Characteristics and Causes of Construction Accidents in a Large-Scale Development Project

Abstract

1. Introduction

Background of the Kai Tak Development

2. Accident Causation Models

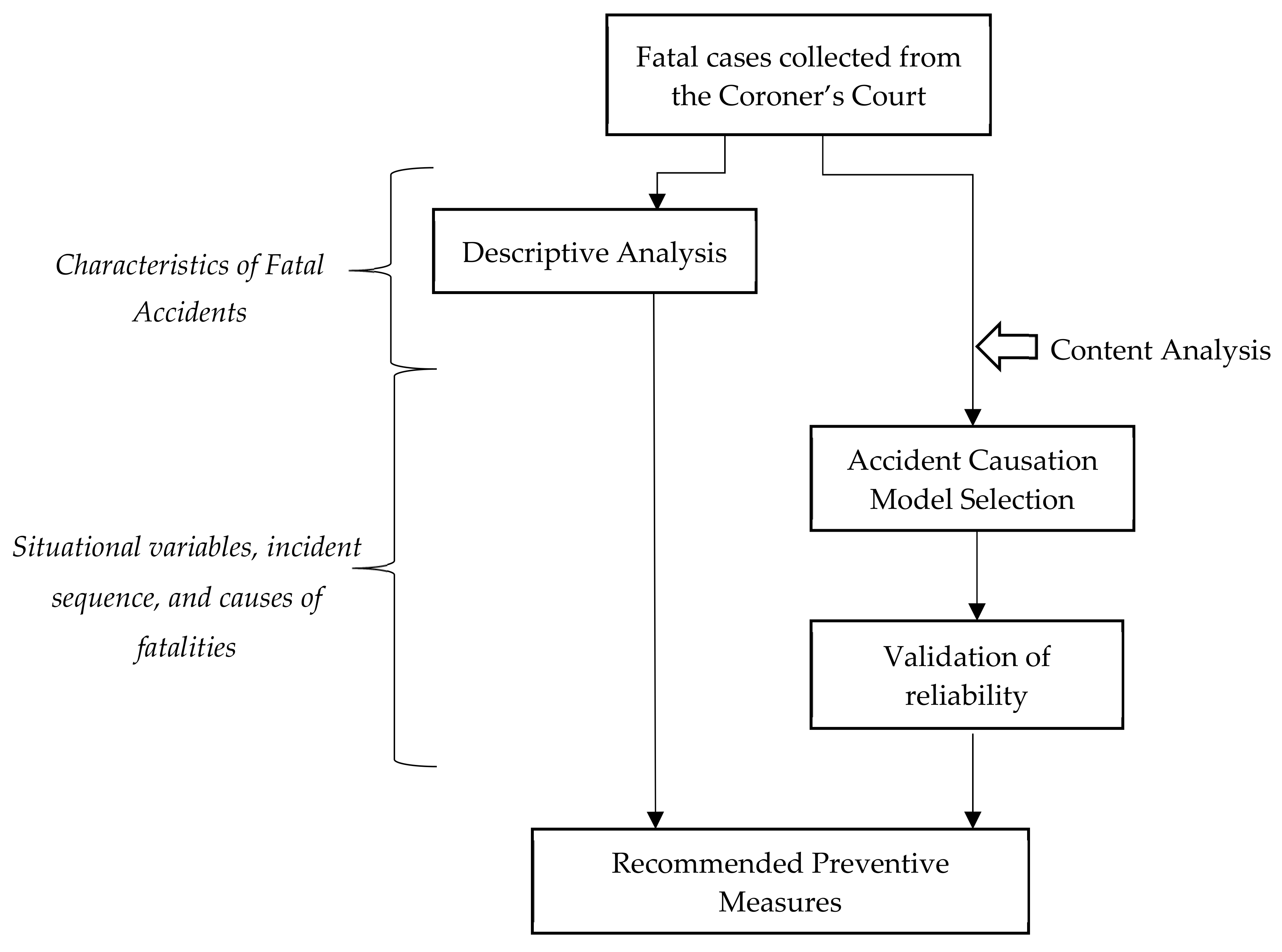

3. Methods

3.1. Data Collection and Processing

3.2. Descriptive Analysis

3.3. Selection of Appropriate Causation Model

3.4. Identification of Root Causes by Applying the Selected Model

3.5. Validity and Reliability

3.6. Classification of Preventive Measures

4. Results and Discussion

4.1. Characteristics of Fatal Accidents

4.2. Situational Variables, Incident Sequence, and Causes of Fatal Accidents

4.2.1. Fall Accidents

4.2.2. Struck-by Accidents

5. Recommended Preventive Measures

6. Conclusions and Future Studies

- Management approach: The clients, the main contractors, and subcontractors should establish an effective safety management system, which should consist of risk assessment, safety supervision, safe work procedures, and effective safety training programs. A comprehensive risk assessment should be conducted for each specific work procedure, especially that involving working at height or nearby heavy equipment, by qualified personnel with sufficient knowledge and experience. The main contractors should take active roles in helping subcontractors improve safety performance by enhancing safety supervision and safety training. In particular, regular safety training should be offered to “aging workers”, “newcomers”, and “ethnic minorities”. Furthermore, the project stakeholders are encouraged to share good experiences and safety management failures, cultivating a learning culture in the construction industry.

- Safety technologies: Various safety technologies could be implemented to reduce potential risks and enhance the implementation of relevant safety programs. For instance, computer vision-based recognition technologies or wearable technologies could be leveraged to monitor the proximal distance between humans and moving objects automatically. A digital documentation system could serve as a platform for managing all necessary safety-related information, thereby supporting safety management in construction projects.

- Regulatory control: Governmental safety inspection should be strictly enforced, given that “illegal workers” and “working on weekends” are two critical risk factors identified from the fatal accidents of the KTD projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| The Incident Sequence of Case 4 | The Structure Suddenly Collapsed, Causing the Workers to Fall Together with the Collapsing Structure | Unstable Condition of the Reinforcement Bar Structure without Sufficient Support | No Extra Measures to Stabilize the Reinforcement Structure | No Provision of Shielding, Soil Stabilizing Treatment | An Irresponsible Subcontractor to Execute and Supervise the Construction of the Structure | No Competent Safety Personnel to Assess the Risks of the Construction of the Structure | |

|---|---|---|---|---|---|---|---|

| Causation Model | |||||||

| Modified loss causation model (MLCM) | Incident consequence | Unsafe conditions | Lack of measures | Underlying job factors | |||

| Human factor and classification system (HFACS) | NA | Hazard by others (preconditions for unsafe acts) | Planned inappropriate operations (unsafe supervision) | Supervisory violations (unsafe supervision) | Organizational process (organizational influences) | ||

| Constraint-response | Incident consequence | Inappropriate site conditions | Inappropriate construction control | Inappropriate construction control | Inappropriate construction planning | ||

| Mitropoulos’s system model | Incident consequence | Errors in conditions | No efforts to control conditions | Errors in management | |||

| Loughborough construction accident causation model (ConCa) | NA | Local hazards (immediate factors) | Inadequate supervision (shaping factors) | Inadequate risk management (originating factors) | |||

References

- Nawaz, W.; Linke, P.; Koҫ, M. Safety and sustainability nexus: A review and appraisal. J. Clean Prod. 2019, 216, 74–87. [Google Scholar] [CrossRef]

- Hinze, J.; Godfrey, R.; Sullivan, J. Integration of construction worker safety and health in assessment of sustainable construction. J. Constr. Eng. Manag. ASCE 2013, 139, 594–600. [Google Scholar] [CrossRef]

- Haupt, T.C.; Pillay, K. Investigating the true costs of construction accidents. J. Eng. Des. Technol. 2016, 14, 373–419. [Google Scholar] [CrossRef]

- Li, R.Y.M.; Tang, B.; Chau, K.W. Sustainable construction safety knowledge sharing: A partial least square-structural equation modeling and a feedforward neural network approach. Sustainability 2019, 11, 5831. [Google Scholar] [CrossRef]

- Hinze, J.; Gambatese, J. Factors that influence safety performance of specialty contractors. J. Constr. Eng. Manag. ASCE 2003, 129, 159–164. [Google Scholar] [CrossRef]

- Winge, S.; Albrechtsen, E.; Mostue, B.A. Causal factors and connections in construction accidents. Saf. Sci. 2019, 112, 130–141. [Google Scholar] [CrossRef]

- Halabi, Y.; Xu, H.; Long, D.; Chen, Y.; Yu, Z.; Alhaek, F.; Alhaddad, W. Causal factors and risk assessment of fall accidents in the US construction industry: A comprehensive data analysis (2000–2020). Saf. Sci. 2022, 146, 105537. [Google Scholar] [CrossRef]

- Labour Department. Occupational Safety and Health Statistics. 2010–2020. 2022. Available online: https://www.labour.gov.hk/eng/osh/content10.htm (accessed on 4 March 2022).

- Drupsteen, L.; Guldenmund, F.W. What is learning? A review of the safety literature to define learning from incidents, accidents and disasters. J. Conting. Crisis Man. 2014, 22, 81–96. [Google Scholar] [CrossRef]

- Littlejohn, A.; Margaryan, A.; Vojt, G.; Lukic, D. Learning from Incidents Questionnaire (LFIQ): The Validation of an Instrument Designed to Measure the Quality of Learning from Incidents in Organisations. Saf. Sci. 2017, 99, 80–93. [Google Scholar] [CrossRef]

- Drupsteen, L.; Hasle, P. Why do organizations not learn from incidents? Bottlenecks, causes and conditions for a failure to effectively learn. Accid. Anal. Prev. 2014, 72, 351–358. [Google Scholar] [CrossRef]

- Behm, M.; Schneller, A. Application of the Loughborough construction accident causation model: A framework for organizational learning. Constr. Manag. Econ. 2013, 31, 580–595. [Google Scholar] [CrossRef]

- Dong, X.; Fujimoto, A.; Ringen, K.; Men, Y. Fatal falls among Hispanic construction workers. Accid. Anal. Prev. 2009, 41, 1047–1052. [Google Scholar] [CrossRef] [PubMed]

- Chi, C.F.; Lin, Y.Y.; Ikhwan, M. Flow diagram analysis of electrical fatalities in construction industry. Saf. Sci. 2012, 50, 1205–1214. [Google Scholar] [CrossRef]

- Wong, L.; Wang, Y.; Law, T.; Lo, C.T. Association of root causes in fatal fall-from-height construction accidents in Hong Kong. J. Constr. Eng. Manag. 2016, 142, 4016018. [Google Scholar] [CrossRef]

- Doloi, H.; Iyer, K.C.; Sawhney, A. Structural equation model for assessing impacts of contractor’s performance on project success. Int. J. Proj. Manag. 2011, 29, 687–695. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Yang, Y.; Darko, A. Construction accidents in a large-scale public infrastructure project: Severity and prevention. J. Constr. Eng. Manag. 2018, 144, 5018010. [Google Scholar] [CrossRef]

- Hatipkarasulu, Y. Project level analysis of special trade contractor fatalities using accident investigation reports. J. Saf. Res. 2010, 41, 451–457. [Google Scholar] [CrossRef]

- Hon, C.K.; Chan, A.P. Fatalities of repair, maintenance, minor alteration, and addition works in Hong Kong. Saf. Sci. 2013, 51, 85–93. [Google Scholar] [CrossRef]

- Civil and Aviation Department. Kai Tak Airport 1925–1998. Available online: https://www.cad.gov.hk/english/kaitak.html (accessed on 5 March 2022).

- Civil Engineering and Development Department. Kai Tak Office. Available online: https://www.ktd.gov.hk/eng/index.html (accessed on 5 March 2022).

- Mitropoulos, P.; Abdelhamid, T.S.; Howell, G.A. Systems model of construction accident causation. J. Constr. Eng. Manag. ASCE 2005, 131, 816–825. [Google Scholar] [CrossRef]

- Abdelhamid, T.S.; Everett, J.G. Identifying root causes of construction accidents. J. Constr. Eng. Manag. ASCE 2000, 126, 52–60. [Google Scholar] [CrossRef]

- Underwood, P.; Waterson, P. Systemic accident analysis: Examining the gap between research and practice. Accid. Anal. Prev. 2013, 55, 154–164. [Google Scholar] [CrossRef] [PubMed]

- Rathnayaka, S.; Khan, F.; Amyotte, P. SHIPP methodology: Predictive accident modeling approach. Part I: Methodology and model description. Process Saf. Environ. 2011, 89, 151–164. [Google Scholar] [CrossRef]

- Branford, K. Seeing the big picture of mishaps: Applying the AcciMap approach to analyze system accidents. Aviat. Psychol. Appl. Hum. Factors 2011, 1, 31–37. [Google Scholar] [CrossRef]

- Rasmussen, J. Risk Management in a Dynamic Society: A Modelling Problem. Saf. Sci. 1997, 27, 183–213. [Google Scholar] [CrossRef]

- Leveson, N. A New Accident Model. for Engineering Safer Systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Salmon, P.M.; Cornelissen, M.; Trotter, M.J. Systems-based accident analysis methods: A comparison of Accimap, HFACS, and STAMP. Saf. Sci. 2012, 50, 1158–1170. [Google Scholar] [CrossRef]

- Hollnagel, E. FRAM: The Functional Resonance Analysis Method: Modelling Complex Socio-technical Systems; Ashgate Publishing, Ltd.: Farnham, UK, 2012. [Google Scholar]

- Suraji, A.; Duff, A.R.; Peckitt, S.J. Development of causal model of construction accident causation. J. Contr. Eng. Manag. ASCE 2001, 127, 337–344. [Google Scholar] [CrossRef]

- Suraji, A. Construction accidents and the lesson learnt from 1000 cases. Int. J. Constr. Manag. 2003, 3, 41–49. [Google Scholar] [CrossRef]

- Chua, D.K.; Goh, Y.M. Incident causation model for improving feedback of safety knowledge. J. Constr. Eng. Manag. 2004, 130, 542–551. [Google Scholar] [CrossRef]

- Mitropoulos, P.; Cupido, G.; Namboodiri, M. Cognitive approach to construction safety: Task demand-capability model. J. Constr. Eng. Manag. ASCE 2009, 135, 881–889. [Google Scholar] [CrossRef]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.F.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef] [PubMed]

- Harvey, E.J.; Waterson, P.; Dainty, A.R. Beyond ConCA: Rethinking causality and construction accidents. Appl. Ergon. 2018, 73, 108–121. [Google Scholar] [CrossRef] [PubMed]

- Wiegmann, D.A.; Shappell, S.A. Human Error Analysis of Commercial Aviation Accidents Using the Human Factors Analysis and Classification System (HFACS) (No. DOT/FAA/AM-01/3); Office of Aviation Medicine: Washington, DC, USA, 2001.

- Goncalves Filho, A.P.; Waterson, P.; Jun, G.T. Improving accident analysis in construction–Development of a contributing factor classification framework and evaluation of its validity and reliability. Saf. Sci. 2021, 140, 105303. [Google Scholar] [CrossRef]

- Rosa, L.V.; Haddad, A.N.; de Carvalho, P.V.R. Assessing risk in sustainable construction using the Functional Resonance Analysis Method (FRAM). Cogn. Technol. Work 2015, 17, 559–573. [Google Scholar] [CrossRef]

- França, J.E.; Hollnagel, E.; dos Santos, I.J.; Haddad, A.N. FRAM AHP approach to analyse offshore oil well drilling and construction focused on human factors. Cogn. Technol. Work 2020, 22, 653–665. [Google Scholar] [CrossRef]

- Zhou, W.; Zhao, T.; Liu, W.; Tang, J. Tower crane safety on construction sites: A complex sociotechnical system perspective. Saf. Sci. 2018, 109, 95–108. [Google Scholar] [CrossRef]

- Cooke, T.; Lingard, H. A retrospective analysis of work-related deaths in the Australian construction industry. In Proceedings of the Association of Researchers in Construction Management Twenty-Seventh Annual Conference, Bristol, UK, 5–7 September 2011; Egbu, C., Lou, E.C.W., Eds.; ARCOM: Bristol, UK, 2011; Volume 279, p. 88. [Google Scholar]

- Fass, S.; Yousef, R.; Liginlal, D.; Vyas, P. Understanding causes of fall and struck-by incidents: What differentiates construction safety in the Arabian Gulf region? Appl. Ergon. 2017, 58, 515–526. [Google Scholar] [CrossRef]

- Ye, G.; Tan, Q.; Gong, X.; Xiang, Q.; Wang, Y.; Liu, Q. Improved HFACS on human factors of construction accidents: A China perspective. Adv. Civ. Eng. 2018, 2018, 4398345. [Google Scholar] [CrossRef]

- Salmon, P.M. Bridging the gap between research and practice in ergonomics methods: Part II. Methodological issues in ergonomics science. Theor. Issues Ergon. Sci. 2016, 17, 459–467. [Google Scholar] [CrossRef]

- Stemler, S. Content Analysis. Emerging Trends in the Social and Behavioral Sciences; John Wiley & Sons: Hoboken, NJ, USA, 2015; ISBN 978-1-118-90077-2. [Google Scholar]

- Branford, K. An Investigation into the Validity and Reliability of the Accimap Approach. Ph.D. Thesis, Australian National University, Canberra, Australian, 2007. [Google Scholar]

- Goncalves Filho, A.P.; Jun, G.T.; Waterson, P. Four studies, two methods, one accident—An examination of the reliability and validity of Accimap and STAMP for accident analysis. Saf. Sci. 2019, 113, 310–317. [Google Scholar] [CrossRef]

- Carael, M. Assessing the validity and reliability of self-reported behavioral data. In Evaluating Programs for HIV/AIDS Prevention and Care in Developing Countries: A Handbook for Program Managers and Decision; Magnani, R., Ed.; Makers: Arlington, VA, USA, 2001. [Google Scholar]

- Böiger, F.; Wright, G. Reliability and validity in expert judgment. In Expertise and Decision Support; Wright, G., Bolger, F., Eds.; Plenum Press: New York, NY, USA, 1992. [Google Scholar]

- O’Connor, P. HFACS with an additional layer of granularity: Validity and utility in accident analysis. Aviat. Space Environ. Med. 2008, 79, 599–606. [Google Scholar] [CrossRef] [PubMed]

- Pounds, J.; Isaac, A. Validation of the JANUS Technique: Causal Factors of Human Error in Operational Errors; Technical Report; Federal Aviation Administration Oklahoma City Ok Civil Aeromedical Inst.: Oklahoma City, OK, USA, 2003.

- Goldenhar, L.M.; Schulte, P.A. Intervention research in occupational health and safety. J. Occup. Med. 1994, 36, 763–775. [Google Scholar] [PubMed]

- Siu, O.; Phillips, D.R.; Leung, T. Age differences in safety attitudes and safety performance in Hong Kong construction workers. J. Saf. Res. 2003, 34, 199–205. [Google Scholar] [CrossRef]

- Peng, L.; Chan, A.H. Influential factors associated with construction managers’ propensity to implement safety measures for older workers. Saf. Sci. 2021, 141, 105349. [Google Scholar] [CrossRef]

- Ilmarinen, J.E. Aging workers. Occup. Environ. Med. 2001, 58, 546. [Google Scholar] [CrossRef] [PubMed]

- Anwer, S.; Li, H.; Antwi-Afari, M.F.; Umer, W.; Wong, A.Y.L. Evaluation of physiological metrics as real-time measurement of physical fatigue in construction workers: State-of-the-art review. J. Constr. Eng. Manag. ASCE 2021, 145, 3121001. [Google Scholar] [CrossRef]

- Yi, W.; Chan, A. Health profile of construction workers in Hong Kong. Int. J. Environ. Res. Public Health 2016, 13, 1232. [Google Scholar] [CrossRef]

- Choi, S.D. Safety and ergonomic considerations for an aging workforce in the US construction industry. Work 2009, 33, 307–315. [Google Scholar] [CrossRef]

- Chi, C.F.; Chang, T.C.; Ting, H.I. Accident patterns and prevention measures for fatal occupational falls in the construction industry. Appl. Ergon. 2005, 36, 391–400. [Google Scholar] [CrossRef]

- Ayim Gyekye, S.; Salminen, S. Organizational safety climate and work experience. Int. J. Occup. Saf. Ergon. 2010, 16, 431–443. [Google Scholar] [CrossRef][Green Version]

- Sawacha, E.; Naoum, S.; Fong, D. Factors affecting safety performance on construction sites. Int. J. Proj. Manag. 1999, 17, 309–315. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D. Why operatives engage in unsafe work behavior: Investigating factors on construction sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Man, S.S.; Chan, A.H.S.; Wong, H.M. Risk-taking behaviors of Hong Kong construction workers—A thematic study. Saf. Sci. 2017, 98, 25–36. [Google Scholar] [CrossRef]

- Hasanzadeh, S.; Esmaeili, B.; Dodd, M. Measuring the Impacts of Safety Knowledge on Construction Workers’ Attentional Allocation and Hazard Detection Using Remote Eye-Tracking Technology. J. Manag. Eng. ASCE 2017, 33, 4017024. [Google Scholar] [CrossRef]

- Huang, X.; Hinze, J. Analysis of Construction Worker Fall Accidents. J. Constr. Eng. Manag. ASCE 2003, 129, 262–271. [Google Scholar] [CrossRef]

- Wong, F.K.W.; Chan, A.P.C.; Wong, A.K.D.; Hon, C.K.H.; Choi, T.N.Y. Accidents of Electrical and Mechanical Works for Public Sector Projects in Hong Kong. Int. J. Environ. Res. Public Health 2018, 15, 485. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, P. Risk compensation behaviours in construction workers’ activities. Int. J. Inj. Control Saf. 2015, 22, 40–47. [Google Scholar] [CrossRef]

- Peltzman, S. The effects of automobile safety regulation. J. Political Econ. 1975, 83, 677–725. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Wong, F.K.W.; Hon, C.K.; Javed, A.A.; Lyu, S.N. Construction safety and health problems of ethnic minority workers in Hong Kong. Eng. Constr. Arch. Manag. 2017, 24, 901–919. [Google Scholar] [CrossRef]

- Chan, A.P.; Wong, F.K.; Hon, C.K.; Lyu, S.; Javed, A.A. Investigating ethnic minorities’ perceptions of safety climate in the construction industry. J. Saf. Res. 2017, 63, 9–19. [Google Scholar] [CrossRef]

- Lingard, H.C.; Blismas, N.; Stewart, P. Corporate social responsibility in the Australian construction industry. In Corporate Social Responsibility in the Construction Industry; Routledge: London, UK, 2013; pp. 362–391. [Google Scholar]

- Brolin, K.; Lanner, D.; Halldin, P. Work-related traumatic brain injury in the construction industry in Sweden and Germany. Saf. Sci. 2021, 136, 105147. [Google Scholar] [CrossRef]

- Finneran, A.; Gibb, A. W099—Safety and Health in Construction, Research Roadmap—Report for Consultation; International Council for Research and Innovation in Building and Construction (CIB) Publication: Ottawa, ON, Canada, 2013; ISBN 978-90-6363-078-2. [Google Scholar]

- Nielsen, J. Struggles for health and safety in the Danish construction industry. Int. J. Occup. Environ. Health 2007, 13, 21–26. [Google Scholar] [CrossRef] [PubMed]

- Lingard, H.C.; Townsend, K.; Bradley, L.; Brown, K. Alternative work schedule interventions in the Australian construction industry: A comparative case study analysis. Constr. Manag. Econ. 2008, 26, 1101–1112. [Google Scholar] [CrossRef]

- Lingard, H.C.; Francis, V.; Turner, M. The rhythms of project life: A longitudinal analysis of work hours and work-life experiences in construction. Constr. Manag. Econ. 2010, 28, 1085–1098. [Google Scholar] [CrossRef]

- Shin, I.J. Factors that affect safety of tower crane installation/dismantling in construction industry. Saf. Sci. 2015, 72, 379–390. [Google Scholar] [CrossRef]

- Fang, D.; Zhao, C.; Zhang, M. A cognitive model of construction workers’ unsafe behaviors. J. Constr. Eng. Manag. ASCE 2016, 142, 4016039. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, M.; Xia, B.; Liu, J. Exploring construction workers’ attitudinal ambivalence: A system dynamics approach. Eng. Constr. Archit. Manag. ASCE 2021. [Google Scholar] [CrossRef]

- Construction and Miscellaneous Services Statistics Section. Key Statistics on Business Performance and Operating Characteristics of the Building, Construction and Real Estate Sectors in 2015. Government of the Hong Kong Special Administrative Reg. 2015. Available online: https://www.info.gov.hk/gia/general/201611/28/P2016112800334.htm (accessed on 11 March 2022).

- ONS. Construction Statistic Annual 2011; O.N.S.: Newport, RI, USA, 2011.

- Chiang, Y. Subcontracting and its ramifications: A survey of the building industry in Hong Kong. Int. J. Proj. Manag. 2009, 27, 80–88. [Google Scholar] [CrossRef]

- ILO. The Construction Industry in the Twenty-First Century: Its Image, Employment Prospects and Skill Requirements; ILO: Geneva, Switzerland, 2001. [Google Scholar]

- Manu, P.; Ankrah, N.; Proverbs, D.; Suresh, S. Mitigating the health and safety influence of subcontracting in construction: The approach of main contractors. Int. J. Proj. Manag. 2013, 31, 1017–1026. [Google Scholar] [CrossRef]

- Shaw, M. Promotion of occupational safety and health for small and medium sized enterprises—Canadian experience. Hong Kong J. Green Cross 1998, 8, 40–45. [Google Scholar]

- Winge, S.; Albrechtsen, E.; Arnesen, J. A comparative analysis of safety management and safety performance in twelve construction projects. J. Saf. Res. 2019, 71, 139–152. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Jin, R. A comparison of subgroup construction workers’ perceptions of a safety program. Saf. Sci. 2015, 74, 15–26. [Google Scholar] [CrossRef]

- Kang, Y.; Siddiqui, S.; Suk, S.J.; Chi, S.; Kim, C. Trends of Fall Accidents in the U.S. Construction Industry. J. Constr. Eng. Manag. ASCE 2017, 143, 4017043. [Google Scholar] [CrossRef]

- Hinze, J.; Huang, X.; Terry, L. The nature of struck-by accidents. J. Constr. Eng. Manag. ASCE 2005, 131, 262–268. [Google Scholar] [CrossRef]

- Rubio-Romero, J.C.; Rubio, M.C.; García-Hernández, C. Analysis of Construction Equipment Safety in Temporary Work at Height. J. Constr. Eng. Manag. ASCE 2013, 139, 9–14. [Google Scholar] [CrossRef]

- Ronk, C.J.; Dennerlein, J.T.; Hoffman, E.; Perry, M.J. Is renovation riskier than new construction? An observational comparison of risk factors for stepladder-related fall. Am. J. Ind. Med. 2011, 54, 579–585. [Google Scholar] [CrossRef]

- Labour Department. Code of Practice for Bamboo Scaffolding Safety, 4th ed.; Occupational Safety and Health Branch, Labour Department: Hong Kong, 2017.

- So, F.; Chan, S.L. Stability design of mixed bamboo-steel scaffolding systems. In Proceedings of the Sixth International Conference on Advances in Steel Structures and Progress in Structural Stability and Dynamics (ICASS ‘09/IJSSD), Hong Kong, 16–18 December 2009; Hong Kong Institute of Steel Construction: Hong Kong, 2009; pp. 1109–1112. [Google Scholar]

- Lestari, R.I.; Guo, B.H.; Goh, Y.M. Causes, solutions, and adoption barriers of falls from roofs in the Singapore construction industry. J. Constr. Eng. Manag. ASCE 2019, 145, 4019027. [Google Scholar] [CrossRef]

- Griffin, M.A.; Neal, A. Perceptions of safety at work: A framework for linking safety climate to safety performance, knowledge, and motivation. J. Occup. Health Psych. 2000, 5, 347–358. [Google Scholar] [CrossRef]

- OSHC. Safe Systems of Work. Occupational Safety and Health Branch, Labour Department. 2004. Available online: https://www.labour.gov.hk/eng/public/os/D/SafeSystem.pdf (accessed on 28 March 2022).

- Kim, H.; Kim, K.; Kim, H. Vision-based object-centric safety assessment using fuzzy inference: Monitoring struck-by accidents with moving objects. J. Comput. Civ. Eng. 2016, 30, 4015075. [Google Scholar] [CrossRef]

- Pinto, A.; Nunes, I.L.; Ribeiro, R.A. Occupational risk assessment in construction industry—Overview and reflection. Saf. Sci. 2011, 49, 616–624. [Google Scholar] [CrossRef]

- Gadd, S.A.; Keeley, D.M.; Balmforth, H.F. Pitfalls in risk assessment: Examples from the U.K. Saf. Sci. 2004, 42, 841–857. [Google Scholar] [CrossRef]

- Hale, A.R.; Walker, D.; Walters, N.; Bolt, H. Developing the understanding of underlying causes of construction fatal accidents. Saf. Sci. 2012, 50, 2020–2027. [Google Scholar] [CrossRef]

- Development Bureau. Technical Circular (Works) No. 3/2020 Digital Works Supervision System. 2020. Available online: https://www.devb.gov.hk/filemanager/technicalcirculars/en/upload/374/1/C-2020-03-01.pdf (accessed on 28 March 2022).

- Wu, C.; Wang, F.; Zou, P.X.W.; Fang, D. How safety leadership works among owners, contractors and subcontractors in construction projects. Int. J. Proj. Manag. 2016, 34, 789–805. [Google Scholar] [CrossRef]

- Zhou, Q.; Fang, D.; Mohamed, S. Safety climate improvement: Case study in a Chinese construction company. J. Constr. Eng. Manag. ASCE 2011, 137, 86–95. [Google Scholar] [CrossRef]

- Chi, S.; Caldas, C.H. Image-Based Safety Assessment: Automated Spatial Safety Risk Identification of Earthmoving and Surface Mining Activities. J. Constr. Eng. Manag. ASCE 2012, 138, 341–351. [Google Scholar] [CrossRef]

- Kim, J.; Hwang, J.; Chi, S.; Seo, J. Towards database-free vision-based monitoring on construction sites: A deep active learning approach. Autom. Constr. 2020, 120, 103376. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Autom. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

- Awolusi, I.; Nnaji, C.; Marks, E.; Hallowell, M. Enhancing construction safety monitoring through the application of internet of things and wearable sensing devices: A review. In Proceedings of the Computing in Civil Engineering 2019: Data, Sensing, and Analytics 2019, Atlanta, GA, USA, 17–19 June 2019. [Google Scholar]

- Saifullah, N.M.; Ismail, F. Integration of occupational safety and health during pre-construction stage in Malaysia. Procedia-Soc. Behav. Sci. 2012, 35, 603–610. [Google Scholar] [CrossRef]

- Alli, B. Fundamental Principles of Occupational Health and Safety, 2nd ed.; International Labour Organization (ILO): Geneva, Switzerland, 2008. [Google Scholar]

- Mollo, L.G.; Emuze, F.; Smallwood, J. Using a safety management system to reduce errors and violations. Proc. Inst. Civ. Eng.-Munic. Eng. 2021, 174, 136–143. [Google Scholar] [CrossRef]

- Stemn, E.; Bofinger, C.; Cliff, D.; Hassall, M.E. Failure to learn from safety incidents: Status, challenges and opportunities. Saf. Sci. 2018, 101, 313–325. [Google Scholar] [CrossRef]

| Accident Causation Model | Features | References |

|---|---|---|

| AcciMap | Graphically represent how and why an organizational accident occurred throughout the sociotechnical system across government policy and budgeting; regulatory bodies and associations; local area government planning and budgeting (including company management), technical and operational management; physical processes and actor activities; and equipment and surroundings | [27] |

| Systems Theoretic Accident Model and Processes (STAMP) | A constraints-based model, viewing accidents as the result of the inadequate control of safety-related constraints, potentially as comprehensive as AcciMap | [28,29] |

| Functional Resonance Accident Model (FRAM) | The interaction of three components: Organizational, technical, and human | [30] |

| Constraint-response model | A constraints-based model, viewing accidents as the result of constraints and responses experienced by all construction project participants | [31,32] |

| Modified loss causation model (MLCM) | Classify the causes of construction accidents into three categories: Immediate causes, safety management system failures, and underlying factors | [33] |

| Mitropoulos’s system model | View errors and accidents as the result of joint effects of task unpredictability, production pressure, and efficient behaviors | [22,34] |

| Loughborough construction accident causation model (ConCa) | Classify the causes of construction accidents into three groups: Immediate circumstances, shaping factors, and originating influences | [35,36] |

| Human factor and classification system (HFACS) | Classify accident causes into four layers: organizational influences, unsafe management, preconditions for unsafe acts, and unsafe acts themselves | [37] |

| Case Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Year | 2014 | 2020 | 2020 | 2020 | 2020 | 2021 | 2021 | 2021 |

| Month | July | June | July | July | July | April | April | April |

| Day of the week | Thursday | Saturday | Tuesday | Tuesday | Thursday | Wednesday | Sunday | Wednesday |

| Time | 11:00 | 14:00 | 9:00 | 14:30 | 12:30 | 14:00 | 9:30 | 16:00 |

| Age | 59 | 41 | 42 | 51 | 54 | 54 | 52 | 43 |

| Gender | M | M | M | M | M | M | M | M |

| Nationality | Chinese | Indonesia | Chinese | Chinese | Chinese | Chinese | Illegal worker from mainland china | Chinese |

| Length of experience in the construction industry | NA | NA | 8 years | 10 years | Over 15 years | Over 20 years | NA | Less than one year |

| Length of experience in KTD project | 32 days | 2 months | 4 months | 3 months | 1 month | 6 months | NA | 1 month |

| Type of employer | Main contractor | 2nd tier Subcontractor | 2nd tier Subcontractor | 2nd tier Subcontractor | 3rd tier Subcontractor | 2nd tier Subcontractor | 2nd tier Subcontractor | 3rd tier Subcontractor |

| Type of project | Public (Cruise terminal) | Private residential | Public (Hospital) | Infrastructure | Private residential | Public residential | Private residential | Infrastructure |

| Work trade | Electrical worker | Bamboo scaffolder | Laborer | Bar bender and fixer | Piling operative | Laborer | Bamboo scaffolder | Concretor |

| Taxonomy | Sub-Taxonomy | Case 1 | Case 2 | Case 5 | Case 7 |

|---|---|---|---|---|---|

| Situational variables | Type of location | On a wooden folding stepladder | On a bamboo scaffold | On ground | On a bamboo scaffold |

| Type of equipment/structure involved | Stepladder | Bamboo scaffold | Piling equipment | Bamboo scaffold | |

| Type of work | Electrical wiring | Erection of scaffold | Piling | Erection of scaffold | |

| Type of interacting works | NA | A metal beam was being installed vertically atop the scaffold | NA | NA | |

| Type of accident | Fall on and from a ladder Industrial and construction area | Fall on and from scaffolding Industrial and construction area | Other fall from one level to another Industrial and construction area | Fall on and from scaffolding Industrial and construction area | |

| Incident sequence | Consequences | Death | Death | Death | Death |

| Contact event | Fall from ladder | Fall from scaffold | Fall together with the piling equipment | Fall from a bamboo scaffold | |

| Breakdown event | Lost balance | Strike against the scaffold by a metal beam | The ground suddenly subsided | NA | |

| Immediate causes | Substandard/unsafe conditions | Improper and unsafe means of support, i.e., wooden stepladder with no rigid ladder lock | The upper metal beam was unstably supported using undesirable welded joints | The piling equipment was not placed and operated on firm ground with sufficient load-bearing capacity | Substandard members of the bamboo scaffolds, part of standards (vertical bamboo members), and ledgers (horizontal bamboo members) of the bamboo scaffolds were missing. Moreover, there were no bracings in some inner planes of the bamboo scaffolds |

| Substandard/unsafe behaviors | Riding on the stepladder, fail to maintain three-point contact | Working in a dangerous zone | Not wearing any safety helmet or safety belt | ||

| Safety management system failures | Lack/inadequate of safety measures | Lack of safety measures for work-at-height activities, i.e., no safety net, no anchorage for the safety belt. | No precautions such as providing suitable shelters to prevent workers from being struck by any falling objects | There is no investigation or assessment to ensure the piling equipment is placed on firm ground with sufficient load-bearing capacity. | No fall protection measures and lack of independent lifeline or anchorage points for safety harness |

| No rigid ladder locker for stabilizing the ladder, but only a nylon rope was connected to the ladder legs | The dangerous zone was not fenced off properly, and no warning notices were displayed | Lack of suitable working platforms with proper access and egress | |||

| Underlying factors | Job factors | Failure to provide and maintain a safe system for the conduit wiring work | Failure to conduct an assessment on the conditions of the welded joint of the metal beam | Inadequate supervision and inspection of the piling work | Failure to provide information, instruction, training, and supervision |

| No specific risk assessment and method statement for the work and failure to provide and maintain a safe system regarding the erection of scaffold | No comprehensive site investigation before the commencement of piling work and no specific risk assessment on the piling work | No specific risk assessment and method statement for the work and failure to provide and maintain a safe system for work | |||

| Organizational factors | NA | NA | NA | Employment of an illegal worker | |

| Taxonomy | Sub-Taxonomy | Case 3 | Case 4 | Case 6 | Case 8 |

|---|---|---|---|---|---|

| Situational variables | Type of location | On the loading platform of a lorry | Inside a tunnel | On the crane compartment | On ground |

| Type of equipment/structure involved | Machine component (4 Tons) | Reinforcement bar structure | A pile of panels (600 kg) | Concrete skip | |

| Type of work | Material handling | Reinforcement Fixing | Material handling | Concreting work | |

| Type of interacting works | NA | A team of workers was working on a reinforcement bar structure | NA | NA | |

| Type of accident | Struck by thrown, projected, or falling object-Industrial and construction area | Struck by thrown, projected, or falling object-Industrial and construction area | Struck by thrown, projected, or falling object-Industrial and construction area | Struck by thrown, projected, or falling object-Industrial and construction area | |

| Incident sequence | Consequences | Death | One fatality and six injuries | Death | Death |

| Contact event | Struck by the displaced machine component | Struck by the falling reinforcement bar structure | Struck by the displaced pile of panels | Struck by the concrete skip under lifting | |

| Breakdown event | The sudden displacement of the machine component | The collapse of the reinforcement bar structure | The pile of panels under uploading displaced | The excavation suddenly tilted | |

| Immediate causes | Substandard/unsafe conditions | Squatting on the loading platform of a lorry to secure a machine component that had been loaded in a slanting position on the platform | Unstable condition of the reinforcement bar structure without sufficient support | Working in the vicinity of the crane to give the operator hand signals | Poor working environment, ground condition was uneven with slopes; Poor housekeeping, impracticable to maintain unobstructed passageway |

| Substandard/unsafe behaviors | NA | Working next to the lorry-mounted crane (dangerous zone) | |||

| Safety management system failures | Lack/inadequate of safety measures | No communication about necessary safety measures between the decedent and his co-worker for the loading operation, even it was the first time to do this work | No extra measures to stabilize the reinforcement structure; No provision of shielding, soil stabilizing treatment | NA | No segregation for separating workers from entering the working zone |

| Underlying factors | Job factors | No supervision on the loading work | An irresponsible subcontractor to execute and supervise the construction of the structure | Failure to provide instruction and supervision for the operation of the crane | Inadequate risk assessment, supervision, and monitoring of crane operation |

| No safe work procedures were provided as all work arrangement made at the accident scene was based on the workers’ decision only | No competent safety personnel to assess the risks of the construction of the structure | Failure to provide risk assessment and method statement to the signalman | |||

| Preventive Measures | Case Number | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Frequency | |

| Administrative controls | |||||||||

| Appointing a competent person to conduct task-specific risk assessments. | 8 | ||||||||

| Establishing and implementing an effective monitoring and control system. | - | 8 | |||||||

| Formulating safe work methods and procedures for the work. | - | - | 6 | ||||||

| Appointing a professional engineer with adequate qualifications, competence, and experience to design the structure. | - | - | - | - | - | - | 2 | ||

| Ensuring that the structure is installed strictly in accordance with the specification and method statement. | - | - | - | - | - | - | 2 | ||

| Ensuring that the scaffolds are erected by trained workmen with adequate experience and suitable safety harness. | - | - | - | - | - | - | 2 | ||

| Carrying out a thorough site investigation on the ground conditions. | - | - | - | - | - | - | - | 2 | |

| Ensuring that the crane, every chain, rope, or other lifting gear has been certified in safe working order through tests and thorough examinations. | - | - | - | - | - | - | 2 | ||

| Ensuring that the crane is only operated by a person who holds a valid certificate. | - | - | - | - | - | - | 2 | ||

| Ensuring that all site personnel and workers involved are competent. | - | - | - | - | - | - | - | 1 | |

| Engineering controls | |||||||||

| Avoiding carrying out any work underneath the structure being erected/altered/dismantled. | - | - | - | - | - | - | 2 | ||

| Ensuring piling equipment is placed and operated on firm ground with sufficient load-bearing capacity. | - | - | - | - | - | - | 2 | ||

| Ensuring that no workers/employees work or stay underneath the materials being lifted. | - | - | - | - | - | - | 2 | ||

| Where it is not reasonably practicable to fence off the lifting zones, taking effective measures, such as appointment of sufficient watch-out personnel. | - | - | - | - | - | - | 2 | ||

| Ensuring that the structure being erected is properly and securely supported. | - | - | - | - | - | - | 2 | ||

| Ensuring the vehicle platform on which the load to be handled is of sufficient length and width and the load projection should not exceed the relevant legal requirements. | - | - | - | - | - | - | - | 1 | |

| Where work underneath the structure being erected/altered/dismantled cannot be avoided, taking necessary precautions, such as providing suitable shelters to prevent workers from being struck by any falling objects. | - | - | - | - | - | - | - | 1 | |

| Provide and properly maintain suitable and adequate safe means of access to and egress from every place of work. | - | - | - | - | - | - | - | 1 | |

| Setting the mobile crane on solid ground and using suitable mat or timber blocking with area of at least three times of the outrigger’s float. | - | - | - | - | - | - | - | 1 | |

| When operating close to the edge of a soil slope or an unsupported soil excavation, ensuring that a safe distance from the edge should be maintained. | - | - | - | - | - | - | - | 1 | |

| Behavioral controls | |||||||||

| Providing all workers/employees concerned with necessary safety information, instruction and training, and personal protective equipment. | 8 | ||||||||

| Observing manufacturer’s recommendations and instructions to ensure the stability of the crane. | - | - | - | - | - | - | - | 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, A.P.C.; Yang, Y.; Choi, T.N.Y.; Nwaogu, J.M. Characteristics and Causes of Construction Accidents in a Large-Scale Development Project. Sustainability 2022, 14, 4449. https://doi.org/10.3390/su14084449

Chan APC, Yang Y, Choi TNY, Nwaogu JM. Characteristics and Causes of Construction Accidents in a Large-Scale Development Project. Sustainability. 2022; 14(8):4449. https://doi.org/10.3390/su14084449

Chicago/Turabian StyleChan, Albert P. C., Yang Yang, Tracy N. Y. Choi, and Janet Mayowa Nwaogu. 2022. "Characteristics and Causes of Construction Accidents in a Large-Scale Development Project" Sustainability 14, no. 8: 4449. https://doi.org/10.3390/su14084449

APA StyleChan, A. P. C., Yang, Y., Choi, T. N. Y., & Nwaogu, J. M. (2022). Characteristics and Causes of Construction Accidents in a Large-Scale Development Project. Sustainability, 14(8), 4449. https://doi.org/10.3390/su14084449