Abstract

Background: To effectively avoid accidents caused by practitioners’ unsafe state in the process of coal mine production processes, it is necessary to clarify the factors influencing the practitioners’ unsafe state, and take corresponding control measures accordingly. Methods: With the help of literature research and on-site interviews, grounded theory was used to construct the influencing factor index system of the coal mine practitioners’ unsafe state. The index system primary includes indices of four core categories, physiology, psychology, organization, and technology, and secondary indices of fourteen main categories. An AHP-DEMATEL model was constructed to calculate the comprehensive degree of influence of each influencing factor and rank it. Results: The results show that the main factors affecting the coal mine practitioners’ unsafe state are physical quality, degree of fatigue, safety attitude, safety awareness, safety culture, and vigilance. Physical quality and degree of fatigue are the key factors that affect the coal mine practitioners’ unsafe state, which is more consistent with the actual situation of coal mine practitioners. With the findings of this study, coal mine managers can take relevant countermeasures to intervene in coal mine practitioners’ unsafe state and reduce the occurrence of accidents.

1. Introduction

The National Mine Safety Administration reported that in 2021, there were 356 accidents and 503 deaths in mines across the country. Among these, there were 91 coal mine accidents and 178 deaths, with a mortality rate of 0.044 per million tons [1]. Under the influence of the production safety situation at home and abroad, China’s mine-safety work has achieved significant results. However, the safety situation remains complex and serious due to the severe impact of the coronavirus disease in 2019. Serious accidents have not yet been eliminated, and major accidents have occurred from time to time. Excessive energy release in the production process can lead to accidents in industrial enterprises, and unsafe human behavior can lead to the accidental release of energy [2]. Human error has been demonstrated as the primary factor in mine accidents; through the investigation and analysis of many coal-mine-safety accidents, it can be concluded that the occurrence of coal mine accidents in China mainly stems from the practitioners’ unsafe behavior [3]. Practitioners’ unsafe behavior or state is the direct cause of the accident, which is also considered the first cause [4]. The preconditions for unsafe behavior are mentioned in Reason’s Swiss cheese model [5]. Harris and Li divided preconditions for unsafe behaviors into decision-making errors and skill errors caused by individuals’ readiness, mental state, physiological state, and physical and intellectual deficits [6]. They used neural networks to predict unsafe behaviors from the preconditions of unsafe behaviors. In the Human Factors Analysis and Classification System, the operator’s state is considered one of the preconditions for the occurrence of unsafe behavior; that is, unsafe human behavior is dominated by the individual’s state of being [7]. Unsafe state in this paper means a scenario that may lead to coal mine practitioners’ unsafe behaviors under the joint action of time and space in a specific environment. This unsafe state is affected by physiology, psychology, knowledge, and so on [8].

Unsafe states can have a direct impact on human behavior, which can lead to accidents [9]. The main cause of the roof accident on August 14 in Xinjiang was that the miners worked intensively for a long time and were mentally exhausted. Workers’ poor mental states, insufficient safety awareness, and lack of vigilance may increase the occurrence of violations. If miners do not have safety requirements for training and testing and eat poorly, they will be poorly prepared for their work. The cause of the coal mine fire accident on December 26 in Hebei was mainly that the miners worked long hours, did not meet the rest suggestions, and were weak and lacking in energy. Thus, the miners’ skills decreased significantly, leading to an increased rate of behavior errors, which led to an increased likelihood of accidents. Personal states, such as physical illness, lack of professional knowledge, poor safety awareness, inadequate training, and lack of emergency response capacity, have a significant impact on unsafe behaviors. Therefore, the key to reducing accidents is to ensure that practitioners are in a good personal state.

In the production process of coal businesses, practitioners’ behavior is closely related to their operation process, which directly determines the safety of the whole production process. Therefore, it is essential to monitor unsafe states, which are the source of unsafe behavior. From the perspective of human factors, it is necessary to study the safety of practitioners’ states and the influence mechanism of unsafe states in the current severe situation of coal mine production processes. This study used typical accidents from 2007 to 2021 as a sample. Combined with on-site interview, the grounded theory method was used to extract the factors influencing coal mine practitioners’ unsafe state. The relationship between the influencing factors was clarified by the AHP-DEMATEL model. It is then the responsibility of the mine managers to take appropriate measures to intervene in practitioners’ unsafe state, reduce unsafe behavior, and prevent the occurrence of accidents.

The organization of the paper is as follows. Section 2 introduces a review of the literature related to the study of coal mine practitioners’ unsafe state. Section 3 introduces the research methods of this paper. Section 4 analyzes the data and obtains the results. Section 5 discusses the results of this study. Section 6 summarizes the conclusions of this study.

2. Literature Review

Studies have shown that the state of the individual has a significant impact on unsafe behavior, and an unsafe individual state accounts for 10% of the direct causes of work-related injuries [10]. Due to the lack of effective management of personnel in coal businesses, the safety state of personnel cannot be guaranteed. Xie and Guo constructed a predictive model to achieve a dynamic quantitative assessment of human risk. By determining the status of personnel safety, the personnel deemed to be in a poor safety state are screened out to prevent accidents [11]. Poor human health is regarded as a factor that affects unsafe behavior. The poor health and safety of miners positively affect the probability of underground accidents in coal mines [12]. Employees’ physical conditions and negative emotions affect their mental state and render them prone to unsafe behaviors [13,14]. Inamasu et al. found that 84% of patients had a car accident after a seizure [15]. Diabetes and poor vision can also lead to more accidents [16]. Chen et al. concluded that workers’ physical state, encompassing factors such as mental fatigue, illness, and physical fatigue, is an important factor leading to unsafe behaviors through accident investigations [17]. Psychological and physiological fatigue are two states that can lead to unsafe behavior. Psychological fatigue is the result of long-term cognitive activities. When fatigue reaches a certain level, it can lead to a decrease in behavioral performance [18]. When the workload of employees is large, an unsafe state of fatigue often occurs. Accidents occur more frequently when coal mine operations continue in this state [8]. With increased physical exhaustion, coal miners’ work enthusiasm and efficiency also decrease significantly [19]. Tsai identified fatigue by detecting workers’ brain wave rhythms and heart rate variability, monitoring workers’ physiological status and reducing the occurrence of unsafe behaviors [20]. Lee et al. constructed a driver alertness level evaluation system based on physiological state, and the results show that the system can estimate alertness level with great accuracy [21]. Alertness can be used as an index to detect surgeons’ state during operations and patients’ mental state in the fields of medical treatment and quality inspection [22].

Through a survey of shipbuilders, Jeong et al. found that self-reported psychological characteristics is an important factor in predicting unsafe behaviors leading to industrial accidents [23]. Individual states, such as attitudes, consciousness, and emotions, will affect the individual’s perception and evaluation of their environment. Accidents are caused by influences affecting operational behavior [24]. Heinrich reported that poor employee attitudes lead to nasty accidents. Safety attitude is the psychological tendency of people in a specific field to judge the value and emotional color of a particular object in terms of safety. It is a recognition of safety norms. Therefore, we will maintain a conscientious implementation of safety guidelines at work. People instinctively pay attention to their safety state. People hold a safety attitude towards certain types of hazards through safety education and training and their own experience, and form their perspective through cognition and evaluation. Li et al. believed that the safety attitude of coal miners could change their unsafe status and prevent unsafe behaviors. A good attitude can also improve an organization’s industry performance [25]. When an employee has a positive attitude toward an unsafe behavior, it will manifest as a behavioral intention. They believe they have mastered the ability and resources needed to engage in the behavior and put themselves in a safe state. Shin et al. found that adjusting employees’ safety attitudes can keep them in good working order and reduce accidents [26]. By analyzing the data of 58 coal mine fatalities, Wang et al. concluded that safety awareness is an important factor affecting mine safety. The stronger the safety awareness, the better the individual state, which can ensure the safeness of their behavior [27]. Studies have shown that working while fatigued can not only make employees suffer from physical fatigue, but also make employees suffer from anxiety, irritability, and other negative emotions [28]. Emotion is the manifestation of the human state. Yang et al. believed that one of the main reasons for coal-mine-safety accidents was that the emotional state affected the unsafe behaviors of miners [29]. Anger is a common negative emotion. Studies have shown that anger can put drivers in a state with a weak perception of danger. The sight range is affected, which may lead to unsafe behaviors, such as driver deviation from the road [30].

Many accidents are caused by people’s unsafe states, and organizational factors directly affect people’s states. Safety culture encompasses a recognition of dangers in operation safety, a fundamental measure to prevent accidents, and the best “firewall” to block accidents [31]. Safety culture can create an extremely safe atmosphere and environment, thereby improving the safety quality of employees and maintaining individuals’ safety at work. Huang et al. developed a new scale to measure safety climate by taking truck drivers as an example. The results show that the organization’s safety climate could affect the driver’s safety state level [32]. Lee et al. proposed that education and safety training should be strengthened so that employees can experience the effects of safety activities first-hand [33]. At the same time, it can also improve employees’ safety awareness and ensure they have the correct attitude. Establishing a healthy safety concept, strengthening safety education for employees, cultivating employees’ safety awareness, and forming a good safety atmosphere are fundamental to preventing accidents.

Although there are more and more explorations on the unsafe state of personnel, the research in the field of coal mines still needs to be developed, and a relatively complete system framework is needed. To make up for this research gap, this study used a literature review and on-site interviews for systematic analysis. It used grounded theory to screen the factors influencing coal mine practitioners’ unsafe state. On this basis, the weight of each factor is calculated by the method of AHP and DEMATEL, and the main and key influencing factors are determined. Based on this, countermeasures to prevent coal mine practitioners’ unsafe state are put forward. It is expected that the study results will encourage coal mine managers to develop a deeper understanding of coal mine practitioners’ unsafe state and on-site safety management. At the same time, we hope to point out the direction for further research in this field.

3. Method

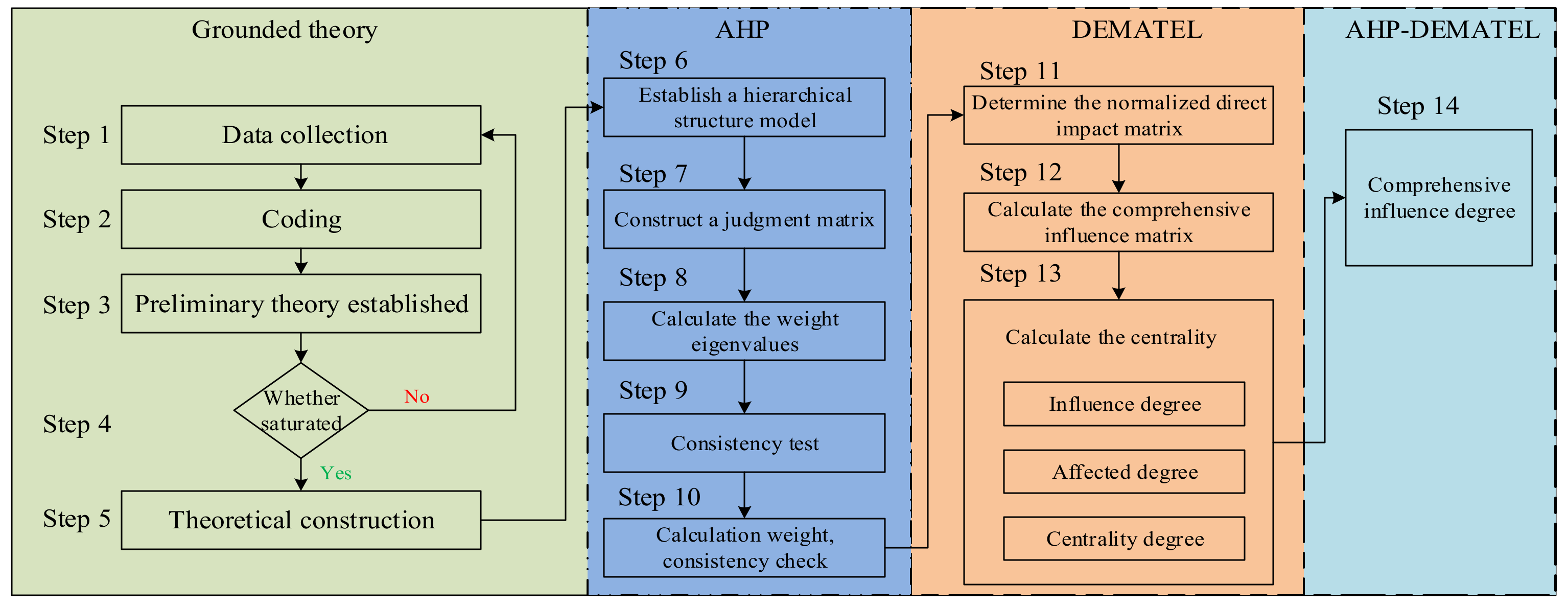

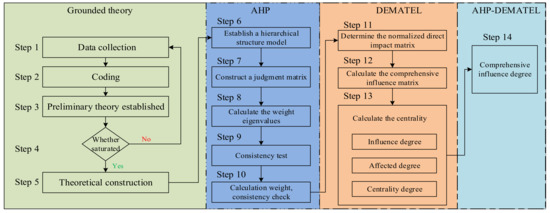

In this paper, based on grounded theory, an index system of factors influencing coal mine practitioners’ unsafe state is established. Then, combined with AHP and DEMATEL methods, the comprehensive degree of influence of each factor is calculated to judge its impact on coal mine practitioners’ unsafe state. The overall calculation framework flow chart is shown in Figure 1.

Figure 1.

Overall Calculation Framework Flow Chart.

3.1. Grounded Theory

Grounded theory is a qualitative research method that organizes and summarizes theories from original data. Its preciseness and effectiveness are widely recognized [34]. It is a bottom-up mature exploratory research method based on experience and various sources, which makes concepts and categories more natural and substantively objective. This method is often used to construct theories of influencing factors and their properties [35].

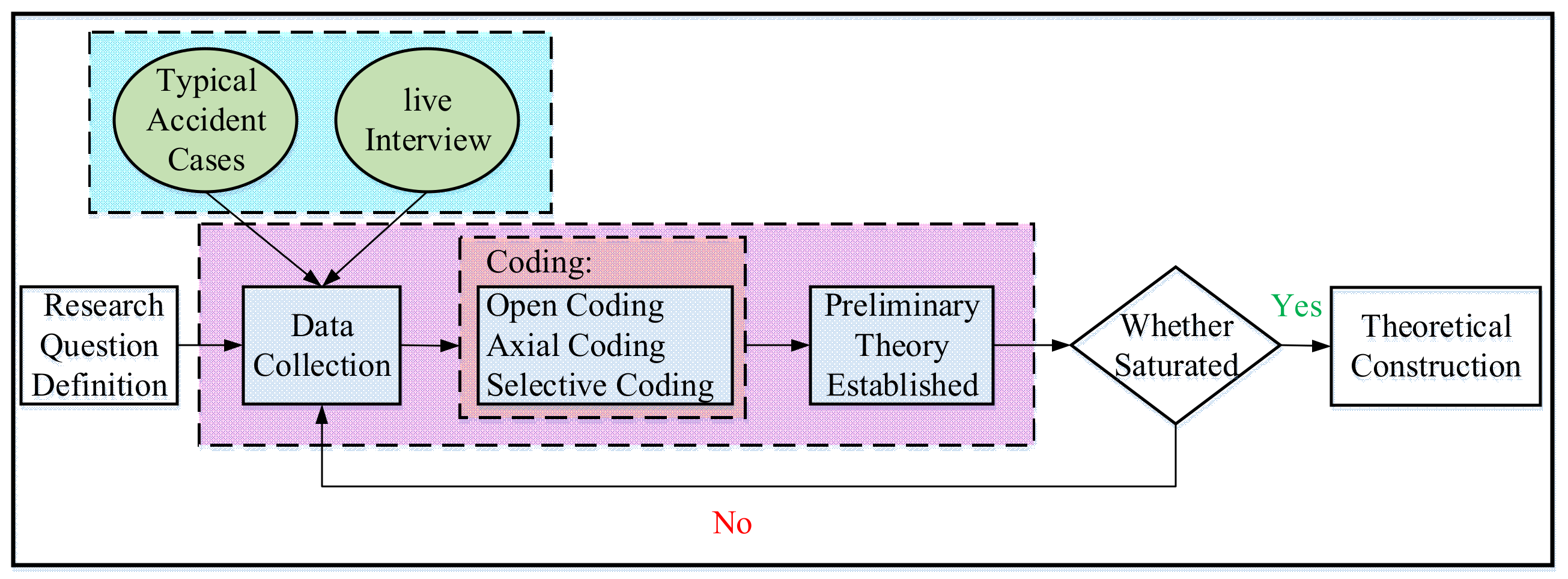

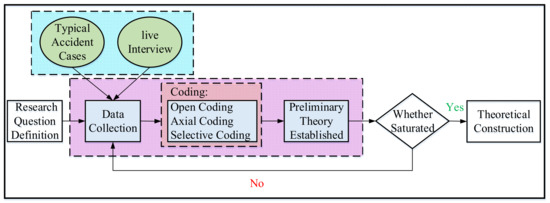

The steps of the method include data acquisition, open coding, axial coding, selective coding, and a theoretical saturation test, as shown in Figure 2. Open coding requires researchers to break up the originally collected data with an open mind, create new concepts, and then recombine them in a new way. The main task of axial coding is to find and establish various connections between conceptual categories, and to express the organic relationship between various parts of the data. Selective coding involves sorting out the relationship between the main categories based on axial coding, abstracting the core categories that can generalize all categories, and clarifying the relationship between the core categories and secondary categories via a story plot. To ensure the reliability and integrity of the model, a saturation test is required. If the concept or category generated by using the newly collected data is incorporated into the existing concept or category, and there is no new concept or category development, the conceptual model is considered saturated in theory.

Figure 2.

The process diagram of grounded theory.

In this study, the primary way of obtaining the factors influencing coal mine practitioners’ unsafe state is to collect typical accident cases and on-site interviews. Based on grounded theory, this paper studies and extracts the event types and causes from interview contents one by one, and then constructs the influencing factor index system of coal mine practitioners’ unsafe state.

3.2. Analytic Hierarchy Processing

The analytic hierarchy process (AHP) is an effective multicriteria and multiobjective method to determine the weight coefficient [36]. Through the combination of qualitative and quantitative measures, the research problems are divided into multiple levels. Then, the relative importance of each level is compared and expressed quantitatively with objective data. Finally, the weight values of each level are calculated and sorted [37,38]. American professor Saaty. T.L. proposed the method, and it has been widely used in the research of accident cause analysis, management evaluation, and other fields. It mainly includes the following steps:

Step 1: Establish a hierarchical structure model. According to the specific problems, the factors related to the coal mine practitioners’ unsafe state are divided into three levels: target layer A, criterion layer B, and index layer C. Relations existing at different levels are indicated with a line.

Step 2: Construct a judgment matrix, . Relevant managers in the coal mine field and university experts engaged in coal-mine-safety research were invited to score each influencing factor according to a comparative scale from 1 to 9, as shown in Table 1. Additionally, the properties of the following Equation were met: .

Table 1.

Judgment matrix 1~9 comparison scale table.

Step 3: Calculate the weight eigenvalues.

The calculation Equation is:

where, is the maximum eigenvalue in the matrix M. W is the normalized eigenvector of the corresponding . This vector is normalized to obtain the vector weights of the hierarchical model.

Step 4: Consistency test.

The calculation Equation is:

where, CR represents the stochastic consistency index. is the consistency inspection index. is the maximum eigenvalue in the matrix M. n is the order of the matrix. RI is the average random consistency index, which corresponds to different RI values according to the order n of the matrix, as shown in Table 2.

Table 2.

RI values corresponding to matrices of order 1~9.

Finally, the calculated weights of all elements are sorted into a hierarchical order, and then the consistency test is carried out. The calculation Equation is:

3.3. Decision-Making Trial and Evaluation Laboratory

The decision-making trial and evaluation laboratory is a method that uses the principles of matrix calculus and graph theory to intuitively express the logical relationship between various factors in a complex system with a coordinate system [39]. The analysis of the importance and function of each factor in the system leads to improved outcomes [40,41]. The specific steps are as follows:

Step 1: Determine the direct degree of influence between the influencing factors of the research object. Using the 0 to 4 scale method to compare the strengths and weaknesses of the influencing factors, determine the direct influence matrix U. 0, 1, 2, 3, and 4 indicate no effect, weak influence, weak influence, strong influence, and strong influence, respectively.

Step 2: Normalize the direct influence matrix to obtain the normalized direct influence matrix V. The main calculation Equation is as follows:

Step 3: Calculate the comprehensive influence matrix T. The Equation is:

where, E is the identity matrix. tij represents the degree of direct or indirect influence of factor i on factor j, or the degree of comprehensive influence of factor j from factor i.

Step 4: Calculate the centrality.

The comprehensive influence matrix T is calculated using MATLAB software. Then, the centrality is obtained by using matrix T. The main calculation Equation is as follows:

where, represents the degree of influence. represents the affected degree. represents the centrality degree.

3.4. AHP-DEMATEL Model

AHP treats each indicator as an independent factor, which is prone to bias when calculating the weight. DEMATEL considers the degree of influence of each index, but there are deficiencies in the weight calculation [42]. To reduce the subjective and one-sided drawbacks of AHP and DEMATEL methods, the comprehensive degree of influence can be obtained by calculating the weight and centrality of indicators, which can integrate the advantages of the above two methods and more accurately express the importance of various factors [43,44]. Combined with the weight calculated by AHP and Equation (7), Equation (8) for calculating the comprehensive degree of influence is obtained. The calculation Equation is as follows:

where, x represents the comprehensive degree of influence. h represents centrality. w represents the weight value calculated by AHP.

4. Results

4.1. Construction of Influencing Factor System of the Coal Mine Practitioners’ Unsafe State

4.1.1. Collection of Data

Data collection in grounded theory is guided by research questions. Researchers purposefully select data sources that they believe may provide rich information about these issues. The data contain everything, which can be words, the perspective of the research object, experience, or historical events. The data in this study were mainly derived from on-site interviews and typical accident cases. These two types of data can be combined and supplemented with each other.

Through literature research, relevant topics were selected for on-site interviews. Based on previous research, this paper designed an interview outline from three aspects as shown in Table 3: influencing factors, unsafe states, and results. The interviewees in this article were mainly the employees, safety officers, and supervisors closely related to the front-line production of coal mines. These employees understand unsafe states and can provide a lot of information. To make the information obtained sufficiently representative, the interviewees for this study were drawn from front-line practitioners with relevant expertise. The interviewees included one department safety supervisor, five safety supervisors, and fourteen front-line staff, for a total of twenty people. The average interview time per respondent was about 30 min. In addition to asking questions according to the interview outline, the interviewees were asked to talk about their views on the factors influencing unsafe states according to their professional knowledge and work experience, to obtain more data. Before the interview, we introduced the purpose and content of the interview to the interviewees. With the interviewees’ consent, we recorded the content of the interview. After the interview, we compiled the contents into Word documents for further analysis. A total of 50 typical accident cases in the last five years were selected as the original data. These data contain detailed accident processes and cause analysis, which is suitable for grounded theoretical analysis.

Table 3.

Interview outline.

4.1.2. Open Coding

The collected field interview answers were conceptualized to form concepts and categories. The resulting concepts were further refined and analyzed to associate similar concepts with established categories [45]. A total of 70% of the selected 50 accident cases were open-coded. The results are shown in Table 4.

Table 4.

Open coding (excerpt).

4.1.3. Axial Coding

Axial coding involves performing clustering and association analysis on the formed concepts and categories to form the main category [46]. After an in-depth interview and analysis of case accidents, the category formed by open coding was simplified to extract the main concepts for classification, and finally the axial coding was obtained, as shown in Table 5.

Table 5.

Axial coding.

4.1.4. Selective Coding

Based on axial coding, the category and main category with certain generic correlations were selected for systematic generalization, and the core category that can command all categories was obtained [47]. Finally, four core categories were obtained: physiological factors, psychological factors, organizational factors, and technical factors.

4.1.5. Theoretical Saturation Test

Theoretical saturation refers to testing a certain category with new data until there are no new codes and categories. It is the standard for grounded theory stopping sampling [48]. Using the remaining 30% of typical accident cases to recode, none of the new categories obtained could affect the main categories and core categories that had been generated. Therefore, the theoretical category was saturated, and the core category was relatively accurate. The theoretical saturation test was passed.

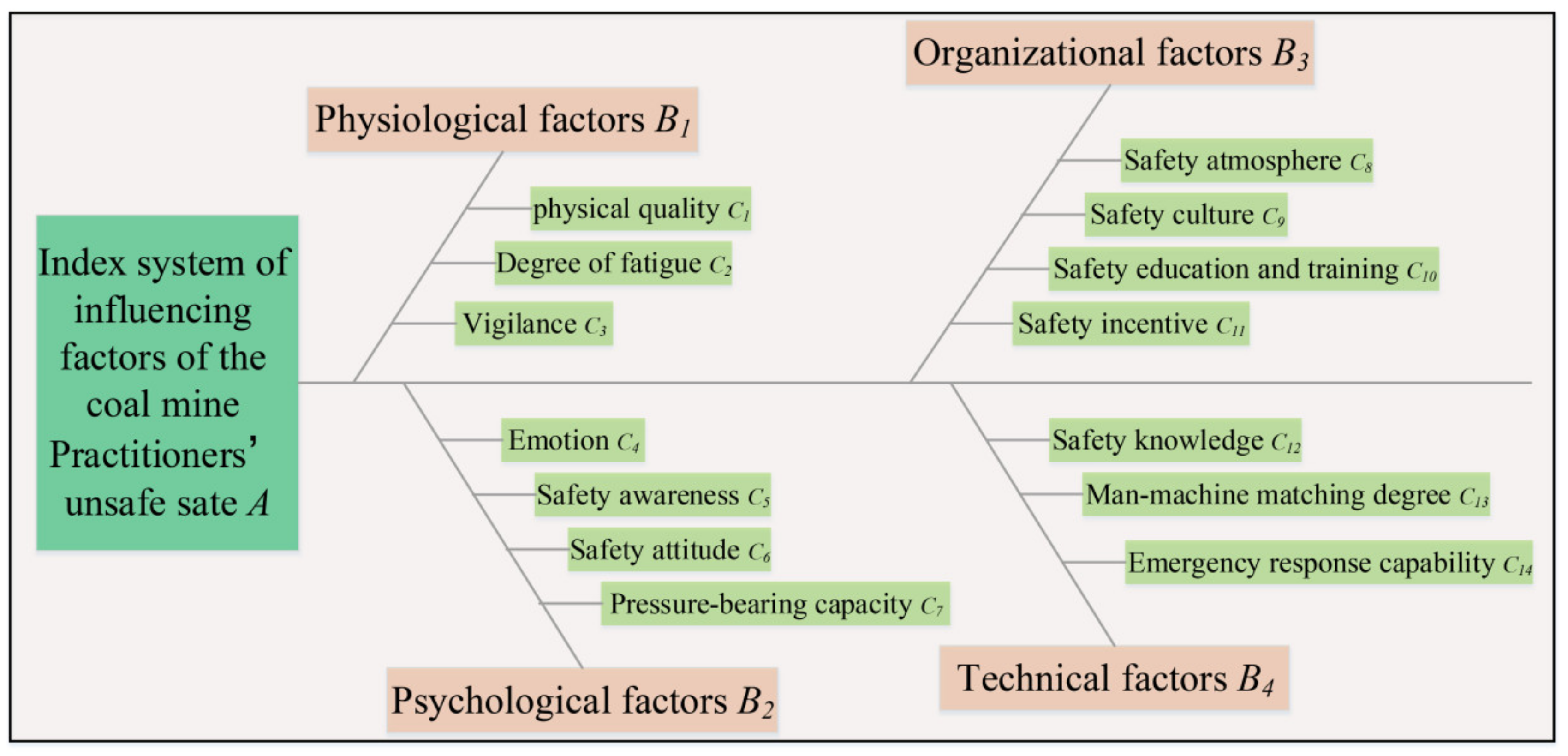

4.1.6. Index System of Factors Influencing Coal Mine Practitioners’ Unsafe State

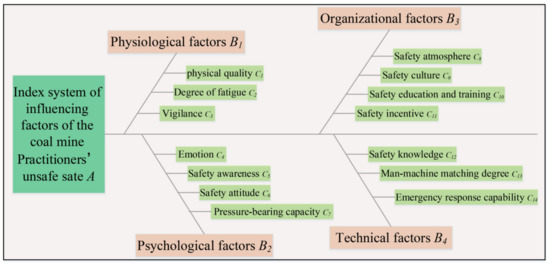

Through open coding, axial coding, selective coding, and the theoretical saturation test, 4 core categories and 14 main categories were obtained. An index system of factors influencing coal mine practitioners’ unsafe state was constructed, as shown in Figure 3.

Figure 3.

Index system of factors influencing coal mine practitioners’ unsafe state.

4.2. Determination of Index Weight

The degree of influence of each influencing factor in the index on the coal mine practitioners’ unsafe state is different. In this study, AHP was used to determine the weight of each influencing factor in the index. The factors influencing coal mine practitioners’ unsafe state were decomposed into three levels: target layer, criterion layer, and index layer. In this study, ten people were selected to score each influencing factor according to the rules in Table 1, build a judgment matrix, and calculate the weight. There were three coal mine management personnel, two coal mine technicians, two coal mine front-line workers, and three university experts. Equations (1)–(3) were used to test the consistency of the judgment matrix and obtain the weight of each index, as shown in Table 6.

Table 6.

Results of AHP.

4.3. Calculation of Comprehensive Degree of Influence

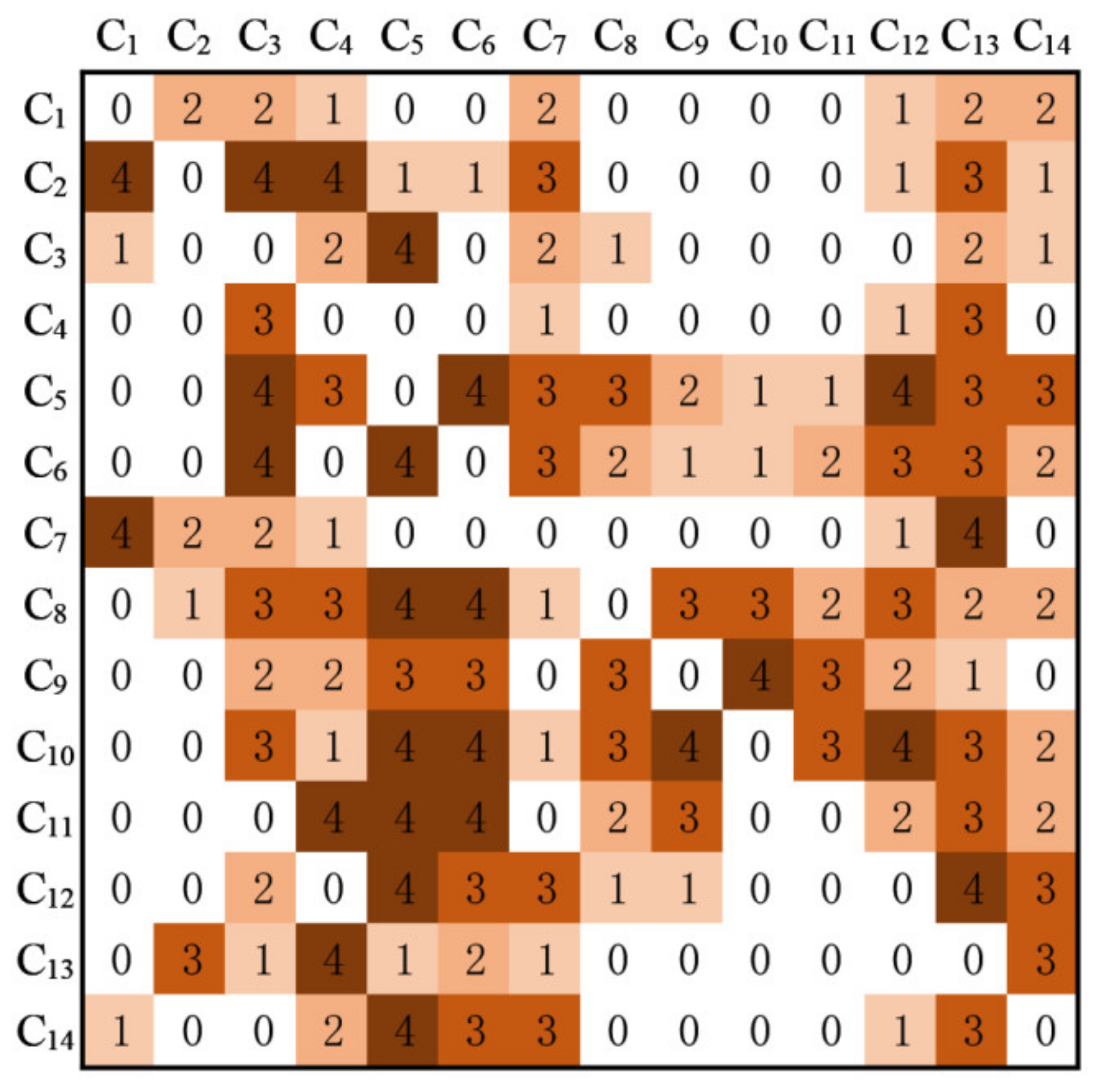

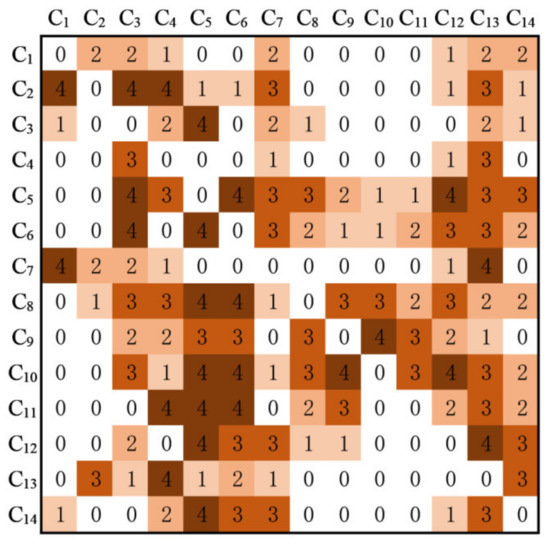

The direct influence matrix was established by expert scoring, as shown in Figure 4. Equations (4)–(7) of the DEMATEL method were used to measure the degree of influence, centrality, and causation degree of each level index in the influencing factor system used to determine the coal mine practitioners’ unsafe state. Then, combined with the weight of each index obtained by the AHP, the comprehensive degree of influence was calculated by the AHP-DEMATEL model (Equation (8)), as shown in Table 7.

Figure 4.

Direct impact matrix of secondary indicators.

Table 7.

Calculation table of comprehensive degree of influence.

5. Discussion

This study explored the factors that affect coal mine practitioners’ unsafe state by establishing the AHP-DEMATEL model. As a result, some valuable and unexpected findings have been obtained, which can be used to provide suggestions for improving coal mine practitioners’ safe state and reducing the accident rate in coal mines.

5.1. Results Analysis

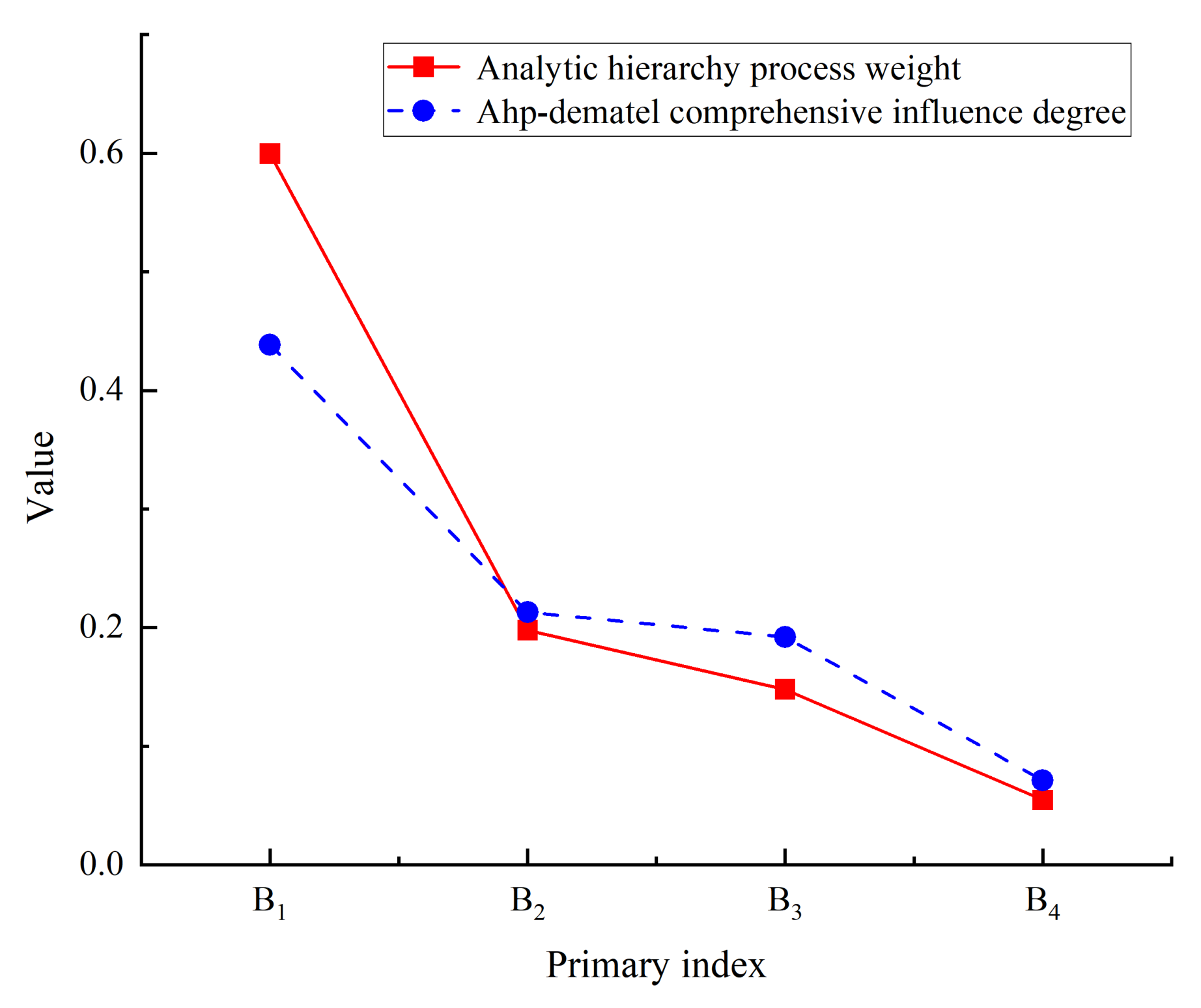

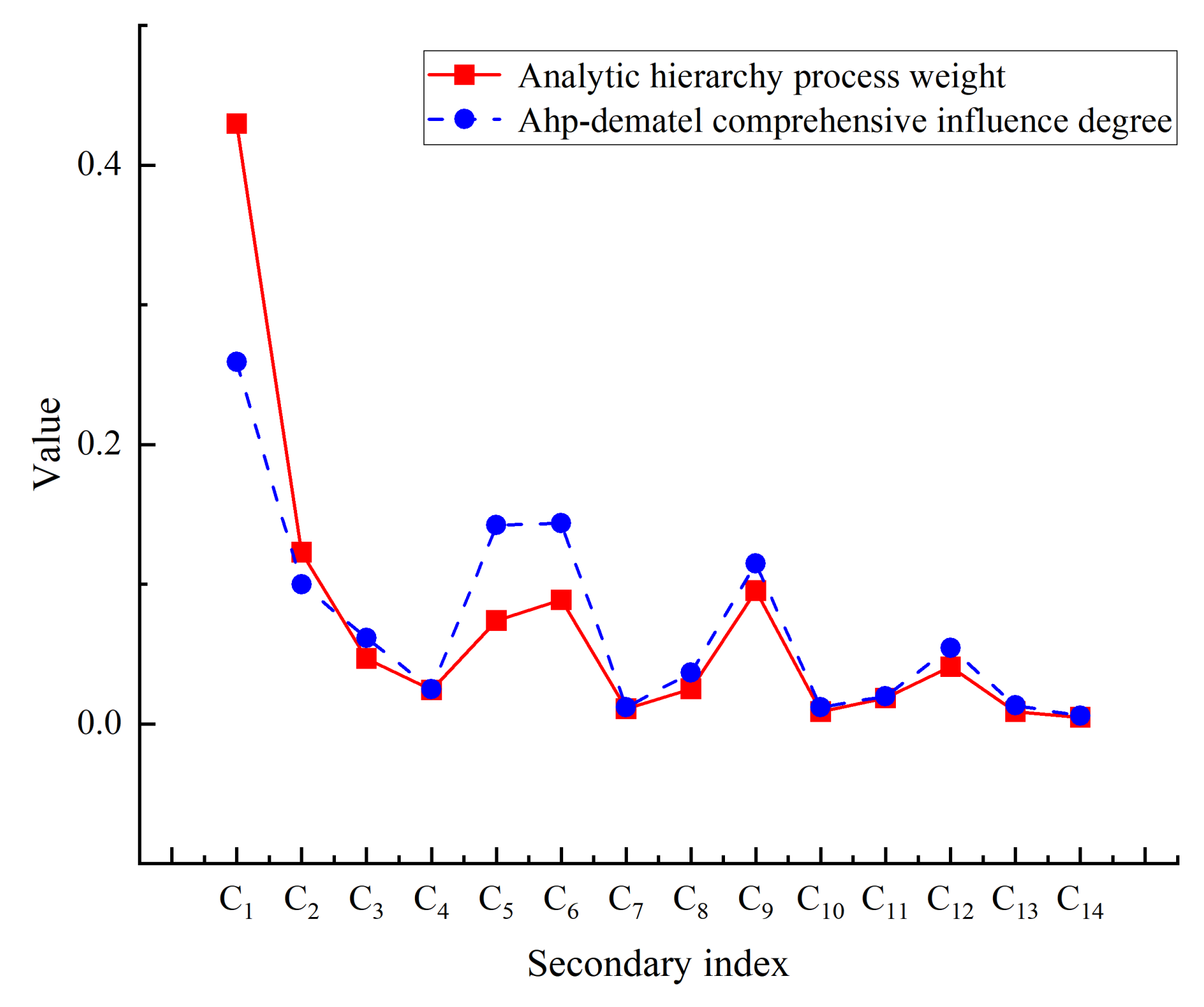

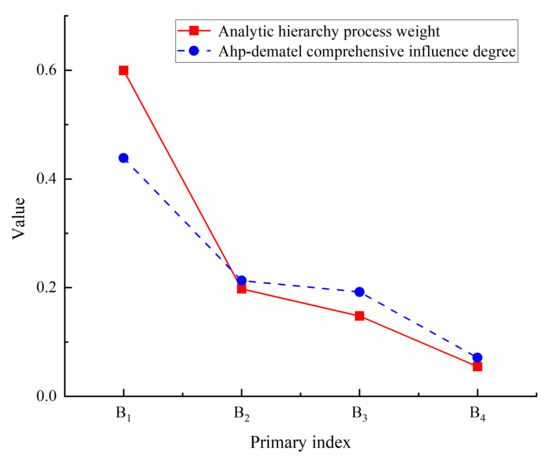

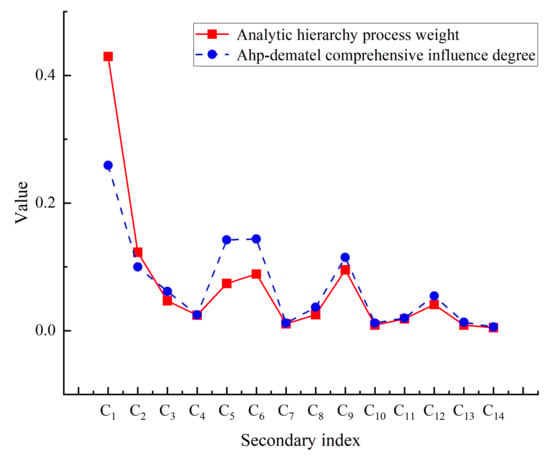

To make the research results more intuitive, the critical data in Table 6 and Table 7 are visually displayed in Figure 5 and Figure 6.

Figure 5.

AHP weight and comprehensive degree of influence of the primary index.

Figure 6.

AHP weight and comprehensive degree of influence of the secondary index.

It can be seen from Figure 5 that the weight of the primary index calculated by the AHP was consistent with the result calculated by the AHP-DEMATEL model, indicating that the constructed AHP-DEMATEL model has strong generality and applicability. Through the calculation results of the two methods, the physiological factors in the primary index were found to have the most significant impact on the coal mine practitioners’ unsafe state. When intervening in front-line practitioners’ unsafe state, coal mine management personnel should focus on the influence of physiological factors.

According to the calculation results in Figure 6, the secondary index showed the significant comprehensive influence of the factors physical quality, degree of fatigue, safety attitude, safety awareness, safety culture, and vigilance. The index weight calculated by AHP was mostly consistent with the result calculated by the AHP-DEMATEL model, and the calculation result is consistent with the actual situation. The centrality of safety awareness and safety attitude was at a high level, indicating that safety awareness and safety attitude have a significant influence on coal mine practitioners’ unsafe state. Combined with the weight calculated by AHP, it can be concluded that the weight and comprehensive degree of influence of physical quality and degree of fatigue were relatively high, and can thus be considered key factors affecting the coal mine practitioners’ unsafe state. Safety culture and vigilance had the second highest degree of influence on the coal mine practitioners’ unsafe state.

According to the comprehensive degree of influence of the research results, the following results can be obtained from the analysis of the four levels of the primary index:

Physiological factor level. The comprehensive degree of influence from large to small was: physical quality, degree of fatigue, and vigilance. Previous studies have shown that physical fitness, fatigue, and other factors have a significant impact on coal mine practitioners’ unsafe state [49]. A good physique is usually considered the basis of an ability to work, and the degree of fatigue can affect people’s functional changes. The workload is often used to measure the degree of fatigue of humans. Due to the working rules of coal mine practitioners, the shift system leads to long continuous working hours and insufficient rest and sleep time, and employees working at night are more prone to fatigue [50]. Only when the workload of coal mine practitioners is within a reasonable range can the regular operation of various body functions be ensured. At the same time, employees should always pay attention to potential dangers during the work process, maintain a good working state, and avoid unsafe behaviors and accidents caused by these reasons. Vigilance refers to the ability of a person to remain alert to external stimuli and maintain this alertness for some time. Research has shown that employee fatigue affect people’s vigilance and slow the response time to safety alarms [51]. When coal mine practitioners work underground and face emergencies, they cannot respond in time when their vigilance is low. At this time, employees will be in a poor state, making it more likely they will engage in unsafe behaviors and cause accidents.

Psychological factor level. The comprehensive degree of influence from large to small was: safety attitude, safety awareness, emotion, and pressure-bearing capacity. Safety attitude reflects employees’ cognition and feelings about safety policies and measures [52]. Safety awareness is expressed as a mental state of alertness of employees to various situations that may cause harm to themselves or others in the working environment during production activities. Miners with good safety awareness can keep themselves in a good state, change their behavior patterns, and reduce accidents [53]. The complexity of the working environment of coal mine practitioners determines their way of life. Employees should maintain a clear cognition of unsafe factors in the working environment while the physiological index meets the requirements. It is necessary to always focus on the safety of groups and individuals, be vigilant about the risk factors that may cause accidents, and ensure that safe production can be carried out. A good safety attitude and safety awareness can have a lasting impact on coal mine practitioners. By imperceptibly improving employees’ mental and physical state, they can be guided to engage in safe behavior in the face of unsafe events. In high-risk industries such as coal mines, emotion is an “invisible killer” endangering employees’ lives, guiding people to engage in corresponding behaviors [54]. Emotions are diverse. Positive emotions can improve human function and form a driving force to promote human activities. Negative emotions will slow people’s reactions, weaken people’s physical strength and energy, and make people feel uncomfortable. The emotions involved in this study primarily refer to negative emotions. Li et al. verified, by simulating the underground environment of a coal mine, that anxiety and depression will put the miners in an unsafe state, thus prompting the miners to engage in unsafe behaviors [55]. Coal mine practitioners driven by negative emotions are in an unsafe state. They easily make mistakes at work and engage in unsafe behavior. The pressure-bearing capacity of people is limited. Coal mine practitioners are affected by poor working environments and long working hours, which cause individuals to be too stressed and prone to physical and psychological problems.

Organizational factor level. The comprehensive degree of influence from large to small was: safety culture, safety atmosphere, safety incentives, and safety education and training. The foundation of safe production in enterprises is the establishment and promotion of a safety culture, which is the guiding ideology of the work of coal mine practitioners. Yu et al.’s research show that a safe atmosphere can keep miners in a safe state and reduce unsafe behaviors [56]. According to the social exchange theory [57], when the enterprise provides a good safety atmosphere, employees feel that the enterprise attaches importance to safety. Therefore, they will generate feedback, recognize and consciously follow the safety standards set by the enterprise, carry out work in a good state, and improve the level of safety behavior. At the same time, employees can improve their safety attitude and safety awareness in a safe atmosphere, restraining themselves and putting themselves in a good state. Safety education and training and safety incentives are the main ways to prevent accidents, guaranteeing psychological support that will help coal mine practitioners to work better.

Technical factor level. The comprehensive degree of influence from large to small was: safety knowledge, man–machine matching degree, and emergency response capability. Technical factors play a significant role in influencing unsafe behavior levels. An unsafe state, as the precondition of unsafe behavior, is also affected by factors at the non-technical level [7]. Safety knowledge is a necessary safety operation and function for practitioners, and provide a good emergency response ability in the face of emergencies [58]. Coal mine practitioners can work well in a good state, and it is very important to learn safety knowledge. Through the study and understanding of safety knowledge, they can cultivate safety awareness and subjectively establish a good line of defense. Coal mine practitioners can only work comfortably if they are proficient in the operation and use of machines. If the employee is unskilled at their work, they may feel anxiety, resulting in an unsafe state and accidents. When the potential danger is transformed into an accident, the emergency response ability of coal mine practitioners is also reflected in the rational cognition of the environment and the nature of the event, and in their ability to use technology to respond to the accident in time to reduce casualties and property losses.

5.2. Countermeasures and Suggestions to Improve Coal Mine Practitioners’ Unsafe State

Since the influence of each factor influencing coal mine practitioners’ unsafe state is complex, non-linear, and interactive, when assessing coal mine practitioners’ unsafe state, it is necessary to consider the current situation of coal mine production processes, and conduct a dynamic assessment and improve its accuracy. Therefore, the following countermeasures and suggestions are proposed for daily safety measures in coal mines.

- (1)

- Implement the “four six-hour shifts” work system in coal mines to improve the quality of life of practitioners. Currently, coal mine production adopts the “three eight-hour shifts” work system. Employees have long working hours, heavy workloads, and less time to restore physical function, often leading to an unsafe state. Good physical quality ensures that employees can complete their work. Coal mine management personnel should strengthen the guidance for coal mine practitioners, reasonably organize appropriate activities, and encourage workers’ participation in sports and exercise.

- (2)

- Correct employee safety attitudes and enhance safety awareness. Coal mines should strengthen publicity and education to change the mindset of employees from “want me to be safe” to “I want to be safe.”. Use pre-shift meetings, mutual supervision, and family influence to improve employees’ safety awareness and responsibility.

- (3)

- Improve various rules and regulations and strengthen safety education and training. Establish and improve coal-mine-safety production management systems and rules and regulations, and urge employees to operate in strict accordance with safety technical operation procedures. Carry out safety education and training to improve safety awareness, so that employees can understand norms, understand operations, make no mistakes, and regulate their psychological and behavioral patterns.

- (4)

- Create a safe atmosphere and establish a communication and incentive mechanism. Enterprises should create a good safety atmosphere to influence and promote employees to take safety actions consciously. Encourage employees to communicate well with others and give timely feedback on problems encountered in daily work and life.

- (5)

- Provide knowledge and skills learning opportunities to improve ability. To ensure that employees can genuinely master relevant knowledge and skills in practice, enterprises should carry out activities such as competition awards, regular refreshments, and tests to improve employees’ emergency response and coordination capabilities.

5.3. Limitations and Future Research

Through literature research, on-site interviews, and grounded theory, this study identified the factors influencing coal mine practitioners’ unsafe state, and constructed an index system. However, this study had some limitations that should be highlighted.

This study combined AHP and DEMATEL methods to avoid the disadvantages of using them separately. Still, the unsafe state of coal mine practitioners is a systematic problem. It was impossible to incorporate all the factors that affect coal mine practitioners’ unsafe state into the model. These studies can also be carried out in the future:

- (1)

- The ISM method can be combined to decompose the systematic problem into several levels or several subsystems for research.

- (2)

- With the help of the TOPSIS method, the common mechanism of various factors influencing the coal mine practitioners’ unsafe state could be studied and ranked. Or use fuzzy DEMATEL and rough DEMATEL to explore the application of different methods for the same problem.

- (3)

- It would be possible to analyze and identify influencing factors from more dimensions, and to study the coal mine practitioners’ unsafe state comprehensively and from multiple perspectives. For example, the improved AHP-DEMATEL method could be used to re-explore the factors influencing coal mine practitioners’ unsafe state for comparison with this study.

6. Conclusions

This study used the data obtained from literature research and on-site interviews as the data source. Based on grounded theory, an index system of factors influencing coal mine practitioners’ unsafe state was constructed. Combined with the AHP-DEMATEL model, we studied the formation mechanism of coal mine practitioners’ unsafe state. The main conclusions are as follows:

- (1)

- The influencing factors of coal mine practitioners’ unsafe state are summarized. Through literature research and on-site interviews, an index system of factors influencing coal mine practitioners’ unsafe state was constructed using grounded theory. It includes 4 primary indices and 14 secondary indices.

- (2)

- The AHP-DEMATEL model was applied to analyze the comprehensive influence of various influencing factors on coal mine practitioners’ unsafe state. The results have shown that physical quality, safety attitude, safety awareness, safety culture, degree of fatigue, and vigilance have significant effects on coal mine practitioners’ unsafe state. Physical quality and degree of fatigue are the key factors that affect coal mine practitioners’ unsafe state.

- (3)

- By analyzing and constructing the influencing factor index system of coal mine practitioners’ unsafe state, this study can effectively guide the intervention of coal mine management personnel in the practitioners’ state. The example verification shows that the index weights calculated by AHP are mostly consistent with the results calculated by the AHP-DEMATEL model, and are consistent with the actual situation, which has a good promotion and application value. Based on this, coal mine management personnel can take corresponding management measures to improve coal mine practitioners’ safety state level and reduce the possibility of accidents caused by human errors.

Author Contributions

Conceptualization, L.C. and H.L.; methodology, L.C. and S.T.; validation, H.L.; formal analysis, L.C.; investigation, L.C.; resources, S.T.; data curation, L.C.; writing—original draft, L.C.; writing—review and editing, L.C., H.L. and S.T.; visualization, L.C.; supervision, H.L.; project administration, H.L. and S.T.; funding acquisition, H.L. and S.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (grant nos. 51874237; U1904210; 71273208) and the National Social Science Foundation of China (grant no. 20XGL025).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon reasonable request (chenlei@stu.xust.edu.cn).

Conflicts of Interest

The authors declare no conflict of interest.

References

- The National Conference on Mine Safety Production was Held in Beijing. Available online: https://www.chinamine-safety.gov.cn/xw/mtxx/202201/t20220110_406532.shtml (accessed on 9 June 2022).

- Haddon, W., Jr. Energy damage and the 10 countermeasure strategies. 1973. Inj. Prev. 1995, 13, 40–44. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Cao, Q.; Han, C.; Song, J.; Qu, N. Group dynamics analysis and the correction of coal miners’ unsafe behaviors. Arch. Environ. Occup. Health 2021, 76, 188–209. [Google Scholar] [CrossRef] [PubMed]

- Fa, Z.; Li, X.; Liu, Q.; Qiu, Z.; Zhai, Z. Correlation in Causality: A Progressive Study of Hierarchical Relations within Human and Organizational Factors in Coal Mine Accidents. Int. J. Environ. Res. Public Health 2021, 18, 5020. [Google Scholar] [CrossRef] [PubMed]

- Reason, J.T. Human Error; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Harris, D.; Li, W. Using Neural Networks to predict HFACS unsafe acts from the pre-conditions of unsafe acts. Ergonomics 2017, 62, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Cheng, W.; Yu, Y.; Xu, Q. Human factors analysis of major coal mine accidents in China based on the HFACS-CM model and AHP method. Int. J. Ind. Ergon. 2018, 68, 270–279. [Google Scholar] [CrossRef]

- Chen, L.; Li, H.; Zhao, L.; Tian, F.; Tian, S.; Shao, J. The effect of job satisfaction regulating workload on miners’ unsafe state. Sci. Rep. 2022, 12, 16375. [Google Scholar] [CrossRef]

- Amiri Ebrahimabadi, A.; Soltanzadeh, A.; Ghiyasi, S. Analysis of Occupational Accidents Based on the Human Factors Analysis and Classification System (HFACS): A Case Study in a Copper Mine. Iran. J. Ergon. 2020, 8, 12–20. [Google Scholar] [CrossRef]

- Kim, E.; Yu, I.; Kim, K.; Kim, K. Optimal set of safety education considering individual characteristics of construction workers. Can. J. Civ. Eng. 2011, 38, 506–518. [Google Scholar] [CrossRef]

- Xie, X.; Guo, D. Human factors risk assessment and management: Process safety in engineering. Process Saf. Environ. Prot. 2018, 113, 467–482. [Google Scholar] [CrossRef]

- Mahdevari, S.; Shahriar, K.; Esfahanipour, A. Human health and safety risks management in underground coal mines using fuzzy TOPSIS. Sci. Total Environ. 2014, 488, 85–89. [Google Scholar] [CrossRef]

- Liang, Q.; Zhou, Z.; Ye, G.; Shen, L. Unveiling the mechanism of construction workers’ unsafe behaviors from an occupational stress perspective: A qualitative and quantitative examination of a stress-cognition-safety model. Saf. Sci. 2022, 145, 105486. [Google Scholar] [CrossRef]

- Deng, M.; Wu, F.; Wang, J.; Sun, L. Musculoskeletal disorders, personality traits, psychological distress, and accident proneness of Chinese coal miners. Work 2017, 57, 441–449. [Google Scholar] [CrossRef]

- Inamasu, J.; Nakatsukasa, M.; Tomiyasu, K. Seizures occurring while driving in patients with and without diagnosis of epilepsy:Frequency and association with automobile accidents. J. Clin. Neurosci. 2019, 59, 75–78. [Google Scholar] [CrossRef]

- Khoshakhlagh, A.H.; Yazdanirad, S.; Laal, F.; Sarsangi, V. The relationship between illnesses and medical drug consumption with the occurrence of traffic accidents among truck and bus drivers in Tehran, Iran. Chin. J. Traumatol. 2019, 22, 142–147. [Google Scholar] [CrossRef]

- Chen, Z.; Qiao, G.; Zeng, J. Study on the Relationship between Worker States and Unsafe Behaviours in Coal Mine Accidents Based on a Bayesian Networks Model. Sustainability 2019, 11, 5021. [Google Scholar] [CrossRef]

- Li, J.; Li, H.; Wang, H.; Umer, W.; Fu, H.; Xing, X.J. Evaluating the impact of mental fatigue on construction equipment operators’ ability to detect hazards using wearable eye-tracking technology. Autom. Constr. 2019, 105, 102835. [Google Scholar] [CrossRef]

- Ren, D.; Li, Z.; Xu, X.; Yuan, Q.; Yang, W. Relations between human energy consumption and physical state in the simulation environment of coal mine. Fresenius Environ. Bull 2017, 26, 6632–6636. [Google Scholar]

- Tsai, M.K. Applying Physiological Status Monitoring in Improving Construction Safety Management. KSCE J. Civ. Eng. 2017, 21, 2061–2066. [Google Scholar] [CrossRef]

- Lee, B.G.; Lee, B.L.; Chung, W.Y. Wristband-Type Driver Vigilance Monitoring System Using Smartwatch. IEEE Sens. J. 2015, 15, 5624–5633. [Google Scholar] [CrossRef]

- Witek, T.J.; Canestrari, D.A.; Miller, R.D.; Yang, J.; Riker, D.K. The effects of phenindamine tartrate on sleepiness and psychomotor performance. J. Allergy Clin. Immunol. 1992, 90, 953–961. [Google Scholar] [CrossRef]

- Jeong, I.; Jeong, D. Analysis of Structural Relation between the Shipyard Workers’ Ego-state, Safe and Unsafe Behaviors, and Industrial Accidents. J. Korean Soc. Saf. 2018, 33, 101–108. [Google Scholar]

- McCrae, R.R.; Costa, P.T. Trait explanations in personality psychology. Eur. J. Pers. 1995, 9, 231–252. [Google Scholar] [CrossRef]

- Li, Y.; Wu, L.; Gao, Y. Impact of safety attitude on the safety behavior of coal miners in China. Sustainability 2019, 11, 6382. [Google Scholar] [CrossRef]

- Shin, M.; Lee, H.S.; Park, M.; Moon, M.; Han, S. A system dynamics approach for modeling construction workers’ safety attitudes and behaviors. Accid. Anal. Prev. 2014, 68, 95–105. [Google Scholar] [CrossRef]

- Wang, L.; Cao, Q.; Zhou, L. Research on the influencing factors in coal mine production safety based on the combination of DEMATEL and ISM. Saf. Sci. 2018, 103, 51–61. [Google Scholar] [CrossRef]

- Coffey, M.; Coleman, M. The relationship between support and stress in forensic community mental health nursing. J. Adv. Nurs. 2001, 34, 397–407. [Google Scholar] [CrossRef]

- Yang, X.; Tian, Y.; Feng, K.; Yang, J.; Zhang, S.H.; Wang, S. Signal game analysis on the effectiveness of coal mine safety supervision based on the affective events theory. Complexity 2020, 2020, 5710419. [Google Scholar] [CrossRef]

- Zhang, T.; Chan, A.H.S.; Li, S.; Zhang, W.; Qu, X. Driving anger and its relationship with aggressive driving among Chinese drivers. Transp. Res. Part F Traffic Psychol. Behav. 2018, 56, 496–507. [Google Scholar] [CrossRef]

- Schöbel, M.; Klostermann, A.; Lassalle, R.; Beck, J.; Manzey, D. Digging deeper! Insights from a multi-method assessment of safety culture in nuclear power plants based on Schein’s culture model. Saf. Sci. 2017, 95, 38–49. [Google Scholar] [CrossRef]

- Huang, Y.; Zohar, D.; Robertson, M.M.; Garabet, A.; Jin, L.; Murphy, L.A. Development and validation of safety climate scales for lone workers using truck drivers as exemplar. Transp. Res. Part F Traffic Psychol. Behav. 2013, 17, 5–19. [Google Scholar] [CrossRef]

- Lee, S.H.; Jung, D.Y.; Lee, Y.M. A study on the prevention of industrial disaster of the coal mining industry through safety education. J. Korean Soc. Ind. Technol. 2010, 11, 4489–4495. [Google Scholar]

- Chun Tie, Y.; Birks, M.; Francis, K. Grounded theory research: A design framework for novice researchers. Open Med. 2019, 7, 2050312118822927. [Google Scholar] [CrossRef]

- Yaraghi, N.; Langhe, R.G. Critical success factors for risk management systems. J. Risk Res. 2011, 14, 551–581. [Google Scholar] [CrossRef]

- Beynon, M. An analysis of distributions of priority values from alternative comparison scales within AHP. Eur. J. Oper. Res. 2002, 140, 104–117. [Google Scholar] [CrossRef]

- Qiao, G.; Zhu, Y.; He, G. Evaluation of coal miners’ safety behavior based on AHP-GRAP and MATLAB. J. Comput. Methods Sci. Eng. 2016, 16, 49–55. [Google Scholar] [CrossRef]

- Alosta, A.; Elmansuri, O.; Badi, I. Resolving a location selection problem by means of an integrated AHP-RAFSI approach. Rep. Mech. Eng. 2021, 2, 135–142. [Google Scholar] [CrossRef]

- Kannan, G.; Roohollah, K.; Amin, V. Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert Syst. Appl. 2015, 42, 7207–7220. [Google Scholar]

- Asan, U.; Kadaifci, C.; Bozdag, E.; Soyer, A.; Serdarasan, S. A new approach to DEMATEL based on interval-valued hesitant fuzzy sets. Appl. Soft Comput. 2018, 66, 34–49. [Google Scholar] [CrossRef]

- Koca, G.; Yıldırım, S. Bibliometric analysis of DEMATEL method. Decis. Mak. Appl. Manage. Eng. 2021, 4, 85–103. [Google Scholar] [CrossRef]

- Du, Y.; Zhou, W. New improved DEMATEL method based on both subjective experience and objective data. Eng. Appl. Artif. Intell. 2019, 83, 57–71. [Google Scholar] [CrossRef]

- Sara, J.; Stikkelman, R.M.; Herder, P.M. Assessing relative importance and mutual influence of barriers for CCS deployment of the ROAD project using AHP and DEMATEL methods. Int. J. Greenh. Gas Control 2015, 41, 336–357. [Google Scholar] [CrossRef]

- Cheng, L.; Cao, D.; Guo, H. Analysis of coal mine occupational disease hazard evaluation index based on AHP-DEMATEL. Arch. Environ. Occup. Health 2020, 76, 372–384. [Google Scholar] [CrossRef] [PubMed]

- Mullen, P.D.; Reynolds, R. The Potential of Grounded Theory for Health Education Research Linking Theory and Practice. Health Educ. Monogr. 1978, 6, 280–294. [Google Scholar] [CrossRef] [PubMed]

- Tavakol, M.; Murphy, R.; Torabi, S. A Needs Assessment for a Communication Skills Curriculum in Iran. Teach. Learn. Med. 2010, 17, 36–41. [Google Scholar] [CrossRef] [PubMed]

- McCann, T.V.; Clark, E. Grounded theory in nursing research Part 3-Application. Nurse Res. 2003, 11, 29–39. [Google Scholar] [CrossRef] [PubMed]

- Anselm, S.; Juliet, C. Basics of qualitative research: Grounded theory procedures and techniques. Modern Lang. J. 2006, 77, 235–236. [Google Scholar]

- Aliabadi, M.M.; Aghaei, H.; Kalatpour, O.; Soltanian, A.R.; SeyedTabib, M. Effects of human and organizational deficiencies on workers’ safety behavior at a mining site in Iran. Epidemiol. Health 2018, 40, e2018019. [Google Scholar] [CrossRef]

- Rudin-Brown, C.M.; Harris, S.; Rosberg, A. How shift scheduling practices contribute to fatigue amongst freight rail operating employees: Findings from Canadian accident investigations. Accid. Anal. Prev. 2018, 126, 64–69. [Google Scholar] [CrossRef]

- Hildebrandt, G.; Rohmert, W.; Rutenfranz, J. 12 and 24 h Rhythms in error frequency of locomotive drivers and the influence of tiredness. Int. J. Chronobiol. 1974, 2, 175–180. [Google Scholar]

- Henning, J.B.; Stufft, C.J.; Payne, S.C.; Bergman, M.E.; Mannan, M.S.; Keren, N. The influence of individual differences on organizational safety attitudes. Saf. Sci. 2009, 47, 337–345. [Google Scholar] [CrossRef]

- Yu, K.; Cao, Q.G.; Xie, C.Z.; Qu, N.; Zhou, L. Analysis of intervention strategies for coal miners’ unsafe behaviors based on analytic network process and system dynamics. Saf. Sci. 2019, 118, 145–157. [Google Scholar] [CrossRef]

- McDermott, R. Emotion and Security. Commun. ACM 2012, 55, 35–37. [Google Scholar] [CrossRef]

- Li, L.; Wang, S.; Huang, L.; Zhi, M.; Cai, Q.; Fang, Z.; Yan, Z.; Xi, K.; Feng, D. The Impacts of Workplace Environment on Coal Miners’ Emotion and Cognition Depicted in a Mouse Model. Front. Behav. Neurosci. 2022, 16, 896545. [Google Scholar] [CrossRef]

- Yu, M.; Li, J. Psychosocial safety climate and unsafe behavior among miners in China: The mediating role of work stress and job burnout. Psychol. Health Med. 2020, 25, 793–801. [Google Scholar] [CrossRef]

- Tucker, S.; Chmiel, N.; Turner, N.; Hershcovis, M.S.; Stride, C.B. Perceived Organizational Support for Safety and Employee Safety Voice: The Mediating Role of Coworker Support for Safety. J. Occup. Health Psychol. 2008, 13, 319–330. [Google Scholar] [CrossRef]

- You, M.; Li, S.; Li, D.; Xia, Q. Study on the Influencing Factors of Miners’ Unsafe Behavior Propagation. Front. Psychol. 2019, 10, 2467. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).