Abstract

The servitization of manufacturing enterprises has two main directions: production servitization and product servitization. The value co-creation model describes the transformation process of servitization of manufacturing enterprises; it is far more complex than that of service enterprises, and requires more in-depth research. This paper explores the value co-creation model and upgrading path based on the servitization of manufacturing enterprises, based on the idea that the value network supported by information technology has become a vital support for the servitization value co-creation of manufacturing enterprises. Referring to the degree of servitization of manufacturing enterprises and the degree of integration of complementary resources among value network members, we explore the value co-creation model between manufacturing enterprises and each network subject. We obtain four models: double-low model, servitization leading model, resource complementary leading model, and double-high model. We then clarify the characteristics, scope of application, advantages, and disadvantages of each model, and the means of value creation. We also apply the rough set method to empirically test the feasibility of the classification parameters of the value co-creation model and the accuracy of the classification rules, using Chinese listed and non-listed manufacturing enterprises as a sample. The findings provide a theoretical reference and practical guidance for manufacturing enterprises to achieve sustainable development and determine the upgrade path of the value co-creation model.

1. Introduction

Value co-creation is the main way for manufacturing enterprises to achieve upgrading and add value. Over the years, the research on value co-creation has attracted continuous attention. Through value co-creation, enterprises can cooperate with various participating subjects and create a wide range of value [1,2]. Value co-creation is becoming increasingly critical for manufacturing enterprises to address volatile environments and current dynamic development [3], and is playing a vital role in the sustainability of the manufacturing enterprise [4]. However, the traditional value co-creation model research can no longer meet the needs of modern manufacturing enterprises.

The servitization of manufacturing is the most important characteristic of a servitization society, which emphasizes the need for manufacturing enterprises to provide more service value in addition to physical products. In the competitive market environment of excess manufacturing products, modern manufacturing industries are developing in the direction of high integration with services in order to alleviate the trend of gradually decreasing marginal benefits, rebuild competitive advantages, and obtain new marketing opportunities. Servitization has become the primary means of creating value for manufacturing enterprises, providing them with a continuous and stable source of income [5]. However, with technological developments (such as the Internet of Things) [6], the interactive support of service value and tangible product value has become more obvious, and each value co-creation subject has an increasing impact on overall value. The value output type of manufacturing value co-creation has changed from service value to a mixture of service and tangible product value, resulting in changes in the value contribution of different value co-creation participants, a gradual decrease in the role of consumers or customers, a mismatch between the value co-creation model based on service-dominant logic and practice, and increasing complexity [7], which requires equal emphasis on a new service-dominant logic and product-led logic. Therefore, the new sustainable value co-creation models which can integrate new service-dominant logic and product-led logic are needed to be explored in line with the development of the times to ensure sustainable development [8].

The development of information technology has further prompted the shift in the Internet from a “consumer Internet” to an “industrial Internet” [9], “ecological Internet”, and “value Internet” [10]. By using “network” thinking to integrate complex interactions and resources between enterprises and their partners to form value networks has become a means of business organization and value transfer. Many enterprises had reconstructed new productivity factors and new production relations in the network era [11], such as the advanced manufacturing model oriented to a global value network, Haier’s innovative practice of intelligent manufacturing model of connected factory [12], and Lenovo’s intelligent manufacturing model [13]. Among these value network-based smart manufacturing models, the value co-creation model based on service-dominant logic solves the problem of value diversity but cannot meet the need for networked value co-creation of physical products. In addition, the value co-creation model based on service-dominant logic cannot promote the integrated development of the digital economy and the real economy, and makes it difficult to guide manufacturing enterprises to promote the transformation and upgrade of the manufacturing enterprise. Further, different types of manufacturing enterprises cannot judge their own value co-creation stage and cannot adapt to the sustainable development strategy. Therefore, in order to fill in the above research blank, we need to study the value co-creation problem from a more macro level of complex network systems and identify the value co-creation model of manufacturing enterprise from the perspective of value network in line with the current network environment [14].

This paper breaks through the limitations of single service-dominant logic and service value co-creation, combines the new characteristics of value network resource integration, and constructs a matrix model based on resource integration theory and service-dominant logic. Furthermore, this paper extends the value co-creation model from the concept and model evaluation to the practical level, focusing on the value co-creation realization activities and implementation level of manufacturing enterprises. It reveals the essence of value co-creation in the new environment of manufacturing enterprises, provides a feasible path for the sustainable development of value co-creation and upgrading of manufacturing enterprises, and provides practical guidance for manufacturing enterprises in servitization to position their value co-creation model. It helps manufacturing enterprises use the advantages of digital and intelligent value to achieve upgrading and sustainable development.

2. Theoretical Background

2.1. Manufacturing Enterprise Servitization and Value Co-Creation Model

The concept of “servitization” was first proposed by Vandermerwe and Rada in 1988, who argued that manufacturing enterprises should not only produce goods but also adopt a comprehensive “product-service package” model [15]. The servitization of manufacturing enterprises is essentially the process of transformation of manufacturing enterprises from traditional commodity providers to service providers. That is, they form an operating model in which manufacturing enterprises can improve their competitive advantage by continuously integrating services into commodities. Several scholars have explored the servitization of the manufacturing enterprise from the perspective of value co-creation, believing that the servitization of manufacturing should focus on “value”. From this perspective, value co-creation is divided into four servitization models [16]. Ding Zhaoguo summarized the value evolution process of servitization manufacturing and elaborated on four different value creation models of manufacturing in the process of servitization [17]. Some scholars have also explored the perspective of service derivation and expounded on the mechanism of value creation of manufacturing enterprises, stating that there are two main types: service-derived value creation and enhanced service-derived value creation [18]. Research on the overall servitization of manufacturing enterprises and manufacturing industries not only focuses on value creation but also goes deeper to examine value co-creation.

With the gradual replacement of commodity-driven logic by service-dominant logic [3], research related to the value co-creation model has also gradually shifted to the problem of the change of value co-creation subjects—that is, the value-added problem of service value—resulting in the concept of value co-creation. Windahl indicated that value creation should focus on value creation systems that include multiple actors, emphasizing that participants rather than the enterprise itself co-create value [19]. Lavie stated that the value creation mechanism is the process by which all partners in the system create value and share profits [20]. Jian Zhaoquan et al. proposed that the value creation method in the process of servitization of manufacturing has shifted from the traditional “enterprise–customer” and “enterprise–stakeholder” binary relationship to an ecosystem that includes more value creation subjects [5]. The three different degrees of value co-creation servitization, use-oriented, and result-oriented are integrated into the three interactive levels of micro, meso, and macro to create a value co-creation model matrix, and create nine kinds of manufacturing enterprise servitization value co-creation models. In the process of studying the evolution of manufacturing servitization from the perspective of value co-creation, some scholars have summarized five manufacturing servitization value co-creation models: product extension servitization, product enhancement servitization, leading product servitization, business unit servitization, and core capability servitization [21]. According to the different subjects involved, the value co-creation model can be divided into three categories: (1) the value co-creation of enterprises and upstream suppliers; (2) the value co-creation of enterprises and consumers, of which the primary view is that the traditional value co-creation model led by enterprises is no longer suitable for the current era, and enterprises should adopt customer-led value co-creation model, as enterprises are only collaborators of value co-creation and customers are the leading value co-creation [22]; and (3) value co-creation through the participation of many stakeholders [23],which entails a value co-creation model in which enterprises, as manufacturing service integrators, suppliers, financial institutions, and research institutes as professional service providers, and the government and the media as potential stakeholders, jointly integrate relationships and knowledge resources to interact with customers. The value co-creation model based on servitization value can be summarized as the strategic leading layer, with business management providing cultural, institutional, and organizational support and the financial layer providing financial support and information mapping, jointly promoting co-creation, sharing, and symbiosis value between the value co-creation layer and enterprise stakeholders [24], and revealing the sustainability characteristics of servitization.

The value co-creation model based on the service-dominant logic only emphasizes the “value co-production” method, and has a limited practical effect on guiding the value co-creation of manufacturing enterprises. As the value co-creation model extends from traditional enterprise and consumer fields to the value co-creation model between enterprises and enterprises, research related to the value co-creation model also extends from the traditional consumption field to the industrial production field. The model emphasizes that the sources of sustainable value creation are information interaction and knowledge innovation. Thus, such research has focused on value co-creation cooperation channels, such as virtual brand communities or social media, wherein the value co-creation model is created by two parties and emphasizes customer participation. Transformed into a multi-party value co-creation model with the participation of multiple value network members, the value co-creation model mainly includes commitment, interaction, resource integration, collaboration, and so on. Regarding the value co-creation model between enterprises, few scholars have touched on the problem of value co-creation in the process of servitization of manufacturing enterprises, and few have associated the servitization of manufacturing enterprises with value co-creation. Therefore, it is vital to study the value co-creation model within the context of servitization of manufacturing enterprises, to systematically analyze its scope of application, advantages and disadvantages; and to examine how each model creates value and realizes value co-creation in different stages of servitization. Therefore, exploring the role of servitization in value co-creation is crucial to the sustainable development of manufacturing enterprises.

2.2. Value Co-Creation Model from the Perspective of Value Network

The study of value co-creation model from the perspective of value network is the study of value co-creation model by many stakeholders to achieve sustainable development. From the network perspective, the model breaks the traditional perspectives of value creation in the value chain; that is, the linear relationship between enterprises is considered the basis for the transmission of resources and for value flow, which makes value creation shift toward networking. Most scholars have focused on enterprise value networks, including the different types of value networks at different stages of servitization [25], the mechanism of value creation through value networks [15], the characteristics of value networks from multiple dimensions (such as network density and network size) [26], and the innovation of business models based on different value networks [27]. The identity of manufacturing enterprises is transformed into manufacturing service integrators in the network, professional service providers and other stakeholders are collectively referred to as network subjects, and manufacturing enterprises realize value co-creation by leveraging the sustainable features of value networks with each network subject, including customers [15,28,29].

Applying the value network perspective to the servitization research field allows us to analyze how enterprises and their partners effectively take advantage of value networks to achieve value co-creation and promote manufacturing servitization through opening the “black box” within the process of the servitization value co-creation in manufacturing enterprises [15]. The development of the industrial internet has led to a significant decrease in the costs of communication and transaction among value network members. Thus, reduction in the costs of co-creation of tangible product value requires a new value co-creation model to guide enterprise value co-creation practices. Value co-creation from the perspective of value networks can change traditional single modes of thinking about value creation based on value chains and shift attention to the interaction between subjects and resource integration, broaden the perspective of problem research, and reveal the origin of value co-creation [25]. Value co-creation emphasizes that each participating subject has an important impact on overall value in the process of value creation. Feng Changli explored how value co-creation is carried out between different subjects and argued that the sources of value co-creation are the interactive activities and resource integration between subjects [28]. The service-dominant logic rooted in core competence theory and resource advantage theory considers all economic and social actors as resource integrators, indicating that the context of value co-creation is networked. The resources required for value co-creation exceed the enterprise–customer interface; therefore, other stakeholders, such as suppliers, employees, and alliances, also need to be added to the value co-creation network. Due to the lack of their resource integration capabilities and the increase in time cost, some manufacturing enterprises are unable to quickly improve their service levels to meet the requirements of value co-creation. This requires manufacturing enterprises to interactively couple to form an open innovation ecosystem value co-creation model through mergers and acquisitions, inter-enterprise collaboration, and industry–university–research cooperation. Xuemei Xie and Hongwei Wang posited the “industry–university–research cooperation model, inter-enterprise collaboration model, cooperation model with intermediaries, technology purchase model, technology innovation model, technology innovation model, technology purchase model, social media platform strategy model, and merger and acquisition model, which are regarded as open innovation ecosystem value co-creation models. The three equivalent paths of different value co-creation models were extracted using fuzzy set qualitative comparative analysis [30]. Based on the enterprise core open innovation ecosystem, which satisfies the characteristics of pluralism, competition, co-evolution, and complex interaction, Qiongwen Cheng and Yixuan Zhao proposed three models of value co-creation: the mergers and acquisitions model, the joint venture model, and the cooperation model. Their findings indicated that the mergers and acquisitions model and the cooperation models could enhance the value co-creation effect, while the joint venture model does not have a significant effect on the value co-creation effect [31].

With the establishment of the industrial internet system, the rapid spread of internet technologies such as 5G, and the strong support of national policies for high-tech industries, most scholars in the field have paid attention to high-tech industries and explored enterprises with a high degree of “Internet+” development for new value co-creation models. Therefore, how to take advantage of the Internet to help the sustainable development of the manufacturing enterprise is particularly important. For example, Liping Wang, Juxiang Li, and Qiong Li built an in-depth value co-creation model for the innovation ecosystem of the science and technology service industry based on the elements of the ecosystem of the science and technology service industry [32]. Yongkai Ma, Shiming Li, and Jingming Pan studied more than 50 domestic and foreign industrial internet platform enterprises and proposed the “three links” value co-creation model with four subjects: manufacturers, suppliers, retailers, and customers. The value of “linkage” creation eventually becomes a co-creation “joint body” [33]. Jinghui Yao adopted five dimensions: initiating subject, core competence, value proposition, promotion mechanism, and value realization. These studies distinguished between three typical innovation ecosystem value co-creation models of Internet+ enterprises—namely, institution-led, community-driven, and institution-community synergy—and adopted three case studies (Multipoint, Hapu, and WeChat applet) for comparative analysis [34].

The previous study addressed value co-creation and partly explored the problem of value co-creation in value networks, but ignored the integration of network members’ resources in value co-creation and the fact that the value network of manufacturing enterprises is still the main value carrier of physical products (or parts), so that the value co-creation model of manufacturing enterprises based on value networks should have its unique way, which is worth studying.

3. Building a Matrix of Value Co-Creation Models

In this section, we begin to construct a network-based value co-creation model coordinating system using two dimensions—degree of servitization and degree of resource integration—and create a basis for the division of the value co-creation model matrix. Manufacturing enterprises are distinguished and identified on the basis of the bivariate control of different degrees of the two dimensions.

3.1. Degree of Servitization

The implementation of a servitization strategy to promote consumer demand is a prerequisite for value co-creation by enterprises. In addition, in servitization strategies, enterprises interact with various actors at different levels according to their stage of servitization to provide diversified services to customers, such that all parties involved gain economies of scale and thus achieve value co-creation [29]. Different degrees of servitization will lead to different service values created by enterprises, and value co-creation methods also differ greatly; thus, the degree of servitization is a key driving factor of sustainability in value network. Yuan Chang presented several strategies for servitization, as well as the discovery and classification of effective service models at both the product and project levels, and offered a few insights into sustainable value creation from the perspective of service innovation [8]. Combining the sustainability characteristics of servitization, the degree of servitization is included in the value co-creation consideration.

3.2. Degree of Resource Integration

The effective use of resources is a prerequisite for achieving a higher degree of matching between supply and demand. In addition, resources are an important factor for manufacturing enterprises to create value by removing capacity and inventory in deepening supply-side structural reform, as well as to support enterprises to carry out servitization in depth [18]. The effective use of resources is also an important prerequisite for servitization manufacturing enterprises to achieve value co-creation [35]. Gadrey found that the technical participation of system actors and resource advantages are causally related to the provision of PSS (product-service systems) by manufacturing enterprises, and that value co-creation is essentially the result of resource support for PSS through the participation of multiple socio-technical competence actors. The purpose of providing PSS is to improve service quality and thus enhance the service experience of customers, which is a challenge to current resource needs and capability requirements of enterprises; thus, the integration of resources and complementary advantages is important for value creation [36]. Pott pointed out that the key to value co-creation is the interaction between network subjects, and indicated that interaction activity mainly manifests in the integration of resources [37]. Windahl suggested that resources controlled by subjects can only create value through integration, thus enabling subjects to achieve value co-creation [38]. The interaction between subjects and the degree of absorption and integration of enterprise network resources are important factors influencing the realization of value co-creation. In fact, the interaction between subjects aids in identifying, integrating, sharing, and matching resources. Achieving sustainable development of resources is a prerequisite for enterprises to achieve value co-creation. Enterprises need to create value through the external effects of value networks so that each actor has different resources to co-create value and the exploration of value co-creation can go beyond the resource perspective at the enterprise level to the resource perspective at the network level [15].

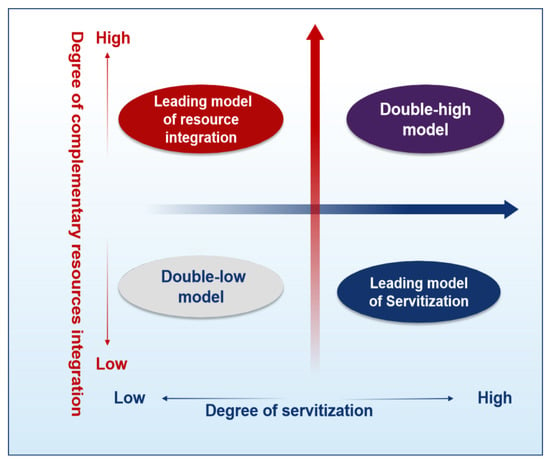

With manufacturing enterprises continuing to upgrade their services, such services are shifting from basic additional services to comprehensive solutions centered around “products + services”. In the process of this transformation, there is greater demand for enterprise resources. The cooperation and interaction among subjects in a network is one way in which to obtain the relevant resources required for value creation, and enterprises can realize value co-creation in the process of interaction, integration, and application of resources among subjects [29,37,39]. The prerequisite for value co-creation is a process of interaction, integration, and application, along with servitization, and the basis for this transformation is interaction between subjects. The essence of interaction focuses on the integration of complementary resources by using “network” thinking. Thus, the degree of utilization and integration of complementary resources in each stage of servitization is a key influencing factor on whether manufacturing enterprises can achieve sustainable value co-creation in servitization transformation. Therefore, based on the degree of servitization and the degree of resource integration, we propose four types of manufacturing enterprises’ value co-creation models, as shown in Figure 1.

Figure 1.

Classification of value co-creation models for manufacturing enterprises.

4. Value Co-Creation Model and Characteristics

4.1. Double-Low Model

The double-low model is in the lower-left corner of the coordinate system, as in Figure 1. Here, the degrees of servitization and complementary resource integration are both low, such that there is basically no interactive activity between the enterprise and each network subject, the degree of complementary resource integration is at its lowest level, sustainable development capability is weak and the scope of value co-creation is the smallest.

Manufacturing enterprises in this mode are in the early stages of servitization and mostly provide basic extension services centered around products, with insufficient service experience and low service innovation capability. Their service types are basically after-sales-related, such as providing basic logistics, installation, maintenance, training, and other supporting services related to the sale of products. Such supporting services are mainly based on the use of internal resources to carry out relevant services to achieve value creation, and the efficiency of value innovation is low. The enterprise takes the leading position in the process of value co-creation and the customer is a passive recipient; the value flows to the customer through the value chain alone and rarely complements the subjects in the value network. In the value network, there is little dialogue between such enterprises and the network subjects, and the transparency of enterprises is extremely low, resulting in the external value network not yet being formed, lacking external network resources, and mainly using the enterprise’s own internal resources to provide commodity-based extension services. Enterprises spend the only resources they have on technological innovation in core product development to meet customer needs. Greater focus on high quality and stable product manufacturing results mostly in exchange value and rarely has co-creation value.

4.2. Leading Model of Servitization

The leading model of servitization occupies the lower-right corner of the coordinate system. This entails enterprises with a high degree of servitization dominated by a service-dominant logic, but with a low degree of integration of complementary resources. On the basis of providing additional services for commodities, such enterprises extend their services along the value chain to pre-sales, in-sales, and after-sales, such as providing extended services including R&D and design, maintenance, and instructions for use. Alternately, they directly meet customer needs to provide functional services of goods, such as sharing and leasing, without directly providing goods. Manufacturing enterprises in this model usually have certain service experience and strong service innovation capability, giving full play to the sustainability of servitization and shifting the value concept of the enterprise from being centered on producing products to focusing on providing services.

Simultaneously, along with deepening of the degree of service, enterprises pay more attention to the service cooperation with each network subject, and the number of subjects participating in the enterprise value network gradually increases along with the frequency of interaction between subjects, causing the external value network to be formed. Customized services and customized products increase among the network subjects, and service technologies and concepts are constantly updated. Enterprises will choose to provide different services according to their own conditions and characteristics, as well as the characteristics of the value network subjects. The diversified types of services produce heterogeneous service effects.

As a result of the deepening of servitization and the expansion of its breadth, the barriers to competitive advantage built by manufacturing enterprises in the leading model of servitization are relatively higher than those built in the double-low model, and the services provided by enterprises begin to show heterogeneity, thus enhancing customer loyalty. The value of related services has increased and gradually becomes the main source of enterprise value, which can provide a continuous and stable source of value for the enterprise’s income. However, with the increase in the number of value network service subjects, enterprises face higher risks due to their own limited internal resources and their inability to meet the demand for resources to provide diversified service types by themselves. For example, the China media group provides integrated solutions to its customers, including financial electronics, satellite navigation systems, and wireless communications. The R&D products, design and manufacturing, and after-sales services included in its integrated solutions are provided by its internal organization, which is highly servitization. However, as the group enriches its own internal resources, mostly by absorbing and merging to set up internal organizations and through working with foreign enterprises to set up joint ventures or holding subsidiaries (such as Grgbanking International Trading Co., Ltd., Hague Communications Co., Ltd., technology center organizations, etc.), it needs to invest a large amount of capital and resources when providing integrated solutions to its customers, which leads to high financial and operational risks, and any minor problems in the overall solutions provided could lead to significant losses for the business.

4.3. Leading Model of Resource Integration

The resource integration leading mode is in the upper-left corner of the coordinate system, wherein the degree of enterprise complementary resources integration is higher, product-led logic is key, but the service degree is lower. The purpose of such enterprises in integrating resources is mainly focused on the R&D of the enterprise’s core products; there is greater focus on upgrading products to meet the basic needs of customers as the starting point to provide a type of product, but the development of product extension services is ignored, resulting in a low degree of enterprise service and a lack of competitive advantage in the market.

During the operation of an enterprise, its internal and external resources are continuously expanded through absorptions and mergers, signing strategic partners, etc., and the network subjects are absorbed into an integrated system with external network resources that can be utilized and are at an advanced stage of complementary resource integration. The number of subjects participating in the value network will continue to increase, the frequency of interaction between subjects is accelerated, dialogue between the enterprise and each network subject is open, transparency is achieved with each network subject, trust between the parties is extremely high, and there is a willingness to share risks. Multiple parties also have rich experience in cooperation and strong innovation abilities, and jointly participate in researching, designing, consulting, training, providing financing platforms, promoting, and other overall activities, maintaining long-term and stable cooperation and mutually beneficial relationships to realize value co-creation.

4.4. Double-High Model

The double-high model is located in the upper-right corner of the coordinate system. Here, enterprises have a higher degree of servitization and of integration of complementary resources, and the service-dominant logic and the product-led logic go hand-in-hand. In the process of increasing servitization, enterprises achieve sustainable multi-party value co-creation through frequent interactions with network subjects to fully integrate network resources. In this model, the value network is open, the frequency of interaction between subjects and the degree of integration of complementary resources are at their highest level, the enterprise’s value innovation is highly efficient, and the scope of value co-creation is the largest.

As a carrier of value co-creation, the resources and capabilities in the network are the origins of value co-creation in the process of providing overall servitization solutions for customers through manufacturing enterprises in this model. With the deeper interaction between manufacturing enterprises and each network subject, the complementary resources in the value network are highly integrated to meet the resource needs of providing total servitization solutions, enhancing the service innovation capability of enterprises, and providing a better service experience for customers. This also alleviates the pressure on enterprise capital and resource diversity, enabling enterprises to allocate capital and resources to other areas for diversification, significantly reducing the financial and operational risks of enterprises on the basis of securing stable returns. For example, when providing overall servitization solutions, Huawei employs and integrates complementary resources owned by subjects in the value network, including operational resources owned by network subjects such as software and hardware service enterprises and consulting enterprises, as well as a large number of customer resources owned by telecom operators. Huawei has cooperated with and used the relevant resources of 3com to work on enterprise network data, developed product solutions on storage and security protection with Symantec, and arrived at strategic agreements with domestic operators such as China Telecom and China Mobile to integrate general customer resources, while collaborating with operators to focus on the development of overall service solutions in communications.

5. Empirical Tests

In order to verify the rationality of the value co-creation model matrix constructed above and the validity of the identification results, we conducted a questionnaire survey with well-known listed and non-listed manufacturing enterprises in China as the research object. The degree of servitization and the degree of resource integration are measured and the results of the corresponding value co-creation patterns of the enterprises are obtained via a fuzzy set algorithm based on the quantitative results of enterprises’ performance in each dimension.

5.1. Measurement Scale Design

This section assesses the current degree of servitization of manufacturing enterprises using a seven-level scale system to quantify the indicators. The indicators covered in the questionnaire are based on the research of Fu Jian, Xin Wu, Laura Johanna Oberle, Jiguo Liu, Yiting Zhao, Jun Zhang, Bill McEvily, Alfred Marcus, and other scholars [40,41,42], combined with the situation of Chinese manufacturing enterprises. The questions were designed to comprehensively measure the degree of servitization of enterprises from two major aspects: service input and service output of the manufacturing enterprises, as shown in Table 1.

Table 1.

Measurement of servitization degree.

This part of the paper, the measurement scale of the degree of complementary resource integration refers mainly to the studies of Yan Si, Hao Xu, Yuqin Liu, Erming Xu, and Kai Xu [43,44,45] and reviews the actual situation of complementary resources in domestic manufacturing enterprises. The eight items are summarized in Table 2, which is used to compose the research questionnaire.

Table 2.

Measurement scale for complementary resources.

5.2. Data Collection

5.2.1. Sampling Procedure

The data used in this paper are 80 questionnaires from 40 enterprises from the following sectors: Automobile, Electric apparatus manufacture, Pharmaceutical manufacturing, Chemical engineering manufacturing, and else. In addition, the Google search engine and Wechat have also been explored to get contact information regarding the industries of interest. In order to solicit the respondent’s participation in the survey and to maximize the response rate, the manager of each firm was first contacted via email and phone calls. Further, the questionnaire has been sent to these industries including a cover letter stating the purpose of the survey, a promise to keep the secrecy of data, and to provide a detailed report. After one week after the initial mailing, the first reminder was sent as an email to the participants. At the end of the second week, the participants, who did not respond after the first reminder, were contacted via phone call, as a second reminder.

5.2.2. Reliability and Validity Tests

SPSS software (version 16) was used to carry out reliability and validity tests, the results are shown in Table 3 and Table 4.

Table 3.

Cronbach’s reliability analysis.

Table 4.

KMO and Bartlett’s test.

From Table 3, we can see that the reliability coefficient value is 0.962, which is greater than 0.9, thus indicating the high quality of the reliability of the questionnaire. For the “alpha coefficient of deleted items”, the reliability coefficient does not increase significantly when any item is deleted, thus indicating that the item should not be deleted. For the “CITC values”, the CITC values of the analyzed items are all greater than 0.4, which indicates that there is a good correlation between the analyzed items, and also indicates that the reliability level is good.

The validity was verified using KMO and Bartlett’s test. As seen in Table 4: the KMO value was 0.927, which is greater than 0.8. In addition, the p value is 0, which is less than 0.05. In summary, the test results indicate that the questionnaire is of high-reliability quality and good validity. The data can be used for further analysis.

5.3. Empirical Methodology

5.3.1. Theory and Applications Related to Rough Sets

Rough set theory, as a data analysis and processing theory, was introduced in 1982 by the Polish scientist Pawlak. It is a mathematical tool used to deal with uncertainty based on probability theory, fuzzy sets, and evidence theory. The availability of a large amount of information and various uncertainties make it difficult to arrive at scientific and rational decisions. Decision support systems comprise tools that assist in decision-making, and their key feature is the ability to perform “IF THEN” rules for judgment analysis. Rough set theory can find these rules based on the analysis of a large amount of previous empirical data, and decision support systems based on rough sets make up for the shortcomings of conventional decision-making methods in this regard by allowing some less clear and less complete attributes in the decision object and by reasoning to reach essentially positive conclusions.

As the application of rough sets becomes more widespread, rough set tool application software is also becoming more comprehensive. There are ROSE, LERS, KDD-R, MATLAB, and Rosetta—the latter of which is a general-purpose tool that was jointly developed by Warsaw University in Poland and the Norwegian University of Science and Technology. After careful consideration, this paper used Rosetta to measure the degree of servitization and the degree of integration of complementary resources.

5.3.2. Related Concepts of Rough Sets

Definition 1.

A decision table

is a knowledge representation system, where

is a thesis domain,

is a non-empty finite set of attributes ,

is a set of conditional attributes, and

is a decision attribute. The distinguished matrix

is an

matrix with any element of , for

satisfying

and , or and , or , and .

Definition 2.

The distinguishing function is denoted by, which is a Boolean function that specifies a Boolean variable for each propertyin the knowledge expression system, a Boolean letterif, denoted byand a Boolean constant 1 if. The distinguishing functionis defined as:

The distinguishing function has the following property: All ensemble fetches in the minimal value-taking paradigm of the function are all refinements .

Definition 3 (attribute approximation).

For the attribute set, find all the savable attributes byusing the distinguished matrix and the distinguished function. An algorithmis said to be contrastive if all attributesare non-saveable. An algorithmis said to be an approximate determination ofwhenis adversarial and compatible.

Definition 4 (rule approximation).

For each decision rule in the system, find the equivalence class of decision attributes and the equivalence class of each attribute to find the minimum set of conditional attributes that satisfy therelationship. This is a simplification of the original rule.

Definition 5.

In the information system, forand the equivalence relation, define the upper and lower approximations of the subset with respect to theequivalence relation, as follows:

whereis the set of all elements in the representation that are equivalent tounder the relation. The set is called theboundary domain of,is the positive domain of, andis the negative domain of.

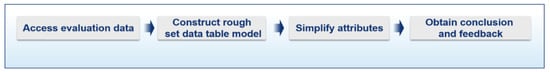

5.3.3. The Rough Set Analysis Process

Rough sets, as an effective data analysis method, can process uncertain assessment data and extract potentially valuable assessment information from a large amount of uncertain information. In this paper, we mainly apply the methods of rough set attribute approximation and importance judgment to study the value co-creation model of manufacturing enterprises.

The process of classifying the value co-creation model for manufacturing enterprises using the rough set approach can be divided into four steps, as shown in Figure 2.

Figure 2.

Analysis process of rough set-based model evaluation.

5.4. Empirical Analysis

5.4.1. Establishment of Rules

Rosetta machine learning builds rules that are typically logical and semantically explicit, that describe objective laws or domain concepts implied by the data distribution, and that can be written in the form if...then.... A set of rules is learned from the training data that can be used to discriminate between unseen examples. Clearly, each rule in the set can be viewed as a submodel, where the rule set is an integration of these submodels, and increasing the number of training samples improves the ability to describe the sample space.

At the stage of establishing rules via machine learning, this paper combines the summaries of previous scholars to classify the servitization involved in manufacturing enterprises into eight categories and the complementary resources into eight categories. As mentioned earlier, dummy variables are set to correspond to the above eight categories of servitization situations and eight categories of complementary resources situations. This approach is also used to design a research questionnaire with a seven-level scale system. In order to ensure the universality of the research results for each manufacturing enterprise, valid questionnaire data of 20 listed manufacturing enterprises, such as Xi’an Sitech Electric Co., Ltd., Foshan Haday Food Co., Ltd., and Yutong Bus Co., Ltd.; and 10 non-listed manufacturing enterprises, such as Shaanxi Iron and Steel Group Co., Ltd., Taian Jinshi Machinery Co., Ltd., and Xi’an Baiyue Goat Dairy Group Co., Ltd. were selected after consulting with relevant experts to ensure the validity of the data used to establish the rules.

The research questionnaire was quantified and imported into the rough set analysis software Rosetta, and the genetic algorithm was used to approximate the classification. In the mode classification stage, the initial assessment system needs to be approximate, even if there is some redundant knowledge, because the attributes in the information system are not equally important; this guarantees the streamlining of the assessment system. The genetic algorithm (RESE) in the Rosetta software was selected in this paper to simplify the initial assessment system, and the error tolerance was set to 0.2 according to the experience of previous scholars. A total of 405 rules were generated, and this large number of complete rules guaranteed the feasibility of the method. Using the rule preview function of Rosetta, we were able to see that the generated rules were based on different combinations of questions and scores to calculate the 0–1 score of the corresponding validation items—i.e., “I think we have a complementary degree of resource integration in tripartite value co-creation”, “I think we have a complementary degree of resource integration in tripartite value co-creation”, and “I think we have a complementary degree of resource integration in tripartite value co-creation”, etc.

5.4.2. Proving of Rules

Twenty manufacturing enterprises were selected as validation samples and the seven-level scale data of the attribute column of the degree of servitization and the attribute column of the degree of integration of complementary resources were standardized from 0–1 before the software was run; i.e., enterprises with scores greater than 3 were standardized to 1, whereas the rest were 0. The Rosetta software then analyzed the imported attribute column data according to the generated rules to obtain the judgment column.

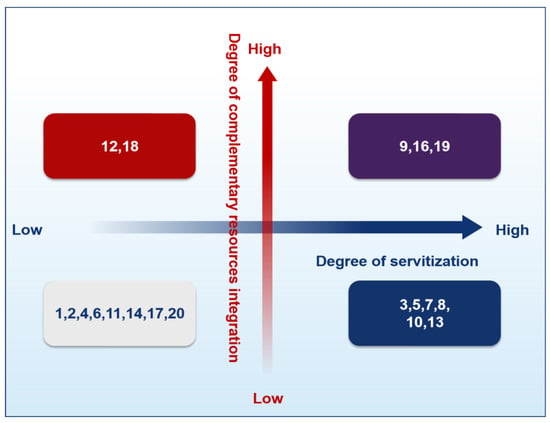

The scores of the rnterprises judged by the software were aggregated to derive the value co-creation model for each enterprise, as shown in Table 5.

Table 5.

Classification results of the value co-creation model for the validation sample.

The classification of the value co-creation model of the validation sample enterprises is plotted according to Figure 3.

Figure 3.

Sample enterprise classification results.

As shown in Figure 3, the 20 manufacturing enterprises were classified into four models. When the classification results were compared with the self-assessment results of the enterprises, it was found that only individual enterprises produced errors. After the error results were fed back to experts and scholars who have conducted in-depth research in manufacturing enterprises, they concluded that the classification results of this method were more in line with the actual situation of the enterprises. This indicates that the rules generated using the rough set software Rosetta according to the sample data are applicable and accurate, and the classification results of the value co-creation model are valid.

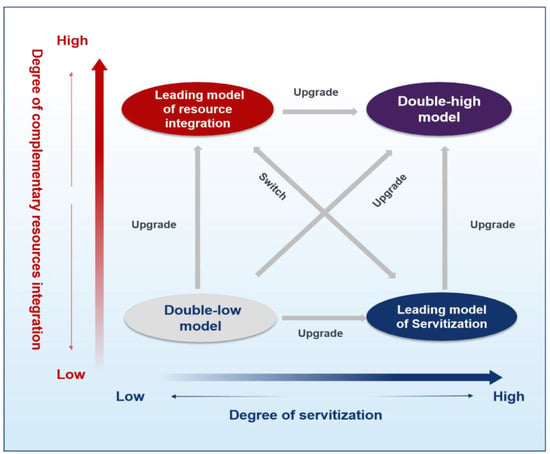

6. Value Co-Creation Model Upgrade Path

Through empirical verification, the value co-creation mode division method in this paper can accurately divide manufacturing enterprises so that they can precisely and quickly locate the existing mode in the process of value co-creation according to the specific situation of the degree of servitization and resource integration of enterprises. This paper proposes several upgrade paths to help enterprises develop sustainable development strategies and help manufacturing enterprises achieve higher levels of value co-creation, as shown in Figure 4.

Figure 4.

Upgrade path of value co-creation model for manufacturing enterprises.

6.1. Single-Servitization Upgrade Path

The single-service upgrade path is suitable for enterprises using a double-low model or a leading model of resource integration.

Such manufacturing enterprises should re-examine the industrial chain, reconstruct the value network around customer needs, shift from traditional product production to providing customers with total solutions that include services, and reshape the management of the service extension value chain derived from it. On the other hand, when centering on customer needs and opening up the service industry chain process, it is necessary to increase service element investment, develop industrial cooperative R&D services, develop customized design services, carry out whole-life-cycle management, innovate distribution and logistics transparency services, and enhance energy-saving and environmental protection services to encourage suppliers and customers to participate in value co-creation and enhance the servitization stage.

Complementary resource integration leads manufacturing enterprises to get rid of the lower levels of service development as well as the service low-end lock, but also to enhance their core competitiveness to attract the network of external resources to participate in service upgrading. It also encourages them to pay attention to the value perception of each value network subject to attract them to actively participate in value network servitization collaboration activities and realize the highly dynamic matching of service supply and demand in mutual collaboration [46]. Small- and medium-sized manufacturing enterprises can make use of the value perception of the value network. Such enterprises can build a service feedback exchange platform with the help of internet technology and use “network” thinking to collect feedback from all parties at relatively low service costs. Large manufacturing enterprises with strength can realize added value by providing high-end customized services with high heterogeneity and competitive advantages for customers. Under the premise of guaranteeing the centralization of core technology, manufacturing enterprises can decentralize non-core service businesses and take advantage of value network cooperative enterprises to realize service upgrading. For example, joint logistics enterprises can provide traceable logistics services, joint financial enterprises can provide a digital platform with transparent cost and revenue, joint big data mining enterprises can realize consumer behavior prediction and inventory remote calling services, etc.

Manufacturing enterprises can also take advantage of the development of Internet+ and digital economy elements to fully reduce interaction barriers between manufacturing and various network subjects, break the inertia of the traditional production model, change to a modern service economy development model, update and establish a development concept compatible with the current internet era as soon as possible, improve managers’ knowledge of new industries and technologies, and use modern technology to improve the servitization capabilities of their enterprises [47]. Such enterprises can also use modern technology to improve their servitization capabilities. Utilizing the sustainability features of the service and “integrating services into manufacturing” is a way for manufacturing enterprises to upgrade from a double-low model or a leading model of resource integration to a leading model of service or a double-high model.

6.2. Single-Resource-Integration Upgrade Path

The single-resource-integration upgrade path is applicable to manufacturing enterprises with a double-low model or a leading model of servitization.

In the double-low model, to achieve resource integration capacity enhancement, manufacturing enterprises should first clarify the type of resources to be integrated, such as customer resources, technical resources, information resources, etc., with limited internal resources to leverage external sustainability resources. These enterprises should target integration on the customer side and establish a resource matching or customer service platform that meets the actual situation of the enterprises to collect and integrate various customer resources in response to the growing personalized needs of customers. Further, manufacturing enterprises with a high degree of servitization can integrate supplier resources through information sharing, material planning, e-procurement, cooperative R&D, production collaboration, inventory management, and other activities with suppliers on servitization platforms or resource matching platforms. At the same time, customer participation resources are shared with suppliers, and the actual capabilities of the demand side and suppliers are highly matched to ensure a dynamic balance between the supply side and the demand side.

The key for manufacturing enterprises to carry out sustainability resource integration comprises technical resources. Manufacturing enterprises need to establish technical cooperation mechanisms across enterprise boundaries; guarantee zero distance, zero time difference, and zero intermediary communication of technical resources; build strategic alliances and partnerships of mutual trust, interdependence, long-term cooperation, and common development; and reduce innovation R&D risks and innovation pressure [48]. In a free and efficiently flowing, open, and active market [49], we can guarantee the effective communication and flow of knowledge, talent, and capital among technology resource integration enterprises.

Manufacturing enterprises should pay more attention to the integration of intangible resources on top of the integration of tangible resources. With the improvement of IoT traceability, platform capability, and computing service capability [50], many enterprises have achieved the digital transformation of production factors, and these intangible digital elements, which are the key direction of resource integration in the future of manufacturing enterprises, are also important elements of value co-creation inputs for manufacturing enterprises. Therefore, integrating intangible resources in the network requires enterprises to undertake special planning and construction in their organizational structure and personnel literacy, stimulate the potential of employees, and broaden the depth and breadth of organizational learning through underlying technical changes to drive top-level organizational structure changes. From the perspective of change of manufacturing, value network member enterprises should strive to integrate digital elements and other resources, cooperate with enterprises to change from physical to digital, foster the digital transformation of the manufacturing enterprise from the point-line-value network radiation structure, and realize the improvement of the integration degree of intangible resources of the whole value network [47]. Tapping the tangible and intangible resources of sustainability, and thus upgrading the level of value co-creation in manufacturing enterprises.

6.3. An Upgrade Path with Equal Emphasis on Servitization and Resource Integration

The upgrade path of servitization and resource integration is suitable for manufacturing enterprises using the double-low model as well as manufacturing enterprises in the leading mode of servitization and the leading mode of resource complementation. The latter two are unilateral development modes. Neglecting any one of these factors will affect the sustainability of the business. So, the two-pronged upgrade path is particularly important to avoid neglecting the other side of the enterprise caused to the loss of one side and avoiding the emergence of an uncertain situation.

From a production-oriented manufacturing enterprise to a servitization manufacturing enterprise, the relationship between manufacturing enterprises and customers and the relationship with upstream and downstream suppliers have changed, and enterprises need to adjust and restructure their management model, organizational structure, and business processes accordingly [47]. This can be achieved by more effectively embedding these aspects in the loosely coupled servitization manufacturing network system structure and striving to become the core node enterprise in the network structure so as to integrate services and resources in the value network. With the development of Internet+ and big data, the servitization transformation of manufacturing enterprises requires them to purposefully create, extend, and modify their current resource base that is closely related to manufacturing [51] in order to integrate customers into the online marketing and sales process and into the internet service care system. For example, the urgent shipment of goods may require the selection of air freight service resources; global marketing of customers may require the selection of warehouse network resources integrated with other countries; customers’ requirement for visibility of the production process inevitably raises the requirement for the selection of webcast resources, and so on. Cooperative interaction with various value network subjects is also an effective way to avoid the risks of servitization of enterprises [52]. Therefore, the process of servitization of manufacturing enterprises is actually the process of implementing sustainable strategies to optimize resource allocation.

Manufacturing enterprises need to promote servitization and resource integration to complement each other, play a dual sustainable role and develop synergies to enhance value co-creation. Since complementary resources in the servitization process are important factors supporting enterprises in value co-creation, even large manufacturing enterprises with strong resources need to conduct network resource integration to create more value. In order to guarantee effective interaction of resources, enterprises need to broaden the channels connecting each department with external value networks by reducing the levels of organizational structure, realize the interaction and information sharing between each level and the external network subject, improve the application mechanism of complementary resource interaction, implement information and resources from all parties into manufacturing planning in a timely manner, make timely responses to the needs of customers and partners, adjust the degree of enterprise servitization, improve the degree of matching resources and servitization, and realize the matching of supply and demand. Enterprises also need internal management changes and should follow the rules of synergy and interaction, self-learning, self-organization, and self-adaptive adjustment, as well as enhancing the internal self-organization of synergy and interactive cooperation ability, implementing “information management talent + resource integration talent + market management talent” in their servitization manufacturing talent development system, and relying on the government. Key talent projects increase the training of talent in the field of servitization manufacturing [47]. This would help realize the synergistic development of service and resource integration and provide deeper source power for matching supply and demand.

7. Conclusions and Implications

The prerequisite for value co-creation in manufacturing enterprises is servitization, and resources are the key elements of value creation in this process, while network subjects are resource integrators who can achieve value co-creation through interaction and integration of complementary resources. This paper explores the value co-creation model against the background in which the value network supported by information technology provides vital support for the servitization value co-creation of manufacturing enterprises. Thus, it has theoretical innovation significance.

Although the “value co-creation model” has been widely analyzed in digital contexts and various types of services [53], it has always been considered as a single way named “service-dominant logic” which is different from traditional value production way. So there lacks of classification research on value co-creation. Previous research on the value co-creation model first focused on measuring and managing the value co-creation process; these studies proposed a range of models and techniques for managing and measuring customer input, empowerment, innovation, and so on [54]. Many studies researched the co-creation activities or interactive behaviors model of actors. Several of them proposed the maturity model of value co-creation with four measurement indicators consisting of articulation, interaction, platform, and management which reveal the behavioral dimensions of multi value co-creation [55]. Some scholars also studied the business models of value cocreation [56], such as Indonesian researchers who applied a business model canvas based on service-dominant logic to investigate the blueprint for cooperation and creativity, aiming at expediting the process of innovation and invention in the healthy-food industry by applying value co-creation [57], but value co-creation models in these studies are mostly classified with single-dimensional indicators.

With the development of information technology and the deepening of servitization level of manufacturing enterprises, “industry-specific value co-creation” is becoming the trend [58]. Some researchers study industry business model innovation [59] and the value co-creation of the collaborative network of tourism in three border zone between Brazil–Argentina–Paraguay, and construct a user value co-creation model for web applications [60], also study value co-creation by multiple stakeholders with different capabilities and even conflicting objectives in the Finnish commercial inland fishery [55]. Based on the same theoretical context, our research has filled the gap in the value co-creation of tangible products and intangible services in manufacturing enterprises, which is a further extension of the PSS which has been defined as “a marketable set of products and services capable of jointly fulfilling a user’s need” [61]. The new models proposed in this paper, thoroughly extend the value co-creation model types and classifications from the pure service field and suggest a comprehensive and neural understanding of servitization and resource integration in the PSS. Our value co-creation model also strengthens the links among PSS, value co-creation, sustainability, and information technology in the context of value network [62]. Our value co-creation model focuses on two main aspects of value co-creation and investigates the model with two-dimensional indicators from the strategic view instead of business or activities views.

Meanwhile, from the perspective of the value network as the analytical dimension of the value creation model, the degree of integration of complementary resources and the degree of servitization can help enterprises of all scales locate their current situation in time, find counter-measures to grasp opportunities, and achieve a greater degree of matching supply and demand. When manufacturing enterprises transform into servitization enterprises, the “network” resources are often scattered. Within this context, it is difficult for the accumulated resources to support the service projects. Enterprises may doubt whether the implementation of servitization is correct. Therefore, the value co-creation model of servitization from the perspective of the value network is conducive to the timely adjustment of reform direction, grasping the key elements, acquiring information resources, sharing the risk with each network subject, and further realizing the sustainable development of value co-creation. Thus, the value co-creation model provides positioning standards and upgrading paths for manufacturing enterprises, which can then obtain stronger practical outcomes in the servitization.

According to the needs of the four value co-creation models and their upgrading paths, manufacturing enterprises need to build or reconstruct their value networks through cooperative business networks. This pathway can be roughly divided into two steps: building and managing the value network of value co-creation. In the first step of establishing a co-creation network, it is important for enterprises to build awareness about the benefits of taking part in a co-creation network, especially for the small manufacturing enterprises which have a very limited understanding of the potential benefits of co-creating with other enterprises. Manufacturing enterprises need to build sourcing and relational competencies in this step [63]. In the first step of building a value co-creation network, manufacturing enterprises should not only focus on the resource level, but also consider the servitization level of the whole network and the embeddedness of the actors. Therefore, the selection criteria for such network members should be more composite and more explicit not only in the value creation, interaction, and actor behavior [64], but also in servitization and complementary resources. In managing the value network, manufacturing enterprises should share value propositions for complementary resources contracting, organization of resource integration, and cultivation of coproduction output [65]. They need to manage the relationship equity, shared responsibility, and relationship dependence to leverage resources to achieve better value co-creation [66]. Based on applying social media digital networks and platforms [67] to facilitate value co-creation [14]. Most manufacturing value network actors should apply more new technologies including artificial intelligence [68], virtual reality [69], virtual communities [70], digital twins, and so on [71] to integrate resources, competencies, and responsibilities to attain new value co-created. Moreover, manufacturing enterprises should take the open innovation way to encounter the challenges of sustainability and value co-creation [4], such as sustainable production, green value innovation [72], and circular co-creation ecosystem construction [73].

In addition, from the value network perspective, the exploration of the upgrading path of manufacturing enterprises is in the preliminary research stage, and there is still considerable work to be done. Further research should consider alternative approaches to identify the value co-creation model, such as the dynamic supply and demand matching model and the co-creation of value process.

Author Contributions

Conceptualization, G.L.; methodology, G.L. and J.W.; software, J.W.; validation, G.L., J.W. and N.L.; formal analysis, J.W.; investigation, N.L.; resources, J.W. and N.L.; data curation, J.W.; writing—original draft preparation, G.L. and J.W.; writing—review and editing, J.W. and N.L.; supervision, G.L.; project administration, G.L.; funding acquisition, G.L. All authors have read and agreed to the published version of the manuscript.

Funding

Project supported by the Soft Science Research Program of Shaanxi Province, China (NO.2019KRM162); the Soft Science Research Program of Shaanxi Province, China (No.2020KRM185); the National Social Science Foundation of China (No.16BGL015).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Questionnaire:

Dear Enterprise Manager/Account Executive:

First of all, we sincerely hope that you can participate in this questionnaire on the research of value co-creation model between manufacturing enterprises and customers and suppliers. The purpose of this study is to study the value co-creation model of manufacturing enterprises based on the two dimensions of the degree of servitization and complementary resource integration.

When filling in the questionnaire, please select the closest option based on your experience. We sincerely invite you to take 3–5 min out of your busy schedule to fill in the following questionnaire. All the survey data are only used for academic research and will be strictly confidential. The research results only show comprehensive data and never involve any personal information. We sincerely thank you for your active participation! Thank you for your cooperation!

Please read the following questions carefully and choose the one that best suits your enterprise’s situation. The three parties include manufacturers, suppliers and customers.

1. Disagree at all

2. Basically disagree

3. A little disagreement

4. Opinion neutrality

5. A little agreement

6. Basic agreement

Questions:

- Manufacturing enterprises, suppliers and customers have a complete plan for collaborative R&D service activities [single choice]

- There is a perfect transportation and warehousing service system among the three parties [single choice]

- There is a perfect platform for three parties to exchange demand characteristics and preference information [single choice]

- There is a perfect product remote diagnosis and maintenance guidance system among the three parties [single choice]

- The three parties are committed to finding and developing more efficient service activities [single choice]

- A professional service business department has been set up among the three parties [single choice]

- The supply chain response time among the three parties is significantly shortened [single choice]

- The proportion of service business performance among the three parties in the total performance is high [single choice]

- I think our service degree in the tripartite value creation [single choice]

- The three parties can bridge the resource gap [single choice]

- Regular or irregular technical and related personnel exchange meetings have been established among the three parties [single choice]

- The three parties have established a negotiation mechanism on key technological breakthroughs [single choice]

- A sharing platform for technology and information exchange has been established among the three parties [single choice]

- There are plans among the three parties to integrate resources according to development needs [single choice]

- There is an emergency plan for resource integration among the three parties to deal with external changes [single choice]

- Achievements of innovation goals among enterprises have been significantly improved [single choice]

- The rationality of resource allocation among the three parties has been significantly improved [single choice]

- I think the degree of our complementary resource integration in the value co creation of the three parties [single choice]

References

- Grönroos, C. Service Logic Revisited: Who Creates Value? And Who Co-Creates? Eur. Bus. Rev. 2008, 20, 298–314. [Google Scholar] [CrossRef]

- Vargo, S.L.; Lusch, R.F. Service-Dominant Logic: Continuing the Evolution. J. Acad. Mark. Sci. 2008, 36, 1–10. [Google Scholar] [CrossRef]

- Vargo, S.L.; Maglio, P.P.; Akaka, M.A. On Value and Value Co-Creation: A Service Systems and Service Logic Perspective. Eur. Manag. J. 2008, 26, 145–152. [Google Scholar] [CrossRef]

- Almeida, R.P.; Proença, J.F.; Ferreira, F.N.H. Value Co-Creation and Sustainability: A Systematic Literature Review. Int. J. Mark. Commun. New Media 2021, 7, 104–125. [Google Scholar]

- Kerui, L.; Zhaoquan, J. The Research on the Value Co-Creation Model of Manufacturing Servitization—A Service Ecosystem Perspective. East China Econ. Manag. 2017, 31, 84–92. [Google Scholar]

- Badarinath, R.; Prabhu, V.V. Advances in Internet of Things (Iot) in Manufacturing. In Proceedings of the IFIP International Conference on Advances in Production Management Systems 2017, Hamburg, Germany, 3–7 September 2017; Springer: Cham, Germany, 2017. [Google Scholar]

- Wang, G.H.; Zhu, X.F. Conflict of Interest and Balancing Mechanism in the Integration of Toubro File under the Perspective of Value Co-Creation Conflict of Interest and Balancing Mechanism Research. Res. Libr. Sci. 2020, 8, 27–33. [Google Scholar]

- Chang, Y.; Ming, X.; Zhang, X.; Zhou, T.; Liao, X.; Cao, S. Servitization and Sustainable Value Creation Strategy for China’s Manufacturing Industry: A Multiple Case Study in the Belt and Road Initiative. Sustainability 2021, 13, 11334. [Google Scholar] [CrossRef]

- Serror, M.; Hack, S.; Henze, M.; Schuba, M.; Wehrle, K. Challenges and Opportunities in Securing the Industrial Internet of Things. IEEE Trans. Ind. Inform. 2021, 17, 2985–2996. [Google Scholar] [CrossRef]

- Weber, P.; Morar, D.; Lasi, H. Transforming Value Chains into Internet-Based Ecosystems: A Testbed Approach. In Proceedings of the Paper presented at the 2018 Portland International Conference on Management of Engineering and Technology (PICMET) 2018, Honolulu, HI, USA, 19–23 August 2018. [Google Scholar]

- Xianli, H. The Revolution of Human Lives in the Era of “Internet Plus”. Ph.D. Thesis, Heilongjiang University, Heilongjiang, China, 2020. [Google Scholar]

- Li, H.; Yang, C. Digital Transformation of Manufacturing Enterprises. Procedia Comput. Sci. 2021, 187, 24–29. [Google Scholar] [CrossRef]

- Mele, M.; Giampaolo, C. A New Method for the Design of Knowledge-Based Engineering Systems for Manufacturing. Int. J. Interact. Des. Manuf. 2021, 15, 417–428. [Google Scholar] [CrossRef]

- Sashi, C.M. Digital Communication, Value Co-Creation and Customer Engagement in Business Networks: A Conceptual Matrix and Propositions. Eur. J. Mark. 2021, 55, 1643–1663. [Google Scholar] [CrossRef]

- Jinghua, L.; Lin, L.; Weitao, Y. The Value Co-Creation Mechanism of Servitization: An Explorative Case Study on Value Network Perspective. Sci. Sci. Manag. S. T. 2017, 38, 85–100. [Google Scholar]

- Tianzhu, L.; Xiaoqin, L.; Xiaoxiao, L. Some Theoretical Analysis About the Service of Manufacturing Industry. Forum Sci. Technol. China 2018, 6, 75–82. [Google Scholar]

- Zhaoguo, D.; Qing, J.; Zhong, Z. On Valae Creation of Service Manufacturing Companies. Forum Sci. Technol. China 2013, 5, 91–96. [Google Scholar]

- Yanping, Z.; Yating, G.; Jianqiang, L.; Qinghua, F. Manufacturing Enterprise Service Derivative Classification and Value Creation. Soft Sci. 2017, 31, 103–107. [Google Scholar]

- Windahl, C.; Lakemond, N. Developing Integrated Solutions: The Importance of Relationships within the Network. Ind. Mark. Manag. 2006, 35, 806–818. [Google Scholar] [CrossRef]

- Lavie, D. Alliance Portfolios and Firm Performance: A Study of Value Creation and Appropriation in the U.S. Software Industry. Strateg. Manag. J. 2007, 28, 1187–1212. [Google Scholar] [CrossRef]

- Xiaoxiao, L. Modes and Evolutions of Manufacturing Servitization—A Value Co-Creation Perspective. Master’s Thesis, University of Science and Technology Liaoning, Anshan, China, 2018. [Google Scholar]

- Na, L. Research on the Mechanism of Co-Creation Value Based on Customer-Dominant Logic. Master’s Thesis, Harbin University of Science and Technology, Harbin, China, 2020. [Google Scholar]

- Jing, L.; Yingyan, C. Study of Value Co-Creation Model for Digital Construction of Cultural Tourism. Ludong Univ. J. Philos. Soc. Sci. Ed. 2021, 38, 85–90. [Google Scholar]

- Lina, W.; Zhang, C.; Zhu, W. Research on Value Co-Creation Model of Servitization in Manufacturing Industry in the Internet Era—Based on Haier’s Servitization Transformation Practice. Enterp. Econ. 2019, 38, 68–76. [Google Scholar]

- Zhang, W.; Yingwu, C.; Huibin, S. Research on the Cooperative Network of the Servitization of Equipment Manufacturing Industry: Types and Characteristics. Sci. Technol. Prog. Policy 2015, 32, 55–60. [Google Scholar]

- Anderson, J.C.; Håkansson, H.; Johanson, J. Dyadic Business Relationships within a Business Network Context. J. Mark. 1994, 58, 1–15. [Google Scholar] [CrossRef]

- Wang, Q. Business Model Innovation Based on the Reconfiguration of Value Network. China Ind. Econ. 2011, 1, 79–88. [Google Scholar]

- Feng, C.-L.; Liu, H.-T. Value Co-Creation Model in the Process of Service Transition of Manufacturing Enterprises from the Network Perspective:Research Based on the Shanxi Blower Case. J. Manag. Case Stud. 2016, 9, 472–484. [Google Scholar]

- Hao, X.J.; Yao, S.J.; Tong, S.L. Research on Value Co-Creation Network in Service-Oriented Manufacturing Model. Sci. Technol. Prog. Policy 2015, 32, 60–66. [Google Scholar]

- Xie, X.M.; Wang, H.W. The Mode and Mechanism of Value Co-Creation of Open Innovation Ecosystem. Stud. Sci. Sci. 2020, 38, 912–924. [Google Scholar]

- Cheng, Q.; Yixuan, Z. The Impact of Value Co-Creation Model of Open Innovation Ecosystem on Value Co-Creation Effect : Based on the Model of Cross Level Regulation Effect. Sci. Technol. Prog. Policy 2021, 38, 87–96. [Google Scholar]

- Wang, L.; Juxiang, L.; Qiong, L. The Value Co-Creating Model and the Coordination Mechanism Research of Science and Technology Service Industry Innovation Ecosystem. Sci. Technol. Prog. Policy 2017, 34, 69–74. [Google Scholar]

- Ma, Y.; Shiming, L.; Jingming, P. Value Co-Creation Model for Industrial Iot. J. Manag. World 2020, 36, 211–222. [Google Scholar]

- Yao, J. Research on the Value Co-Creation Behavior and Models of “Internet+” Enterprise Innovation Ecosystem; Hangzhou Dianzi University: Hangzhou, China, 2020. [Google Scholar]

- Zhang, J.; Yong, H. Impact of Service-Dominant Logic Orientation and Resource Interaction Upon Value Co-Creation. Sci. Res. Manag. 2014, 35, 115–122. [Google Scholar]

- Jean, G. The Characterization of Goods and Services: An Alternative Approach. Rev. Income Wealth 2000, 46, 369–387. [Google Scholar]

- Jason, P.; Hartley, J.; Banks, J.; Burgess, J.; Cobcroft, R.; Cunningham, S.; Montgomery, L. Consumer Co-Creation and Situated Creativity. Ind. Innov. 2008, 15, 459–474. [Google Scholar]

- Charlotta, W.; Lakemond, N. Integrated Solutions from a Service-Centered Perspective: Applicability and Limitations in the Capital Goods Industry. Ind. Mark. Manag. 2010, 39, 1278–1290. [Google Scholar]

- Sally, H.; Winklhofer, H.; Temerak, M.S. Customers as Resource Integrators. J. Serv. Res. 2012, 15, 247–261. [Google Scholar]

- Jian, F. Measuring Servitization of Chinese Manufacturing and Research of Its Influencing Factors. Master’s Thesis, Nanjing University, Nanjing, China, 2015. [Google Scholar]

- Xin, W. Study on the Influence Factors of Servitization Strategy of Manufacturing Enterprise. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2014. [Google Scholar]

- Bill, M.; Marcus, A. Embedded Ties and the Acquisition of Competitive Capabilities. Strateg. Manag. J. 2005, 26, 1033–1055. [Google Scholar]