Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers

Abstract

:1. Introduction

1.1. Industrial Symbiosis

1.2. Emerging Market Countries

1.3. Frontier Market Countries

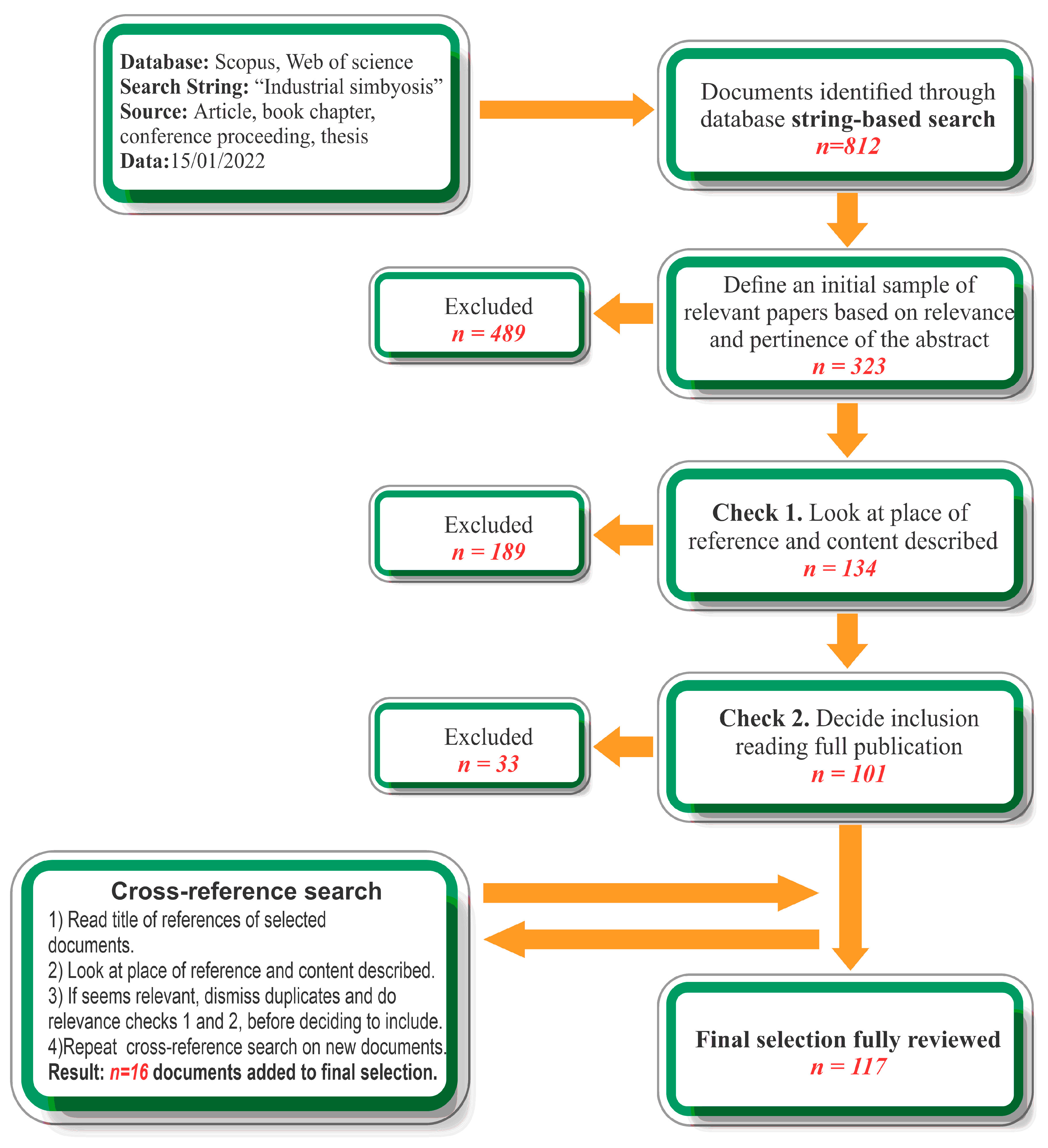

2. Materials and Methods

- RQ1.

- What is the geographical distribution of emerging and frontier market countries conducting IS research?

- RQ2.

- In which economic sectors have IS studies been conducted?

- RQ3.

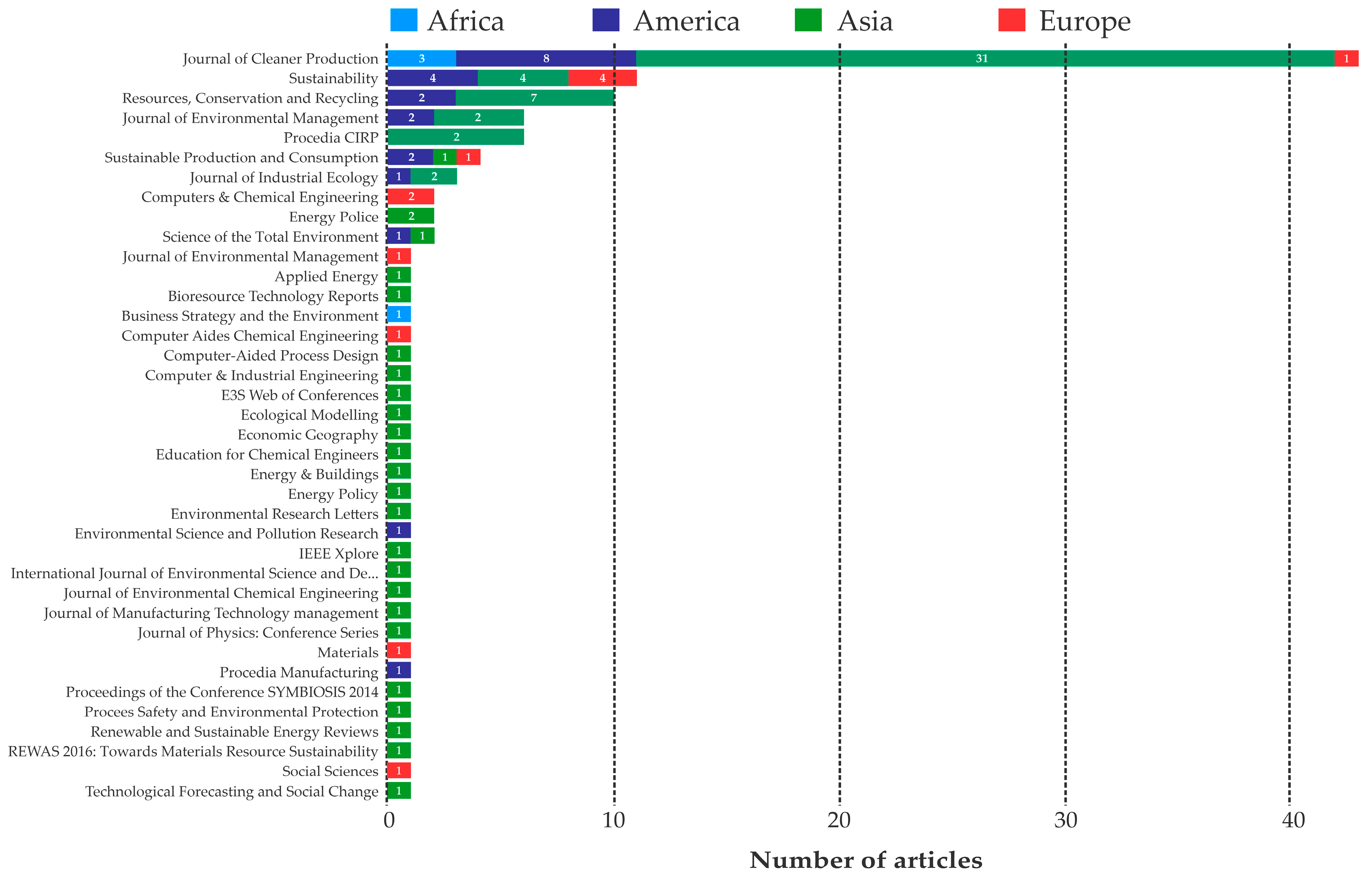

- What has been the contribution of journals to the evolution of published articles?

- RQ4.

- What has been the evolution of articles published on IS and the research methods used in the cases analyzed?

- RQ5.

- What type of resource integration is present in the case studies?

- (A)

- Geographic distribution: this classification determines the continent, country, and region in which the research was conducted, and identifies whether it concerns emerging market or frontier market countries. Regarding the geographical distribution of the countries researching IS, the classification was made according to the location of the case study. In addition, theoretical studies were classified in cases with multiple institutions in an investigation, taking into account the nationality of the largest number of authors.

- (B)

- Type of industries involved in industrial symbiosis: a categorization is made according to the economic sector in which the studies were carried out.

- (C)

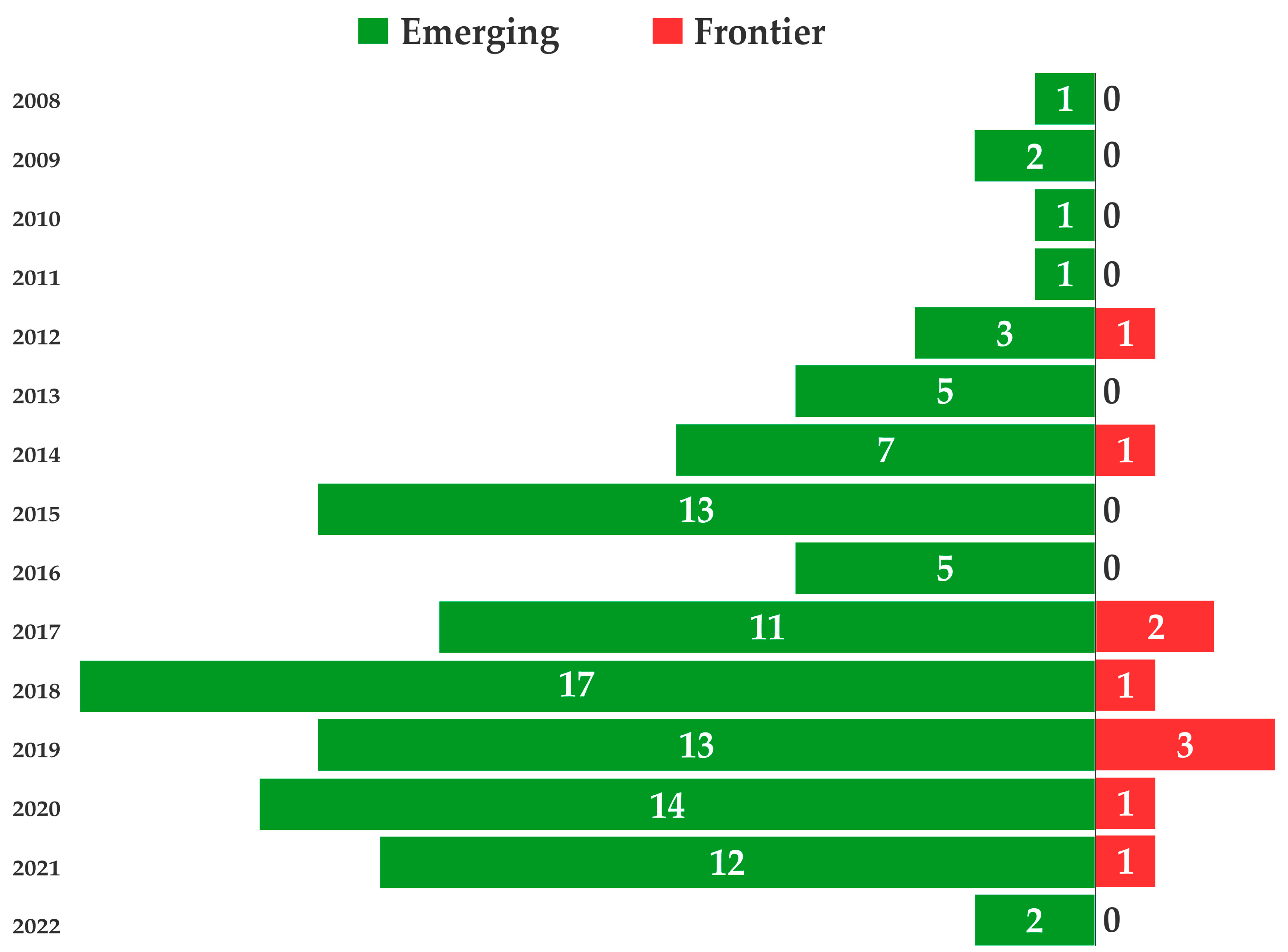

- Evolution of the number of published articles: this shows how articles on IS have varied from year to year in emerging and frontier market countries. The methods used in each case study being analyzed are identified.

- (D)

- Contribution of journals: selected articles are classified according to the journal in which they were published.

- (E)

- Resource integration: the main resource integrations present in the case studies analyzed are identified.

3. Results

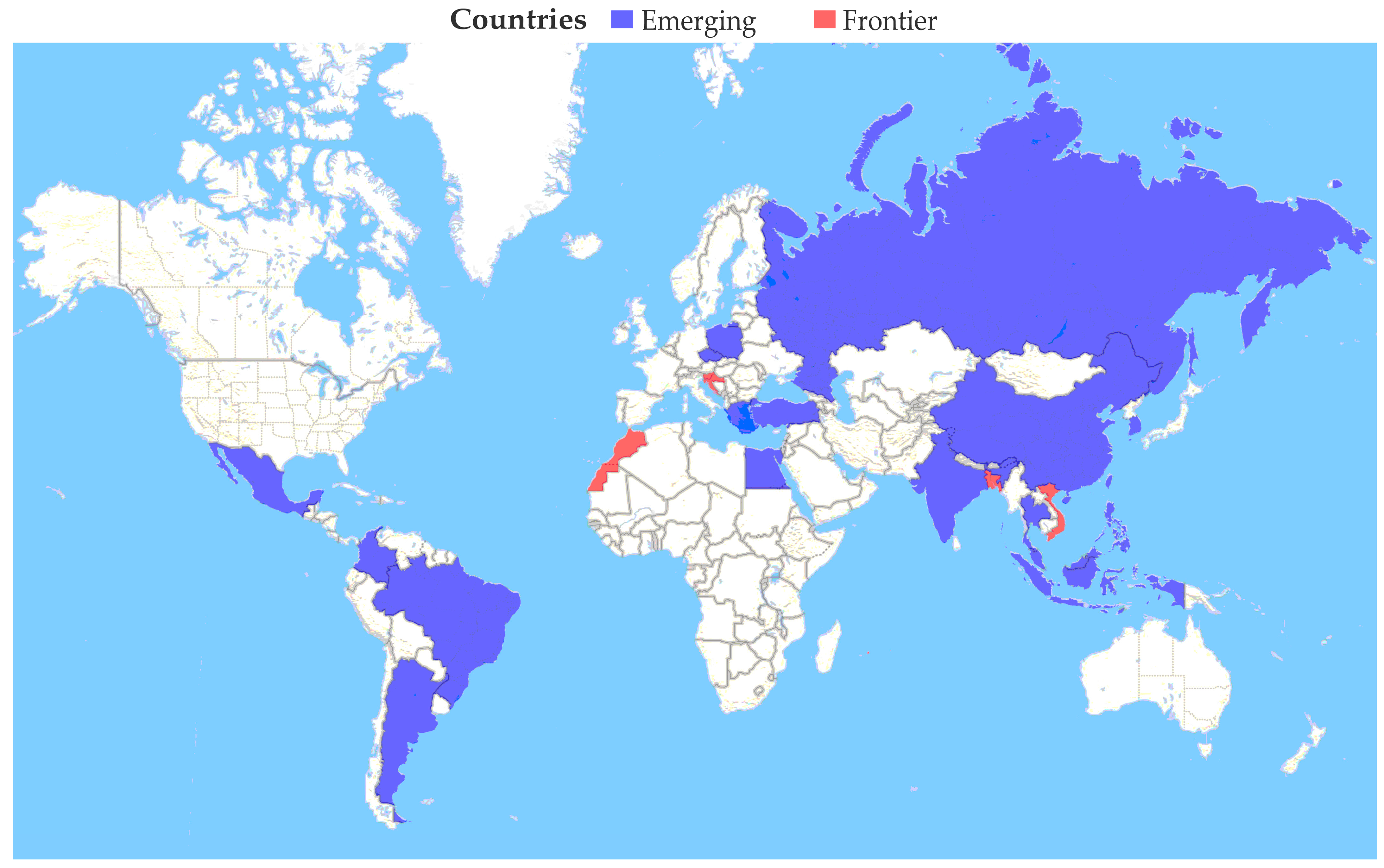

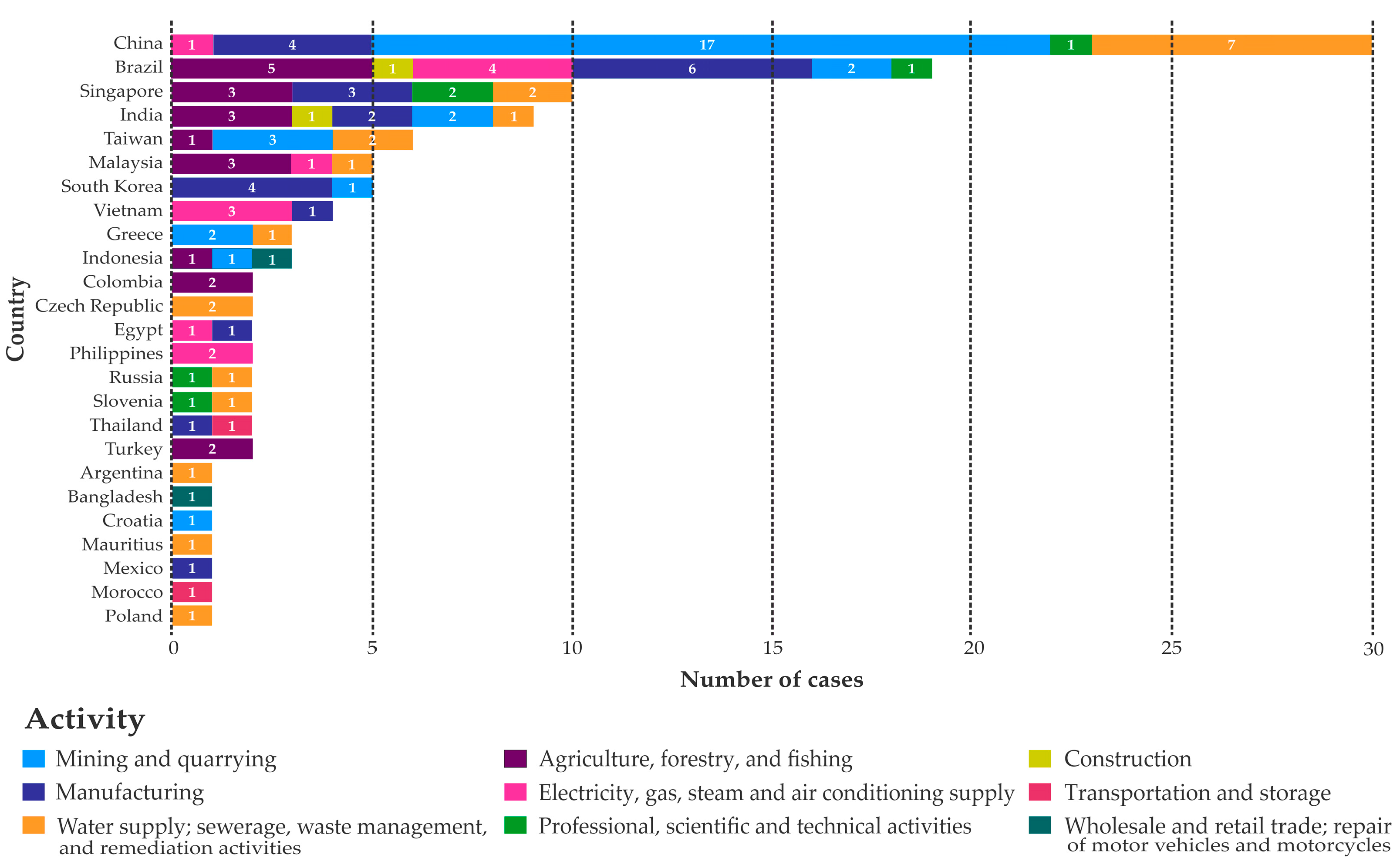

3.1. Geographic Distribution

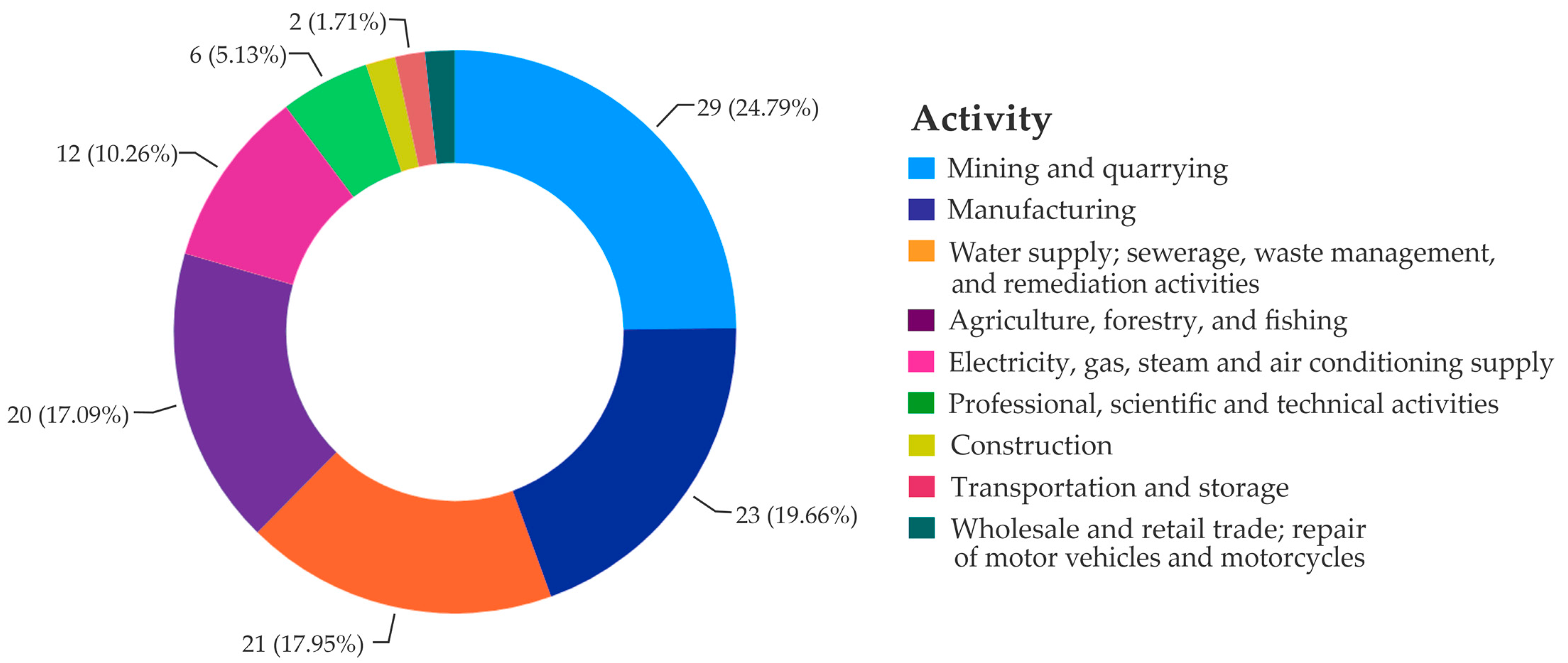

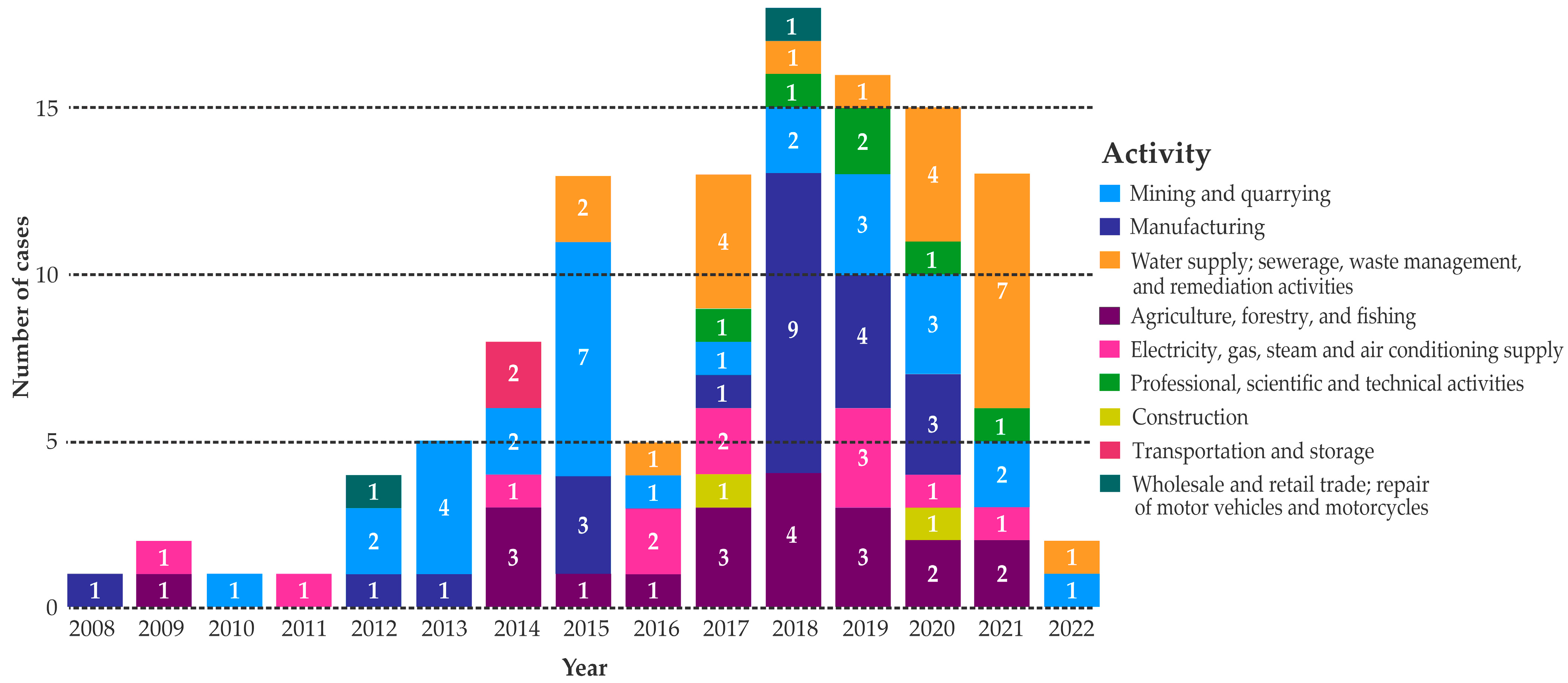

3.2. Type of Productive Activity Involved in Industrial Symbiosis

- A:

- Agriculture, forestry, and fishing.

- B:

- Mining and quarrying.

- C:

- Manufacturing.

- D:

- Electricity, gas, steam, and air conditioning supply.

- E:

- Water supply: sewerage, waste management, and remediation activities.

- F:

- Construction.

- G:

- Wholesale and retail trade: repair of motor vehicles and motorcycles.

- H:

- Transportation and storage.

- I:

- Professional, scientific, and technical activities.

3.3. Contribution of Journals in the Evolution of Published Articles

3.4. Evolution of the Number of Published Articles

3.5. Resource Integration

3.5.1. Waste Integration

3.5.2. Water Integration

3.5.3. Energy Integration

3.5.4. Carbon Integration

4. Discussion

4.1. Barriers to IS in Emerging and Frontier Countries

4.1.1. Financial Barriers to Promoting IS

4.1.2. Lack of Knowledge of the Concept of Waste Trading

4.1.3. Lack of Awareness of IS Projects

4.1.4. Deficiency of Regulatory Frameworks

4.1.5. Absence of Landfill Fees

4.1.6. Business Confidentiality

4.1.7. Lack of Innovation in the Business Sector

4.1.8. Lack of Green Technology

4.1.9. Lack of Infrastructure

4.1.10. Social Barriers

4.1.11. Imbalance between Availability and Demand

4.2. Drivers of IS in Emerging and Frontier Countries

4.2.1. Finance—Controlling Costs and Reinforcing Efficiency

4.2.2. Governance—Creating Trust and Promoting Positive Financial Outcomes

4.2.3. Legislation—Compliance with Environmental Protection Requirements

4.2.4. Understanding the Broader Market and Recognizing Megatrends

4.2.5. Digital—Embracing Technology and Improving Productivity

4.2.6. Innovations—Circular Business Models as a Competitive Advantage

4.2.7. People—Retaining Employees and Developing High-Quality Teams

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ajwani-Ramchandani, R.; Figueira, S.; Torres de Oliveira, R.; Jha, S. Enhancing the circular and modified linear economy: The importance of blockchain for developing economies. Resour. Conserv. Recycl. 2021, 168, 105468. [Google Scholar] [CrossRef]

- Frig, M.; Sorsa, V.P. Nation branding as sustainability governance: A case comparative case analysis. Bus. Soc. 2020, 59, 1153–1180. [Google Scholar] [CrossRef]

- Oskam, I.; Bossink, B.; de Man, A.P. Valuing Value in Innovation Ecosystems: How Cross-Sector Actors Overcome Tensions in Collaborative Sustainable Business Model Development. Bus. Soc. 2020, 60, 1059–1091. [Google Scholar] [CrossRef]

- Goyal, S.; Chauhan, S.; Mishra, P. Circular economy research: A bibliometric analysis (2000–2019) and future research insights. J. Clean. Prod. 2021, 287, 125011. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Södergren, K.; Palm, J. The role of local governments in overcoming barriers to industrial symbiosis. Clean. Environ. Syst. 2021, 2, 100014. [Google Scholar] [CrossRef]

- Lim, M.K.; Lai, M.; Wang, C.; Lee, S.Y. Circular economy to ensure production operational sustainability: A green-lean approach. Sustain. Prod. Consum. 2022, 30, 130–144. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M.; Jabbour, C.J.C.; Bhalaji, R.K.A. Inhibitors to circular economy practices in the leather industry using an integrated approach: Implications for sustainable development goals in emerging economies. Sustain. Prod. Consum. 2021, 27, 1554–1568. [Google Scholar] [CrossRef]

- Lonca, G.; Lesage, P.; Majeau-Bettez, G.; Bernard, S.; Margni, M. Assessing scaling effects of circular economy strategies: A case study on plastic bottle closed-loop recycling in the USA PET market. Resour. Conserv. Recycl. 2020, 162, 105013. [Google Scholar] [CrossRef]

- Tang, X.; He, Y.; Salling, M. Optimal pricing and production strategies for two manufacturers with industrial symbiosis. Int. J. Prod. Econ. 2021, 235, 108084. [Google Scholar] [CrossRef]

- Foong, S.Z.Y.; Ng, D.K.S. Simultaneous design and integration of multiple processes for eco-industrial park development. J. Clean. Prod. 2021, 298, 126797. [Google Scholar] [CrossRef]

- Herczeg, G.; Akkerman, R.; Hauschild, M.Z. Supply chain collaboration in industrial symbiosis networks. J. Clean. Prod. 2018, 171, 1058–1067. [Google Scholar] [CrossRef]

- Miemczyk, J.; Johnsen, T.E.; Macquet, M. Sustainable purchasing and supply management: A structured literature review of definitions and measures at the dyad, chain and network levels. Supply Chain Manag. Int. J. 2012, 17, 478–496. [Google Scholar] [CrossRef]

- De Pascale, A.; Arbolino, R.; Szopik-Depczyńska, K.; Limosani, M.; Ioppolo, G. A systematic review for measuring circular economy: The 61 indicators. J. Clean. Prod. 2021, 281, 124942. [Google Scholar] [CrossRef]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_ typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Kobayashi, H.; Murata, H.; Fukushige, S. Connected lifecycle systems: A new perspective on industrial symbiosis. Procedia CIRP 2020, 90, 388–392. [Google Scholar] [CrossRef]

- Chiu, A.S.F.; Yong, G. On the industrial ecology potential in Asian developing countries. J. Clean. Prod. 2004, 12, 1037–1045. [Google Scholar] [CrossRef]

- The Balance. MSCI Index and What It Measures. Available online: https://www.thebalance.com/msci-index-what-is-it-and-what-does-it-measure-3305948 (accessed on 15 December 2021).

- CFI. Emerging Markets. Corporate Finance Institute. Available online: https://corporatefinanceinstitute.com/resources/knowledge/economics/emerging-markets/ (accessed on 15 November 2021).

- Chourou, L.; Grira, J.; Saadi, S. Does empathy matter in corporate social responsibility? Evidence from emerging markets. Emerg. Mark. Rev. 2021, 46, 100776. [Google Scholar] [CrossRef]

- Khanna, T.; Palepu, K.G. Why focused strategies may be wrong for emerging markets. Harv. Bus. Rev. 1997, 75, 41–51. [Google Scholar]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A comprehensive review of industrial symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- Vahidzadeh, R.; Bertanza, G.; Sbaffoni, S.; Vaccari, M. Regional industrial symbiosis: A review based on social network analysis. J. Clean. Prod. 2021, 280, 124054. [Google Scholar] [CrossRef]

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ. Environ. 2015, 28, 32–53. [Google Scholar] [CrossRef]

- Lawal, M.; Wan Alwi, S.R.; Manan, Z.A.; Ho, W.S. Industrial symbiosis tools—A review. J. Clean. Prod. 2021, 280, 124327. [Google Scholar] [CrossRef]

- Khan, M.; Lockhart, J.; Bathurst, R. The institutional analysis of CSR: Learnings from an emerging country. Emerg. Mark. Rev. 2021, 46, 100752. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Ecosystem indicators for measuring industrial symbiosis. Ecol. Econ. 2021, 183, 106944. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Schwarz, E.J.; Steininger, K.W. Implementing nature’s lesson: The industrial recycling network enhancing regional development. J. Clean. Prod. 1997, 5, 47–56. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Earley, K. Industrial symbiosis: Harnessing waste energy and materials for mutual benefit. Renew. Energy Focus 2015, 16, 75–77. [Google Scholar] [CrossRef]

- Lombardi, D.R.; Laybourn, P. Redefining Industrial Symbiosis: Crossing Academic-Practitioner Boundaries. J. Ind. Ecol. 2012, 16, 28–37. [Google Scholar] [CrossRef]

- Albino, V.; Fraccascia, L. The industrial symbiosis approach: A classification of business models. Procedia Environ. Sci. Eng. Manag. 2015, 2, 217–223. [Google Scholar]

- Simboli, A.; Taddeo, R.; Morgante, A. The potential of Industrial Ecology in agri-food clusters (AFCs): A case study based on valorisation of auxiliary materials. Ecol. Econ. 2015, 111, 65–75. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A.; Erkman, S. The Development of Industrial Symbiosis in Existing Contexts. Experiences from Three Italian Clusters. Ecol. Econ. 2017, 139, 55–67. [Google Scholar] [CrossRef]

- Yuan, Z.; Shi, L. Improving enterprise competitive advantage with industrial symbiosis: Case study of a smeltery in China. J. Clean. Prod. 2009, 17, 1295–1302. [Google Scholar] [CrossRef]

- Kokoulina, L.; Ermolaeva, L.; Patala, S.; Ritala, P. Championing processes and the emergence of industrial symbiosis. Reg. Stud. 2019, 53, 528–539. [Google Scholar] [CrossRef]

- Ashraf, B.N.; Qian, N.; Shen, Y. The impact of trade and financial openness on bank loan pricing: Evidence from emerging economies. Emerg. Mark. Rev. 2021, 47, 100793. [Google Scholar] [CrossRef]

- The World Bank. World Bank Country and Lending Groups. Available online: https://datahelpdesk.worldbank.org/knowledgebase/articles/906519 (accessed on 17 November 2021).

- Erdoğan, S.; Gedikli, A.; Çevik, E.İ. Volatility spillover effects between Islamic stock markets and exchange rates: Evidence from three emerging countries. Borsa Istanb. Rev. 2020, 20, 322–333. [Google Scholar] [CrossRef]

- MSCI. MSCI Global Market Accessibility Review; MSCI: New York, NY, USA, 2021. [Google Scholar]

- Cagliesi, G.; Guidi, F. A three-tiered nested analytical approach to financial integration: The case of emerging and frontier equity markets. Int. Rev. Financ. Anal. 2021, 74, 101698. [Google Scholar] [CrossRef]

- Guney, Y.; Karpuz, A.; Komba, G. The effects of board structure on corporate performance: Evidence from East African frontier markets. Res. Int. Bus. Financ. 2020, 53, 101222. [Google Scholar] [CrossRef]

- Santa-Maria, T.; Vermeulen, W.J.V.; Baumgartner, R.J. Framing and assessing the emergent field of business model innovation for the circular economy: A combined literature review and multiple case study approach. Sustain. Prod. Consum. 2021, 26, 872–891. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Cuentas, S.; Peñabaena-Niebles, R.; Garcia, E. Support vector machine in statistical process monitoring: A methodological and analytical review. Int. J. Adv. Manuf. Technol. 2017, 91, 485–500. [Google Scholar] [CrossRef]

- Mileva-Boshkoska, B.; Rončević, B.; Uršič, E.D. Modeling and evaluation of the possibilities of forming a regional industrial symbiosis networks. Soc. Sci. 2018, 7, 13. [Google Scholar] [CrossRef] [Green Version]

- Guarnieri, P.; Cerqueira-Streit, J.A.; Batista, L.C. Reverse logistics and the sectoral agreement of packaging industry in Brazil towards a transition to circular economy. Resour. Conserv. Recycl. 2020, 153, 104541. [Google Scholar] [CrossRef]

- Pereira, T.; Fernandino, G. Evaluation of solid waste management sustainability of a coastal municipality from northeastern Brazil. Ocean Coast. Manag. 2019, 179, 104839. [Google Scholar] [CrossRef]

- Park, J.; Duque-Hernández, J.; Díaz-Posada, N. Facilitating business collaborations for industrial symbiosis: The pilot experience of the sustainable industrial network program in Colombia. Sustainability 2018, 10, 3637. [Google Scholar] [CrossRef] [Green Version]

- Gupta, D.; Ghersi, F.; Vishwanathan, S.S.; Garg, A. Achieving sustainable development in India along low carbon pathways: Macroeconomic assessment. World Dev. 2019, 123, 104623. [Google Scholar] [CrossRef]

- Falebita, O.; Koul, S. From developing to sustainable economy: A comparative assessment of India and Nigeria. Environ. Dev. 2018, 25, 130–137. [Google Scholar] [CrossRef]

- Singh, M.P.; Chakraborty, A.; Roy, M. Developing an extended theory of planned behavior model to explore circular economy readiness in manufacturing MSMEs, India. Resour. Conserv. Recycl. 2018, 135, 313–322. [Google Scholar] [CrossRef]

- Vu, K.M. Embracing globalization to promote industrialization: Insights from the development of Singapore’s petrochemicals industry. China Econ. Rev. 2018, 48, 170–185. [Google Scholar] [CrossRef]

- World Bank. Government Expenditure on R&D. Available online: https://data.worldbank.org/indicator/GC.XPN.TOTL.GD.ZS (accessed on 2 December 2021).

- Cheah, S.L.Y.; Ho, Y.P.; Li, S. How the effect of opportunity discovery on innovation outcome differs between DIY laboratories and public research institutes: The role of industry turbulence and knowledge generation in the case of Singapore. Technol. Forecast. Soc. Chang. 2020, 160, 120250. [Google Scholar] [CrossRef]

- GII. Global Innovation Index. Available online: https://www.globalinnovationindex.org/Home (accessed on 11 November 2021).

- Wu, C.Y.; Hu, M.C.; Ni, F.C. Supporting a circular economy: Insights from Taiwan’s plastic waste sector and lessons for developing countries. Sustain. Prod. Consum. 2021, 26, 228–238. [Google Scholar] [CrossRef] [PubMed]

- Eunomia. Recycling-Who Really Leads the World? European Environmental Bureau: Brussels, Belgium, 2018. [Google Scholar]

- Huang, Y.F.; Azevedo, S.G.; Lin, T.J.; Cheng, C.S.; Lin, C.T. Exploring the decisive barriers to achieve circular economy: Strategies for the textile innovation in Taiwan. Sustain. Prod. Consum. 2021, 27, 1406–1423. [Google Scholar] [CrossRef]

- United Nations. International Standard Industrial Classification of All Economic Activities (ISIC), Rev. 4; Department of Economic and Social Affairs: New York, NY, USA, 2008. [Google Scholar]

- Wu, W.; Sheng, L.; Tang, F.; Zhang, A.; Liu, J. A system dynamics model of green innovation and policy simulation with an application in Chinese manufacturing industry. Sustain. Prod. Consum. 2021, 28, 987–1005. [Google Scholar] [CrossRef]

- Wu, J.; Lu, J.; Jin, R. Quantitative indicators for evolution of a typical iron and steel industrial symbiosis network. J. Clean. Prod. 2021, 287, 125491. [Google Scholar] [CrossRef]

- Huang, L.; Zhen, L.; Yin, L. Waste material recycling and exchanging decisions for industrial symbiosis network optimization. J. Clean. Prod. 2020, 276, 124073. [Google Scholar] [CrossRef]

- Lu, C.; Wang, S.; Wang, K.; Gao, Y.; Zhang, R. Uncovering the benefits of integrating industrial symbiosis and urban symbiosis targeting a resource-dependent city: A case study of Yongcheng, China. J. Clean. Prod. 2020, 255, 120210. [Google Scholar] [CrossRef]

- Wang, S.; Lu, C.; Gao, Y.; Wang, K.; Zhang, R. Life cycle assessment of reduction of environmental impacts via industrial symbiosis in an energy-intensive industrial park in China. J. Clean. Prod. 2019, 241, 118358. [Google Scholar] [CrossRef]

- Wu, J.; Lv, J.; Shang, J.; Guo, Y.; Pu, G. Evaluating chromium coupled with carbon metabolism and environmental performance in the chromate industrial symbiosis network in China. Resour. Conserv. Recycl. 2019, 149, 188–196. [Google Scholar] [CrossRef]

- Zhang, B.; Du, Z.; Wang, Z. Carbon reduction from sustainable consumption of waste resources: An optimal model for collaboration in an industrial symbiotic network. J. Clean. Prod. 2018, 196, 821–828. [Google Scholar] [CrossRef]

- de Araújo, I.F.; Perobelli, F.S.; Faria, W.R. Regional and global patterns of participation in value chains: Evidence from Brazil. Int. Econ. 2021, 165, 154–171. [Google Scholar] [CrossRef]

- Baldwin, R.; Lopez-Gonzalez, J. Supply-chain Trade: A Portrait of Global Patterns and Several Testable Hypotheses. World Econ. 2015, 38, 1682–1721. [Google Scholar] [CrossRef]

- Mantese, G.C.; Bianchi, M.J.; Amaral, D.C. The industrial symbiosis in the product development: An approach through the DFIS. Procedia Manuf. 2018, 21, 862–869. [Google Scholar] [CrossRef]

- de Oliveira, F.R.; França, S.L.B.; Rangel, L.A.D. Challenges and opportunities in a circular economy for a local productive arrangement of furniture in Brazil. Resour. Conserv. Recycl. 2018, 135, 202–209. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.T.; Magalhães, L.; Zancul, E.; Cauchick-Miguel, P.A. Exploring the challenges for circular business implementation in manufacturing companies: An empirical investigation of a pay-per-use service provider. Resour. Conserv. Recycl. 2018, 135, 3–13. [Google Scholar] [CrossRef]

- Martinelli, L.A.; Naylor, R.; Vitousek, P.M.; Moutinho, P. Agriculture in Brazil: Impacts, costs, and opportunities for a sustainable future. Curr. Opin. Environ. Sustain. 2010, 2, 431–438. [Google Scholar] [CrossRef]

- Vannozzi Brito, V.; Borelli, S. Urban food forestry and its role to increase food security: A Brazilian overview and its potentialities. Urban For. Urban Green. 2020, 56, 126835. [Google Scholar] [CrossRef]

- Wahrlich, J.; Simioni, F.J. Industrial symbiosis in the forestry sector: A case study in southern Brazil. J. Ind. Ecol. 2019, 23, 1470–1482. [Google Scholar] [CrossRef]

- Sanyé-Mengual, E.; Martinez-Blanco, J.; Finkbeiner, M.; Cerdà, M.; Camargo, M.; Ometto, A.R.; Velásquez, L.S.; Villada, G.; Niza, S.; Pina, A.; et al. Urban horticulture in retail parks: Environmental assessment of the potential implementation of rooftop greenhouses in European and South American cities. J. Clean. Prod. 2016, 172, 3081–3091. [Google Scholar] [CrossRef]

- Saraceni, A.V.; Resende, L.M.; de Andrade Júnior, P.P.; Pontes, J. Pilot testing model to uncover industrial symbiosis in Brazilian industrial clusters. Environ. Sci. Pollut. Res. 2017, 24, 11618–11629. [Google Scholar] [CrossRef]

- Mantese, G.C.; Amaral, D.C. Comparison of industrial symbiosis indicators through agent-based modeling. J. Clean. Prod. 2017, 140, 1652–1671. [Google Scholar] [CrossRef]

- Felicio, M.; Amaral, D.; Esposto, K.; Gabarrell Durany, X. Industrial symbiosis indicators to manage eco-industrial parks as dynamic systems. J. Clean. Prod. 2016, 118, 54–64. [Google Scholar] [CrossRef]

- Ceglia, D.; de Abreu, M.C.S.; Da Silva Filho, J.C.L. Critical elements for eco-retrofitting a conventional industrial park: Social barriers to be overcome. J. Environ. Manag. 2017, 187, 375–383. [Google Scholar] [CrossRef]

- Raabe, B.; Low, J.S.C.; Juraschek, M.; Herrmann, C.; Tjandra, T.B.; Ng, Y.T.; Kurle, D.; Cerdas, F.; Lueckenga, J.; Yeo, Z.; et al. Collaboration Platform for Enabling Industrial Symbiosis: Application of the By-product Exchange Network Model. Procedia CIRP 2017, 61, 263–268. [Google Scholar] [CrossRef]

- Kerdlap, P.; Low, J.S.C.; Tan, D.Z.L.; Yeo, Z.; Ramakrishna, S. M3-IS-LCA: A Methodology for Multi-level Life Cycle Environmental Performance Evaluation of Industrial Symbiosis Networks. Resour. Conserv. Recycl. 2020, 161, 104963. [Google Scholar] [CrossRef]

- Singh, R.; Chanda, R. Technical regulations, intermediate inputs, and performance of firms: Evidence from India. J. Int. Econ. 2021, 128, 103412. [Google Scholar] [CrossRef]

- Khurana, S.; Haleem, A.; Luthra, S.; Mannan, B. Evaluating critical factors to implement sustainable oriented innovation practices: An analysis of micro, small, and medium manufacturing enterprises. J. Clean. Prod. 2021, 285, 125377. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Rajak, S.; Kandasamy, J. Analysis of network design for a circular production system using multi-objective mixed integer linear programming model. J. Manuf. Technol. Manag. 2019, 30, 628–646. [Google Scholar] [CrossRef]

- Gopinath, A.; Bahurudeen, A.; Appari, S.; Nanthagopalan, P. A circular framework for the valorisation of sugar industry wastes: Review on the industrial symbiosis between sugar, construction and energy industries. J. Clean. Prod. 2018, 203, 89–108. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Kumar, N.; Fine, C.; Olivetti, E. Industrial symbiosis among small and medium scale enterprises: Case of Muzaffarnagar, India. In REWAS 2016, towards Materials Resource Sustainability; Springer: Berlin/Heidelberg, Germany, 2016; pp. 173–177. [Google Scholar] [CrossRef]

- Bain, A.; Ashton, W.; Shenoy, M. Resource reuse and recycling in an Indian industrial network: Efficiency and flexibility considerations. In Proceedings of the 2009 Second International Conference on Infrastructure Systems and Services: Developing 21st Century Infrastructure Networks (INFRA), Nagar, India, 9–11 December 2009; pp. 1–7. [Google Scholar] [CrossRef]

- Ashton, W.S.; Bain, A.C. Assessing the “Short Mental Distance” in Eco-Industrial Networks. J. Ind. Ecol. 2012, 16, 70–82. [Google Scholar] [CrossRef]

- Bain, A.; Shenoy, M.; Ashton, W.; Chertow, M. Industrial symbiosis and waste recovery in an Indian industrial area. Resour. Conserv. Recycl. 2010, 54, 1278–1287. [Google Scholar] [CrossRef]

- Li, J.; Pan, S.Y.; Kim, H.; Linn, J.H.; Chiang, P.C. Building green supply chains in eco-industrial parks towards a green economy: Barriers and strategies. J. Environ. Manag. 2015, 162, 158–170. [Google Scholar] [CrossRef]

- Lai, H.C.; Shyu, J.Z. A comparison of innovation capacity at science parks across the Taiwan Strait: The case of Zhangjiang High-Tech Park and Hsinchu Science-based Industrial Park. Technovation 2005, 25, 805–813. [Google Scholar] [CrossRef]

- Kim, H.W.; Ohnishi, S.; Fujii, M.; Fujita, T.; Park, H.S. Evaluation and Allocation of Greenhouse Gas Reductions in Industrial Symbiosis. J. Ind. Ecol. 2018, 22, 275–287. [Google Scholar] [CrossRef]

- Park, H.S.; Behera, S.K. Methodological aspects of applying eco-efficiency indicators to industrial symbiosis networks. J. Clean. Prod. 2014, 64, 478–485. [Google Scholar] [CrossRef]

- Behera, S.K.; Kim, J.H.; Lee, S.Y.; Suh, S.; Park, H.S. Evolution of “designed” industrial symbiosis networks in the Ulsan Eco-industrial Park: “Research and development into business” as the enabling framework. J. Clean. Prod. 2012, 29–30, 103–112. [Google Scholar] [CrossRef]

- Stucki, J.; Flammini, A.; van Beers, D.; Phuong, T.T.; Anh, N.T.; Dong, T.D.; Huy, V.Q.; Hieu, V.T.M. Eco-industrial park (EIP) development in Viet Nam: Results and key insights from UNIDO’s EIP project (2014–2019). Sustainability 2019, 11, 4667. [Google Scholar] [CrossRef] [Green Version]

- ElMassah, S. Industrial symbiosis within eco-industrial parks: Sustainable development for Borg El-Arab in Egypt. Bus. Strategy Environ. 2018, 27, 884–892. [Google Scholar] [CrossRef]

- Sakr, D.; Baas, L.; El-Haggar, S.; Huisingh, D. Critical success and limiting factors for eco-industrial parks: Global trends and Egyptian context. J. Clean. Prod. 2011, 19, 1158–1169. [Google Scholar] [CrossRef]

- Mauthoor, S. Uncovering industrial symbiosis potentials in a small island developing state: The case study of Mauritius. J. Clean. Prod. 2017, 147, 506–513. [Google Scholar] [CrossRef]

- Cerceau, J.; Mat, N.; Junqua, G.; Lin, L.; Laforest, V.; Gonzalez, C. Implementing industrial ecology in port cities: International overview of case studies and cross-case analysis. J. Clean. Prod. 2014, 74, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Bonilla-Gámez, N.; Toboso-Chavero, S.; Parada, F.; Civit, B.; Arena, A.P.; Rieradevall, J.; Gabarrell Durany, X. Environmental impact assessment of agro-services symbiosis in semiarid urban frontier territories. Case study of Mendoza (Argentina). Sci. Total Environ. 2021, 774, 145682. [Google Scholar] [CrossRef]

- Liar, F.; Stolte, B.; Bertolucci, L.A.; Gobbo, J.A. Proposal of an assessment tool to diagnose industrial symbiosis readiness. Sustain. Prod. Consum. 2022, 30, 916–929. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Murakami, F.K.; Butturi, M.A.; Marinelli, S.; Kadel, N.; Rimini, B. Barriers, drivers, and relationships in industrial symbiosis of a network of Brazilian manufacturing companies. Sustain. Prod. Consum. 2021, 26, 443–454. [Google Scholar] [CrossRef]

- Oliveira Pavan, M.; Soares Ramos, D.; Yones Soares, M.; Carvalho, M.M. Circular business models for bioelectricity: A value perspective for sugar-energy sector in Brazil. J. Clean. Prod. 2021, 311, 127615. [Google Scholar] [CrossRef]

- Faria, E.; Caldeira-Pires, A. Social, Economic, and Institutional Configurations of the Industrial Symbiosis Process: A Comparative Analysis of the Literature and a Proposed Theoretical and Analytical Framework. Sustainability 2021, 13, 7123. [Google Scholar] [CrossRef]

- de Souza, F.F.; Ferreira, M.B.; Saraceni, A.V.; Betim, L.M.; Pereira, T.L.; Petter, R.R.H.; Pagani, R.N.; de Resende, L.M.M.; Pontes, J.; Piekarski, C.M. Temporal comparative analysis of industrial symbiosis in a business network: Opportunities of circular economy. Sustainability 2020, 12, 1832. [Google Scholar] [CrossRef] [Green Version]

- Cunha, G.; dos Santos, B.T.; Alves, J.R.; Alves Silva, I.A.; de Souza Cruz, D.R.; Romão, L.P.C. Applications of magnetic hybrid adsorbent derived from waste biomass for the removal of metal ions and reduction of 4-nitrophenol. J. Environ. Manag. 2018, 213, 236–246. [Google Scholar] [CrossRef]

- Santos, V.E.N.; Magrini, A. Biorefining and industrial symbiosis: A proposal for regional development in Brazil. J. Clean. Prod. 2018, 177, 19–33. [Google Scholar] [CrossRef]

- Mantese, G.C.; Amaral, D.C. Agent-based simulation to evaluate and categorize industrial symbiosis indicators. J. Clean. Prod. 2018, 186, 450–464. [Google Scholar] [CrossRef]

- Freitas, L.; Magrini, A. Waste management in industrial construction: Investigating contributions from industrial ecology. Sustainability 2017, 9, 1251. [Google Scholar] [CrossRef] [Green Version]

- Elabras Veiga, L.B.; Magrini, A. Eco-industrial park development in Rio de Janeiro, Brazil: A tool for sustainable development. J. Clean. Prod. 2009, 17, 653–661. [Google Scholar] [CrossRef]

- Morales, E.M.; Diemer, A.; Cervantes, G.; Carrillo-González, G. “By-product synergy” changes in the industrial symbiosis dynamics at the Altamira-Tampico industrial corridor: 20 Years of industrial ecology in Mexico. Resour. Conserv. Recycl. 2019, 140, 235–245. [Google Scholar] [CrossRef]

- Zhao, X.; Xue, Y.; Ding, L. Implementation of low carbon industrial symbiosis systems under financial constraint and environmental regulations: An evolutionary game approach. J. Clean. Prod. 2020, 277, 124289. [Google Scholar] [CrossRef]

- Cao, X.; Wen, Z.; Zhao, X.; Wang, Y.; Zhang, H. Quantitative assessment of energy conservation and emission reduction effects of nationwide industrial symbiosis in China. Sci. Total Environ. 2020, 717, 137114. [Google Scholar] [CrossRef]

- He, M.; Jin, Y.; Zeng, H.; Cao, J. Pricing decisions about waste recycling from the perspective of industrial symbiosis in an industrial park: A game model and its application. J. Clean. Prod. 2020, 251, 119417. [Google Scholar] [CrossRef]

- Sun, L.; Fujii, M.; Li, Z.; Dong, H.; Geng, Y.; Liu, Z.; Fujita, T.; Yu, X.; Zhang, Y. Energy-saving and carbon emission reduction effect of urban-industrial symbiosis implementation with feasibility analysis in the city. Technol. Forecast. Soc. Chang. 2020, 151, 119853. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, Z.; Wu, J.; He, Y.; Xu, H. Which factors promote or inhibit enterprises’ participation in industrial symbiosis? An analytical approach and a case study in China. J. Clean. Prod. 2020, 244, 118600. [Google Scholar] [CrossRef]

- Zhang, X.; Chai, L. Structural features and evolutionary mechanisms of industrial symbiosis networks: Comparable analyses of two different cases. J. Clean. Prod. 2019, 213, 528–539. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Song, X. Evolution model with time lag effects for the coal industrial symbiosis system: A case study of Ordos, China. J. Clean. Prod. 2018, 187, 863–876. [Google Scholar] [CrossRef]

- Dong, L.; Liang, H.; Zhang, L.; Liu, Z.; Gao, Z.; Hu, M. Highlighting regional eco-industrial development: Life cycle benefits of an urban industrial symbiosis and implications in China. Ecol. Model. 2017, 361, 164–176. [Google Scholar] [CrossRef]

- Li, B.; Xiang, P.; Hu, M.; Zhang, C.; Dong, L. The vulnerability of industrial symbiosis: A case study of Qijiang Industrial Park, China. J. Clean. Prod. 2017, 157, 267–277. [Google Scholar] [CrossRef]

- Sun, L.; Li, H.; Dong, L.; Fang, K.; Ren, J.; Geng, Y.; Fujii, M.; Zhang, W.; Zhang, N.; Liu, Z. Eco-benefits assessment on urban industrial symbiosis based on material flows analysis and emergy evaluation approach: A case of Liuzhou city, China. Resour. Conserv. Recycl. 2017, 119, 78–88. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Adams, M.; Cote, R.P.; Geng, Y.; Chen, Q.; Liu, W.; Sun, L.; Yu, X. Comprehensive development of industrial symbiosis for the response of greenhouse gases emission mitigation: Challenges and opportunities in China. Energy Policy. 2017, 102, 88–95. [Google Scholar] [CrossRef]

- Guo, B.; Geng, Y.; Sterr, T.; Dong, L.; Liu, Y. Evaluation of promoting industrial symbiosis in a chemical industrial park: A case of Midong. J. Clean. Prod. 2016, 135, 995–1008. [Google Scholar] [CrossRef]

- Dong, L.; Fujita, T.; Dai, M.; Geng, Y.; Ren, J.; Fujii, M.; Wang, Y.; Ohnishi, S. Towards preventative eco-industrial development: An industrial and urban symbiosis case in one typical industrial city in China. J. Clean. Prod. 2016, 114, 387–400. [Google Scholar] [CrossRef]

- Li, H.; Dong, L.; Ren, J. Industrial symbiosis as a countermeasure for resource dependent city: A case study of Guiyang, China. J. Clean. Prod. 2015, 107, 252–266. [Google Scholar] [CrossRef]

- Yu, B.; Li, X.; Shi, L.; Qian, Y. Quantifying CO2 emission reduction from industrial symbiosis in integrated steel mills in China. J. Clean. Prod. 2015, 103, 801–810. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Yang, F. The disposition of chromite ore processing residue (COPR) incorporating industrial symbiosis. J. Clean. Prod. 2015, 95, 156–162. [Google Scholar] [CrossRef]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Liu, C.; Côté, R.P.; Zhang, K. Implementing a three-level approach in industrial symbiosis. J. Clean. Prod. 2015, 87, 318–327. [Google Scholar] [CrossRef]

- Yu, F.; Han, F.; Cui, Z. Evolution of industrial symbiosis in an eco-industrial park in China. J. Clean. Prod. 2015, 87, 339–347. [Google Scholar] [CrossRef]

- Dong, L.; Gu, F.; Fujita, T.; Hayashi, Y.; Gao, J. Uncovering opportunity of low-carbon city promotion with industrial system innovation: Case study on industrial symbiosis projects in China. Energy Policy 2014, 65, 388–397. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, H.; Fujita, T.; Ohnishi, S.; Li, H.; Fujii, M.; Dong, H. Environmental and economic gains of industrial symbiosis for Chinese iron/steel industry: Kawasaki’s experience and practice in Liuzhou and Jinan. J. Clean. Prod. 2013, 59, 226–238. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, L.; Li, H.; Fujita, T.; Ohnishi, S.; Tang, Q. Analysis of low-carbon industrial symbiosis technology for carbon mitigation in a Chinese iron/steel industrial park: A case study with carbon flow analysis. Energy Policy 2013, 61, 1400–1411. [Google Scholar] [CrossRef]

- Dong, L.; Fujita, T.; Zhang, H.; Dai, M.; Fujii, M.; Ohnishi, S.; Geng, Y.; Liu, Z. Promoting low-carbon city through industrial symbiosis: A case in China by applying HPIMO model. Energy Policy 2013, 61, 864–873. [Google Scholar] [CrossRef]

- Chen, P.C.; Liu, K.H. Development of an interactive industrial symbiosis query system with structured industrial waste database in Taiwan. J. Clean. Prod. 2021, 297, 126673. [Google Scholar] [CrossRef]

- Maynard, N.J.; Vaishnav Raj, K.S.; Hua, C.Y.; Lo, S.F. Industrial symbiosis in Taiwan: Case study on Linhai industrial park. Sustainability 2020, 12, 4564. [Google Scholar] [CrossRef]

- Tseng, M.L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.F.; Kuo, T.C. Circular economy meets industry 4.0, Can big data drive industrial symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Kundu, D.; Banerjee, S.; Karmakar, S.; Banerjee, R. Valorization of citrus lemon wastes through biorefinery approach: An industrial symbiosis. Bioresour. Technol. Rep. 2021, 15, 100717. [Google Scholar] [CrossRef]

- Cherian, P.; Palaniappan, S.; Menon, D.; Anumolu, M.P. Comparative study of embodied energy of affordable houses made using GFRG and conventional building technologies in India. Energy Build. 2020, 223, 110138. [Google Scholar] [CrossRef]

- Chertow, M.R.; Gordon, M.; Hirsch, P.; Ramaswami, A. Industrial symbiosis potential and urban infrastructure capacity in Mysuru, India. Environ. Res. Lett. 2019, 14, 75003. [Google Scholar] [CrossRef]

- Yong, W.N.; Liew, P.Y.; Woon, K.S.; Wan Alwi, S.R.; Klemeš, J.J. A pinch-based multi-energy targeting framework for combined chilling heating power microgrid of urban-industrial symbiosis. Renew. Sustain. Energy Rev. 2021, 150, 111482. [Google Scholar] [CrossRef]

- Misrol, M.A.; Wan Alwi, S.R.; Lim, J.S.; Manan, Z.A. An optimal resource recovery of biogas, water regeneration, and reuse network integrating domestic and industrial sources. J. Clean. Prod. 2021, 286, 125372. [Google Scholar] [CrossRef]

- Sharib, S.; Halog, A. Enhancing value chains by applying industrial symbiosis concept to the Rubber City in Kedah, Malaysia. J. Clean. Prod. 2017, 141, 1095–1108. [Google Scholar] [CrossRef]

- Ng, R.T.L.; Ng, D.K.S.; Tan, R.R.; El-Halwagi, M.M. Disjunctive fuzzy optimisation for planning and synthesis of bioenergy-based industrial symbiosis system. J. Environ. Chem. Eng. 2014, 2, 652–664. [Google Scholar] [CrossRef]

- Ng, R.T.L.; Hassim, M.H.; Ng, D.K.S.; Tan, R.R.; El-Halwagi, M.M. Multi-Objective Design of Industrial Symbiosis in Palm Oil Industry. Comput. Aided Chem. Eng. 2014, 34, 579–584. [Google Scholar] [CrossRef]

- Yin, C.Y.; Lee, L.Y. Teaching chemical engineering students industrial symbiosis using online resources: A Singapore case study. Educ. Chem. Eng. 2019, 27, 28–34. [Google Scholar] [CrossRef]

- Kerdlap, P.; Low, J.S.C.; Steidle, R.; Tan, D.Z.L.; Herrmann, C.; Ramakrishna, S. Collaboration platform for enabling industrial symbiosis: Application of the industrial-symbiosis life cycle analysis engine. Procedia CIRP 2019, 80, 655–660. [Google Scholar] [CrossRef]

- Yeo, Z.; Low, J.S.C.; Tan, D.Z.L.; Chung, S.Y.; Tjandra, T.B.; Ignatius, J. A collaboration platform for enabling industrial symbiosis: Towards creating a self-learning waste-to-resource database for recommending industrial symbiosis transactions using text analytics. Procedia CIRP 2019, 80, 643–648. [Google Scholar] [CrossRef]

- Kerdlap, P.; Low, J.S.C.; Ramakrishna, S. Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour. Conserv. Recycl. 2019, 151, 104438. [Google Scholar] [CrossRef]

- Song, B.; Yeo, Z.; Kohls, P.; Herrmann, C. Industrial Symbiosis: Exploring Big-data Approach for Waste Stream Discovery. Procedia CIRP 2017, 61, 353–358. [Google Scholar] [CrossRef]

- Kastner, C.A.; Lau, R.; Kraft, M. Quantitative tools for cultivating symbiosis in industrial parks; a literature review. Appl. Energy 2015, 155, 599–612. [Google Scholar] [CrossRef]

- Bin, S.; Zhiquan, Y.; Jonathan, L.S.C.; Jiewei, D.K.; Kurle, D.; Cerdas, F.; Herrmann, C. A big data analytics approach to develop industrial symbioses in large cities. Procedia CIRP 2015, 29, 450–455. [Google Scholar] [CrossRef]

- Yeşilkaya, M.; Daş, G.S.; Türker, A.K. A multi-objective multi-period mathematical model for an industrial symbiosis network based on the forest products industry. Comput. Ind. Eng. 2020, 150, 106883. [Google Scholar] [CrossRef]

- Alkaya, E.; Böğürcü, M.; Ferda, U. Industrial symbiosis in Iskenderun Bay: A journey from pilot applications to a national Program in Turkey. In Proceedings of the Conference SYMBIOSIS, Athens, Greece, 21 June 2014; pp. 1–8. Available online: http://uest.ntua.gr/conference2014/pdf/alkaya_et_al.pdf (accessed on 3 November 2021).

- Tseng, M.L.; Bui, T.D. Identifying eco-innovation in industrial symbiosis under linguistic preferences: A novel hierarchical approach. J. Clean. Prod. 2017, 140, 1376–1389. [Google Scholar] [CrossRef]

- Aviasti, A.; Nugraha, N.; Amaranti, R.; Nurrahman, A.A. Industrial symbiosis of fragrant lemongrass distillation in West Java. J. Phys. Conf. Ser. 2019, 1375, 12054. [Google Scholar] [CrossRef]

- Ismail, Y. Promoting Industrial Symbiosis at Supply Chain. E3S Web. Conf. 2018, 68, 1003. [Google Scholar] [CrossRef]

- Ulhasanah, N.; Goto, N. Preliminary Design of Eco-City by Using Industrial Symbiosis and Waste Co-Processing Based on MFA, LCA, and MFCA of Cement Industry in Indonesia. Int. J. Environ. Sci. Dev. 2012, 6, 553–561. [Google Scholar] [CrossRef]

- Kim, H.W.; Dong, L.; Choi, A.E.S.; Fujii, M.; Fujita, T.; Park, H.S. Co-benefit potential of industrial and urban symbiosis using waste heat from industrial park in Ulsan, Korea. Resour. Conserv. Recycl. 2018, 135, 225–234. [Google Scholar] [CrossRef]

- Park, H.S.; Rene, E.R.; Choi, S.M.; Chiu, A.S.F. Strategies for sustainable development of industrial park in Ulsan, South Korea-From spontaneous evolution to systematic expansion of industrial symbiosis. J. Environ. Manag. 2008, 87, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Bacudio, L.R.; Benjamin, M.F.D.; Eusebio, R.C.P.; Holaysan, S.A.K.; Promentilla, M.A.B.; Yu, K.D.S.; Aviso, K.B. Analyzing barriers to implementing industrial symbiosis networks using DEMATEL. Sustain. Prod. Consum. 2016, 7, 57–65. [Google Scholar] [CrossRef]

- Aviso, K.B. Design of robust water exchange networks for eco-industrial symbiosis. Process Saf. Environ. Prot. 2014, 9, 160–170. [Google Scholar] [CrossRef]

- Panyathanakun, V.; Tantayanon, S.; Tingsabhat, C.; Charmondusit, K. Development of eco-industrial estates in Thailand: Initiatives in the northern region community-based eco-industrial estate. J. Clean. Prod. 2013, 51, 71–79. [Google Scholar] [CrossRef]

- Gregson, N.; Crang, M.; Ahamed, F.U.; Akter, N.; Ferdous, R.; Foisal, S. Territorial Agglomeration and Industrial Symbiosis: Sitakunda-Bhatiary, Bangladesh, as a Secondary Processing Complex. Econ. Geogr. 2012, 88, 37–58. [Google Scholar] [CrossRef]

- Fan, Y.V.; Varbanov, P.S.; Klemeš, J.J.; Romanenko, S.V. Urban and industrial symbiosis for circular economy: Total EcoSite Integration. J. Environ. Manag. 2021, 279, 111829. [Google Scholar] [CrossRef] [PubMed]

- Chin, H.H.; Varbanov, P.S.; Klemeš, J.J.; Bandyopadhyay, S. Subsidised water symbiosis of eco-industrial parks: A multi-stage game theory approach. Comput. Chem. Eng. 2021, 155, 107539. [Google Scholar] [CrossRef]

- Momirski, L.A.; Mušič, B.; Cotič, B. Urban strategies enabling industrial and urban symbiosis: The case of slovenia. Sustainability 2021, 13, 4616. [Google Scholar] [CrossRef]

- Chatzidimitriou, T.; Gentimis, T.; Michalopoulos, C.; Kokossis, A.C.; Dalamagas, T. Intelligent Management Platform for Material Exchange Optimization and Industrial Symbiosis. In 31 European Symposium on Computer Aided Process Engineering; Türkay, M., Gani, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 50, pp. 761–766. [Google Scholar] [CrossRef]

- Cecelja, F.; Raafat, T.; Trokanas, N.; Innes, S. E-Symbiosis: Technology-enabled support for Industrial Symbiosis targeting Small and Medium Enterprises and innovation. J. Clean. Prod. 2015, 98, 336–352. [Google Scholar] [CrossRef] [Green Version]

- Raafat, T.; Trokanas, N.; Cecelja, F.; Bimi, X. An ontological approach towards enabling processing technologies participation in industrial symbiosis. Comput. Chem. Eng. 2013, 59, 33–46. [Google Scholar] [CrossRef]

- Flegar, M.; Serdar, M.; Londono-Zuluaga, D.; Scrivener, K. Regional waste streams as potential raw materials for immediate implementation in cement production. Materials 2020, 13, 5456. [Google Scholar] [CrossRef]

- Tolstykh, T.; Shmeleva, N.; Gamidullaeva, L. Evaluation of circular and integration potentials of innovation ecosystems for industrial sustainability. Sustainability 2020, 12, 4574. [Google Scholar] [CrossRef]

- Czaplicka-Kotas, A.; Kulczycka, J.; Iwaszczuk, N. Energy clusters as a new urban symbiosis concept for increasing renewable energy production-a case study of Zakopane city. Sustainability 2020, 12, 5634. [Google Scholar] [CrossRef]

- King, S.; Lusher, D.; Hopkins, J.; Simpson, G.W. Industrial symbiosis in Australia: The social relations of making contact in a matchmaking marketplace for SMEs. J. Clean. Prod. 2020, 270, 122146. [Google Scholar] [CrossRef]

- Al-Saidi, M.; Das, P.; Saadaoui, I. Circular Economy in Basic Supply: Framing the Approach for the Water and Food Sectors of the Gulf Cooperation Council Countries. Sustain. Prod. Consum. 2021, 27, 1273–1285. [Google Scholar] [CrossRef]

- Al-Thani, N.A.; Al-Ansari, T. Comparing the convergence and divergence within industrial ecology, circular economy, and the energy-water-food nexus based on resource management objectives. Sustain. Prod. Consum. 2021, 27, 1743–1761. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Ruiz-Puente, C. Bringing Facilitated Industrial Symbiosis and Game Theory Together to Strengthen Waste Exchange in Industrial Parks. Sci. Total Environ. 2021, 771, 145400. [Google Scholar] [CrossRef]

- Kamat, S.; Bandyopadhyay, S. A hybrid approach for heat integration in water conservation networks through non-isothermal mixing. Energy 2021, 233, 121143. [Google Scholar] [CrossRef]

- Mahmood, D.; Javaid, N.; Ahmed, G.; Khan, S.; Monteiro, V. A review on optimization strategies integrating renewable energy sources focusing uncertainty factor—Paving path to eco-friendly smart cities. Sustain. Comput. Inform. Syst. 2021, 30, 100559. [Google Scholar] [CrossRef]

- Yang, M.; Tang, W. Air pollution, political costs, and earnings management. Emerg. Mark. Rev. 2021, 100867. [Google Scholar] [CrossRef]

- Darmandieu, A.; Garcés-Ayerbe, C.; Renucci, A.; Rivera-Torres, P. How does it pay to be circular in production processes? Eco-innovativeness and green jobs as moderators of a cost-efficiency advantage in European small and medium enterprises. Bus. Strategy Environ. 2021, 31, 1184–1203. [Google Scholar] [CrossRef]

- Mauthoor, S.; Mohee, R.; Kowlesser, P.; Musruck, R. An analysis of the wastes emanating from edible oil refineries in Mauritius: A SIDS perspective. Waste Manag. 2015, 40, I–II. [Google Scholar] [CrossRef]

- Yazan, D.M.; Fraccascia, L. Sustainable operations of industrial symbiosis: An enterprise input-output model integrated by agent-based simulation. Int. J. Prod. Res. 2020, 58, 392–414. [Google Scholar] [CrossRef]

- de Paiva Duarte, F. Barriers to Sustainability: An Exploratory Study on Perspectives from Brazilian Organizations. Sustain. Dev. 2015, 23, 425–434. [Google Scholar] [CrossRef]

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for promoting industrial symbiosis: A systematic review. J. Ind. Ecol. 2019, 23, 1087–1108. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Fang, H.; Jacoby, G.; Li, G.; Wu, Z. Environmental regulations and innovation for sustainability? Moderating effect of political connections. Emerg. Mark. Rev. 2021, 50, 100835. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Relva, S.G.; da Silva, V.O.; Gimenes, A.L.V.; Udaeta, M.E.M.; Ashworth, P.; Peyerl, D. Enhancing developing countries’ transition to a low-carbon electricity sector. Energy 2021, 220, 119659. [Google Scholar] [CrossRef]

- Stadelmann, M.; Castro, P. Climate policy innovation in the South—Domestic and international determinants of renewable energy policies in developing and emerging countries. Glob. Environ. Chang. 2014, 29, 413–423. [Google Scholar] [CrossRef] [Green Version]

- Browning, S.; Beymer-Farris, B.; Seay, J.R. Addressing the challenges associated with plastic waste disposal and management in developing countries. Curr. Opin. Chem. Eng. 2021, 32, 100682. [Google Scholar] [CrossRef]

- Wilson, D.C.; Velis, C.A.; Rodic, L. Integrated sustainable waste management in developing countries. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2013, 166, 52–68. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus. Strategy Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

| Country | Market | Activity | No. of Enterprises | Method |

|---|---|---|---|---|

| Africa | ||||

| Egypt | E | Manufacturing | 39 | Literature review, interviews [98] |

| Electricity, gas, steam, and air conditioning supply | Statistical data collected from private and public sources, field visits, inspection reports of the factories [99] | |||

| Mauricio | F | Agriculture, agroindustry, forestry, plastic | 3 | Interviews, industrial waste audit reports, hazardous waste inventory and national issues [100] |

| Morocco | F | Transportation and storage | On-site visits, and individual or collective interviews performed on site [101] | |

| America | ||||

| Argentina | E | Water supply: sewerage, waste management, and remediation activities | Environmental impact assessment, conducted according to the surface multifunctionality and eco-efficiency assessment methods [102] | |

| Brazil | E | Mining and quarrying | 6 | Literature review, exchange resources analysis [103] |

| Mining and quarrying | 8 | Literature review, guided tours by the plants, consultation of internal documents of the companies, open interviews, feedback from the respondents [104] | ||

| Agriculture, forestry, and fishing | 172 | Literature review, archetypal models—recycling, cascading, and repurposing, organic feedstock models [105] | ||

| Professional, scientific, and technical activities | Literature review [106] | |||

| Manufacturing | 8 | Quiz format, survey of opportunities [107] | ||

| Agriculture, forestry, and fishing | 24 | Questionnaire, visits to forestry companies [76] | ||

| Manufacturing | 1 | Semi-structured and non-structured interviews, onsite observations, and longitudinal data related to the business model’s implementation [73] | ||

| Manufacturing | Chemical synthesis, adsorption and desorption assays, statistical analysis [108] | |||

| Manufacturing | 1 | Survey of the material streams and synergy matrix, environmental impact assessment, inventory of the productive units, interviews with coordinators [109] | ||

| Manufacturing | 24 | Simulation of IS indicators through extreme conditions scenarios [72] | ||

| Manufacturing | Simulation of IS indicators through extreme conditions scenarios [71] | |||

| Agriculture, forestry, and fishing | Proposal of the design for IS [110] | |||

| Agriculture, forestry, and fishing | Literature review, questionnaire [78] | |||

| Construction | 2 | Direct observations; indicators of quantitative data analysis and SWOT analysis [111] | ||

| Electricity, gas, steam, and air conditioning supply | Agent-based modeling [79] | |||

| Electricity, gas, steam, and air conditioning supply | 13 | Survey of companies and institutions [81] | ||

| Agriculture, forestry, and fishing | 1 | Short-term potential implementation of rooftop greenhouses in industrial and logistic parks [77] | ||

| Electricity, gas, steam, and air conditioning supply | Systematic literature review [80] | |||

| Electricity, gas, steam, and air conditioning supply | 2 | Analysis of case studies [112] | ||

| Mexico | E | Manufacturing, textile industry | 15 | Open and face-to-face interviews, and on-site visits [113] |

| Colombia | E | Agriculture, forestry, and fishing | 36 | Workshops, surveys, semi-structured interviews [50] |

| Agriculture, forestry, and fishing | 1 | Short-term potential implementation of Rooftop Greenhouses in industrial and logistic parks [77] | ||

| Asia | ||||

| China | E | Mining and quarrying | 1 | Material flow analysis, ecological energy analysis [63] |

| Mining and quarrying | 2 | Multi-objective model [64] | ||

| Manufacturing | Literature review, modeling, simulation [114] | |||

| Electricity, gas, steam, and air conditioning supply | Comprehensive bottom-up technology structure simulation and energy conservation and emission reduction effects evaluation system [115] | |||

| Water supply: sewerage, waste management and remediation activities | An integrated framework to uncover symbiotic performance quantitatively [65] | |||

| Manufacturing | Literature review, modelation [116] | |||

| Water supply: sewerage, waste management and remediation activities | Cost-benefit analysis, feasibility analysis [117] | |||

| Water supply: sewerage, waste management and remediation activities | Data analysis [118] | |||

| Mining and quarrying | 9 | Life cycle assessment [66] | ||

| Mining and quarrying | Analysis of industrial processes [67] | |||

| Mining and quarrying | Centrality and centralization measures, average clustering coefficient, average path length, and power law distribution of degree [119] | |||

| Mining and quarrying | Input-output matrix, fuzzy goals programming, optimization model, simulation [68] | |||

| Mining and quarrying | Mathematical analysis, simulation, and theorem validation [120] | |||

| Water supply: sewerage, waste management and remediation activities | A hybrid model with the integration of process-based life cycle assessment (or material flow analysis), and input-output analysis [121] | |||

| Mining and quarrying | 14 | Participant observation, interviews, questionnaire-based survey, and simulation analysis [122] | ||

| Water supply: sewerage, waste management and remediation activities | Material flow analysis [123] | |||

| Professional, scientific, and technical activities | Analysis of documents, networks, projects, national programs, and national statistical sources [124] | |||

| Mining and quarrying | 19 | Material flow analysis [125] | ||

| Water supply: sewerage, waste management and remediation activities | Literature review, evaluation of direct and indirect environmental impacts [126] | |||

| Water supply: sewerage, waste management and remediation activities | Material flow analysis [127] | |||

| Mining and quarrying | Data analysis, reports of the enterprise, expert interviews, and literature reviews [128] | |||

| Mining and quarrying | 13 | Surveys, material flow analysis [128] | ||

| Mining and quarrying | Literature review, analysis of documents, data analysis [129] | |||

| Mining and quarrying | 5 | Questionnaires and field surveys, flow analysis and resource productivity indicator [130] | ||

| Manufacturing | 20 | Literature review, data analysis [131] | ||

| Manufacturing | 31 | Data analysis, literature review, interview, questionary, material flow analysis [132] | ||

| Mining and quarrying | Analysis of the IS network [133] | |||

| Mining and quarrying | 1 | Material flow analysis [134] | ||

| Mining and quarrying | Carbon flow analysis [135] | |||

| Mining and quarrying | 7 | Material flow analysis, cost analysis [136] | ||

| Taiwan | E | Water supply: sewerage, waste management, and remediation activities | Analysis industrial waste database [137] | |

| Mining and quarrying | Historical background and development analysis [138] | |||

| Water supply: sewerage, waste management, and remediation activities | Big data and internet of things [139] | |||

| Mining and quarrying | 27 | Material flow and energy flow analyses [92] | ||

| Agriculture, forestry, and fishing | Material flow and energy flow analyses [92] | |||

| Mining and quarrying thermoelectric | 482 | Material flow and energy flow analyses [92] | ||

| India | E | Agriculture, forestry, and fishing | Biochemical analysis, statistical analysis [140] | |

| Construction | 1 | Analysis material flow, data analysis [141] | ||

| Manufacturing | 1 | Multi-objective mixed-integer linear programming model and sensitivity analysis [86] | ||

| Water supply: sewerage, waste management, and remediation activities | 1 | Public and private data sources, list of industrial and manufacturing establishments [142] | ||

| Manufacturing | Literature review [87] | |||

| Agriculture, forestry, and fishing | Direct observations, literature review, data analysis [88] | |||

| Mining and quarrying | 12 | Field surveys, structured interviews, material flow analysis, social network analysis, statistical network correlation analyses, and quantitative and qualitative measures [90] | ||

| Mining and quarrying | >14 | Structured interviews with managers and material flow analysis [91] | ||

| Agriculture, forestry, and fishing | 13 | Field data collection, interviews, material flow analysis, and network analysis [89] | ||

| Malaysia | E | Electricity, gas, steam, and air conditioning supply | Pinch-based targeting methodologies [143] | |

| Water supply: sewerage, waste management, and remediation activities | Mathematical model [144] | |||

| Agriculture, forestry, and fishing | 5 | On-site survey, stakeholder analysis [145] | ||

| Agriculture, forestry, and fishing | 4 | Mathematical model [146] | ||

| Agriculture, forestry, and fishing | Multi-objective design [147] | |||

| Singapore | E | Agriculture, forestry, and fishing | Data analysis, literature review [83] | |

| Professional, scientific, and technical activities | Teaching method based on usage of online resources [148] | |||

| Agriculture, forestry, and fishing | Matrix-based model [149] | |||

| Professional, scientific, and technical activities | Text analytics [150] | |||

| Manufacturing | Literature review [151] | |||

| Water supply: sewerage, waste management, and remediation activities | Data analysis [152] | |||

| Agriculture, forestry, and fishing | Simulation subsystem [82] | |||

| Manufacturing | Literature review [153] | |||

| Water supply: sewerage, waste management, and remediation activities | Data analysis [154] | |||

| Turkey | E | Agriculture, forestry, and fishing | 10 | Life cycle assessment method. Multi-objective multi-period mathematical mode [155] |

| Agriculture, forestry, and fishing | 10 | Literature review, establishment of a pilot scale network, creation of database, site visits and discussions with local stakeholders [156] | ||

| Vietnam | F | Electricity, gas, steam, and air conditioning supply | 57 | Survey, company interventions, policy development [97] |

| Electricity, gas, steam, and air conditioning supply | 58 | Survey, company interventions, policy development [97] | ||

| Electricity, gas, steam, and air conditioning supply | 22 | Survey, company interventions, policy development [97] | ||

| Manufacturing | Fuzzy set theory, fuzzy Delphi method, factor analysis and fuzzy importance-performance analysis [157] | |||

| Indonesia | E | Agriculture, forestry, and fishing | Literature review, data analysis, designing models [158] | |

| Wholesale and retail trade: repair of motor vehicles and motorcycles | Theoretical analysis [159] | |||

| Mining and quarrying | 1 | Data analysis [160] | ||

| South Korea | E | Manufacturing | 11 | Theoretical analysis. Three by-product impact allocation methods [161] |

| Manufacturing | 2 | Cost-benefit analysis [94] | ||

| Mining and quarrying | 21 | Theoretical analysis [95] | ||

| Manufacturing | 41 | Theoretical analysis [96] | ||

| Manufacturing | 7 | Describe national policies and the developmental activities [162] | ||

| Philippines | E | Electricity, gas, steam, and air conditioning supply | 1 | On-site survey and questionnaires [163] |

| Electricity, gas, steam, and air conditioning supply | Mathematical model [164] | |||

| Thailand | E | Transportation and storage | On-site visits, and individual or collective interviews performed on site [101] | |

| Manufacturing | 61 | Surveys of the surrounding communities, participative observations [165] | ||

| Bangladesh | F | Wholesale and retail trade: repair of motor vehicles and motorcycles | Interviews [166] | |

| Europe | ||||

| Czech Republic | E | Water supply: sewerage, waste management and remediation activities | A pinch analysis-based method for solid waste integration [167] | |

| Water supply: sewerage, waste management and remediation activities | IS model considering the cost and environmental objectives [168] | |||

| Slovenia | F | Water supply: sewerage, waste management and remediation activities | Analysis of documents, networks, projects, national programs and national statistical sources [169] | |

| Professional, scientific, and technical activities | 7 | Literature review [47] | ||

| Greece | E | Water supply: sewerage, waste management and remediation activities | Knowledge graphs, data analysis [170] | |

| Mining and quarrying | 1 | Ontology engineering, tacit knowledge from experts with explicit knowledge from participants [171] | ||

| Mining and quarrying | 15 | A new ontological framework that supports processing technologies participation in IS [172] | ||

| Croatia | F | Mining and quarrying | 19 | Characterization of raw materials, evaluation of the potential of waste materials [173] |

| Russia | E | Professional, scientific, and technical activities | Literature review, semi-structured interviews [174] | |

| Professional, scientific, and technical activities | Literature review [174] | |||

| Poland | E | Water supply: sewerage, waste management, and remediation activities | Data analysis [175] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boom-Cárcamo, E.; Peñabaena-Niebles, R. Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability 2022, 14, 4223. https://doi.org/10.3390/su14074223

Boom-Cárcamo E, Peñabaena-Niebles R. Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability. 2022; 14(7):4223. https://doi.org/10.3390/su14074223

Chicago/Turabian StyleBoom-Cárcamo, Efrain, and Rita Peñabaena-Niebles. 2022. "Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers" Sustainability 14, no. 7: 4223. https://doi.org/10.3390/su14074223

APA StyleBoom-Cárcamo, E., & Peñabaena-Niebles, R. (2022). Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability, 14(7), 4223. https://doi.org/10.3390/su14074223