Comprehensive Diagnosis Method of the Health of Tailings Dams Based on Dynamic Weight and Quantitative Index

Abstract

:1. Introduction

2. Materials and Methods

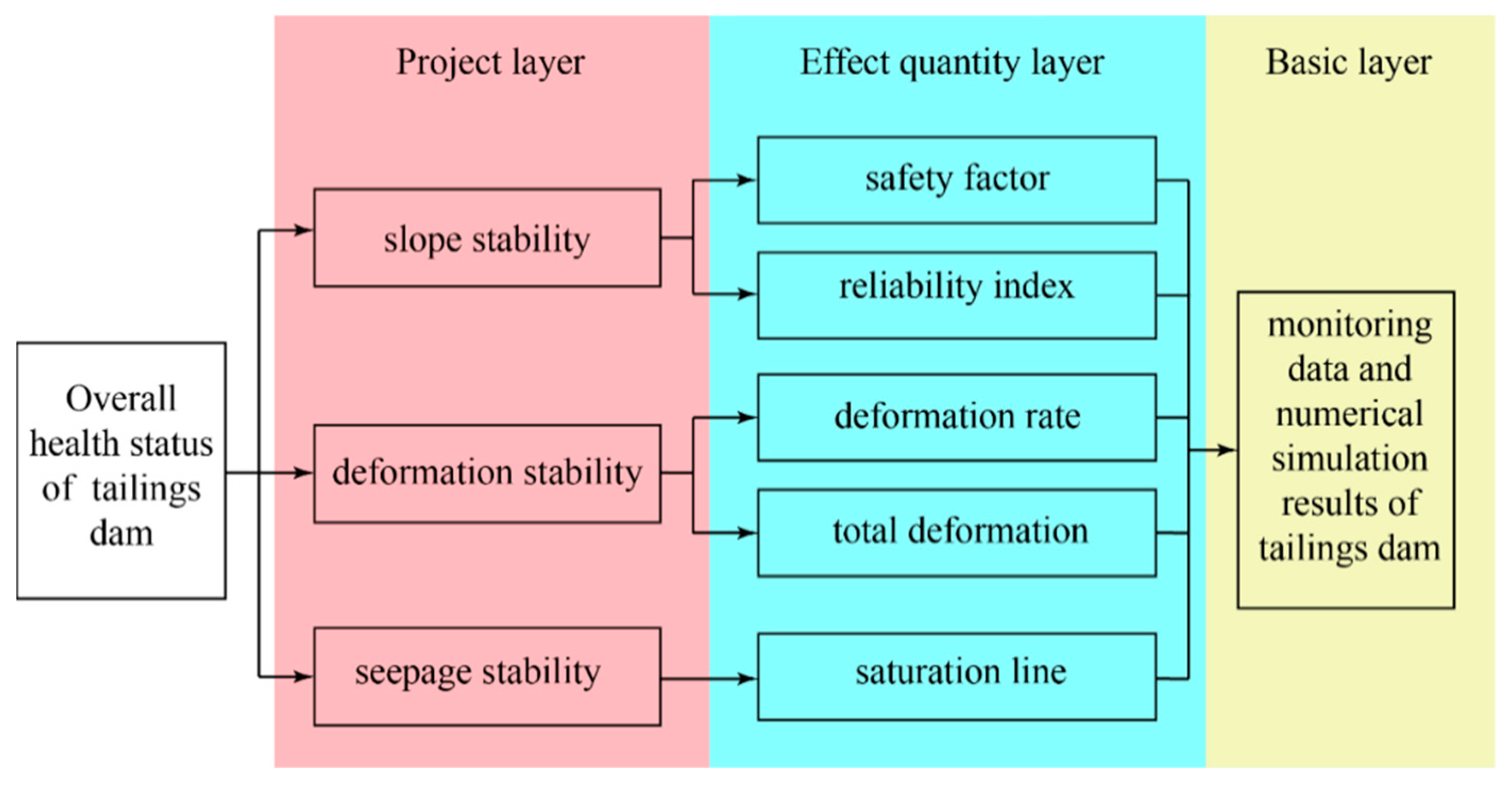

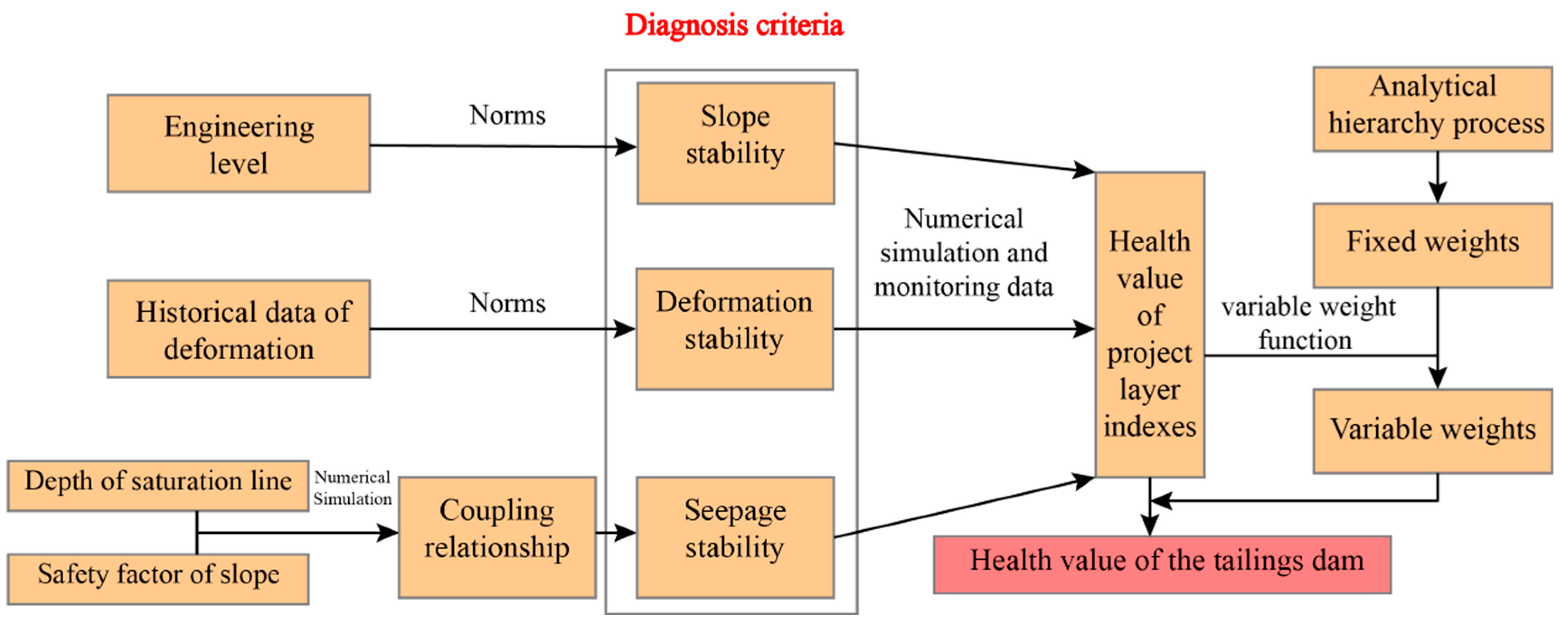

2.1. Construction of Diagnosis Index System for Tailings Dam Health

2.1.1. Diagnosis Index

2.1.2. Classification of Health Levels

2.1.3. Standardization Method of Health Value

2.2. Determination of Dynamic Weight of Diagnosis Indexes

2.2.1. The Analytical Hierarchy Process

- (1)

- Hierarchical structure reflects the relationship between indexes, and the proportion of each index in the same target layer is quantitatively analyzed by the judgment matrix . The judgment matrix is positive and the reciprocal matrix is constructed by comparing the factors in pairs, and is generally represented by the scale of 1–9.

- (2)

- The constructed judgment matrix has a certain degree of inconsistency, so its rationality is checked for consistency. When the consistency index CR < 0.1, the consistency of the judgment matrix is considered acceptable, and the weight coefficients are allocated reasonably.

- (3)

- The maximum eigenvalue and the corresponding eigenvector x are obtained by solving the judgment matrix , and the weights of indexes are obtained by normalizing eigenvector x.

2.2.2. The Penalty Variable Weight Method

2.3. Diagnosis Method of the Index of Effect Quantity Layer

2.3.1. Slope Stability Project

- (1)

- Regarding the deterministic safety factor index, the minimum safety factor stipulated in the code is regarded as u1, which is the threshold value of the healthy and diseased level. u1*u1 is taken as that is the upper limit value. The norm [35] describes that the tailings dams with a minimum safety factor of less than 0.95 times the stipulated value belong to the dangerous reservoir, so this value is taken as u2, which is the threshold value of the diseased and dangerous level, and the safety factor of 1 is taken as , which is the lower limit value.

- (2)

2.3.2. Deformation Stability Project

Deformation Rate

Total Deformation

2.3.3. Seepage Stability Project

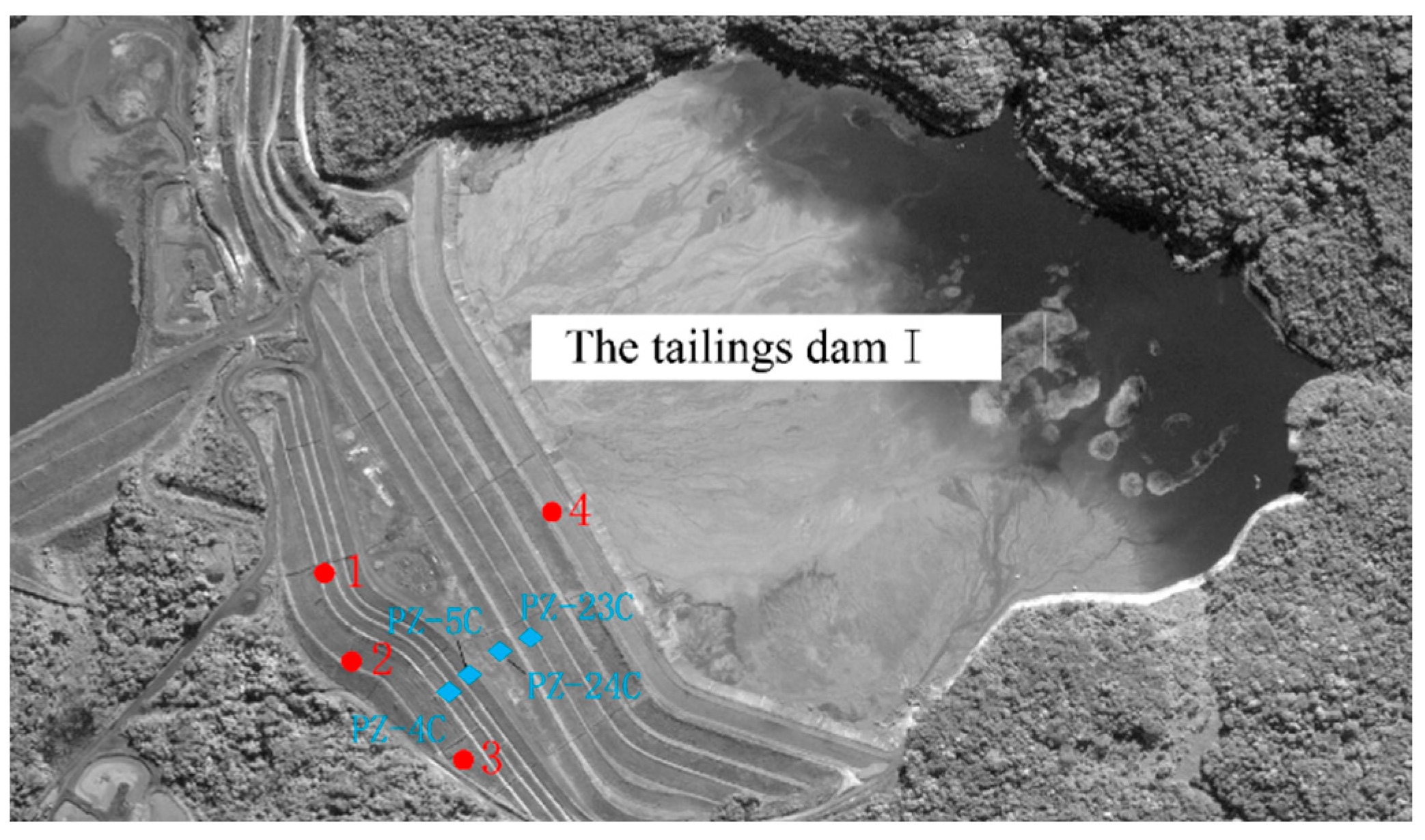

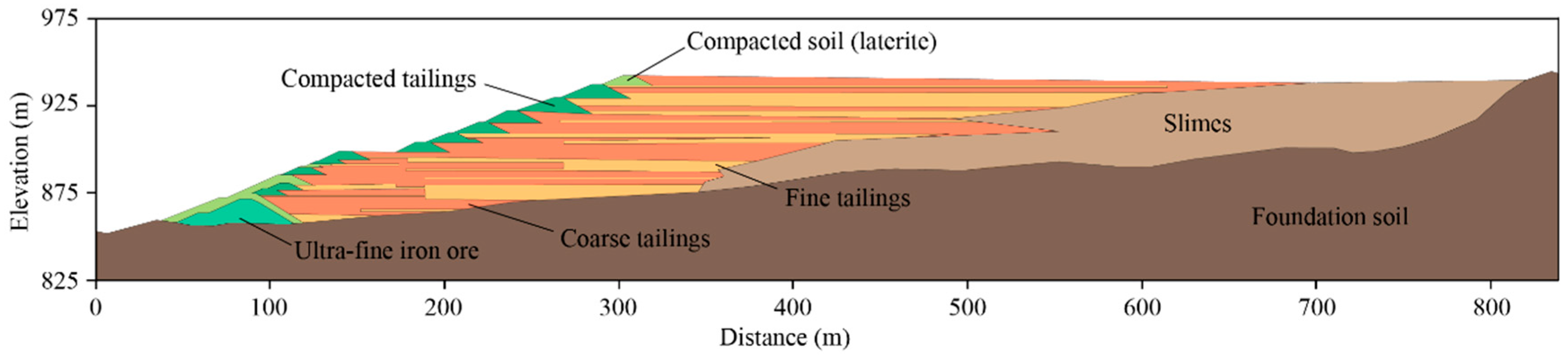

3. Case Study

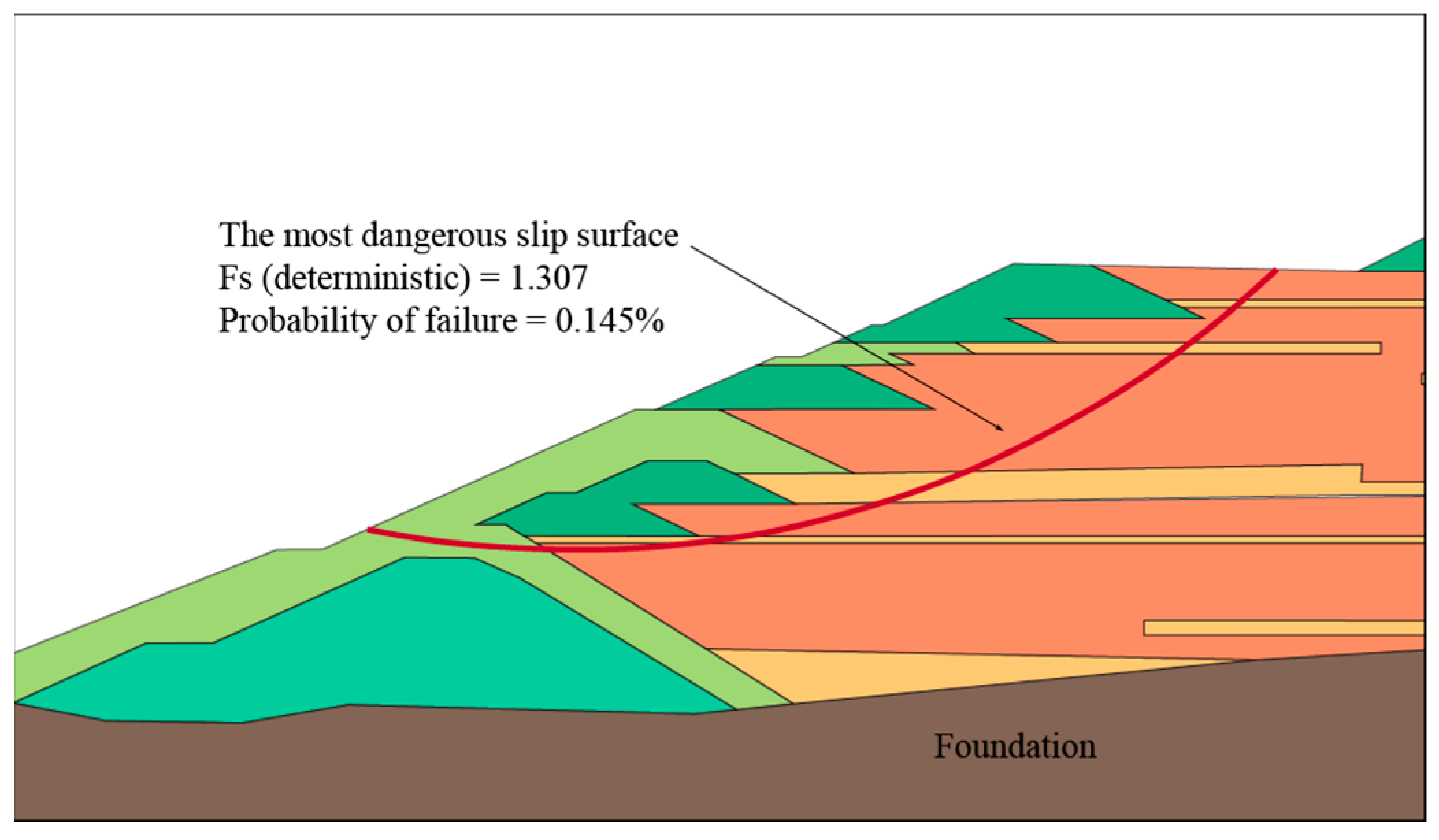

3.1. Diagnosis of the Slope Stability Project

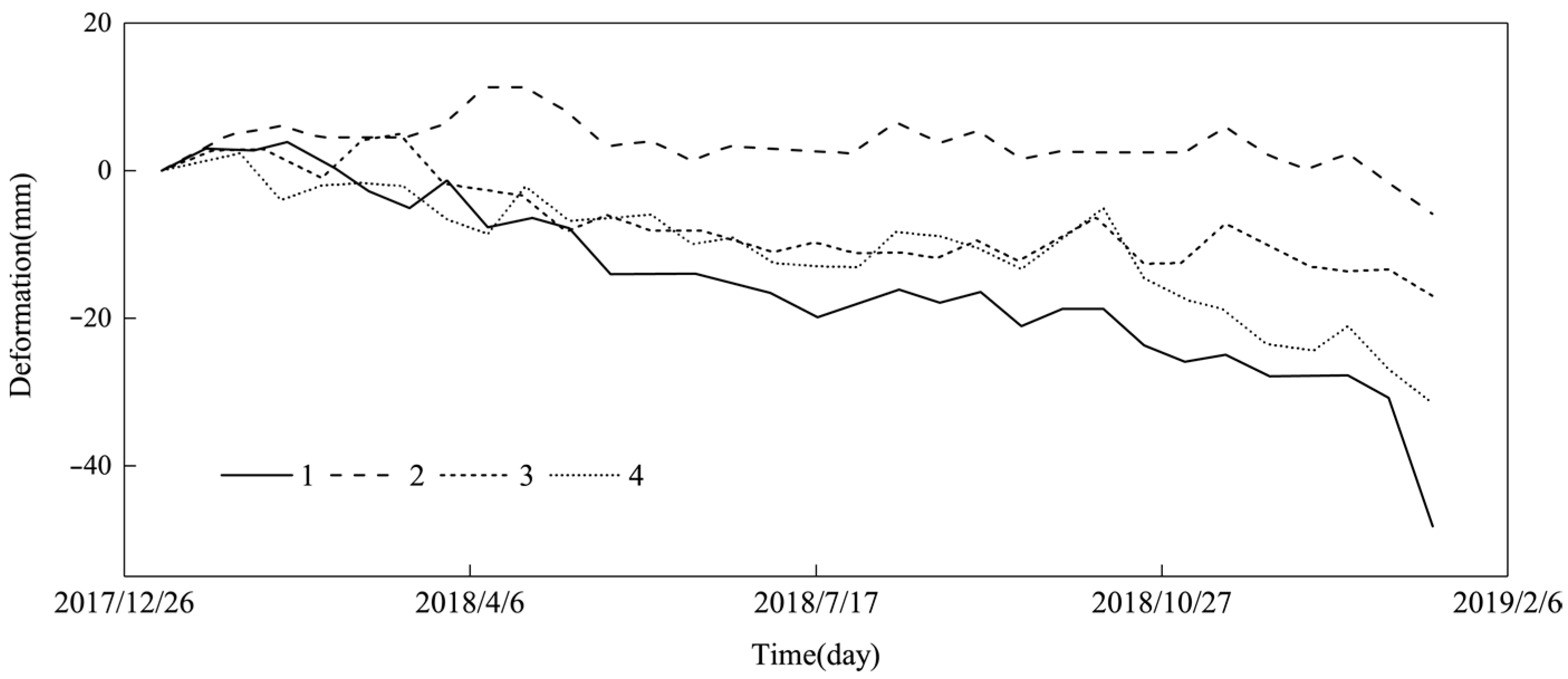

3.2. Diagnosis of the Deformation Stability Project

3.2.1. Deformation Rate Index

3.2.2. Total Deformation Index

3.3. Diagnosis of the Seepage Stability Project

3.4. Comprehensive Health Diagnosis

4. Conclusions

- (1)

- The index system of comprehensive diagnosis of tailings dam health is established, and the dynamic change of index weight is realized based on the analytical hierarchy process and the penalty variable weight method, which increases the importance of the deterioration index in comprehensive diagnosis and makes the diagnosis result more accurate and reasonable.

- (2)

- Based on numerical simulation and the statistical analysis method, the diagnosis method of the indexes of effect quantity layer is put forward, and the quantitative standard of each index is determined. The comprehensive diagnosis method of tailings dam health based on monitoring data is put forward, and the quantitative diagnosis of tailings dam health status is realized.

- (3)

- This method was applied to tailing dam I, and the health value of 0.3109 indicates that the tailings dam is in a dangerous state before the dam failure, which is consistent with the actual situation and verifies the accuracy and applicability of the method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McDermott, R. The Aznalcóllar Tailings Dam Accident—A Case Study. Miner. Resour. Eng. 2000, 9, 101–118. [Google Scholar] [CrossRef]

- Fourie, A.B.; Blight, G.E.; Papageorgiou, G. Static liquefaction as a possible explanation for the Merriespruit tailings dam failure. Can. Geotech. J. 2001, 38, 707–719. [Google Scholar] [CrossRef]

- Guodong, M. Quantitative Assessment Method Study Based on Weakness Theory of Dam Failure Risks in Tailings Dam. Procedia Eng. 2011, 26, 1827–1834. [Google Scholar] [CrossRef] [Green Version]

- Byrne, P.; Hudson-Edwards, K.A.; Bird, G.; Macklin, M.G.; Brewer, P.; Williams, R.D.; Jamieson, H.E. Water quality impacts and river system recovery following the 2014 Mount Polley mine tailings dam spill, British Columbia, Canada. Appl. Geochem. 2018, 91, 64–74. [Google Scholar] [CrossRef]

- Burritt, R.L.; Christ, K. Water risk in mining: Analysis of the Samarco dam failure. J. Clean. Prod. 2018, 178, 196–205. [Google Scholar] [CrossRef]

- Su, H.Z.; Hu, J.; Wu, Z.R. A study of safety evaluation and early-warning method for dam global behavior. Struct. Health Monit. 2012, 11, 269–279. [Google Scholar]

- Xu, Q.; Xu, K. Assessment of air quality using a cloud model method. R. Soc. Open Sci. 2018, 5, 171580. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Jing, H.; Yu, L.; Su, H.; Luo, N. Set pair analysis for risk assessment of water inrush in karst tunnels. Bull. Eng. Geol. Environ. 2016, 76, 1199–1207. [Google Scholar] [CrossRef]

- Zhu, L. Research and application of AHP-fuzzy comprehensive evaluation model. Evol. Intell. 2020, 13, 1–7. [Google Scholar] [CrossRef]

- Do, T.; Laue, J.; Mattsson, H.; Jia, Q. Numerical Analysis of an Upstream Tailings Dam Subjected to Pond Filling Rates. Appl. Sci. 2021, 11, 6044. [Google Scholar] [CrossRef]

- Li, W.; Ye, Y.; Hu, N.; Wang, X.; Wang, Q. Real-Time Warning and Risk Assessment of Tailings Dam Disaster Status Based on Dynamic Hierarchy-Grey Relation Analysis. Complexity 2019, 2019, 5873420. [Google Scholar] [CrossRef]

- Yuan, L.W.; Li, X.M.; Li, S.M.; Chen, Y.M. Study on Risk Assessment Method for Tailings Pond Disaster Based on Improved Index Weight Method. Adv. Mater. Res. 2015, 1092–1093, 753–761. [Google Scholar] [CrossRef]

- Krupskaya, L.; Zvereva, V.P.; Kirienko, O.A.; Imranova, E.L.; Volobueva, N.G. Using an comprehensive method for evaluation of environment state in a zone of influence of a tailing dam. Russ. J. Gen. Chem. 2016, 86, 3012–3014. [Google Scholar] [CrossRef]

- Liu, C.; Shen, Z.; Gan, L.; Xu, L.; Zhang, K.; Jin, T. The Seepage and Stability Performance Assessment of a New Drainage System to Increase the Height of a Tailings Dam. Appl. Sci. 2018, 8, 1840. [Google Scholar] [CrossRef] [Green Version]

- He, L.; Gao, B.; Luo, X.; Jiao, J.; Qin, H.; Zhang, C.; Dong, Y. Health Risk Assessment of Heavy Metals in Surface Water near a Uranium Tailing Pond in Jiangxi Province, South China. Sustainability 2018, 10, 1113. [Google Scholar] [CrossRef] [Green Version]

- Pan, K.; Dong, Y. Risk Assessment of Tailings Pond Based on Triangular Fuzzy Theory. Adv. Mater. Res. 2012, 524–527, 515–519. [Google Scholar] [CrossRef]

- Chu, H.; Xu, G.; Yasufuku, N.; Yu, Z.; Liu, P.; Wang, J. Risk assessment of water inrush in karst tunnels based on two-class fuzzy comprehensive evaluation method. Arab. J. Geosci. 2017, 10, 179. [Google Scholar] [CrossRef]

- Gu, H.; Fu, X.; Zhu, Y.; Chen, Y.; Huang, L. Analysis of Social and Environmental Impact of Earth-Rock Dam Breaks Based on a Fuzzy Comprehensive Evaluation Method. Sustainability 2020, 12, 6239. [Google Scholar] [CrossRef]

- Wang, G.; Tian, S.; Hu, B.; Chen, J.; Kong, X. Regional Hazard Degree Evaluation and Prediction for Disaster Induced by Discharged Tailings Flow from Dam Failure. Geotech. Geol. Eng. 2020, 39, 2051–2063. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, Y.; Lv, Q.; Zhu, Y.; Jiang, C. A safety assessment of the new Xiangyun phosphogypsum tailings pond. Miner. Eng. 2011, 24, 1084–1090. [Google Scholar] [CrossRef]

- Xu, B.; Wang, Y. Stability analysis of the Lingshan gold mine tailings dam under conditions of a raised dam height. Bull. Eng. Geol. Environ. 2014, 74, 151–161. [Google Scholar] [CrossRef]

- Wang, D.; Shen, Z.Z.; Tao, X.H. Three-dimensional finite element analysis and safety assessment for seepage field of a tailings dam. J. Hohai Univ. (Nat.Sci.) 2012, 3, 307–312. (In Chinese) [Google Scholar]

- Li, Q.; Gao, S.; Niu, H.K.; Shang, Y.L. Analytical solution to saturation line of tailings pond and its applicability analysis. Rock Soil Mechannics 2020, 41, 9. (In Chinese) [Google Scholar]

- Dong, L.; Shu, W.; Sun, D.; Li, X.; Zhang, L. Pre-Alarm System Based on Real-Time Monitoring and Numerical Simulation Using Internet of Things and Cloud Computing for Tailings Dam in Mines. IEEE Access 2017, 5, 21080–21089. [Google Scholar] [CrossRef]

- Li, Q.M.; Yuan, H.N.; Zhong, M.H. Safety assessment of waste rock dump built on existing tailings ponds. J. Cent. South Univ. 2015, 22, 2707–2718. [Google Scholar] [CrossRef]

- Dong, L.; Deng, S.; Wang, F. Some developments and new insights for environmental sustainability and disaster control of tailings dam. J. Clean. Prod. 2020, 269, 122270. [Google Scholar] [CrossRef]

- Tan, Q.W.; Xin, B.Q.; Wan, L.; Dong, Y.; Du, S. Risk evaluation indexes and gradation method of major hazard installations for tailings pond. J. Saf. Sci. Technol. 2018, 14, 99–106. (In Chinese) [Google Scholar]

- Jiang, F.; Wu, H.; Liu, Y.; Chen, G.; Guo, J.; Wang, Z. Comprehensive evaluation system for stability of multiple dams in a uranium tailings reservoir: Based on the TOPSIS model and bow tie model. R. Soc. Open Sci. 2020, 7, 191566. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ANCOLD. Guideline on Risk Assessment; Australian National Committee on Large Dams: Sydney, Australia, 2003. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Tailings Facility Design Specification; GB50863–2013; China Planning Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Australia, Western. Guidelines on the Safe Design and Operating Standards for Tailings Storage. Department of Minerals and Energy Western Austrlia. 1999. Available online: https://www.scribd.com/document/235421799/Guidelines-Safe-Design-Operating-Standards-for-Tailings-Storage-Wa (accessed on 1 December 2020).

- Ishizaka, A.; Labib, A. Review of the main developments in the analytic hierarchy process. Expert Syst. Appl. 2011, 38, 14336–14345. [Google Scholar] [CrossRef] [Green Version]

- Jena, R.; Pradhan, B.; Beydoun, G.; Nizamuddin, N.; Ardiansyah; Sofyan, H.; Affan, M. Integrated model for earthquake risk assessment using neural network and analytic hierarchy process: Aceh province, Indonesia. Geosci. Front. 2019, 11, 613–634. [Google Scholar] [CrossRef]

- Li, H.X. Factor space and mathematical frame of knowledge representation (Ⅷ)—Variable weights analysis. Fuzzy Syst. Math. 1995, 3, 1–9. (In Chinese) [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Unified Standard for Reliability Design of Hydraulic Engineering Structures; GB50199–2013; China Planning Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Palmer, J. Anatomy of a Tailings Dam Failure and a Caution for the Future. Engineering 2019, 5, 605–606. [Google Scholar] [CrossRef]

- Robertson, P.K.; Melo, L.; Williams, D.J.; Wilson, G.W. Report of the Expert Panel on the Technical Causes of the Failure of Feijão Dam I. Australia. 2019. Available online: https://www.resolutionmineeis.us/documents/robertson-et-al-2019. (accessed on 1 December 2020).

| Health Level | Healthy | Diseased | Dangerous |

|---|---|---|---|

| Health value | [1.0, 0.67) | [0.67, 0.33) | [0.33, 0] |

| Structural Safety Level | 1 | 2 | 3 | |

|---|---|---|---|---|

| Category of destruction | The first | 3.7 | 3.2 | 2.7 |

| The second | 4.2 | 3.7 | 3.2 | |

| Structural Safety Levels | Tailings Dam | Reliability Index | Dam Break Probability |

|---|---|---|---|

| 1 | 1 | 3.7 | 1.08 × 10−4 |

| 2 | 2,3 | 3.2 | 6.87 × 10−4 |

| 3 | 4,5 | 2.7 | 3.47 × 10−3 |

| Project Layer | Effect Quantity Layer | Healthy | Diseased | Dangerous | |

|---|---|---|---|---|---|

| Dam slope stability | Safety fator | Normal operating conditions | [1.690, 1.300] | (1.300, 1.235] | (1.235, 1.000] |

| Reliability | Reliability index | [4.348, 3.200] | (3.200, 2.464] | (2.464, 1.485] | |

| Probability of failure | [6.87 × 10−6, 6.87 × 10−4] | (6.87 × 10−4, 6.87 × 10−3] | (6.87 × 10−3,6.87 × 10−2] | ||

| Deformationstability | Deformation rate(mm/d) | 1 | [0.244, 0.317) | [0.317, 0.488) | [0.488, 0.732] |

| 2 | [0.203, 0.264) | [0.264, 0.406) | [0.406, 0.609] | ||

| 3 | [0.222, 0.288) | [0.288, 0.443) | [0.443, 0.666] | ||

| 4 | [0.240, 0.312) | [0.312, 0.480) | [0.480, 0.720] | ||

| Total deformation | Deformation safety factor | [2.6, 2) | [2, 1.3) | [1.3, 1] | |

| Seepagestability | Depth of the saturation line | PZ-4C | [13.60, 6.80) | [6.80, 4.40] | [4.40, 2.47] |

| PZ-5C | [22.60, 11.30) | [11.30, 7.50) | [7.50, 2.87] | ||

| PZ-24C | [28.92, 14.46) | [14.46, 9.21) | [9.21, 3.20] | ||

| PZ-23C | [36.50, 18.25) | [18.25, 11.46) | [11.46, 3.53] | ||

| Parameters | γ (KN/m3) | c (kPa) | φ (°) | kh (m/s) | kv/kh |

|---|---|---|---|---|---|

| Coarse tailings | 26.5 | 0 | 33 | 5.00 × 10−6 | 0.2 |

| Fine tailings | 26.0 | 0 | 32 | 1.00 × 10−7 | 0.2 |

| Compacted tailings | 27.5 | 0 | 36 | 5.00 × 10−7 | 0.2 |

| Ultra-fine iron ore | 25 | 0 | 35 | 1.20 × 10−6 | 1 |

| Compacted soil (laterite) | 20 | 12 | 29 | 1.20 × 10−9 | 1 |

| Slimes | 23 | 0 | 25 | 1.00 × 10−7 | 0.2 |

| Foundation soil | 23 | 15 | 30 | 9.30 × 10−7 | 1 |

| Measuring Points | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Deformation rate (mm/d) | 0.82 | 0.33 | 0.28 | 0.42 |

| Health value | 0.000 | 0.5066 | 0.7100 | 0.4479 |

| Measuring Points | PZ-4C | PZ-5C | PZ-24C | PZ-23C |

|---|---|---|---|---|

| Depth of the saturation line (m) | 14.29 | 21.48 | 15.55 | 10.47 |

| Health value | 1.000 | 0.9673 | 0.6949 | 0.2888 |

| Project Layer | Effect Quantity Layer | Basic Layer | |||

|---|---|---|---|---|---|

| Dam slope stability | 0.5568 | Safety fator | 0.6759 | Safety fator of dam slope | 0.6759 |

| Reliability | 0.4376 | Reliability index | 0.4376 | ||

| Deformation stability | 0.2080 | Deformation rate | 0.4161 | 1 | 0.0000 |

| 2 | 0.5066 | ||||

| 3 | 0.7100 | ||||

| 4 | 0.4479 | ||||

| Total deformation | 0.0000 | Deformation safety factor | 0.0000 | ||

| Seepage stability | 0.7378 | Depth of the saturation line | 0.7378 | PZ-4C | 1.0000 |

| PZ-5C | 0.9673 | ||||

| PZ-24C | 0.6949 | ||||

| PZ-23C | 0.2888 | ||||

| Experts | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | Results | |

|---|---|---|---|---|---|---|---|---|---|---|

| project-layer | Slope stability | 0.4934 | 0.5396 | 0.2402 | 0.6250 | 0.3874 | 0.1740 | 0.6337 | 0.4934 | 0.4483 |

| Deformation | 0.3108 | 0.1634 | 0.5499 | 0.1365 | 0.1692 | 0.3715 | 0.1919 | 0.1958 | 0.2612 | |

| Seepage | 0.1958 | 0.2970 | 0.2098 | 0.2385 | 0.4434 | 0.4545 | 0.1744 | 0.3108 | 0.2905 | |

| Consistency index | 0.0517 | 0.0088 | 0.0176 | 0.0157 | 0.0176 | 0.0166 | 0.0089 | 0.0516 | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, K.; Mi, Z.; Yang, D. Comprehensive Diagnosis Method of the Health of Tailings Dams Based on Dynamic Weight and Quantitative Index. Sustainability 2022, 14, 3068. https://doi.org/10.3390/su14053068

Dong K, Mi Z, Yang D. Comprehensive Diagnosis Method of the Health of Tailings Dams Based on Dynamic Weight and Quantitative Index. Sustainability. 2022; 14(5):3068. https://doi.org/10.3390/su14053068

Chicago/Turabian StyleDong, Kai, Zhankuan Mi, and Dewei Yang. 2022. "Comprehensive Diagnosis Method of the Health of Tailings Dams Based on Dynamic Weight and Quantitative Index" Sustainability 14, no. 5: 3068. https://doi.org/10.3390/su14053068

APA StyleDong, K., Mi, Z., & Yang, D. (2022). Comprehensive Diagnosis Method of the Health of Tailings Dams Based on Dynamic Weight and Quantitative Index. Sustainability, 14(5), 3068. https://doi.org/10.3390/su14053068