An Innovative Risk Matrix Model for Warehousing Productivity Performance

Abstract

1. Introduction

2. Literature Review

2.1. Risk Assessment and Its Applications

2.2. Warehouse Operation Risk Categories

| Author(s) | External Risk | Internal Risk | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PER | MarR | RegR | OR | HR | FR | IR | ResR | SR | MagR | |

| [13] | √ | √ | √ | √ | √ | √ | √ | |||

| [38] | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| [39] | √ | |||||||||

| [40] | √ | √ | ||||||||

| [41] | √ | √ | √ | √ | √ | √ | ||||

| [42] | √ | √ | √ | |||||||

| [43] | √ | |||||||||

| [44] | √ | √ | √ | √ | ||||||

| [45] | √ | √ | √ | |||||||

2.3. Risks Assessment Methods

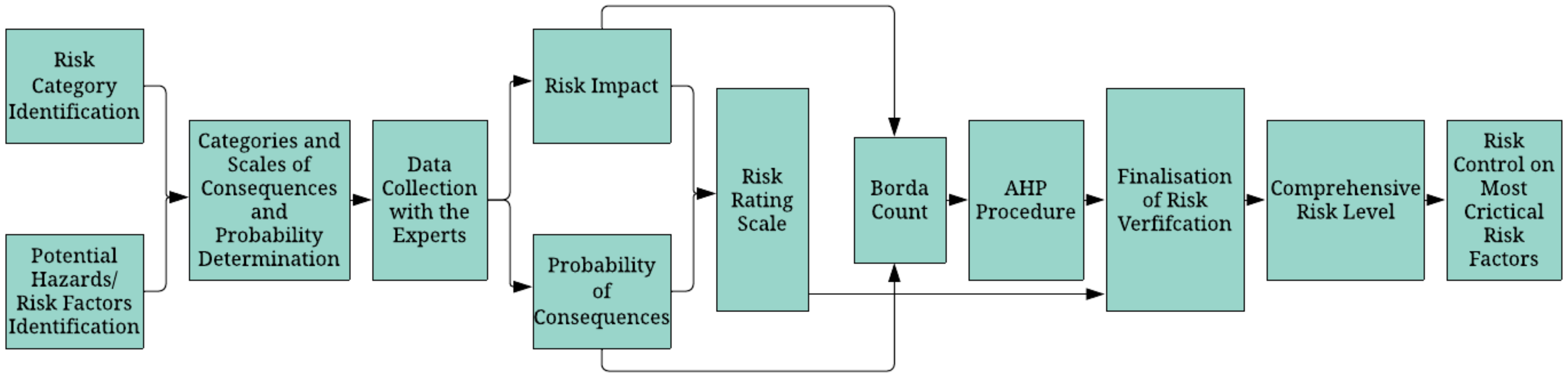

3. Construction of the Innovative Risk Matrix Model for the Warehouse Productivity Performance Risk Assessment

3.1. Risk Matrix Model

- Object to Analyse: Identifies the risk category and risk factor used to evaluate the impact and severity of the risk towards warehouse performance productivity.

- Impact: The occurrence of undesirable consequences falls into five categories and is addressed using a scale ranging from one to five, used in this study. The illustrative definition is to recognise the risk category level related to warehouse operations from a productivity perspective, as shown in Table 2. Level one denotes having no impact or incurring no losses because of an incident on productive performance, whereas level five denotes having the greatest impact, resulting in a performance failure or fatalities (people).

- Probability: Probability or frequency of occurrence is divided into five categories, as shown in Table 3. The range of probability or frequency is presented as a percentage in which an illustrative interpretation is used to evaluate the likelihood of occurrence, of the risk factors, under each risk category.

| Probability Category | Range | Interpretation |

|---|---|---|

| Unlikely (A) | 0–10% | Very Unlikely to Occur |

| Seldom (B) | 11–40% | Unlikely to Occur |

| Occasional (C) | 41–60% | May Occur About Half of the Time |

| Likely (D) | 61–90% | Likely to Occur |

| Frequent (E) | 91–100% | Very Likely to Occur |

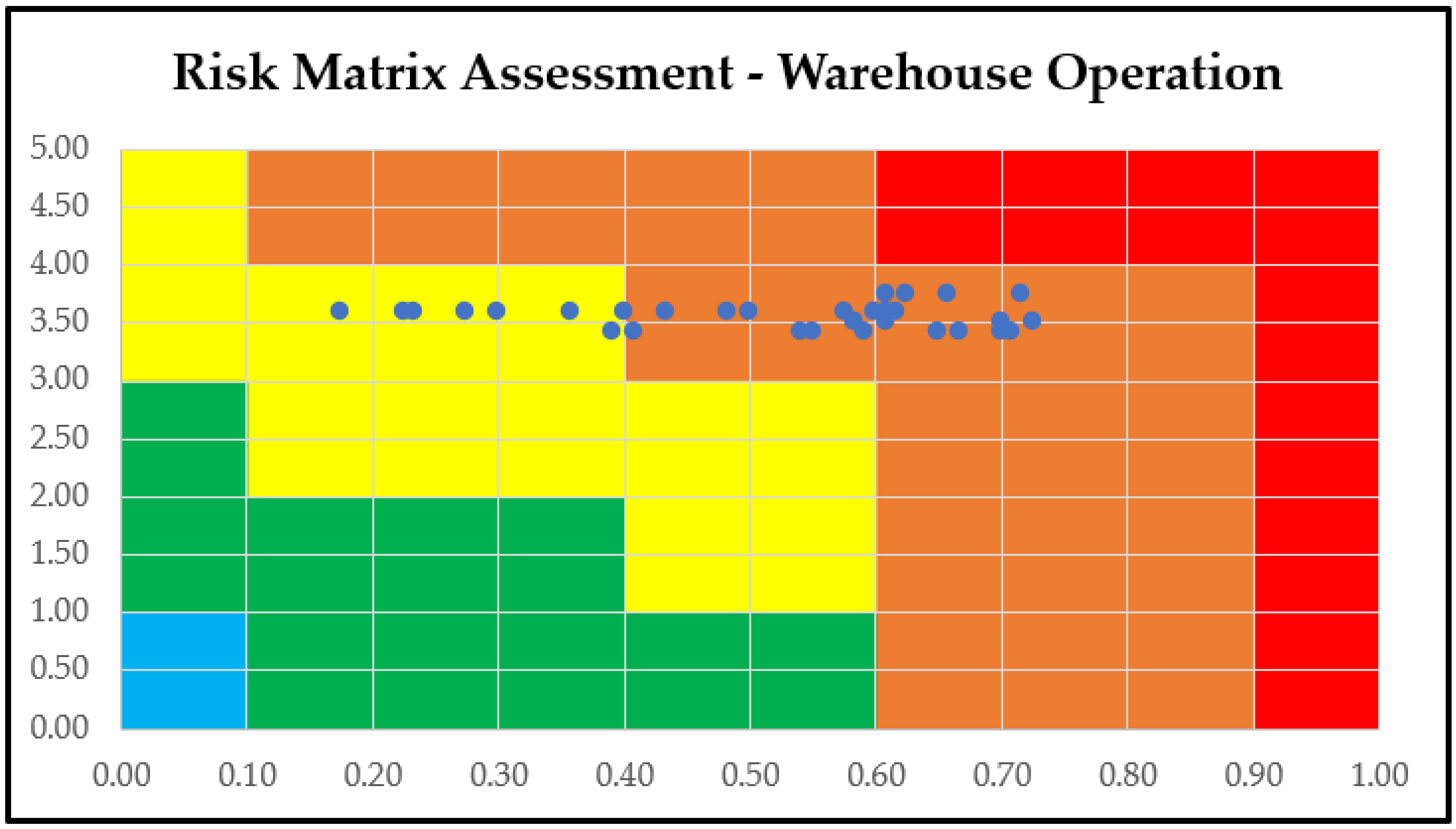

- Risk Rating Scale: Table 4 illustrates 5 × 5 matrix cells with irregularly shaped risk zones. The matrix comprises a square divided into several boxes, with each box representing a different underlying estimation of risk [64]. The main reason for using a risk matrix is to access and prioritise a list of risks at the same level. The use of blue, green, yellow, orange, and red colours reflects the categorisation of the risk into negligible, low, medium, high, and extreme, respectively.

| Critical | Medium | High | High | Extreme | Extreme |

| Serious | Medium | Medium | High | High | Extreme |

| Moderate | Low | Medium | Medium | High | Extreme |

| Minor | Low | Low | Medium | High | Extreme |

| Negligible | Negligible | Low | Medium | High | Extreme |

| Origin | 0.00–0.10 | 0.10–0.04 | 0.04–0.60 | 0.60–0.90 | 0.90–1.00 |

- Analysis and Results: The final step is to verify the most critical risks according to the results obtained from the risk rating scale, Borda rank and AHP ranking.

3.2. Borda Order Value Method

3.3. Analytical Hierarchy Process (AHP)

3.3.1. Building a Judgement Matrix

3.3.2. Calculating the Weight Value and Checking Consistency Ratio

4. Application of the Risk Matrix Model

4.1. Establish the Architecture of Warehouse Operation Risk Set

4.2. Data Collection and Processing

4.3. Risk Matrix Assessment

4.3.1. Borda Count Assessment

4.3.2. AHP Methods Procedures

5. Discussion

6. Conclusions

6.1. Research Implication

6.2. Practical Implication

6.3. Limitation and Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Razik, M.; Radi, B.; Okar, C. An empirical investigation of the factors affecting warehousing performance improvement in a supply chain. In Proceedings of the 2nd International Conference Project and Logistic, Agadir, Morocco, 5–6 May 2016; pp. 1–17. [Google Scholar]

- Richards, G. Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse [e-Book]. 2011. Available online: https://books.google.co.nz (accessed on 25 January 2020).

- EUROSTAT; European Commission. European Business: Facts and Figures. 2009. Available online: https://ec.europa.eu/eurostat/documents/3217494/5706863/KS-BW-09-001-EN.PDF.pdf/b6e57fad-f0f8-42ae-b617-6183c6e8e5f0?t=1414774191000 (accessed on 10 February 2020).

- Wieland, A.; Marcus Wallenburg, C. Dealing with supply chain risks: Linking risk management practices and strategies to performance. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 887–905. [Google Scholar] [CrossRef]

- Jüttner, U.; Peck, H.; Christopher, M. Supply chain risk management: Outlining an agenda for future research. Int. J. Logist. Res. Appl. 2003, 6, 197–210. [Google Scholar] [CrossRef]

- Muha, R.; Škerlič, S.; Erčulj, V. The importance of risk management for the introduction of modern warehouse technologies. Promet-Traffic Transp. 2020, 32, 321–333. [Google Scholar] [CrossRef]

- Lynch, R.L.; Cross, K.F. Measure up!—Yardsticks for Continuous Improvement, 2nd ed.; Blackwell Business: Cambridge, MA, USA, 1995. [Google Scholar]

- Tang, C.S. Perspectives in supply chain risk management. Int. J. Prod. Econ. 2006, 103, 451–488. [Google Scholar] [CrossRef]

- Stefenson, T. Performance Measurement at DHL Solutions. Master’s Thesis, Luleå University of Technology, Lulea, Sweden, 2004. Available online: https://www.diva-portal.org/smash/get/diva2:1027664/FULLTEXT01.pdf (accessed on 10 February 2020).

- Karim, N.H.; Abdul Rahman, N.S.F.; Md Hanafiah, R.; Hamid, S.A.; Ismail, A.; Muda, M.S. Revising the warehouse productivity measurement indicators: Ratio-based benchmark. Marit. Bus. Rev. 2020, 6, 49–71. [Google Scholar] [CrossRef]

- Abdul Rahman, N.S.F.; Karim, N.H.; Md Hanafiah, R.; Abdul Hamid, S.; Mohammed, A. Decision analysis of warehouse productivity performance indicators to enhance logistics operational efficiency. Int. J. Product. Perform. Manag. 2021. [Google Scholar] [CrossRef]

- Stevenson, W.J.; Hojati, M. Operations Management; McGraw-Hill Education: Boston, MA, USA, 2007. [Google Scholar]

- Elbarky, S.; Morssi, M. Warehousing risk management in different industrial. In Proceedings of the 6th International Conference on Information Systems, Logistics and Supply Chain (ILS International Conference), Bordeaux, France, 1–4 June 2016; Available online: http://ils2016conference.com/wp-content/uploads/2015/03/ILS2016_SB04_3.pdf (accessed on 19 January 2020).

- Faizal, K.; Palaniappan, P.L.K. Risk assessment and management in supply chain. Glob. J. Res. Eng. 2014, 14, 19–30. [Google Scholar]

- James, L.W. Risk Assessment Approaches: Testimony before U.S. Congress 1993. Available online: https://www.fema.gov/media-library-data/20130726-1545-20490-4252/mhira_ra.pdf (accessed on 13 February 2020).

- Rout, B.K.; Sikdar, B.K. Hazard identification, risk assessment, and control measures as an effective tool of occupational health assessment of hazardous process in an iron ore pelletizing industry. Indian J. Occup. Environ. Med. 2017, 21, 56. [Google Scholar] [CrossRef] [PubMed]

- White, D. Application of systems thinking to risk management: A review of the literature. Manag. Decis. 1995, 33, 35–45. [Google Scholar] [CrossRef]

- Mohammed, A.; Yazdani, M.; Oukil, A.; Gonzalez, E.D. A hybrid MCDM approach towards resilient sourcing. Sustainability 2021, 13, 2695. [Google Scholar] [CrossRef]

- Mohammed, A.; Harris, I.; Soroka, A.; Naim, M.; Ramjaun, T.; Yazdani, M. Gresilient supplier assessment and order allocation planning. Ann. Oper. Res. 2021, 296, 335–362. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D. Ripple effect and supply chain disruption management: New trends and research directions. Int. J. Prod. Res. 2021, 59, 102–109. [Google Scholar] [CrossRef]

- Ivanov, D.; Das, A. Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: A research note. Int. J. Integr. Supply Manag. 2020, 13, 90–102. [Google Scholar] [CrossRef]

- Heydari, J.; Govindan, K.; Nasab, H.R.E.; Taleizadeh, A.A. Coordination by quantity flexibility contract in a two-echelon supply chain system: Effect of outsourcing decisions. Int. J. Prod. Econ. 2019, 225, 107586. [Google Scholar] [CrossRef]

- Namdar, J.; Li, X.; Sawhney, R.; Pradhan, N. Supply chain resilience for single and multiple sourcing in the presence of disruption risks. Int. J. Prod. Res. 2018, 56, 2339–2360. [Google Scholar] [CrossRef]

- Christopher, M.; Mena, C.; Khan, O.; Yurt, O. Approaches to managing global sourcing risk. Supply Chain Manag. 2011, 16, 67–81. [Google Scholar] [CrossRef]

- Louis, M.; Pagell, M. Categorizing supply chain risks: Review, integrated typology, and future research. In Revisiting Supply Chain Risk; Springer International Publishing: Cham, Switzerland, 2019; pp. 329–366. [Google Scholar]

- DuHadway, S.; Carnovale, S.; Hazen, B. Understanding risk management for intentional supply chain disruptions: Risk detection, risk mitigation, and risk recovery. Ann. Oper. Res. 2019, 283, 179–198. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Henke, M. Revisiting Supply Chain Risk; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Wu, T.; Blackhurst, J.; Chidambaram, V. A model for inbound supply risk analysis. Comput. Ind. 2006, 57, 350–365. [Google Scholar] [CrossRef]

- Rogers, H.; Srivastava, M.; Pawar, K.S.; Shah, J. Supply chain risk management in India—Practical insights. Int. J. Logist. Res. Appl. 2016, 19, 278–299. [Google Scholar] [CrossRef]

- Christopher, M.; Holweg, M. Supply Chain 2.0: Managing supply chains in the era of turbulence. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 63–82. [Google Scholar] [CrossRef]

- Spekman, R.E.; Davis, E.W. Risky business: Expanding the discussion on risk and the extended enterprise. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 414–433. [Google Scholar] [CrossRef]

- Jüttner, U. Supply chain risk management: Understanding the business requirements from a practitioner perspective. Int. J. Logist. Manag. 2005, 16, 120–141. [Google Scholar] [CrossRef]

- Tang, C.; Tomlin, B. The power of flexibility for mitigating supply chain risks. Int. J. Prod. Econ. 2008, 116, 12–27. [Google Scholar] [CrossRef]

- Monroe, R.W.; Teets, J.M.; Martin, P.R. Supply chain risk management: An analysis of sources of risk and mitigation strategies. Int. J. Appl. Manag. Sci. 2014, 6, 4–21. [Google Scholar] [CrossRef]

- Ho, W.; Zheng, T.; Yildiz, H.; Talluri, S. Supply chain risk management: A literature review. Int. J. Prod. Res. 2015, 53, 5031–5069. [Google Scholar] [CrossRef]

- Karim, N.H.; Abdul Rahman, N.S.F.; Shah, S.F.S.S.J. Empirical evidence on failure factors of warehouse productivity in Malaysian logistic service sector. Asian J. Shipp. Logist. 2015, 34, 151–160. [Google Scholar] [CrossRef]

- Ennouri, W. Risks management: New literature review. Pol. J. Manag. Stud. 2013, 8, 288–297. [Google Scholar]

- Lam, H.Y.; Choy, K.L.; Ho, G.T.S.; Cheng, S.W.; Lee, C.K.M. A knowledge-based logistics operation planning system for mitigating risk in warehouse order fulfilment. Int. J. Prod. Econ. 2015, 170, 763–779. [Google Scholar] [CrossRef]

- Cedillo-Campos, M.G.; Cedillo-Campos, H.O. w@reRISK method: Security risk level classification of stock keeping units in a warehouse. Saf. Sci. 2015, 79, 358–368. [Google Scholar] [CrossRef]

- Abdul Rahman, I.; Azis, N.A.; Mahmood, S.; Mohd Rohani, J.; Zaidi, N.A.F.; Mohd Sukri, S.; Mohd Zain, M.A.A. Development of a Survey Instrument for Measuring Workers Satisfaction on Usability of Manual Handling Equipments at the Warehouse: A Pilot Study. In Human-Centered Technology for a Better Tomorrow; Springer: Singapore, 2022; pp. 583–592. [Google Scholar]

- Zheng, C.; Peng, B.; Wei, G. Operational risk modeling for cold chain logistics system: A Bayesian network approach. Kybernetes 2020, 50, 550–567. [Google Scholar] [CrossRef]

- Inam, R.; Raizer, K.; Hata, A.; Souza, R.; Forsman, E.; Cao, E.; Wang, S. Risk assessment for human-robot collaboration in an automated warehouse scenario. In Proceedings of the 2018 IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA), Turin, Italy, 4–7 September 2018; pp. 743–751. [Google Scholar]

- Jahani, H.; Abbasi, B.; Hosseinifard, Z.; Fadaki, M.; Minas, J.P. Disruption risk management in service-level agreements. Int. J. Prod. Res. 2021, 59, 226–244. [Google Scholar] [CrossRef]

- Jawab, F.; Arif, J. Risk matrix model applied to the outsourcing of logistics’ activities. J. Ind. Eng. Manag. 2015, 8, 1179–1194. [Google Scholar] [CrossRef][Green Version]

- Kulińska, E.; Giera, J. Identification and analysis of risk factors in the process of receiving goods into the warehouse. Found. Manag. 2019, 11, 103–118. [Google Scholar] [CrossRef]

- Alhawari, S.; Karadsheh, L.; Talet, A.N.; Mansour, E. Knowledge-based risk management framework for information technology project. Int. J. Inf. Manag. 2012, 32, 50–65. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Wallenius, J.; Dyer, J.S.; Fishburn, P.C.; Steuer, R.E.; Zionts, S.; Deb, K. Multiple criteria decision making, multiattribute utility theory: Recent accomplishments and what lies ahead. Manag. Sci. 2008, 54, 1336–1349. [Google Scholar] [CrossRef]

- Rashidi, K.; Noorizadeh, A.; Kannan, D.; Cullinane, K. Applying the triple bottom line in sustainable supplier selection: A meta-review of the state-of-the-art. J. Clean. Prod. 2020, 269, 122001. [Google Scholar] [CrossRef]

- Ayyildiz, E.; Gumus, A.T. Interval-valued Pythagorean fuzzy AHP method-based supply chain performance evaluation by a new extension of SCOR model: SCOR 4.0. Complex Intell. Syst. 2021, 7, 559–576. [Google Scholar] [CrossRef]

- Mastrocinque, E.; Ramírez, F.J.; Honrubia-Escribano, A.; Pham, D.T. An AHP-based multi-criteria model for sustainable supply chain development in the renewable energy sector. Expert Syst. Appl. 2020, 150, 113321. [Google Scholar] [CrossRef]

- Govindan, K.; Mangla, S.K.; Luthra, S. Prioritising indicators in improving supply chain performance using fuzzy AHP: Insights from the case example of four Indian manufacturing companies. Prod. Plann. Control. 2017, 28, 552–573. [Google Scholar] [CrossRef]

- Chand, P.; Thakkar, J.J.; Ghosh, K.K. Analysis of supply chain complexity drivers for Indian mining equipment manufacturing companies combining SAP-LAP and AHP. Resour. Policy 2018, 59, 389–410. [Google Scholar] [CrossRef]

- Ganguly, K.; Kumar, G. Supply chain risk assessment: A fuzzy AHP approach. Oper. Supply Chain Manag. Int. J. 2019, 12, 1–13. [Google Scholar] [CrossRef]

- Vishnu, C.R.; Sridharan, R.; Kumar, P.R. Supply chain risk inter-relationships and mitigation in Indian scenario: An ISM-AHP integrated approach. Int. J. Logist. Syst. Manag. 2019, 32, 548–578. [Google Scholar] [CrossRef]

- Junaid, M.; Xue, Y.; Syed, M.W.; Li, J.Z.; Ziaullah, M. A neutrosophic AHP and Topsis framework for supply chain risk assessment in automotive industry of Pakistan. Sustainability 2020, 12, 154. [Google Scholar] [CrossRef]

- Fanghua, H.; Guanchun, C. A fuzzy multi-criteria group decision-making model based on weighted Borda scoring method for watershed ecological risk management: A case study of three gorges reservoir area of China. Water Resour. Manag. 2010, 24, 2139–2165. [Google Scholar] [CrossRef]

- Zarghami, M. Soft computing of the Borda count by fuzzy linguistic quantifiers. Appl. Soft Comput. 2011, 11, 1067–1073. [Google Scholar] [CrossRef]

- Jozi, S.A.; Shoshtary, M.T.; Zadeh, A.R.K. Environmental risk assessment of dams in construction phase using a multi-criteria decision-making (MCDM) method. Hum. Ecol. Risk Assess. Int. J. 2015, 21, 1–16. [Google Scholar] [CrossRef]

- Da Rocha, P.M.; de Barros, A.P.; da Silva, G.B.; Costa, H.G. Analysis of the operational performance of Brazilian airport terminals: A multicriteria approach with De Borda-AHP integration. J. Air Transp. Manag. 2016, 51, 19–26. [Google Scholar] [CrossRef]

- Yao, J.; Jiang, Y. Research on the risk assessment of urban power network planning based on improved risk matrix. Int. J. Inf. Electron. Eng. 2014, 4, 129–132. [Google Scholar] [CrossRef][Green Version]

- Garvey, P.R.; Lansdowne, Z.F. Risk matrix: An approach for identifying, assessing, and ranking program risks. Air Force J. Logist. 1998, 22, 18–21. [Google Scholar]

- Engelhardt-Nowitzki, C.; Zsifkovits, H. Complexity-induced supply chain risks–interdependencies between supply chain risk and complexity management. In Managing Risks in Supply Chains: How to Build Reliable Collaboration in Logistics, Operations and Technology Management, 1st ed.; Kersten, W., Bemeleit, B., Kersten-Blecker, Eds.; Erich Schmidt Verlag GmbH & Co.: Berlin, Germany, 2016; pp. 37–56. [Google Scholar]

- Franks, A.; Whitehead, R.; Crossthwaite, P.; Smail, L. Application of QRA in Operational Safety Issues; HSE Books: London, UK, 2002. Available online: https://www.hse.gov.uk/research/rrpdf/rr025.pdf (accessed on 10 January 2020).

- Peace, C. The risk matrix: Uncertain results? J. Policy Pract. Health Saf. 2017, 15, 131–144. [Google Scholar] [CrossRef]

- Emerson, P. The original Borda count and partial voting. Soc. Choice Welf. 2013, 40, 353–358. [Google Scholar] [CrossRef]

- Fu, S.; Zhou, H.; Xiao, Y. The application of a risk matrix method on campus network system risk assessment. In Proceedings of the IEEE 3rd International Conference on Communication Software and Networks, Xi’an, China, 27–29 May 2011; pp. 474–478. [Google Scholar]

- Engert, P.; Lansdowne, Z. Risk Matrix User’s Guide Version 2.2; The MITRE Corporation: Bedford, MA, USA, 1999. [Google Scholar]

- Liu, R. Preliminary analysis of smart grid risk index system and evaluation methods. Energy Power Eng. 2013, 5, 807. [Google Scholar] [CrossRef]

- Alonso, J.A.; Lamata, M.T. Consistency in the analytic hierarchy process: A new approach. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2006, 14, 445–459. [Google Scholar] [CrossRef]

- Ni, H.; Chen, A.; Chen, N. Some extensions on risk matrix approach. Saf. Sci. 2010, 48, 1269–1278. [Google Scholar] [CrossRef]

- Duijm, N.J. Recommendations on the use and design of risk matrices. Saf. Sci. 2015, 76, 21–31. [Google Scholar] [CrossRef]

- Taherdoost, H. Sampling methods in research methodology; how to choose a sampling technique for research. Int. J. Acad. Res. Manag. 2016, 5, 18–27. [Google Scholar] [CrossRef]

- Bruce, J.C.; Langley, G.C.; Tjale, A.A. The use of experts and their judgments in nursing research: An overview. Curationis 2008, 31, 57–61. [Google Scholar] [CrossRef]

- Zhang, K.; Duan, M.; Luo, X.; Hou, G. A fuzzy risk matrix method and its application to the installation operation of subsea collet connector. J. Loss Prev. Process. Ind. 2017, 45, 147–159. [Google Scholar] [CrossRef]

| Impact Category | Scale | Description |

|---|---|---|

| Negligible (N) | 1 | Risk had almost no effect on the warehousing productivity performance. |

| Minor (Mi) | 2 | Risk had slightly affected but could meet the objectives. |

| Moderate (Mo) | 3 | Moderate risk affected the warehousing productivity, but part of the objectives can be achieved. |

| Serious (S) | 4 | Serious risk led to a significant decrease in warehousing productivity. |

| Critical (C) | 5 | Critical risk directly affects the poor performance of warehousing productivity. |

| Saaty’s Scale | Definition |

|---|---|

| 1 | Equally important (E. Imp) |

| 3 | Weakly important (W. Imp) |

| 5 | Fairly important (F. Imp) |

| 7 | Strongly important (S. Imp) |

| 9 | Absolutely important (A. Imp) |

| 2, 4, 6, 8 | The intermittent values between two adjacent scales |

| n | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

| 39.9676 | 42.7375 | 45.5074 | 48.2774 | 51.0473 | 53.8172 | 56.5872 | 59.3571 | |

| RI | 1.5978 | 1.6086 | 1.6181 | 1.6265 | 1.6341 | 1.6409 | 1.6470 | 1.6526 |

| n | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 |

| 62.1270 | 64.8969 | 67.6669 | 70.4368 | 73.2067 | 75.9767 | 78.7466 | 81.5165 | |

| RI | 1.6577 | 1.6624 | 1.6667 | 1.6706 | 1.6743 | 1.6777 | 1.6809 | 1.6839 |

| n | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 |

| 84.2864 | 87.0564 | 89.8263 | 92.5962 | 95.3662 | 98.1361 | 100.9060 | 103.6759 | |

| RI | 1.6867 | 1.6893 | 1.6917 | 1.6940 | 1.6962 | 1.6982 | 1.7002 | 1.7020 |

| Subject | Risk Category | Risk Factor |

|---|---|---|

| Risk Factors for Warehouse Operation | Physical Environment Risk (C1) The physical environment such as natural disasters would affect warehouse operations resulting in the interruption of service, damage to cargo and warehouse facilities | F1: Natural Disaster: Flood, Earthquake, Windstorm |

| F2: Epidemic, Disease | ||

| F3: Fire | ||

| F4: Temperature | ||

| Operational Risk (C2) This results from the breakdown of internal procedures, systems, and people when the factors directly affect the process of internal warehouse operations | F5: Information System Shutdown: Warehouse Management System, RFID | |

| F6: Unexpected order change | ||

| Human Risk (C3) Warehouse labour/staff with insufficient knowledge to carry out the logistics services | F7: Manual Handling Injuries | |

| F8: Lack of skills and knowledge | ||

| F9: Ignorance and negligence | ||

| F10: Wrong estimation or judgement resulting in poor planning of the warehouse operations | ||

| Market Risk (C4) The company may suffer a loss due to the warehouse’s market situation and customer preference | F11: Market Change | |

| F12: Loss of key customers | ||

| Resource Risk (C5) The warehouse may suffer a loss due to the unavailability of resources | F13: Utility Failure | |

| F14: Machinery and equipment breakdown | ||

| F15: Storage space utilisation resulting in limited space in accommodating inbound quantities | ||

| F16: Ageing of facilities, equipment, and machinery | ||

| Managerial Risk (C6) Refers to poor managerial skills of senior management and insufficient conceptual skills to solve the problems and complex situations related to the warehouse | F17: Change in future business development direction | |

| F18: Culture gap | ||

| F19: Miscommunication | ||

| Financial Risk (C7) Refers to the cash flow problem of a warehouse. | F20: Non-filling the warehouse | |

| F21: Delay in customer payment | ||

| F22: Poor financial planning | ||

| Security Risk (C8) Security concerns such as anti-theft facilities and security of the IT system are important to protect the customers’ goods, especially high-value goods and ensure the safety of confidential customer information. | F23: Criminal Activities (e.g., stolen cargoes) | |

| F24: Information security | ||

| Regulatory Risk (C9) An unfavourable change in regulations and policy would bring pressure and risk when the warehouse tries to fit in with the new environment. | F25: War, Civil Disobedience | |

| F26: Import and Export Regulations | ||

| Inventory Risk (C10) Dealing with the security risk classification of Stock Keeping Units (SKU) located in the warehouse. | F27: Damage to the product | |

| F28: Damage to stuff | ||

| F29: Property Damage | ||

| F30: Terrorism | ||

| F31: Material Smuggling | ||

| F32: Human Smuggling |

| Name | Designation/Position | Years of Experience | Warehouse Services (*) |

|---|---|---|---|

| Expert 1 | Warehouse Manager | 10 years | D; C; CD |

| Expert 2 | Warehouse Operation Manager | 20 years | I; D |

| Expert 3 | Warehouse Manager | 10 years | D; CD |

| Expert 4 | Warehouse Assistant Manager | 3 years | D; C; CD |

| Expert 5 | Senior Manager | 10 years | I; D; R; C; E; CD |

| Expert 6 | Warehouse Executive | 23 years | I; D |

| Expert 7 | Director of Business and Development | 19 years | D; E |

| Expert 8 | Branch Manager | 20 years | D |

| Expert 9 | Warehouse Manager | 16 years | D; C |

| Expert 10 | Warehouse Manager | 12 years | D; R; E; CD |

| Expert 11 | Operation Manager | 10 years | D |

| Expert 12 | Head of Warehouse | 15 years | CD; T |

| Severity | Impact | Ms | ks | Probability | Probability Range | Np | kp |

|---|---|---|---|---|---|---|---|

| 4–5 | Critical | 0 | N/A | 5 | 91–100% | 0 | 0 |

| 3–4 | Serious | 0 | N/A | 4 | 61–90% | 13 | 7 |

| 2–3 | Moderate | 32 | 16.5 | 3 | 41–60% | 11 | 19 |

| 1–2 | Minor | 0 | N/A | 2 | 11–40% | 8 | 15.5 |

| 0–1 | Negligible | 0 | N/A | 1 | 0–10% | 0 | N/A |

| Risk Category | Risk Factor | Impact | Probability | Risk Rating Scale | rs | rp | Borda Count Value bi | Borda Rank | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Category | Scale | Category | Scale | |||||||

| C1 | F1 | Moderate | 3.58 | Seldom | 0.23 | Medium | 16.50 | 15.5 | 32 | 13 |

| F2 | Moderate | 3.58 | Seldom | 0.30 | Medium | 16.50 | 15.5 | 32 | 13 | |

| F3 | Moderate | 3.58 | Occasional | 0.43 | High | 16.50 | 19 | 29 | 21 | |

| F4 | Moderate | 3.58 | Seldom | 0.36 | Medium | 16.50 | 15.5 | 32 | 13 | |

| C2 | F5 | Moderate | 3.50 | Likely | 0.61 | High | 16.50 | 7 | 41 | 0 |

| F6 | Moderate | 3.50 | Likely | 0.70 | High | 16.50 | 7 | 41 | 0 | |

| C3 | F7 | Moderate | 3.42 | Occasional | 0.41 | High | 16.50 | 19 | 29 | 21 |

| F8 | Moderate | 3.42 | Occasional | 0.55 | High | 16.50 | 19 | 29 | 21 | |

| F9 | Moderate | 3.42 | Likely | 0.67 | High | 16.50 | 7 | 41 | 0 | |

| F10 | Moderate | 3.42 | Likely | 0.65 | High | 16.50 | 7 | 41 | 0 | |

| C4 | F11 | Moderate | 3.42 | Likely | 0.71 | High | 16.50 | 7 | 41 | 0 |

| F12 | Moderate | 3.42 | Likely | 0.70 | High | 16.50 | 7 | 41 | 0 | |

| C5 | F13 | Moderate | 3.75 | Likely | 0.61 | High | 16.50 | 7 | 41 | 0 |

| F14 | Moderate | 3.75 | Likely | 0.66 | High | 16.50 | 7 | 41 | 0 | |

| F15 | Moderate | 3.75 | Likely | 0.72 | High | 16.50 | 7 | 41 | 0 | |

| F16 | Moderate | 3.75 | Likely | 0.63 | High | 16.50 | 7 | 41 | 0 | |

| C6 | F17 | Moderate | 3.42 | Occasional | 0.54 | High | 16.50 | 19 | 29 | 21 |

| F18 | Moderate | 3.42 | Seldom | 0.39 | Medium | 16.50 | 15.5 | 32 | 13 | |

| F19 | Moderate | 3.42 | Occasional | 0.59 | High | 16.50 | 19 | 29 | 21 | |

| C7 | F20 | Moderate | 3.50 | Occasional | 0.58 | High | 16.50 | 19 | 29 | 21 |

| F21 | Moderate | 3.50 | Likely | 0.73 | High | 16.50 | 7 | 41 | 0 | |

| F22 | Moderate | 3.50 | Occasional | 0.58 | High | 16.50 | 19 | 29 | 21 | |

| C8 | F23 | Moderate | 3.58 | Occasional | 0.58 | High | 16.50 | 19 | 29 | 21 |

| F24 | Moderate | 3.58 | Likely | 0.62 | High | 16.50 | 7 | 41 | 0 | |

| C9 | F25 | Moderate | 3.58 | Seldom | 0.23 | Medium | 16.50 | 15.5 | 32 | 13 |

| F26 | Moderate | 3.58 | Likely | 0.61 | High | 16.50 | 7 | 41 | 0 | |

| C10 | F27 | Moderate | 3.58 | Occasional | 0.60 | High | 16.50 | 19 | 29 | 21 |

| F28 | Moderate | 3.58 | Occasional | 0.50 | High | 16.50 | 19 | 29 | 21 | |

| F29 | Moderate | 3.58 | Occasional | 0.48 | High | 16.50 | 19 | 29 | 21 | |

| F30 | Moderate | 3.58 | Seldom | 0.18 | Medium | 16.50 | 15.5 | 32 | 13 | |

| F31 | Moderate | 3.58 | Seldom | 0.40 | Medium | 16.50 | 15.5 | 32 | 13 | |

| F32 | Moderate | 3.58 | Seldom | 0.28 | Medium | 16.50 | 15.5 | 32 | 13 | |

| Risk Category | Risk Factor | Weight Value | Rank |

|---|---|---|---|

| C1 | F1 | 0.0236 | 2 |

| F2 | 0.0236 | 2 | |

| F3 | 0.0053 | 6 | |

| F4 | 0.0236 | 2 | |

| C2 | F5 | 0.0633 | 1 |

| F6 | 0.0633 | 1 | |

| C3 | F7 | 0.0053 | 6 |

| F8 | 0.0051 | 7 | |

| F9 | 0.0633 | 1 | |

| F10 | 0.0633 | 1 | |

| C4 | F11 | 0.0633 | 1 |

| F12 | 0.0633 | 1 | |

| C5 | F13 | 0.0633 | 1 |

| F14 | 0.0633 | 1 | |

| F15 | 0.0633 | 1 | |

| F16 | 0.0633 | 1 | |

| C6 | F17 | 0.0049 | 8 |

| F18 | 0.0187 | 3 | |

| F19 | 0.0047 | 9 | |

| C7 | F20 | 0.0046 | 10 |

| F21 | 0.0633 | 1 | |

| F22 | 0.0044 | 11 | |

| C8 | F23 | 0.0042 | 12 |

| F24 | 0.0633 | 1 | |

| C9 | F25 | 0.0126 | 4 |

| F26 | 0.0633 | 1 | |

| C10 | F27 | 0.0041 | 13 |

| F28 | 0.0039 | 14 | |

| F29 | 0.0037 | 15 | |

| F30 | 0.0083 | 5 | |

| F31 | 0.0083 | 5 | |

| F32 | 0.0083 | 5 | |

| TOTAL | 1.000 |

| Risk Category | Risk Factor | Risk Matrix | Borda Count | AHP |

|---|---|---|---|---|

| C1 | F1 | |||

| F2 | ||||

| F3 | ✓ | |||

| F4 | ||||

| C2 | F5 | ✓ | ✓ | ✓ |

| F6 | ✓ | ✓ | ✓ | |

| C3 | F7 | ✓ | ||

| F8 | ✓ | |||

| F9 | ✓ | ✓ | ✓ | |

| F10 | ✓ | ✓ | ✓ | |

| C4 | F11 | ✓ | ✓ | ✓ |

| F12 | ✓ | ✓ | ✓ | |

| C5 | F13 | ✓ | ✓ | ✓ |

| F14 | ✓ | ✓ | ✓ | |

| F15 | ✓ | ✓ | ✓ | |

| F16 | ✓ | ✓ | ✓ | |

| C6 | F17 | ✓ | ||

| F18 | ||||

| F19 | ✓ | |||

| C7 | F20 | ✓ | ||

| F21 | ✓ | ✓ | ✓ | |

| F22 | ✓ | |||

| C8 | F23 | ✓ | ||

| F24 | ✓ | ✓ | ✓ | |

| C9 | F25 | |||

| F26 | ✓ | ✓ | ✓ | |

| C10 | F27 | ✓ | ||

| F28 | ✓ | |||

| F29 | ✓ | |||

| F30 | ||||

| F31 | ||||

| F32 |

| Risk Category | Risk Factor | Risk Control (Action Plan) |

|---|---|---|

| C2 | F5 |

|

| F6 |

| |

| C3 | F9 |

|

| F10 |

| |

| C4 | F11 |

|

| F12 |

| |

| C5 | F13 |

|

| F14 |

| |

| F15 |

| |

| F16 |

| |

| C7 | F21 |

|

| C8 | F24 |

|

| C9 | F26 |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Md Hanafiah, R.; Karim, N.H.; Abdul Rahman, N.S.F.; Abdul Hamid, S.; Mohammed, A.M. An Innovative Risk Matrix Model for Warehousing Productivity Performance. Sustainability 2022, 14, 4060. https://doi.org/10.3390/su14074060

Md Hanafiah R, Karim NH, Abdul Rahman NSF, Abdul Hamid S, Mohammed AM. An Innovative Risk Matrix Model for Warehousing Productivity Performance. Sustainability. 2022; 14(7):4060. https://doi.org/10.3390/su14074060

Chicago/Turabian StyleMd Hanafiah, Rudiah, Nur Hazwani Karim, Noorul Shaiful Fitri Abdul Rahman, Saharuddin Abdul Hamid, and Ahmed Maher Mohammed. 2022. "An Innovative Risk Matrix Model for Warehousing Productivity Performance" Sustainability 14, no. 7: 4060. https://doi.org/10.3390/su14074060

APA StyleMd Hanafiah, R., Karim, N. H., Abdul Rahman, N. S. F., Abdul Hamid, S., & Mohammed, A. M. (2022). An Innovative Risk Matrix Model for Warehousing Productivity Performance. Sustainability, 14(7), 4060. https://doi.org/10.3390/su14074060