Abstract

Waste electrical and electronic equipment (WEEE) has become one of the fastest growing waste streams around the world, putting tremendous pressure on the environment, resources, and public health. A practically driven question about how to promote the development of the WEEE recycling industry plagues many countries, especially in developing economies such as China. This study uses an expert decision-making system based on the fuzzy Delphi technique and improved Decision-Making Trial and Evaluation Laboratory (DEMATEL) method to identify the critical barriers and their cause–effect relationships in the Chinese WEEE recycling industry. First, using the fuzzy Delphi technique, we find that nine barriers significantly impact the development of the Chinese WEEE recycling industry. Then, three critical barriers which include the implementation of policies and regulations, qualified disassembly, and unqualified disassembly are identified by employing the improved DEMATEL method. Furthermore, implementation of policies and regulations belong to the cause group, and the other two barriers belong to the effect group. Finally, some practical implications are proposed to promote the sustainable development of the Chinese WEEE recycling industry. To be specific, the Chinese government should optimize the implementation details of the e-waste take-back legislation, establish a flexible reward–supervision–penalty mechanism to support the formal collector, and improve the collection efficiency. The results of this paper are of value to firms that participate in WEEE recycling and to the government that aims to promote the sustainable development of the WEEE recycling industry.

1. Introduction

Advanced industrialization, diverse demands, and economic development contribute to the rapid increase in electrical and electronic equipment (EEE), and the obsolete EEE will eventually become WEEE [1]. According to the Global E-waste Monitor, 53.6 million metric tons (Mt) of WEEE were generated globally in 2019. It is estimated that the generation of WEEE will increase substantially over the next decades, reaching 120 Mt annually by 2050 [2]. Currently, WEEE is one of the fastest growing waste streams around the world, with an annual growth rate of 4–5% [3,4]. Compliant recycling procedures can yield substantial economic benefits because precious metals which include gold, copper, and iron are contained in WEEE. However, incompliant recycling procedures will put triple pressures on the environment, resources, and public health due that to the majority of WEEE contains heavy metals such as mercury, cadmium, and nickel. In order to collect and recycle WEEE effectively, many countries have taken measures such as enacting e-waste laws and regulations, constructing the subsidy–penalty mechanism, and establishing recycling infrastructure to promote the sustainable development of the WEEE recycling industry [5,6,7]. However, these policies, regulations, and measures do not achieve the expected results. Only 20% of the total WEEE produced in the world can be collected and properly recycled every year [8].

China, as the second-largest EEE abandoner, is facing severe threats from WEEE [9]. During the last decade, the annual growth rate of WEEE in China has reached 13–15%, and the amount of WEEE will reach 27.22 Mt in 2030 [10,11]. Furthermore, in developed countries, stringent take-back laws and regulations as well as high labor costs have driven recycling operations to developing countries such as China, India, and Pakistan. To be specific, 50% and 80% of WEEE produced by developed countries is being exported to Asian and African countries [12], which aggravates the difficulties to collect and recycle WEEE in China. The incremental growth of total WEEE volume requires a comprehensive recycling system. However, only 20% of WEEE in China is properly recycled and treated through the formal channels [13].

Previous literature has extensively examined the barriers that impact the development of the Chinese WEEE recycling industry, such as government policies and regulations [14,15], manufacturers’ abilities of eco-design and green selling [3,16], competition between formal and informal collectors [10,17], and green behaviors and attitudes of consumers [10]. Recognizing and understanding these barriers and their internal relationships can help policy-makers to operate and manage the WEEE recycling industry effectively.

In practice, policy-makers may face some challenges in recognizing and understanding the development barriers of the WEEE recycling industry. First, the dynamic nature of the WEEE recycling industry makes policy-makers face a complicated decision environment. It is difficult to make quantitative judgments because of a level of ambiguity and uncertainty in the mind of policy-makers. Furthermore, the complicated decision environment and the subjectivity of policy-makers aggravate the extent of ambiguity and uncertainty. Second, it is difficult for policy-makers to establish annual plans by determining the critical barriers. Since many barriers influence the WEEE recycling industry, it is impossible and not practical to overcome these barriers simultaneously. Hence, finding the most critical barriers is the key to promoting the development of the WEEE recycling industry for the government. However, policy-makers have different preferences, experiences, and cognition, and their judgments of the critical barriers are often different in practice. Third, these barriers influence each other and, as such, are interlinked. Eliminating one barrier can aggravate or lessen the importance of another barrier. Hence, the cause–effect relationships between barriers and their impact on the development of the WEEE recycling industry need to be considered when the policy maker implements policies to resolve these barriers.

Obviously, the development of the Chinese WEEE recycling industry is influenced by multiple barriers. Meanwhile, the complicated decision environment and the subjective judgment make it difficult for policy-makers to recognize and understand these barriers. These barriers negatively impact the Chinese WEEE recycling industry and cannot be overcome simultaneously. Therefore, identifying the critical barriers and their cause–effect relationships are of great significance for promoting the sustainable development of the Chinese WEEE recycling industry. This motivates our research questions: (1) what factors hinder the development of the Chinese WEEE recycling industry; (2) among these factors, which are the key development barriers; and (3) how can policy-makers tackle these critical barriers?

To address these research questions, we developed an expert decision-making system. First, 30 barriers were obtained through extensive reading, analyzing, and summarizing of relevant literature. Second, eight experts were invited to filter barriers by using the fuzzy Delphi technique. Third, the direct-relation matrix, indirect-relation matrix, and overall-relation matrix were calculated by using the improved DEMATEL method. Finally, the values of prominence and relation of each barrier were obtained based on the overall-relation matrix, and the critical barriers and their cause–effect relationships are determined from the values of prominence and relation.

The contributions of this work are as follows. (1) Through employing the hybrid approach, we identify the importance of development barriers in Chinese WEEE recycling industry. (2) The proposed expert decision-making system addresses the ambiguity and uncertainty of experts’ subjective judgments, improving the accuracy and rationality of our results. (3) We develop a deeper understanding of the barriers and their cause–effect relationships, yielding new insights in terms of how the policy-makers should formulate take-back laws and regulate the WEEE recycling industry.

The rest of this paper is organized as follows. In the following section, we briefly discuss the related literature. An expert decision-making system is developed in Section 3. Section 4 is devoted to applying this hybrid approach to identify the critical barriers and their cause–effect relationships. We propose some practical implications in Section 5, and summarize conclusions and outline the limitations of this work and possible directions for future research in Section 6.

2. Literature Review

Our work builds on three streams of literature. The first stream is operations management in the WEEE recycling industry, the second stream is recycling operations in closed-loop supply chains, and the third stream is multi-criterion decision-making analysis (MCDA) methods in the waste recycling industry.

2.1. Operations Management in WEEE Recycling Industry

With the increasing attention of the environment, resources, and public health caused by the WEEE problem, the issues related to operations management in the WEEE recycling industry have been studied in depth. On the tactical side, the existing literature has focused on significant topics such as product design [18,19], remanufacturing [20,21,22], reverse logistics [23], and take-back legislation [1,24,25]. On the strategic side, some important topics such as technology choice [26,27], market segmentation [28,29], and recycling competition [30] have been investigated extensively over the past few decades. This stream of literature focuses on the equilibrium collection, manufacturing, and remanufacturing decisions of an OEM or/and the independent remanufacturer based on different market conditions and operating factors. Different from the above literature, our work does not determine the producers’ optimal decisions but comprehensively considers the systematic efficiency from the government’s perspective in the WEEE recycling industry.

2.2. Recycling Operations in Closed-Loop Supply Chains

In essence, the WEEE recycling activity belongs to the scope of closed-loop supply chains, and the government, manufacturer, collector, and consumer are the key members in a closed-loop supply chain. The existing literature in recycling operations of closed-loop supply chains has extensively discussed the interactive mechanism and fundamental conflict between these members.

The government, as the administrator, has the decisive and significant role in the design of the top-level system for the development of the WEEE recycling industry. A stream of research in the closed-loop supply chain literature has analyzed several environmental policy instruments such as the recycling subsidies, deposit–refund models, and pre-disposal fees [11,31,32,33,34,35]. This stream of literature mainly focuses on the efficiency comparison of e-waste take-back policy implementations from perspectives of social welfare, environment, or/and consumer surplus, and concludes that different environmental policy instruments have advantages and disadvantages under different model settings and market conditions. Different from this stream of literature, we do not compare the economic and environmental performance of policies and regulations, but adopt the most prevailing and common reward–penalty mechanism to find the critical barriers which impact the sustainable development of WEEE recycling industry.

Collectors are the vital link between consumers and manufacturers in a closed-loop supply chain, and their behaviors of compliance with WEEE recycling standards are beneficial for the development of the WEEE recycling industry. The existing literature analyzes the stability and profitability of formal and informal collectors by using questionnaires, stylized game-theoretic models, and multi-agent cost–benefit analysis, and puts forward some useful managerial implications about how to regulate the informal collectors [10,17,36]. An important conclusion from the above papers is that the informal collector is an important supply chain member in the WEEE recycling industry, which provides a basis for determining and finding influencing factors. Furthermore, the convenience of recycling strongly impacts consumers’ motivations when selecting formal or informal collections, and informal collectors can better meet the needs of consumers. However, their unqualified disassembly activities do not meet governmental standards, and such illegal practices waste resources and pollute the environment.

This stream of literature has extensively examined the recycling operations in closed-loop supply chains from multiple perspectives and provides good foundations for our work. However, consumers’ perceptions and behaviors can significantly impact the development of the WEEE recycling industry, but the existing literature does not take the consumers’ green behaviors into account. Additionally, few research studies comprehensively consider the interaction mechanism between supply chain members (which includes the government, manufacturer, collector, and consumer). To fill these gaps, we developed an expert decision-making system by considering the supply chain members and their behaviors, aiming to identify critical barriers and their cause–effect relationships in the Chinese WEEE recycling industry.

2.3. MCDA Methods in Waste Recycling Industry

Our work also relates to the MCDA methods in the waste recycling industry. Many research papers use Analytical Network Process (ANP), Analytic Hierarchy Process (AHP), interpretive structural modeling (ISM), and the traditional DEMETAL method to solve management problems in the fields of solid waste, WEEE, plastic waste, packaging waste, and end-of-life vehicles [37,38,39,40,41].

Differently, our work is based on a hybrid fuzzy Delphi and improved DEMATEL approach. The traditional Delphi technique can also be used to identify the barriers which impact the development of the Chinese WEEE recycling industry. However, this method cannot address the uncertainty and ambiguity of experts’ subjective judgments. Therefore, a fuzzy Delphi technique is adopted in our paper to filter barriers that have a lower influence on the development of the Chinese WEEE recycling industry. Furthermore, an improved DEMATEL approach is utilized to recognize the critical barriers and understand the cause–effect relationships among these barriers by developing a causal diagram. Although there are other MCDA methods such as AHP, ANP, ISM, and Elimination and Choice Expressing Reality (ELECTRE), these methods are only able to prioritize the factors and fail to identify the cause–effect relationships. A comprehensive understanding of cause–effect relationships can help closed-loop supply chain members to recognize the internal mechanism of the WEEE recycling system and make better decisions. Furthermore, the hybrid fuzzy Delphi and DEMATEL approach has been widely used to solve problems in supply chain sustainability [42], the automotive industry [43], online reputation management [44], safety science [45], and corporate social responsibility [46]. However, to our knowledge, the existing literature does not employ this hybrid approach to address the management problems in the WEEE recycling field. To fill this gap, we develop an expert decision-making system by using the fuzzy Delphi and improved DEMETAL methods in Chinese WEEE recycling industry, yielding new insights in terms of how the government should manage the WEEE recycling industry to achieve economic and environmental benefits.

3. Research Methodology

In this study, our primary objectives are to identify barriers to the sustainable development of the Chinese WEEE recycling market and determine their cause–effect relationship. To better achieve these objectives, a hybrid decision-making network, including the Fuzzy Delphi technique and the improved DEMATEL method, is proposed to improve the accuracy and scientifically of the results. First, the fuzzy Delphi technique rejects some barriers that have a lower impact on the sustainable development of the Chinese WEEE recycling industry. Second, the improved DEMATEL method determines the critical barriers and their cause–effect relationship.

3.1. Fuzzy Delphi Technique

The Delphi technique was initially proposed by the RAND corporation [47]. Ishikawa et al. [48] applied fuzzy theory to the traditional Delphi technique to create the fuzzy Delphi technique. The fuzzy Delphi technique uses statistical analysis and fuzzy operations to transform subjective judgments of experts into quasi-objective data. Applying the fuzzy Delphi technique to filter factors takes the uncertainty and ambiguity of experts’ subjective judgments into account, thus effectively rejecting some low-impact factors in the system. At present, the fuzzy Delphi technique has been extensively promoted and applied in areas such as environmental protection [49], green supply chain management [50], tourism management [51], and freight transport [52].

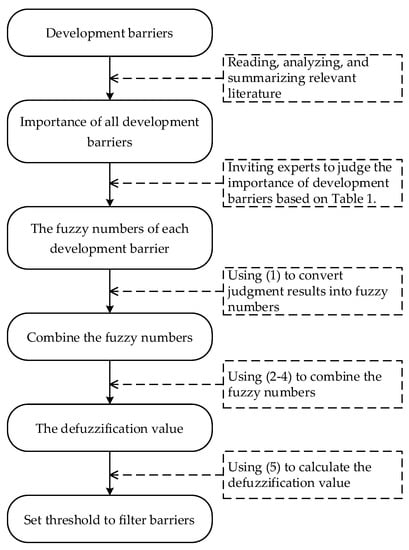

The realized steps of the fuzzy Delphi technique are summarized as follows (depicted in Figure 1):

Figure 1.

Resolution process of the fuzzy Delphi technique.

Step 1: Collect all influencing factors related to the research area by reading, organizing, and analyzing relevant literature.

Step 2: Design and distribute the questionnaire and ask expert to judge the importance of all factors. The results are indicated by numbers 1–5. The transformations between experts’ linguistic variables and numbers are shown in Table 1.

Table 1.

Linguistic variables, rating, and fuzzy numbers of experts’ judgments.

Step 3: Convert judgment results of th expert are into fuzzy numbers, which are given in Table 1. Let fuzzy number represent the th factor provided by th expert.

Step 4: Combine the fuzzy numbers of experts on the factor based on Equations (2)–(4).

where , .

Step 5: Calculate the defuzzification value by using the mean method, which is given below:

Step 6: Set threshold to select or reject the factor. If , then select the factor. If , then reject the factor.

3.2. Improved DEMATEL Method

DEMATEL is an effective multi-criteria decision-making method used for determining the critical factors and the cause–effect relationship among factors [53]. It can provide decision-makers with a quantitative and visual relationship between factors through matrices or diagraphs. Although there are other multi-criteria decision-making methods such as AHP, ANP, ISM, and Elimination and Choice Expressing Reality (ELECTRE), these methods are only able to prioritize the factors and fail to identify the cause–effect relationships. Therefore, we used the DEMATEL approach to recognize the critical barriers and understand the cause–effect relationships among these barriers by developing a causal diagram. Furthermore, vagueness and uncertainty in subjective judgments of experts are not considered in the traditional DEMATEL method, which may result in considerable errors in the decision-making process. In order to tackle this issue, we employed an improved DEMATEL method which set up the direct-relation matrix by using the 2-tuple fuzzy linguistic representation model to reduce ramifications of subjective judgments [54]. The improved DEMATEL method has been widely used to solve problems in supply chain management [55], emergency management [56], and health care [57].

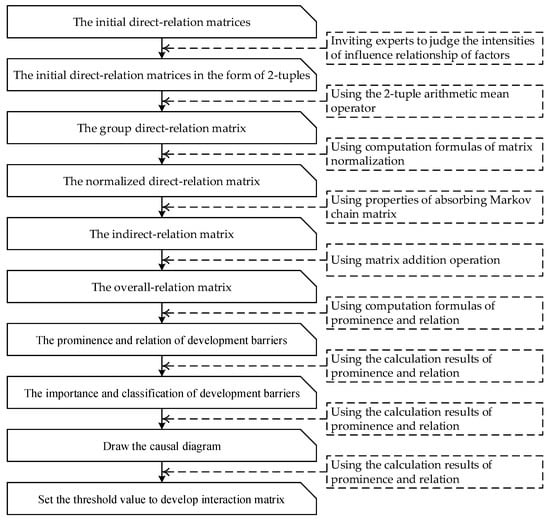

The realized steps of the improved DEMATEL method are summarized as follows (depicted in Figure 2):

Figure 2.

Resolution process of the improved DEMETAL method.

Step 1: Set up initial direct-relation matrix . Invite expert to judge the existences and intensities of influence relationship among factors by using ordered linguistic term set, which is given in Table 2. Let represent the judgment on the existence and intensity of the influence relationship between factors and provided by expert , . Particularly, factor has no influence on itself. Thus, the initial direct-relation matrix () provided by expert can be constructed.

Table 2.

Ordered linguistic term set for the improved DEMATEL method.

Step 2: Transform matrix into matrix in the form of 2-tuples by the following expressions.

where is a linguistic term, and we use the function to obtain the corresponding 2-tuple of .

Step 3: Combine the judgement results of experts to develop group direct-relation matrix . The combined equation is shown below.

where and are two functions. The expressions of the functions and are given in Equations (8) and (9).

Step 4: Normalize group direct-relation matrix to matrix . Calculate the expression of as follows.

Step 5: Construct indirect-relation matrix .

where is unit matrix.

Step 6: Construct overall-relation matrix , and is represented by Equation (12).

where denotes the overall intensity of the direct and indirect influence relationship between factor and factor .

Step 7: Calculate the value of prominence and relation of each factor. Let be the value of prominence for factor , and it represents the overall importance of factor . Let be the value of relation for factor , and it is an indicator that is used to judge whether factor is a cause factor () or an effect factor (). The value of and of each factor are calculated by Equations (13) and (14).

Step 8: Identify the importance and cause–effect relationship of factors based on the calculated results of and ().

Step 9: Draw the causal diagram based on and ().

Step 10: Develop interaction matrix by setting a threshold value to avoid minor impact, and is represented by Equation (15).

where is the number of elements in overall-relation matrix . The elements of overall-relation matrix which are greater than form interaction matrix that represents the inter-relationship between the factors.

4. Application of the Expert Decision-Making System

To better realize the hybrid decision-making network, a team of eight experts from academia and industry was utilized: three professors that have been studying the WEEE management of closed-loop supply chains, green supply chains, and operations management for many years; two managers (collection, production, and environment) from two different companies (actual company name kept confidential) that have more than 20 years of experience in the WEEE recycling industry; and in addition, three PhD students that are familiar with the background of WEEE recycling and have published several articles in international journals. The basic information of the eight experts is shown in Table 3.

Table 3.

Personal information of the 8 experts.

4.1. Filter Barriers

In this section, the fuzzy Delphi technique is used to filter barriers that have low implications on the development of the Chinese WEEE recycling industry. First, through reading, analyzing, and summarizing relevant literature, 30 barriers in the WEEE recycling industry are determined. The total barriers consist of two sides that are macro-level barriers and micro-level barriers. There are six barriers at the macro level. Furthermore, we divide the micro level barriers into five subsets from stakeholders’ perspectives, i.e., the government (six barriers), manufacturers (four barriers), formal collectors (six barriers), informal collectors (four barriers), and consumers (four barriers). We summarize all development barriers in Table 4.

Table 4.

Development barriers in the WEEE recycling industry.

At the macro level, we conclude that six barriers affect the development of the Chinese WEEE recycling industry. The first barrier is the construction of policies and regulations . This means that the government enacts WEEE take-back policies and regulations to lead the development of the WEEE recycling industry. Without the relevant policies and regulations, the negative impact of uncollected WEEE on the environment, resources, and public health will persist [58,59]. The second barrier is the implementation of policies and regulations . China enacted two prevailing and common WEEE take-back policy implementations, i.e., rate and tax modes. Currently, the two legislative models cannot divert as much e-waste as possible from landfills and provide design incentives for electronic producers [24,60]. The third barrier is recycling infrastructure development . A major challenge to implementing take-back legislation in China is the lack of formal recycling infrastructure [61,62]. Fourth is the barrier of the access threshold of the WEEE recycling market . The access threshold of the WEEE recycling market is relatively low in China, resulting in large amounts of WEEE being recycled and dismantled by unqualified recyclers such as individual retail stalls, waste recycling stations, and illegal dismantling workshops [10]. The fifth barrier is the WEEE inventory . This refers to the total amount of WEEE on the market that is not collected and recycled. At present, the Chinese WEEE market processes quite a lot of WEEE inventory, because only 20% of WEEE is properly recycled and treated through the formal channel every year [63]. The sixth barrier is the annual amount of e-waste . The quantity of WEEE in China will reach 27.22 Mt in 2030, with an average annual growth rate of 10.4%. The repaid growth of e-waste brings great pressure to the Chinese WEEE recycling industry [25].

At the micro level, we summarize six barriers from the government’s perspective. The first barrier is levy product disposing fund . Without a product disposing fund, the government may bear additional financial burden [33]. The second barrier is grant financial subsidy . The subsidy amount of the Chinese government to formal collectors is insufficient [14,33]. The third barrier is product categories of subsidy . There are few categories of WEEE that can accept subsidies according to the existing policies and regulations [11]. The fourth barrier is the social propaganda of WEEE . The government does not promote public awareness of the value and harm of WEEE [64]. The fifth barrier is the regulatory mechanism . The government does not enact an effective regulatory mechanism to supervise the behaviors of manufacturers and collectors [65]. The sixth barrier is encourage product design . The existing e-waste policies and regulations cannot promote electronic producers to manufacture products with environmental attributes [16,66,67].

At the micro level, we summarize four barriers from the manufacturer’s perspective. The first barrier is to take recyclability and reusability into account at the product design period . The product design ability of the manufacturer is insufficient, resulting in a relatively high recycling cost for collectors [14,16,68,69]. The second barrier is green sales . The manufacturer does not reduce environmental pollution in the sales process by decreasing product packaging and using green materials [70,71]. The third barrier is collection channels . The inconvenience and blockage of collection channels lead to diseconomies of scale [72,73]. The fourth barrier is to cooperate with formal collectors . Manufacturers and formal collectors operate e-waste management independently [74,75].

At the micro level, we summarize six barriers from the formal collector’s perspective. The first barrier is qualified disassembly . A relatively higher compliance cost results in a lower profit for the formal collector [10,36,76]. The second barrier is additional investment costs . The additional investment costs of purchasing green technologies and equipment bring the cost burden for formal collectors [36,77]. The third barrier is the quality of staff . The staff is not proficient in the technology of dismantling or treating WEEE [78,79]. The fourth barrier is collection efficiencies . The collection efficiency of formal collectors is low because of the existence of informal collectors [9,72]. The fifth barrier is mandatory targets . The mandatory target in the take-back legislation increases the recycling costs of formal collectors [40,80]. The sixth barrier is the quality of WEEE . The quality of WEEE impacts the recycling efficiency and the profit of formal collectors [12].

At the micro level, we summarize four barriers from the informal collector’s perspective. The first barrier is unqualified disassembly . The illegal activity of informal collectors negatively effects the development of the WEEE recycling industry [10,76,81]. The second barrier is tradeoffs between benefits and penalty . This means that informal collectors make tradeoffs between benefits and the government’s penalty mechanism. Currently, for the informal collectors, the benefit from treating WEEE is higher than the penalty due to unqualified disassembly [76,81,82]. The third barrier is the upgrade to formal collectors . This means that the informal collector introduces environmental technologies and equipment and upgrades the original production line to satisfy the recycling standards. However, the informal collector can obtain higher profits from unqualified disassembly than from qualified disassembly. Hence, the informal collector is not willing to upgrade to a formal collector [10,76]. The fourth barrier is cooperative behaviors . The informal collector has no incentives to cooperate with other stakeholders to collect and recycle WEEE [83].

At the micro level, we summarize four barriers from the consumer’s perspective. The first barrier is public awareness towards WEEE . Some consumers are not aware of the ramifications of WEEE on resources, the environment, and public health [10,12,84]. The second barrier is green recycling behaviors . Most consumers will not take WEEE to the formal collection channel [40,85,86]. The third barrier is a preference for green products . The consumer’s willingness to pay for green products is lower than for new products [40,87]. The fourth barrier is recognition of formal and informal collectors . Consumers cannot accurately identify formal and informal collectors, resulting in much WEEE flow to the informal sector [78].

Then, we invited and sent the questionnaire to the eight experts, who used linguistic variables to judge the importance of 30 barriers, and the results are shown in Table A1, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7 and Table A8 of Appendix A. To simplify, we used barrier as an example to illustrate the calculation process of the fuzzy Delphi technique. Using statistical results of the questionnaire, the judgment results of the eight experts on barrier were obtained, as shown in Table 5.

Table 5.

Judgment results of .

Next, based on Equations (2)–(4), the integrated fuzzy number was obtained by combining the judgment results of the eight experts on barrier . Furthermore, the defuzzification values of were calculated according to Equation (5). The specific calculations are as follows.

Finally, the threshold is set to 0.6 in this paper. This threshold is taken from the linguistic scale (given in Table 1) and it is the average of the minimum value of the linguistic variable “important” (0.5) and the maximum value of the linguistic variable “normal” (0.7) [43,44]. The threshold value acts as a criterion to filter barriers. Due to , we selected the barrier .

Similarly, integrated fuzzy numbers and defuzzification values of other barriers can be obtained. By comparing the defuzzification values of each barrier to the threshold value, the decision to select or reject a barrier can be made. All the selected and rejected barriers are given in Table 6. As can be seen from Table 6, selected barriers in the sustainable development of the Chinese WEEE recycling market are construction of policies and regulations (C1), implementation of policies and regulations (C2), grant financial subsidy (C3), the regulatory mechanism (C4), encourage product design (C5), qualified disassembly (C6), unqualified disassembly (C7), public awareness towards WEEE (C8), and green recycling behaviors (C9).

Table 6.

The result of using fuzzy Delphi technique.

4.2. Identifying Critical Barriers and Their Cause–Effect Relationships

By calculating and analyzing in Section 4.1, nine barriers that influence the sustainable development of the Chinese WEEE recycling industry were obtained. This section identifies critical barriers and their cause–effect relationships using the improved DEMATEL method.

First of all, eight experts were invited to provide their judgments on the existences and intensities of the influence relationships among nine barriers. The judgment results provided by the eight experts in the form of linguistic terms according to Table 2, i.e., eight initial direct-relation matrices, are shown in Table A9, Table A10, Table A11, Table A12, Table A13, Table A14, Table A15 and Table A16 of Appendix B. Then, matrices were transformed into by using Equations (6) and (7), and the results are shown in Appendix B. Furthermore, the group direct-relation matrix (as shown in Table 7) was constructed by combining direct-relation matrices based on Equations (8)–(12).

Table 7.

Group direct-relation matrix .

From Equation (13), matrix was changed into normalized direct-relation matrix (as shown in Table 8).

Table 8.

Normalized direct-relation matrix .

Based on matrix , indirect-relation matrix (as shown in Table 9) was constructed using Equation (14).

Table 9.

Indirect-relation matrix .

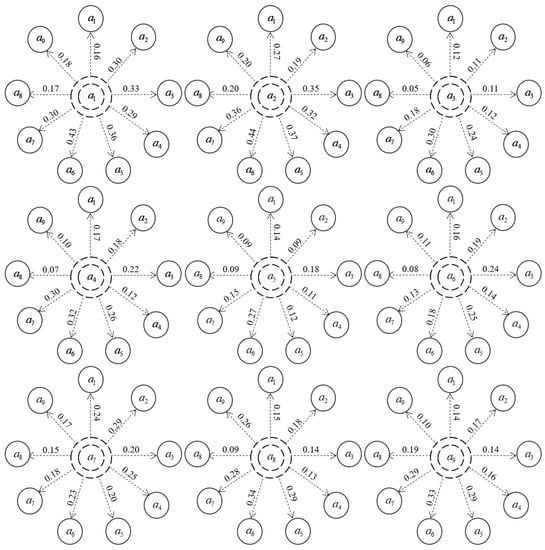

Based on matrices and , overall-relation matrix (as shown in Table 10) was developed using Equation (15). According to matrix , the overall relation of each barrier to other ones are vividly shown in Figure 3.

Table 10.

Overall-relation matrix .

Figure 3.

Overall relation between the barriers.

Further, and values of each barrier were calculated according to Table 10 and Equations (16) and (17). The importance of each barrier was obtained based on values, and cause and effect barriers were identified based on values, as given in Table 11.

Table 11.

The prominence and relation of barriers.

Finally, threshold value was calculated by using Equation (18), and we obtained the interaction matrix , as shown in Table 12.

Table 12.

Interaction matrix (the symbol * means that the row barriers have great influence on column barriers).

4.3. Result and Discussion

An expert decision-making system based on the fuzzy Delphi technique and the improved DEMATEL method is developed in this paper to analyze and identify various barriers that significantly impact the development of the Chinese WEEE recycling industry. A total of nine barriers were selected through the fuzzy Delphi technique. Then, the improved DEMATEL method provided the prominence of barriers and divided them into cause factors and effect factors.

The values of in Table 11 reflect the prominence (i.e., the overall importance) of each barrier, and the prominence in a descending order was obtained as: C2 > C6 > C7 > C1 > C5 > C4 > C3 > C9 > C8. Further, these nine barriers were divided into cause factors and effect factors based on their positive and negative values of . Out of the nine barriers, five barriers, i.e., implementation of policies and regulations (C2), construction of policies and regulations (C1), public awareness towards WEEE (C8), green recycling behaviors (C9), and regulatory mechanism (C4) belong to the cause group and are the major driving barriers in the development of the Chinese WEEE recycling industry. Additionally, negative values of put the barriers, which include qualified disassembly (C6), encourage eco-design (C5), grant financial subsidy (C3), and unqualified disassembly (C7), into the effect group.

It is clear from Table 11 that “implementation of policies and regulations (C2)” has the highest importance among all barriers. Meanwhile, it is a cause factor and has the highest inter-relationship with the other eight barriers, as shown in the third row of the interaction matrix (see Table 12). This result means that the current Chinese e-waste take-back policy implementations cannot effectively divert as much WEEE as possible from landfills and provide design incentives for producers. Furthermore, our results also show that qualified disassembly (C6) and unqualified disassembly (C7) have relatively higher importance among all barriers. Both the two barriers belong to the effect group and are significantly affected by other barriers, as shown in the seventh and eighth rows of the interaction matrix, respectively. This result implies that the informal activities indeed pose challenges to the whole WEEE recycling industry in China. The informal collectors’ unqualified disassembly methods harm the environment, and their complex networks and process efficiency contribute to the failure of some formal initiatives. In addition, public awareness towards WEEE (C8) has the least importance and also has no or a low inter-relationship with other barriers. Hence, this barrier is the most independent factor among all barriers.

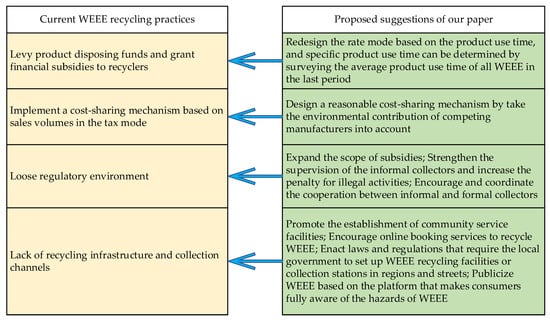

5. Practical Implications

Through the expert decision-making system based on the hybrid fuzzy Delphi and improved DEMETAL approach, we conclude that implementation of policies and regulations (C2), qualified disassembly (C6), and unqualified disassembly (C7) are the three most critical barriers among all factors that influence the development of the Chinese WEEE recycling industry. Therefore, the inefficiency of e-waste take-back legislation (i.e., the difficulty in applying Extended Producer Responsibility), that fact that formal and informal collectors coexist in the market, and that informal activities negatively influence the closed-loop supply chains (in collection, refurbishment, treatment, recycling, and secondary markets) are the main challenges faced by the Chinese government. According to the status quo of the Chinese WEEE recycling industry, we put forward the following practical implications:

- (1) Optimize the implementation details of the e-waste take-back legislation. Currently, there exist two prevailing e-waste take-back policies that differ in the manufacturer responsibility in China. In the rate mode, the electronic producer is operationally responsible for WEEE recycling activities and collects and recycles its own brand-name products independently. Meanwhile, the government subsidizes electronic producers based on the end-of-life products they collect and imposes the mandatory target to them. In this type of take-back legislation, the product disposal fund collected by the government from electronic manufacturers is not sufficient to provide disposal subsidies. To address this issue, the government should redesign the rate mode based on the product use time, and specific product use time can be determined by surveying the average product use time of all WEEE in the last period. For WEEE that during the product use time is recycled by formal collectors, they can receive financial subsidies according to the amount and type of recycled WEEE. The residual value and recyclability of WEEE, which is beyond its product use time, are low, and these used cores are virtually impossible to remanufacture for resale. Thus, these used cores are recycled by the government to avoid the ramifications of WEEE on the environment and public health. The improved EPR system clarifies collectors’ responsibilities and goals and alleviates the government’s fiscal deficit.

- In the tax mode, the government operates the WEEE recycling activity, while electronic manufacturers are financially responsible for e-waste management and should equally pay the relevant recycling costs based on a previously agreed rule (e.g., return volumes or market shares). Some electronic manufacturers argue that the tax mode forces an unfair sharing of product recycling costs among competing manufacturers and does not reward product designs that facilitate product recycling, thus diminishing incentives for design for product recovery. Therefore, the important factor in improving the cost efficiency in tax model is designing a reasonable cost-sharing mechanism by taking the environmental contribution of competing manufacturers into account. Moreover, the government should correctly return shares to reflect the actual rates of sales volumes and account for the recycling cost heterogeneity and group incentive compatibility in the tax mode.

- (2) Establish a flexible reward–supervision–penalty mechanism to support the formal collector. First, the government should design flexible product categories and standards of the subsidy. At present, the Chinese government subsidizes five major types of household appliances (televisions, refrigerators, washing machines, air conditioners, and microcomputers), but not other types of EEE such as tablets, kettles, and keyboards. Meanwhile, higher subsidy standards for some EEE, such as refrigerators, negatively impact the sustainable development of the WEEE recycling industry. Therefore, the government should gradually expand the scope of subsidies to reduce the impact of WEEE on the environment, resources, and public health. In addition, a dynamic subsidy standard should be established according to the surveys and forecasts by the national statistical department.

- Second, a soft supervision–penalty mechanism should be established. The government should strengthen the supervision of the informal collectors and increase the penalty for illegal activities. However, the penalty should not be too high. The reason is that many people earn their living by collecting and dismantling WEEE, and many informal recyclers will leave the market if the fines are too high. Cutting off the source of income for these people would affect the stability of society. Thus, it is necessary to establish a soft supervision–penalty mechanism.

- Finally, the government should encourage and coordinate the cooperation between informal and formal collectors, which can combine the market advantages of informal collectors with the advanced technologies of formal collectors to promote the sustainable development of the WEEE recycling industry. In addition, the government should encourage manufacturers to practice product eco-design implementations to decrease the disposal costs of collectors. For manufacturers who choose product eco-design, the government should reduce their environmental taxes. In contrast, the government should maintain the same percentage of taxation for manufacturers who do not choose the eco-design strategy.

- (3) Improve the collection efficiency. It is known that convenience is a key factor in the consumer selection of collectors. Hence, the government should promote the establishment of community service facilities. As a key development task of the service facility, the collection station will dramatically improve its convenience. Furthermore, with the development of the internet and the mobile internet, the government may encourage online booking services to recycle WEEE. For example, the YiFeiBao that has been tried relies on the application platforms of mobile phones; the web-based Gome shopping mall and Baidu online recovery station are also providing convenient services. The collection station is bound to be eventually integrated into the network platform. Consumers could then obtain their community services in the shortest amount of time without leaving their homes. Therefore, the consumer is likely to be willing to select the formal collection station in the near future.

- The lack of collecting channels for formal collectors is also due to insufficient recycling infrastructure. The government should enact laws and regulations that require the local government to set up WEEE recycling facilities or collection stations in regions and streets and cooperate with formal collectors to take the collected WEEE to them. Mandatory legislation will prevent WEEE from diverting into informal collecting channels to the greatest extent possible. In addition, the government should publicize WEEE based on the platform that makes consumers fully aware of the hazards of WEEE to resources, the environment, and public health, thus promoting consumers to voluntarily submit their WEEE to formal collectors and improving the development of the WEEE recycling industry.

- Finally, we provide Figure 4 to summarize and compare the current WEEE recycling practices in China and the proposed suggestions of this paper.

Figure 4. Current WEEE recycling practices and proposed suggestions.

Figure 4. Current WEEE recycling practices and proposed suggestions.

6. Conclusions and Limitations

In this paper, we developed an expert decision-making system to understand the barriers that influence the development of the Chinese WEEE recycling industry. First, we determined barriers by using the fuzzy Delphi technique. Then, we identified critical barriers and their cause–effect relationships by using the improved DEMETAL method.

Our results show that nine barriers influence the sustainable development of Chinese WEEE recycling industry. Among these development barriers, implementation of policies and regulations (C2), qualified disassembly (C6), and unqualified disassembly (C7) are the three most critical barriers among all factors. Furthermore, implementation of policies and regulations (C2) belongs to the cause group, and it has the highest inter-relationship with the other eight barriers. Qualified disassembly (C6) and unqualified disassembly (C7) belong to the effect group, and they are significantly affected by other barriers. Our results demonstrate that the inefficiency of e-waste take-back legislation, the fact that formal and informal collectors coexist in the market, and that informal activities negatively influence the closed-loop supply chains are the main challenges faced by the Chinese government. Based on the status quo of the Chinese WEEE recycling industry, we suggest that the government should optimize the implementation details of the e-waste take-back legislation, establish a flexible reward–supervision–penalty mechanism to support the formal collector, and improve the collection efficiency.

There are some limitations in this work. Although a significant number of experts are involved in this study, there might be some bias in the opinion of the experts. A hierarchical DEMETAL method, which is suitable for the complex systems with numerous system factors, multiple types of influences, and the existence of hierarchy, can effectively reduce bias. How to improve the development of the WEEE recycling industry is a significant problem around the world. Next, we will study the WEEE recycling industry in different countries and regions to provide general conclusions and managerial implications in the future research. In addition, the improved DEMATEL method used in this study has the inherent drawback of over-relying on the subjective judgment of experts. In terms of future research, some new methods need to be developed to solve the problems of development barrier identification with hybrid interdependent information such as numerical values, interval numbers, and linguistic terms.

Author Contributions

Conceptualization, X.W.; methodology, X.W.; formal analysis, Q.W.; investigation, Q.W.; resources, Q.W.; data curation, X.W.; writing—original draft preparation, X.W.; writing—review and editing, Q.W.; visualization, X.W.; supervision, Q.W.; project administration, Q.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. KYCX22_0386); General Project of Philosophy and Social Sciences Research in Jiangsu Universities (2021SJA0486).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Initial direct-relation matrix .

Table A1.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | H | VH | VH | VH | H | VL | VL | VL |

| C2 | H | No | VH | VH | H | L | VL | VL | VL |

| C3 | L | No | No | No | VH | VH | H | No | No |

| C4 | L | No | H | No | H | H | VH | No | No |

| C5 | L | No | VH | L | No | H | H | No | No |

| C6 | VH | VH | H | No | H | No | No | No | No |

| C7 | VH | VH | L | VH | VL | No | No | VH | H |

| C8 | VL | VL | No | No | VH | VH | VH | No | VH |

| C9 | VL | VL | No | VL | VH | VH | VH | H | No |

Table A2.

Initial direct-relation matrix .

Table A2.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | H | L | VL | VL | VH | L | VH | H |

| C2 | VL | No | No | L | L | VH | VH | H | H |

| C3 | No | No | No | No | VH | VH | No | No | No |

| C4 | No | VL | No | No | No | VH | VH | No | No |

| C5 | No | No | No | No | No | L | No | L | VL |

| C6 | VL | H | H | No | No | No | No | No | No |

| C7 | No | VH | No | No | No | No | No | No | No |

| C8 | No | L | No | No | VL | H | No | No | VH |

| C9 | No | VL | No | No | VL | H | L | VL | No |

Table A3.

Initial direct-relation matrix .

Table A3.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | H | H | VH | VH | H | H | L | VL |

| C2 | H | No | VH | VH | VH | VH | VH | H | H |

| C3 | VL | No | No | L | VH | VH | H | No | No |

| C4 | L | No | H | No | L | H | VH | No | L |

| C5 | L | No | VH | VL | No | VH | L | No | No |

| C6 | H | H | VH | H | VH | No | No | No | No |

| C7 | VH | VH | No | VH | VL | No | No | No | No |

| C8 | L | L | No | L | VH | VH | VH | No | VH |

| C9 | VL | VL | No | L | VH | VH | VH | H | No |

Table A4.

Initial direct-relation matrix .

Table A4.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | H | H | H | H | VH | L | H | L |

| C2 | L | No | H | H | L | H | H | H | L |

| C3 | No | No | No | No | VH | VH | H | No | No |

| C4 | No | L | L | No | L | H | VH | No | No |

| C5 | L | No | VL | L | No | H | L | L | L |

| C6 | VL | VH | H | No | L | No | No | No | No |

| C7 | VL | VH | L | VL | No | No | No | L | VL |

| C8 | No | VL | No | No | H | VL | H | No | VH |

| C9 | No | VL | No | VL | H | VL | H | VL | No |

Table A5.

Initial direct-relation matrix .

Table A5.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | VH | H | H | H | VH | H | VL | VL |

| C2 | H | No | VH | VH | H | VH | VH | L | L |

| C3 | L | No | No | VH | VH | VH | L | No | No |

| C4 | L | L | H | No | VH | VH | VH | No | No |

| C5 | L | No | H | No | No | H | No | No | No |

| C6 | No | No | H | L | L | No | No | No | L |

| C7 | VH | VH | No | VH | No | No | No | No | L |

| C8 | No | No | No | No | VH | VH | H | No | VH |

| C9 | No | VL | No | VL | VH | VH | VH | H | No |

Table A6.

Initial direct-relation matrix .

Table A6.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | L | H | H | H | H | VL | VL | VL |

| C2 | L | No | VH | VH | H | H | H | VL | VL |

| C3 | VL | VL | No | No | No | VH | L | No | No |

| C4 | VL | VL | No | No | H | H | VH | VL | VL |

| C5 | VL | VL | L | No | No | H | No | VL | VL |

| C6 | L | L | L | No | L | No | No | L | L |

| C7 | H | H | No | VH | No | No | No | H | H |

| C8 | VL | VL | No | No | H | VH | VH | No | VH |

| C9 | VL | VL | No | No | H | VH | VH | VH | No |

Table A7.

Initial direct-relation matrix .

Table A7.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | H | VH | VH | H | VH | L | L | L |

| C2 | H | No | VH | VH | L | H | H | L | L |

| C3 | No | No | No | No | VH | VH | L | No | No |

| C4 | No | L | L | No | H | VH | VH | No | No |

| C5 | L | No | No | VL | No | VH | VL | L | L |

| C6 | VL | VH | H | No | H | No | No | VL | VL |

| C7 | VH | VH | L | VL | No | No | No | L | VL |

| C8 | No | VL | No | No | VL | H | H | No | VH |

| C9 | No | VL | No | VL | H | VH | H | VH | No |

Table A8.

Initial direct-relation matrix .

Table A8.

Initial direct-relation matrix .

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | No | VH | H | H | H | VH | L | No | No |

| C2 | H | No | VH | VH | H | VH | VH | VL | VL |

| C3 | L | VL | No | VL | No | VH | VL | No | No |

| C4 | L | VL | L | No | H | VH | VH | No | No |

| C5 | L | No | L | No | No | H | L | No | No |

| C6 | No | VL | L | L | VH | No | No | No | L |

| C7 | VH | VH | H | VH | No | No | No | No | L |

| C8 | VL | VL | No | No | H | VH | VH | No | VH |

| C9 | VL | VL | No | VL | H | VH | VH | H | No |

Appendix B

Table A9.

Initial direct-relation matrix in the form of 2-tuples.

Table A9.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (H,0) | (VH,0) | (VH,0) | (VH,0) | (H,0) | (VL,0) | (VL,0) | (VL,0) |

| C2 | (H,0) | (No,0) | (VH,0) | (VH,0) | (H,0) | (L,0) | (VL,0) | (VL,0) | (VL,0) |

| C3 | (L,0) | (No,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (H,0) | (No,0) | (No,0) |

| C4 | (L,0) | (No,0) | (H,0) | (No,0) | (H,0) | (H,0) | (VH,0) | (No,0) | (No,0) |

| C5 | (L,0) | (No,0) | (VH,0) | (L,0) | (No,0) | (H,0) | (H,0) | (No,0) | (No,0) |

| C6 | (VH,0) | (VH,0) | (H,0) | (No,0) | (H,0) | (No,0) | (No,0) | (No,0) | (No,0) |

| C7 | (VH,0) | (VH,0) | (L,0) | (VH,0) | (VL,0) | (No,0) | (No,0) | (VH,0) | (H,0) |

| C8 | (VL,0) | (VL,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (VH,0) | (No,0) | (VH,0) |

| C9 | (VL,0) | (VL,0) | (No,0) | (VL,0) | (VH,0) | (VH,0) | (VH,0) | (H,0) | (No,0) |

Table A10.

Initial direct-relation matrix in the form of 2-tuples.

Table A10.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (H,0) | (L,0) | (VL,0) | (VL,0) | (VH,0) | (L,0) | (VH,0) | (H,0) |

| C2 | (VL,0) | (No,0) | (No,0) | (L,0) | (L,0) | (VH,0) | (VH,0) | (H,0) | (H,0) |

| C3 | (No,0) | (No,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (No,0) | (No,0) | (No,0) |

| C4 | (No,0) | (VL,0) | (No,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (No,0) | (No,0) |

| C5 | (No,0) | (No,0) | (No,0) | (No,0) | (No,0) | (L,0) | (No,0) | (L,0) | (VL,0) |

| C6 | (VL,0) | (H,0) | (H,0) | (No,0) | (No,0) | (No,0) | (No,0) | (No,0) | (No,0) |

| C7 | (No,0) | (VH,0) | (No,0) | (No,0) | (No,0) | (No,0) | (No,0) | (No,0) | (No,0) |

| C8 | (No,0) | (L,0) | (No,0) | (No,0) | (VL,0) | (H,0) | (No,0) | (No,0) | (VH,0) |

| C9 | (No,0) | (VL,0) | (No,0) | (No,0) | (VL,0) | (H,0) | (L,0) | (VL,0) | (No,0) |

Table A11.

Initial direct-relation matrix in the form of 2-tuples.

Table A11.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (H,0) | (H,0) | (VH,0) | (VH,0) | (H,0) | (H,0) | (L,0) | (VL,0) |

| C2 | (H,0) | (No,0) | (VH,0) | (VH,0) | (VH,0) | (VH,0) | (VH,0) | (H,0) | (H,0) |

| C3 | (VL,0) | (No,0) | (No,0) | (L,0) | (VH,0) | (VH,0) | (H,0) | (No,0) | (No,0) |

| C4 | (L,0) | (No,0) | (H,0) | (No,0) | (L,0) | (H,0) | (VH,0) | (No,0) | (L,0) |

| C5 | (L,0) | (No,0) | (VH,0) | (VL,0) | (No,0) | (VH,0) | (L,0) | (No,0) | (No,0) |

| C6 | (H,0) | (H,0) | (VH,0) | (H,0) | (VH,0) | (No,0) | (No,0) | (No,0) | (No,0) |

| C7 | (VH,0) | (VH,0) | (No,0) | (VH,0) | (VL,0) | (No,0) | (No,0) | (No,0) | (No,0) |

| C8 | (L,0) | (L,0) | (No,0) | (L,0) | (VH,0) | (VH,0) | (VH,0) | (No,0) | (VH,0) |

| C9 | (VL,0) | (VL,0) | (No,0) | (L,0) | (VH,0) | (VH,0) | (VH,0) | (H,0) | (No,0) |

Table A12.

Initial direct-relation matrix in the form of 2-tuples.

Table A12.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (H,0) | (H,0) | (H,0) | (H,0) | (VH,0) | (L,0) | (H,0) | (L,0) |

| C2 | (L,0) | (No,0) | (H,0) | (H,0) | (L,0) | (H,0) | (H,0) | (H,0) | (L,0) |

| C3 | (No,0) | (No,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (H,0) | (No,0) | (No,0) |

| C4 | (No,0) | (L,0) | (L,0) | (No,0) | (L,0) | (H,0) | (VH,0) | (No,0) | (No,0) |

| C5 | (L,0) | (No,0) | (VL,0) | (L,0) | (No,0) | (H,0) | (L,0) | (L,0) | (L,0) |

| C6 | (VL,0) | (VH,0) | (H,0) | (No,0) | (L,0) | (No,0) | (No,0) | (No,0) | (No,0) |

| C7 | (VL,0) | (VH,0) | (L,0) | (VL,0) | (No,0) | (No,0) | (No,0) | (L,0) | (VL,0) |

| C8 | (No,0) | (VL,0) | (No,0) | (No,0) | (H,0) | (VL,0) | (H,0) | (No,0) | (VH,0) |

| C9 | (No,0) | (VL,0) | (No,0) | (VL,0) | (H,0) | (VL,0) | (H,0) | (VL,0) | (No,0) |

Table A13.

Initial direct-relation matrix in the form of 2-tuples.

Table A13.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (VH,0) | (H,0) | (H,0) | (H,0) | (VH,0) | (H,0) | (VL,0) | (VL,0) |

| C2 | (H,0) | (No,0) | (VH,0) | (VH,0) | (H,0) | (VH,0) | (VH,0) | (L,0) | (L,0) |

| C3 | (L,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (VH,0) | (L,0) | (No,0) | (No,0) |

| C4 | (L,0) | (L,0) | (H,0) | (No,0) | (VH,0) | (VH,0) | (VH,0) | (No,0) | (No,0) |

| C5 | (L,0) | (No,0) | (H,0) | (No,0) | (No,0) | (H,0) | (No,0) | (No,0) | (No,0) |

| C6 | (No,0) | (No,0) | (H,0) | (L,0) | (L,0) | (No,0) | (No,0) | (No,0) | (L,0) |

| C7 | (VH,0) | (VH,0) | (No,0) | (VH,0) | (No,0) | (No,0) | (No,0) | (No,0) | (L,0) |

| C8 | (No,0) | (No,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (H,0) | (No,0) | (VH,0) |

| C9 | (No,0) | (VL,0) | (No,0) | (VL,0) | (VH,0) | (VH,0) | (VH,0) | (H,0) | (No,0) |

Table A14.

Initial direct-relation matrix in the form of 2-tuples.

Table A14.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (L,0) | (H,0) | (H,0) | (H,0) | (H,0) | (VL,0) | (VL,0) | (VL,0) |

| C2 | (L,0) | (No,0) | (VH,0) | (VH,0) | (H,0) | (H,0) | (H,0) | (VL,0) | (VL,0) |

| C3 | (VL,0) | (VL,0) | (No,0) | (No,0) | (No,0) | (VH,0) | (L,0) | (No,0) | (No,0) |

| C4 | (VL,0) | (VL,0) | (No,0) | (No,0) | (H,0) | (H,0) | (VH,0) | (VL,0) | (VL,0) |

| C5 | (VL,0) | (VL,0) | (L,0) | (No,0) | (No,0) | (H,0) | (No,0) | (VL,0) | (VL,0) |

| C6 | (L,0) | (L,0) | (L,0) | (No,0) | (L,0) | (No,0) | (No,0) | (L,0) | (L,0) |

| C7 | (H,0) | (H,0) | (No,0) | (VH,0) | (No,0) | (No,0) | (No,0) | (H,0) | (H,0) |

| C8 | (VL,0) | (VL,0) | (No,0) | (No,0) | (H,0) | (VH,0) | (VH,0) | (No,0) | (VH,0) |

| C9 | (VL,0) | (VL,0) | (No,0) | (No,0) | (H,0) | (VH,0) | (VH,0) | (VH,0) | (No,0) |

Table A15.

Initial direct-relation matrix in the form of 2-tuples.

Table A15.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (H,0) | (VH,0) | (VH,0) | (H,0) | (VH,0) | (L,0) | (L,0) | (L,0) |

| C2 | (H,0) | (No,0) | (VH,0) | (VH,0) | (L,0) | (H,0) | (H,0) | (L,0) | (L,0) |

| C3 | (No,0) | (No,0) | (No,0) | (No,0) | (VH,0) | (VH,0) | (L,0) | (No,0) | (No,0) |

| C4 | (No,0) | (L,0) | (L,0) | (No,0) | (H,0) | (VH,0) | (VH,0) | (No,0) | (No,0) |

| C5 | (L,0) | (No,0) | (No,0) | (VL,0) | (No,0) | (VH,0) | (VL,0) | (L,0) | (L,0) |

| C6 | (VL,0) | (VH,0) | (H,0) | (No,0) | (H,0) | (No,0) | (No,0) | (VL,0) | (VL,0) |

| C7 | (VH,0) | (VH,0) | (L,0) | (VL,0) | (No,0) | (No,0) | (No,0) | (L,0) | (VL,0) |

| C8 | (No,0) | (VL,0) | (No,0) | (No,0) | (VL,0) | (H,0) | (H,0) | (No,0) | (VH,0) |

| C9 | (No,0) | (VL,0) | (No,0) | (VL,0) | (H,0) | (VH,0) | (H,0) | (VH,0) | (No,0) |

Table A16.

Initial direct-relation matrix in the form of 2-tuples.

Table A16.

Initial direct-relation matrix in the form of 2-tuples.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | (No,0) | (VH,0) | (H,0) | (H,0) | (H,0) | (VH,0) | (L,0) | (No,0) | (No,0) |

| C2 | (H,0) | (No,0) | (VH,0) | (VH,0) | (H,0) | (VH,0) | (VH,0) | (VL,0) | (VL,0) |

| C3 | (L,0) | (VL,0) | (No,0) | (VL,0) | (No,0) | (VH,0) | (VL,0) | (No,0) | (No,0) |

| C4 | (L,0) | (VL,0) | (L,0) | (No,0) | (H,0) | (VH,0) | (VH,0) | (No,0) | (No,0) |

| C5 | (L,0) | (No,0) | (L,0) | (No,0) | (No,0) | (H,0) | (L,0) | (No,0) | (No,0) |

| C6 | (No,0) | (VL,0) | (L,0) | (L,0) | (VH,0) | (No,0) | (No,0) | (No,0) | (L,0) |

| C7 | (VH,0) | (VH,0) | (H,0) | (VH,0) | (No,0) | (No,0) | (No,0) | (No,0) | (L,0) |

| C8 | (VL,0) | (VL,0) | (No,0) | (No,0) | (H,0) | (VH,0) | (VH,0) | (No,0) | (VH,0) |

| C9 | (VL,0) | (VL,0) | (No,0) | (VL,0) | (H,0) | (VH,0) | (VH,0) | (H,0) | (No,0) |

References

- Wang, Q.; Li, B.; Chen, B.; Cheng, Y.; Wang, Z. Implication of take-back and carbon emission capacity regulations on remanufacturing in a competitive market. J. Clean. Prod. 2021, 325, 129231. [Google Scholar] [CrossRef]

- Zhao, X.; Bai, X. How to motivate the producers’ green innovation in WEEE recycling in China?–An analysis based on evolutionary game theory. Waste Manag. 2021, 122, 26–35. [Google Scholar] [CrossRef]

- Zlamparet, G.I.; Ijomah, W.; Miao, Y.; Awasthi, A.K.; Zeng, X.L.; Li, J.H. Remanufacturing strategies: A solution for WEEE problem. J. Clean. Prod. 2017, 149, 126–136. [Google Scholar] [CrossRef]

- Islam, M.T.; Abdullah, A.B.; Shahir, S.A.; Kalam, M.A.; Masjuki, H.H.; Shumon, R.; Rashid, M.H. A public survey on knowledge, awareness, attitude and willingness to pay for WEEE management: Case study in Bangladesh. J. Clean. Prod. 2016, 137, 728–740. [Google Scholar] [CrossRef]

- Fu, J.J.; Zhang, H.Y.; Zhang, A.Q.; Jiang, G.B. E-waste Recycling in China: A Challenging Field. Environ. Sci. Technol. 2018, 52, 6727–6728. [Google Scholar] [CrossRef] [PubMed]

- Sousa, R.; Agante, E.; Cerejeira, J.; Portela, M. EEE fees and the WEEE system–A model of efficiency and income in European countries. Waste Manag. 2018, 79, 770–780. [Google Scholar] [CrossRef]

- Zeng, X.L.; Duan, H.B.; Wang, F.; Li, J.H. Examining environmental management of e-waste: China’s experience and lessons. Renew. Sust. Energ. Rev. 2017, 72, 1076–1082. [Google Scholar] [CrossRef]

- Zuo, L.S.; Wang, C.; Sun, Q. Sustaining WEEE collection business in China: The case of online to offline (O2O) development strategies. Waste Manag. 2020, 101, 222–230. [Google Scholar] [CrossRef]

- Wang, B.; Ren, C.Y.; Dong, X.Y.; Zhang, B.; Wang, Z.H. Determinants shaping willingness towards on-line recycling behaviour: An empirical study of household e-waste recycling in China. Resour. Conserv. Recycl. 2019, 143, 218–225. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.X.; Chen, B.X.; Wang, Y. Evolutionary game analysis on behavioral strategies of multiple stakeholders in E-waste recycling industry. Resour. Conserv. Recycl. 2020, 155, 104618. [Google Scholar] [CrossRef]

- Wang, J.F.; Wang, Y.H.; Liu, J.; Zhang, S.J.; Zhang, M. Effects of fund policy incorporating Extended Producer Responsibility for WEEE dismantling industry in China. Resour. Conserv. Recycl. 2018, 130, 44–50. [Google Scholar] [CrossRef]

- Liu, H.; Lei, M.; Deng, H.; Keong Leong, G.; Huang, T. A dual channel, quality-based price competition model for the WEEE recycling market with government subsidy. Omega 2016, 59, 290–302. [Google Scholar] [CrossRef]

- Liu, X.B.; Tanaka, M.; Matsui, Y. Electrical and electronic waste management in China: Progress and the barriers to overcome. Waste Manag. Res. 2006, 24, 92–101. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.F.; Wu, Y.F.; Xu, M.; Wang, H.D.; Zuo, T.Y. To realize better extended producer responsibility: Redesign of WEEE fund mode in China. J. Clean. Prod. 2017, 164, 347–356. [Google Scholar] [CrossRef]

- Zhang, X.-M.; Li, Q.-W.; Liu, Z.; Chang, C.-T. Optimal pricing and remanufacturing mode in a closed-loop supply chain of WEEE under government fund policy. Comput. Ind. Eng. 2021, 151, 106951. [Google Scholar] [CrossRef]

- Wang, H.D.; Gu, Y.F.; Li, L.Q.; Liu, T.L.; Wu, Y.F.; Zuo, T.Y. Operating models and development trends in the extended producer responsibility system for waste electrical and electronic equipment. Resour. Conserv. Recycl. 2017, 127, 159–167. [Google Scholar] [CrossRef]

- Gu, Y.; Wu, Y.; Xu, M.; Wang, H.; Zuo, T. The stability and profitability of the informal WEEE collector in developing countries: A case study of China. Resour. Conserv. Recycl. 2016, 107, 18–26. [Google Scholar] [CrossRef]

- Wang, Q.; Li, B.; Chen, B.; Wang, Z.; Liu, W.; Cheng, Y. Impact of product design on remanufacturing under environmental legislation. Comput. Ind. Eng. 2022, 165, 107889. [Google Scholar] [CrossRef]

- Pourakbar, M.; van der Laan, E.; Dekker, R. End-of-Life Inventory Problem with Phaseout Returns. Prod. Oper. Manag. 2014, 23, 1561–1576. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Liu, Z.; Cheng, J.; Chen, X. Strategic management of product recovery and its environmental impact. Int. J. Prod. Res. 2020, 59, 6104–6124. [Google Scholar] [CrossRef]

- Chen, Y.; Li, B.; Zhang, G.; Bai, Q. Quantity and collection decisions of the remanufacturing enterprise under both the take-back and carbon emission capacity regulations. Transp. Res. Part E Logist. Transp. 2020, 141, 102032. [Google Scholar] [CrossRef]

- Liu, W.; Li, B.; Wang, Z.; Wang, Q.; Chen, Y.; Cheng, Y. Consequence analysis for integrating remanufactured products for social donation (RSD) under mandatory take-back regulation. Comput. Ind. Eng. 2022, 171, 108468. [Google Scholar] [CrossRef]

- Miao, Z.; Fu, K.; Xia, Z.; Wang, Y. Models for closed-loop supply chain with trade-ins. Omega 2017, 66, 308–326. [Google Scholar] [CrossRef]

- Esenduran, G.; Kemahlıoğlu-Ziya, E.; Swaminathan, J.M. Take-back legislation: Consequences for remanufacturing and environment. Decision Sci. 2016, 47, 219–256. [Google Scholar] [CrossRef]

- Esenduran, G.; Kemahlıoğlu-Ziya, E.; Swaminathan, J.M. Impact of take-back regulation on the remanufacturing industry. Prod. Oper. Manag. 2017, 26, 924–944. [Google Scholar] [CrossRef]

- Krass, D.; Nedorezov, T.; Ovchinnikov, A. Environmental taxes and the choice of green technology. Prod. Oper. Manag. 2013, 22, 1035–1055. [Google Scholar] [CrossRef]

- Drake, D.F.; Kleindorfer, P.R.; Van Wassenhove, L.N. Technology choice and capacity portfolios under emissions regulation. Prod. Oper. Manag. 2016, 25, 1006–1025. [Google Scholar] [CrossRef]

- Ovchinnikov, A. Revenue and cost management for remanufactured products. Prod. Oper. Manag. 2011, 20, 824–840. [Google Scholar] [CrossRef]

- Ovchinnikov, A.; Blass, V.; Raz, G. Economic and environmental assessment of remanufacturing strategies for product+ service firms. Prod. Oper. Manag. 2014, 23, 744–761. [Google Scholar] [CrossRef]

- Toyasaki, F.; Boyacι, T.; Verter, V. An analysis of monopolistic and competitive take-back schemes for WEEE recycling. Prod. Oper. Manag. 2011, 20, 805–823. [Google Scholar] [CrossRef]

- Wang, W.B.; Ding, J.F.; Sun, H. Reward-penalty mechanism for a two-period closed-loop supply chain. J. Clean. Prod. 2018, 203, 898–917. [Google Scholar] [CrossRef]

- Heacock, M.; Kelly, C.B.; Asante, K.A.; Birnbaum, L.S.; Bergman, A.L.; Brune, M.N.; Buka, I.; Carpenter, D.O.; Chen, A.M.; Huo, X.; et al. E-Waste and Harm to Vulnerable Populations: A Growing Global Problem. Environ. Health Persp. 2016, 124, 550–555. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, J.; Li, B.Y.; Wang, Z. Trade-off between remanufacturing and recycling of WEEE and the environmental implication under the Chinese Fund Policy. J. Clean. Prod. 2017, 167, 97–109. [Google Scholar] [CrossRef]

- Shan, F.; Xiao, W.; Yang, F. Comparison of three E-Waste take-back policies. Int. J. Prod. Econ. 2021, 242, 108287. [Google Scholar] [CrossRef]

- Calcott, P.; Walls, M. Can downstream waste disposal policies encourage upstream ”design for environment”? Am. Econ. Rev. 2000, 90, 233–237. [Google Scholar] [CrossRef]

- Zhou, W.H.; Zheng, Y.F.; Huang, W.X. Competitive advantage of qualified WEEE recyclers through EPR legislation. Eur. J. Oper. Res. 2017, 257, 641–655. [Google Scholar] [CrossRef]

- Nouri, D.; Sabour, M.; Lak, M.G. Environmental and technical modeling of industrial solid waste management using analytical network process; A case study: Gilan-Iran. World Acad. Sci. Eng. Technol. 2011, 81, 130–136. [Google Scholar]

- Kumar, S.; Hassan, M.I. Selection of a Landfill Site for Solid Waste Management: An Application of AHP and Spatial Analyst Tool. J. Indian Soc. Remote 2013, 41, 45–56. [Google Scholar] [CrossRef]

- Ravi, V. Analysis of interactions among barriers of eco-efficiency in electronics packaging industry. J. Clean. Prod. 2015, 101, 16–25. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, G. Evaluating critical barriers to implementation of WEEE management using DEMATEL approach. Resour. Conserv. Recycl. 2018, 131, 101–121. [Google Scholar] [CrossRef]

- Ahmed, S.; Ahmed, S.; Shumon, M.R.H.; Falatoonitoosi, E.; Quader, M.A. A comparative decision-making model for sustainable end-of-life vehicle management alternative selection using AHP and extent analysis method on fuzzy AHP. Int. J. Sust. Dev. World 2016, 23, 83–97. [Google Scholar] [CrossRef]

- Kumar, M.S.; Sunil, L.; Kumar, J.S.; Mohit, T.; Eknath, N.B.; Angappa, G. Benchmarking the logistics management implementation using Delphi and fuzzy DEMATEL. Benchmarking-Int. J. 2018, 25, 1795–1828. [Google Scholar]

- Singh, P.K.; Sarkar, P. A framework based on fuzzy Delphi and DEMATEL for sustainable product development: A case of Indian automotive industry. J. Clean. Prod. 2020, 246, 118991. [Google Scholar] [CrossRef]

- Kumar, A.; Dash, M.K. Causal modelling and analysis evaluation of online reputation management using fuzzy Delphi and DEMATEL. Int. J. Strateg. Decis. Sci. 2017, 8, 27–45. [Google Scholar] [CrossRef][Green Version]

- Mohandes, S.R.; Sadeghi, H.; Fazeli, A.; Mahdiyar, A.; Hosseini, M.R.; Arashpour, M.; Zayed, T. Causal analysis of accidents on construction sites: A hybrid fuzzy Delphi and DEMATEL approach. Safety Sci. 2022, 151, 105730. [Google Scholar] [CrossRef]

- Liao, H.L. A Study on the Key Factors of CSR Indicators for Tenderers in Procurement Screening Using the Delphi Method and DEMATEL-Based Analytic Network Process. Adm. Sci. 2022, 12, 151. [Google Scholar]

- Dalkey, N.; Helmer, O. An experimental application of the Delphi method to the use of experts. Manag. Sci. 1963, 9, 458–467. [Google Scholar] [CrossRef]

- Ishikawa, A.; Amagasa, M.; Shiga, T.; Tomizawa, G.; Tatsuta, R.; Mieno, H. The max-min Delphi method and fuzzy Delphi method via fuzzy integration. Fuzzy Sets Syst. 1993, 55, 241–253. [Google Scholar] [CrossRef]

- Bui, T.D.; Tsai, F.M.; Tseng, M.L.; Ali, M.H. Identifying sustainable solid waste management barriers in practice using the fuzzy Delphi method. Resour. Conserv. Recycl. 2020, 154, 104625. [Google Scholar] [CrossRef]

- Bhosale, V.A.; Kant, R. An integrated fuzzy Delphi and fuzzy inference system for ranking the solutions to overcome the supply chain knowledge flow barriers. Int. J. Inf. Decis. Sci. 2019, 11, 320–354. [Google Scholar] [CrossRef]

- Zhang, J.K. Evaluating regional low-carbon tourism strategies using the fuzzy Delphi-analytic network process approach. J. Clean. Prod. 2017, 141, 409–419. [Google Scholar] [CrossRef]

- Wang, Y.; Yeo, G.-T. Intermodal route selection for cargo transportation from Korea to Central Asia by adopting Fuzzy Delphi and Fuzzy ELECTRE I methods. Marit. Policy. Manag. 2018, 45, 3–18. [Google Scholar] [CrossRef]

- Gabus, A.; Fontela, E. Perceptions of the World Problematique: Communication Procedure, Communicating with Those Bearing Collective Responsibility; Battelle Geneva Research Centre: Geneva, Switzerland, 1973. [Google Scholar]

- Fan, Z.; Suo, W.; Feng, B. Identifying risk factors of IT outsourcing using interdependent information: An extended DEMATEL method. Expert Syst. Appl. 2012, 39, 3832–3840. [Google Scholar] [CrossRef]

- Li, D.F.; Wan, S.P. A fuzzy inhomogenous multiattribute group decision making approach to solve outsourcing provider selection problems. Knowl.-Based Syst. 2014, 67, 71–89. [Google Scholar] [CrossRef]

- Ju, Y.B.; Wang, A.H.; You, T.H. Emergency alternative evaluation and selection based on ANP, DEMATEL, and TL-TOPSIS. Nat. Hazards. 2015, 75, S347–S379. [Google Scholar] [CrossRef]

- Liu, H.C.; You, J.X.; Lu, C.; Chen, Y.Z. Evaluating health-care waste treatment technologies using a hybrid multi-criteria decision making model. Renew. Sust. Energ. Rev. 2015, 41, 932–942. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Li, B.Y.; Liu, Z.; Zhu, X.D.; Wang, Q.X. Closed-loop supply chain models with product recovery and donation. J. Clean. Prod. 2019, 227, 861–876. [Google Scholar] [CrossRef]

- Cole, C.; Gnanapragasam, A.; Cooper, T.; Singh, J. An assessment of achievements of the WEEE Directive in promoting movement up the waste hierarchy: Experiences in the UK. Waste Manag. 2019, 87, 417–427. [Google Scholar] [CrossRef] [PubMed]

- Shittu, O.S.; Williams, I.D.; Shaw, P.J. Global E-waste management: Can WEEE make a difference? A review of e-waste trends, legislation, contemporary issues and future challenges. Waste Manag. 2021, 120, 549–563. [Google Scholar] [CrossRef]

- Gui, L. Recycling infrastructure development under extended producer responsibility in developing economies. Prod. Oper. Manag. 2020, 29, 1858–1877. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, C.; Zhou, Y.; Zuo, L.; Tang, J. Dominant platform capability, symbiotic strategy and the construction of “Internet+ WEEE collection” business ecosystem: A comparative study of two typical cases in China. J. Clean. Prod. 2020, 254, 120074. [Google Scholar] [CrossRef]

- Lu, C.Y.; Zhang, L.; Zhong, Y.G.; Ren, W.X.; Tobias, M.; Mu, Z.L.; Ma, Z.X.; Geng, Y.; Xue, B. An overview of e-waste management in China. J. Mater. Cycles Waste Manag. 2015, 17, 1–12. [Google Scholar] [CrossRef]

- Yu, Z.; Xiong, Y.; Minyue, J. Less is more: Consumer education in a closed-loop supply chain with remanufacturing. Omega 2020, 101, 102259. [Google Scholar]

- Yoon, J.-H.; Sim, K.-H. Why is South Korea’s renewable energy policy failing? A qualitative evaluation. Energ. Policy 2015, 86, 369–379. [Google Scholar] [CrossRef]

- Rodrigues, V.P.; Pigosso, D.C.A.; McAloone, T.C. Process-related key performance indicators for measuring sustainability performance of ecodesign implementation into product development. J. Clean. Prod. 2016, 139, 416–428. [Google Scholar] [CrossRef]

- Shan, H.Y.; Yang, J.L. Promoting the implementation of extended producer responsibility systems in China: A behavioral game perspective. J. Clean. Prod. 2020, 250, 119446. [Google Scholar] [CrossRef]

- Marconi, M.; Favi, C. Eco-design teaching initiative within a manufacturing company based on LCA analysis of company product portfolio. J. Clean. Prod. 2020, 242, 118424. [Google Scholar] [CrossRef]

- Matarazzo, A.; Tuccio, G.; Teodoro, G.; Failla, F.; Giuffrida, V.A. Mass balance as green economic and sustainable management in WEEE sector. Energy Procedia 2019, 157, 1377–1384. [Google Scholar] [CrossRef]

- Udokporo, C.K.; Anosike, A.; Lim, M.; Nadeem, S.P.; Garza-Reyes, J.A.; Ogbuka, C.P. Impact of Lean, Agile and Green (LAG) on business competitiveness: An empirical study of fast moving consumer goods businesses. Resour. Conserv. Recycl. 2020, 156, 104714. [Google Scholar] [CrossRef]

- Zhang, H.; Geng, Z.R.; Yin, R.S.; Zhang, W. Regional differences and convergence tendency of green development competitiveness in China. J. Clean. Prod. 2020, 254, 119922. [Google Scholar] [CrossRef]

- Abdulrahman, M.D.; Gunasekaran, A.; Subramanian, N. Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int. J. Prod. Econ. 2014, 147, 460–471. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. Reverse logistics and closed-loop supply chain of Waste Electrical and Electronic Equipment (WEEE)/E-waste: A comprehensive literature review. Resour. Conserv. Recycl. 2018, 137, 48–75. [Google Scholar] [CrossRef]

- Guo, L.; Qu, Y.; Tseng, M.-L.; Wu, C.; Wang, X. Two-echelon reverse supply chain in collecting waste electrical and electronic equipment: A game theory model. Comput. Ind. Eng. 2018, 126, 187–195. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S.; Kumar, A. Assessing enablers of e-waste management in circular economy using DEMATEL method: An Indian perspective. Environ. Sci. Pollut. Res. 2020, 27, 13325–13338. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Kong, L.; Li, J.; Li, B.; Wang, F. Behavioral evolutionary analysis between the government and uncertified recycler in China’s E-waste recycling management. Int. J. Environ. Res. Public Health 2020, 17, 7221. [Google Scholar] [CrossRef]

- Garlapati, V.K. E-waste in India and developed countries: Management, recycling, business and biotechnological initiatives. Renew. Sust. Energ. Rev. 2016, 54, 874–881. [Google Scholar] [CrossRef]

- Cao, J.; Chen, Y.Y.; Shi, B.; Lu, B.; Zhang, X.M.; Ye, X.H.; Zhai, G.S.; Zhu, C.B.; Zhou, G.G. WEEE recycling in Zhejiang Province, China: Generation, treatment, and public awareness. J. Clean. Prod. 2016, 127, 311–324. [Google Scholar] [CrossRef]