Abstract

To effectively prevent the occurrence of poisoning and asphyxiation accidents in underground mines, this paper establishes an evaluation index system for the factors influencing accidents, constructs a combined assignment model to solve the problem of low accuracy of assignment results caused by a single algorithm, predicts the CO concentration after blasting because CO poisoning is the main cause of accidents, explores the accuracy of different time series prediction methods, and projects the required ventilation after blasting to ensure the safe operation of personnel. Firstly, starting from “man-machine-environment-management”, social factors are introduced to build an evaluation index system. Secondly, three combinatorial allocation models were compared, namely rough set theory–G1 method (RS-G1), entropy method–G1 method (Entropy-G1), and CRITIC method–G1 method (CRITIC-G1). The best model was selected and the allocation rating model was constructed in combination with the cloud model, and the mine risk level was evaluated by using the model. Thirdly, the GM(1,1) model, the quadratic exponential smoothing method, and the ARIMA model were compared by calculating posterior differences and errors, and the method with the highest accuracy was selected for predicting CO concentration. The results show that the inclusion of social assessment indexes in the assessment index system makes the consideration of assessment indexes more comprehensive. The RS-G1 combined assignment model achieved higher accuracy than other combined assignment models, and the GM(1,1) model had the highest accuracy and the best prediction effect. The results of the study can help provide targeted prevention and management measures for poisoning and asphyxiation accidents in underground mines.

1. Introduction

According to statistics, accidents and deaths in underground mines account for more than half of the total number of accidents and deaths in metal and non-metal mines. Poisoning and asphyxiation accidents come in second. Poisoning and suffocation accidents have become the main problems restricting the safe production of metal and non-metal mines. Moreover, in most mines, the CO concentration after blasting is usually measured by the operator entering the tunnel. Not knowing when the CO concentration drops to the allowable value (24 ppm) will cause the operator to enter the tunnel to test the CO concentration multiple times, resulting in personnel inhaling excessive carbon monoxide, threatening the life and safety of personnel. Therefore, the prevention of poisoning and suffocation accidents in underground mines requires a grasp of the main factors affecting the occurrence of accidents in order to assess the risk level of the mine and predict when the CO concentration will drop to the permissible value to determine the reasonable ventilation time after blasting.

Regarding the causes and risk assessment of poisoning and asphyxiation accidents in underground mines, as well as the prediction of CO concentration, scholars have conducted considerable research and analysis. On the one hand, Liu Ningwu et al. [1] analyzed the toxic and hazardous gas composition of gun smoke and proposed measures to prevent poisoning and asphyxiation accidents. Cao Yang et al. [2] analyzed the causal mechanism of poisoning and asphyxiation accidents caused by gun smoke and proposed corresponding preventive measures. Li Yanqiang et al. [3] analyzed the causes of poisoning and asphyxiation accidents in mines and proposed preventive countermeasures. Fu Zhiqiang et al. [4] used FTA to analyze the causes and potential factors of poisoning and asphyxiation accidents and formulated preventive countermeasures. Li Hui et al. [5] used the hierarchical analysis method to assess the risk of poisoning and asphyxiation accidents and put forward suggestions for accident prevention. On the other hand, in a study about CO after blasting, Xie Zhenhua et al. [6] used FLuent to simulate the diffusion law of gun smoke after blasting to provide a basis for providing a reasonable ventilation method. Hu Yang et al. [7] analyzed the diffusion law of CO concentration in gun smoke, established the calculation method of the time to reduce CO concentration to the standard value, and proposed measures that operators can apply to work safely. Cao Yang et al. [8] studied the cannon smoke detected, calculated the ventilation time, and derived the formula of the ventilation time to provide a reference for the calculation of the ventilation time after blasting. Xu Jiajun et al. [9] studied the diffusion law of the cannon smoke after blasting, and used the linear regression method to derive the formula of the time when the CO concentration dropped to the standard value to provide a basis for the operators to continue working. Gao Zhangbao et al. [10] developed and designed a monitoring and analysis system of toxic and hazardous substances to grasp the changing pattern of gun smoke concentration and protect the safety of operators. Wu Bo et al. [11] used the CFD method to analyze the flow field characteristics and discuss the effect of CO concentration distribution on ventilation, and concluded that the use of a two-stage ventilation scheme can improve ventilation efficiency and reduce energy consumption. Wang Yuehong et al. [12] used the ARIMA model to predict dust, and the results showed that the prediction using this method has small errors and favorable effects. Most of these studies explored gas transport laws, derived ventilation time calculation formulas, and designed toxic and hazardous gas monitoring systems; the few articles that used algorithms to predict CO concentrations mostly chose only one prediction method and did not calculate the prediction accuracy, which made it difficult to guarantee the accuracy of the prediction results. Relevant scholars have used different methods to study the poisoning and asphyxiation accidents in underground mines and CO after blasting, and all of them have achieved acceptable results. However, most of the studies on poisoning and asphyxiation accidents are still at the level of analyzing the causes and proposing preventive measures, and a few scholars have used a single algorithm for research; however, it is difficult to guarantee the accuracy of the assignment results by using a single algorithm, and the advantages of the subjective assignment method and objective assignment method are not considered comprehensively, which may easily lead to the low accuracy of the assignment results and make the assessment results have certain deviations. Moreover, in terms of constructing the assessment index system, most of the indicators are established for a specific site environment, without fully considering the social assessment indicators, ignoring the importance of emergency rescue and the impact of market supervision on mine safety [5,13].

The combined assignment model combines subjective and objective assignment methods for index assignment, which can effectively solve the problem of low accuracy of a single algorithm and avoid the possibility of error in weight judgment. The cloud model is a model that naturally converts qualitative concepts and quantitative descriptions, which can effectively solve the randomness and ambiguity of assessment and is widely used in risk analysis and security assessment. The time series prediction method can find out the change characteristics and development pattern of data from time series to make the effective prediction. In this paper, we introduce social factors in the causal chain theory of “human–machine–environment–control” from the Kitagawa–Tsuzan accident, add two new indicators for emergency rescue and market supervision, and build a relatively comprehensive assessment system. The subjective G1 method and the objective rough set theory, entropy weight method, and CRITIC method are combined to build a combination weighting model, and the model is selected by comparing the indicator assignment results. The combination weighting model is used to calculate the combined weight of the indicators, and the combined weight is substituted into the cloud model, and the normal cloud diagram is generated by MATLAB software to judge the risk level of the mine intuitively. Moreover, we can learn that CO is the main factor leading to accidents through statistical accident cases, so the CO concentration after blasting at the working face is predicted to obtain a reasonable ventilation time after blasting to avoid the situation that personnel enter the tunnel several times to measure the CO concentration and protect the safety of personnel. Based on the assessment of the risk level of the mine and the prediction of CO concentration after blasting, it provides a relevant basis for preventing and reducing the occurrence of poisoning and asphyxiation accidents in the mine and facilitates targeted accident prevention measures.

2. Materials and Methods

2.1. Construction of the Index System of Accident Impact Factor Assessment

- (1)

- Statistics of poisoning and asphyxiation cases in underground mines

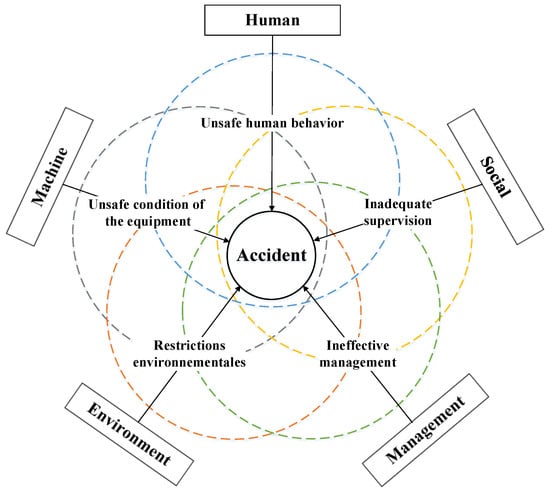

Accidents are caused by the interaction of several factors. We analyzed the direct and indirect causes of accidents by reviewing relevant literature, books, news reports, and investigation reports of poisoning and asphyxiation accidents in underground mines issued by emergency management departments, and we screened 24 cases of accidents caused by CO poisoning from them. The factors influencing the accidents in the relevant cases all covered the four elements of safety, namely “human–machine–environment–management”, and some social factors. The accident causation model is shown in Figure 1, and the index system was constructed based on these 24 cases. The specific accident case information is shown in Table 1.

Figure 1.

Cause model of poisoning asphyxia accident.

Table 1.

Information statistics of 24 typical cases of poisoning and suffocation accidents. (See Appendix A Table A1 for details.)

As can be seen from the table, the causes of accidents are mainly divided into five categories, namely unsafe human behavior, such as illegal entry into the unventilated tunnel and unauthorized commands; unsafe state of things, such as failure to install ventilation devices and failure to replace the paralyzed ventilation system; environmental restrictions, such as rock fall blocking the ventilation channel and too many turns in the tunnel affecting normal ventilation; management defects, such as not starting the emergency rescue plan after the accident and an unsound safety production system; and ineffective market supervision, such as mining enterprises without qualification procedures, the “fight against non-compliance” special rectification work not being in place, and other social factors.

- (2)

- Establishing evaluation indicators

At present, there are few relevant studies on the assessment of poisoning and asphyxiation accidents in underground mines, and a unified assessment index system has not been established. Through the analysis of previous research results, it can be learned that they have not considered establishing the index system comprehensively enough and neglected certain social assessment indicators [5,13].

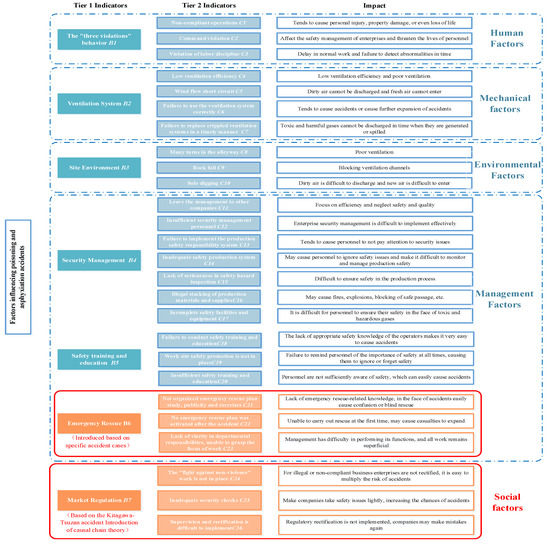

Therefore, we combined the previous research results to introduce social factors in the causal chain theory of the Kitagawa–Tsuzan accident from the perspective of “human–machine–environment–management”, analyzed the accident investigation reports to find the social causes of the accidents, and used them as the first-level indicators in the evaluation index system. By analyzing the accident investigation reports, it is also known that the importance of an emergency rescue plan was neglected by the previous authors in establishing the assessment indexes. Therefore, when establishing the evaluation indicators, we take emergency rescue as part of the management factors in combination with the unpredictability of accidents. The emergency rescue plan should be studied and drilled before the accident, and the emergency rescue plan should be activated immediately after the accident to minimize casualties and property losses. In addition, due to the unclear objectives of market supervision and the imperfect system, the phenomena of illegal operation and illegal mining have emerged one after another, and the risk of accidents has increased exponentially, so market supervision was added to the construction of the index system as a social factor. Finally, the evaluation index system was divided into five categories, namely human unsafe behavior, physical unsafe condition, environmental factors, management factors, and social factors, including seven primary indicators such as “three violations”, ventilation system, and safety management, and 26 secondary indicators such as illegal operation, the substitution of management by contract, and low ventilation efficiency, as shown in Figure 2.

Figure 2.

The evaluation system of influencing factors of poisoning asphyxia accident and its influence.

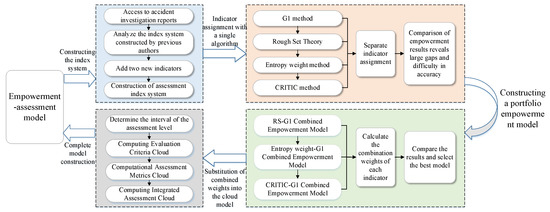

2.2. Construction of the Empowerment Rating Model

To improve the accuracy of the risk level assessment, a combined weighting model was constructed to solve the resulting bias when a single algorithm weights the index. Then, the combined empowerment model was combined with the cloud model to build an empowerment rating model to avoid the randomness and ambiguity of evaluation. The main process is shown in Figure 3.

Figure 3.

Flowchart of building an empowerment assessment model.

- (1)

- Single algorithm for empowerment

To calculate the weights of each indicator, one subjective assignment method and three objective assignment methods were chosen in this paper, namely the sequential relationship analysis method (G1 method), the rough set theory (RS), the entropy weight method, and the CRITIC method. The basic information is shown in Table 2, and the specific calculation steps are described in references [14,15,16,17,18,19,20,21,22].

Table 2.

Four empowerment methods.

In Table 2, Wj is the weight, rj is the relative importance of neighboring indicators, is the attribute importance of indicators, is the systematic dependency, is the dependency after removing indicator Ai, Hj is the variability coefficient of indicators, and Cj is the information of indicators.

- (2)

- Constructing a portfolio empowerment model

The index weights of the influencing factors of poisoning asphyxiation accidents obtained by the subjective empowerment method are mainly determined by human factors, which sometimes affect the accuracy of the assessment results. Indicator weights obtained using objective weighting are derived from objective data, but sometimes with the help of expert experience, as objective conditions change [23]. It can be seen that the accuracy of the results of empowering indicators with a single algorithm cannot be guaranteed. Therefore, the qualitative subjective empowerment method and the quantitative objective empowerment method can be combined, the weight of the subjective empowerment method can be modified by the objective empowerment method, and the weighting calculation of the two can be obtained by using Equation (1).

where Wj is the combined weight, Wj(1) is the weight obtained by the subjective assignment method, and Wj(2) is the weight obtained by the objective assignment method.

- (3)

- Cloud model

Due to the randomness and uncertainty of accidents, cloud models can better solve such problems and clearly describe the characteristics of accidents [24]. Therefore, we chose to combine the combined weights with the cloud model to build an empowerment rating model to assess the risk level of the mine. Cloud models can naturally transform qualitative concepts from quantitative descriptions, and each qualitative influencing factor has a corresponding quantitative description [25]. By substituting the combined weights calculated by the combinatorial weighting model into the cloud model, the characteristic parameters of the cloud model, namely expected Ex, entropy En, and super-entropy He [26], were calculated to determine the evaluation standard cloud, evaluation index cloud, and synthetic cloud of the influencing factors. Then, MATLAB software was used to draw a normally distributed cloud map, and the risk level of the mine was judged by observing which standard cloud the synthetic cloud is closer to. The main calculation formula is shown below, and the specific calculation steps are shown in the reference [27].

① Computing evaluation criteria cloud

where v represents different risk levels, v = 1, 2, 3, 4, 5. are the upper and lower critical values of a risk level interval. k is a constant, adjusted according to the actual degree of ambiguity required for the project, and the value k = 0.5 is taken in this paper.

② Computing evaluation metrics cloud Cj (Exj, Enj, Hej)

where Zij is the score corresponding to each indicator. Sj is the standard deviation. j is a different indicator, j = 1, 2, …, n.

③ Computing integrated cloud C(Ex, En, He)

where Wj is the indicator weight.

2.3. Time Series Prediction Method and Accuracy Test Method

- Three prediction methods

To predict CO concentration and estimate the reasonable ventilation time after blasting, three prediction methods are used: the GM(1,1) model, the quadratic exponential smoothing method, and the ARIMA model. Their basic details are shown in Table 3, and the specific calculation steps are shown in references [28,29,30,31,32].

Table 3.

Three forecasting methods.

In Table 3, is the predicted value, is the true value, a and b are the parameter vectors, at and bt are the prediction model parameters, is the primary prediction value, is the second prediction value, T is the number of prediction periods, represents the prediction model of the quadratic exponential smoothing method, is the difference series, is the noise series, φ is the AR model fitting parameter, and θ is the MA model fitting parameter.

- 2.

- Post-check difference and error

To quantitatively analyze the accuracy of the prediction results, we selected the posterior difference test [33,34] and the error assessment index [35,36] to comprehensively assess the accuracy of the three prediction methods in terms of both residuals and errors, which are calculated as follows.

- (1)

- Post hoc test

① Calculate the standard deviation of the residuals of the original time series, denoted as S1 and S2, respectively, with the following formula.

where is the residual of each indicator and is the mean of the residuals. K = 1, 2, …, n.

② Calculate the post-test difference test indicator C, formula:;

③ Calculate the small error probability P with the formula: .

Based on the calculated C and P, the accuracy level of the prediction method can be judged by comparing the post-check accuracy criteria.

- (2)

- Error evaluation index

Error is the deviation between the predicted value and the true value. Three prediction error evaluation indicators are used here: symmetric mean absolute percentage error (SMAPE), mean squared error (MSE), and mean absolute error (MAE). The calculation method is as follows.

where is the predicted value, is the true value, and k = 1, 2, …, n.

3. Results and Discussion

3.1. Comparison and Analysis of Assignment Results of Combined Assignment Models

Taking Hunan Province as an example (see Appendix A Table A2 for details), the company studies the influence of accident factors in order of influence and compares and selects the combined allocation model. According to the accident investigation report, the main causes of the accident were poisoning and asphyxiation caused by carbon monoxide. Through the analysis of the accident case, combined with the evaluation index system in Figure 2, we can understand that the top three first-level indicators with the greatest impact on this accident are safety management B4, “three violations” B1, and safety training and education B5. The top three secondary indicators with the greatest impact on the mine are insufficient safety training and education C20, non-compliance C1, and poor implementation of safety production responsibilities C13.

According to the theoretical knowledge of assignment methods in Section 2.2, the G1 method, rough set theory, entropy method, and CRITIC method were used to assign weights to each influencing factor, and the calculation results are shown in Table 4 and Table 5.

Table 4.

Weight statistics of primary evaluation index B1~B7.

Table 5.

Weight statistics of primary evaluation index C1~C26.

By analyzing the statistical results of the weights in Table 4 and Table 5, the weight values obtained when one of the four allocation methods alone is used for weight calculation, whether it is subjective or objective distribution, are inconsistent. The weighted ranking obtained by the subjective G1 method is roughly the same as that obtained by the objective rough set method and the entropy method, while the weight ranking obtained by the CRITIC method is different from these three algorithms. In other words, the accuracy of the results cannot be guaranteed by either the subjective or objective assignment method when a particular algorithm is used alone, so the combination of the subjective and objective assignment methods is chosen to build a combined assignment model, considering both subjective and objective aspects, to improve the accuracy of the assignment results. To select the optimal combined assignment model, the four algorithms are combined two by two according to the combined weight calculation formula in Section 2.2, and the weight values of each influencing factor are calculated. The specific results are shown in Table 6 and Table 7.

Table 6.

Weight comparison of primary indicators.

Table 7.

Weight comparison of secondary indicators.

From the accident investigation report and consulting experts, we know that the weighting of the primary indicators of this accident is B4 > B1 > B5 > B2 > B6 > B7 > B3. Due to a large number of secondary indicators, only the top three indicators of weighting are listed here, i.e., C20, C13, and C1. According to the calculation results of different combinations of weighting models shown in Table 6 and Table 7, the following conclusions can be drawn.

- (1)

- In the weight statistics table of the first-level index, the weight ranking obtained by the RS-G1 combined weighting model is completely consistent with the actual situation. The weighted ranking obtained by the Entropy-G1 combinatorial weighting model is different from the actual situation. However, the ranking of the impact degree of the first-level indicators obtained by the CRITIC-G1 combined empowerment model is quite different from the actual situation. Therefore, the CRITIC-G1 combinatorial empowerment model is first excluded from combining the weighting of indicators.

- (2)

- In the weight statistics table of the secondary indicators, it can be seen from the first three indicators with a large degree of influence listed that the results obtained by the Entropy-G1 combined weighting model are slightly different from the actual situation. The results obtained by the RS-G1 combinatorial empowerment model are completely consistent with the actual situation. Therefore, the RS-G1 combined empowerment method was finally adopted.

3.2. Accident Risk Level Assessment Results

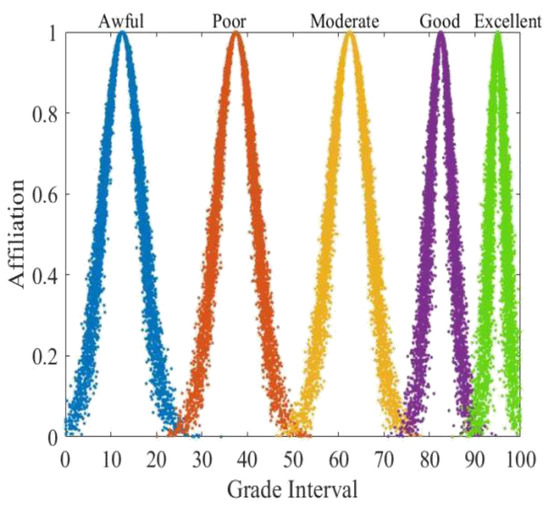

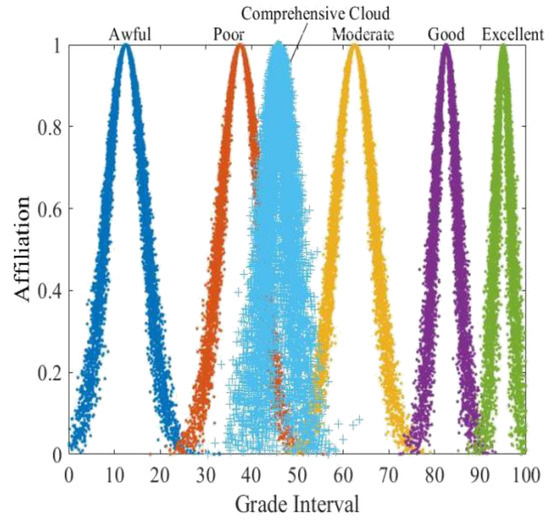

According to the accident classification of the Regulations on the Reporting and Investigation of Production Safety Accidents and the “blacklist” in the field of work safety released in 2022, the evaluation level range of the cloud model is divided according to the occurrence of accidents and the number of deaths: “awful” corresponds to major and particularly serious accidents (10 deaths or more), “poor” corresponds to major accidents (3~9 deaths), “moderate” corresponds to general accidents (1~2 deaths), “good” corresponds to accidents that occur but do not cause deaths, and “excellent” corresponds to no accidents. Since qualitative indicators are difficult to accurately quantify, the reference [37] of this paper defines five risk assessment grade intervals. A 100-point system was used for judging, and five score intervals were quantified according to the principle that the greater the score, the smaller the risk. They are “awful”—[0, 25], “poor”—(25, 50], “moderate”—(50, 75], “good”—(75, 90], and “excellent”—(90, 100). According to Equation (2), we calculate the standard cloud corresponding to each grade interval. The specific evaluation level division is shown in Table 8, and the corresponding cloud diagram is shown in Figure 4.

Table 8.

Evaluation levels and corresponding cloud models.

Figure 4.

Standard cloud chart of safety assessment level.

Ten experts (see Appendix A Table A3 for details) with in-depth research and work experience in underground mines were invited to score the indicators, build an evaluation matrix according to the scoring situation, and calculate the evaluation index cloud of each index according to Equation (3); the specific results are shown in Table 9. The RS-G1 combined empowerment model selected in Section 3.1 was combined with the cloud model to construct the empowerment rating model. First, the RS-G1 combinatorial weighting model was used to calculate the combined weight Wj of each index. Then, the cloud model was used to calculate the evaluation index cloud Cj (Exj, Enj, Hej), and the combined weight Wj and the evaluation index cloud Cj (Exj, Enj, Hej) were substituted together (4) to obtain the comprehensive assessment cloud C (45.9, 2.4, 1.3) of the influencing factors of the mine poisoning asphyxiation. According to the characteristic parameters of the cloud model, the comprehensive evaluation cloud map was generated by MATLAB software. The risk level of the mine is judged by observing the fit between the “comprehensive cloud” and the five “standard clouds”. The final result is shown in Figure 5.

Table 9.

Evaluation index and its cloud model.

Figure 5.

Comprehensive evaluation of cloud model.

According to the investigation report of the “3.10” poisoning and asphyxiation accident in Yaogang Xian mine, it is known that the accident caused eight deaths, which is a large accident, and the risk level corresponding to the large accident is “poor” according to Table 8. The cloud model calculates an assessment cloud of C (45.9, 2.4, 1.3), and Figure 5 judges that the mine risk level is also “poor”. It shows that the evaluation results are consistent with the actual situation, which proves that the allocation rating model has strong reliability and practicability.

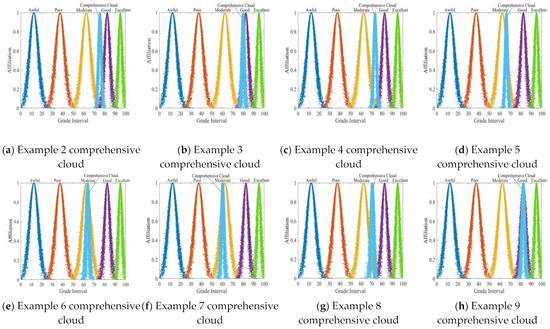

The comprehensive assessment cloud of the remaining mine instances can be calculated using the same method as Example 1. First, the RS-G1 combined empowerment model and the cloud model are used to construct the empowerment rating model. Then, we calculate the characteristic parameters of the comprehensive evaluation cloud model of each mine. Finally, MATLAB software is used to draw the corresponding cloud map. The comprehensive assessment cloud map of each mine can be obtained so that the risk level of each mine can be intuitively judged, and the specific results are shown in Figure 6. As can be seen from Figure 6, each mine is located in a different evaluation grade range due to the different evaluation comprehensive clouds calculated by it. The more the “synthetic cloud” fits into which “standard cloud”, the risk level of the mine is determined by which assessment level. As shown in Figure 6a, the risk rating of the corresponding mine is “good”, and the risk level of the corresponding mine in Figure 6d is “medium”.

Figure 6.

Comprehensive evaluation of cloud images of other mine examples.

3.3. Comparison and Analysis of CO Prediction Results

- (1)

- Source of CO concentration data

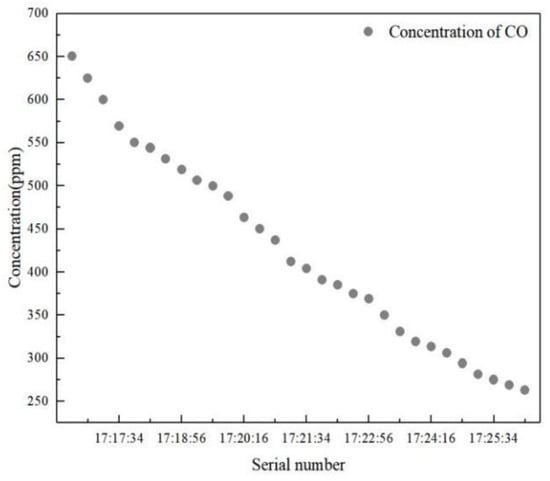

According to the statistical results of 24 accident cases in Table 1, CO is the main factor causing accidents. Therefore, the CO concentration after blasting the working face is estimated to predict the reasonable ventilation time after blasting.

The plateau mine has a high altitude, low air pressure, and low oxygen concentration, and the flue gas diffusion increases after blasting, and ventilation is difficult. Compared with non-highland mines, poisoning asphyxiation accidents are more likely to occur, and the consequences are more serious. Therefore, the highland underground mine located in the northwest is the object of study. It mainly adopts the ventilation mode of natural ventilation, central air intake, and two-wing pumping. Relevant instruments were used to measure the concentration data of toxic and harmful gases in the middle section and working area of the mine in the summer (August) and winter (December). Only CO concentration data after blasting the excavation face are used here. The data are shown in Figure 7. After blasting the excavation face, the CPR-KF4 4-in-1 gas detector was used to record the data of CO concentration every 20 s, and the measurement time period was 17:16:36~17:33:18. Due to the limitations of the instrument and the consideration of safety factors, the valid data of CO concentration after blasting are not complete, but it can be seen that the overall CO concentration is decreasing, and for the convenience of subsequent calculation and plotting, the measurement time is indicated by serial number.

Figure 7.

Measured data on CO concentration.

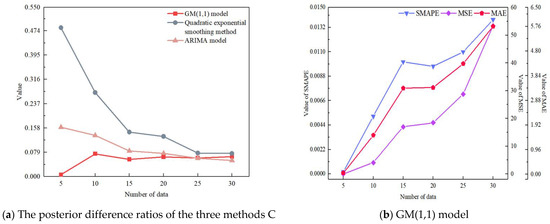

Because the measured sample size was large and the ventilation method did not change throughout the measurement process, only some of the measured data were selected as the original time series for the subsequent prediction of CO concentration. To obtain more accurate results, the influence of the number of data on the accuracy of the calculation results is determined first, and 5, 10, 15, 20, 25, and 30 data are selected as a group. The GM(1,1) model, the quadratic exponential smoothing method, and the ARIMA model were then applied to fit and predict the measured CO concentration. The posterior difference index and error evaluation index of the three methods were calculated, and the comparative analysis was carried out to select the best number of data and the optimal prediction method for prediction. Then, this method was used to make subsequent predictions and calculate the time when the CO concentration drops to the allowable value.

- (2)

- The influence of the number of starting data on the accuracy of the results

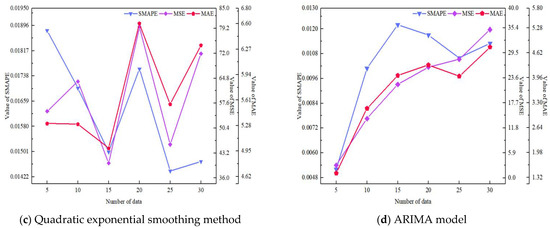

To investigate the influence of the number of data on the accuracy of the prediction results, the minimum number of data (5) required for prediction by the GM(1,1) model was used as the basis, and 5, 10, 15, 20, and 25 data were selected as a group. Three prediction methods were used to fit the prediction. The posterior difference indexes and error evaluation indexes of the three prediction methods were calculated according to the results of the fitted prediction, and the accuracy was compared. The results are shown in Figure 8.

Figure 8.

Posterior difference and error variation.

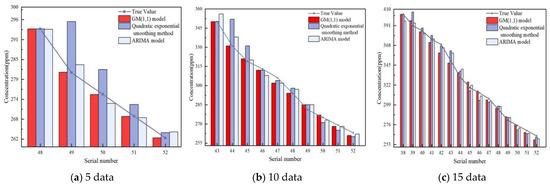

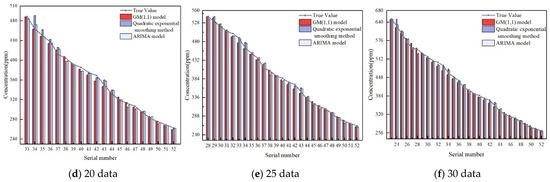

It can be seen from Figure 8 that with the increase in the number of data, the posterior difference ratio of the GM(1,1) model does not change significantly linearly, and the SMAPE value, MSE value, and MAE value all increase linearly. The posterior difference ratio of the quadratic exponential smoothing method and the ARIMA model showed a linear downward trend, and the three errors of the quadratic exponential smoothing method increased linearly. The three errors of the ARIMA model fluctuate without obvious change rules. It can be seen that the influence of the number of data on accuracy cannot be derived from the change in accuracy. As a result, the optimal number of data for the prediction cannot be determined, and further comparative analysis is required. Therefore, the fitting effect of the three prediction methods under different numbers of data is plotted. Due to the large amount of data, only 5 data, 10 data, and 15 data are displayed here. The results are shown in Figure 9.

Figure 9.

Comparison of the true value and the fitted value of the three prediction methods.

According to Figure 9, as the number of data increases, the fitting effect of the prediction using the three methods gradually becomes better, but combined with the calculation results of the posterior differences and errors in the previous section, no valid conclusion can be drawn to illustrate the effect of the number of data on the accuracy of the prediction results. Therefore, it is still necessary to analyze the influence of the number of data on the accuracy of the results by combining the specific values of the posterior difference ratio C and the three errors of SMAPE, MSE, and MAE. From the principles of SMAPE, MSE, and MAE, it is known that the smaller the value of the errors, the higher the accuracy, and then combined with Figure 8 and Figure 9, it is finally determined that the results obtained when the number of data is 15 are the most accurate, so these 15 data with serial numbers 38~52 are used as the original time series for the subsequent prediction calculation.

- (3)

- Comparison of the prediction effects of three time series forecasting methods

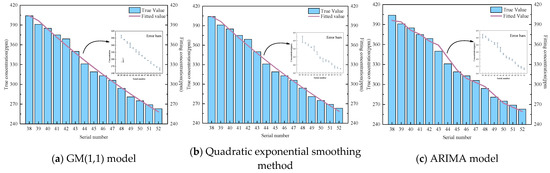

The data with serial numbers 38~52 were selected as the original time series, and three forecasting methods were used to fit the forecast. Error bars represent the error between the real value and the fitted value. The longer the error bar, the greater the difference between the fitted value and the true value. The final result is shown in Figure 10.

Figure 10.

Fitting effect chart.

It can be seen from the fitting effect diagram of the three methods that when forecasting with the original time series composed of 15 data, the fitting effect of the three forecasting methods is better, and the difference between the prediction results is not obvious. For this reason, it is necessary to combine the specific results of the posterior difference and error for further analysis and comparison, as shown in Table 10.

Table 10.

Comparison of posterior difference and error results of three prediction methods.

As can be seen from Table 10, the GM(1,1) model was used to fit the CO concentration, and the posterior difference ratio C, symmetric mean absolute percentage error (SMAPE), mean square error (MSE), and mean absolute error (MAE) of the obtained results were the smallest among the three prediction methods. The GM(1,1) model was finally selected for the subsequent CO concentration prediction in combination with the results of the posterior difference test.

Without changing the ventilation method, using the GM(1,1) model, it can be calculated that after blasting at the excavation workface, it takes 43 min for the CO concentration to drop to the CO concentration (24 ppm) allowed for safe production in the mine, which means that after blasting at the excavation workface, ventilation is required for 43 min before the operator can continue production operations. After reviewing the relevant mine blasting safety operation procedures, we learned that after underground blasting in metal and non-metal mines, ventilation is generally required for more than 30 min if the ventilation conditions are good, or 2 h if the ventilation conditions are poor. Therefore, the results obtained by prediction in this paper are consistent with the actual mine safety production regulations.

4. Conclusions

- (1)

- The assessment index system is more comprehensive and accurate after the introduction of social factors and the inclusion of two indicators of emergency rescue and market supervision, compared with the traditional index system based on the four factors of “human–machine–environment–management” safety, which takes into account the factors that may lead to accidents and makes the construction of the assessment index system more objective. It is reasonable.

- (2)

- The comparison between the three combined assignment models and the accident investigation report shows that the RS-G1 combined assignment model is more accurate than other combined assignment models. The model solves the problem of insufficient accuracy when using a single algorithm for weight calculation and reduces the problem of error in weight judgment and the subjective tendency of scoring items. The assignment evaluation model built by combining with the cloud model can better solve the ambiguity and randomness of the evaluation. The assessment results are consistent with the actual results, and the accuracy of the calculation results is effectively improved.

- (3)

- The GM(1,1) model has the highest accuracy and the lowest error in prediction. The prediction of CO concentration in this mine example using the GM(1,1) model shows that ventilation is required for 43 min after blasting at the working face before the operator can continue working. The model can be applied to underground mines with the same type of ventilation in predicting CO concentration after blasting in the excavated working face, and the ventilation dilution time of CO concentration can be accurately derived to effectively avoid the unsafe behavior of personnel entering the tunnel several times to measure CO concentration.

Author Contributions

Conceptualization, J.L. and Q.M.; methodology, Q.M.; software, Q.M., H.Z., G.Y. and X.H.; formal analysis, G.Y. and H.Z.; investigation, Q.M.; data curation, Q.M., G.Y. and H.Z.; writing—original draft preparation, J.L. and Q.M.; writing—review and editing, J.L., Q.M., W.W., L.T. and X.L.; supervision, J.L. and W.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Yunnan Province Key R & D Program Project (grant number 202003AC100002), Yunnan Fundamental Research Projects (grant number 202201AU070110), and the Scientific Research Fund Project of Yunnan University of Finance and Economics (grant number 2021D04).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

This study does not report any data.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Information statistics of 24 typical cases of poisoning and suffocation accidents.

Table A1.

Information statistics of 24 typical cases of poisoning and suffocation accidents.

| NO. | Case | Number of Deaths | Accident Level | Root Cause | Direct Cause | Indirect Causes |

|---|---|---|---|---|---|---|

| 1 | “3.7” Henan | 10 | Major | CO | Personnel violated the law to open the closed pit; sand and gravel fell, causing poor ventilation; local ventilation fan power failure | Supervision instead of management, give up safety management; “fight against non-compliance” is not in place, and personnel without safety production qualifications |

| 2 | “5.25” Xinjiang | 8 | Larger | CO | No local ventilation fan installed; many turns in the tunnel, difficult to discharge the gun smoke; personnel enter the unventilated tunnel illegally | Lack of safety management personnel; inadequate market supervision and safety inspection |

| 3 | “7.14” Guangdong | 4 | Larger | CO | The local ventilation fan is not connected to the windpipe, which cannot effectively discharge the smoke of the gun; the “fight against non-compliance” is not in place, and the company practices illegal mining | Solo digging, ventilation difficulties; insufficient safety training and education; no emergency rescue plan drills |

| 4 | “3.4” Guangxi | 8 | Larger | CO, NOx | Illegal installation of light fixtures in the chamber where blasting equipment was stored; failure to establish a separate return air duct to the explosives storage chamber | Illegal mining; supervision instead of management; lack of professional safety management personnel; power departments involved in running mines and enterprises |

| 5 | “2.17” Jiangsu | 7 | Larger | CO, NOx | The warehouse manager threw unextinguished cigarette butts in the warehouse, igniting the explosives; rescuers not wearing safety gear | The warehouse manager does not stack production materials in accordance with regulations; no independent exhaust system in the explosives store |

| 6 | “4.27” Gansu | 8 | Larger | CO | The CO concentration in the abandoned mine cave is severely over the limit | Failure to conduct safety hazard investigation; failure to implement safety management regulations; lack of safety education and training for relevant personnel |

| 7 | “4.17” Hunan | 4 | Larger | H2S | Illegal mining; without any ventilation facilities; H2S concentration exceeds the standard | Lack of security managers |

| 8 | “7.24” Jiangxi | 1 | General | CO2 | CO2 concentration in the well exceeds the standard | Illegal mining; inadequate safety education and training; violation of rules and regulations; lax supervision of the banned mines by the Office for the Fight against Illegality |

| 9 | “12.12” Anhui | 2 | General | CO | There is no fan air supply after the release of the cannon, and the cannon smoke is not discharged into the underground work | Inadequate safety education and training; inadequate safety production system |

| 10 | “11.1” Shanxi | 0 | CO2 | No mechanical ventilation facilities; insufficient oxygen supply | Many turns in the tunnel, resulting in poor ventilation | |

| 11 | “10.3” Sichuan | 4 | Larger | CO, NOx | Inadequate underground ventilation system; entering without underground gas detection after blasting | Safety training and education are not in place, and staff safety awareness is weak; emergency rescue drills are not carried out |

| 12 | “1.17” Hebei | 1 | General | CO, NOx | Employees enter the working surface alone without local ventilation equipment for harmful gas detection | Violation of operating procedures, single-person, single-post operation; lack of implementation of the production safety responsibility system, lax safety management; inadequate safety training and education |

| 13 | “3.8” Anhui | 5 | Larger | CO2 | Command violation; illegal operation; without any local ventilation facilities | Safety production responsibility system is not implemented; safety management is not in place; safety training and education are not in place; safety hazard investigation is not conducted |

| 14 | “8.3” Chongqing | 5 | Larger | CO2 | Workers work in violation of the law; the open fire caused a gas explosion | Illegal mining; unsound production safety system; incomplete safety facilities |

| 15 | “1.14” Shanxi | 2 | General | CO, NOx | The concentration of gun smoke exceeds the standard; not properly using ventilation equipment | Violation of rules and regulations; inadequate safety production system |

| 16 | “1.14” Inner Mongolia | 3 | Larger | CO, NOx | Blasting operations did not open the main fan and local ventilation fan to disperse the gun smoke, resulting in the concentration of toxic and harmful gases | Inadequate safety production system; lack of safety management personnel; incomplete safety facilities and equipment |

| 17 | “5.3” Inner Mongolia | 4 | Larger | CO | Ventilation facilities are not installed in the correct position, blowing the gun smoke to the working face | The local ventilation fan is not installed in the single-headed roadway; the production safety system is not sound; the safety facilities and equipment are not complete |

| 18 | “6.28” Yunnan | 5 | Larger | CO | Incorrect location of local ventilation fan installation; lack of safety management personnel; unauthorized command | Safety hazard investigation is not in place; safety training and education are not in place; emergency rescue plan is not activated |

| 19 | “9.13” Hunan | 7 | Larger | H2S, SO2 | Inadequate ventilation facilities, toxic gases cannot be discharged; workers work in violation of the law; ventilation equipment is not installed in the lone headway | Lack of safety management personnel; unsound safety production system; failure to organize study of emergency rescue plans; inadequate safety inspection; substitution of management by supervision |

| 20 | “11.9” Yunnan | 3 | Larger | CO2 | No blocking of abandoned mining areas; no mechanical ventilation facilities in the pit; workers operating in violation of the law | Illegal production; “fight against non-compliance” is not in place; safety inspection is not in place |

| 21 | “4.6” Shanxi | 12 | Major | CO, NOx | Underground ventilation system is paralyzed; workers enter the working face without ventilation after releasing the cannon | The production safety system is not sound; lack of safety management personnel; emergency rescue plan is not activated; safety facilities and equipment are not complete |

| 22 | “8.25” Fujian | 3 | Larger | CO, NOx | Low awareness of worker safety; violation of labor discipline | Inadequate safety training and education; inadequate safety body system; lack of safety management personnel |

| 23 | “8.17” Shandong | 3 | Larger | CO | Non-compliant operations | Safety production responsibility system is not implemented; violation of rules and regulations; lack of emergency rescue drills; lack of safety management personnel |

| 24 | “3.10” Hunan | 8 | Larger | CO, NOx | Rockfall block the ventilation channel, the gun smoke cannot be discharged; personnel illegally enter the unventilated roadway | The ventilation system is paralyzed and not dealt with on time; the safety production system is not sound; market supervision is not effective and safety inspection is not in place |

| 24 | “3.10” Hunan | 8 | Larger | CO, NOx | Rockfall block the ventilation channel, the gun smoke cannot be discharged; personnel illegally enter the unventilated roadway | The ventilation system is paralyzed and not dealt with on time; the safety production system is not sound; market supervision is not effective and safety inspection is not in place |

Table A2.

Information about the “3.10” poisoning and asphyxiation accident at Yaogang Xian tungsten mine in Hunan Province.

Table A2.

Information about the “3.10” poisoning and asphyxiation accident at Yaogang Xian tungsten mine in Hunan Province.

| Incident Name | Number of Deaths | Accident Level | Accident History | Direct Cause of the Accident | Indirect Causes of the Accident | Web Link |

|---|---|---|---|---|---|---|

| “3.10” large poisoning and asphyxiation accident at Yaogang Xian tungsten mine in Hunan Province | 8 | Larger | At 18:40 on March 10, a total of six operators of the preparation shift of the accident quarry went to the work area for a pre-shift meeting to prepare for the morning shift on March 11. At 20:30, three of them found that the blasting pile of rocks was blocking the passage but did not report it, after which they felt a reaction of poisoning but did not successfully evacuate. At 21:00, the other three did not see the aforementioned three, and sensing that something was wrong, they called other shift members, five in total, to rescue, but were also unsuccessful in evacuating due to poisoning from being stranded for too long. |

|

| https://www.docin.com/p-709137450.html&key=%E4%B8%AD%E6%AF%92%E6%80%8E%E4%B9%88%E6%B2%BB (accessed on 29 September 2022) |

Table A3.

Information on 10 experts.

Table A3.

Information on 10 experts.

| Expert Type | Work Unit | Professional Position | Access Time | Access Mode | Interview Length |

|---|---|---|---|---|---|

| Academy specialist A | Southwest University of Science and Technology | Professor | July 2022 | Online (e-mail) | 15 min |

| Academy specialist B | Kunming University of Science and Technology | Associate Professor | July 2022 | Offline (on-site) | 30 min |

| Mine Manager C | Emergency Linkage Command Center | Senior Engineer | August 2022 | Online (phone) | 15 min |

| Mine Manager D | Security Technical Services Ltd. | Senior Engineer | August 2022 | Online (phone) | 18 min |

| Mine Manager E | Institute of Safety Science and Technology | Full Senior Engineer | August 2022 | Online (phone) | 12 min |

| Security Engineer F | Safety Inspectorate | Engineer | August 2022 | Offline (on-site) | 25 min |

| Security Engineer G | Safety Inspectorate | Senior Engineer | September 2022 | Offline (on-site) | 20 min |

| Mine Safety Expert H | Production Safety Monitoring Center | Senior Engineer | September 2022 | Online (e-mail) | 10 min |

| Mine Safety Expert I | Bureau of Mines Affairs | Full Senior Engineer | September 2022 | Online (phone) | 15 min |

| Mine Safety Expert J | Institute of Safety Science and Technology | Full Senior Engineer | September 2022 | Online (e-mail) | 30 min |

References

- Liu, N.W.; Zhu, H.W.; Mei, G.D.; He, X.J. Research on accidents mechanism and prevention measures towards poisoning and asphyxiation of explosion smoke. Nonferrous Met. (Mine Sect.) 2012, 64, 1–6. [Google Scholar]

- Cao, Y.; Ji, H.; You, S.; Li, S. Research on Mechanism of Blasting Fume Poisoning and Prevention Technology. Ind. Saf. Environ. Prot. 2015, 41, 73–75. [Google Scholar]

- Li, Y.; Song, Y.; Zhang, R.; Zhao, Y. Statistic analysis and countermeasures of harmful gas accident in mine. J. Inn. Mong. Univ. Sci. Technol. 2016, 35, 16–18. [Google Scholar]

- Fu, Z.; Zhang, B.; Zhang, G.; Zuo, L.; Zhang, M. Risk Analysis of Poisoning and Asphyxiation Accident in Underground Mine Capital Construction Period Based on FTA. World Nonferrous Met. 2019, 16, 203–204. [Google Scholar]

- Li, H.; He, L.; Song, W.; Li, Y.; Wang, J. Risk Analysis of Poisoning and Asphyxiation in Oil and Gas Wells in Mining Face. Coal Technol. 2019, 38, 126–128. [Google Scholar] [CrossRef]

- Zhen, H.; Zheng, L.; Yu, Z. Numerical Simulation on Blasting Fume Diffusion in Blind Roadway with FLUENT. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2013. [Google Scholar]

- Hu, Y.; Kang, H.; Zhu, J.; Chen, S. Migration Law and Controlling Measures for Toxic and Harmful Gas After Underground Blasting. Saf. Coal Mines 2016, 47, 39–42. [Google Scholar]

- Cao, Y.; Ji, H.; Pei, F. Study of the Calculation Model of Ventilation Time of Dummy Tunnel in A Gold Mine. Mod. Min. 2017, 33, 199–201. [Google Scholar]

- Xu, J.; Xia, F.; Liang, J. Study on the smoke dispersion law of dedicated pedestrian mining and blasting. Coal Chem. Ind. 2020, 43, 117–120. [Google Scholar] [CrossRef]

- Gao, Z.; Zhong, Y.; Wu, F.; Yang, W.; Liu, J.; Leng, L. Design and Realization of Remote Monitoring and Analysis System for Toxic and Hazardous Substances in Mines. China Tungsten Ind. 2020, 35, 74–77. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, M.; Zhao, S. Establishment and application of mine dust concentration prediction model. China Min. Mag. 2021, 30, 178–181. [Google Scholar]

- Wu, B.; Zhao, R.; Meng, G.; Xu, S.; Qiu, W.; Chen, H. A numerical study on CO migration after blasting in high-altitude tunnel by inclined shaft. Sci. Rep. 2022, 12, 14696. [Google Scholar] [CrossRef]

- Wang, G.; Shang, L.; Liu, X.; Tang, L.; Cheng, Q. Study on causes of poisoning and asphyxiation in roadway opening by AHP-entropy weight method. J. Saf. Sci. Technol. 2021, 31, 187–192. [Google Scholar] [CrossRef]

- Ming, J.; Junyan, Z.; Shuo, C.; Mei, K.; Yi, X.; Rongxin, X.; Zhenye, Y. Research on comprehensive evaluation of data link based on G1 method and entropy weight method. J. Phys. Conf. Ser. 2021, 1820, 012115. [Google Scholar]

- Hu, B.; Gao, Y.; Wei, B. Propeller design rule extraction based on rough set theory. J. Aerosp. Power 2022, 1–9. [Google Scholar] [CrossRef]

- Xue, Y.; Li, Y. Cohesion of Agricultural Crowdfunding Risk Prevention under Sustainable Development Based on Gray–Rough Set and FAHP-TOPSIS. Sustainability 2022, 14, 12709. [Google Scholar] [CrossRef]

- Scuderi, A.; Sturiale, L.; Timpanaro, G.; Matarazzo, A.; Zingale, S.; Guarnaccia, P. A Model to Support Sustainable Resource Management in the “Etna River Valleys” Biosphere Reserve: The Dominance-Based Rough Set Approach. Sustainability 2022, 14, 4953. [Google Scholar] [CrossRef]

- Tianxing, M.; Yun, L.; Xiaobin, Z.; Mingzhi, Z. Grading Evaluation of Goaf Stability Based on Entropy and Normal Cloud Model. Adv. Civ. Eng. 2022, 2022, 9600909. [Google Scholar]

- Rui, W.; Qiang, Z.; Hui, S.; Xuedong, Z.; Yuyue, W. Risk Assessment Model Based on Set Pair Analysis Applied to Airport Bird Strikes. Sustainability 2022, 14, 12877. [Google Scholar]

- Xie, D.; Han, J.; Zhang, H.; Wang, K.; Du, Z.; Miao, T. Risk Assessment of Water Inrush from Coal Seam Roof Based on Combination Weighting-Set Pair Analysis. Sustainability 2022, 14, 11978. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.; Mi, Z.; Pu, L.; Cui, Y. Grading evaluation of power quality based on CRITIC and improved Grey-TOPSIS. Power Syst. Prot. Control 2022, 50, 1–8. [Google Scholar] [CrossRef]

- Qiu, D.; Wu, Y.; Li, L. Evaluation of the Gas Drainage Effect in Deep Loose Coal Seams Based on the Cloud Model. Sustainability 2022, 14, 12418. [Google Scholar] [CrossRef]

- Huang, J.; Xia, Y.; Lin, M. Study on prediction of rock burst by multi-dimensional cloud model based on improved combined weight. J. Saf. Sci. Technol. 2019, 29, 26–32. [Google Scholar]

- Xue, X.; Jianyun, Z.; Yanqing, L.; Kairong, L.; Xin, G.; Tian, L.; Jianfeng, L.; Feiyan, S. Cloud model combined with multiple weighting methods to evaluate hydrological alteration and its contributing factors. J. Hydrol. 2022, 610, 127794. [Google Scholar] [CrossRef]

- Yu, X.; Dezhong, K.; Zhanbo, C.; Guiyi, W.; Qi, Z. The Comprehensive Identification of Roof Risk in a Fully Mechanized Working Face Using the Cloud Model. Mathematics 2021, 9, 2072. [Google Scholar]

- He, Y.; Liu, J. Electric Internet of Things Security Risk Assessment Based on Combined Weighting-cloud Model. Power Syst. Technol. 2020, 44, 4302–4309. [Google Scholar] [CrossRef]

- Yan, J.; Liu, S. Cloud model evaluation of autonomous capability of ground-attack UAV based on combined weighting. J. Beijing Univ. Aeronaut. Astronaut. 2022, 1–14. [Google Scholar] [CrossRef]

- Gao, C.; Kong, Z.; Shen, X. Freeze-thaw Resistance Evaluation of Lightweight Aggregate Concrete with Stress Damage Based on GM(1,1). Adv. Eng. Sci. 2021, 53, 184–190. [Google Scholar] [CrossRef]

- Gao, H.; Tang, Q.; Li, D.; Chen, S. Application of Quadratic Exponential Smoothing and Markov Chain in Computer Predicting Total Amount. J. Phys. Conf. Ser. 2021, 2033, 012014. [Google Scholar] [CrossRef]

- Li, W.; Qin, Z.; Guanwen, H.; Jie, T. GPS Satellite Clock Bias Prediction Based on Exponential Smoothing Method. Geomat. Inf. Sci. Wuhan Univ. 2017, 42, 995–1001. [Google Scholar]

- Li, Y.; Han, T.; Wang, J.; Quan, W. Application of ARIMA Model for Mid-and Long-term Forecasting of Ozone Concentration. Environ. Sci. 2021, 42, 3118–3126. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, X.; Yan, Y.; Lang, Q.; Wang, H.; Ai, Q. Dynamic Warning Method for Structural Health Monitoring Data Based on ARIMA: Case Study of Hong Kong-Zhuhai-Macao Bridge Immersed Tunnel. Sensors 2022, 22, 6185. [Google Scholar] [CrossRef]

- Jian, Y.; Xianlai, Z.; Ming, C. Estimating the construction waste generation in Jinan using the grey system theory. China Environ. Sci. 2020, 40, 3894–3902. [Google Scholar] [CrossRef]

- Ma, J.; Wu, Z.; Zou, Y.; Ren, P.; Li, Q. Water quality prediction of Nansi Lake based on grey Markov model. Water Resour. Prot. 2021, 37, 153–158. [Google Scholar]

- Ye, J.; Wei, X.; Huang, Q.; Xie, R.; Huang, C.; Zhao, S. Short-Term Forecast of wind power based on BSO-ELM-ADABOOST with grey correlation analysis. Acta Energ. Sol. Sin. 2022, 43, 426–432. [Google Scholar] [CrossRef]

- Meng, H.; Tong, X.; Shi, Y.; Zhu, L.; Feng, K.; Hei, X. Cloud server aging prediction method based on hybrid model of auto-regressive integrated moving average andrecurrent neural network. J. Commun. 2021, 42, 163–171. [Google Scholar]

- Tian, Q. Research on Safety Evaluation of Assembly Building Construction Based on Cloud Model. Master’s Thesis, Anhui University of Construction, Hefei, China, 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).