Research on Vehicle Active Steering Stability Control Based on Variable Time Domain Input and State Information Prediction

Abstract

1. Introduction

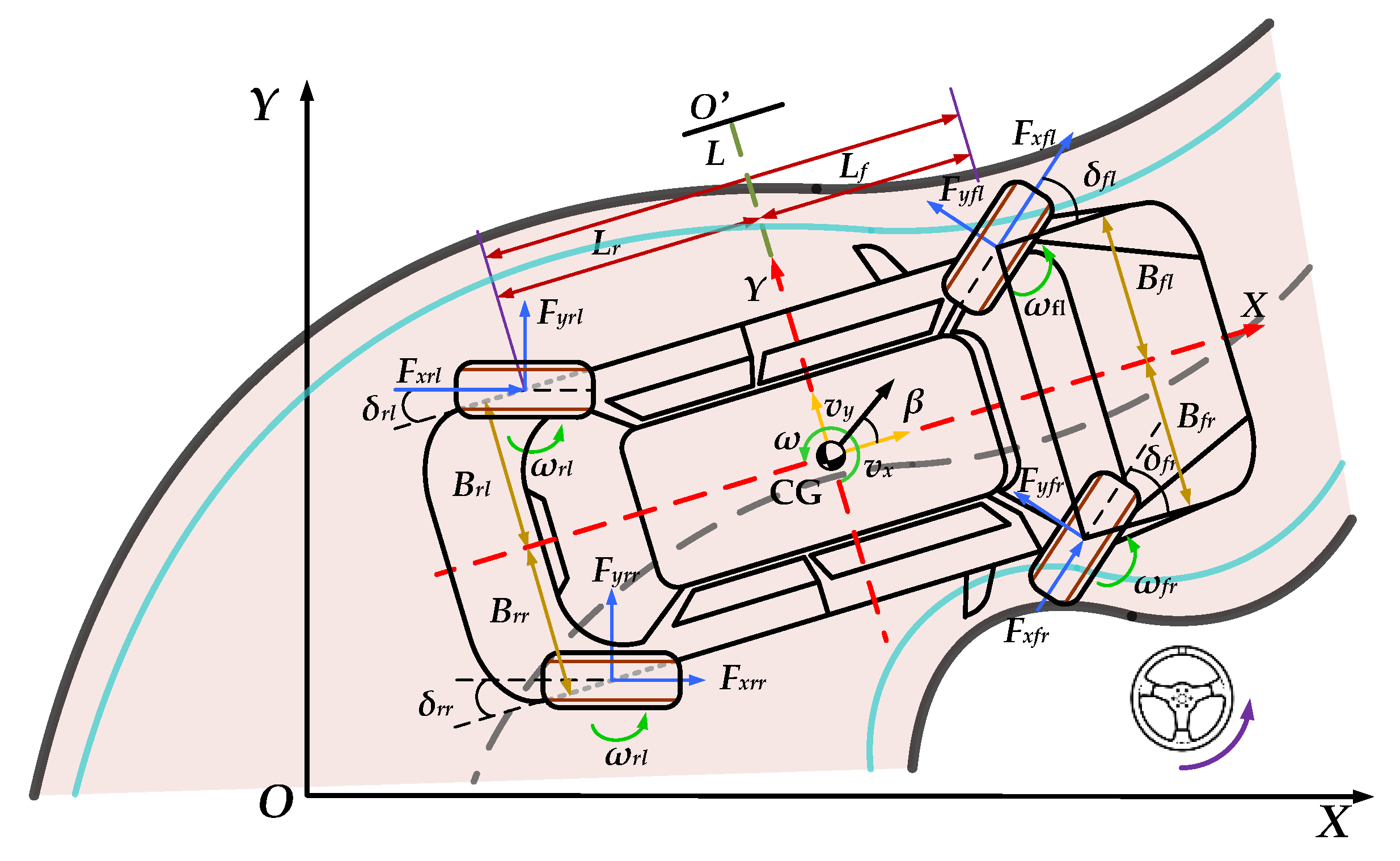

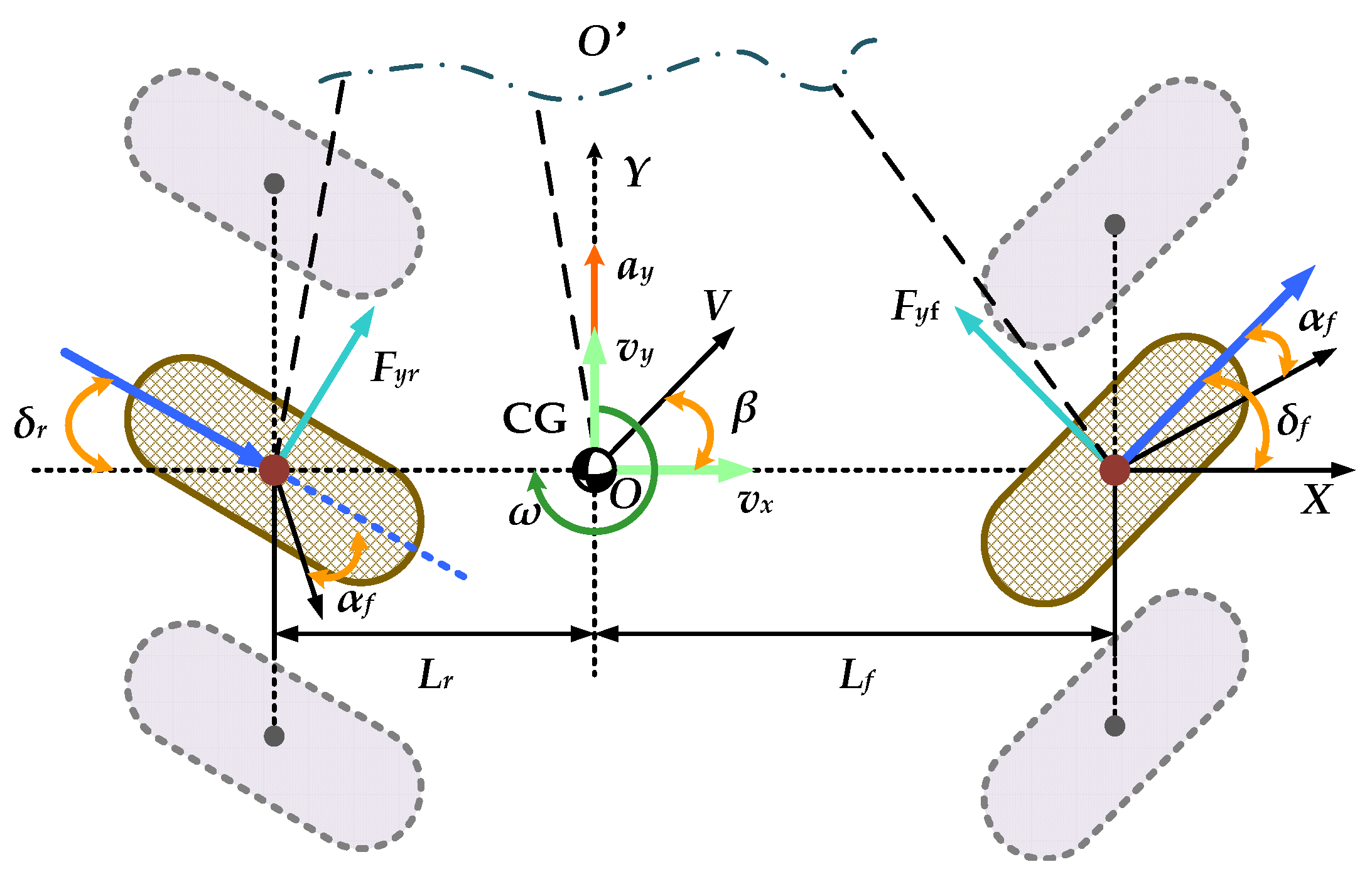

2. Nonlinear Vehicle Dynamics Model

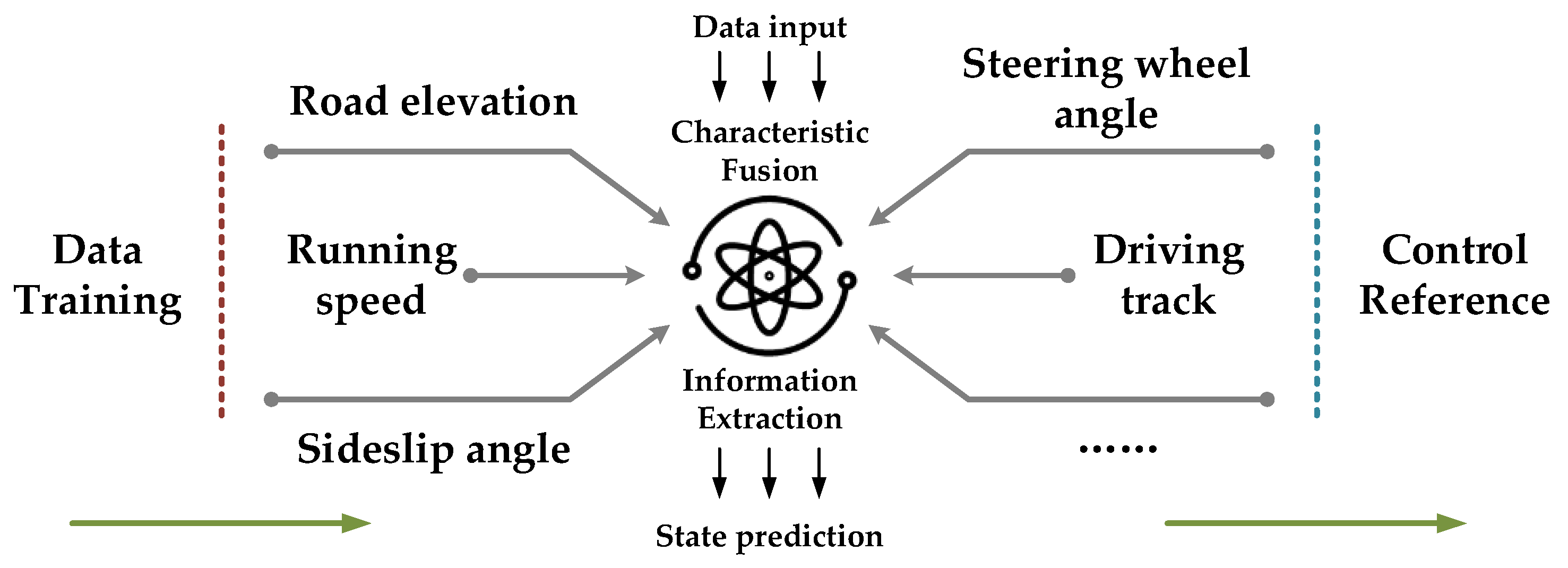

3. Design of LSTM Network with Variable Scale Input

3.1. Prediction Network Construction Based on LSTM Network

3.2. Optimization Calculation of Variable Time Domain State Length

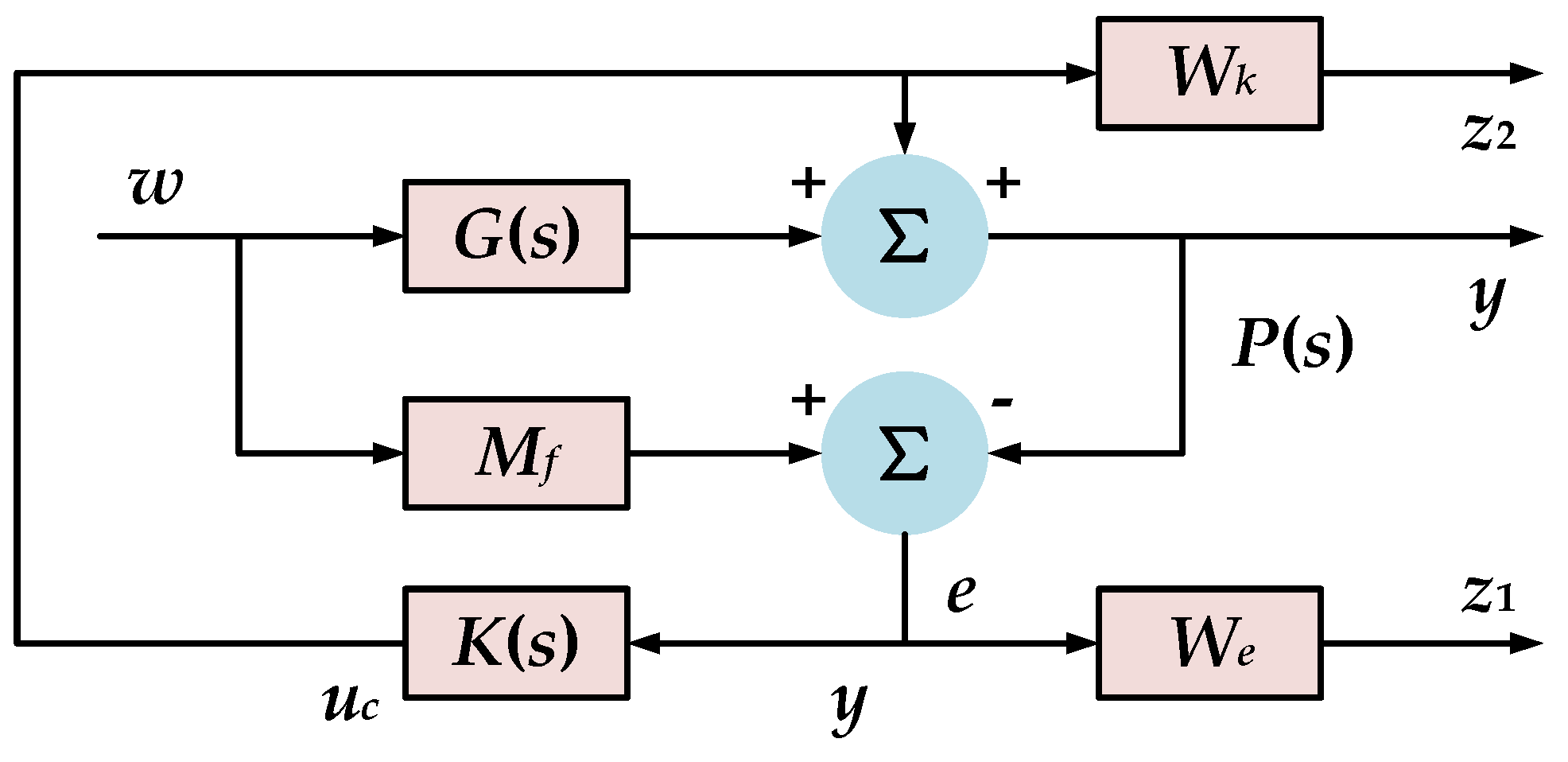

4. Robust Controller Design for Vehicle Stability

4.1. Design of Active Stable Steering Controller

4.2. Solution of Mixed Sensitivity Problem of System

5. Discussion on Research Results of System Numerical Calculation

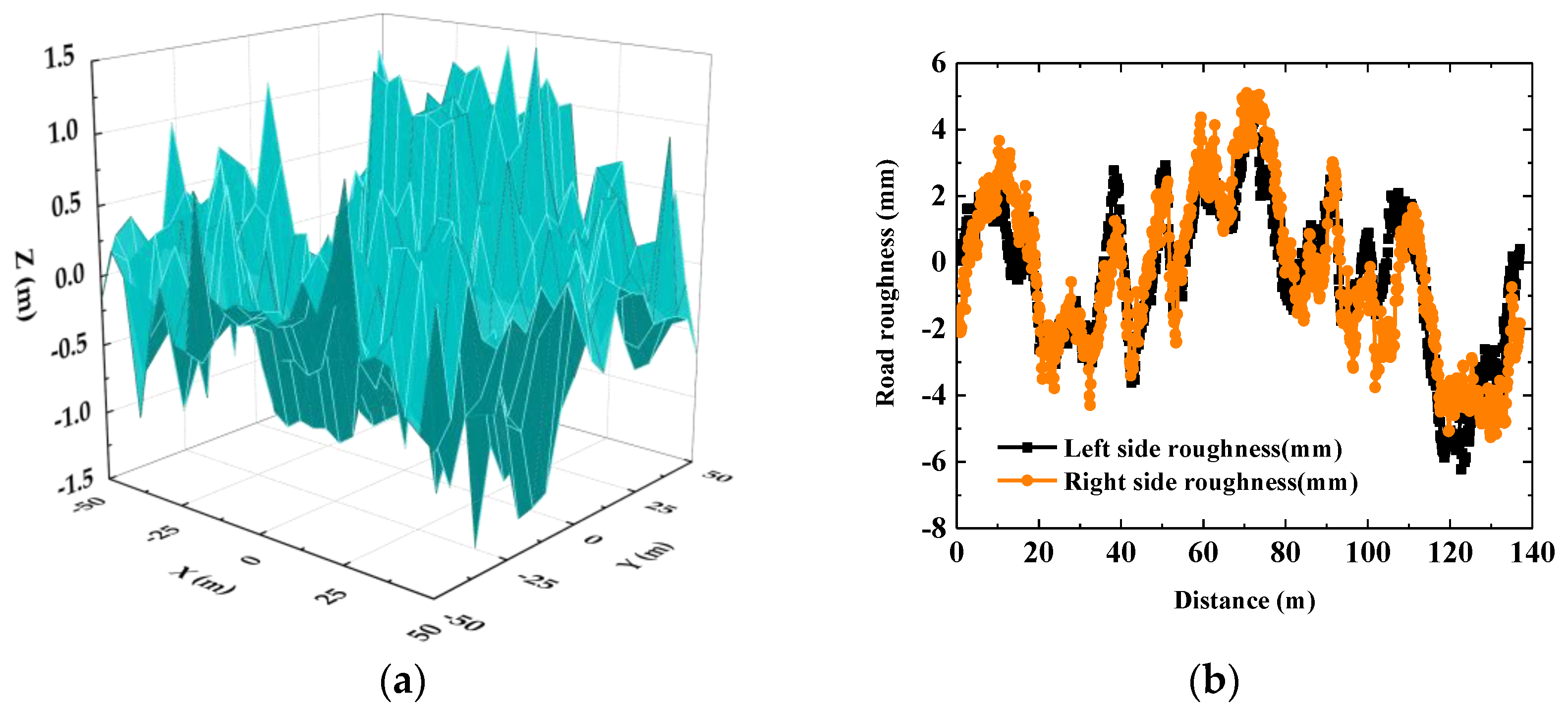

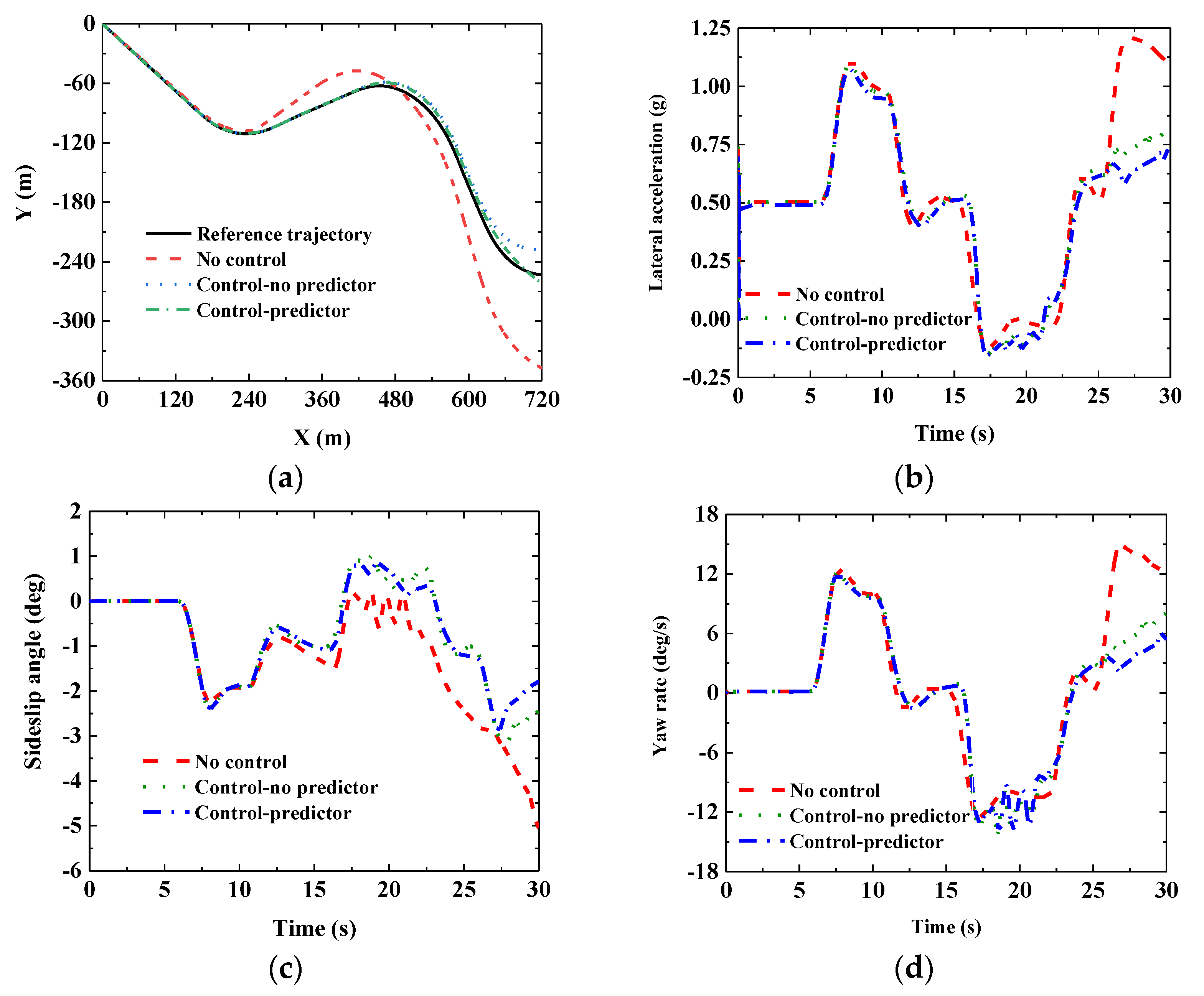

5.1. Numerical Calculation Research under Condition 1

5.2. Numerical Calculation Research under Condition 2

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Song, X.; Li, X.; Tang, W.; Zhang, W. A fusion strategy for reliable vehicle positioning utilizing RFID and in-vehicle sensors. Inf. Fusion 2016, 31, 76–86. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Z.Q.; Wang, X.P.; Deng, J.J.; Dorrell, D.G. Chassis Coordinated Control for Full X-by-Wire Vehicles-A Re-view. Chin. J. Mech. Eng. 2021, 34, 42. [Google Scholar] [CrossRef]

- Rajput, S.K.; Patni, J.C.; Alshamrani, S.S.; Chaudhari, V.; Dumka, A.; Singh, R.; Rashid, M.; Gehlot, A.; AlGhamdi, A.S. Au-tomatic Vehicle Identification and Classification Model Using the YOLOv3 Algorithm for a Toll Management System. Sustainability 2022, 14, 9163. [Google Scholar] [CrossRef]

- Dong, J.; Zhuang, D.; Huang, Y.; Fu, J. Advances in Multi-Sensor Data Fusion: Algorithms and Applications. Sensors 2009, 9, 7771–7784. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.; Lee, W.; Hwang, K.; Yoon, Y. Vision Transformer for Detecting Critical Situations and Extracting Functional Scenario for Automated Vehicle Safety Assessment. Sustainability 2022, 14, 9680. [Google Scholar] [CrossRef]

- Yao, X.; Gu, X.; Jiang, P. Coordination control of active front steering and direct yaw moment control based on stability judgment for AVs stability enhancement. Proc. Inst. Mech. Eng. Part D: J. Automob. Eng. 2021, 236, 59–74. [Google Scholar] [CrossRef]

- Kim, B.; Yi, K. Probabilistic and Holistic Prediction of Vehicle States Using Sensor Fusion for Application to Integrated Vehicle Safety Systems. IEEE Trans. Intell. Transp. Syst. 2014, 15, 2178–2190. [Google Scholar] [CrossRef]

- Mozaffari, S.; Al-Jarrah, O.Y.; Dianati, M.; Jennings, P.; Mouzakitis, A. Deep Learning-Based Vehicle Behavior Prediction for Autonomous Driving Applications: A Review. IEEE Trans. Intell. Transp. Syst. 2020, 23, 33–47. [Google Scholar] [CrossRef]

- Hsu, L.-Y.; Chen, T.-L. Vehicle Full-State Estimation and Prediction System Using State Observers. IEEE Trans. Veh. Technol. 2008, 58, 2651–2662. [Google Scholar] [CrossRef]

- Qian, L.P.; Feng, A.; Yu, N.; Xu, W.; Wu, Y. Vehicular Networking-Enabled Vehicle State Prediction via Two-Level Quantized Adaptive Kalman Filtering. IEEE Internet Things J. 2020, 7, 7181–7193. [Google Scholar] [CrossRef]

- Xing, Y.; Lv, C.; Cao, D.; Lu, C. Energy oriented driving behavior analysis and personalized prediction of vehicle states with joint time series modeling. Appl. Energy 2020, 261, 114471. [Google Scholar] [CrossRef]

- Jo, Y.; Jang, J.; Ko, J.; Oh, C. An In-Vehicle Warning Information Provision Strategy for V2V-Based Proactive Traffic Safety Management. IEEE Trans. Intell. Transp. Syst. 2022, 23, 19387–19398. [Google Scholar] [CrossRef]

- Xiao, H.P.; Wang, C.Q.; Li, Z.X.; Wang, R.D.; Bo, C.; Sotelo, M.A.; Xu, Y.c. UB-LSTM: A Trajectory Prediction Method Com-bined with Vehicle Behavior Recognition. J. Adv. Trans. 2021, 2020, 8859689. [Google Scholar]

- Shi, K.; Yuan, X.; He, Q. Double-layer Dynamic Decoupling Control System for the Yaw Stability of Four Wheel Steering Vehicle. Int. J. Control. Autom. Syst. 2019, 17, 1255–1263. [Google Scholar] [CrossRef]

- Lee, S.-H.; Lee, U.-K.; Ha, S.-K.; Han, C.-S. Four-Wheel Independent Steering (4WIS) System for Vehicle Handling Improvement by Active Rear Toe Control. JSME Int. J. Ser. C 1999, 42, 947–956. [Google Scholar] [CrossRef][Green Version]

- Riccardo, M.; Stefano, S.; Fabio, C. Nonlinear PI front and rear steering control in four wheel steering vehicles. Veh. Syst. Dyn. 2007, 45, 1149–1168. [Google Scholar]

- Marino, R.; Cinili, F. Input–Output Decoupling Control by Measurement Feedback in Four-Wheel-Steering Vehicles. IEEE Trans. Control Syst. Technol. 2009, 17, 1163–1172. [Google Scholar] [CrossRef]

- Tian, J.; Ding, J.; Tai, Y.; Chen, N. Hierarchical Control of Nonlinear Active Four-Wheel-Steering Vehicles. Energies 2018, 11, 2930. [Google Scholar] [CrossRef]

- Meng, Q.; Sun, Z.-Y.; Li, Y. Finite-time Controller Design for Four-wheel-steering of Electric Vehicle Driven by Four In-wheel Motors. Int. J. Control Autom. Syst. 2018, 16, 1814–1823. [Google Scholar] [CrossRef]

- Wang, C.; Heng, B.; Zhao, W. Yaw and lateral stability control for four-wheel-independent steering and four-wheel-independent driving electric vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 234, 409–422. [Google Scholar] [CrossRef]

- He, S.; Tang, T.; Ye, M.; Xu, E.; Deng, J.; Tang, R. A domain association hierarchical decomposition optimization method for cab vibration control of commercial vehicles. Measurement 2019, 138, 497–513. [Google Scholar] [CrossRef]

- He, S.; Tang, T.; Xu, E.; Ye, M.; Zheng, W. Vibration control analysis of vehicle steering system based on combination of finite-element analysis and modal testing. J. Vib. Control 2019, 26, 88–101. [Google Scholar] [CrossRef]

- Yang, L.; Luo, J.C.; Song, X.W.; Li, M.L.; Wen, P.W.; Xiong, Z.X. Robust Vehicle Speed Measurement Based on Feature In-formation Fusion for Vehicle Multi-Characteristic Detection. Entropy 2021, 23, 910. [Google Scholar] [CrossRef] [PubMed]

- Mazzilli, V.; De Pinto, S.; Pascali, L.; Contrino, M.; Bottiglione, F.; Mantriota, G.; Gruber, P.; Sorniotti, A. Integrated chassis control: Classification, analysis and future trends. Annu. Rev. Control 2021, 51, 172–205. [Google Scholar] [CrossRef]

- Im, S.J.; Oh, J.S.; Kim, G.-W. Simultaneous Estimation of Unknown Road Roughness Input and Tire Normal Forces Based on a Long Short-Term Memory Model. IEEE Access 2022, 10, 16655–16669. [Google Scholar] [CrossRef]

- Hang, P.; Chen, X. Towards Autonomous Driving: Review and Perspectives on Configuration and Control of Four-Wheel Independent Drive/Steering Electric Vehicles. Actuators 2021, 10, 184. [Google Scholar] [CrossRef]

- Kim, J. Effect of vehicle model on the estimation of lateral vehicle dynamics. Int. J. Automot. Technol. 2010, 11, 331–337. [Google Scholar] [CrossRef]

- Dahmani, H.; Pages, O.; El Hajjaji, A.; Daraoui, N. Observer-Based Robust Control of Vehicle Dynamics for Rollover Mitigation in Critical Situations. IEEE Trans. Intell. Transp. Syst. 2013, 15, 274–284. [Google Scholar] [CrossRef]

- Zhao, W.Z.; Li, Y.J.; Wang, C.Y.; Zhang, Z.Q.; Xu, C.L. Research on control strategy for differential steering system based on H mixed sensitivity. Int. J. Automot. Technol. 2013, 14, 913–919. [Google Scholar] [CrossRef]

- Yu, Y.; Si, X.; Hu, C.; Zhang, J. A Review of Recurrent Neural Networks: LSTM Cells and Network Architectures. Neural Comput. 2019, 31, 1235–1270. [Google Scholar] [CrossRef]

- Graber, T.; Lupberger, S.; Unterreiner, M.; Schramm, D. A Hybrid Approach to Side-Slip Angle Estimation With Recurrent Neural Networks and Kinematic Vehicle Models. IEEE Trans. Intell. Veh. 2018, 4, 39–47. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Li, J.; Sun, Q.; Wang, H. NGCU: A New RNN Model for Time-Series Data Prediction. Big Data Res. 2021, 27, 100296. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, K.; Jia, S.; Lin, W.; Hou, X.; Liu, B.; Qiu, G. Bidirectional Long Short-Term Memory Network for Vehicle Behavior Recognition. Remote Sens. 2018, 10, 887. [Google Scholar] [CrossRef]

- Shi, Y.; Li, Y.; Fan, J.; Wang, T.; Yin, T. A Novel Network Architecture of Decision-Making for Self-Driving Vehicles Based on Long Short-Term Memory and Grasshopper Optimization Algorithm. IEEE Access 2020, 8, 155429–155440. [Google Scholar] [CrossRef]

- Yeon, K.; Min, K.; Shin, J.; Sunwoo, M.; Han, M. Ego-Vehicle Speed Prediction Using a Long Short-Term Memory Based Re-current Neural Network. Int. J. Automot. Technol. 2019, 20, 713–722. [Google Scholar] [CrossRef]

- Hao, W.; Rong, D.; Yi, K.; Zeng, Q.; Gao, Z.; Wu, W.; Wei, C.; Scepanovic, B. Traffic Status Prediction of Arterial Roads Based on the Deep Recurrent Q-Learning. J. Adv. Transp. 2020, 2020, 1–17. [Google Scholar] [CrossRef]

- Wang, J.; Wang, R.; Jing, H.; Chen, N. Coordinated Active Steering and Four-Wheel Independently Driving/Braking Control with Control Allocation. Asian J. Control 2015, 18, 98–111. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, L.F.; Zhang, J.Z.; Li, F. Robust vehicle yaw stability controlby active front steering with active disturbance rejection controller. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2019, 233, 1127–1135. [Google Scholar] [CrossRef]

- Zhu, S.; Gelbal, S.Y.; Aksun-Guvenc, B.; Guvenc, L. Parameter-Space Based Robust Gain-Scheduling Design of Automated Vehicle Lateral Control. IEEE Trans. Veh. Technol. 2019, 68, 9660–9671. [Google Scholar] [CrossRef]

- Elmi, N.; Ohadi, A.; Samadi, B. Active front-steering control of a sport utility vehicle using a robust linear quadratic regulator method, with emphasis on the roll dynamics. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 1636–1649. [Google Scholar] [CrossRef]

| States Parameters | Parameter Value | Unit |

|---|---|---|

| mb | 1455 | kg |

| m | 1775 | kg |

| Lf | 1070 | mm |

| Lr | 1560 | mm |

| Bi(i = fl, fl, rl, rr) | 915 | mm |

| Ix | 730.5 | kg·m2 |

| Iy | 2260.5 | kg·m2 |

| Iz | 2260.5 | kg·m2 |

| Ad | 2.9 | m2 |

| Cd | 0.3 |

| Centroid States Parameters | Lateral Acceleration (g) | Sideslip Angle (deg) | Yaw Rate (deg) |

|---|---|---|---|

| No predictive control | 0.56 | 2.90 | 23.90 |

| Predictive control | 0.55 | 2.56 | 20.91 |

| Centroid States Parameters | Lateral Acceleration (g) | Sideslip Angle (deg) | Yaw Rate (deg) |

|---|---|---|---|

| No predictive control | 0.60 | 1.34 | 6.84 |

| Predictive control | 0.57 | 1.20 | 6.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Feng, J.; Wang, C.; Cao, Y.; Qin, B.; Zhang, T.; Tan, S.; Zeng, R.; Ren, H.; Ma, T.; et al. Research on Vehicle Active Steering Stability Control Based on Variable Time Domain Input and State Information Prediction. Sustainability 2023, 15, 114. https://doi.org/10.3390/su15010114

Gao Z, Feng J, Wang C, Cao Y, Qin B, Zhang T, Tan S, Zeng R, Ren H, Ma T, et al. Research on Vehicle Active Steering Stability Control Based on Variable Time Domain Input and State Information Prediction. Sustainability. 2023; 15(1):114. https://doi.org/10.3390/su15010114

Chicago/Turabian StyleGao, Zepeng, Jianbo Feng, Chao Wang, Yu Cao, Bonan Qin, Tao Zhang, Senqi Tan, Riya Zeng, Hongbin Ren, Tongxin Ma, and et al. 2023. "Research on Vehicle Active Steering Stability Control Based on Variable Time Domain Input and State Information Prediction" Sustainability 15, no. 1: 114. https://doi.org/10.3390/su15010114

APA StyleGao, Z., Feng, J., Wang, C., Cao, Y., Qin, B., Zhang, T., Tan, S., Zeng, R., Ren, H., Ma, T., Hou, Y., & Xiao, J. (2023). Research on Vehicle Active Steering Stability Control Based on Variable Time Domain Input and State Information Prediction. Sustainability, 15(1), 114. https://doi.org/10.3390/su15010114