Solar-Powered Direct Contact Membrane Distillation System: Performance and Water Cost Evaluation

Abstract

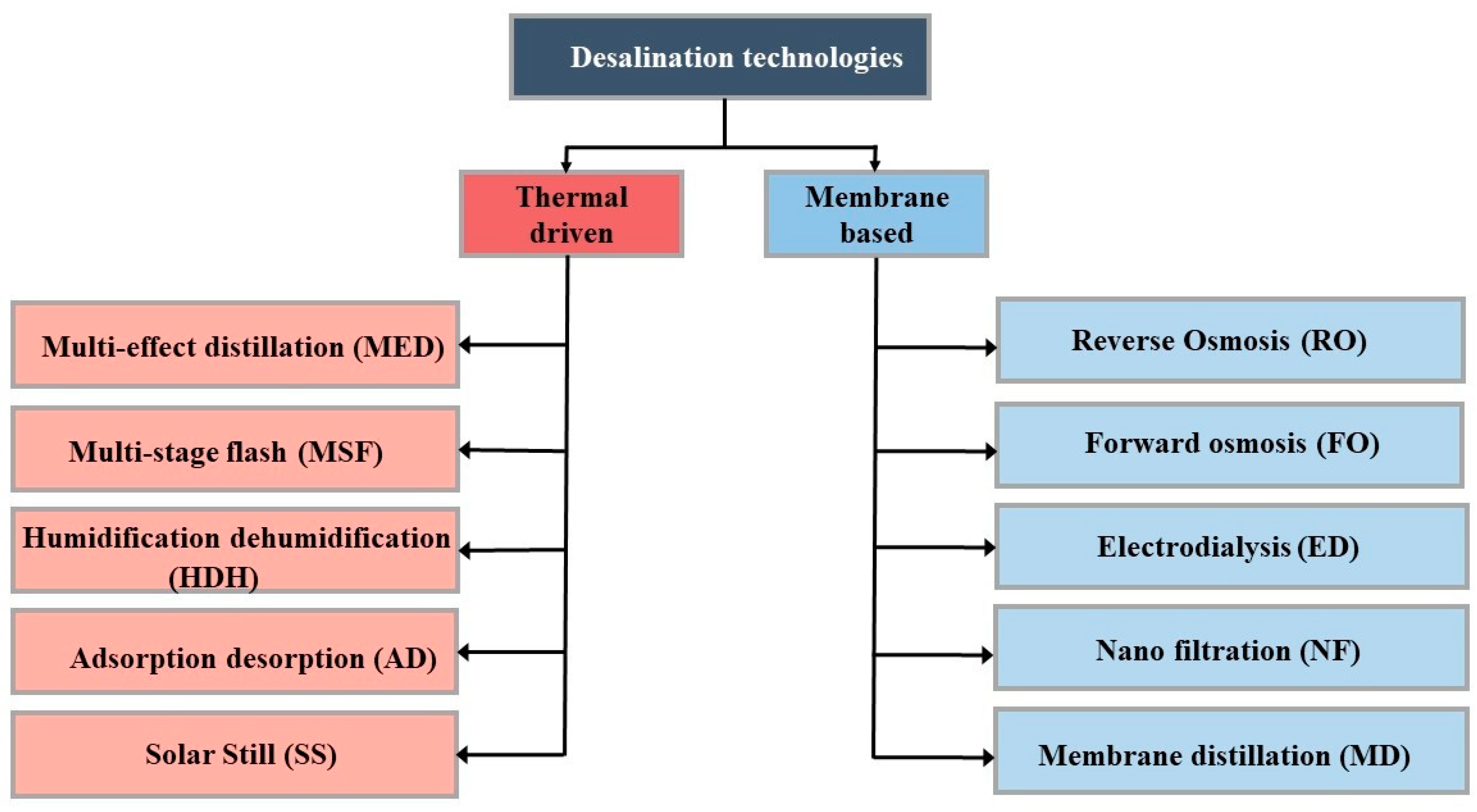

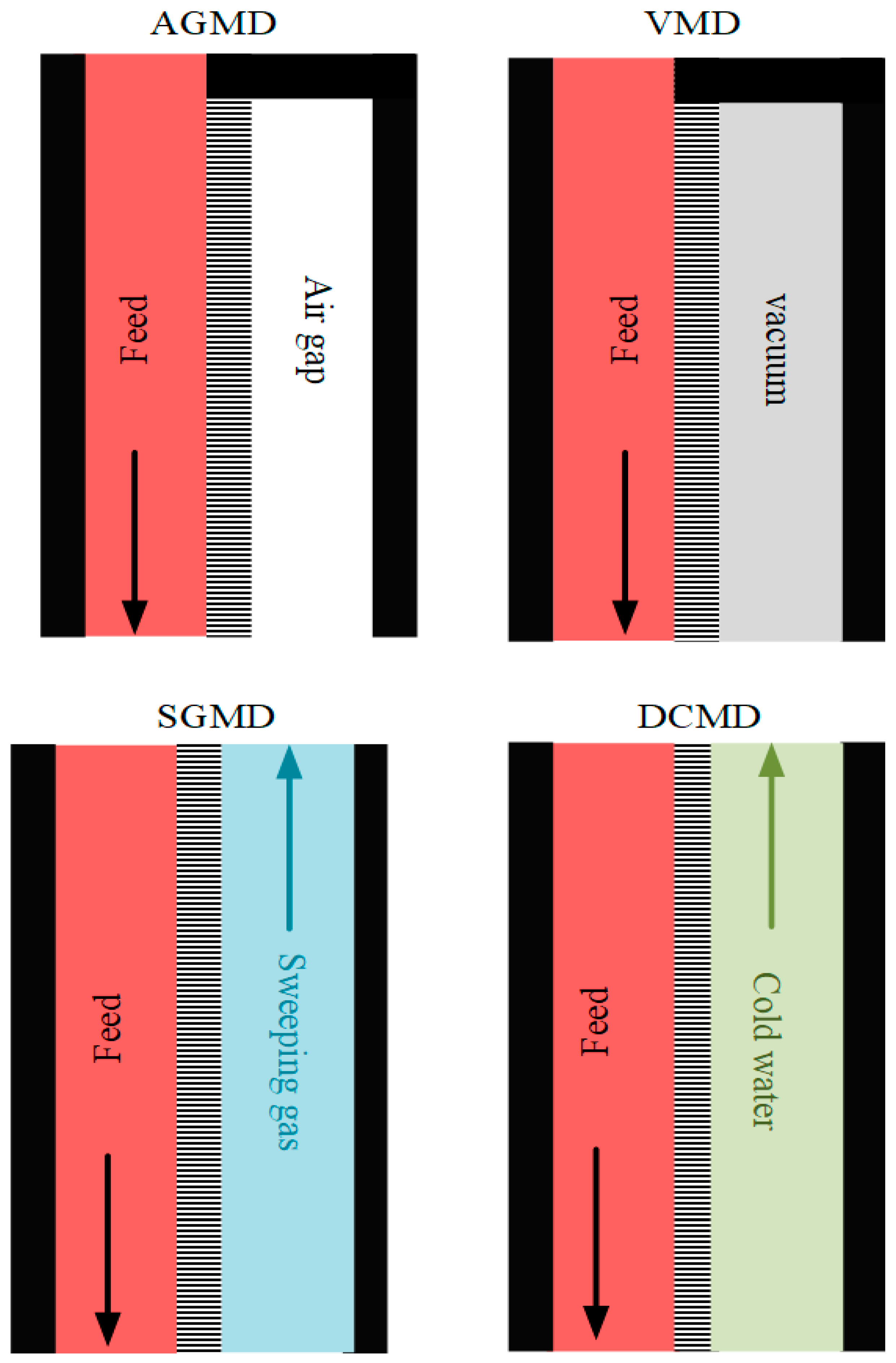

1. Introduction

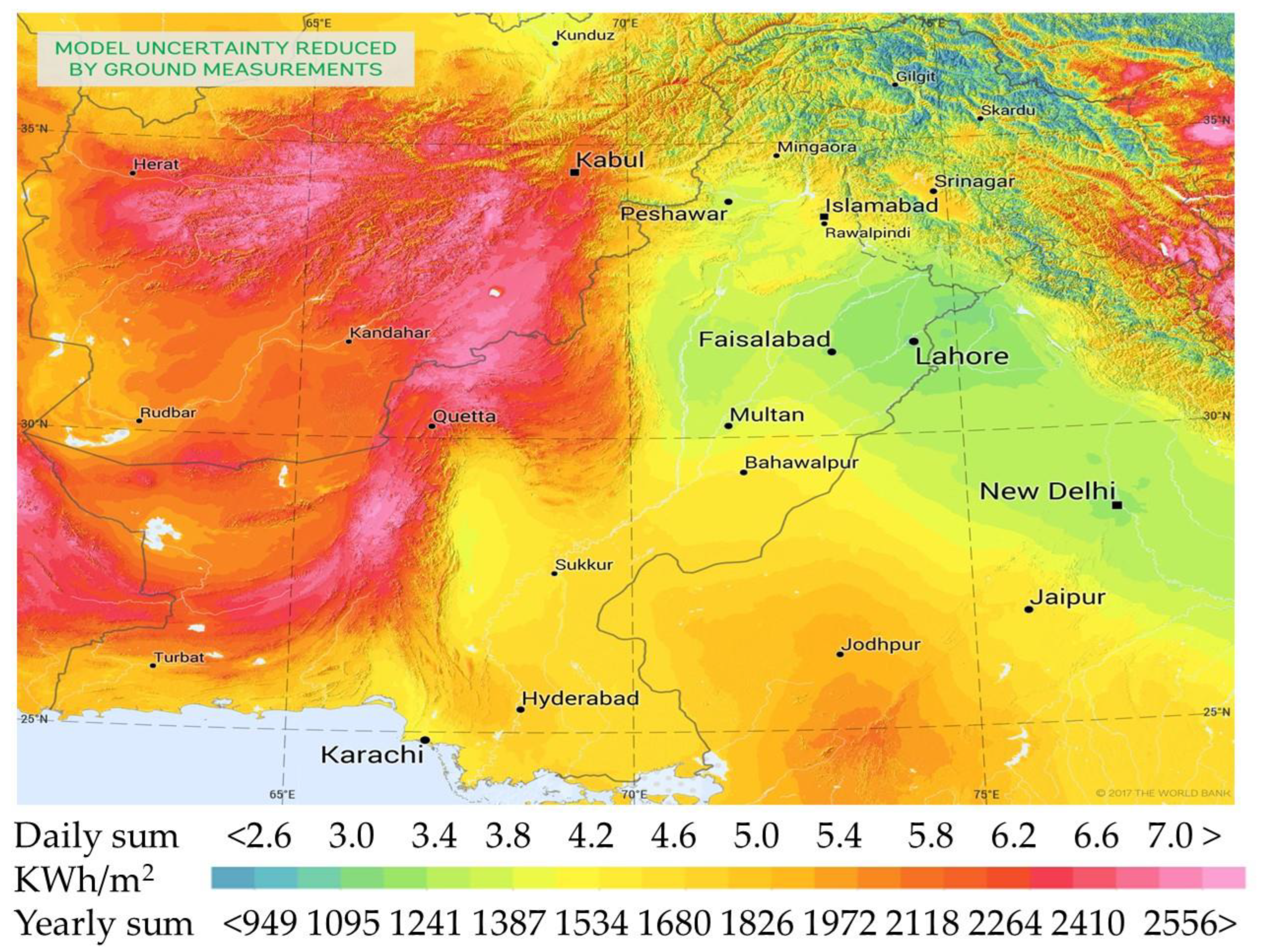

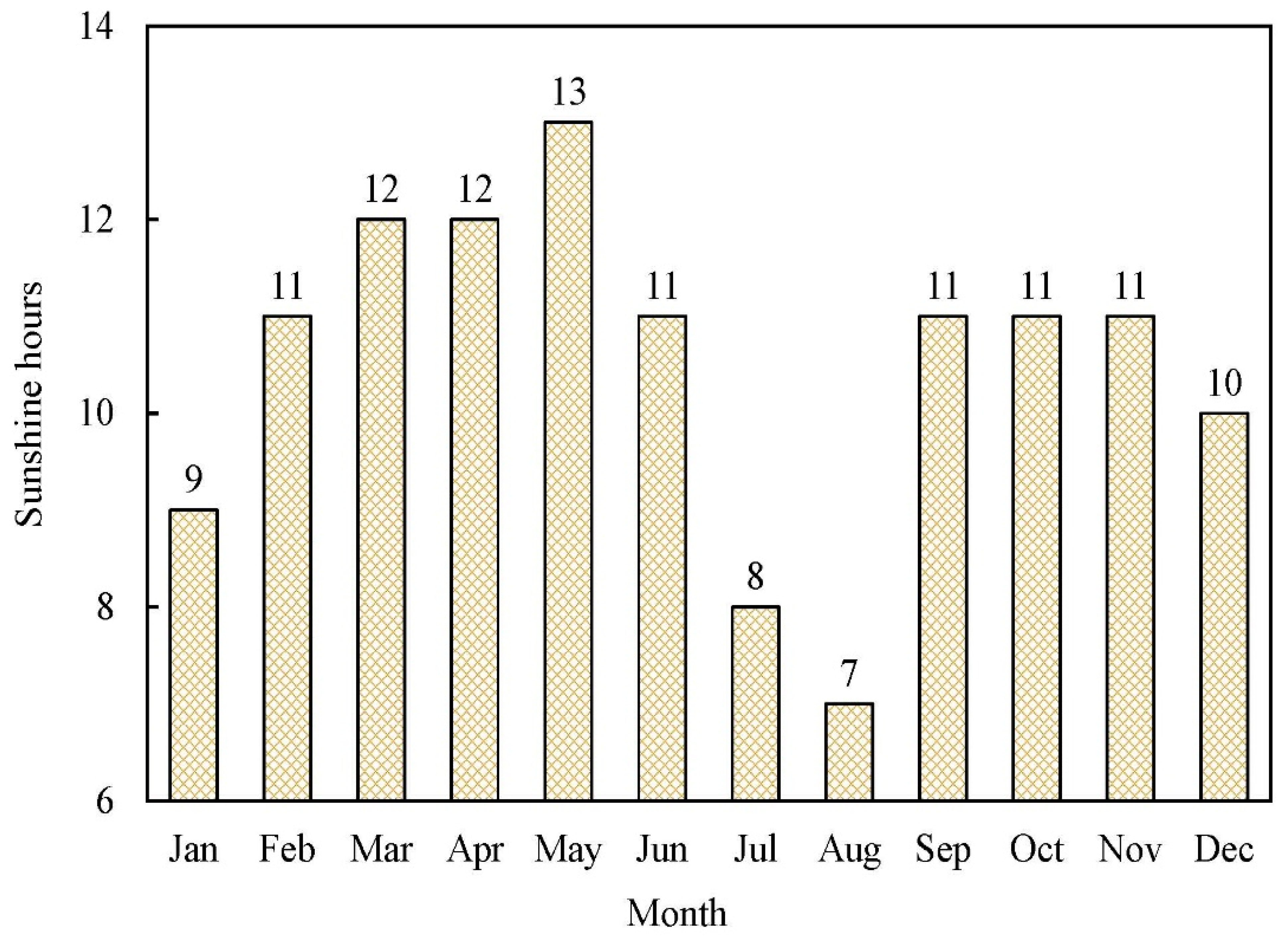

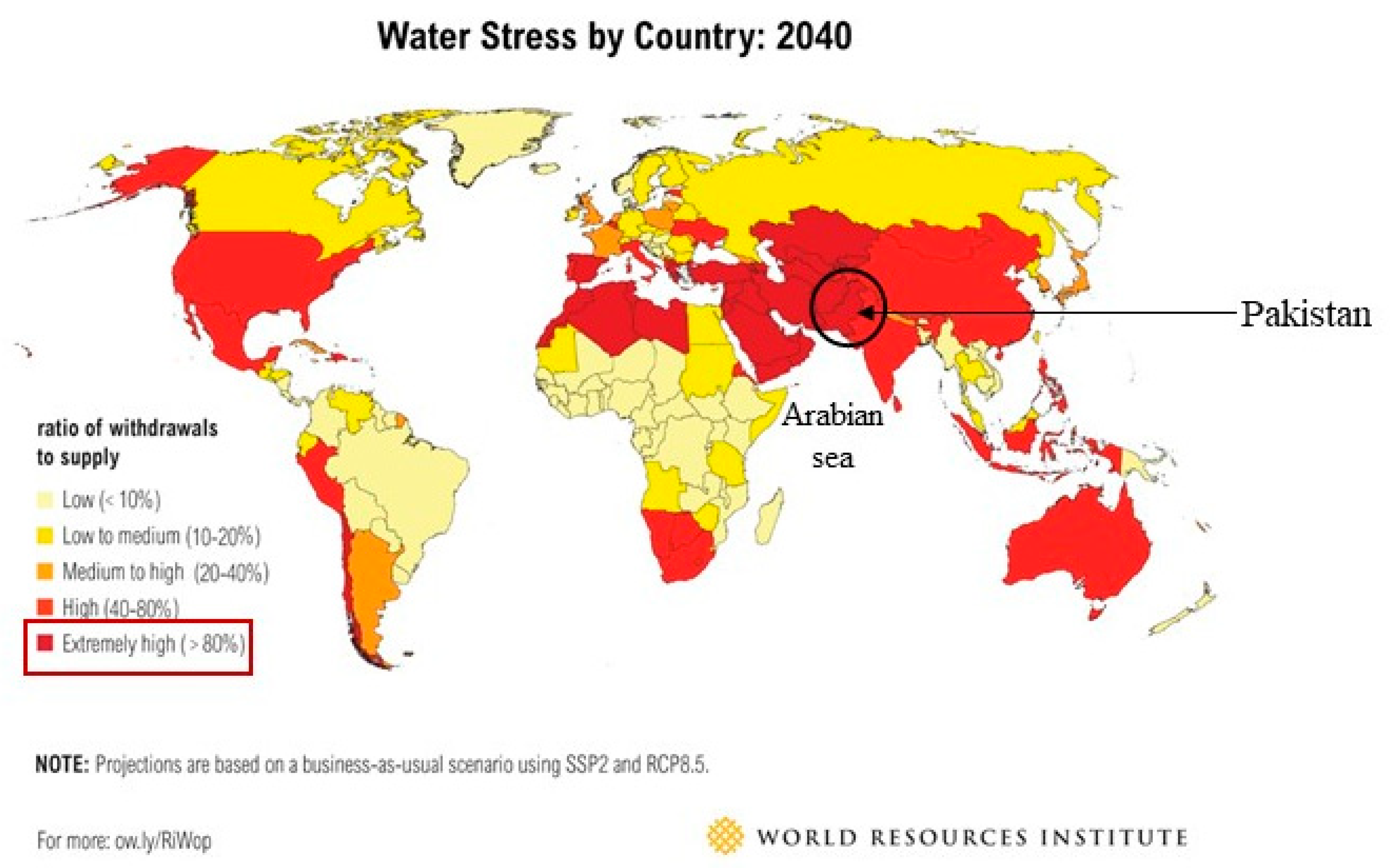

2. Solar Energy Potential in Pakistan

3. Fresh Water Status in Pakistan

- Fresh water <500 ppm;

- Brackish water 5000–35,0000 ppm;

- Saline water 35,000 and 45,000 ppm;

- Brine >45,000 ppm.

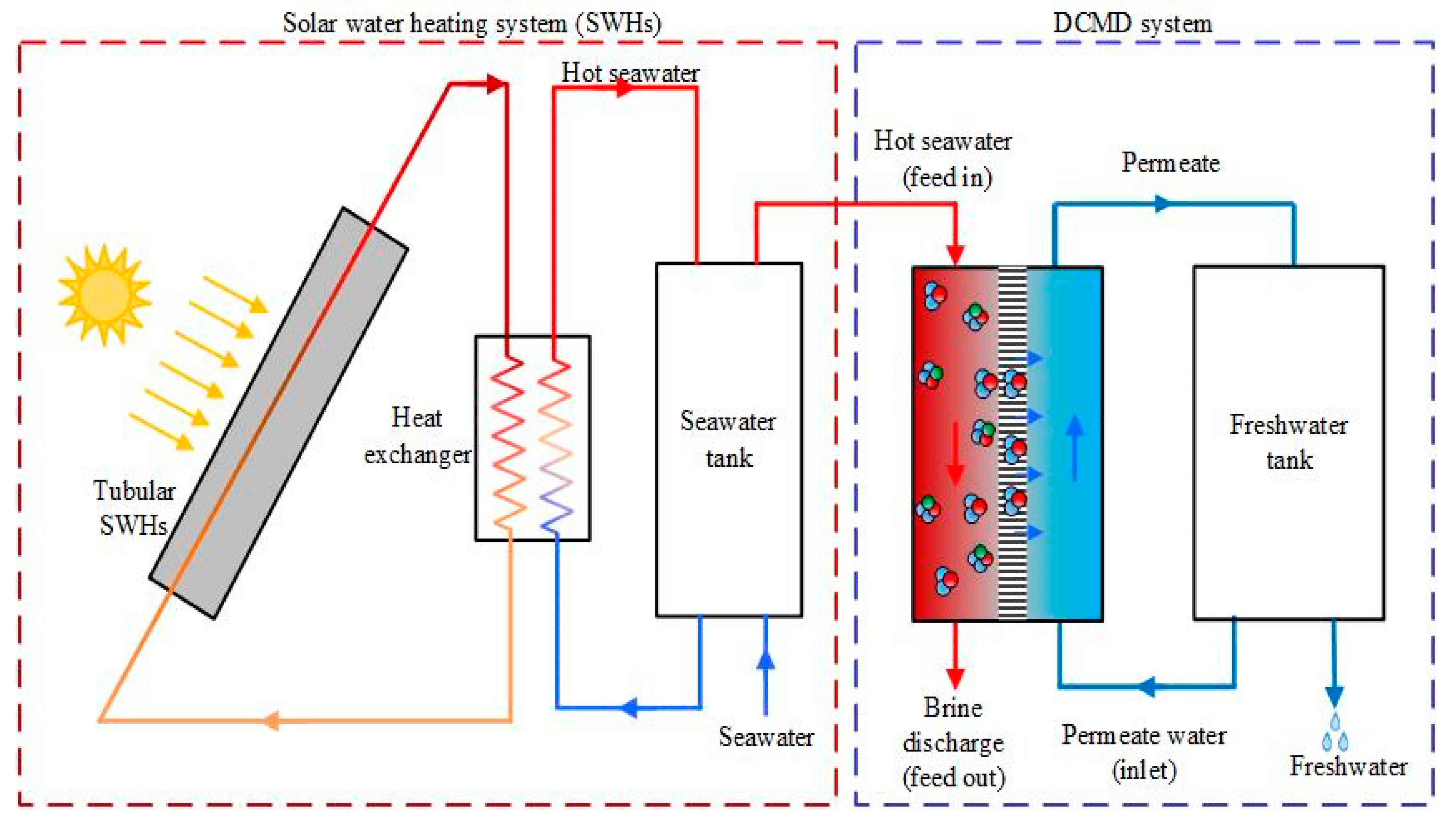

4. System Description

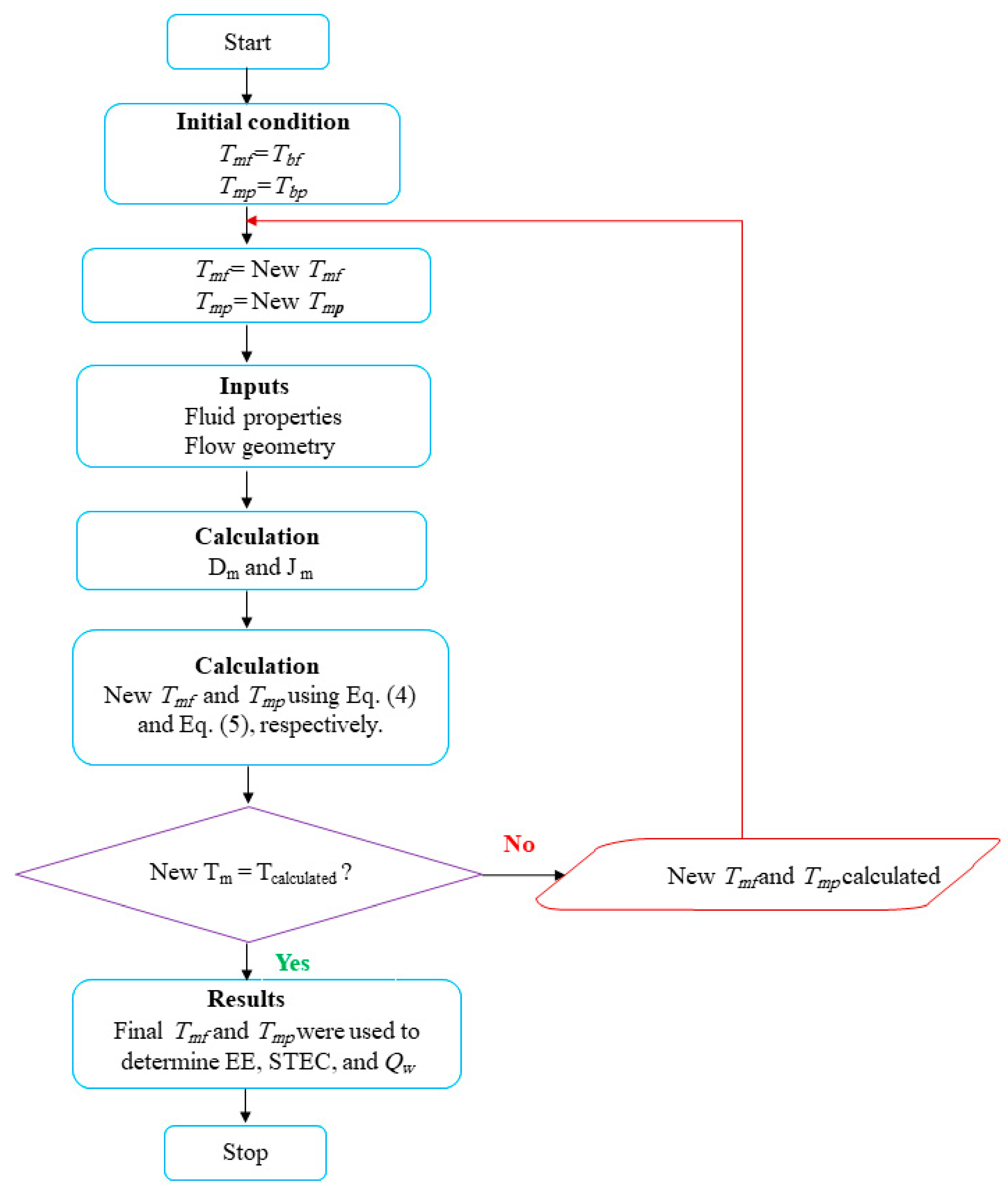

5. Methodology

5.1. Solar Water Heating System

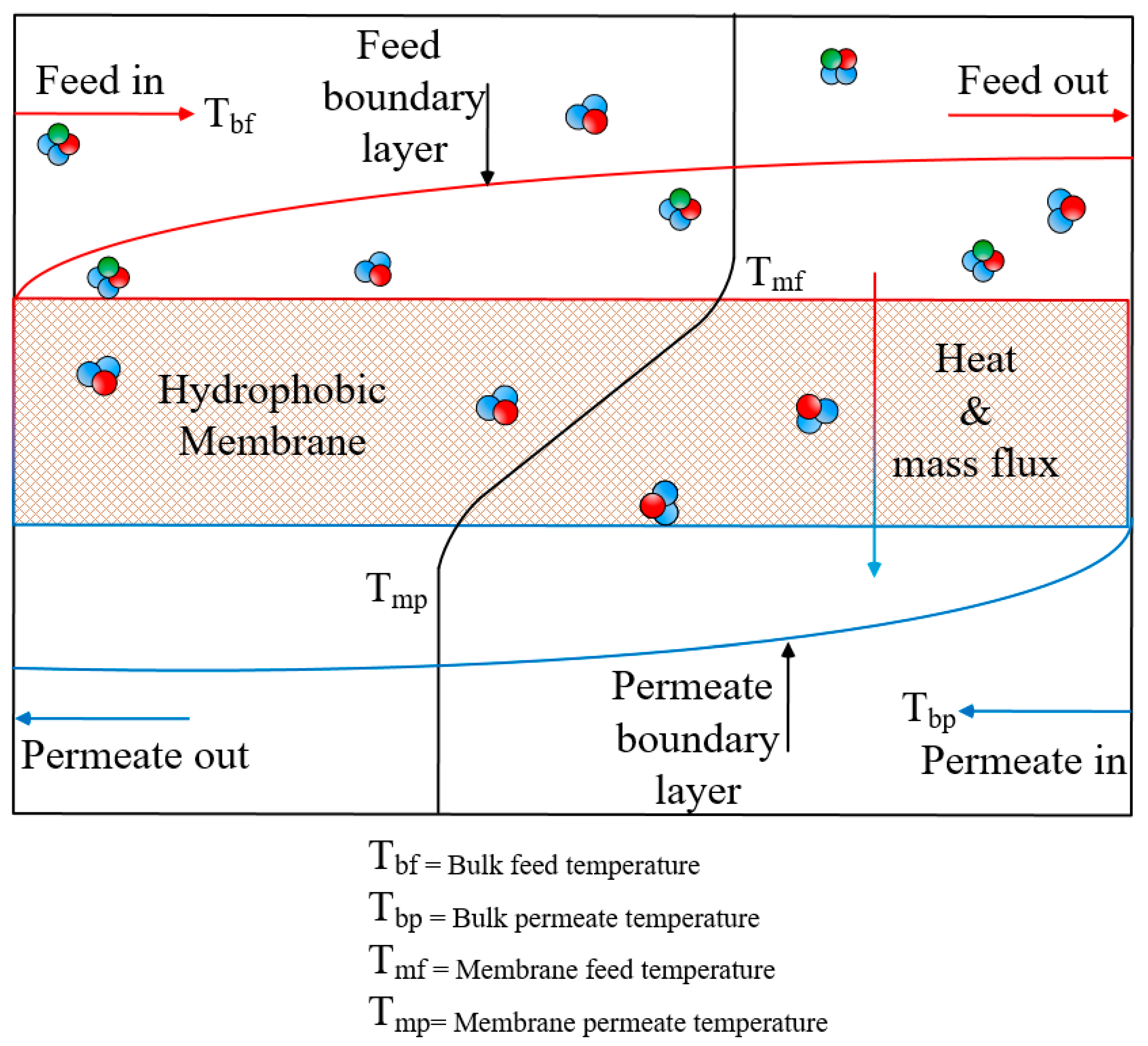

5.2. DCMD System

5.3. DCMD System Performance

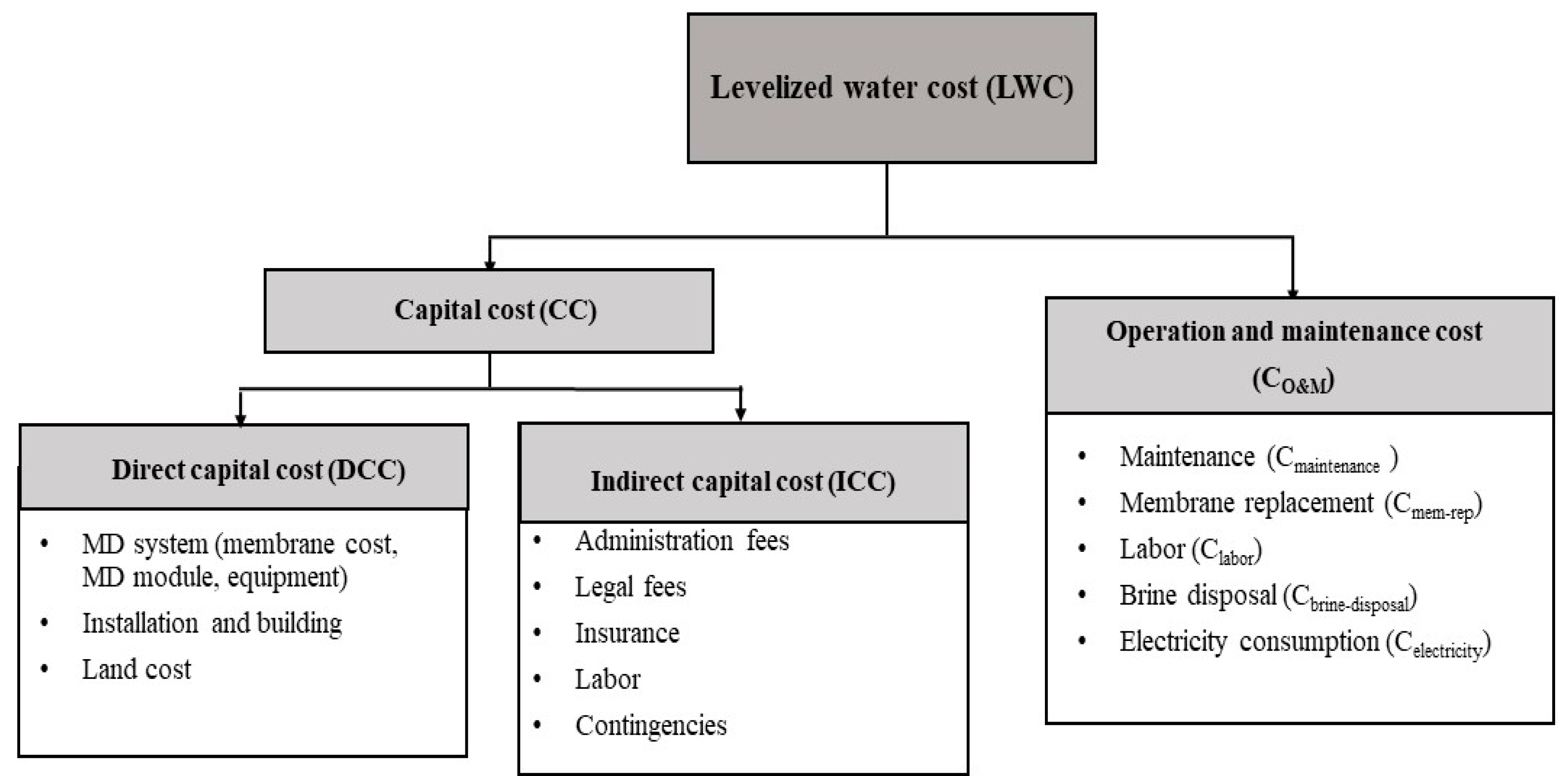

5.4. Water Cost Evaluation

6. Results and Discussions

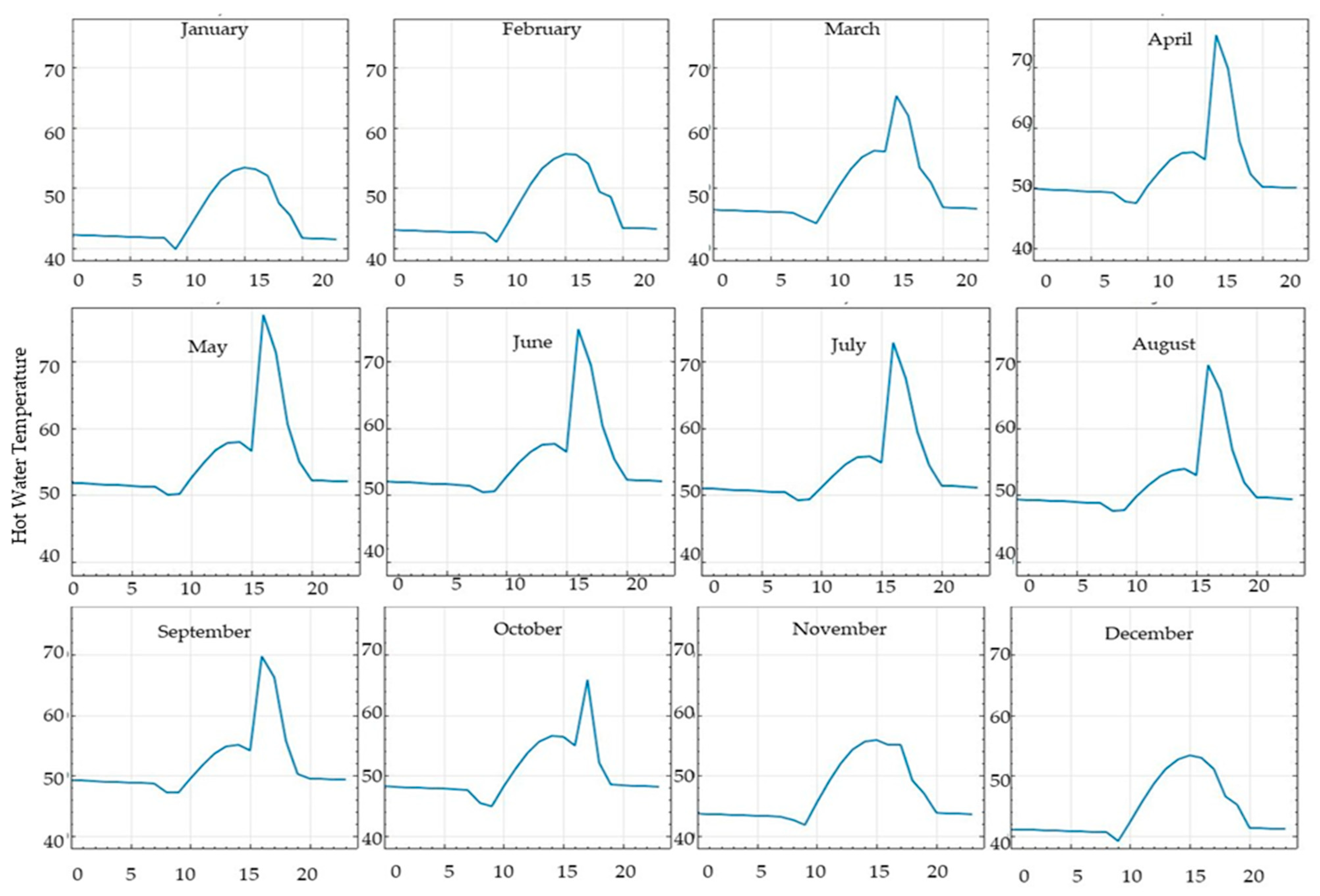

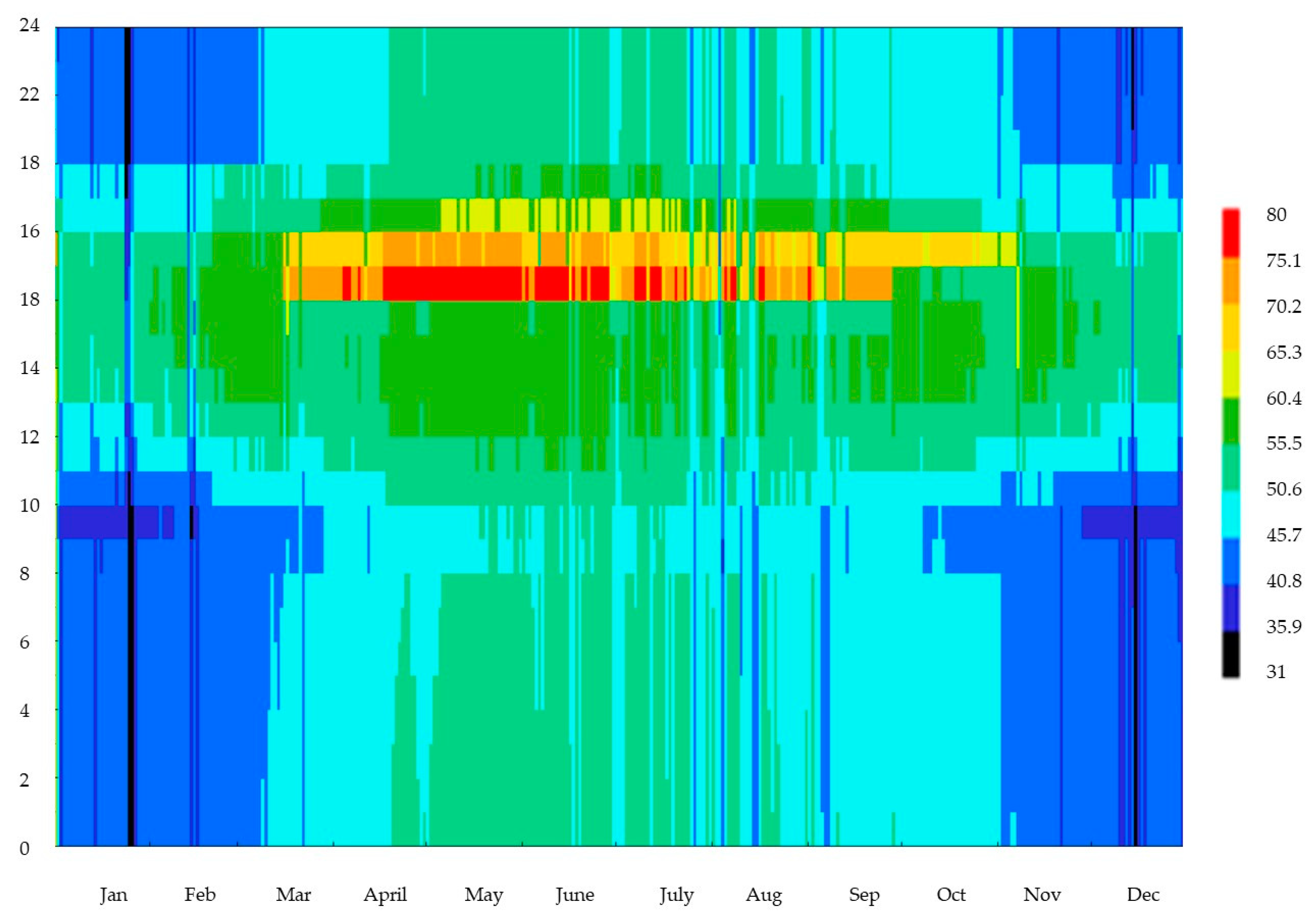

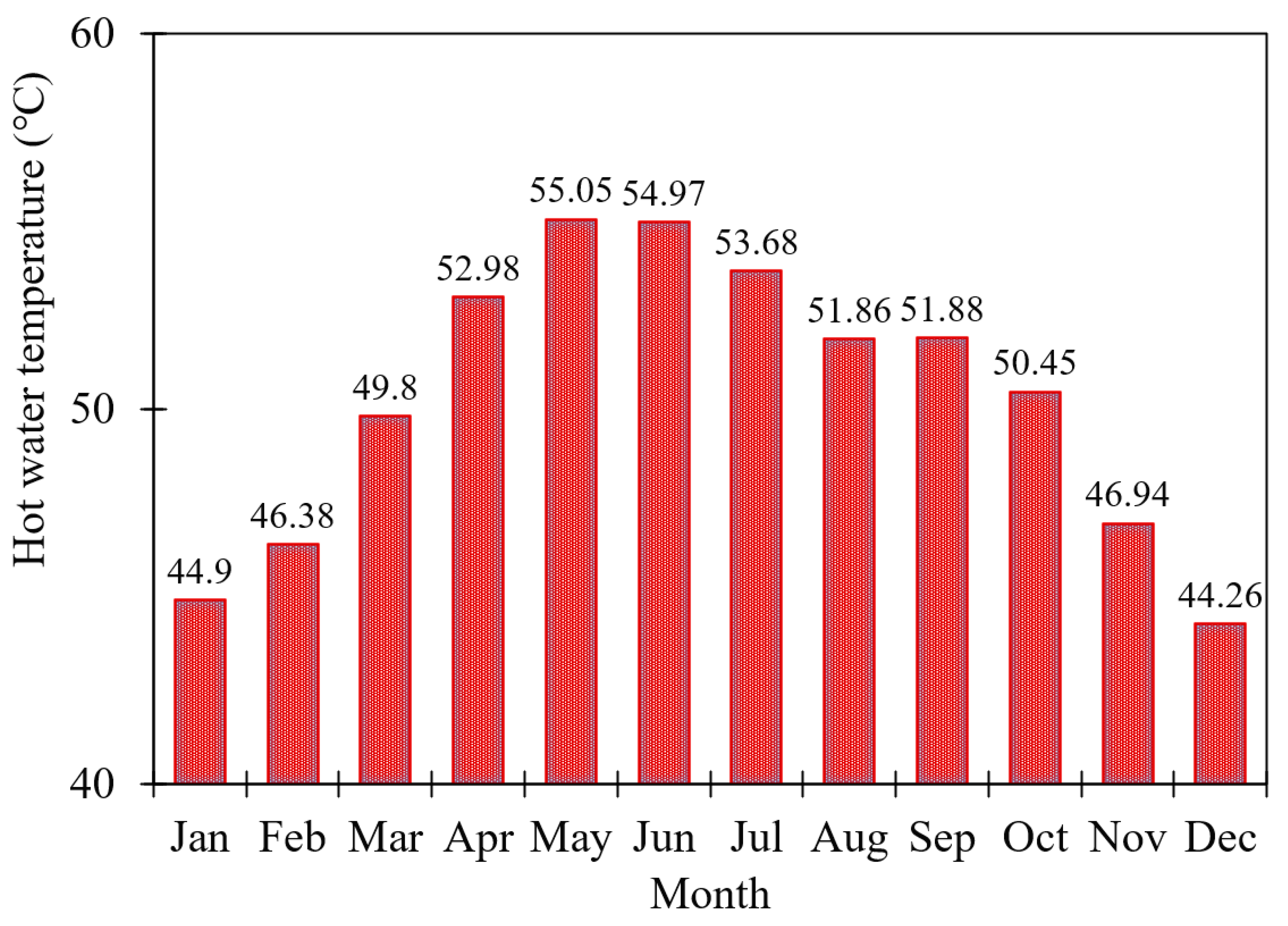

6.1. Solar Water Heating System (SWHS)

6.2. DCMD System

6.3. Water Cost Evaluation

7. Conclusions

- The maximum hot water temperature (76.91 °C) was obtained in May, whereas the minimum hot water temperature (53.44 °C) was achieved in January. In particular, the average highest hot water temperature (55.05 °C) was observed in May and the average lowest hot water temperature (44.26 °C) in December.

- The capacity factor and solar fraction of the solar water heating system were found to be 27.9% and 87%, respectively. The economical evaluation showed that the net capital cost of the solar water system was 16,035 USD.

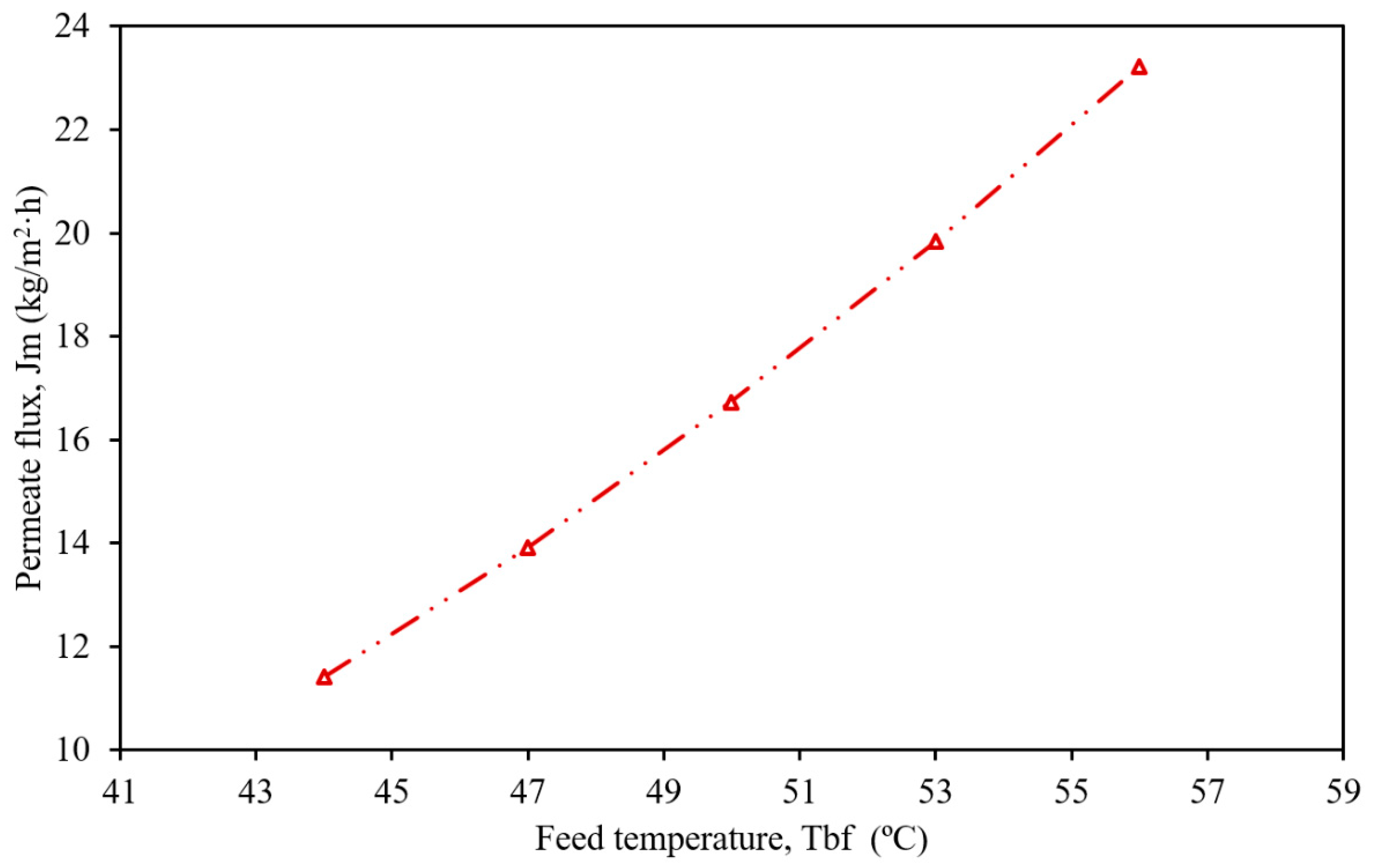

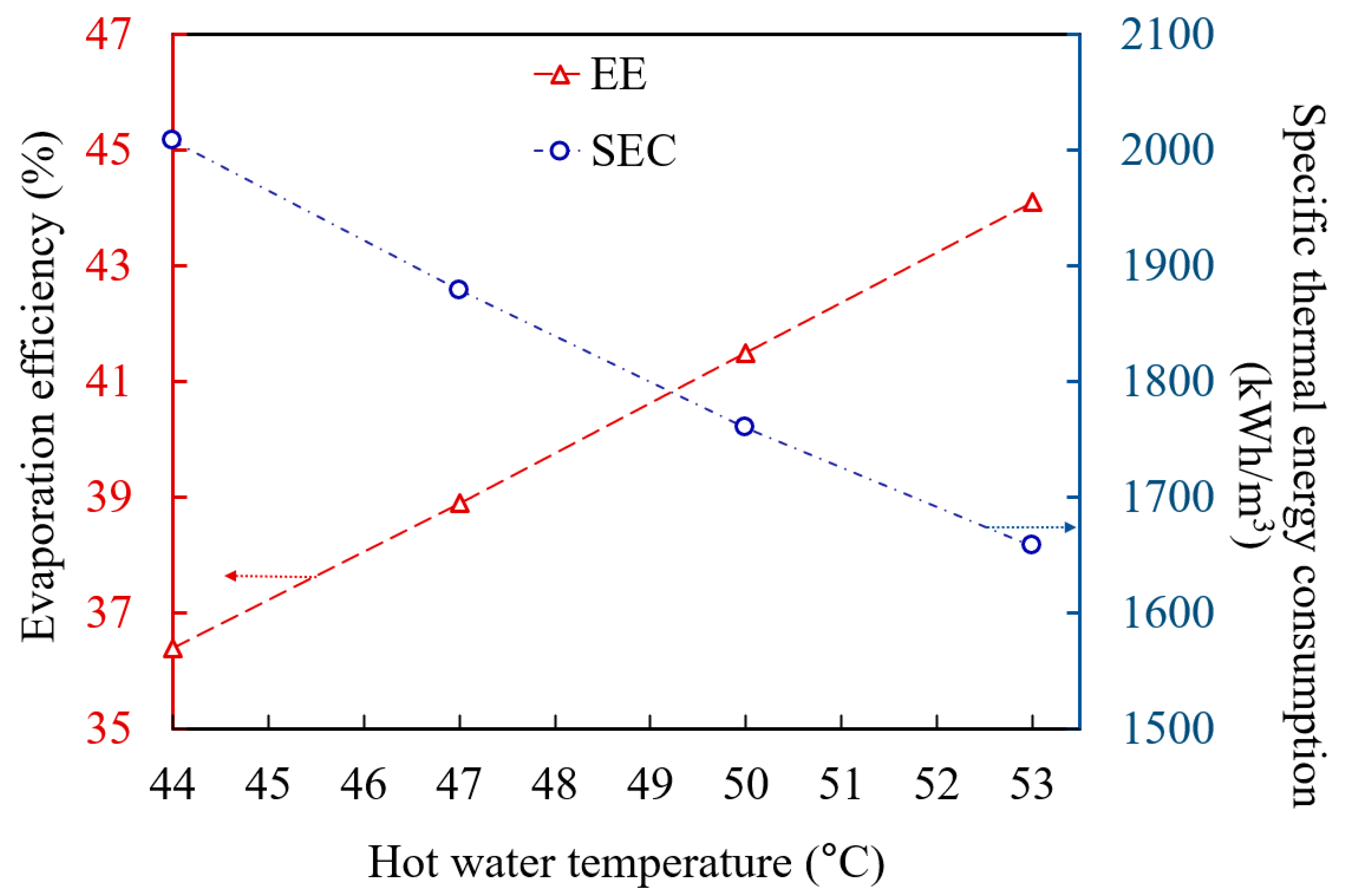

- For the DCMD system, an exponential increase in permeate flux from 11.4 kg/m2·h to 23.23 kg/m2·h was observed with increasing hot water temperatures from 44 °C to 56 °C. In addition, the evaporation efficiency of the DCMD system improved from 36.4% to 46.65% when the hot water temperature was increased from 44 °C to 56 °C. In contrast, the specific thermal energy consumption of the DCMD system reduced from 2008 kWh/m3 to 1567 kWh/m3 when the hot water temperature was increased from 44 °C to 56 °C.

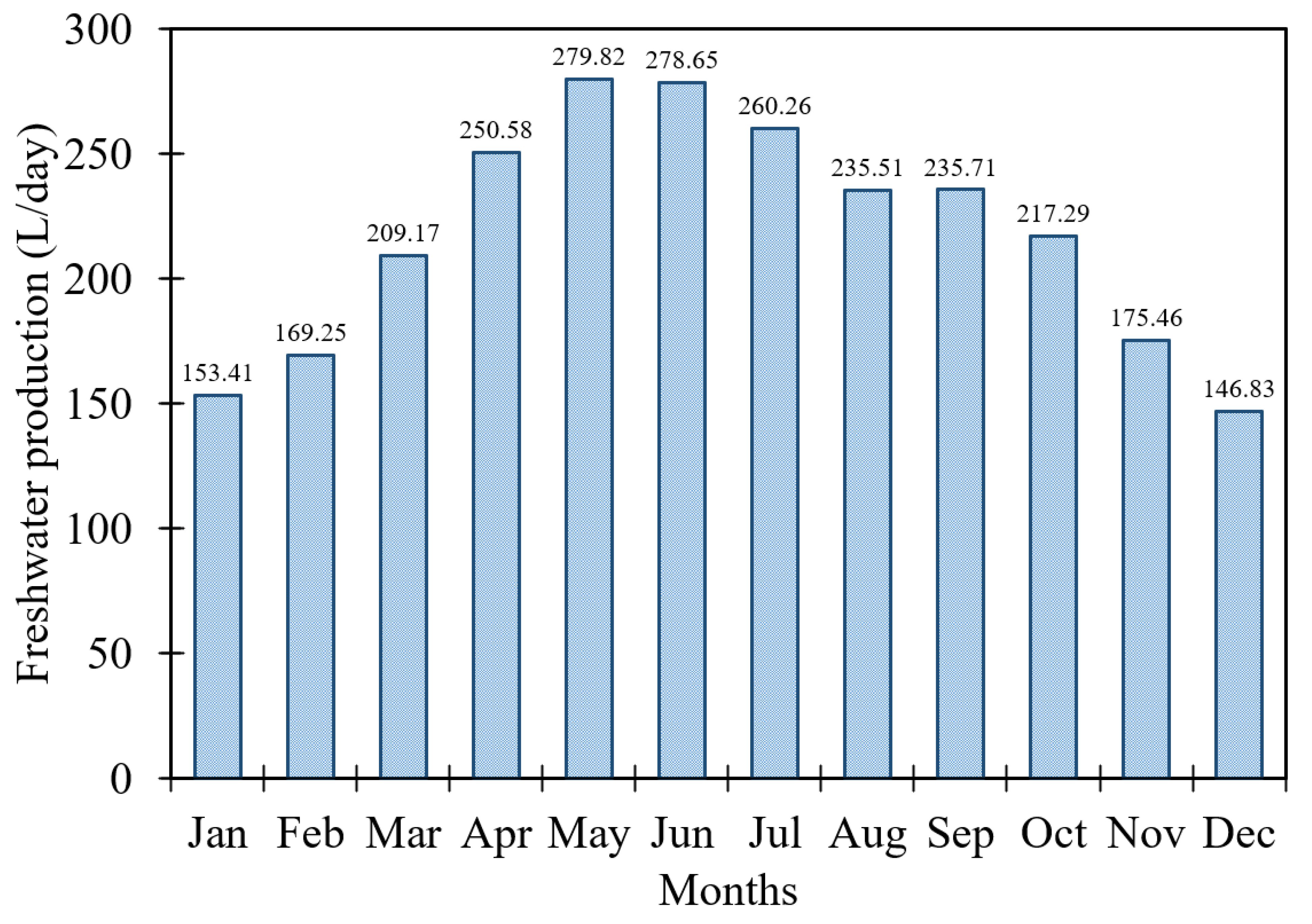

- The fresh water production reached the maximum in summers and the minimum in winters. Specifically, fresh water production was at the maximum (279.82 L/day) in May, and it was at the minimum (146.83 L/day) in December. On average, the solar-powered DCMD system produced 217.66 L/day of fresh water with LWC of 23.01 USD/m3, which is approximately 3.91 Pakistani rupees per liter. The LWC of the solar-powered DCMD system was found to be higher. Nonetheless, it is justifiable for small-scale, isolated, and remote residential zones in order to fulfill the fresh water demand without affecting the environment, especially for water-stressed countries such as Pakistan.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saleem, K.B.; Lounes, K.A.; Alshara, K.; Kolsi, L. Double-diffusive natural convection in a solar distiller with external fluid stream cooling. Int. J. Mech. Sci. 2020, 181, 105728. [Google Scholar] [CrossRef]

- Wichelns, D.; Nakao, M. Economic analysis of environmental issues regarding seawater desalination. Water Int. 2007, 32, 230–243. [Google Scholar] [CrossRef]

- World Health Organization. Available online: http://www.who.int/mediacentre/factsheets/fs391/en/ (accessed on 11 December 2020).

- Ali, A.; Ashu, T.R.; Francesca, M.; Efrem, C.; Enrico, D. Membrane technology in renewable-energy-driven desalination. Renew. Sustain. Energy Rev. 2018, 81, 1–21. [Google Scholar] [CrossRef]

- Ghaffour, N.; Bundschuh, J.; Mahmoudi, H.; Goosen, M.F.A. Renewable energy-driven desalination technologies: A comprehensive review on challenges and potential applications of integrated systems. Desalination 2015, 356, 94–114. [Google Scholar] [CrossRef]

- González, D.; Amigo, J.; Suárez, F. Membrane distillation: Perspectives for sustainable and improved desalination. Renew. Sustain. Energy Rev. 2017, 80, 238–259. [Google Scholar] [CrossRef]

- Qtaishat, M.R.; Banat, F. Desalination by solar powered membrane distillation systems. Desalination 2013, 308, 186–197. [Google Scholar] [CrossRef]

- Pal, P.; Manna, A.K. Removal of arsenic from contaminated groundwater by solar-driven membrane distillation using three different commercial membranes. Water Res. 2010, 44, 5750–5760. [Google Scholar] [CrossRef]

- Kim, Y.D.; Thu, K.; Ghaffour, N.; Ng, K.C. Performance investigation of a solar-assisted direct contact membrane distillation system. J. Membr. Sci. 2013, 427, 345–364. [Google Scholar] [CrossRef]

- Shim, W.G.; He, K.; Gray, I.S.; Moon, I.S. Solar energy assisted direct contact membrane distillation (DCMD) process for seawater desalination. Separ. Purifi. Technol. 2015, 143, 94–104. [Google Scholar] [CrossRef]

- Bouguecha, S.T.; Aly, S.E.; Al-Beirutty, M.H.; Hamdi, M.M.; Boubkari, A. Solar driven DCMD: Performance evaluation and thermal energy efficiency. Chem. Eng. Res. Des. 2015, 100, 331–340. [Google Scholar] [CrossRef]

- Lee, J.G.; Kim, W.S.; Choi, J.S.; Ghaffour, N.; Kim, Y.D. Dynamic solar-powered multi-stage direct contact membrane distillation system: Concept design, modeling and simulation. Desalination 2017, 435, 278–292. [Google Scholar] [CrossRef]

- Duong, H.C.; Xia, l.; Ma, Z.; Cooper, P.; Ela, W.; Nghiem, L.D. Assessing the performance of solar thermal driven membrane distillation for seawater desalination by computer simulation. J. Membr. Sci. 2017, 542, 133–142. [Google Scholar] [CrossRef]

- Soomro, M.I.; Kim, W.-S. Performance and economic investigations of solar power tower plant integrated with direct contact membrane distillation system. Energy Convers. Manag. 2018, 174, 626–638. [Google Scholar] [CrossRef]

- Soomro, M.I.; Kim, W.-S. Parabolic-trough plant integrated with direct-contact membrane distillation system: Concept, simulation, performance, and economic evaluation. Sol. Energy 2018, 173, 348–361. [Google Scholar] [CrossRef]

- Soomro, M.I.; Kim, W.-S. Performance and economic evaluation of linear Fresnel reflector plant integrated direct contact membrane distillation system. Renew. Energy 2018, 129, 561–569. [Google Scholar] [CrossRef]

- Soomro, M.I.; Kim, W.-S.; Kim, Y.-D. Performance and cost comparison of different concentrated solar power plants integrated with direct-contact membrane distillation system. Energy Convers. Manag. 2020, 221, 113193. [Google Scholar] [CrossRef]

- SOLARGIS. Available online: https://solargis.com/maps-and-gis-data/download/pakistan (accessed on 11 May 2018).

- System Advisor Model (SAM). National Renewable Energy Laboratory. Available online: https://sam.nrel.gov/weather (accessed on 7 June 2018).

- Annual Weather Averages. Sunshine hours in Karachi, Pakistan. Available online: https://www.holiday-weather.com/karachi/averages/ (accessed on 2 October 2018).

- World Resources Institute. Climate Impacts and Adaptation. Available online: https://www.wri.org/ (accessed on 20 May 2020).

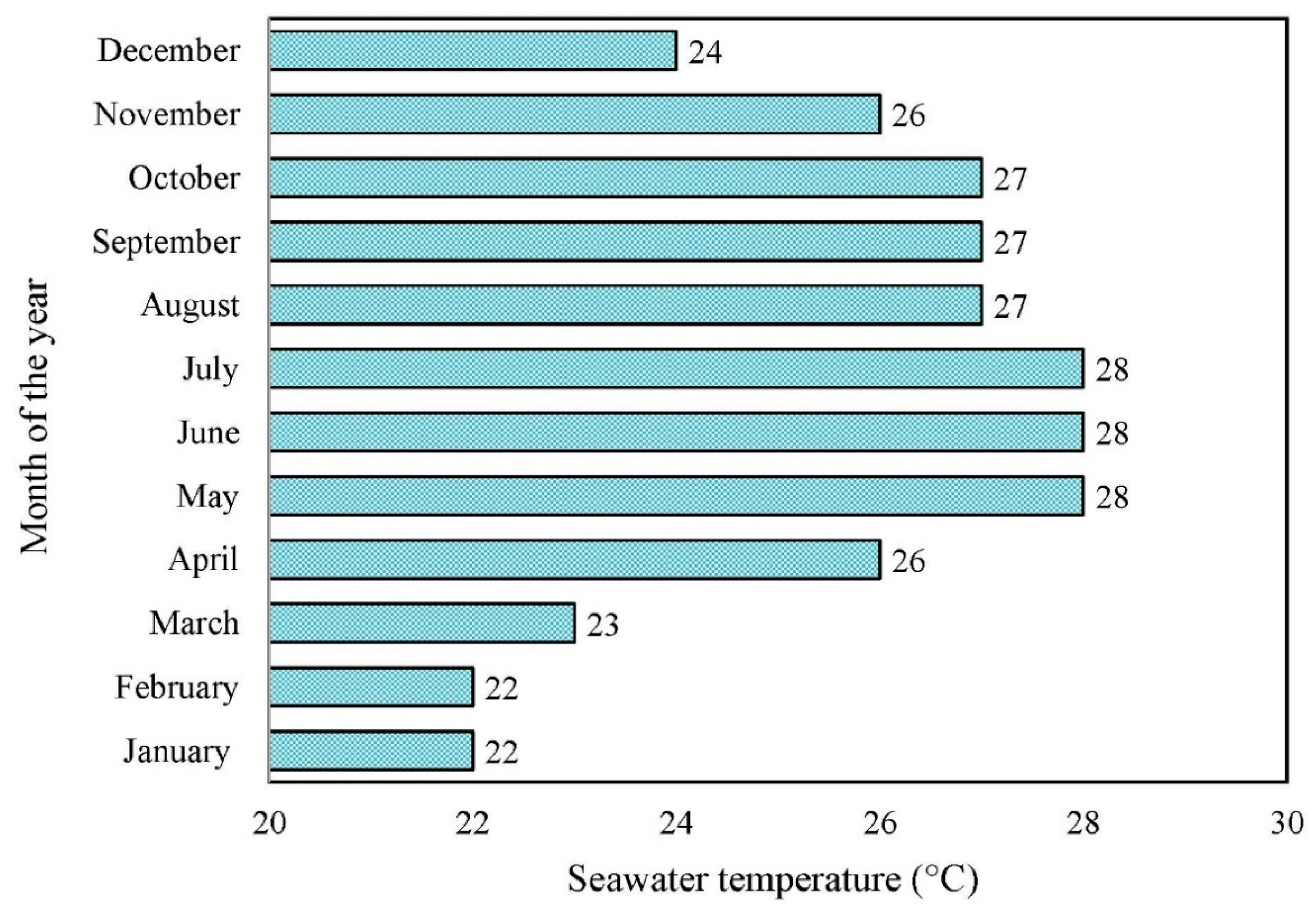

- Sea Temperature Info. Water Temperature in Karachi. Available online: https://seatemperature.info/karachi-water-temperature (accessed on 3 June 2018).

- Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid. Interface Sci. 2011, 164, 56–88. [Google Scholar] [CrossRef]

- Lee, J.G.; Kim, W.S.; Choi, J.S.; Ghaffour, N.; Kim, Y.D. A novel multi-stage direct contact membrane distillation module: Design, experimental and theoretical approaches. Water Res. 2016, 107, 47–56. [Google Scholar] [CrossRef]

- Gustafson, R.D.; Murphy, J.R.; Achilli, A. A stepwise model of direct contact membrane distillation for application to large-scale systems: Experimental results and model predictions. Desalination 2016, 378, 14–27. [Google Scholar] [CrossRef]

- Zhang, L.-Z.; Li, G.-P. Energy and economic analysis of a hollow fiber membrane-based desalination system driven by solar energy. Desalination 2017, 404, 200–214. [Google Scholar] [CrossRef]

- Khalifa, A.; Ahmad, H.; Antar, M.; Laoui, T.; Khayet, M. Experimental and theoretical investigations on water desalination using direct contact membrane distillation. Desalination 2017, 404, 22–34. [Google Scholar] [CrossRef]

- Zuo, G.; Wang, R.; Field, R.; Fane, A.G. Energy efficiency evaluation and economic analyses of direct contact membrane distillation system using Aspen Plus. Desalination 2011, 283, 237–244. [Google Scholar] [CrossRef]

- Banat, F.; Jwaied, N. Economic evaluation of desalination by small-scale autonomous solar-powered membrane distillation units. Desalination 2008, 220, 566–573. [Google Scholar] [CrossRef]

- Macedonio, F.; Curcio, E.; Drioli, E. Integrated membrane systems for seawater desalination: Energetic and exergetic analysis, economic evaluation, experimental study. Desalination 2007, 203, 260–276. [Google Scholar] [CrossRef]

- Al-Obaidani, S.; Curcio, E.; Macedonio, F.; Profio, G.D.; Alhinai, H.; Drioli, E. Potential of membrane distillation in seawater desalination: Thermal efficiency, sensitivity study and cost estimation. J. Membr. Sci. 2008, 323, 85–98. [Google Scholar] [CrossRef]

| Authors | Location | System | Water Production | Cost |

|---|---|---|---|---|

| Pal and Manna (2010) [8] | India | Solar-driven MD | 49.80 kg/m2/h | N/A |

| Kim et al. (2013) [9] | Jeddah, Saudi Arabia | Solar-assisted DCMD | 51.4 kg/m2/h (31 m3/day) | N/A |

| Shim et al. (2015) [10] | Suncheon, South Korea | Solar energy-assisted DCMD | 40.9 L/m2/h | N/A |

| Bouguecha et al. (2015) [11] | Jeddah, Saudi Arabia | Solar-driven DCMD | 3.91–4.59 L/h per module | N/A |

| Lee et al. (2017) [12] | Busan, South Korea | Solar-powered MD | N/A | |

| Duong et al. (2017) [13] | New South Wales, Australia | Solar power-driven MD | 19.7 kg/m2 of solar thermal collector | N/A |

| Soomro and Kim (2018) [14] | South Korea | Solar power tower plant integrated with DCMD | 40,759 L/day | USD 0.392/m3 |

| Soomro and Kim (2018) [15] | Abu Dhabi, United Arab Emirates. | Parabolic trough plant integrated with DCMD | 14.33 m3/day | USD 0.64/m3 |

| Soomro and Kim (2018) [16] | South Korea | Linear Fresnel reflector plant integrated with DCMD | 31,844.6 L/day | USD 0.425/m3 |

| Soomro et al. (2020) [17] | South Korea | Concentrated solar power plants integrated | 38.9 m3/day | 0.314 m3 |

| Item | Unit Cost | Quantity | Estimated Cost |

|---|---|---|---|

| Capital Cost (CC) | |||

| Direct capital cost (DCC) | |||

| Membrane cost | 36 USD/m2 [29] | 0.56 m2 | 20.16 USD |

| MD equipment cost [29] | 61.09 USD | ||

| Total cost of MD Module | 81.25 USD | ||

| Solar collector cost | 120 USD/m2 | 48.1 m2 | 5772 USD |

| Heat storage tank | 1200 USD/m3 | 5 m3 | 6000 USD |

| SWHS installation cost | 3500 USD | ||

| Total DCC | 15,434.5 USD | ||

| Indirect capital cost (ICC) [30] | 1543.4 USD | ||

| CC = DCC + ICC | 16,977.95 USD | ||

| ACfixed = a × CC | 1362.355 USD | ||

| Annual operating and maintenance cost (ACO&M) | |||

| Annual maintenance cost (ACMT) [29] | 272.47 USD | ||

| Membrane replacement cost (ACMR) [29] | 16.25 USD | ||

| Annual labor cost (AClabor) | 0.05 USD/m3 [30] | 3.56 USD | |

| Annual brine disposal cost (ACBD) | 0.0015 USD/m3 [31] | 0.10 USD | |

| Annual electric cost (ACelectricity) | 0.06 kWh/m3 [28] | 0.427 USD | |

| ACO&M | 292.82 USD | ||

| ACtotal = ACfixed + ACO&M | 1655.17 USD | ||

| LWC | 23.21 USD/m3 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soomro, M.I.; Kumar, S.; Ullah, A.; Shar, M.A.; Alhazaa, A. Solar-Powered Direct Contact Membrane Distillation System: Performance and Water Cost Evaluation. Sustainability 2022, 14, 16616. https://doi.org/10.3390/su142416616

Soomro MI, Kumar S, Ullah A, Shar MA, Alhazaa A. Solar-Powered Direct Contact Membrane Distillation System: Performance and Water Cost Evaluation. Sustainability. 2022; 14(24):16616. https://doi.org/10.3390/su142416616

Chicago/Turabian StyleSoomro, Mujeeb Iqbal, Sanjay Kumar, Asad Ullah, Muhammad Ali Shar, and Abdulaziz Alhazaa. 2022. "Solar-Powered Direct Contact Membrane Distillation System: Performance and Water Cost Evaluation" Sustainability 14, no. 24: 16616. https://doi.org/10.3390/su142416616

APA StyleSoomro, M. I., Kumar, S., Ullah, A., Shar, M. A., & Alhazaa, A. (2022). Solar-Powered Direct Contact Membrane Distillation System: Performance and Water Cost Evaluation. Sustainability, 14(24), 16616. https://doi.org/10.3390/su142416616