Techno-Economic Evaluation of Ozone Application to Reduce Sludge Production in Small Urban WWTPs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of Studied WWTP Configurations

- Scenario 1: This scenario is based on a conventional WWTPs that include preliminary treatment (i.e., screening and grit-removal units), followed by an activated sludge unit operated at an SRT of 15 days in order to remove organic matter from wastewater, as well as a tertiary treatment based on chlorination. Generated sludge is dewatered by means of a decanting centrifuge.

- Scenario 2: This scenario is similar to the first one, but a sludge-ozonation unit is implemented to obtain zero sludge production during wastewater treatment. With this alternative, a fraction of the mixed-liquor sludge is continuously transferred to the sludge-ozonation unit for disintegration and is then returned to the biological treatment system for biodegradation.

- Scenario 3: A WWTP is designed with an activated sludge system operated at an SRT of 3 days, combined with a sludge-ozonation unit to produce the same quantity of sludge as in the first scenario.

- Scenario 4: This scenario is similar to the third one, but in this case, the ozonation unit is designed to achieve zero sludge production, so decanting-centrifuge requirements are not considered.

2.2. Mass and Energy Balances

2.3. Methodology for Economic Assessment

- (a)

- Total capital costs include those related to the purchase of main equipment (preliminary treatment, activated sludge system, sludge-ozonation, sludge-dewatering and chlorination units) and for required for piping, instrumentation/electricity, engineering costs and civil work. The ozonation unit involved the incorporation of an ozone generator includes an ozonation tank and two pumps. Equipment capital costs were calculated based on the data and cost functions reported in studies found in the literature [28,29,30]. Costs related to the required equipment for piping, instrumentation/electricity, engineering costs and civil work were estimated as 15%, 25%, 10%, 34%, and 12% of total equipment costs, respectively.

- (b)

- Operating and maintenance costs include energy consumption (due to mixing and pumping, oxygen requirements for biological treatment system, sludge dewatering and ozonation generation), reagents, labor and maintenance. Energy consumption related to the ozonation unit includes the cost of oxygen supply, the energy requirement for the production of ozone and pumping of ozonated sludge. Energy consumption was corrected based on the WWTP size, taking into account results obtained by Trapote et al. (2014) [31]. The price of electricity used was USD 0.095 /kWh [32], and costs associated with sludge disposal were calculated as USD 100 /Ton [33]. The amount of reagents needed for the sludge-dewatering (polyelectrolytes: USD 2/kg) and chlorination processes (sodium hypochlorite: USD 0.52 /kg) was calculated, taking into account a dose of 5 g/kg TSS [22] and 5.1 mg/L, respectively. Maintenance costs were calculated as fixed percentages of the capital cost (1%). The labor cost of operators was assumed to be USD 5.45 /person hour.

3. Results and Discussion

3.1. Effects of Sludge Ozonation on Sludge Production and Energy Consumption

3.2. Economic Impact of Sludge Ozonation on Treatment Costs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Foladori, P.; Andreottola, G.; Ziglio, G. Sludge composition and production in full-plants. In Sludge Reduction Technologies in Wastewater Treatment Plants; IWA Publishing: London, UK, 2010; pp. 7–19. [Google Scholar]

- Campos, J.L.; Figueroa, M.; Vázquez, J.R.; Mosquera-Corral, A.; Roca, E.; Méndez, R. Evaluation of in-situ sludge reduction technologies for wastewater treatment plants. In Sludge: Types, Treatment Processes and Disposal; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2009; pp. 161–186. [Google Scholar]

- Alloul, A.; Ganigué, R.; Spiller, M.; Meerburg, F.; Cagnetta, C.; Rabaey, K.; Vlaeminck, S.E. Capture–ferment-upgrade: A three-step approach for the valorization of sewage organics as commodities. Environ. Sci. Technol. 2018, 52, 6729–6742. [Google Scholar] [CrossRef] [PubMed]

- Amen, T.W.M.; Eljamal, O.; Khalil, A.M.E.; Matsunaga, N. Biochemical methane potential enhancement of domestic sludge digestion by adding pristine iron nanoparticles and iron nanoparticles coated zeolite compositions. J. Environ. Chem. Eng. 2017, 5, 5002–5013. [Google Scholar] [CrossRef]

- Gretzschel, O.; Schmitt, T.G.; Hansen, J.; Siekmann, K.; Jakob, J. Sludge digestion instead of aerobic stabilisation—A cost benefit analysis based on experiences in Germany. Water Sci. Technol. 2014, 69, 430–437. [Google Scholar] [CrossRef] [PubMed]

- INE. Ciudades, Pueblos, Aldeas y Caseríos. 2019. Available online: https://geoarchivos.ine.cl/File/pub/Cd_Pb_Al_Cs_2019.pdf (accessed on 23 November 2021).

- SISS. Superintendencia de Servicios Sanitarios. Informe de Gestión del Sector Sanitario 2019. Available online: https://www.siss.gob.cl/586/articles-17955_recurso_1.pdf (accessed on 14 October 2021).

- Di Iaconi, C.; De Sanctis, M.; Altieri, V.G. Full-scale sludge reduction in the water line of municipal wastewater treatment plant. J. Environ. Manag. 2020, 269, 110714. [Google Scholar] [CrossRef] [PubMed]

- Sid, S.; Volant, A.; Lesage, G.; Heran, M. Cost minimization in a full-scale conventional wastewater treatment plant: Associated costs of biological energy consumption versus sludge production. Water Sci. Technol. 2017, 76, 2473–2481. [Google Scholar] [CrossRef] [Green Version]

- Semblante, G.U.; Hai, F.I.; Ngo, H.H.; Guo, W.; You, S.; Price, W.E.; Nghiem, L.D. Sludge cycling between aerobic, anoxic and anaerobic regimes to reduce sludge production during wastewater treatment: Performance, mechanisms and implications. Bioresour. Technol. 2014, 155, 395–409. [Google Scholar] [CrossRef] [Green Version]

- Van Loosdrecht, M.C.M.; Henze, M. Maintenance, endogeneous respiration, lysis, decay and predation. Water Sci. Technol. 1999, 39, 107–117. [Google Scholar] [CrossRef]

- Guo, J.; Fang, F.; Yan, P.; Chen, Y. Sludge reduction based on microbial metabolism for sustainable wastewater treatment. Bioresour. Technol. 2020, 297, 122506. [Google Scholar] [CrossRef]

- Siatou, A.; Manali, A.; Gikas, P. Energy consumption and internal distribution in activated sludge wastewater treatment plants of Greece. Water 2020, 12, 1204. [Google Scholar] [CrossRef]

- Campbell, K.; Wang, J.; Tucker, R.; Struemph, C. Implementation of long solids retention time activated sludge process for rural residential community. Water Environ. Res. 2020, 93, 174–185. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Miino, M.C.; Torreta, V. What advanced treatments can be used to minimize the production of sewage sludge in WWTPs? Appl. Sci. 2019, 9, 2650. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Wei, W.; Gong, Y.; Yu, Q.; Li, Q.; Sun, J.; Yuan, Z. Technologies for reducing sludge production in wastewater treatment plants: State of the art. Sci. Total Environ. 2017, 587–588, 510–521. [Google Scholar] [CrossRef] [PubMed]

- Chiavola, A.; Salvati, C.; Bongirolami, S.; Di Marcantonio, C.; Boni, M.R. Techno-economic evaluation of ozone-oxidation for sludge reduction at the full-scale. Comparison between the application to the return activated sludge (RAS) and the sludge digestion unit. J. Water Process. Eng. 2021, 42, 102114. [Google Scholar] [CrossRef]

- Hashimoto, K.; Kubota, N.; Okuda, T.; Nakai, S.; Nishijima, W.; Motoshige, H. Reduction of ozone dosage by using ozone in ultrafine bubbles to reduce sludge volume. Chemosphere 2021, 274, 129922. [Google Scholar] [CrossRef] [PubMed]

- Foladori, P.; Andreottola, G.; Ziglio, G. Ozonation. In Sludge Reduction Technologies in Wastewater Treatment Plants; IWA Publishing: London, UK, 2010; pp. 249–294. [Google Scholar]

- Demir, O.; Filibeli, A. Fate of return activated sludge after ozonation: An optimization study for sludge disintegration. Environ. Technol. 2012, 33, 1869–1878. [Google Scholar] [CrossRef] [PubMed]

- Chu, L.; Yan, S.; Xing, X.; Sun, X.; Jurcik, B. Progress and perspectives of sludge ozonation as a powerful pretreatment method for minimization of excess sludge production. Water Res. 2009, 43, 1811–1822. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Stensel, H.D.; Tsuchihashi, R.; Burton, F.L.; Abu-Orf, M.; Bowden, G.; Pfrang, W.; Metcalf & Eddy Inc. Wastewater Engineering: Treatment & Resource Recovery, 5th ed.; McGraw Hill: New York, NY, USA, 2014. [Google Scholar]

- Takács, I. Experiments in Activated Sludge Modelling. Ph.D. Thesis, Ghent University, Gent, Belgium, 2008. [Google Scholar]

- Greenfield, P.F.; Batstone, D.J. Anaerobic digestion: Impact of future greenhouse gases mitigation policies on methane generation and usage. Water Sci. Technol. 2005, 52, 39–47. [Google Scholar] [CrossRef]

- Chiavola, A.; D’Amato, E.; Gori, R.; Lubello, C.; Sirini, P. Techno-economic evaluation of the application of ozone-oxidation in a full-scale aerobic digestion plant. Chemosphere 2013, 91, 656–662. [Google Scholar] [CrossRef]

- Crutchik, D.; Franchi, O.; Caminos, L.; Jeison, D.; Belmonte, M.; Pedrouso, A.; Val del Rio, A.; Mosquera-Corral, A.; Campos, J.L. Polyhydroxyalkanoates (PHAs) production: A feasible economic option for the treatment of sewage sludge in municipal wastewater treatment plants? Water 2020, 12, 1118. [Google Scholar] [CrossRef]

- Manterola, G.; Uriarte, I.; Sancho, L. The effect of operational parameters of the process of sludge ozonation on the solubilization of organic and nitrogenous compounds. Water Res. 2008, 42, 3191–3197. [Google Scholar] [CrossRef]

- Acampa, G.; Giustra, M.G.; Parisi, C. Water Treatment Emergency: Cost Evaluation Tools. Sustainability 2019, 11, 2609. [Google Scholar] [CrossRef] [Green Version]

- Van Starveren, J. Cost Estimating Relationships on Wastewater Treatment Plant Projects: An Analysis to Increase Accuracy on Cost Estimating for Wastewater Treatment Plant Projects; University of Twente: Enschede, The Netherlands, 2019; Available online: http://essay.utwente.nl/80779/1/Staveren-Job-van-%20geanonimiseerd.pdf (accessed on 23 November 2021).

- Sharma, J.R. Development of a Preliminary Cost Estimation Method for Water Treatment Plants. Master’s Thesis, The University of Texas at Arlington, Arlington, TX, USA, 2010. [Google Scholar]

- Trapote, A.; Albaladejo, A.; Simón, P. Energy consumption in an urban wastewater treatment plant: The case of Murcia Region (Spain). Civ. Eng. Environ. Syst. 2014, 31, 304–310. [Google Scholar] [CrossRef] [Green Version]

- ENEL. Tarifas Vigentes. Available online: https://www.enel.cl/es/clientes/informacion-util/tarifas-y-reglamentos/tarifas.html (accessed on 23 September 2021).

- Aguas Nuevas, S.A.; Santiago, Chile. Report of operating management. Private communication, 2021. [Google Scholar]

- Richardson, E.E.; Hanson, A.; Hernández, J. Ozonation of continuous flow activated sludge for reduction of waste solids. Ozone Sci. Eng. 2009, 31, 247–256. [Google Scholar] [CrossRef]

- Boehler, M.; Siegrist, H. Potential of activated sludge disintegration. Water Sci. Technol. 2006, 53, 207–216. [Google Scholar] [CrossRef] [PubMed]

- Gardoni, D.; Ficara, E.; Fornarelli, R.; Parolini, M.; Canziani, R. Long-term effects of the ozonation of the sludge recycling stream on excess sludge reduction and biomass activity at full-scale. Water Sci. Technol. 2011, 63, 2032–2038. [Google Scholar] [CrossRef]

- Yeom, I.T.; Lee, K.R.; Lee, Y.H.; Ahn, K.H.; Lee, S.H. Effects of ozone treatment on the biodegradability of sludge from municipal wastewater treatment plants. Water Sci. Technol. 2002, 46, 421–425. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Yang, J.; Liu, H.; Zhang, J. Sludge ozonation: Disintegration, supernatant changes and mechanisms. Bioresour. Technol. 2009, 100, 1505–1509. [Google Scholar] [CrossRef]

- Yan, S.T.; Chu, L.B.; Xing, X.H.; Yua, A.F.; Sunc, X.L.; Jurcik, B. Analysis of the mechanism of sludge ozonation by a combination of biological and chemical approaches. Water. Res. 2009, 43, 195–203. [Google Scholar] [CrossRef]

- Richardson, E.E.; Hanson, A. Regression modeling of ozonation process in wastewater treatment plants for reduction of waste activated sludge. Ozone Sci. Eng. 2014, 36, 451–464. [Google Scholar] [CrossRef]

- Yasui, H.; Shibata, M. An innovative approach to reducing excess sludge production in the activated sludge process. Water Sci. Technol. 1994, 30, 11–20. [Google Scholar] [CrossRef]

- Yasui, H.; Nakamura, K.; Sakuma, S.; Iwasaki, M.; Sakai, Y. A full-scale operation of a novel activated sludge process without excess sludge production. Water Sci. Technol. 1996, 34, 395–404. [Google Scholar] [CrossRef]

- Fall, C.; Silva-Hernández, B.C.; Hooijmans, C.M.; Lopez-Vazquez, C.M.; Esparza-Soto, M.; Lucero-Chávez, M.; van Loosdrecht, M.C.M. Sludge reduction by ozone: Insights and modeling of the dose response effects. J. Environ. Manag. 2018, 206, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Labelle, M.A.; Ramdani, A.; Deleris, S.; Gadbois, A.; Dold, P.; Comeau, Y. Ozonation of endogenous residue and active biomass from a synthetic activated sludge. Water Sci. Technol. 2011, 63, 297–302. [Google Scholar] [CrossRef]

- Hashimoto, K.; Nakai, S.; Motoshige, H.; Nishijima, W. Sludge reduction in a full-scale wastewater treatment plant using ultrafine- and micro-bubble. Ozone Sci. Eng. 2021, 43, 127–135. [Google Scholar] [CrossRef]

- Sun, X.; Liu, B.; Zhang, L.; Aketagawa, K.; Xue, B.; Ren, Y.; Bai, J.; Zhan, Y.; Chen, S.; Dong, B. Partial ozonation of returned sludge via high-concentration ozone to reduce excess sludge production: A pilot study. Sci. Total Environ. 2022, 807, 150773. [Google Scholar] [CrossRef]

- Gardoni, D.; Ficara, E.; Vergine, P.; Canziani, R. A full-scale plug-flow reactor for biological sludge ozonation. Water Sci. Technol. 2015, 71, 560–565. [Google Scholar] [CrossRef]

- Zhou, H.; Smith, D.W. Ozone mass transfer in water and wastewater treatment: Experimental observations using a 2D laser particle dynamics analyzer. Water Res. 2000, 34, 909–921. [Google Scholar] [CrossRef]

- Torregrossa, M.; Di Bella, G.; Di Trapani, D. Comparison between ozonation and the OSA process: Analysis of excess sludge reduction and biomass activity in two different pilot plants. Water Sci. Technol. 2012, 66, 185–192. [Google Scholar] [CrossRef]

- Meng, X.; Liu, D.; Yang, K.; Song, X.; Zhang, G.; Yu, J.; Zhang, J.; Tang, Y.; Li, K. A full scale anaerobic-anoxic-aerobic process coupled with low-dose ozonation for performance improvement. Bioresour. Technol. 2013, 146, 240–246. [Google Scholar] [CrossRef]

- Sui, P.; Nishimura, F.; Tsuno, H. Nitrogen behavior during sludge ozonation: A long-term observation by pilot experiments. Water Sci. Technol. 2014, 70, 289–296. [Google Scholar] [CrossRef] [Green Version]

- Isazadeh, S.; Urbina Rivas, L.E.; Ozdural Ozcer, P.; Frigon, D. Reduction of waste biosolids by RAS-ozonation: Model validation and sensitivity analysis for biosolids reduction and nitrification. Environ. Model. Softw. 2015, 65, 41–49. [Google Scholar] [CrossRef]

- Carballa, M.; Duran, C.; Hospido, A. Should We Pretreat Solid Waste Prior to Anaerobic Digestion? An Assessment of Its Environmental Cost. Environ. Sci. Technol. 2011, 45, 10306–10314. [Google Scholar] [CrossRef] [PubMed]

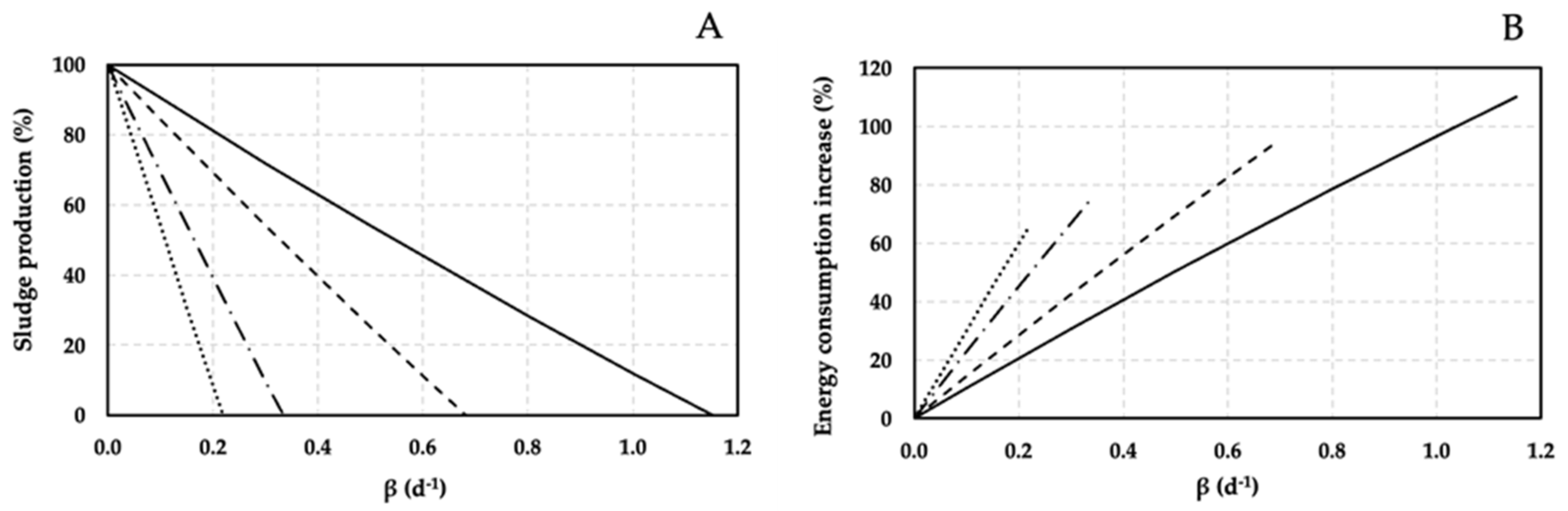

3 d;

3 d;  5 d;

5 d;  10 d;

10 d;  15 d). An ozone dose of 0.03 kg O3/kg TSS, resulting in a sludge solubilization of 25% was used for calculations [26].

15 d). An ozone dose of 0.03 kg O3/kg TSS, resulting in a sludge solubilization of 25% was used for calculations [26].

3 d;

3 d;  5 d;

5 d;  10 d;

10 d;  15 d). An ozone dose of 0.03 kg O3/kg TSS, resulting in a sludge solubilization of 25% was used for calculations [26].

15 d). An ozone dose of 0.03 kg O3/kg TSS, resulting in a sludge solubilization of 25% was used for calculations [26].

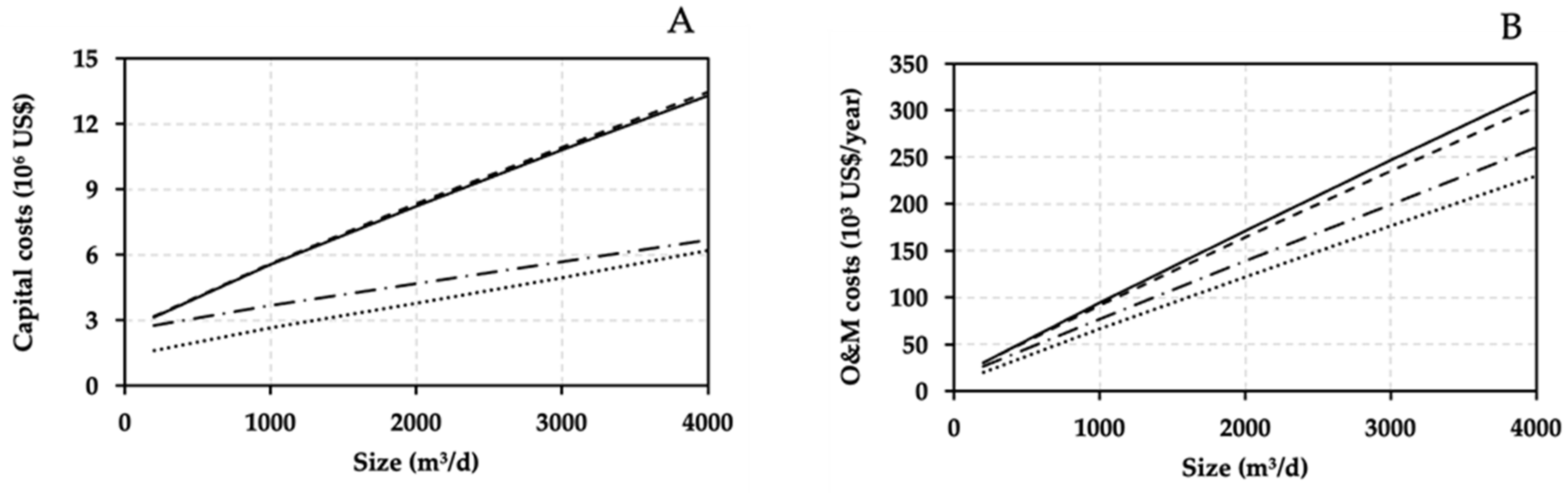

Scenario 1;

Scenario 1;  Scenario 2;

Scenario 2;  Scenario 3;

Scenario 3;  Scenario 4).

Scenario 4).

Scenario 1;

Scenario 1;  Scenario 2;

Scenario 2;  Scenario 3;

Scenario 3;  Scenario 4).

Scenario 4).

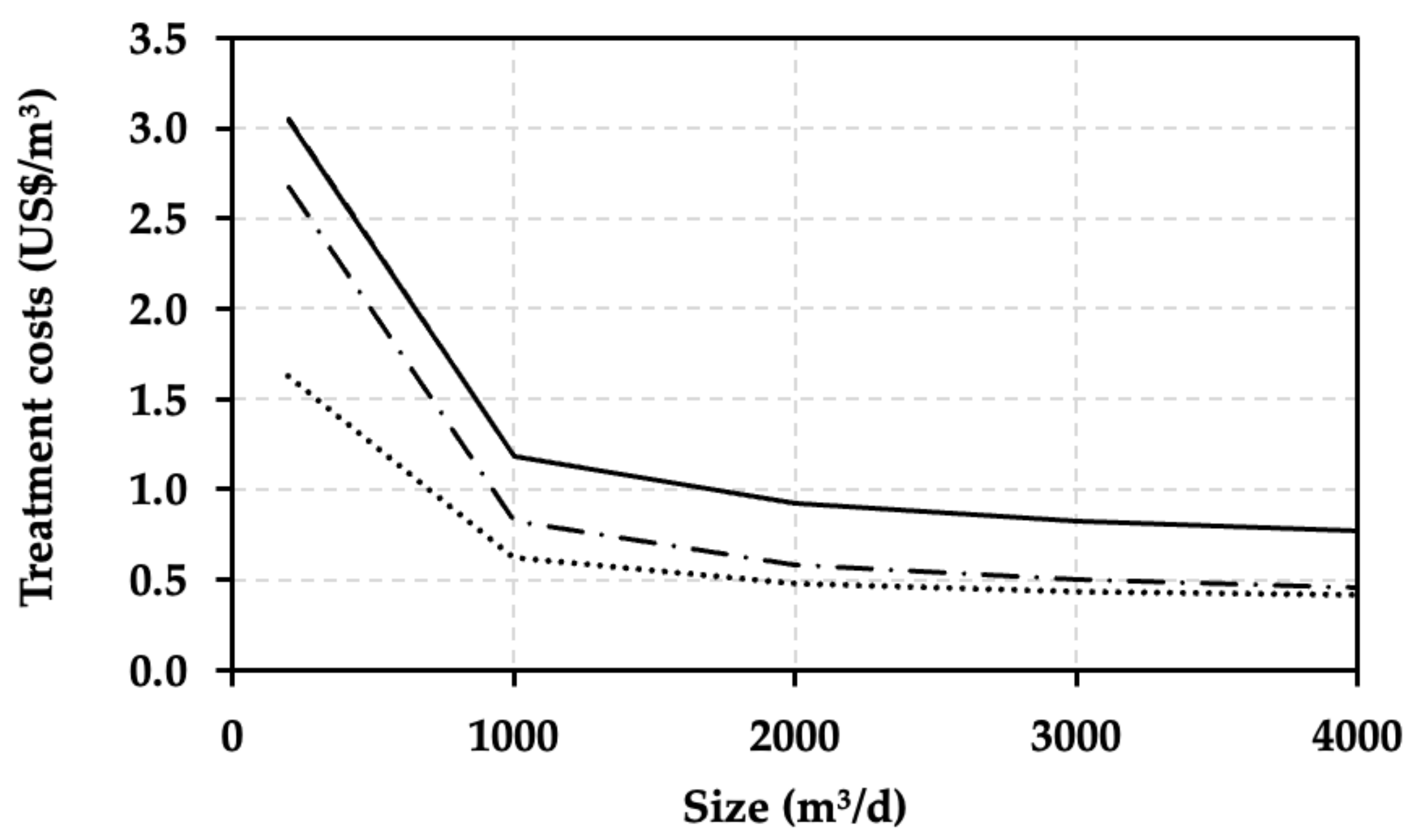

Scenario 1;

Scenario 1;  Scenario 2;

Scenario 2;  Scenario 3;

Scenario 3;  Scenario 4).

Scenario 4).

Scenario 1;

Scenario 1;  Scenario 2;

Scenario 2;  Scenario 3;

Scenario 3;  Scenario 4).

Scenario 4).

| Unit Operation | Values |

|---|---|

| Mass balances | |

| Activated sludge process | Hydraulic retention time (HRT): 0.25 d |

| Biomass concentration in aeration tank: 4 kg VSS/m3 Biomass yield (Yx/s): 0.43 kg VSS/kg CODconsumed [22] Decay coefficient (kd): 0.24 d−1 [22] Volatile suspended solids concentration in the effluent (VSSeffluent): 0.02 kg VSS/m3 Non-biodegradable fraction of heterotrophic biomass (XP/XH): 0.15 [22] | |

| 1.42 kg COD/kg VSS for XP and XH [22] | |

| 1.55 kg COD/kg VSS for XI COD fraction [23] | |

| Oxygen requirement for ammonium oxidation: 4.57 kg O2/kg N [22] | |

| Ozonation unit | XH, XI and XP were solubilized into SS |

| Sludge dewatering | 25% dry matter TSS/VSS ratio: 0.75 kg/kg |

| Energy balances | |

| Wastewater influent pumping | 0.0385 kWh/m3influent [22] |

| Screens | 0.0004 kWh/m3influent [22] |

| Grit removal | 0.008 kWh/m3influent [22] |

| Aeration | 1 kWh/kg O2 [22] |

| Chlorination | 0.00055 kWh/m3influent [22] |

| Sludge pumping | 0.01 kWh/m3influent [22] |

| Centrifuge | 0.3 kWh/kg TSS [24] |

| Ozone generation | 15 kWh/kg O3 [25] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crutchik, D.; Franchi, O.; Jeison, D.; Vidal, G.; Pinto, A.; Pedrouso, A.; Campos, J.L. Techno-Economic Evaluation of Ozone Application to Reduce Sludge Production in Small Urban WWTPs. Sustainability 2022, 14, 2480. https://doi.org/10.3390/su14052480

Crutchik D, Franchi O, Jeison D, Vidal G, Pinto A, Pedrouso A, Campos JL. Techno-Economic Evaluation of Ozone Application to Reduce Sludge Production in Small Urban WWTPs. Sustainability. 2022; 14(5):2480. https://doi.org/10.3390/su14052480

Chicago/Turabian StyleCrutchik, Dafne, Oscar Franchi, David Jeison, Gladys Vidal, Alicia Pinto, Alba Pedrouso, and José Luis Campos. 2022. "Techno-Economic Evaluation of Ozone Application to Reduce Sludge Production in Small Urban WWTPs" Sustainability 14, no. 5: 2480. https://doi.org/10.3390/su14052480

APA StyleCrutchik, D., Franchi, O., Jeison, D., Vidal, G., Pinto, A., Pedrouso, A., & Campos, J. L. (2022). Techno-Economic Evaluation of Ozone Application to Reduce Sludge Production in Small Urban WWTPs. Sustainability, 14(5), 2480. https://doi.org/10.3390/su14052480