1. Introduction

The shield tunneling method has been developed as a main construction method for subway construction owing to its safety for excavation and its low disturbance to the surrounding environment. It is well known that stable soil in the front of the tunnel face, which is determined by the cabin pressure, is a key element in the constructive safety of a shield tunnel. The existing literature shows that insufficient cabin pressure will induce the collapse of the tunnel face, whereas overlarge cabin pressure will lead to soil uplift in the front of the tunnel face. When a shield tunnel is being drilled in a water-rich stratum, the underground water table will be disturbed by the excavation, which induces underground water seepage. However, numerous articles in the literature show that underground water seepage exerts a greatly adverse effect on the face stability. Moreover, the engineering accidents induced by instability of the tunnel face may result in serious casualties and property damage. Therefore, studying the stability of the tunnel face in shield tunnel excavation under the groundwater table is of primary significance.

Currently, numerous scholars have employed various methods to investigate the stability of the tunnel face. Because a limit analysis theorem can be used to effectively investigate the stability of the geotechnical engineering, many scholars have used this method to study this problem. Mollon et al. [

1] established a three-dimensional (3D) multiblock rupture mechanism to study the collapse and the blow-out failure modes of a tunnel face by applying the upper bound method of limit analysis. Later, Mollon et al. [

2] used a spatial discretization technique to establish a 3D rupture mechanism, and they derived a corresponding theoretical solution of the supporting force on the basis of the upper bound approach. By modifying the rupture mechanism proposed by Mollon et al. [

2], Senent et al. [

3] used this improved mechanism in conjunction with the Hoek–Brown yield criterion to study the stability of shield tunnels excavated in cracked rock. Moreover, Yang et al. [

4] studied the influence of the inhomogeneity and anisotropy of soil on the ultimate supporting force of a shield tunnel that was excavated in an anisotropic stratum. Consequently, Xu et al. [

5] proposed a new rotational failure mechanism and used this mechanism in conjunction with a nonlinear failure criterion to compute the theoretical solution of the cabin pressure for tunnel face. Later, Zhang et al. [

6] constructed three-dimensional active and passive failure mechanisms of the tunnel face by investigating the failure features of rock mass in front of the tunnel face. On the basis of these mechanisms, Zhang et al. [

6] obtained the safe range of supporting pressures of the shield tunnel face and validated the effectiveness of the computing results by applying this method in an actual project. To study the safety of a tunnel face when considering tensile strength cutoff, Chen et al. [

7] proposed two improved failure mechanisms in the tunnel face. Using these new failure mechanisms, the limit supporting pressures of the tunnel face for collapse and blow-out modes are calculated and the calculating results are compared with the existing solutions.

Groundwater seepage is a one factor that affects tunnel stability when a tunnel is excavated under the water table. Thus, the study of the influence of seepage on the safety of a shield tunnel has drawn a great deal of attention, for some scholars. By improving on an existing model, Perazzelli et al. [

8] employed the limit equilibrium theory to investigate the safety of the tunnel face under seepage flow conditions. To investigate the influence of pore pressure on the stability of soil in front of a tunnel face, Pan and Dias [

9] calculated the distribution of pore pressure and obtained the theoretical solution for the cabin pressure of the tunnel face. Subsequently, using a modified three-dimensional failure mechanism as a base, Pan and Dias [

10] studied the stability of soil in front of a tunnel face under the water table by employing an upper bound theorem of limit analysis. Later, finding that the study of the coupled flow deformation of a tunnel face is rare, Zou and Qian [

11] developed a theoretical method to calculate the supporting pressure of a tunnel face for a shield tunnel drilled below the water table. Using the discretization technique as a base, Yang and Zhong [

12] proposed a new active failure mechanism to investigate the stability of soil in front of a tunnel face when the tunnel is excavated below the water table. Using this mechanism, Yang and Zhong [

12] calculated the supporting pressure of the tunnel while accounting for the pore pressure and validated the effectiveness of their method by comparing their results with the existing solutions. Finding that most of the existing studies have focused on the stability of tunnel faces excavated in saturated soil, Li et al. [

13] proposed a method to study the stability of a tunnel face by accounting for the unsaturated seepage effect. Using this method, Li et al. [

13] calculated the safety factor of the shield tunnel face and assessed the stability of a tunnel face drilled in saturated stratum. Using the computational fluid dynamics-discrete element method, Fu et al. [

14] investigated the seepage effect on the rupture mode of the underwater tunnel face. Their achievements show that under seepage situations, the rupture region in the front of the tunnel face increases as the water depth increases. Weng et al. [

15] designed a centrifuge test to study the rupture mode of tunnel faces caused by the lengthways slope angle of the tunnel and steady-state seepage. Their model test results present the progressive rupture mode of the excavation face caused by the two factors mentioned above.

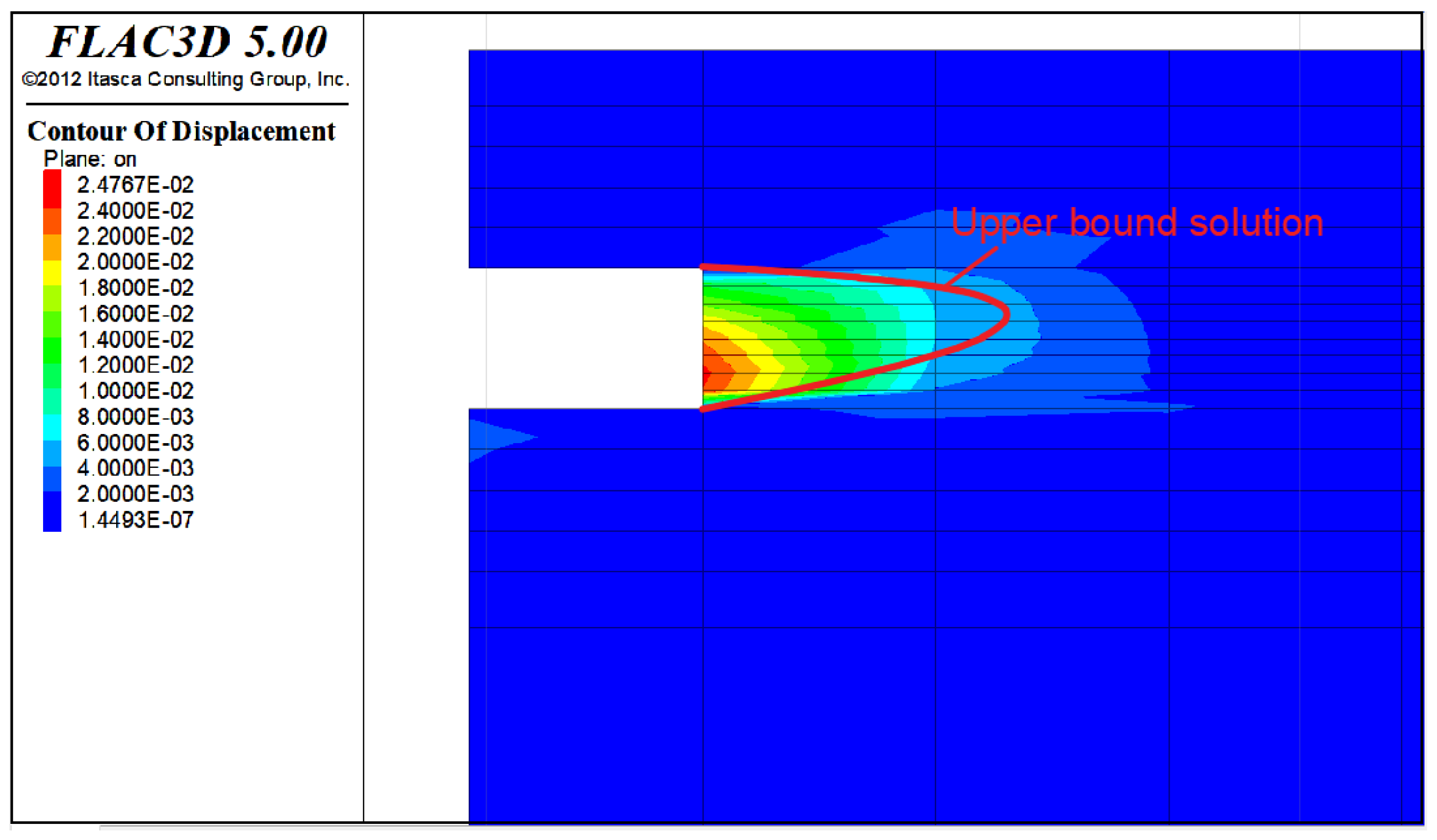

The purpose of our study is to investigate the groundwater seepage effect on shield tunnel face stability. To achieve this target, a new rupture mechanism that can be employed to describe the failure feature of tunnel face induced by insufficient cabin pressure under the water table is constructed. By regarding seepage force as an external force, the external rate of work produced by seepage force is introduced into the virtual equation, and the objective function of the rupture surface for the tunnel face is obtained. In the context of a variational principle, the equation of the rupture surface for the tunnel face at the limit state is derived, and likewise, the shapes of the rupture surface for various parameters are drawn. The proposed method is validated by comparing it with the results that have been provided by numerical simulation. The method can obtain the collapse region of the soil in the front of the tunnel face, which provides a useful reference for a stability assessment of a shield tunnel excavated under the water table.

2. Construction of a Failure Mechanism for a Tunnel Face, Accounting for Groundwater Seepage

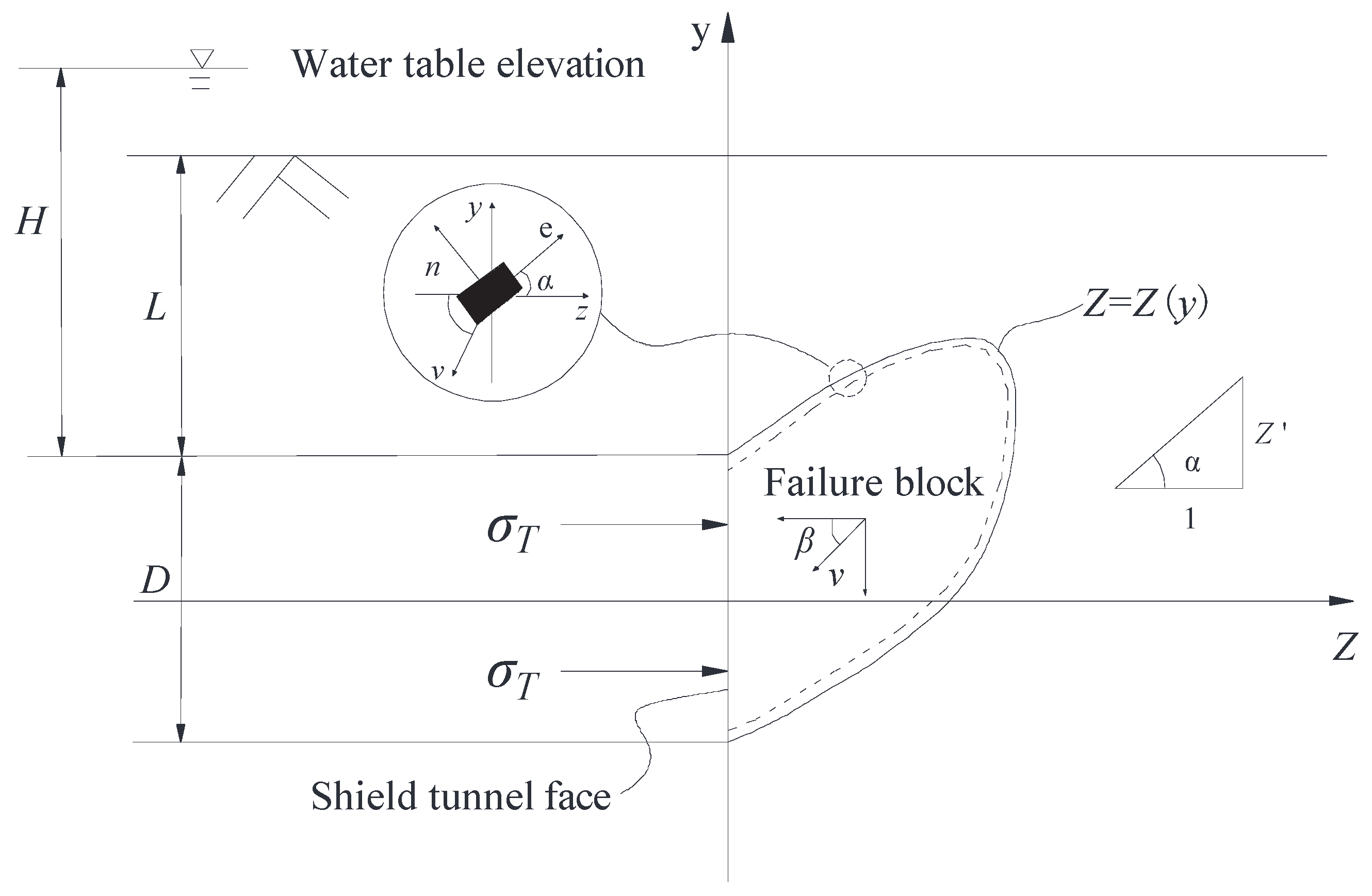

During the shield tunnel construction process, the pressure of the chamber of the shield machine is a key element in maintaining the stability of the tunnel face. The soil in front of the tunnel face may collapse when the soil chamber pressure is deficient to resist the earth pressure produced by the soil in front of the tunnel face. To describe the collapse characteristic of the tunnel face, an upper bound failure mechanism, which is composed of an arbitrary curve

, is constructed, as shown in

Figure 1 and

Figure 2. Curve

extends from the bottom to the top of the tunnel face, and a closed collapse surface forms in front of the tunnel face. The soil within the region of curve

may collapse in the tunnel because of insufficient soil chamber pressure. Furthermore,

is the diameter of the shield tunnel, and

L is the depth of the tunnel.

is the space from the groundwater head to the shield tunnel roof, and

v is the velocity vector of the collapse block. It is assumed that the pressure of the chamber provided by the shield machine is

, which is evenly distributed over the entire excavation face. For calculation simplicity, some assumptions about the failure mechanism are presented, as follows:

The stratum around the tunnel is homogeneous soil, and the stratum is regarded as an ideal elastic-plastic body;

The collapse block is a rigid body, which means the deformation of the collapse block can be ignored.

Figure 1.

Diagram of soil collapse damage in front of excavation.

Figure 1.

Diagram of soil collapse damage in front of excavation.

Figure 2.

Mechanism of soil collapse damage in front of excavation in groundwater seepage.

Figure 2.

Mechanism of soil collapse damage in front of excavation in groundwater seepage.

4. Upper Bound Solution for the Collapse Surface for a Tunnel Face, Accounting for Groundwater Seepage

As Chen [

16] pointed out, the equation of virtual work in the kinematically admissible velocity field comprises the external rate of work and the internal rate of dissipation. Moreover, the external rate of work is produced by the external force of the presented failure mechanism, which includes the soil gravity, the pressure of the chamber, and the seepage force. Thus, the external rate of work generated by the external force can be calculated. The rate of work done by soil gravity can be obtained by applying it to the entire failure surface.

where

is the bulk density of rock/soil. Because the pressure of chamber

is evenly distributed over the entire tunnel face, the rate of work produced by the pressure of the chamber can be expressed by:

As mentioned above, the effect of seepage is a significant factor that should be taken into account in tunnel face stability analysis. Thus, using the expressions of horizontal and vertical components of the seepage force, an expression for the rate of work produced by seepage force can be written as:

On the other hand, the computation of the dissipation rate in the presented rupture mechanism is more complex than the calculation of the external rate of work. The soil is assumed to obey an associated flow law. When the potential surface is in accordance with the yield surface, the potential function is:

Moreover, when the plastic flow occurs in the collapse surface, the strain increment can be expressed as:

where

λ is the plasticity multiplier. As mentioned above, any random point on the collapse surface will obey the principle of small deformation, and the rate of deformation for the point is approximately equal to the rate of strain. Given the geometric relationships illustrated in

Figure 3, the strain increment of any point on the collapse surface is:

where

is the angle between the tangent vector and the

z-axis at any point on the collapse surface. Moreover,

, where

t is the thickness of the plastic flow zone.

By combining Equations (16) and (17), the following equation can be obtained:

Because the energy dissipation occurs only at the velocity discontinuity surfaces, the rate of energy dissipation for any point on the velocity discontinuity surfaces can be calculated only by superimposing the rate of energy dissipation on the normal direction and the tangential direction. Thus, the rate of energy dissipation for any point on the rupture surface is:

For mathematical simplicity, the following equation is introduced:

Merging part of Equation (21) with part of Equation (20), the rate of energy dissipation for any point on the collapse surface is:

On the basis of the geometrical relation illustrated in

Figure 2 and trigonometric function, the following equations are determined.

By applying Equation (22) to the entire collapse surface and combining Equation (23), the total rate of energy dissipation along the collapse surface is:

On the basis of the kinematical approach, the relationship between the rate of external work and the rate of energy dissipation is obtained:

The aim of this study is to investigate the failure mode and failure range of the soil in the front of the tunnel face at limit state. To obtain the analytical equations of the rupture surface at the limit state, it is necessary to establish a target function that includes the equation of the failure surface, by using the external rate of work and the rate of the energy dissipation. By incorporating Equations (12)–(14) and (24) into Equation (25), the target function is determined:

Because independent variable

in Equation (26) is a function, objective function

can be regarded as a functional, which can be expressed as:

where

However, the upper bound solution, which derives from the relation between the external rate of work and the rate of the energy dissipation, is not the real result. According to Chen [

16], the real result of the rupture surface can be obtained only when objective function

J has reached its extreme value. Furthermore, Equation (28) is a special case of the Euler equation, which means that the extreme solution of the functional can be converted into solving the solution of Equation (28) under fixed boundary conditions. Thus, the first incorporation of Equation (28) is:

where

After some simplification, the following equation is derived:

On the basis of Equation (31), the expression of

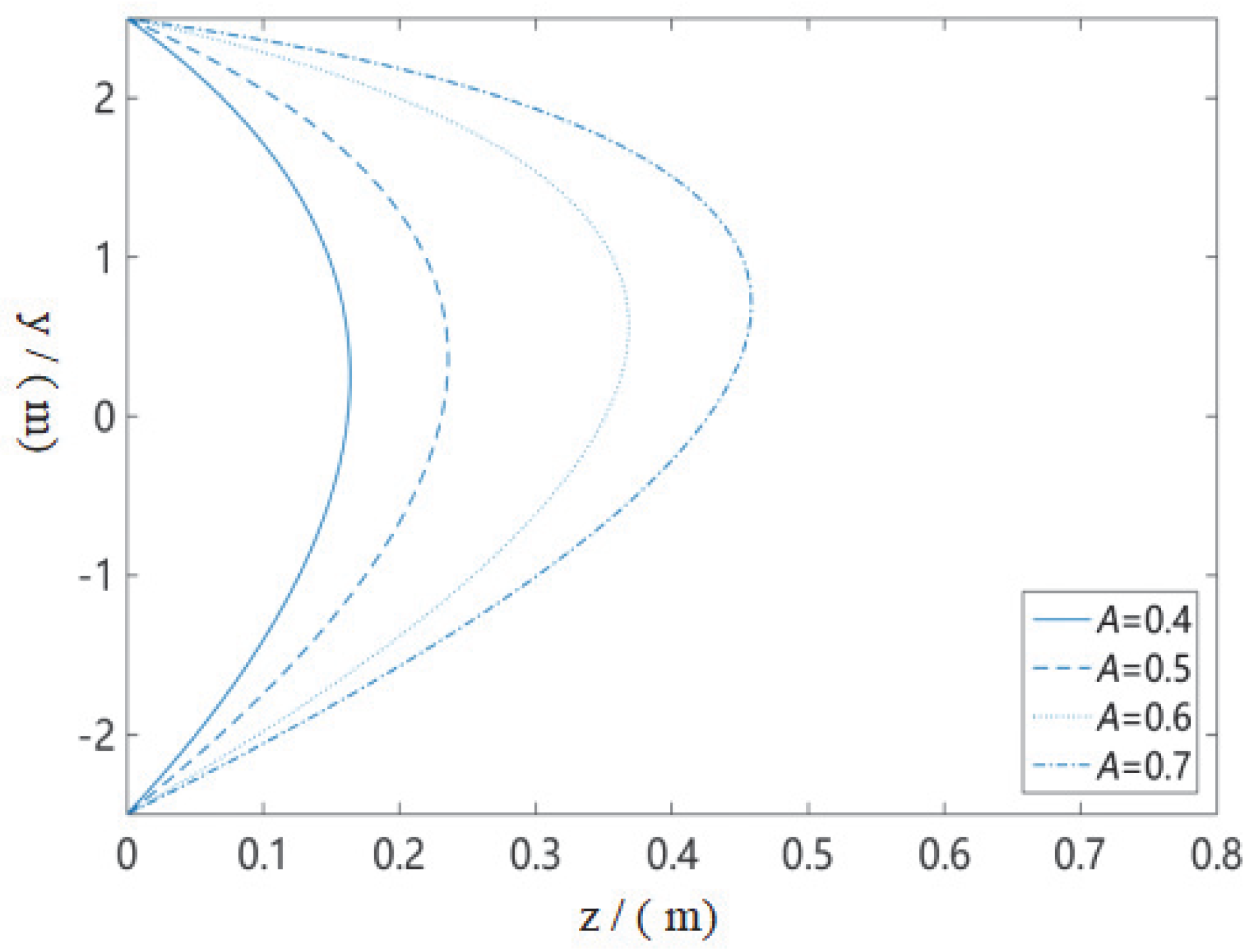

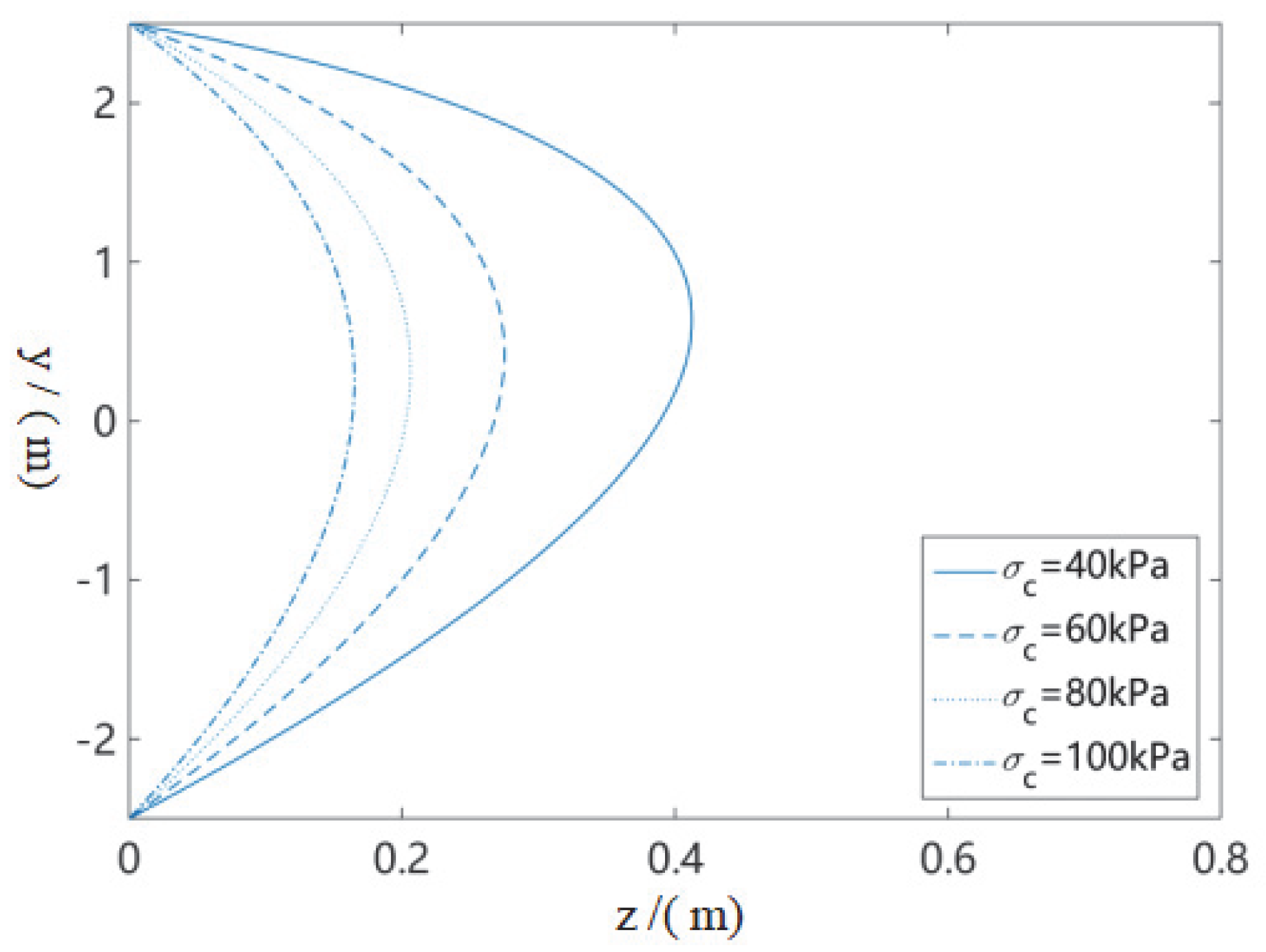

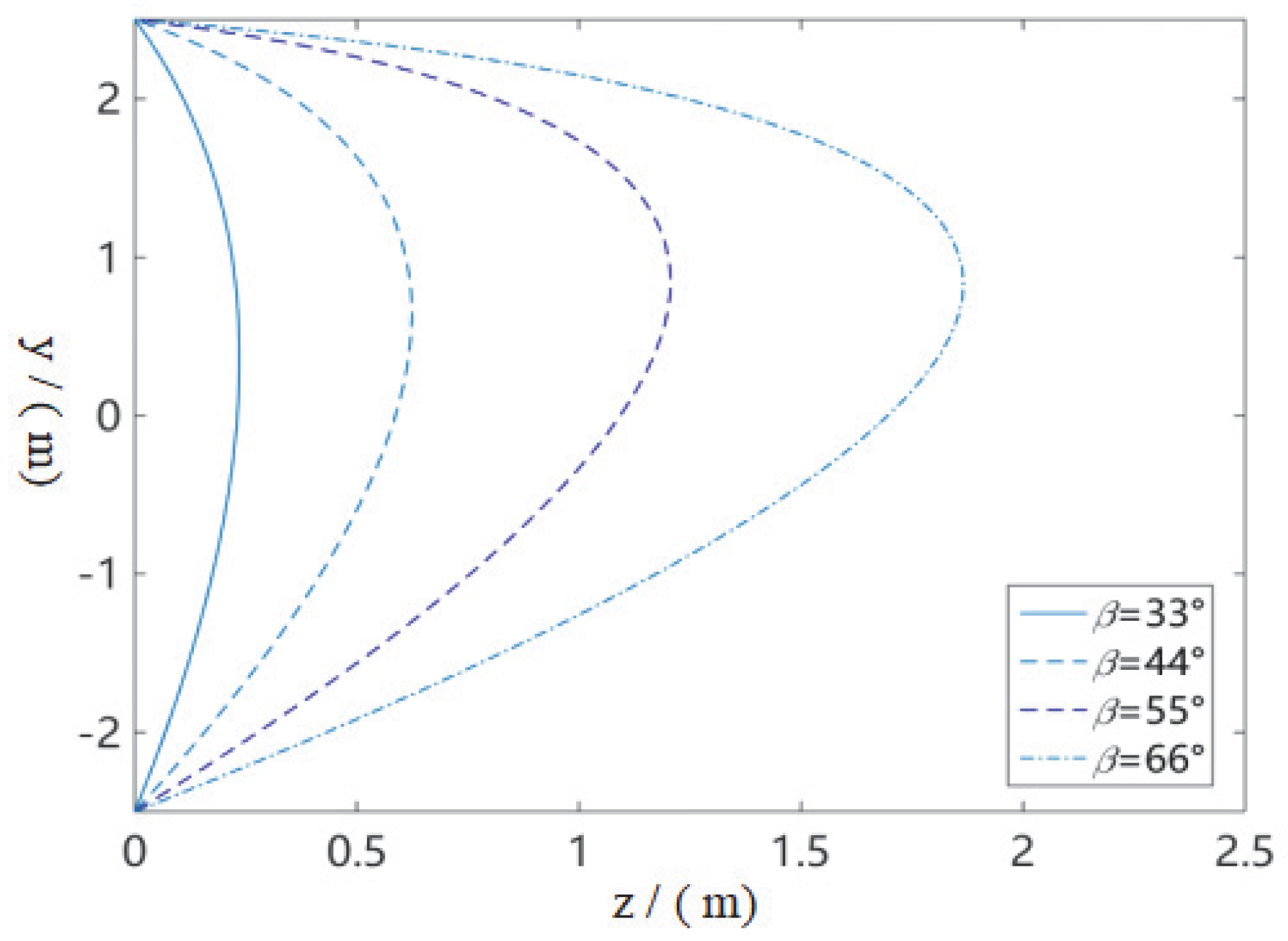

is obtained. After calculating the incorporated expressions, a set of curves that reaches extreme solutions is derived:

where

and

are integration constants. Using geometric boundary conditions

, the values of

and

can be determined.

The value of parameter

B is extremely important for solving Equation (31). According to Hoek and Brown [

17], the value of parameter

B ranges from 0 to 1. However, Equation (31) is a linear differential equation only when

, which can be solved analytically. When

, Equation (31) is a complex nonlinear partial differential equation, which cannot be solved analytically. Therefore, in this study, the equation for a collapse surface of a tunnel face at limit state is discussed only for the parameter

B = 0.5. When parameter

, Equation (31) can be simplified as:

A MATLAB [

18] program is employed to solve this nonlinear partial differential equation. Firstly, a form of Equation (33), which is expressed by separating variables

and

y, can be obtained by using a simplified calculation. Then, by substituting fixed boundary conditions, the values of integration constants

and

are determined. Finally, a particular solution among these solutions that satisfies boundary condition

is found. In summary, the equation for the collapse surface of the soil in front of the shield tunnel face is obtained: