The Impact of Technologies of Traceability and Transparency in Supply Chains

Abstract

1. Introduction

2. Literature Review

2.1. Supply-Chain Traceability (SCT) and Transparency

2.2. Technologies of Traceability and Transparency in Supply Chains

2.3. Blockchain-Based Traceability

2.4. Social Internet of Things Based Traceability

2.5. Artificial Intelligence-Based Traceability

2.6. Traceability and Transparency in the Supply Chain

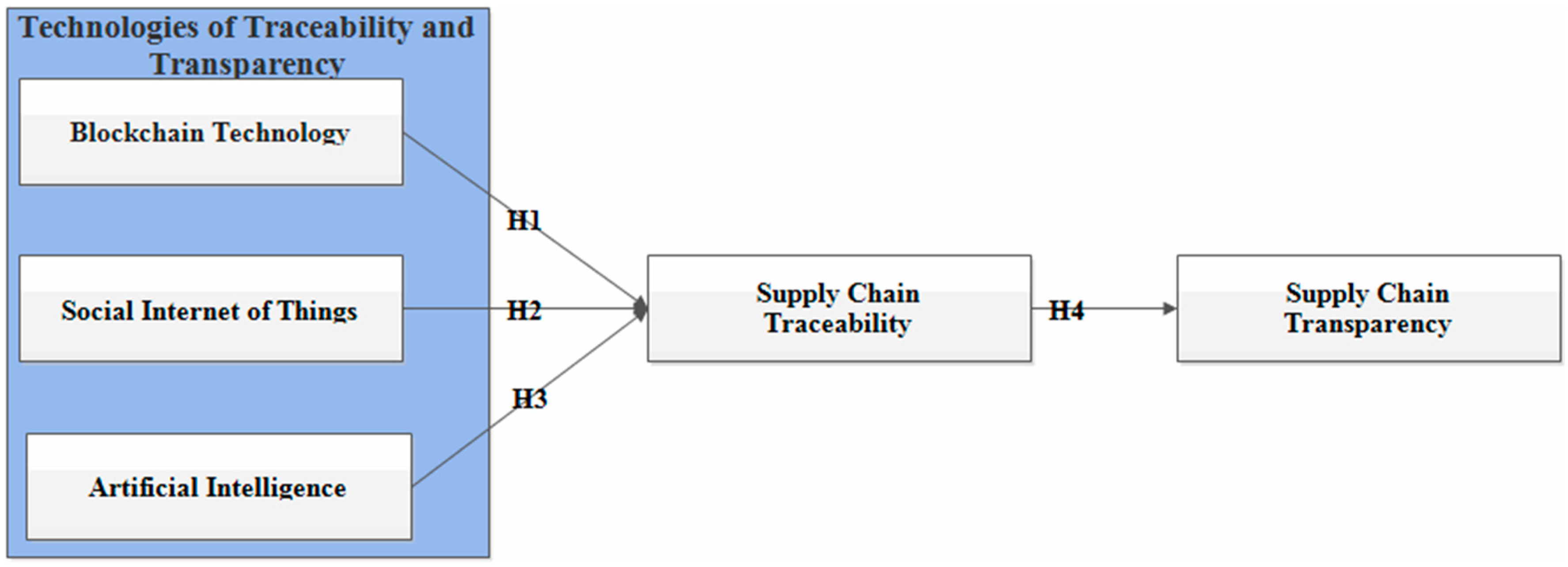

3. Method

3.1. Population and Sampling

3.2. Questionnaire Development and Data Collection

3.3. Descriptive Statistics

4. Results and Analysis

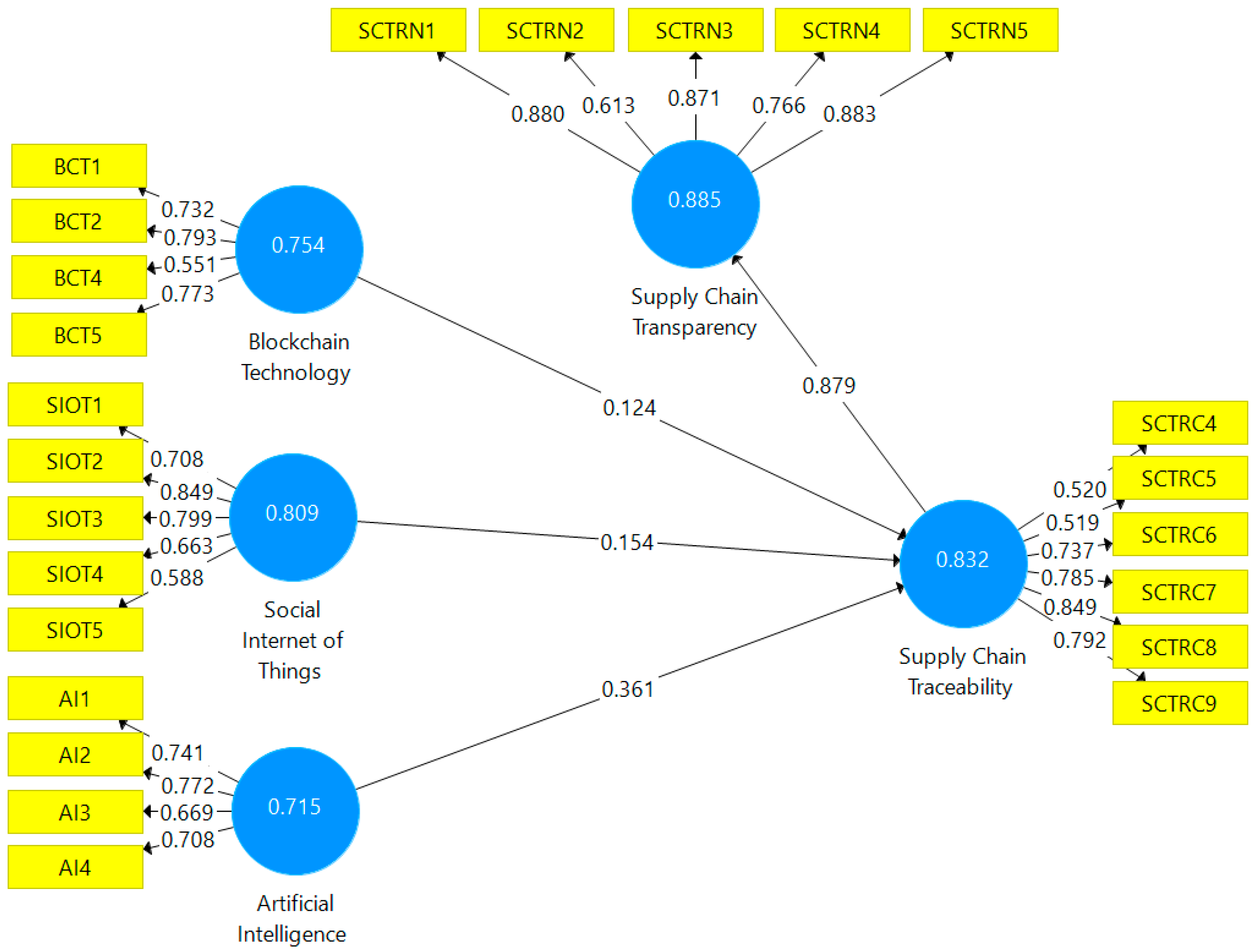

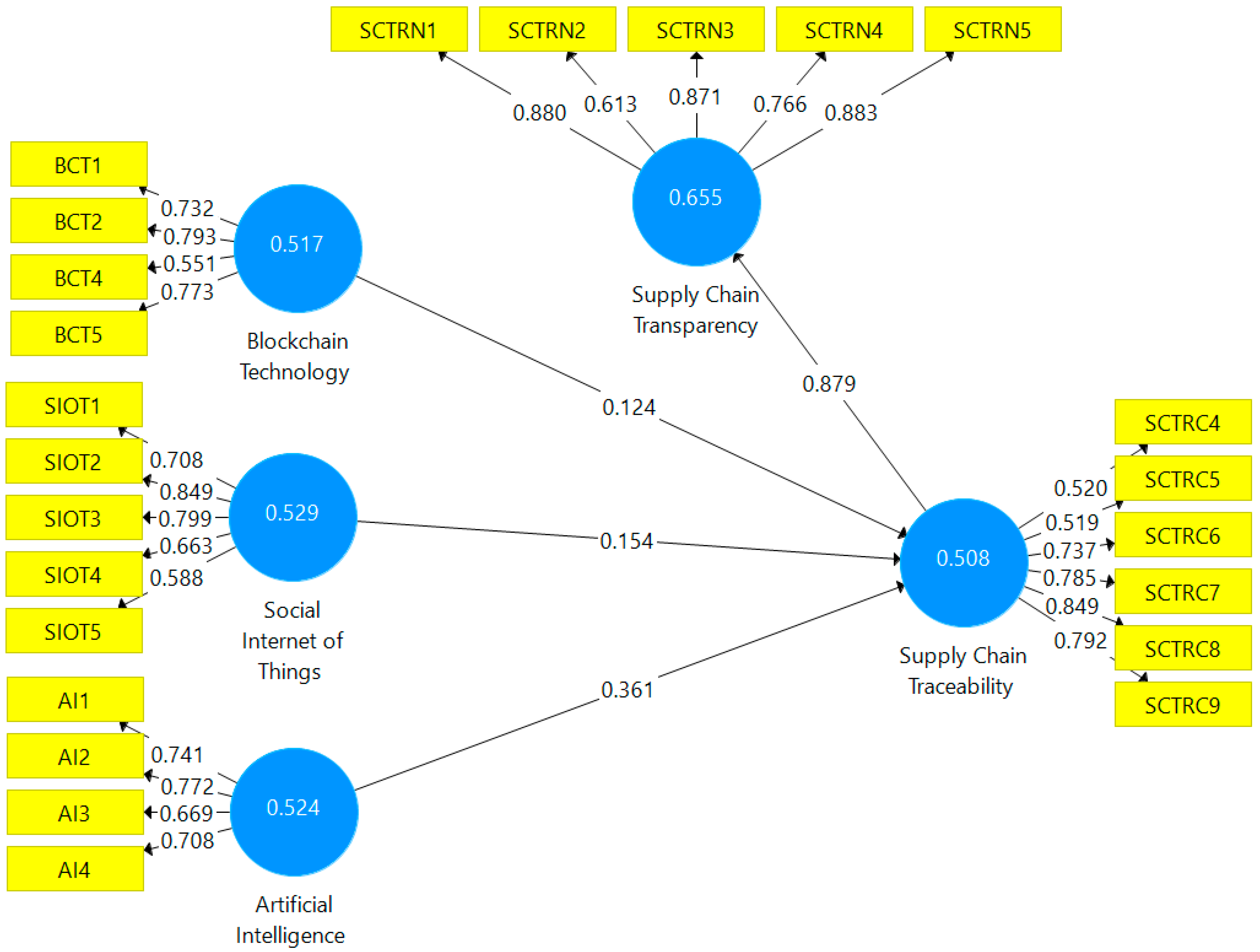

4.1. Evaluation of the Measurement Model

4.2. Measurement Model Reliability

Model Validity

4.3. The Predictive Validity

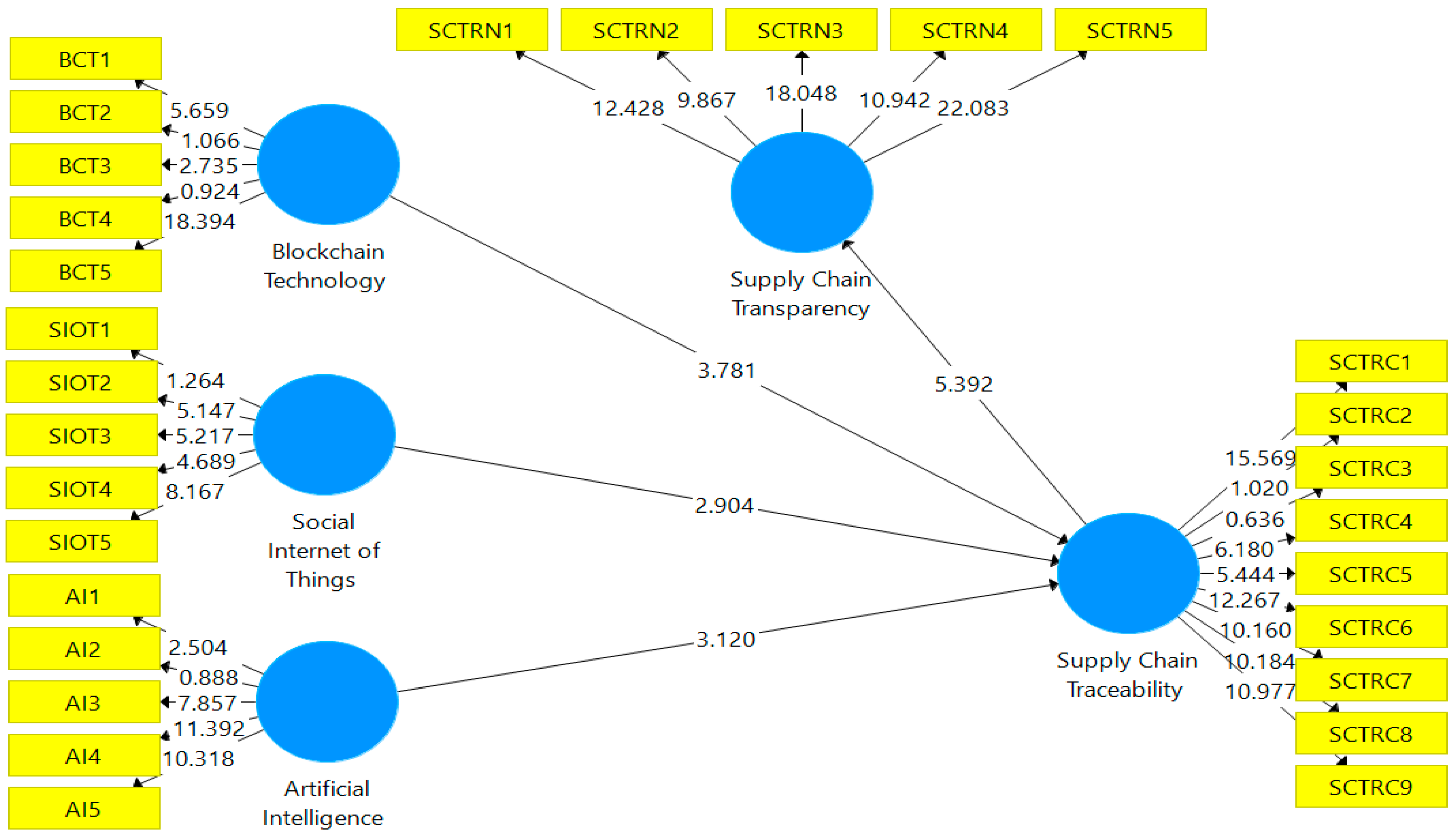

4.4. Hypothesis Testing

5. Findings and Implications

5.1. Contribution to Theory

5.2. Managerial Implications

5.3. Limitations and Future Research Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| S/No | Constructs and Items | References |

| Blockchain Technology (BCT) | ||

| 1 | We use distributed ledger technology for traceability in supply chain (BT1). | [62] |

| 2 | We use distributed ledger technology as it helps to maintain confidentiality, integrity, and availability of the data (BT2). | |

| 3 | We use distributed ledger technology to improve traceability in supply chain (BT3). | |

| 4 | We routinely use distributed ledger technology as a data platform that traces the origins, use, and destination of supplies (BT4). | |

| 5 | We routinely use distributed ledger technology to avoid confusion among partners engaged in supply chain (BT5). | |

| Social Internet of Things (SIoT) | ||

| 1 | My company utilizes social IoT for inter-organization traceability (SIoT1). | [62] |

| 2 | My company utilizes social IoT for intra-organization traceability (SIoT2). | |

| 3 | My company utilizes social IoT to trace and track the information for future use (SIoT3). | |

| 4 | My company utilizes social IoT for management of supply chain (SIoT4). | |

| 5 | I agree with the development of my company’s tracing of the origin of products and ingredients through social IoT (SIoT5). | |

| Artificial Intelligence | ||

| 1 | Artificial intelligence checks human judgment in supply chain (AI1). | [61,62] |

| 2 | Artificial intelligence may prevent errors, it helps to maintain confidentiality (AI2). | |

| 3 | Computers can deal with personal data more carefully than humans to improve traceability in supply chain (AI3). | |

| 4 | In my opinion, humans make more errors than computers (AI4). | |

| 5 | My company uses the artificial intelligence for the tracing and tracking to meet supply chain sustainability (AI5). | |

| Supply-Chain Traceability (SCTRC) | ||

| 1 | Traceability can overcome continuous and sustainable ambiguities in the SC (SCTRC1). | [4,63,64] |

| 2 | Through technology of traceability, the management can control procurement and effectively plan inventory management (SCTRC2). | |

| 3 | I agree with increasing consumers’ confidence in our product and reducing customer complaints (SCTRC3). | |

| 4 | Technology and Traceability can help in increasing the number of customers (SCTRC4). | |

| 5 | We constantly stay in touch with stakeholders until the product reached the consumers (SCTRC5). | |

| 6 | Our company traceability system enables to share of most information regularly and proactively with the stakeholders (SCTRC6). | |

| 7 | Our company traceability system increases access to contracts and markets (SCTRC7). | |

| 8 | Our company regularly traces that product is sourced from appropriate sources (SCTRC8). | |

| 9 | Our company traceability system improves competitiveness of the members of supply chain (SCTRC9). | |

| Supply-Chain Transparency (SCTRN) | ||

| 1 | Traceability enables us to share our supply chain operational plans (SCTRN1). | [57,63] |

| 2 | Through traceability, we routinely gather strategic information related to supply chain (SCTRN2). | |

| 3 | Due to tracking and tracing, we routinely share strategic information (SCTRN3). | |

| 4 | Through, traceability, the entire process of the supply chain in my company is accurately and transparently disclosed (SCTRN4). | |

| 5 | Due to traceability, my company facilitates the stakeholders to get the information they need (SCTRN5). | |

References

- Qian, J.; Dai, B.; Wang, B.; Zha, Y.; Song, Q. Traceability in food processing: Problems, methods, and performance evaluations—A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 679–692. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Blenkinsopp, J. The roles of transparency and trust in the relationship between corruption and citizen satisfaction. Int. Rev. Adm. Sci. 2011, 77, 254–274. [Google Scholar] [CrossRef]

- Parris, D.L.; Dapko, J.L.; Arnold, R.W.; Arnold, D. Exploring transparency: A new framework for responsible business management. Manag. Decis. 2016, 54, 222–247. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- Kandel, C.; Klumpp, M.; Keusgen, T. GPS based track and trace for transparent and sustainable global supply chains. In Proceedings of the 2011 17th International Conference on Concurrent Enterprising, Aachen, Germany, 20–22 June 2011; pp. 1–8. [Google Scholar]

- Xu, D. Research on supply chain management strategy of Longtang Electric Engineering Co. Ltd. Acta Electron. Malays. 2019, 3, 10–13. [Google Scholar] [CrossRef]

- Acharya, A.; Singh, S.K.; Pereira, V.; Singh, P. Big data, knowledge co-creation and decision making in fashion industry. Int. J. Inf. Manag. 2018, 42, 90–101. [Google Scholar] [CrossRef]

- El-Kassar, A.-N.; Singh, S.K. Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technol. Forecast. Soc. Chang. 2019, 144, 483–498. [Google Scholar] [CrossRef]

- Scholten, H.; Verdouw, C.; Beulens, A.; Van der Vorst, J. Defining and analyzing traceability systems in food supply chains. In Advances in Food Traceability Techniques and Technologies; Elsevier: Amsterdam, The Netherlands, 2016; pp. 9–33. [Google Scholar]

- Liu, G. Data collection in mi-assisted wireless powered underground sensor networks: Directions, recent advances, and challenges. IEEE Commun. Mag. 2021, 59, 132–138. [Google Scholar] [CrossRef]

- El Maouchi, M.; Ersoy, O.; Erkin, Z. TRADE: A transparent, decentralized traceability system for the supply chain. In Proceedings of the 1st ERCIM Blockchain Workshop 2018, CWI, Amsterdam, The Netherlands, 5 August 2018. [Google Scholar]

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Sunny, J.; Undralla, N.; Pillai, V.M. Supply chain transparency through blockchain-based traceability: An overview with demonstration. Comput. Ind. Eng. 2020, 150, 106895. [Google Scholar] [CrossRef]

- Vigna, P.; Casey, M.J. The Age of Cryptocurrency: How Bitcoin and the Blockchain are Challenging the Global Economic Order; Macmillan: New York, NY, USA, 2016. [Google Scholar]

- Cecere, L. Moving blockchain forward: Seven use cases for hyperledger in supply chain. Supply Chain. Q. 2017. [Google Scholar]

- Thiruchelvam, S.; Ismail, M.F.; Ghazali, A.; Mustapha, K.N.; Norkhair, F.F.; Yahya, N.; Isa, A.A.M.; Muda, Z.C. Development of humanitraian supply chain performance conceptual framework in creating resilient logistics network. Malays. J. Geosci. (MJG) 2018, 2, 30–33. [Google Scholar] [CrossRef]

- Cooper, M.C.; Ellram, L.M. Characteristics of supply chain management and the implications for purchasing and logistics strategy. Int. J. Logist. Manag. 1993, 4, 13–24. [Google Scholar] [CrossRef]

- Han, Y.; Yan, X.; Piroozfar, P. An overall review of research on prefabricated construction supply chain management. Eng. Constr. Archit. Manag. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Huang, S.; Liu, H. Impact of COVID-19 on stock price crash risk: Evidence from Chinese energy firms. Energy Econ. 2021, 101, 105431. [Google Scholar] [CrossRef] [PubMed]

- Fritz, M.; Schiefer, G. Tracking, tracing, and business process interests in food commodities: A multi-level decision complexity. Int. J. Prod. Econ. 2009, 117, 317–329. [Google Scholar] [CrossRef]

- Tamplin, M.L. Integrating predictive models and sensors to manage food stability in supply chains. Food Microbiol. 2018, 75, 90–94. [Google Scholar] [CrossRef]

- Baraibar-Diez, E.; Odriozola, M.D.; Fernández Sánchez, J.L. A Survey of Transparency: An Intrinsic Aspect of Business Strategy. Bus. Strategy Environ. 2017, 26, 480–489. [Google Scholar] [CrossRef]

- Men, L.R. Internal reputation management: The impact of authentic leadership and transparent communication. Corp. Reput. Rev. 2014, 17, 254–272. [Google Scholar] [CrossRef]

- Najib Razali, M.; Mohd Adnan, Y. Transparency in Malaysian property companies. Prop. Manag. 2012, 30, 398–415. [Google Scholar] [CrossRef]

- Meng, Q.; Lai, X.; Yan, Z.; Su, C.-Y.; Wu, M. Motion planning and adaptive neural tracking control of an uncertain two-link rigid-flexible manipulator with vibration amplitude constraint. IEEE Trans. Neural Netw. Learn. Syst. 2021, 33, 3814–3828. [Google Scholar] [CrossRef]

- Zhou, L.; Mao, H.; Zhao, T.; Wang, V.L.; Wang, X.; Zuo, P. How B2B platform improves Buyers’ performance: Insights into platform’s substitution effect. J. Bus. Res. 2022, 143, 72–80. [Google Scholar] [CrossRef]

- GEODIS. Supply Chain Worldwide Survey. 2017. Available online: https://www.supplychainbrain.com/authors/6126-geodis (accessed on 1 August 2022).

- Raymond, N.; Card, B.; al Achkar, Z. What is ‘Humanitarian communication’?: Towards standard definitions and protections for the humanitarian use of ICTs. In Proceedings of the European Interagency Security Forum (EISF), London, UK, 27 February 2015. [Google Scholar]

- Bjerge, B.; Clark, N.; Fisker, P.; Raju, E. Technology and information sharing in disaster relief. PLoS ONE 2016, 11, e0161783. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.D. Exploring radio frequency identification technology and its impact on business systems. Inf. Manag. Comput. Secur. 2005, 13, 16–28. [Google Scholar] [CrossRef]

- Lal, B.S. Information and Communication Technology for Disaster Management. Disaster Manag. 2008, 2008, 200–213. [Google Scholar]

- Thomas, A.; Kopczak, L.R. Life-saving supply chains. In Building Supply Chain Excellence in Emerging Economies; Springer: Berlin/Heidelberg, Germany, 2007; pp. 93–111. [Google Scholar]

- Bealt, J.; Fernández Barrera, J.C.; Mansouri, S.A. Collaborative relationships between logistics service providers and humanitarian organizations during disaster relief operations. J. Humanit. Logist. Supply Chain Manag. 2016, 6, 118–144. [Google Scholar] [CrossRef]

- Masoud, Y.A. Challenges of Humanitarian Logistics on disaster management: The experience of Corona Pandemic in Tanzania. J. Int. Trade Logist. Law 2022, 8, 97–109. [Google Scholar]

- Opara, L.U. Traceability in agriculture and food supply chain: A review of basic concepts, technological implications, and future prospects. Eur. J. Oper. Res. 2003, 1, 101–106. [Google Scholar]

- Kogure, J.; Kamakura, K.; Shima, T.; Kubo, T. Blockchain technology for next generation ICT. Fujitsu Sci. Tech. J. 2017, 53, 56–61. [Google Scholar]

- Chang, S.E.; Chen, Y.-C.; Lu, M.-F. Supply chain re-engineering using blockchain technology: A case of smart contract based tracking process. Technol. Forecast. Soc. Chang. 2019, 144, 1–11. [Google Scholar] [CrossRef]

- Casey, M.J.; Wong, P. Global supply chains are about to get better, thanks to blockchain. Harv. Bus. Rev. 2017, 13, 1–6. [Google Scholar]

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. In Proceedings of the 2018 IoT Vertical and Topical Summit on Agriculture-Tuscany (IOT Tuscany), Tuscany, Italy, 8 May 2018; pp. 1–4. [Google Scholar]

- Kamath, R. Food traceability on blockchain: Walmart’s pork and mango pilots with IBM. J. Br. Blockchain Assoc. 2018, 1, 3712. [Google Scholar] [CrossRef] [PubMed]

- Hasan, H.; AlHadhrami, E.; AlDhaheri, A.; Salah, K.; Jayaraman, R. Smart contract-based approach for efficient shipment management. Comput. Ind. Eng. 2019, 136, 149–159. [Google Scholar] [CrossRef]

- Zhu, H.; Xue, M.; Wang, Y.; Yuan, G.; Li, X. Fast visual tracking with siamese oriented region proposal network. IEEE Signal Process. Lett. 2022, 29, 1437–1441. [Google Scholar] [CrossRef]

- Biswas, K.; Muthukkumarasamy, V.; Tan, W.L. Blockchain based wine supply chain traceability system. In Proceedings of the Future Technologies Conference (FTC) 2017, Vancouver, BC, Canada, 29–30 November 2017; pp. 56–62. [Google Scholar]

- Amin, F.; Ahmad, A.; Sang Choi, G. Towards trust and friendliness approaches in the social Internet of Things. Appl. Sci. 2019, 9, 166. [Google Scholar] [CrossRef]

- Chiang, C.-C.; Wu, H.-K.; Liu, W.; Gerla, M. Routing in clustered multihop, mobile wireless networks with fading channel. In Proceedings of the IEEE SICON, Online, 14 April 1997; pp. 197–211. [Google Scholar]

- Zhou, L.; Jin, F.; Wu, B.; Wang, X.; Wang, V.L.; Chen, Z. Understanding the role of influencers on live streaming platforms: When tipping makes the difference. Eur. J. Mark. 2022, 56, 2677–2697. [Google Scholar] [CrossRef]

- Nitti, M.; Pilloni, V.; Colistra, G.; Atzori, L. The virtual object as a major element of the internet of things: A survey. IEEE Commun. Surv. Tutor. 2015, 18, 1228–1240. [Google Scholar] [CrossRef]

- Hofstede, G.J.; Beulens, A.; Spaans, L. Transparency: Perceptions, practices and promises. In The Emerging World of Chains and Networks, Bridging Theory and Practice; Reed Business Information: New York, NY, USA, 2004; pp. 285–310. [Google Scholar]

- Lu, S.; Ban, Y.; Zhang, X.; Yang, B.; Yin, L.; Liu, S.; Zheng, W. Adaptive control of time delay teleoperation system with uncertain dynamics. Front. Neurorobotics 2022, 16, 152. [Google Scholar] [CrossRef]

- Sarpong, S. Traceability and supply chain complexity: Confronting the issues and concerns. Eur. Bus. Rev. 2014, 26, 271–284. [Google Scholar] [CrossRef]

- Pant, R.; Prakash, G.; Farooquie, J.A. A framework for traceability and transparency in the dairy supply chain networks. Procedia-Soc. Behav. Sci. 2015, 189, 385–394. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Jeppsson, A.; Olsson, O. Blockchains as a Solution for Traceability and Transparency. 2017. Available online: https://www.lunduniversity.lu.se/lup/publication/8919957 (accessed on 7 August 2022).

- Pizzuti, T.; Mirabelli, G. The Global Track&Trace System for food: General framework and functioning principles. J. Food Eng. 2015, 159, 16–35. [Google Scholar]

- Schwägele, F. Traceability from a European perspective. Meat Sci. 2005, 71, 164–173. [Google Scholar] [CrossRef] [PubMed]

- McGrath, P.; McCarthy, L.; Marshall, D.; Rehme, J. Tools and technologies of transparency in sustainable global supply chains. Calif. Manag. Rev. 2021, 64, 67–89. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Ali, A.; Jehangir, M.; Hassan, N.; Bae, J. A Model for Understanding the Mediating Association of Transparency between Emerging Technologies and Humanitarian Logistics Sustainability. Sustainability 2022, 14, 6917. [Google Scholar] [CrossRef]

- Hair Jr, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: New York, NY, USA, 2021. [Google Scholar]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 7th ed.; In Research Methods for Business Students, Pearson Publication: New York, NY, USA, 2015. [Google Scholar]

- Zhang, G.; Wang, C.L.; Liu, J.; Zhou, L. Why do consumers prefer a hometown geographical indication brand? Exploring the role of consumer identification with the brand and psychological ownership. Int. J. Consum. Stud. 2022, in press. [Google Scholar] [CrossRef]

- Ongena, Y.P.; Haan, M.; Yakar, D.; Kwee, T.C. Patients’ views on the implementation of artificial intelligence in radiology: Development and validation of a standardized questionnaire. Eur. Radiol. 2020, 30, 1033–1040. [Google Scholar] [CrossRef]

- Khan, M.; Imtiaz, S.; Parvaiz, G.S.; Hussain, A.; Bae, J. Integration of Internet-of-Things With Blockchain Technology to Enhance Humanitarian Logistics Performance. IEEE Access 2021, 9, 25422–25436. [Google Scholar] [CrossRef]

- Khan, M.; Lee, H.Y.; Bae, J.H. The Role of Transparency in Humanitarian Logistics. Sustainability 2019, 11, 2078. [Google Scholar] [CrossRef]

- Khan, M.; Sarmad, M.; Ullah, S.; Bae, J. Education for sustainable development in humanitarian logistics. J. Humanit. Logist. Supply Chain Manag. 2020, 10, 573–602. [Google Scholar] [CrossRef]

- Women in supply chain: Why so few? 2022. Available online: Logisticsbureau.com (accessed on 1 August 2022).

- Armstrong, J.S.; Overton, T.S. Estimating nonresponse bias in mail surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Hair Jr, J.F.; Matthews, L.M.; Matthews, R.L.; Sarstedt, M. PLS-SEM or CB-SEM: Updated guidelines on which method to use. Int. J. Multivar. Data Anal. 2017, 1, 107–123. [Google Scholar] [CrossRef]

- Hair Jr, J.F.; Sarstedt, M. Factors versus composites: Guidelines for choosing the right structural equation modeling method. Proj. Manag. J. 2019, 50, 619–624. [Google Scholar] [CrossRef]

- George, D. SPSS for Windows Step by Step: A Simple Study Guide and Reference, 17.0 Update, 10/e; Pearson Education India: Singapore, 2011. [Google Scholar]

- Neter, J.; Wasserman, W.; Kutner, M.H. Applied Regression Models; Richard D. Irwin. Inc.: Homewood, IL, USA, 1983. [Google Scholar]

- Cfroteod, C. CRED Crunch 58—Disaster. Year in Review; CRED: Brussels, Belgium, 2020; p. 58. [Google Scholar]

- Ringle, C.M.; Da Silva, D.; Bido, D.d.S. Modelagem de equações estruturais com utilização do SmartPLS. Rev. Bras. De Mark. 2014, 13, 56–73. [Google Scholar] [CrossRef]

- Chin, W.W. The partial least squares approach to structural equation modeling. Mod. Methods Bus. Res. 1998, 295, 295–336. [Google Scholar]

- Neuman, S.P. Generalized scaling of permeabilities: Validation and effect of support scale. Geophys. Res. Lett. 1994, 21, 349–352. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Voorhees, C.M.; Brady, M.K.; Calantone, R.; Ramirez, E. Discriminant validity testing in marketing: An analysis, causes for concern, and proposed remedies. J. Acad. Mark. Sci. 2016, 44, 119–134. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Erlbaum Associates: Hillsdale, NJ, USA, 1988. [Google Scholar]

- Ben Ayed, R.; Hanana, M. Artificial intelligence to improve the food and agriculture sector. J. Food Qual. 2021, 2021, 1–7. [Google Scholar] [CrossRef]

- Dolgui, A.; Tiwari, M.K.; Sinjana, Y.; Kumar, S.K.; Son, Y.-J. Optimising integrated inventory policy for perishable items in a multi-stage supply chain. Int. J. Prod. Res. 2018, 56, 902–925. [Google Scholar] [CrossRef]

| Classification of Variables | Valid | Frequency | % | Mean | Std. Deviation | Variance | Skewness | Kurtosis | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Statistic | Std. Error | Statistic | Std. Error | ||||||||

| Gender | Male | 313 | 249 | 79.55% | 1.21 | 0.409 | 0.168 | 1.446 | 0.241 | 0.092 | 0.478 |

| Female | 64 | 20.44% | |||||||||

| Age | <22 | 313 | 3 | 0.96% | 4.23 | 1.153 | 1.330 | −0.142 | 0.241 | −0.363 | 0.478 |

| 23–28 | 12 | 3.83% | |||||||||

| 29–35 | 74 | 23.54% | |||||||||

| 36–45 | 86 | 27.48% | |||||||||

| 46–55 | 96 | 30.67% | |||||||||

| 56–60 | 37 | 11.82% | |||||||||

| 61+ | 5 | 1.60% | |||||||||

| Region | Pakistan | 313 | 299 | 95.52% | 1.04 | 0.197 | 0.039 | 4.767 | 0.241 | 21.144 | 0.478 |

| Other | 14 | 4.47% | |||||||||

| Years of Experience | <1 | 313 | 9 | 2.88% | 3.90 | 1.567 | 2.455 | 0.330 | 0.241 | −0.673 | 0.478 |

| 2–5 | 54 | 17.25% | |||||||||

| 6–10 | 86 | 27.48% | |||||||||

| 11–15 | 49 | 21% | |||||||||

| 16–20 | 69 | 15.65% | |||||||||

| 21–25 | 27 | 8.63% | |||||||||

| 26+ | 19 | 6.07% | |||||||||

| Education level | High school or less | 313 | 6 | 1.91% | 3.36 | 0.689 | 0.475 | −0.990 | 0.241 | 1.235 | 0.478 |

| Diploma | 19 | 6.07% | |||||||||

| Bachelor | 143 | 45.69% | |||||||||

| High Edu | 145 | 46.32% | |||||||||

| Occupational Level | Entry | 313 | 34 | 10.86% | 2.74 | 1.079 | 1.164 | 0.243 | 0.241 | −0.736 | 0.478 |

| Supervisor | 108 | 34.50% | |||||||||

| Manager | 80 | 25.56% | |||||||||

| Director | 69 | 22.04% | |||||||||

| Leader | 22 | 7.03% | |||||||||

| Supply-Chain Specialty | Planning | 313 | 19 | 6.07% | 4.19 | 1.509 | 2.277 | −0.547 | 0.241 | −0.694 | 0.478 |

| Procurement | 35 | 11.18% | |||||||||

| Warehousing | 40 | 12.78% | |||||||||

| Transportation | 65 | 20.77% | |||||||||

| Logistics | 83 | 26.51% | |||||||||

| General SC | 71 | 22.68% | |||||||||

| BCT | SIoT | AI | SCTRC | SCTRN | ||

|---|---|---|---|---|---|---|

| N | Valid | 313 | 313 | 313 | 313 | 313 |

| Missing | 0 | 0 | 0 | 0 | 0 | |

| Mean | 4.17 | 3.96 | 4.04 | 4.18 | 3.93 | |

| Std. Error of Mean | 0.045 | 0.055 | 0.056 | 0.057 | 0.070 | |

| Median | 4.20 | 4.00 | 4.00 | 4.20 | 4.00 | |

| Std. Deviation | 0.448 | 0.550 | 0.560 | 0.573 | 0.695 | |

| Skewness | −0.634 | −0.487 | −0.146 | −0.597 | −0.220 | |

| Std. Error of Skewness | 0.241 | 0.241 | 0.241 | 0.241 | 0.241 | |

| Kurtosis | −0.017 | −0.081 | −0.617 | −0.588 | −0.343 | |

| Std. Error of Kurtosis | 0.478 | 0.478 | 0.478 | 0.478 | 0.478 | |

| VIF | 1.301 | 1.941 | 1.385 | 1.243 | 1.265 | |

| R Square | Adjusted R Square | Cronbach’s Alpha | Composite Reliability | Average Variance Extracted | |

|---|---|---|---|---|---|

| Blockchain Technology | 0.764 | 0.754 | 0.517 | ||

| Social Internet of Things | 0.777 | 0.809 | 0.529 | ||

| Artificial Intelligence | 0.740 | 0.715 | 0.524 | ||

| Supply-Chain Traceability | 0.571 | 0.695 | 0.793 | 0.832 | 0.508 |

| Supply-Chain Transparency | 0.378 | 0.359 | 0.864 | 0.885 | 0.655 |

| 1 | 2 | 3 | 4 | 5 | |

|---|---|---|---|---|---|

| Blockchain Technology | 1 | ||||

| Social Internet of Things | 0.336 ** | 1 | |||

| Artificial Intelligence | 0.425 ** | 0.452 ** | 1 | ||

| Supply-Chain Traceability | 0.461 ** | 0.478 ** | 0.520 ** | 1 | . |

| Supply-Chain Transparency | 0.454 ** | 0.384 ** | 0.308 ** | 0.370 ** | 1 |

| SSO | SSE | Q2 (=1 − SSE/SSO) | |

|---|---|---|---|

| Blockchain Technology | 400.000 | 400.000 | |

| Social Internet of Things | 500.000 | 500.000 | |

| Artificial Intelligence | 400.000 | 400.000 | |

| Supply-Chain Traceability | 600.000 | 525.193 | 0.125 |

| Supply-Chain Transparency | 500.000 | 258.654 | 0.483 |

| Path Coefficient | Sample Mean | Std. Deviation | T Statistics | p Values | Supported? | |

|---|---|---|---|---|---|---|

| Blockchain Technology −> Supply-Chain Traceability (HI) | 0.333 | 0.342 | 0.088 | 3.781 | 0.000 | Yes |

| Social Internet of Things −> Supply-Chain Traceability (H2) | 0.262 | 0.280 | 0.090 | 2.904 | 0.004 | Yes |

| Artificial Intelligence −> Supply-Chain Traceability (H3) | 0.281 | 0.282 | 0.090 | 3.120 | 0.002 | Yes |

| Supply-Chain Traceability > Transparency (H4) | 0.399 | 0.432 | 0.074 | 5.392 | 0.000 | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.; Parvaiz, G.S.; Dedahanov, A.T.; Abdurazzakov, O.S.; Rakhmonov, D.A. The Impact of Technologies of Traceability and Transparency in Supply Chains. Sustainability 2022, 14, 16336. https://doi.org/10.3390/su142416336

Khan M, Parvaiz GS, Dedahanov AT, Abdurazzakov OS, Rakhmonov DA. The Impact of Technologies of Traceability and Transparency in Supply Chains. Sustainability. 2022; 14(24):16336. https://doi.org/10.3390/su142416336

Chicago/Turabian StyleKhan, Muhammad, Gohar Saleem Parvaiz, Alisher Tohirovich Dedahanov, Odiljon Sobirovich Abdurazzakov, and Dilshodjon Alidjonovich Rakhmonov. 2022. "The Impact of Technologies of Traceability and Transparency in Supply Chains" Sustainability 14, no. 24: 16336. https://doi.org/10.3390/su142416336

APA StyleKhan, M., Parvaiz, G. S., Dedahanov, A. T., Abdurazzakov, O. S., & Rakhmonov, D. A. (2022). The Impact of Technologies of Traceability and Transparency in Supply Chains. Sustainability, 14(24), 16336. https://doi.org/10.3390/su142416336