Explorative Multiple-Case Research on the Scrap-Based Steel Slag Value Chain: Opportunities for Circular Economy

Abstract

:1. Introduction

2. Literature Overview

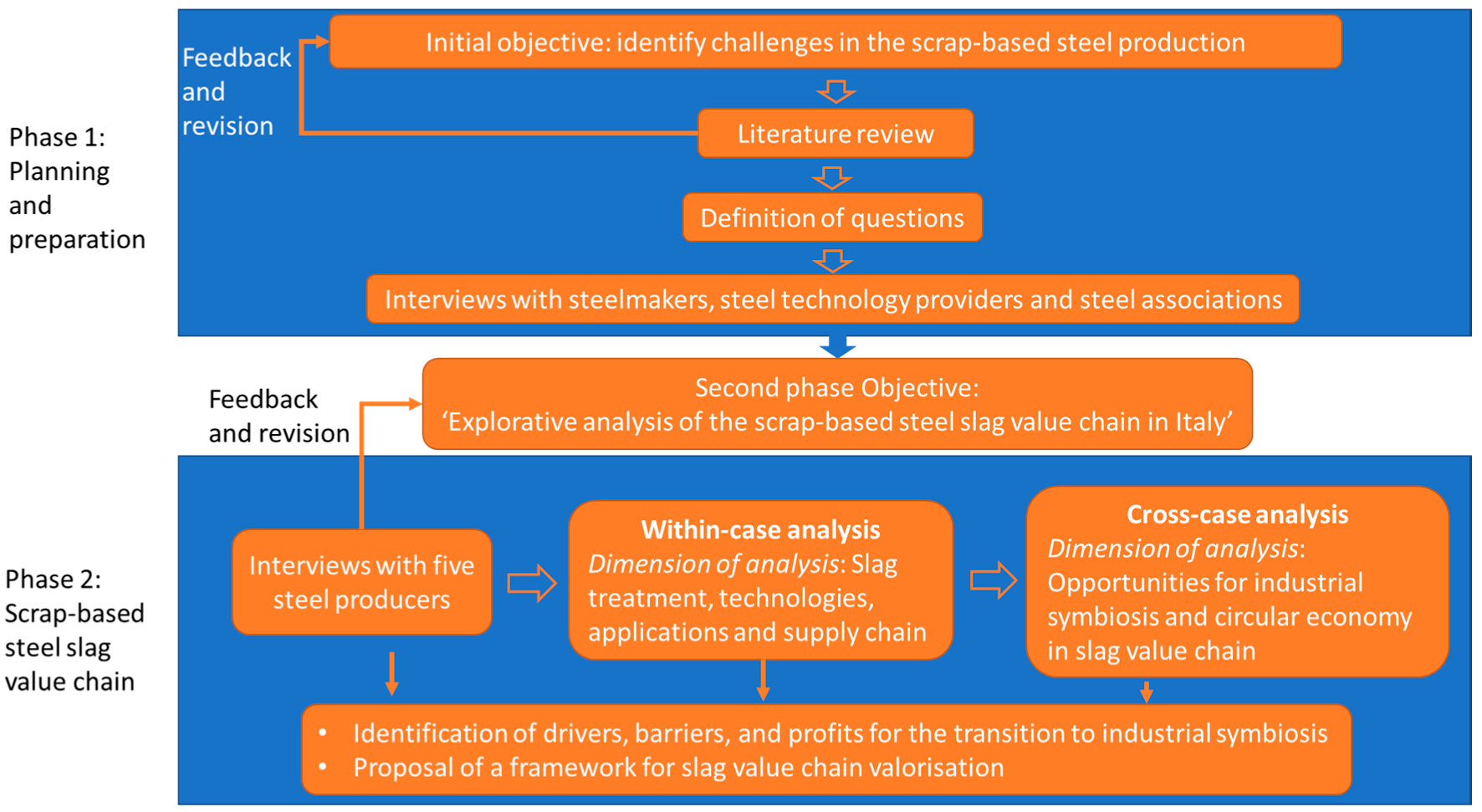

3. Materials and Methods

3.1. Research Design

3.2. Industrial Context

3.3. Description of the Cases

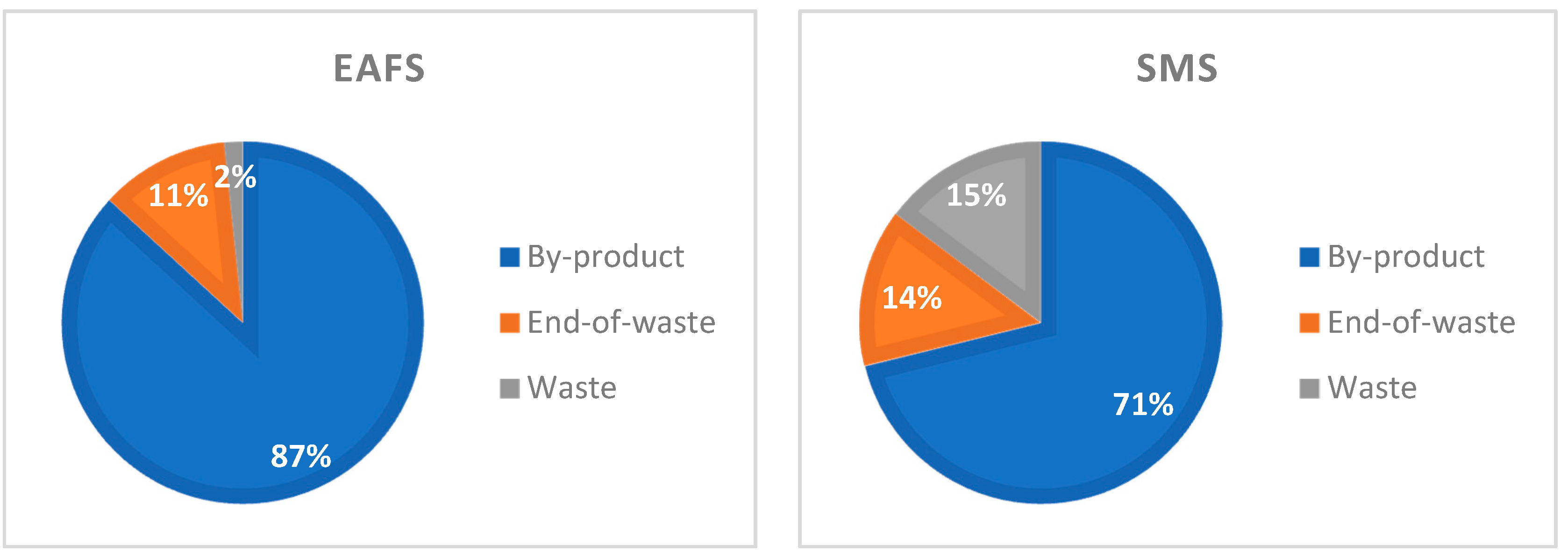

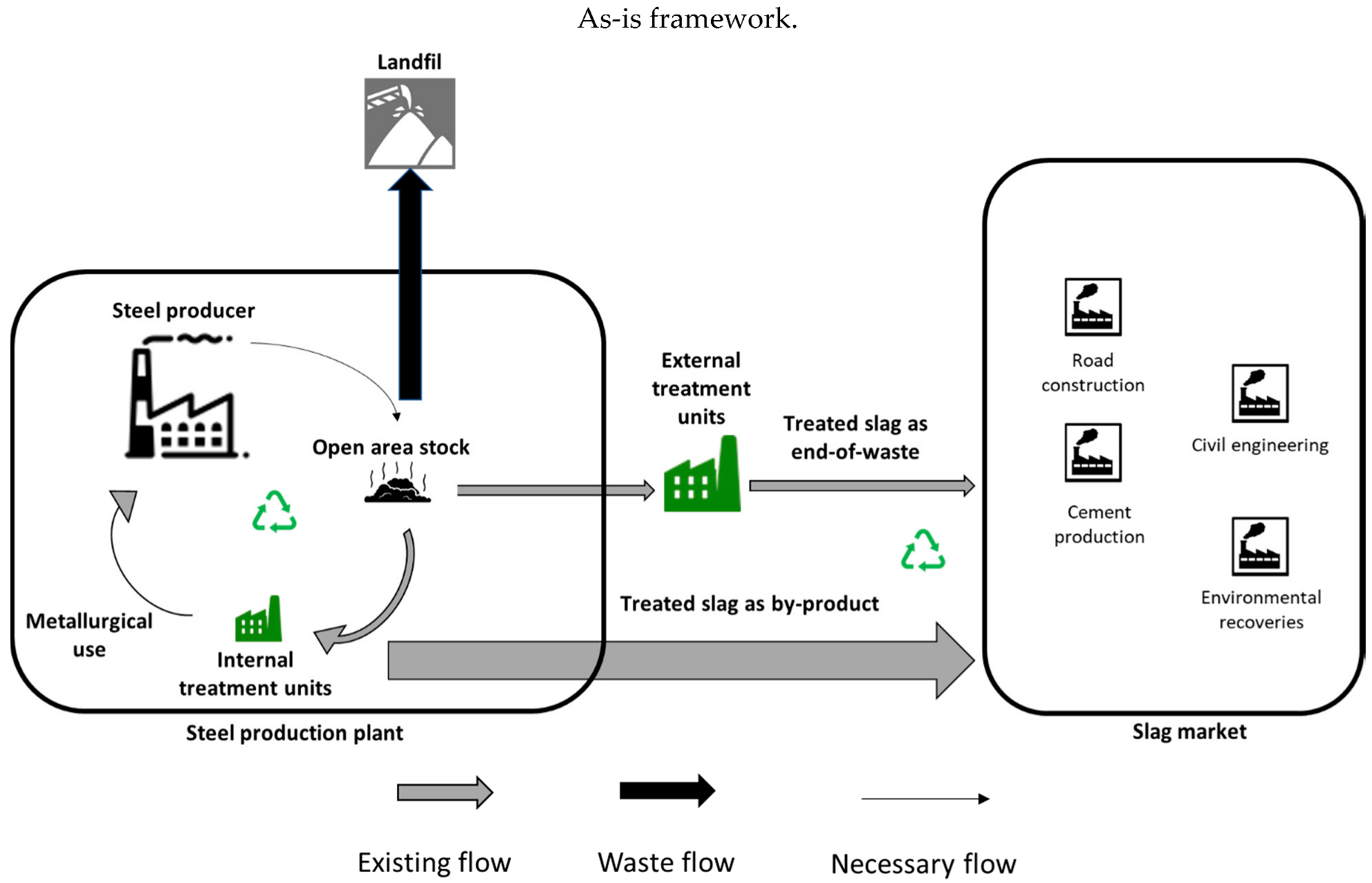

4. Results

- Economic feasibility: consisting of upfront costs of the treatment facilities for each slag type due to investment in the infrastructure and technologies. Additionally, it concerns the revenues and operative costs of treatment.

- Slag volume: the slag amount to be processed by TU should be sufficiently high to satisfy the minimum production capacity.

- Legislation: consisting of the regional and national legislation for slag treatment and use. Additionally, it concerns the willingness of the industries to buy slag in accordance with the legislation or replace natural raw material.

- Technology: some technologies are common among all SMs, and therefore, to establish a TU, there is no concern. However, some technologies are unique to a TU, where they register a patent. This case may derive from a particular treatment for a unique application or a requirement of a group of potential or existing customers.

- Market: it is necessary to identify innovative markets for each slag type produced with a certain treatment procedure and technology. The lack of a specific industrial segment or the unwillingness of such a segment can discourage new technologies from being adopted in a particular region.

- Supply chain: collaboration among the supply chain tiers should be interconnected harmoniously so that the internal and external logistics can be smoothly managed.

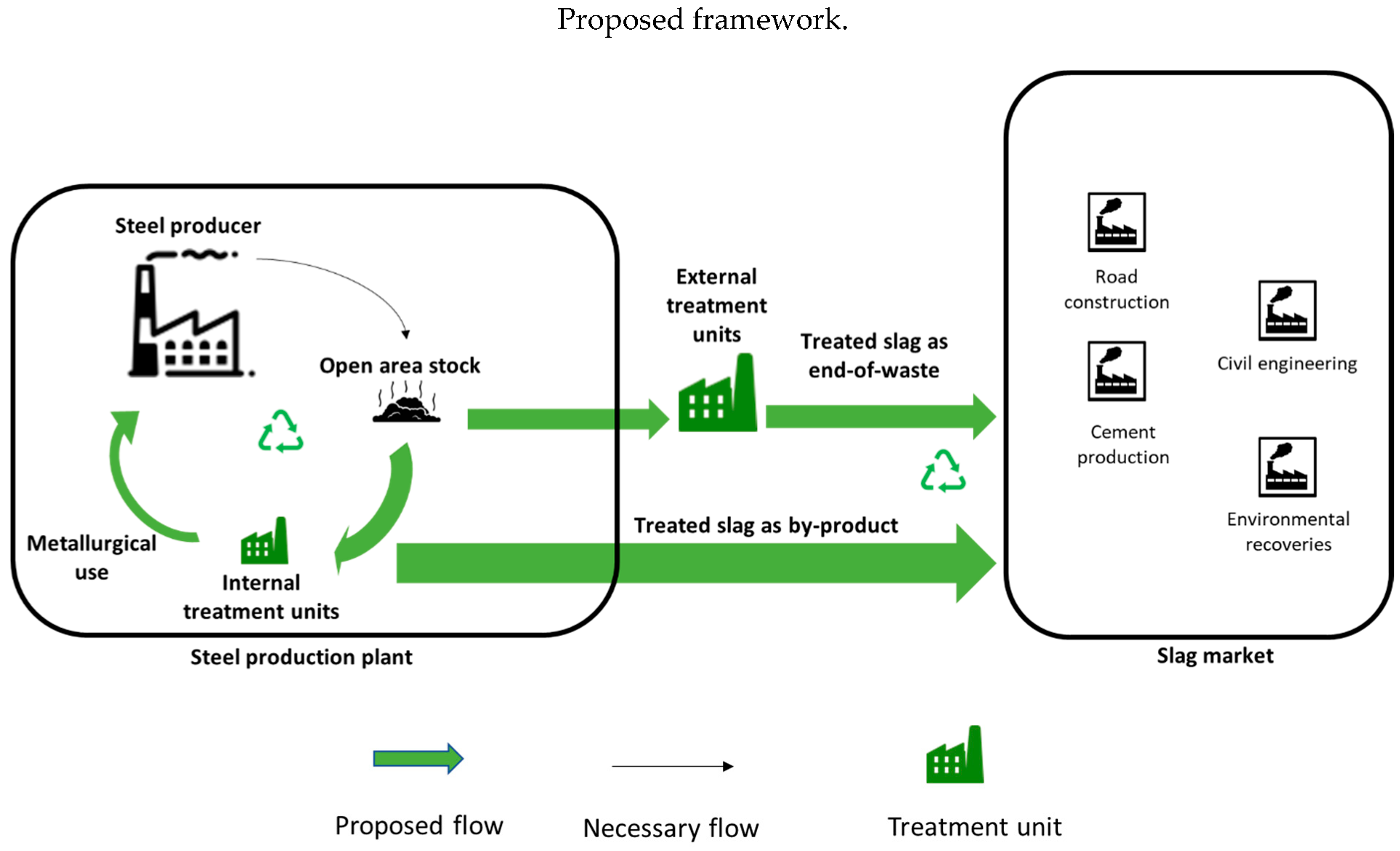

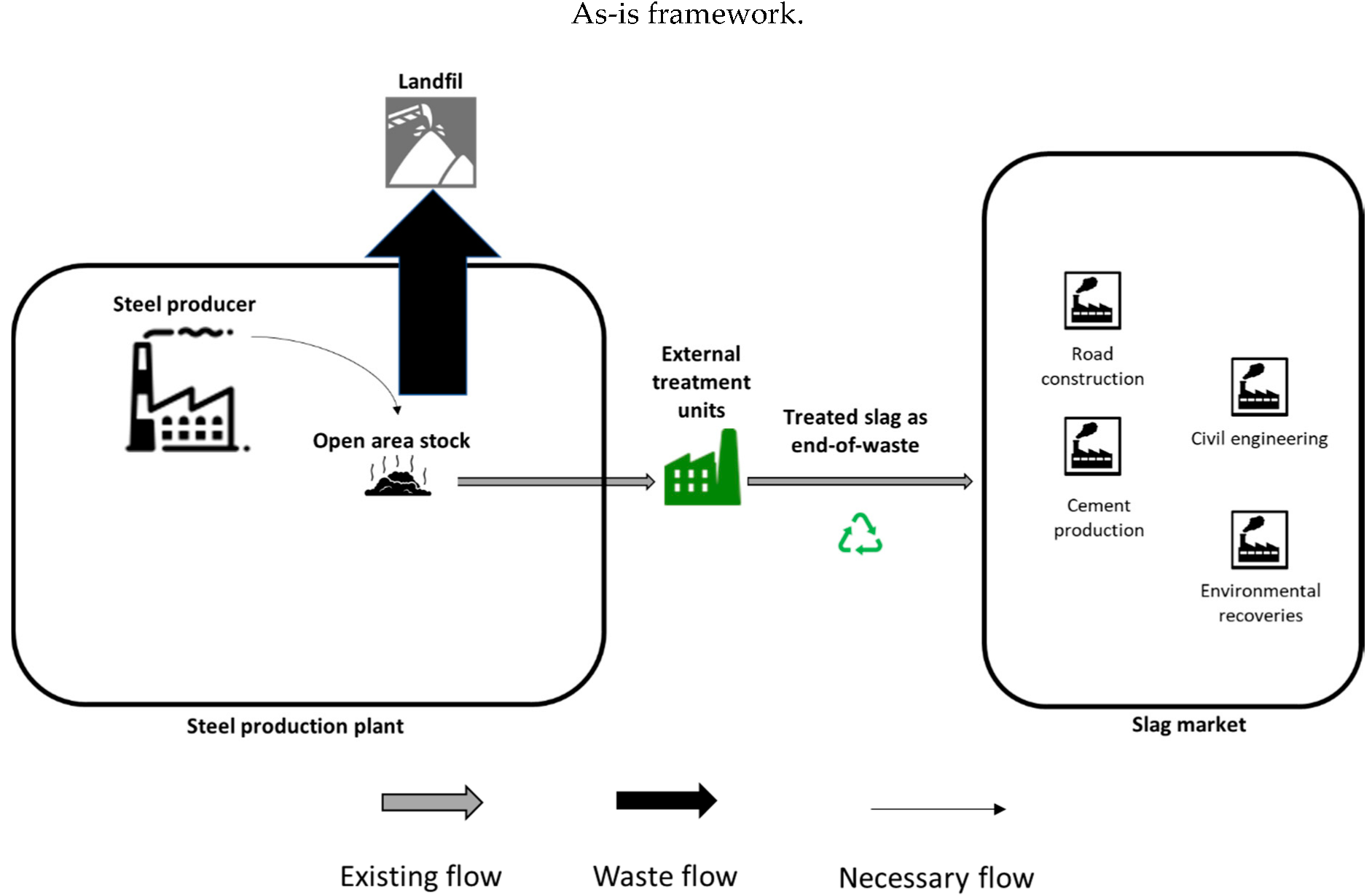

5. Proposed Framework

- Vertical integration: where capital, ownership, and management of slag value chain from its formation in steel plants to final use after treatment is centralised by the SM. This integration results in autonomous SMs facilitating decision-making and agility.

- Horizontal integration: where capital, ownership, and management of slag value chain from its formation in the steel plants to its final use after treatment is decentralised. This integration results in seamless cooperation between the stakeholders in the supply chain, which derives from sharing technology and information systems.

- Single TU established by an SM, where the SM treats its slag and sells the treated slag to the user industries. This case has the minimum material exchange (i.e., exchanging treated slag) between the SM and user industries compared to the other configurations.

- Collaboration of some SMs in the proximity and establishing a central treatment facility. The decision-making is decentralised, and the material exchange is among the collaborating SMs (i.e., exchanging as-received slag) and user industries (i.e., exchanging treated slag). An example is the collaboration of some SMs in the Brescia region to share some treatment activities (i.e., crushing and sieving) for EAFS.

- From a regional perspective, a third-party to manage the entire network of companies in a geographical area. Treatment is carried out by one company attracting the slag from other SMs. The decision-making in this configuration is centralised, and the slag treatment company can be one of the SMs or the intermediary industry.

6. Drivers for the Implementation of the Proposed Framework

7. Conclusions

- Reaching out to the main stakeholders in the Italian steel industry (i.e., SMs, technology providers, academic experts, and steel associations) through case-study surveys to gain comprehensive practical knowledge in the field.

- Comprehensively analysing the methods, technologies, and strategies to avoid, valorise, and re-use scrap-based steel slag. In addition, the use of slag as an alternative and renewable feedstock for scrap-based steel slag was discussed.

- Discussing the feasibility of the introduction of cross-sectorial applications with the other industries in the context of CE and IS.

- Providing best practices in Europe since an increase in the electrification of steelmaking is expected.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- World Steel Association. World Steel in Figures. 2021. Available online: https://worldsteel.org/wp-content/uploads/2021-World-Steel-in-Figures.pdf (accessed on 20 November 2021).

- Siderweb. Il Rottame in 4D (The scrap in 4D), Milan, Italy, 2019. Unpublished Report.

- Çiftçi, B.B. The Future of Global Scrap Availability. 2018. Available online: https://www.worldsteel.org/media-centre/blog/2018/future-of-global-scrap-availability.html (accessed on 10 November 2021).

- SSAB. First in Fossil-Free Steel. Using HYBRIT Technology. 2020. Available online: https://www.ssab.com/company/sustainability/sustainable-operations/hybrit (accessed on 13 September 2020).

- EUROFER (The European Steel Association). Low Carbon Roadmap. Pathways to a CO2-Neutral European Steel Industry. 2019. Available online: https://www.eurofer.eu/publications/reports-or-studies/low-carbon-roadmap-pathways-to-a-co2-neutral-european-steel-industry/ (accessed on 2 October 2021).

- Schweiger, A. Sostenibilità e Circolarità Dell’industria Siderurgica Italiana. In Proceedings of the 36° Convegno Nazionale AIM, Parma, Italy, 21–23 September 2016. [Google Scholar]

- Zhang, H.; Dong, L.; Li, H.; Fujita, T.; Ohnishi, S.; Tang, Q. Analysis of low-carbon industrial symbiosis technology for carbon mitigation in a Chinese iron/steel industrial park: A case study with carbon flow analysis. Energy Policy 2013, 61, 1400–1411. [Google Scholar] [CrossRef]

- Cao, X.; Wen, Z.; Xu, J.; De Clercq, D.; Wang, Y.; Tao, Y. Many-objective optimization of technology implementation in the industrial symbiosis system based on a modified NSGA-III. J. Clean. Prod. 2020, 245, 118810. [Google Scholar] [CrossRef]

- Wen, Z.; Xu, J.; Lee, J.C.; Ren, C. Symbiotic technology-based potential for energy saving: A case study in China’s iron and steel industrial parks. Renew. Sustain. Energy Rev. 2017, 69, 1303–1311. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain directives. Off. J. Eur. Union 2008, 312, 3–30. [Google Scholar]

- European Parliament and Council. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0851&from=EN (accessed on 2 October 2021).

- European Commission. Guidance on the Interpretation of Key Provisions of Directive 2008/98/EC on Waste. 2012. Available online: https://ens.dk/sites/ens.dk/files/Affald/guidance_on_the_interpretation_of_key_provisions_on_waste.pdf (accessed on 10 March 2021).

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and Recycling of By-Products in the Steel Sector: Recent Achievements Paving the Way to Circular Economy and Industrial Symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef] [Green Version]

- Baldassarre, B.; Schepers, M.; Bocken, N.; Cuppen, E.; Korevaar, G.; Calabretta, G. Industrial Symbiosis: Towards a design process for eco-industrial clusters by integrating Circular Economy and Industrial Ecology perspectives. J. Clean. Prod. 2019, 216, 446–460. [Google Scholar] [CrossRef]

- Saavedra, Y.M.B.; Iritani, D.R.; Pavan, A.L.R.; Ometto, A.R. Theoretical contribution of industrial ecology to circular economy. J. Clean. Prod. 2018, 170, 1514–1522. [Google Scholar] [CrossRef]

- Gregson, N.; Crang, M.; Fuller, S.; Holmes, H. Interrogating the circular economy: The moral economy of resource recovery in the EU. Econ. Soc. 2015, 44, 218–243. [Google Scholar] [CrossRef]

- Rossetti, D. The Future of European Steel-Innovation and Sustainability in a Competitive World and EU Circular Economy. 2017. Available online: https://op.europa.eu/en/publication-detail/-/publication/f5a82742-2a44-11e7-ab65-01aa75ed71a1 (accessed on 1 September 2021).

- Dong, L.; Gu, F.; Fujita, T.; Hayashi, Y.; Gao, J. Uncovering opportunity of low-carbon city promotion with industrial system innovation: Case study on industrial symbiosis projects in China. Energy Policy 2014, 65, 388–397. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Sáez-De-Guinoa Vilaplana, A.; García-Armingol, T.; Aranda-Usón, A.; Lausín-González, C.; López-Sabirón, A.M.; Ferreira, G. Evaluation of the steel slag incorporation as coarse aggregate for road construction: Technical requirements and environmental impact assessment. J. Clean. Prod. 2016, 130, 175–186. [Google Scholar] [CrossRef]

- Iacobescu, R.I.; Angelopoulos, G.N.; Jones, P.T.; Blanpain, B.; Pontikes, Y. Ladle metallurgy stainless steel slag as a raw material in Ordinary Portland Cement production: A possibility for industrial symbiosis. J. Clean. Prod. 2016, 112, 872–881. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial symbiosis in the Taranto industrial district: Current level, constraints and potential new synergies. J. Clean. Prod. 2016, 122, 133–143. [Google Scholar] [CrossRef]

- Mauthoor, S. Uncovering industrial symbiosis potentials in a small island developing state: The case study of Mauritius. J. Clean. Prod. 2017, 147, 506–513. [Google Scholar] [CrossRef]

- Pinto, J.T.; Diemer, A. Supply chain integration strategies and circularity in the European steel industry. Resour. Conserv. Recycl. 2020, 153, 104517. [Google Scholar] [CrossRef]

- Watkins, G.; Husgafvel, R.; Pajunen, N.; Dahl, O.; Heiskanen, K. Overcoming institutional barriers in the development of novel process industry residue based symbiosis products—Case study at the EU level. Miner. Eng. 2013, 41, 31–40. [Google Scholar] [CrossRef]

- Li, J.; Pan, S.-Y.; Kim, H.; Linn, J.H.; Chiang, P.-C. Building green supply chains in eco-industrial parks towards a green economy: Barriers and strategies. J. Environ. Manag. 2015, 162, 158–170. [Google Scholar] [CrossRef]

- Felicio, M.; Amaral, D.; Esposto, K.; Durany, X.G. Industrial symbiosis indicators to manage eco-industrial parks as dynamic systems. J. Clean. Prod. 2016, 118, 54–64. [Google Scholar] [CrossRef]

- Wu, J.; Qi, H.; Wang, R. Insight into industrial symbiosis and carbon metabolism from the evolution of iron and steel industrial network. J. Clean. Prod. 2016, 135, 251–262. [Google Scholar] [CrossRef]

- Morales, M.E.; Diemer, A. Industrial Symbiosis Dynamics, a Strategy to Accomplish Complex Analysis: The Dunkirk Case Study. Sustainabillity 2019, 11, 1971. [Google Scholar] [CrossRef] [Green Version]

- Lu, C.; Wang, S.; Wang, K.; Gao, Y.; Zhang, R. Uncovering the benefits of integrating industrial symbiosis and urban symbiosis targeting a resource-dependent city: A case study of Yongcheng, China. J. Clean. Prod. 2020, 255, 120210. [Google Scholar] [CrossRef]

- Renzulli, P.A.; Notarnicola, B.; Tassielli, G.; Arcese, G.; Di Capua, R. Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill. Sustainability 2016, 8, 719. [Google Scholar] [CrossRef] [Green Version]

- Teo, P.T.; Zakaria, S.K.; Salleh, S.Z.; Taib, M.A.A.; Mohd Sharif, N.; Abu Seman, A.; Mohamed, J.J.; Yusoff, M.; Yusoff, A.H.; Mohamad, M.; et al. Assessment of Electric Arc Furnace (EAF) Steel Slag Waste’s Recycling Options into Value Added Green Products: A Review. Metals 2020, 10, 1347. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, H.; Fujita, T.; Ohnishi, S.; Li, H.; Fujii, M.; Dong, H. Environmental and economic gains of industrial symbiosis for Chinese iron/steel industry: Kawasaki’s experience and practice in Liuzhou and Jinan. J. Clean. Prod. 2013, 59, 226–238. [Google Scholar] [CrossRef]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Res. Oper. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef] [Green Version]

- Eisenhardt, K.M.; Graebner, M.E. Theory Building from Cases: Opportunities and Challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Eisenhardt, K.M. Building Theories from Case Study Research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Yin, R. Case Study Research: Design and Methods, 5th ed.; SAGE Publications: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- Agenzia per la Protezione dell’Ambiente e per i Servizi Tecnici (APAT). Il Ciclo Industriale dell’Acciaio da Forno Elettrico in Italia (The Industrial Cycle of the Electric Furnace Steel in Italy). 2003. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/il-ciclo-industriale-dell2019acciaio-da-forno (accessed on 1 December 2021).

- Federacciai. La Siderurgia Italiana in Cifre-The Italian Steel Industry Key Statistics. 2020. Available online: http://federacciai.it/pubblicazioni-varie/ (accessed on 25 March 2021).

- Federacciai. Federazione Imprese Siderurgiche Italiane (Federation of the Italian Siderurgical Companies). 2021. Available online: http://federacciai.it (accessed on 3 October 2021).

- ISTAT. Italian Statistics Database. 2021. Available online: http://dati.istat.it/?lang=en (accessed on 15 November 2021).

- Lombardy Region. 2020. Available online: https://www.regione.lombardia.it (accessed on 12 November 2020).

- Federacciai. Rapporto Ambientale (Environmental Report). 2011; Unpublished Report. [Google Scholar]

- Federacciai. Rapporto di Sostenibilità-Assemblea Annuale 2019 (Sustainability Report). 2019; Unpublished Report. [Google Scholar]

- Regione Lombardia. Osservatorio per l’ Economia Circolare e la Transizione Energetica- Scoria nera da Forno Elettrico (Observatory for the Circular Economy and Energy Transaction-The Black Slag from Electric Furnace). 2020; 1–44, Unpublished Report.

- Borowski, P. Digitization, Digital Twins, Blockchain, and Industry 4.0 as Elements of Management Process in Enterprises in the Energy Sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Fumagalli, L.; Cattaneo, L.; Roda, I.; Macchi, M.; Rondi, M. Data-driven CBM tool for risk-informed decision-making in an electric arc furnace. Int. J. Adv. Manuf. Technol. 2019, 105, 595–608. [Google Scholar] [CrossRef]

- Kang, L.-W.; Chen, Y.-T.; Jhong, W.-C.; Hsu, C.-Y. Deep Learning-Based Identification of Steel Products. In Proceedings of the International Conference Advances in Intelligent Information Hiding and Multimedia Signal Processing, Kaohsiung, Taiwan, 21–23 November 2016; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 315–323. [Google Scholar] [CrossRef]

- Zangiacomi, A.; Oesterle, J.; Fornasiero, R.; Sacco, M.; Azevedo, A. The implementation of digital technologies for operations management: A case study for manufacturing apps. Prod. Plan. Control 2017, 28, 1318–1331. [Google Scholar] [CrossRef]

- Zangiacomi, A.; Pessot, E.; Fornasiero, R.; Bertetti, M.; Sacco, M. Moving towards digitalization: A multiple case study in manufacturing. Prod. Plan. Control 2020, 31, 143–157. [Google Scholar] [CrossRef]

- Camarinha-Matos, L.M.; Fornasiero, R.; Ramezani, J.; Ferrada, F. Collaborative Networks: A Pillar of Digital Transformation. Appl. Sci. 2019, 9, 5431. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, I.; Majumder, S.; Szwarc, E.; Saha, S. Impact of Strategic Cooperation under Competition on Green Product Manufacturing. Sustainability 2020, 12, 10248. [Google Scholar] [CrossRef]

- Niu, S.; Zhuo, H.; Xue, K. DfRem-Driven Closed-Loop Supply Chain Decision-Making: A Systematic Framework for Modeling Research. Sustainability 2019, 11, 3299. [Google Scholar] [CrossRef] [Green Version]

- Lu, B.; Zhu, W.; Weng, Y.; Liu, Z.; Yang, E.H.; Leong, K.F.; Qian, S. Study of MgO-activated slag as a cementless material for sustainable spray-based 3D printing. J. Clean. Prod. 2020, 258, 120671. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S. Printability and physical properties of iron slag powder composites using material extrusion-based 3D printing. J. Iron Steel Res. Int. 2021, 28, 111–121. [Google Scholar] [CrossRef]

- Li, M.; Liu, G.; Mu, Q.; Wu, J. The effect of basalt fiber on mechanical properties of slag cementing slurries. J. Adhes. Sci. Technol. 2020, 34, 1442–1453. [Google Scholar] [CrossRef]

- Yurt, Ü. An experimental study on fracture energy of alkali activated slag composites incorporated different fibers. J. Build. Eng. 2020, 32, 101519. [Google Scholar] [CrossRef]

- Ortiz, N.; Pires, M.; Bressiani, J. Use of steel converter slag as nickel adsorber to wastewater treatment. Waste Manag. 2001, 21, 631–635. [Google Scholar] [CrossRef]

- Roychand, R.; Pramanik, B.K.; Zhang, G.; Setunge, S. Recycling steel slag from municipal wastewater treatment plants into concrete applications–A step towards circular economy. Resour. Conserv. Recycl. 2020, 152, 104533. [Google Scholar] [CrossRef]

- Shi, C.; Hu, S. Cementitious properties of ladle slag fines under autoclave curing conditions. Cem. Concr. Res. 2003, 33, 1851–1856. [Google Scholar] [CrossRef]

- Monkman, S.; Shao, Y.; Shi, C. Carbonated Ladle Slag Fines for Carbon Uptake and Sand Substitute. J. Mater. Civ. Eng. 2009, 21, 657–665. [Google Scholar] [CrossRef]

- Bocci, E. Use of ladle furnace slag as filler in hot asphalt mixtures. Constr. Build. Mater. 2018, 161, 156–164. [Google Scholar] [CrossRef]

- Mahoutian, M.; Ghouleh, Z.; Shao, Y. Carbon dioxide activated ladle slag binder. Constr. Build. Mater. 2014, 66, 214–221. [Google Scholar] [CrossRef]

- Manso, J.M.; Losañez, M.; Polanco, J.A.; Gonzalez, J.J. Ladle Furnace Slag in Construction. J. Mater. Civ. Eng. 2005, 17, 513–518. [Google Scholar] [CrossRef]

- Rieger, J.; Colla, V.; Matino, I.; Branca, T.A.; Stubbe, G.; Panizza, A.; Brondi, C.; Falsafi, M.; Hage, J.; Wang, X.; et al. Residue Valorization in The Iron and Steel Industries: Sustainable Solutions for a Cleaner and More Competitive Future Europe. Metals 2021, 11, 1202. [Google Scholar] [CrossRef]

- Schrama, F.N.H.; Beunder, E.M.; van den Berg, B.; Yang, Y.; Boom, R. Sulphur removal in ironmaking and oxygen steelmaking. Ironmak. Steelmak. 2017, 44, 333–343. [Google Scholar] [CrossRef]

- Schrama, F.N.H.; Beunder, E.M.; Panda, S.K.; Visser, H.-J.; Moosavi-Khoonsari, E.; Sietsma, J.; Boom, R.; Yang, Y. Optimal hot metal desulphurisation slag considering iron loss and sulphur removal capacity part I: Fundamentals. Ironmak. Steelmak. 2021, 48, 1–13. [Google Scholar] [CrossRef]

- ESTEP. European Steel Technology Platform—ESTEP Strategic Research Agenda (SRA). 2017. Available online: https://www.estep.eu/assets/SRA-Update-2017Final.pdf (accessed on 25 March 2021).

- Federacciai. L’Industria Siderurgica Italiana (Italian Siderurgical Industry). 2018. Available online: http://federacciai.it/pubblicazioni-varie/ (accessed on 12 March 2021).

- EUROFER (The European Steel Association). Eurofer Reply to the Feedback Consultation ‘Circular Economy—New Action Plan to Increase Recycling and Reuse of Products in the Eu’. Available online: https://www.eurofer.eu/assets/Uploads/EUROFER-Input-Consultation-on-the-New-Circular-Economy-1.pdf (accessed on 12 February 2021).

- EUROFER (The European Steel Association). Steel and the Circular Economy. Available online: https://www.eurofer.eu/publications/brochures-booklets-and-factsheets/steel-and-the-circular-economy/ (accessed on 12 February 2021).

- EUROFER (The European Steel Association). The Contribution of the Waste Shipment Regulation to EU Ambitions on Circularity and Climate-Position Paper-WSR Review. Available online: https://www.eurofer.eu/publications/position-papers/contribution-of-the-waste-shipment-regulation-to-eu-ambitions-on-circularity-and-climate/ (accessed on 12 February 2021).

- Tello, P.; Weerdmeester, R. SPIRE Roadmap. Available online: https://www.spire2030.eu/sites/default/files/pressoffice/spire-roadmap.pdf (accessed on 20 December 2021).

| Reference | Slag Type | Application | Evaluation Approach | Country | ||||

|---|---|---|---|---|---|---|---|---|

| Reg | IS/SC | Chem | Econ | Env | ||||

| [33] | BOFS, BFS | 1,2 | ✓ | ✓ | ✓ | ✓ | China, Japan | |

| [20] | EAFS | 3 | ✓ | ✓ | Spain | |||

| [28] | EAFS, BOFS, BFS | 4 | ✓ | ✓ | ✓ | China | ||

| [21] | SMS | 1 | ✓ | ✓ | ✓ | Belgium | ||

| [25] | SMS | 5,6,7,8 | ✓ | ✓ | Finland | |||

| [9] | BFS | 1 | ✓ | ✓ | ✓ | China | ||

| [23] | EAFS | 9 | ✓ | ✓ | Mauritius island | |||

| [19] | BOFS, BFS | 1,2 | ✓ | ✓ | China | |||

| [27] | Iron and steel | --- | ✓ | ✓ | ✓ | Brazil | ||

| [8] | BFS | 2,10 | ✓ | ✓ | ✓ | ✓ | China | |

| [30] | Iron and steel | 1 | ✓ | ✓ | China | |||

| [22] | BOFS, BFS | 1,2,3,9,10,11 | ✓ | ✓ | Italy | |||

| [7] | BFS, BOFS | 2 | ✓ | ✓ | ✓ | China | ||

| [29] | All | 1,2,10 | ✓ | ✓ | France | |||

| [24] | All | --- | ✓ | ✓ | Europe | |||

| [26] | BOFS | 1,2,3,9 | ✓ | ✓ | ✓ | Taiwan | ||

| [31] | BFS/ BOFS | 1 | ✓ | ✓ | Italy | |||

| Year | Crude Steel | EAFS | SMS |

|---|---|---|---|

| 2015 | 9,621,208 | 1,353,839 | 360,426 |

| 2016 | 9,952,653 | 1,177,315 | 398,696 |

| 2017 | 10,847,735 | 1,472,369 | 454,030 |

| Company | Production Share among Interviewed Companies | Production Share in Italy | Number of Employees | Revenue (million €) |

|---|---|---|---|---|

| SM1 | 12% | 3.5% | >400 | <400 |

| SM2 | 16% | 4.7% | >2000 | <800 |

| SM3 | 22% | 6.6% | >1000 | <700 |

| SM4 | 49% | 15% | >500 | >800 |

| SM5 | 2% | 0.5% | <200 | <100 |

| Total | 100% | 30.3% |

| Company | SMS | EAFS |

|---|---|---|

| SM1 | - Currently landfilled | - Treated by two third-party recyclers |

| - The SM is in the development phase of a patent to treat the SMS for mechanical application | ||

| SM2 | - 90% is treated as end-of-waste by a third-party recycler | - Treated and sold to three main industries: road construction (such as bituminous asphalt), concrete, and civil engineering. |

| - 10% is landfilled | - The treatment is carried out by the company | |

| SM3 | The treatment is carried out in the plant and is applied in cement production and road construction | |

| SM4 | - Treated inside the plant | - Treated and used in the road construction |

| - Lime and metal scrap are re-used | ||

| - The treatment is carried out by the company | - The treatment is carried out by the company | |

| SM5 | Landfilled | Landfilled |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Falsafi, M.; Fornasiero, R. Explorative Multiple-Case Research on the Scrap-Based Steel Slag Value Chain: Opportunities for Circular Economy. Sustainability 2022, 14, 2284. https://doi.org/10.3390/su14042284

Falsafi M, Fornasiero R. Explorative Multiple-Case Research on the Scrap-Based Steel Slag Value Chain: Opportunities for Circular Economy. Sustainability. 2022; 14(4):2284. https://doi.org/10.3390/su14042284

Chicago/Turabian StyleFalsafi, Mohammadtaghi, and Rosanna Fornasiero. 2022. "Explorative Multiple-Case Research on the Scrap-Based Steel Slag Value Chain: Opportunities for Circular Economy" Sustainability 14, no. 4: 2284. https://doi.org/10.3390/su14042284

APA StyleFalsafi, M., & Fornasiero, R. (2022). Explorative Multiple-Case Research on the Scrap-Based Steel Slag Value Chain: Opportunities for Circular Economy. Sustainability, 14(4), 2284. https://doi.org/10.3390/su14042284