage body after applying the bolt cable to the corresponding mechanical parameter of the nonanchorage specimen. The greater the strengthening coefficient is, the better the anchoring effect of the anchor cable on the anchorage body. Including the elastic modulus strengthening coefficient, axial load strengthening coefficient and residual strength strengthening coefficient, its mathematical expression is as follows:

where K is the strengthening coefficient, W is the value of a mechanical parameter of the anchorage body and W0 is the corresponding mechanical parameter value of the nonanchored specimen.

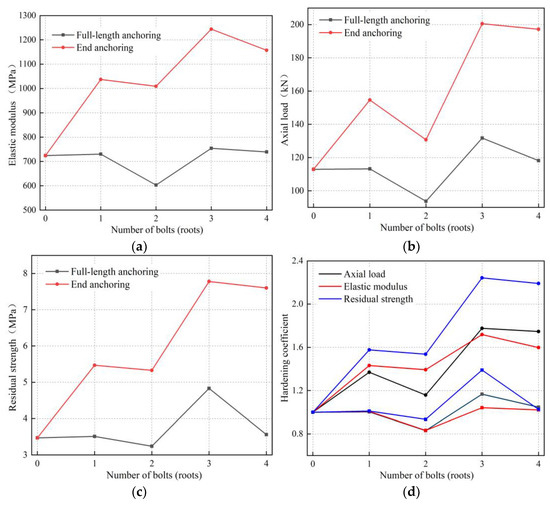

In this group of tests, two influencing factors, density and anchorage mode, were set to study their influence on the elastic modulus, axial load and residual strength of the anchorage. The test results are shown in Figure 13.

Figure 13.

Broken line diagram of bolt test results (a) Relation curve of elastic modulus of anchorage, (b) Axial load relationship curve of anchorage body, (c) Relation curve of residual strength of anchorage, (d) Relationship curve of strengthening coefficient of anchorage.

According to the analysis of the anchoring effect of the bolt, there is a reasonable anchoring length in the anchor strength, and setting a certain length of the free section is beneficial to expand the effective compressive stress zone of the bolt and give full play to the anchoring effect of the bolt. There is also a reasonable value of bolt density. When the bolt density is reasonable, the effective stress areas between the bolts overlap to form an effective bearing structure and improve the strength of the anchorage. When the bolt density is too high, too much drilling will destroy the anchorage’s internal structure and reduce its bearing capacity.

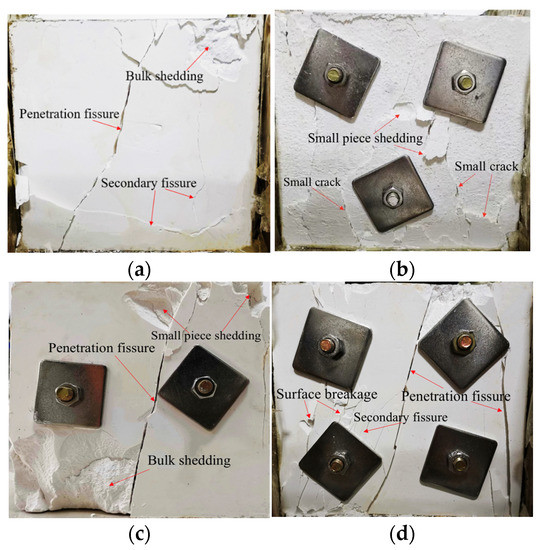

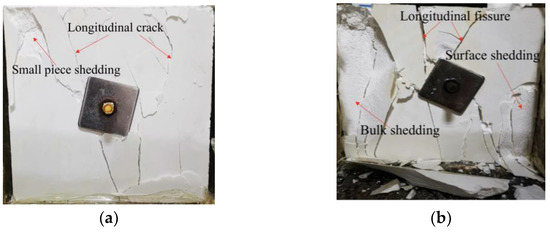

The elastic modulus, axial load and residual strength reach their maximum values when the number of bolts is three and decrease when the number of bolts is two and four. According to the analysis, when uniaxial compression is carried out on the specimen without anchors, longitudinal through cracks will occur in the middle of the free surface, as shown in Figure 14a. When the anchor density is 3, the compressive stress zone formed by the rod body is evenly distributed, which effectively limits the generation and development of through cracks. Small pieces fall off the surface of the anchor body without through cracks, and small longitudinal cracks are mainly on both sides, as shown in Figure 14b. When the bolt density is 2, the compressive stress zone formed by the bolt body is distributed left and right, which cannot limit the development of through cracks in the middle, and the surface of the specimen falls off in large pieces, as shown in Figure 14c. When the anchor rod density is 4, not only will the middle through crack occur on the anchor body surface, but the longitudinal crack will also occur near the anchor rod holes on both sides of the specimen. The surface near the anchor rod is broken, but no large pieces fall off, as shown in Figure 14d.

Figure 14.

Failure mode of the anchor body of the anchor rod. (a) Anchorless specimen, (b) three bolts, (c) two bolts, (d) four bolts.

4.2. Analysis of Anchorage Effect of a Penetrating Anchor Cable

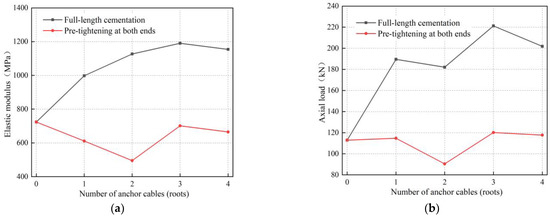

In this group of tests, two factors, density and reinforcement mode were set to study their influence on the anchorage elastic modulus, axial load and residual strength. The test results of anchor cable-penetrating specimens are shown in Figure 15.

Figure 15.

Line diagram of the test results of the anchor cable specimens. (a) Relation curve of elastic modulus of anchorage, (b) Axial load relationship curve of anchorage body, (c) Relation curve of residual strength of anchorage, (d) Relationship curve of strengthening coefficient of anchorage.

According to the test results of the through-anchor cable specimens, the anchorage axial load, elastic modulus and residual strength under full-length cemented reinforcement are higher than those under two-end pretightened reinforcement when the anchor cable density is the same. This is because under the full-length cemented reinforcement mode, the rod body, anchorage agent and specimen are bonded into a whole, and the generated sticky anchor force makes the rod body and borehole surrounding rock form a common bearing structure, which inhibits the deformation of the anchorage body. Pretightening at both ends exerts lateral anchoring force on the anchorage body, which changes the unidirectional stress state into the three-dimensional stress state and improves the anchorage body’s mechanical bearing performance. Only small longitudinal cracks occurred, and small pieces fell off the surface of the specimen, as shown in Figure 16a. Under the pretightening reinforcement mode at both ends, the specimen is only subjected to the pretightening force at both ends. After applying pressure to the specimen, it was damaged at the drilling hole and formed a large crack, which led to large pieces falling off both sides of the specimen surface and reduced the anchorage bearing capacity, as shown in Figure 16b. At the same time, there is a reasonable value of anchor cable density. When the anchor cable density is too small, the anchoring range of the anchor cable is limited; when the density of the anchor cable is too high, the integrity of the anchor body is destroyed, and the bearing capacity of the anchor body is reduced.

Figure 16.

Failure mode of the anchor body through the anchor cable. (a) Full-length cementation, (b) Pretightening at both ends.

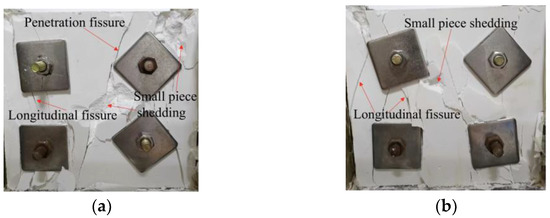

The density variation law of the through anchor cables is basically the same as that of the anchor rods, and the elastic modulus, axial load and residual strength all reach the maximum when the number of through anchor cables is 3. The test results show that when the density of the anchor cable is 3, the development of cracks in the middle part can be effectively limited, the middle part of the specimen produces small bulges due to the pretightening and extrusion of the anchor cable, the overall cracks of the specimen are fewer and the integrity is higher, as shown in Figure 17a. When the density of the anchor cable is 4, longitudinal cracks occur in the middle of the specimen, small pieces fall off in the upper part and large cracks occur in the anchor cable holes on both sides, as shown in Figure 17b.

Figure 17.

Failure mode of the anchor body through the anchor cable. (a) Three opposite anchor cables, (b) Four opposite anchor cables.

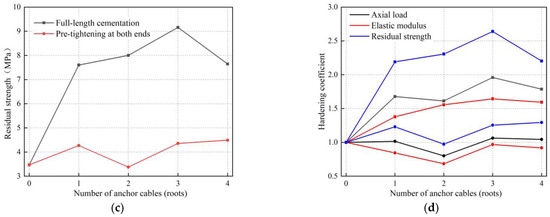

4.3. Anchorage Effect Analysis of the Mixed Arrangement of Bolts and Cables

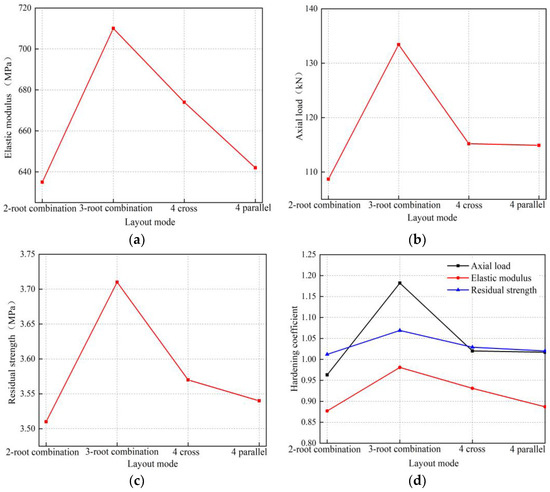

In this experiment, four different arrangements were set up to study their influence on the bearing capacity, elastic modulus, and residual strength of the anchorage. The test results are shown in Figure 18.

Figure 18.

Line diagram of the test results of the combined specimens. (a) Relation curve of elastic modulus of anchorage, (b) Axial load relationship curve of anchorage body, (c) Relation curve of residual strength of anchorage, (d) Relationship curve of strengthening coefficient of anchorage.

According to the analysis of the anchorage effect of the mixed arrangement of bolts and cables, the axial load, elastic modulus and residual strength of the anchorage body increase at first and then decrease with the increasing density of the bolt bodies. Under the combination arrangement of three roots, the values of each parameter reached the maximum. The cross-combination arrangement of four roots was slightly better than the parallel combination arrangement of four roots. Figure 19 shows that under the two arrangements, small pieces fall off the surface of the specimen, there are longitudinal through cracks in the middle of the anchorage body, and there are many small longitudinal cracks near the borehole, which suggests that after applying load to the anchorage body, the damage occurs preferentially in the borehole and surrounding rock mass, which reduces the bearing capacity of the anchorage body.

Figure 19.

Failure mode of the combined anchorage. (a) Cross arrangement, (b) Parallel arrangement.

4.4. Comparative Analysis of the Optimal Arrangement

The above three groups of test schemes were comprehensively compared and analyzed, and the optimal layout scheme was obtained. Table 2 shows the statistics of the average strengthening coefficient of the specimens. Comparing the three layout schemes, the bolt layout under the full-length anchorage mode and the opposite anchor cable layout under the two-end pretightening mode have a weak strengthening effect on the specimen, which is related to its reinforcement mode. The reinforcing effect of all parameters of the specimen under the full-length cementation mode is better than that under the end anchorage mode, which shows that the anchorage effect of bidirectional reinforcement on the specimen is better. According to the Mohr-Coulomb criterion, the lateral strengthening coefficients are 2.17, 1, 1.02 and 0.63, so the average value of the lateral strengthening coefficients is 1.2.

Table 2.

Statistical table of the average strengthening coefficient of the specimens.

The above analysis suggests that when the specimen is strengthened by two-way anchor cables, each anchorage parameter has the highest degree of strengthening of the residual strength of the anchorage (followed by the axial load) and the weakest degree of strengthening of the elastic modulus. The strength of the anchorage body does not increase with the increasing anchorage length, and there is a reasonable anchorage length. With an increasing bolt density, the bolt parameters increase first and then decrease, which shows that the larger the bolt density is, the better, and there is a reasonable anchorage value. The anchor cable provides not only adhesive force to the anchorage body but also exerts lateral anchorage force on it. Anchorage parameters also show a trend of increasing first and then decreasing with the increase of anchor cable density, which shows that the larger the anchor cable density, the better, and there is a reasonable anchorage value. The nonrectangular three-flower arrangement can effectively limit the development of cracks in specimens, especially the development of longitudinal through cracks.

Compared with conventional bolt reinforcement, the strengthening effect of bidirectional cross-penetration reinforcement on mechanical parameters of anchorage is more significant, especially on the strengthening and improvement of residual strength of anchorage, and the control effect on the small coal pillar in the postpeak residual state is better, which is beneficial to the small coal pillar stability control.

5. Engineering Application

5.1. Parameter Design of the Small Coal Pillar Support Scheme

Based on theoretical analysis and test results, reasonable coal pillar width and support parameters were calculated. The small coal pillar bearing capacity and load under different coal pillar widths are obtained from Equation (1), where a is the width of the roadway at 6 m; h is the height of the roadway at 3.9 m; θ1 is the top cutting angle of 15; γ is the bulk density of overlying strata at 25 kN/m3, and the bulk density of coal pillar is 13 kN/m3; M is the mining height of 5.5 m, Kp is the breaking and expanding coefficient of 1.27 and the cutting height of H is 20.57 m. See Table 3 for loads of different coal pillar widths.

Table 3.

Load of coal pillars with different widths.

According to the uniaxial compressive strength of coal samples, Hoek-Brown criterion and geological strength index measured in the laboratory, the laboratory data were modified, in which the GSI value is 35, and the modified residual strength of the small coal pillar is 0.29 MPa.

According to the site support conditions, the commonly used bolt in Gaojiapu Coal Mine is a left-handed resin bolt with a diameter of 22 mm and a pretightening force of 70 kN. The anchor cable specification is a 1 × 19 steel strand with a diameter of 21.6 mm and a pretightening force of 220 kN. According to the design size of the roadway section, the design width of the two gateways in the 301 working face and 302 working face is 6 m, and the height is 3.9 m. After roadway excavation, the roof and solid coal side adopt the original roadway support scheme. The side of the small coal pillar is supported by an anchor rod and anchor cable. After the track gateway of the 302 working face is excavated, anchor rods are used to support small coal pillars for the first time. Three anchor rods are arranged in each row, and the spacing between rows is 1600 × 2000 mm. After the transportation gateway of the 301 working face is excavated, the small coal pillars are reinforced in both directions by using opposite anchor rods. Three to five anchor rods are arranged on both sides of the coal pillars, and the support strength of the coal pillars is provided by anchor rods, as shown in Table 4.

Table 4.

Support scheme of small coal pillar crossing anchor cable.

According to the lateral strengthening coefficient of 1.2, the ultimate bearing strength of the small coal pillar is 0.5 MPa, 0.56 MPa and 0.625 MPa when three, four and five anchor cables are arranged on both sides of the coal pillar. The bearing capacity of each width of the coal pillar is shown in Table 5.

Table 5.

Bearing capacity of coal pillars with different widths.

The above analysis indicates that it is not enough to bear the weight of overlying strata using only the small coal pillar reinforced by the anchor cable, and it is necessary to erect concrete-filled steel tubular piers beside the coal pillar to resist the abutment pressure together with the small coal pillar. Under the condition that the safety factor SF is greater than 1.5, the supporting force required by each width coal pillar is 6275.5 kN, 6893.4 kN, 7511.2 kN, 8129 kN and 8746.9 kN. The supporting resistance required by the roadway support of the concrete-filled steel tubular pier column is shown in Table 6.

Table 6.

Support resistance provided by the concrete-filled steel tubular pier column.

According to reference [32], the reduction factor of the long column is calculated, where L is 3700 mm. Then, the reduction factor and actual bearing capacity of the long column under different pier diameters are shown in Table 7.

Table 7.

Reduction factor and bearing capacity of piers with different diameters.

According to the calculation, the size of the steel tube is Φ194 × 12 mm, the maximum supporting resistance provided by a single pier is 1883 kN and the maximum supporting resistance provided by the pier is 3766 kN when one concrete-filled steel tube pier is erected on both sides of the coal pillar.

In summary, when the width of the coal pillar is 4~5 m, the safety factor SF of the coal pillar under the supporting condition is less than 1.5, which cannot meet the engineering needs. When the width of the coal pillar is 6~8 m, five opposite anchor cables are arranged in each section, three anchor rods are arranged on one side of the coal pillar and one concrete-filled steel tube pier with a size of Φ194 × 12 mm is arranged on both sides of the coal pillar. The width of the coal pillar and design support parameters can ensure that the safety factor SF is greater than 1.5, which meets the engineering needs.

5.2. Field Engineering Application

5.2.1. Layout Scheme of the Double Roadway

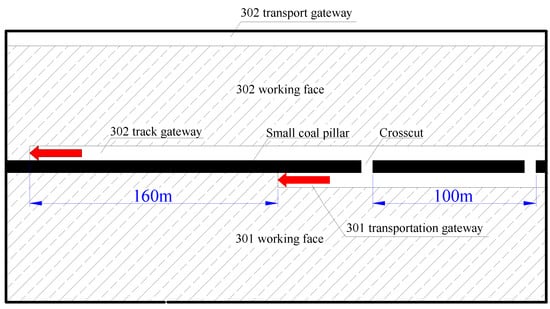

Taking the 301 working face and 302 working face of Gaojiapu Coal Mine of Zhengtong Coal Industry as engineering practice, the roadway driving mode adopts double roadway driving at the same time; that is, 301 transportation gateway and 302 track gateway work in the same direction, and the 302 track gateway driving face is ahead of the 301 transportation gateway driving face. To avoid the influence between heading faces, the staggered distance between two heading faces is set at 160 m, the distance between connecting roadways is 100 m and the width of the small coal pillar between two gateways is 7 m. A schematic diagram of double roadway excavation is shown in Figure 20.

Figure 20.

Schematic diagram of the double roadway excavation layout.

5.2.2. Support Design Scheme

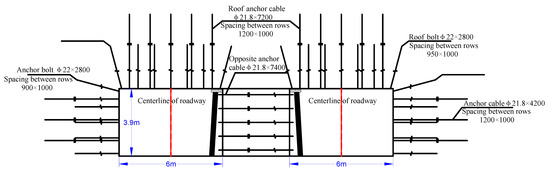

Based on the theoretical calculation, the small coal pillar was set with a width of 7 m, and the roof and solid coal side of 302 track gateway and 301 transportation gateway are supported by bolt and anchor cable. Moreover, the bolt is a left-handed resin bolt, and the anchor cable is a 1 × 19 prestressed steel strand with specifications. The roof bolt is 22 mm in diameter and 2800 mm in length with 950 × 1000 mm spacing between rows. The anchor cable is 21.8 mm in diameter and 7200 mm in length with 1200 × 1000 mm spacing between rows. The diameter of the two bolts is 22 mm, and the length is 2800 mm, with the spacing between rows of 900 × 1000 mm. The diameter of the anchor cable is 21.8 mm, and the length is 4200 mm with the spacing between rows of 1200 × 1000 mm. At the same time, it is supported by a W-shaped steel strip and metal mesh.

The small coal pillar is supported by a bolt + pair-through anchor cable + concrete-filled steel tube pier column. Three bolts are arranged on the side of the coal pillar along the 302 track, with a diameter of 22 mm, a length of 2800 mm and a row spacing of 1600 × 2000 mm. Five two-way pair-through anchor cables are arranged on the coal pillar along the 301 transportation gateway, with a diameter of 21.8 mm, a length of 7400 mm and a row spacing of 800 × 1000 mm. One concrete-filled steel tube pier is arranged on each side of the small coal pillar. The outer diameter of the pier is 194 mm, the wall thickness is 12 mm, the length of the steel tube is 3700 mm, the arrangement spacing is 1000 mm, the spacing between the pier and the small coal pillar is 300 mm, the offset angle to the coal pillar side is 3, the core concrete strength is C40 and the thickness of the upper flexible cushion is 200 mm. The roadway cross-section support diagram is shown in Figure 21.

Figure 21.

Support drawing of roadway section.

5.3. Application Effect Analysis

5.3.1. Station Layout

To verify the application effect of supporting technology with a small coal pillar in a double roadway layout, understand the deformation of the roadway and surrounding rock, test the rationality of the supporting design parameters and monitor the ground pressure of the roadway, two measuring points are set in the transportation gateway of 301 working face. The #1 measuring point was 60 m away from 302 working face, and the #2 measuring point was 90 m away from 302 working face and 30 m away from the #1 measuring point, which was used to monitor the deformation of the top and bottom plate and two sides of 301 transportation gateway before and after mining in 302 working face. The layout of the measuring stations is shown in Figure 22.

Figure 22.

Schematic diagram of the station layout.

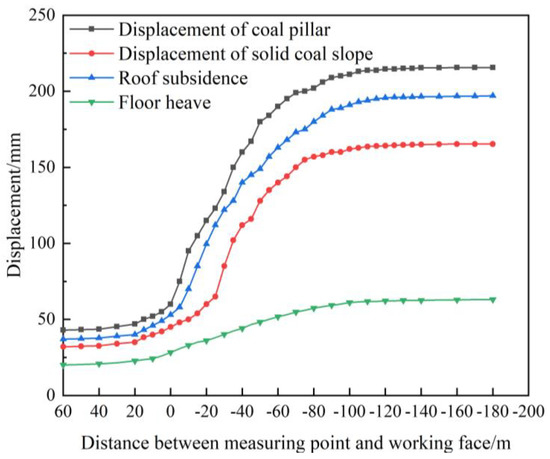

5.3.2. Monitoring Results during Mining of the Working Face

The monitoring data take the average value of the corresponding positions of the two measuring points, obtain the surface displacement of the roadway during the mining period of the 302 working face and compare it with the surface displacement of the traditional gob-side entry driving roadway. See Figure 23 for the monitoring results. According to Figure 23, with the advancement of the working face, at 40 m away from the working face, the deformation of the roof and floor of the roadway and the two sides shows a slowly increasing trend. At 15 m away from the working face, the deformation of the surrounding rock gradually increases. When the working face has passed the measuring point, the moving speed of roadway surface displacement increases rapidly and changes greatly within 70 m after the working face has been pushed. When the working face is 70~130 m behind, the roadway displacement approaching rate becomes slow. When the distance of the lagging working face is more than 130 m, the change in roadway displacement tends to be stable.

Figure 23.

Surface displacement of roadway.

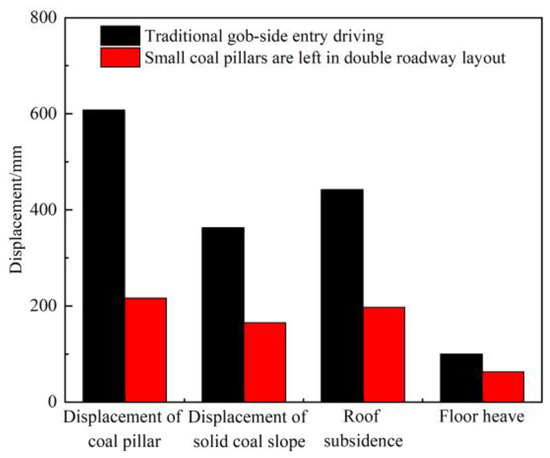

Compared with the traditional gob-side entry driving scheme, as shown in Figure 24. The results show that when the traditional gob-side entry driving method is adopted, the displacement of the coal pillar side is 608 mm, the displacement of the solid coal side is 363 mm, the roadway roof sinks 442 mm and the floor heave is 98 mm. The displacement of the pillar side is 216 mm, the displacement of the solid coal side is 165 mm, the roof of the roadway sinks 197 mm and the floor heave is 63 mm. Compared with the traditional gob-side entry driving method, the displacement is reduced by 64.4%, 54.5%, 55.4% and 35.7%, respectively. The displacement of the roadway is within the controllable range and meets the engineering requirements.

Figure 24.

Comparison of roadway surface displacement.

6. Conclusions

- (1)

- Through the construction of the overburden structure model in the process of excavation and mining, it is analyzed that after the small coal pillar is pushed into the upper section of the working face, the roof will be most affected when it collapses along the cutting line. The stability of the small coal pillar is analyzed, and the load calculation and strength calculation methods of the small coal pillar are obtained. The selection design of the anchor cable and the concrete-filled steel tube pier is given.

- (2)

- The test results show that the average value of the lateral reinforcement coefficient of the anchor cable is 1.2, and the strengthening effect of the two-way reinforcement on the mechanical parameters of the anchor is more significant, which is beneficial to the stability control of small coal pillars in the postpeak state.

- (3)

- According to the monitoring data of retaining small coal pillar support technology for double roadway layout on site, the displacement of coal pillar wall, displacement of solid coal wall, roof subsidence and floor heave under this technology are reduced by 64.4%, 54.5%, 55.4% and 35.7%, respectively, compared with the traditional gob-side entry method, which indicates that the support measures mainly based on the anchor cable can improve the bearing capacity of small coal pillars and effectively control the deformation of small coal pillars.

- (4)

- This paper innovatively put forward the roadway layout mode of double-roadway layout with a small coal pillar that combines the advantages of traditional double-roadway driving and gob-side entry driving technology. This roadway layout solves the tension problem of coal mining excavation succession and reduces the waste of coal resources. Secondly, a new type of small coal pillar reinforcement and support techniques with the opposite anchor cable as the main body is put forward, which can improve the bearing capacity of small coal pillars and solve the long-term stability control problem of small coal pillars under the influence of mining.

Author Contributions

Conceptualization, W.H.; methodology, W.H.; software, M.G.; validation, T.H. and Z.X.; formal analysis, X.W. and S.L.; investigation, T.Z.; resources, T.H. and Z.X.; data curation, S.L.; writing—original draft preparation, S.L.; writing—review and editing, W.H. and S.L.; visualization, L.S.; project administration, W.H.; funding acquisition, W.H. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Natural Science Foundation of China (No. 51774195), the Open Fund by State Key Laboratory of Efficient Mining and Clean Utilization of Coal Resource (No. 2021-KFYB-020), the Natural Science Foundation of Shandong Province (ZR2021QE176).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the finding of this study are available from the corresponding author upon request.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (No. 51774195), the Open Fund by State Key Laboratory of Efficient Mining and Clean Utilization of Coal Resource (No. 2021-KFYB-020), the Natural Science Foundation of Shandong Province (ZR2021QE176) and the support is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zha, W.H.; Shi, H.; Liu, S.; Kang, C.H. Surrounding rock control of gob-side entry driving with narrow coal pillar and roadway side sealing technology in Yangliu Coal Mine. Int. J. Min. Sci. Technol. 2017, 27, 819–823. [Google Scholar] [CrossRef]

- Feng, J.C.; Ma, N.J.; Zhao, Z.Q.; Zhang, H.; Yu, Z.M. Width of narrow coal pillar of roadway driving along goaf at large height mining face in deep mine. J. Min. Saf. Eng. 2014, 31, 580–586. [Google Scholar]

- Zhang, K.X.; Zhang, Y.J.; Ma, Z.Q.; Bi, W.G.; Yang, Y.M.; Li, Y. Determination of the narrow pillar width of gob-side entry driving. J. Min. Saf. Eng. 2015, 32, 446–452. [Google Scholar]

- Li, G.J.; Wang, X.Y.; Bai, J.B.; Wu, B.W.; Wu, W.D. Research on the failure mechanism and control technology of surrounding rock in gob-side entry driving under unstable overlying strata. Eng. Fail. Anal. 2022, 138, 106361. [Google Scholar] [CrossRef]

- Tian, C.; Wang, A.H.; Liu, Y.J.; Jia, T.G. Study on the Migration Law of Overlying Strata of Gob-Side Entry Retaining Formed by Roof Cutting and Pressure Releasing in the Shallow Seam. Shock Vib. 2020, 2020, 8821160. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, J.; Gong, W.; Sun, Z. Model test and numerical study on surrounding rock deformation and overburden strata movement law of gob-side entry retaining via roof cutting. Minerals 2020, 10, 458. [Google Scholar] [CrossRef]

- Qi, F.K.; Zhou, Y.J.; Li, J.W.; Wang, E.Q.; Cao, Z.Z.; Li, N. Top-coal deformation control of gob-side entry with narrow pillars and its application for fully mechanized mining face. Int. J. Min. Sci. Technol. 2016, 26, 417–422. [Google Scholar] [CrossRef]

- Singh, R.; Singh, A.K.; Maiti, J.; Mandal, P.K.; Singh, R.; Kumar, R. An observational approach for assessment of dynamic loading during underground coal pillar extraction. Int. J. Rock Mech. Min. Sci. 2011, 48, 794–804. [Google Scholar] [CrossRef]

- Yang, J.P.; Cao, S.G.; Li, X.H. Failure laws of narrow pillar and asymmetric control technique of gob-side entry driving in island coal face. Int. J. Min. Sci. Technol. 2013, 23, 267–272. [Google Scholar] [CrossRef]

- Zhang, K.; Ji, M.; Guo, H.J.; He, W.R. Study on reasonable width of coal pillar in thick coal seam section. J. Mines Met. Fuels 2019, 67, 99–104. [Google Scholar]

- Zhang, K.; Wu, F.F.; Yue, X. Study on Reasonable Chain Pillar Size in a Thick Coal Seam. Geofluids 2022, 2022, 7290894. [Google Scholar] [CrossRef]

- Zhang, C.W.; Jin, Z.X.; Feng, G.R.; Song, X.M.; Rui, G.; Zhang, Y.J. Double Peaked Stress–Strain Behavior and Progressive Failure Mechanism of Encased Coal Pillars Under Uniaxial Compression. Rock Mech. Rock Eng. 2020, 53, 3253–3266. [Google Scholar] [CrossRef]

- Oleksandr, K.; Viktoriia, K.; Serhii, S. Interaction of rock-bolt supports while weak rock reinforcing by means of injection rock bolts. Min. Miner. Depos. 2021, 15, 8–14. [Google Scholar]

- Feng, F.; Li, X.B.; Luo, L.; Zhao, X.D.; Chen, S.J.; Jiang, N.; Huang, W.P.; Wang, Y.J. Rockburst response in hard rock owing to excavation unloading of twin tunnels at great depth. Bull. Eng. Geol. Environ. 2021, 80, 7613–7631. [Google Scholar] [CrossRef]

- Zaid, M. Three-dimensional finite element analysis of urban rock tunnel under static loading condition: Effect of the rock weathering. Geomech. Eng. A 2021, 25, 99–109. [Google Scholar]

- Zaid, M.; Mishra, S. Numerical Analysis of Shallow Tunnels Under Static Loading: A Finite Element Approach. Geotech. Geol. Eng. 2021, 39, 2581–2607. [Google Scholar] [CrossRef]

- Zaid, M. Dynamic stability analysis of rock tunnels subjected to impact loading with varying UCS. Geomech. Eng. A 2021, 24, 505–518. [Google Scholar]

- Wang, Q.; Jiang, B.; Xu, S.; He, M.C.; Jiang, Z.H.; Li, S.C.; Wei, H.Y.; Xiao, Y.C. Roof-cutting and energy-absorbing method for dynamic disaster control in deep coal mine. Int. J. Rock Mech. Min. Sci. 2022, 158, 105186. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.J.; Wang, Y.J.; Huang, W.P.; Han, Z.Y. Cracking mechanism and strength criteria evaluation of granite affected by intermediate principal stresses subjected to unloading stress state. Int. J. Rock Mech. Min. Sci. 2021, 143, 104783. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. The Hoek-Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. Eng. 2019, 11, 445–463. [Google Scholar] [CrossRef]

- Hoek, E.; Carranza-Torres, C.T.; Corkum, B.; Hoek, E.; Carranza-Torres, C. Hoek-Brown failure criterion—2002 Edition. Proc. NARMS-TAC 2002, 1, 267–273. [Google Scholar]

- Huang, W.P.; Gao, Y.F.; Wen, Z.J.; Gao, L. Technology of gob-side entry retaining using concrete-filledsteel tubular column as roadside supporting. J. China Univ. Min. Technol. 2015, 44, 604–611. [Google Scholar]

- Huang, W.P.; Wang, X.W.; Shen, Y.S.; Feng, F.; Wu, K.; Li, C.L. Application of concrete-filled steel tubular columns in gob-side entry retaining under thick and hard roof stratum: A case study. Energy Sci. Eng. 2019, 7, 2540–2553. [Google Scholar] [CrossRef]

- Huang, W.P.; Yuan, Q.; Tan, Y.L.; Wang, J.; Liu, G.L.; Qu, G.L.; Li, C. An innovative support technology employing a concrete-filled steel tubular structure for a 1000-m-deep roadway in a high in situ stress field. Tunn. Undergr. Space Technol. 2018, 73, 26–36. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Y.F.; He, X.S.; Huang, W.P.; Gao, K.P.; Yang, L.; Feng, S.W. The analysis of roadside supporting parameters and the support technology in the concrete filled steel tubular column in goaf-side entry retaining. J. Min. Saf. Eng. 2015, 32, 943–949. [Google Scholar]

- Sadique, M.R.; Zaid, M.; Alam, M.M. Masroor. Rock Tunnel Performance Under Blast Loading Through Finite Element Analysis. Geotech. Geol. Eng. 2022, 40, 35–56. [Google Scholar] [CrossRef]

- Zaid, M. Preliminary Study to Understand the Effect of Impact Loading and Rock Weathering in Tunnel Constructed in Quartzite. Geotech. Geol. Eng. 2021, 1–29. [Google Scholar] [CrossRef]

- Vu, T.T. Solutions to prevent face spall and roof falling in fully mechanized longwall at underground mines, Vietnam. Min. Miner. Depos. 2022, 16, 127–134. [Google Scholar] [CrossRef]

- Liang, X.; Tang, S.B.; Tang, C.A.; Hu, L.H.; Chen, F. Influence of Water on the Mechanical Properties and Failure Behaviors of Sandstone Under Triaxial Compression. Rock Mech. Rock Eng. 2022, 1–32. [Google Scholar] [CrossRef]

- Chen, S.J.; Feng, F.; Wang, Y.J.; Li, D.Y.; Huang, W.P.; Zhao, X.D.; Jiang, N. Tunnel failure in hard rock with multiple weak planes due to excavation unloading of in-situ stress. J. Cent. South Univ. 2020, 27, 2864–2882. [Google Scholar] [CrossRef]

- Tang, S.B.; Li, J.M.; Ding, S.; Zhang, L.T. The influence of water-stress loading sequences on the creep behavior of granite. Bull. Eng. Geol. Environ. 2022, 81, 482. [Google Scholar] [CrossRef]

- Cai, S.H. Modern Concrete Filled Steel Tube Structure; China Communications Press: Beijing, China, 2003. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).