Circular Bioeconomy in the Amazon Rainforest: Evaluation of Açaí Seed Ash as a Regional Solution for Partial Cement Replacement

Abstract

1. Introduction

2. Background

3. Materials and Methods

3.1. Materials Used in Mortar Production

3.2. Production and Characterization of Self-Leveling Mortars

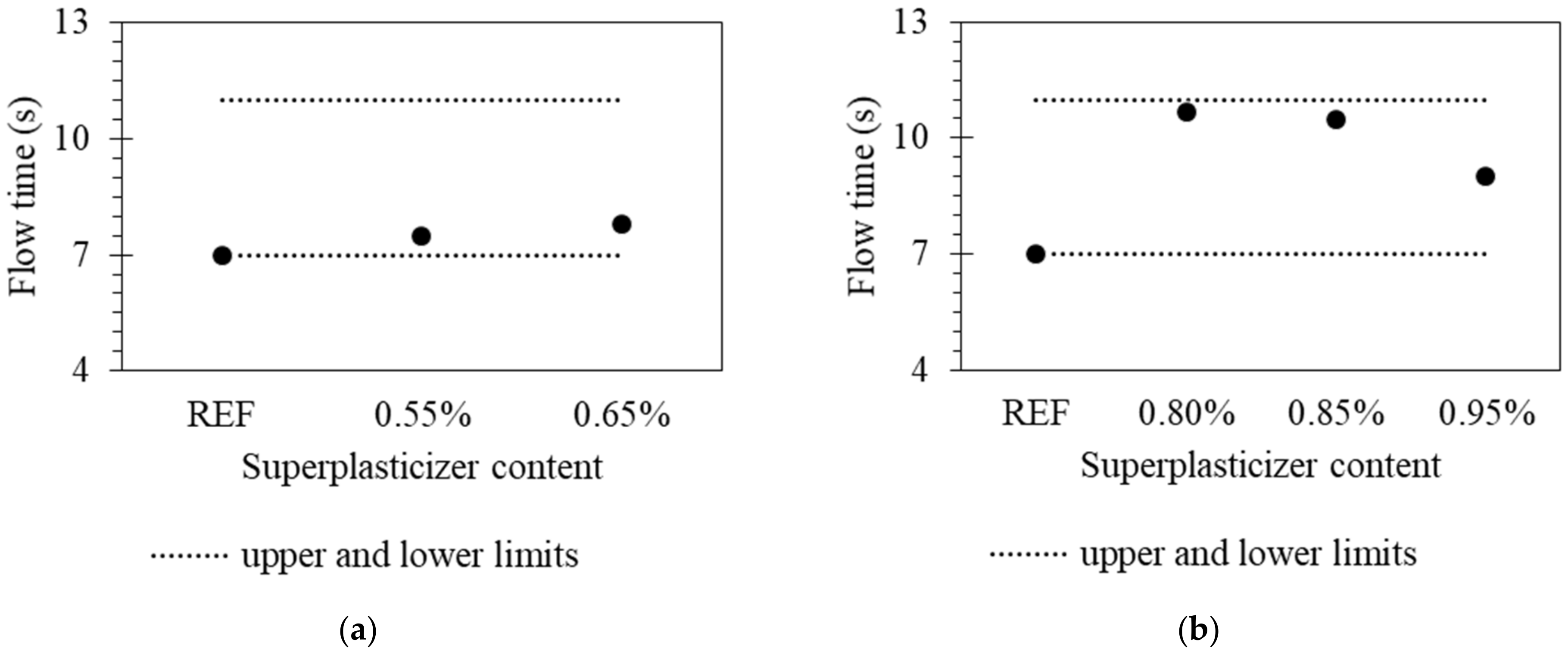

3.2.1. Dosage and Characterization of Self-Leveling Mortars in Fresh State

3.2.2. Control and Characterization of Self-Leveling Mortars in Hardened State

3.3. Life Cycle Assessment (LCA)

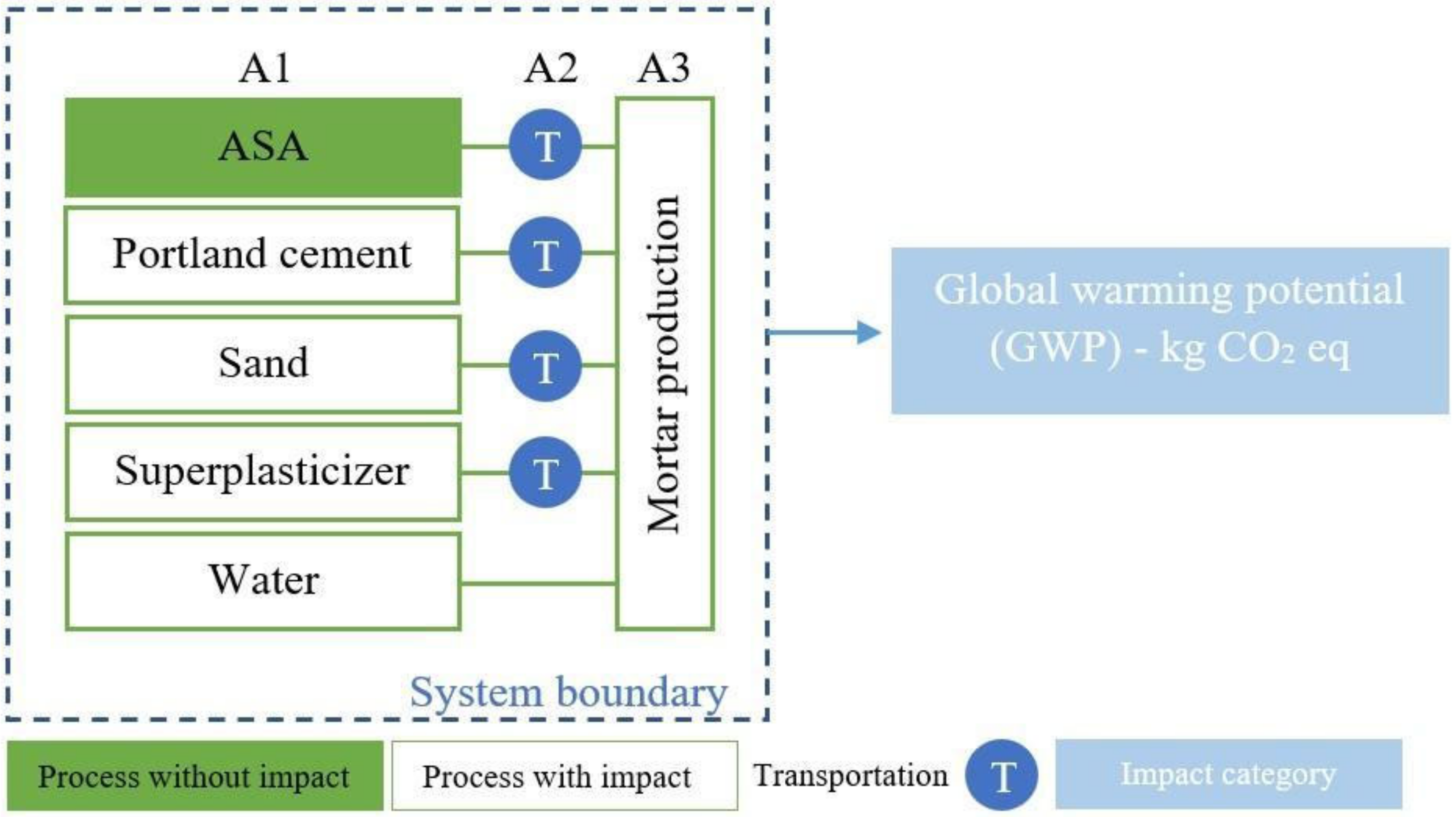

3.3.1. Definition of Goal, Scope, and Functional Unit

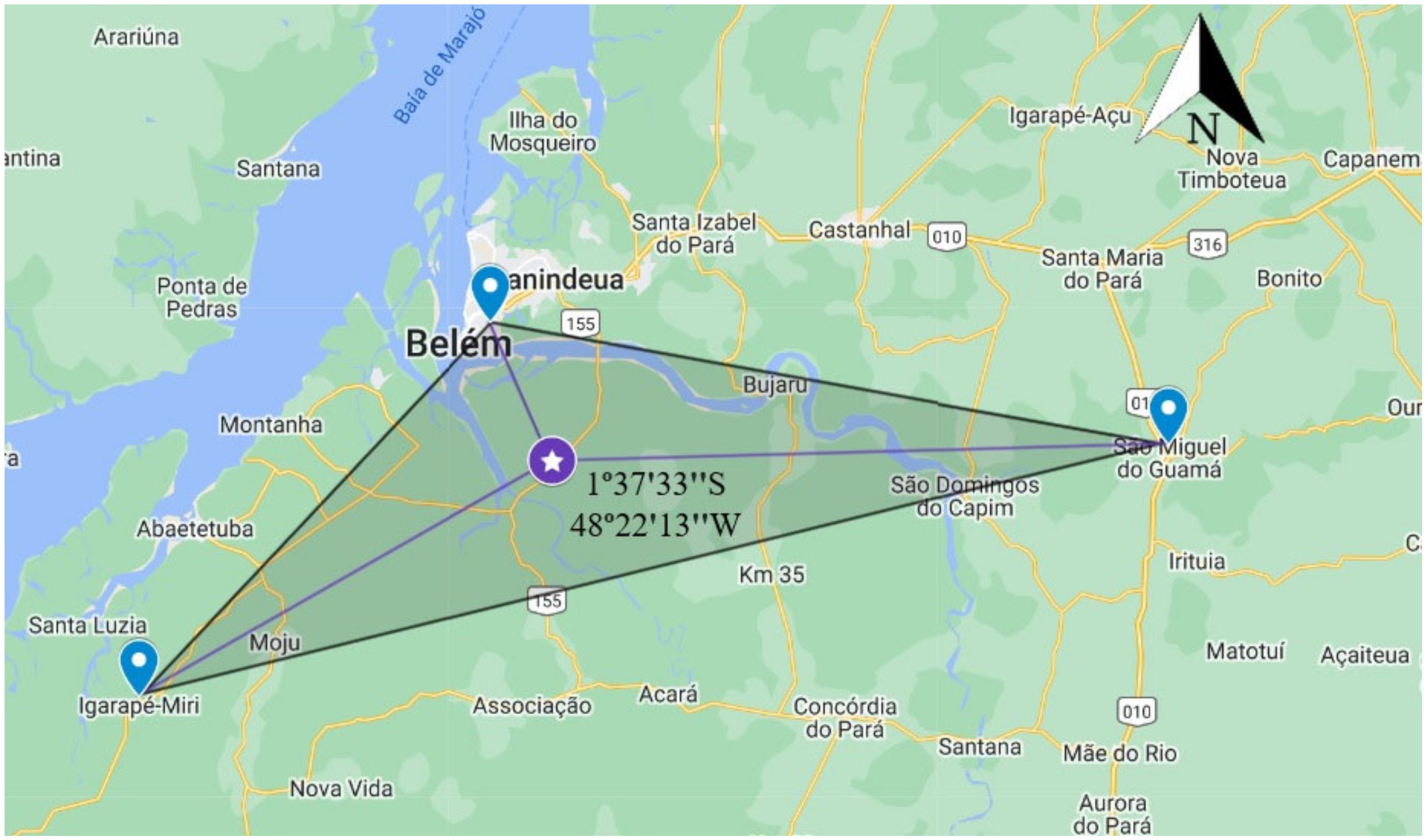

3.3.2. Life Cycle Inventory

3.3.3. Life Cycle Impact Assessment

3.3.4. Sensitivity Analysis

3.4. Carbon-Efficiency Indicator for Self-Leveling Mortars

4. Results and Discussion

4.1. Fresh State Characterization

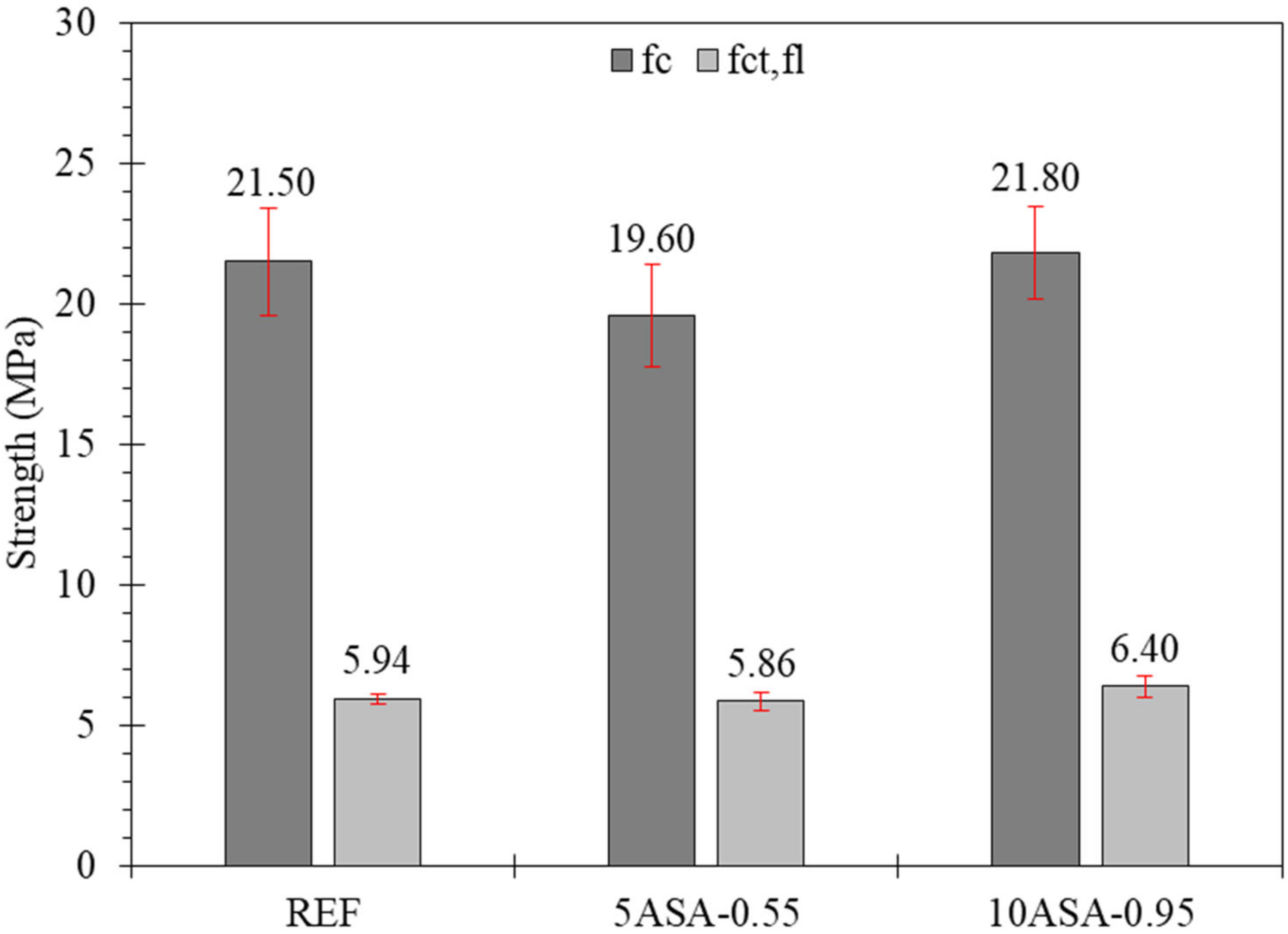

4.2. Hardened State Characterization

4.3. Life Cycle Assessment of Self-Leveling Mortars

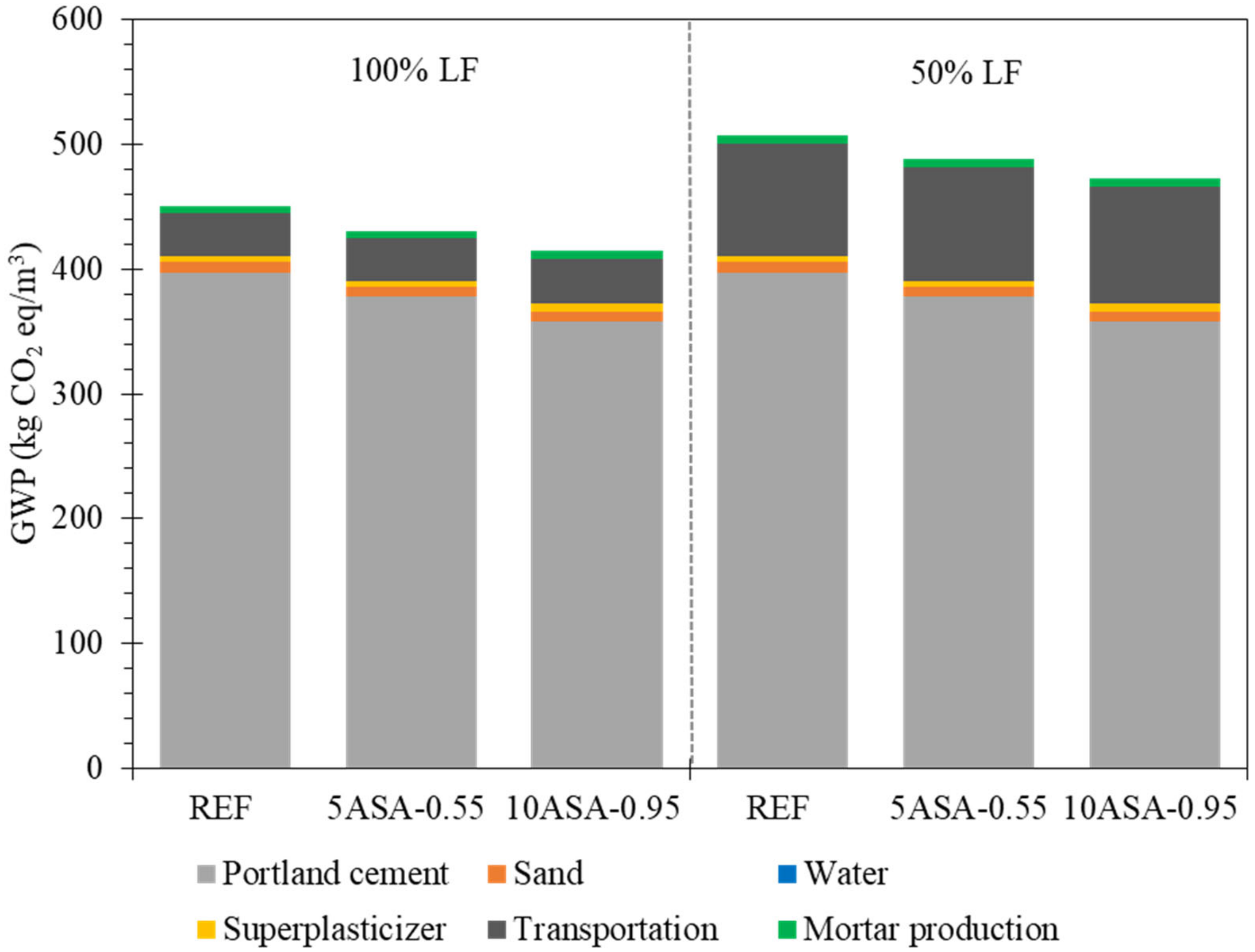

4.3.1. GHG Emissions Assessment

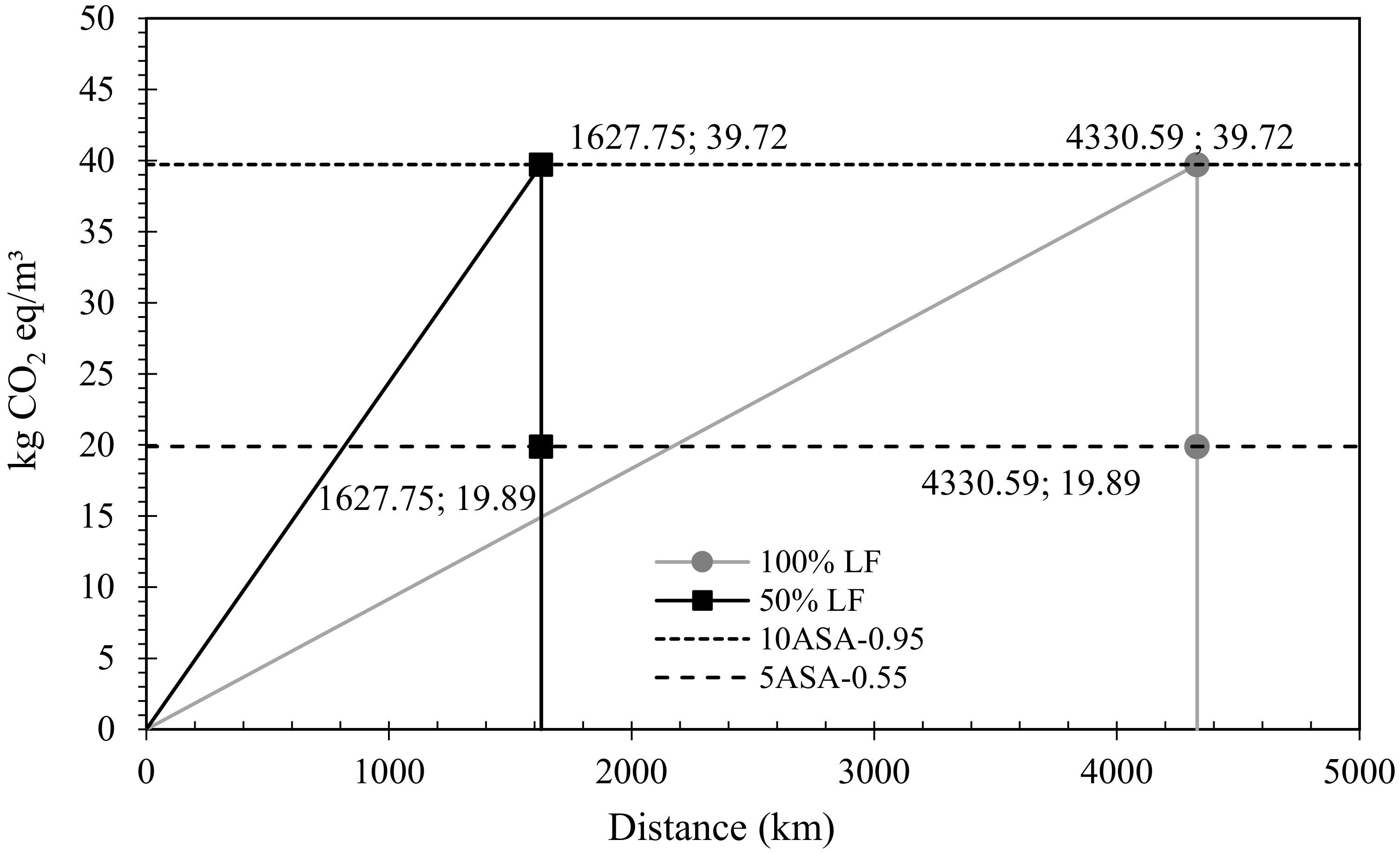

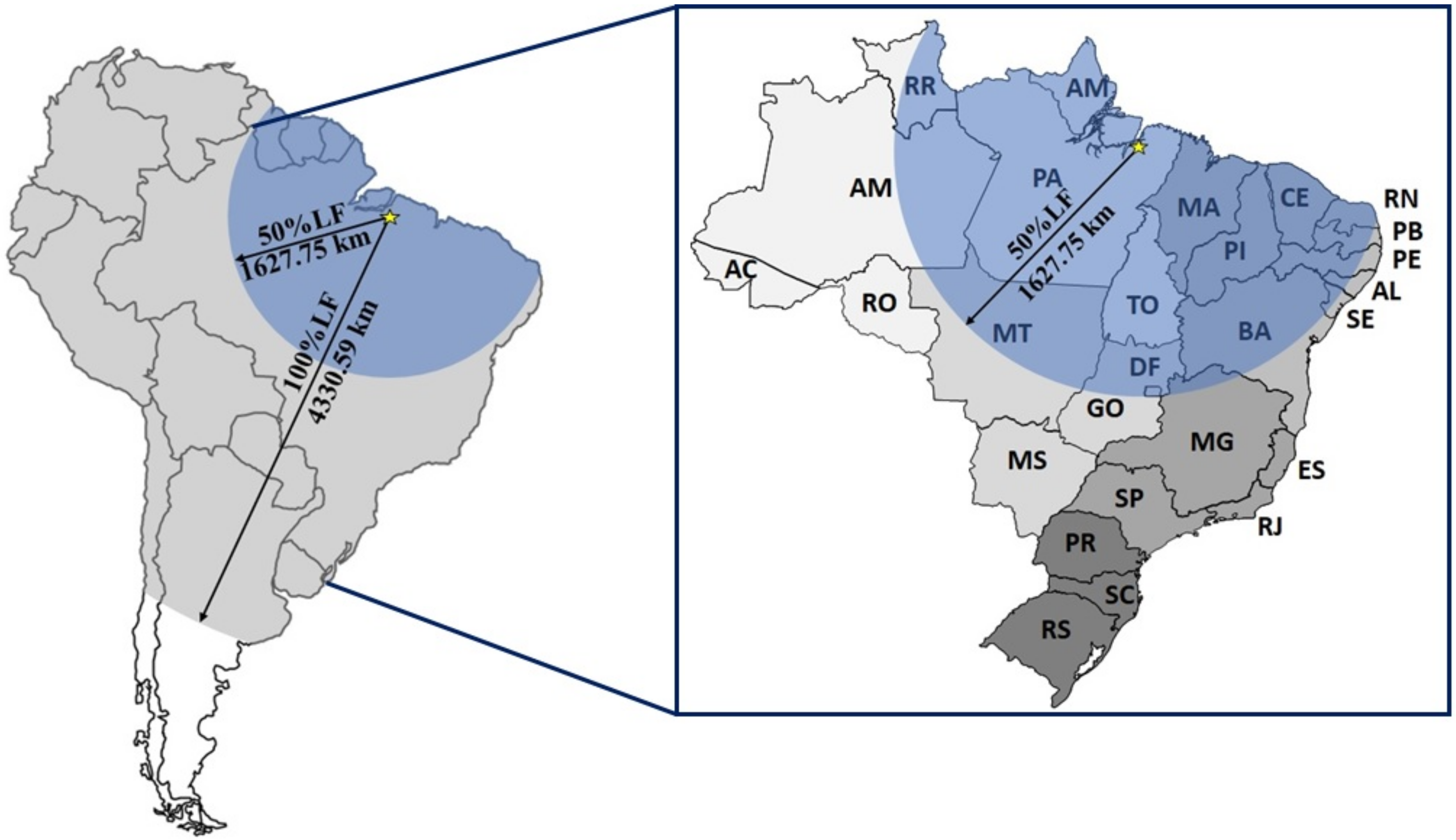

4.3.2. Sensitivity Analysis

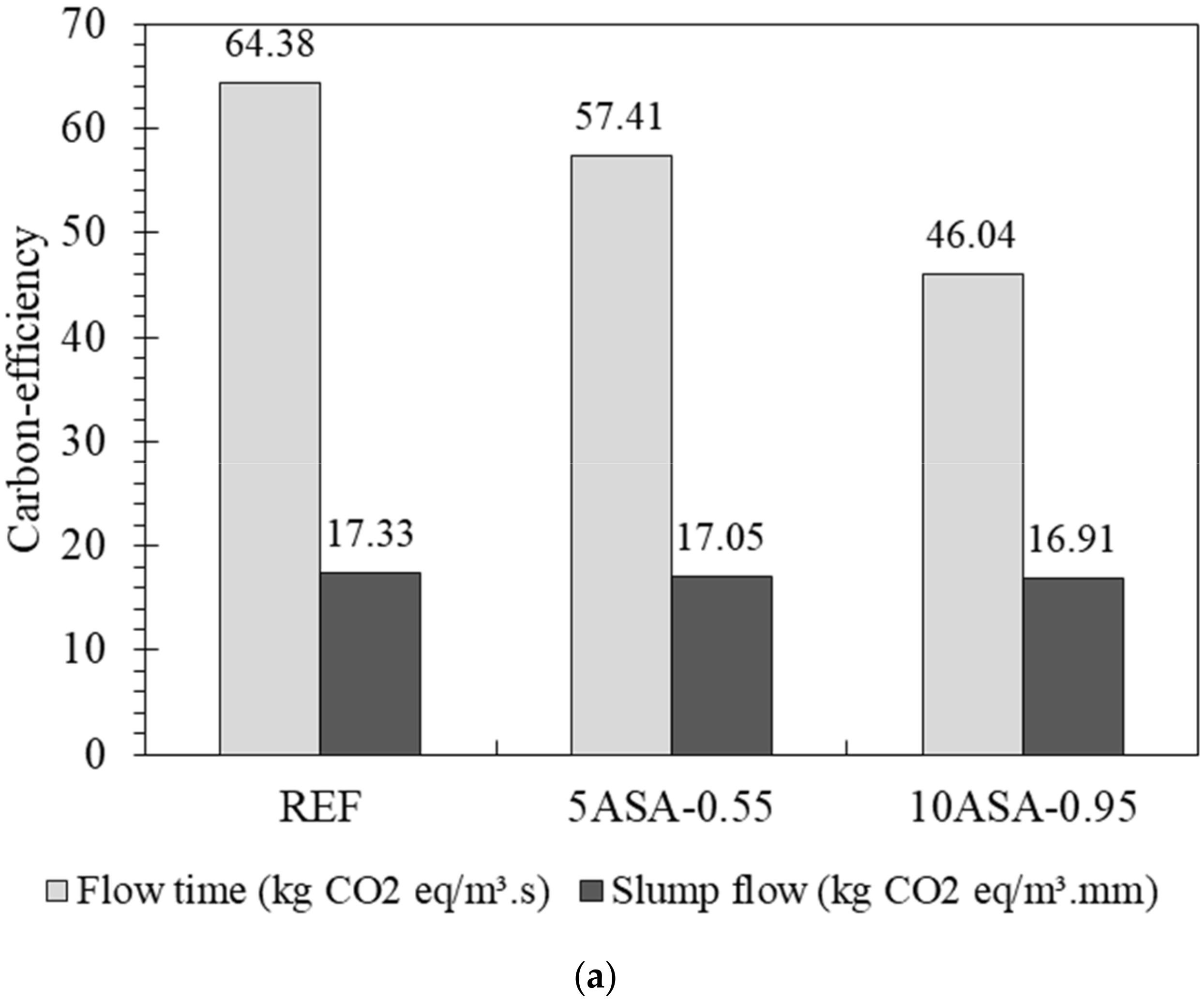

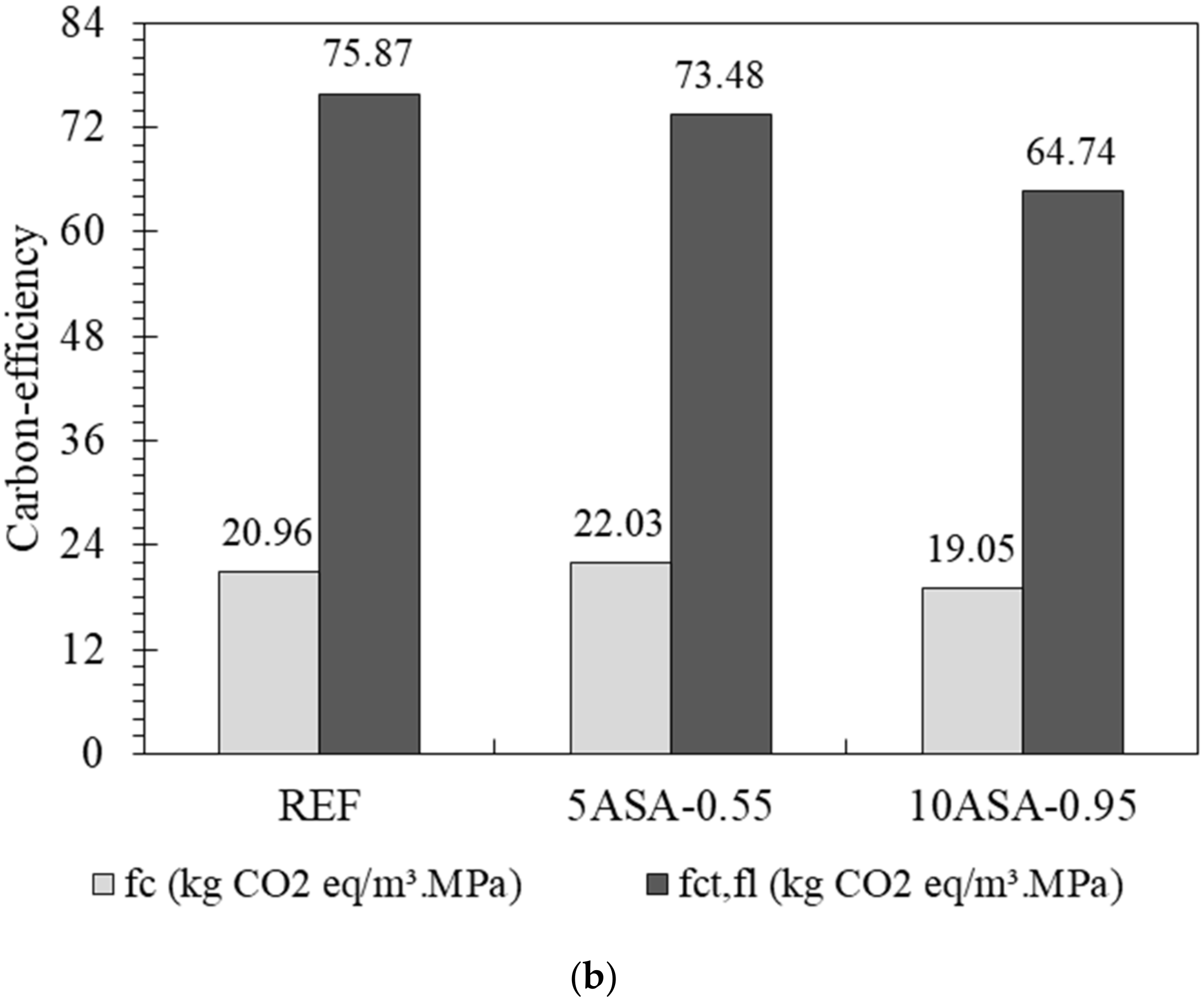

4.3.3. Evaluation of Carbon-Efficiency Indicators

5. Conclusions

- In fresh state, all mortars attended the requirements for SLM with the correct dosage of superplasticizer. However, the increase in ASA content caused a reduction in the workability of mortars, as higher superplasticizer content was required with 10% ASA due to the high specific surface of the ash. However, the increase in superplasticizer content did not significantly impact the global warming potential of ASA mortars.

- In hardened state, there were no statistical differences between the compressive and flexural strength of ASA mortars and the reference. Therefore, the mechanical performance of SLM was maintained when replacing cement by ASA up to 10%. This behavior suggests that the filler effect of ASA particles may justify its use as cement replacement.

- In general, ASA decreased the GHG emissions of mortars up to 8% due to Portland cement replacement, considering the production in the state of Pará, Brazil. However, transportation of ASA to other regions of the country is only feasible when considering more efficient transportation. Otherwise, transportation emits GHG, which may compromise ASA use for longer distances. Therefore, using ASA as a regional construction material may encourage a circular bioeconomy approach for the sustainable development of the Brazilian Amazon.

- The use of 10% ASA as a partial cement replacement considerably decreased the environmental impact of SLM when the results of the fresh and hardened tests were normalized. In this case, the carbon-efficiency indicators proposed in this work were suitable to describe the influence of fresh and hardened properties on the life cycle GHG emissions of self-leveling mortars. Thus, they could be used in new studies with different materials.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rogez, H. Açaí: Preparo, Composição e Melhoramento da Conservação; EDUFPA: Belém, Brazil, 2000. [Google Scholar]

- IBGE. Tabela 4–Área Destinada à Colheita, Área Colhida, Quantidade Produzida, Rendimento Médio e Valor da Produção do Brasil, das Grandes Regiões e das Unidades da Federação, Segundo Os Produtos das Lavouras Permanentes. 2020. Available online: https://www.ibge.gov.br/estatisticas/economicas/agricultura-e-pecuaria/9117-producao-agricola-municipal-culturas-temporarias-e-permanentes.html?=&t=resultados (accessed on 17 February 2022).

- IBGE. Tabela 1—Quantidade e Valor dos Produtos da Extração Vegetal e da Silvicultura, Segundo Os Principais Produtos—Brasil. 2015. Available online: https://www.ibge.gov.br/estatisticas/economicas/agricultura-e-pecuaria/9117-producao-agricola-municipal-culturas-temporarias-e-permanentes.html?edicao=18051&t=downloads (accessed on 17 February 2022).

- Marins, L.F.B.; Freitas, M.C.; Vieira, J.H.A.; Rabelo, A.A.; Neto, E.F. Incorporação da Cinza do Caroço de Açaí Em Formulações de Cerâmica Estrutural. In Proceedings of the 21° CBECIMAT—Congresso Brasileiro de Engenharia e Ciência dos Materiais, Cuiabá, Brazil, 9–13 November 2014; pp. 1538–1544. [Google Scholar]

- De Oliveira, M.A.B.; Costa, R.P.; Brandão, S.C.; Miranda, M.V.M.; da Marques, C.A.C.; Caldas, A.A.; de Assunção, W.R.; Chaves, P. Concreto Leve Não Estrutural Com Substituição Parcial de Seixo Por Caroço de Açaí. Braz. J. Dev. 2021, 7, 72543–72557. [Google Scholar] [CrossRef]

- Nogueira, M.F.M.; Brasil, A.C.M.; Cruz, D.O.A.; Guerra, D.R.S.; Macêdo, E.N.; Rendeiro, G.; Ichihara, J.A.; Duarte, A.A.A.M.; Oliveira, A.G.P.; Rocha, H.M.Z.; et al. Centrais Termoelétricas a Biomassa Vegetal para Comunidades Isoladas da Amazônia: Combustão e Gaseificação; Projeto BRA/99/011; MME-PNUD-UFPA-Fadesp: Belém, Brazil, 2007. [Google Scholar]

- De Cordeiro, L.N.P.; Paes, I.N.L.; Souza, P.S.L.; Azevedo, C.M. Caracterização da Cinza de Caroço de Açaí Residual para Adição Ao Concreto. Ambiente Construído 2019, 19, 45–55. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Mohammadhosseini, H. State-of-the-art-review on rice husk ash: A supplementary cementitious material in concrete. J. King Saud Univ. Eng. Sci. 2021, 33, 294–307. [Google Scholar] [CrossRef]

- Vieira, A.P.; Toledo Filho, R.D.; Tavares, L.M.; Cordeiro, G.C. Effect of Particle Size, Porous Structure and Content of Rice Husk Ash on the Hydration Process and Compressive Strength Evolution of Concrete. Constr. Build Mater. 2020, 236, 117553. [Google Scholar] [CrossRef]

- Hu, L.; He, Z.; Zhang, S. Sustainable Use of Rice Husk Ash in Cement-Based Materials: Environmental Evaluation and Performance Improvement. J. Clean. Prod. 2020, 264, 121744. [Google Scholar] [CrossRef]

- He, J.; Kawasaki, S.; Achal, V. The Utilization of Agricultural Waste as Agro-Cement in Concrete: A Review. Sustainability 2020, 12, 6971. [Google Scholar] [CrossRef]

- De Siqueira, A.A.; Cordeiro, G.C. Properties of Binary and Ternary Mixes of Cement, Sugarcane Bagasse Ash and Limestone. Constr. Build. Mater. 2022, 317, 126150. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Kurtis, K.E. Effect of Mechanical Processing on Sugar Cane Bagasse Ash Pozzolanicity. Cem. Concr. Res. 2017, 97, 41–49. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Kanraj, D.; Gokul Dev, V.; Santhanam, M. Performance Evaluation of Sugarcane Bagasse Ash Blended Cement in Concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar] [CrossRef]

- De Siqueira, A.A.; Cordeiro, G.C. Sustainable Cements Containing Sugarcane Bagasse Ash and Limestone: Effects on Compressive Strength and Acid Attack of Mortar. Sustainability 2022, 14, 5683. [Google Scholar] [CrossRef]

- Umoh, A.A.; Odesola, I. Characteristics of Bamboo Leaf Ash Blended Cement Paste and Mortar. Civ. Eng. Dimens. 2015, 17, 22–28. [Google Scholar] [CrossRef][Green Version]

- Villar-Cociña, E.; Morales, E.V.; Santos, S.F.; Savastano, H.; Frías, M. Pozzolanic Behavior of Bamboo Leaf Ash: Characterization and Determination of the Kinetic Parameters. Cem. Concr. Compos. 2011, 33, 68–73. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Sales, C.P. Pozzolanic Activity of Elephant Grass Ash and Its Influence on the Mechanical Properties of Concrete. Cem. Concr. Compos. 2015, 55, 331–336. [Google Scholar] [CrossRef]

- Nakanishi, E.Y.; Frías, M.; Martínez-Ramírez, S.; Santos, S.F.; Rodrigues, M.S.; Rodríguez, O.; Savastano, H. Characterization and Properties of Elephant Grass Ashes as Supplementary Cementing Material in Pozzolan/Ca(OH)2 Pastes. Constr. Build. Mater. 2014, 73, 391–398. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 Emissions from Cement Production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- UN Environment; Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- IBGE. Pará—Panorama. 2021. Available online: https://cidades.ibge.gov.br/brasil/pa/panorama (accessed on 19 February 2022).

- Fundação João Pinheiro. Deficit Habitacional No Brasil—2016–2019; FJP: Belo Horizonte, Brazil, 2021. [Google Scholar]

- Anjos, M.A.S.; Araújo, T.R.; Ferreira, R.L.S.; Farias, E.C.; Martinelli, A.E. Properties of Self-Leveling Mortars Incorporating a High-Volume of Sugar Cane Bagasse Ash as Partial Portland Cement Replacement. J. Build. Eng. 2020, 32, 101694. [Google Scholar] [CrossRef]

- Andersen, M.S. An Introductory Note on the Environmental Economics of the Circular Economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Ruiz, L.A.L.; Ramón, X.R.; Domingo, S.G. The Circular Economy in the Construction and Demolition Waste Sector—A Review and an Integrative Model Approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Chen, H.-M.; Sharmina, M.; Mendoza, J.M.F. Links between Circular Economy and Climate Change Mitigation in the Built Environment. J. Clean. Prod. 2020, 260, 121115. [Google Scholar] [CrossRef]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building Materials in a Circular Economy: The Case of Wood Waste as CO2-Sink in Bio Concrete. Resour. Conserv. Recycl. 2021, 166, 105346. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of Buildings and the Building Sector: A Review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- De Souza, D.M.; Lafontaine, M.; Charron-Doucet, F.; Chappert, B.; Kicak, K.; Duarte, F.; Lima, L. Comparative Life Cycle Assessment of Ceramic Brick, Concrete Brick and Cast-in-Place Reinforced Concrete Exterior Walls. J. Clean. Prod. 2016, 137, 70–82. [Google Scholar] [CrossRef]

- Garcia, R.; Alvarenga, R.A.F.; Huysveld, S.; Dewulf, J.; Allacker, K. Accounting for Biogenic Carbon and End-of-Life Allocation in Life Cycle Assessment of Multi-Output Wood Cascade Systems. J. Clean. Prod. 2020, 275, 122795. [Google Scholar] [CrossRef]

- Do Nascimento, K.F.S.; Oliveira, T.M.C. Aproveitamento das Cinzas de Caroço de Açaí Na Produção de Concreto Sustentável Analisando Sua Durabilidade. In Proceedings of the CONTECC—Congresso Técnico Científico da Engenharia e da Agronomia, Maceió, AL, Brazil, 22–24 August 2018; pp. 1–5. [Google Scholar]

- Santos, T.; Almeida, J.; Silvestre, J.D.; Faria, P. Life Cycle Assessment of Mortars: A Review on Technical Potential and Drawbacks. Constr. Build. Mater. 2021, 288, 123069. [Google Scholar] [CrossRef]

- Andersen, S.C.; Birgisdottir, H.; Birkved, M. Life Cycle Assessments of Circular Economy in the Built Environment—A Scoping Review. Sustainability 2022, 14, 6887. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Cuenca-Moyano, G.M.; Zanni, S.; Bonoli, A.; Valverde-Palacios, I. Development of the Life Cycle Inventory of Masonry Mortar Made of Natural and Recycled Aggregates. J. Clean. Prod. 2017, 140, 1272–1286. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Martín-Morales, M.; Bonoli, A.; Valverde-Palacios, I. Environmental Assessment of Masonry Mortars Made with Natural and Recycled Aggregates. Int. J. Life Cycle Assess. 2019, 24, 191–210. [Google Scholar] [CrossRef]

- Margallo, M.; Aldaco, R.; Irabien, Á. Environmental Management of Bottom Ash from Municipal Solid Waste Incineration Based on a Life Cycle Assessment Approach. Clean. Technol. Environ. Policy 2014, 16, 1319–1328. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Damgaard, A.; Comans, R.N.J. Life Cycle Assessment of the Reuse of Fly Ash from Biomass Combustion as Secondary Cementitious Material in Cement Products. J. Clean. Prod. 2020, 245, 118937. [Google Scholar] [CrossRef]

- Moro, C.; Francioso, V.; Schrager, M.; Velay-Lizancos, M. TiO2 Nanoparticles Influence on the Environmental Performance of Natural and Recycled Mortars: A Life Cycle Assessment. Environ. Impact. Assess. Rev. 2020, 84, 106430. [Google Scholar] [CrossRef]

- Brás, A.; Faria, P. Effectiveness of Mortars Composition on the Embodied Carbon Long-Term Impact. Energy Build. 2017, 154, 523–528. [Google Scholar] [CrossRef]

- Farinha, C.B.; Silvestre, J.D.; de Brito, J.; do Veiga, M.R. Life Cycle Assessment of Mortars with Incorporation of Industrial Wastes. Fibers 2019, 7, 59. [Google Scholar] [CrossRef]

- Moreno-Juez, J.; Vegas, I.J.; Gebremariam, A.T.; García-Cortés, V.; di Maio, F. Treatment of End-of-Life Concrete in an Innovative Heating-Air Classification System for Circular Cement-Based Products. J. Clean. Prod. 2020, 263, 121515. [Google Scholar] [CrossRef]

- Liapis, A.; Anastasiou, E.K.; Papachristoforou, M.; Papayianni, I. Feasibility Study and Criteria for EAF Slag Utilization in Concrete Products. J. Sustain. Metall. 2018, 4, 68–76. [Google Scholar] [CrossRef]

- Pineda, P.; García-Martínez, A.; Castizo-Morales, D. Environmental and Structural Analysis of Cement-Based vs. Natural Material-Based Grouting Mortars. Results from the Assessment of Strengthening Works. Constr. Build. Mater. 2017, 138, 528–547. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Mateus, R.; Camões, A.; Branco, F.G. Quality and Durability Properties and Life-Cycle Assessment of High Volume Biomass Fly Ash Mortar. Constr. Build. Mater. 2019, 197, 195–207. [Google Scholar] [CrossRef]

- Da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.C.; Arroja, L.; Dias, A.C. Environmental Assessment of Valorisation Alternatives for Woody Biomass Ash in Construction Materials. Resour. Conserv. Recycl. 2019, 148, 67–79. [Google Scholar] [CrossRef]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and Developments in Green Cement and Concrete Technology. Int. J. Sustain. Built. Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef]

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of LCA Studies of Solid Waste Management Systems—Part I: Lessons Learned and Perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Comparative Sustainability Assessment of Binary Blended Concretes Using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

- ASTM C204; Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus. ASTM: West Conshohocken, PA, USA, 2019.

- ABNT NBR 15895; Materiais Pozolânicos—Determinação do Teor de Hidróxido de Cálcio Fixado—Método Chapelle Modificado. ABNT: Sao Paulo, Brazil, 2010.

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM: West Conshohocken, PA, USA, 2019.

- Raverdy, M.; Brivot, F.; Paillere, A.M.; Dron, R. Appreciation de I’activite Pouzzolanique des Constituants Secondaires. In Proceedings of the 7th Congrès International de la Chimie des Ciments, Paris, France, 30 June–4 July 1980. [Google Scholar]

- ABNT NBR NM 248; Agregados—Determinação da Composição Granulométrica. ABNT: Sao Paulo, Brazil, 2003.

- ABNT NBR NM 52; Agregado Miúdo—Determinação da Massa Específica e Massa Específica Aparente. ABNT: Sao Paulo, Brazil, 2003.

- ABNT NBR NM 45; Agregados—Determinação da Massa Unitária e do Volume de Vazios. ABNT: Sao Paulo, Brazil, 2006.

- EFNARC Specification. Guidelines for Self-Compacting Concrete; Association House: London, UK, 2002. [Google Scholar]

- ASTM C1708; Standard Test Methods for Self-Leveling Mortars Containing Hydraulic Cements. ASTM: West Conshohocken, PA, USA, 2016.

- ABNT NBR 7215; Cimento Portland—Determinação da Resistência à Compressão. ABNT: Sao Paulo, Brazil, 2019.

- ABNT NBR 13279; Argamassa para Assentamento e Revestimento de Paredes e Tetos—Determinação da Resistência à Tração Na Flexão e à Compressão. ABNT: Sao Paulo, Brazil, 2005.

- BS EN 15978; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. BS EN: London, UK, 2011.

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus Modular Construction Methods: A Comparative Cradle-to-Gate LCA for Residential Buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction Matters: Comparing Environmental Impacts of Building Modular and Conventional Homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life Cycle Assessment (LCA) of Building Refurbishment: A Literature Review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- BS EN 15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. BS EN: London, UK, 2019.

- Caldas, L.R.; Carvalho, M.T.M.; Toledo Filho, R.D. Avaliação de Estratégias para a Mitigação dos Impactos Ambientais de Revestimentos Argamassados No Brasil. Ambiente Construído 2020, 20, 343–362. [Google Scholar] [CrossRef]

- Paiva, R.D.L.M.; Caldas, L.R.; de Souza Martins, A.P.; Toledo Filho, R.D. Potentiality of Earth-Based Mortar Containing Bamboo Particles for GHG Emissions Reduction. Constr. Build. Mater. 2022, 317, 125971. [Google Scholar] [CrossRef]

- Lee, J.; Lee, T.; Jeong, J.; Jeong, J. Sustainability and Performance Assessment of Binary Blended Low-Carbon Concrete Using Supplementary Cementitious Materials. J. Clean. Prod. 2021, 280, 124373. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, C.; Monteiro, P.J.M. Green Concrete Containing Diatomaceous Earth and Limestone: Workability, Mechanical Properties, and Life-Cycle Assessment. J. Clean. Prod. 2019, 223, 662–679. [Google Scholar] [CrossRef]

- Caldas, L.R.; Sposto, R.M. Emissões de CO2 Referentes Ao Transporte de Materiais de Construção No Brasil: Estudo Comparativo Entre Blocos Estruturais Cerâmicos e de Concreto. Ambiente Construído 2017, 17, 91–108. [Google Scholar] [CrossRef]

- Caldas, L.R.; Pittau, F.; Schaeffer, R.; Saraiva, A.K.E.B.; Paiva, R.D.L.M.; Toledo Filho, R.D. Concrete vs. Ceramic Blocks: Environmental Impact Evaluation Considering a Country-Level Approach. World 2021, 2, 482–504. [Google Scholar] [CrossRef]

- SNIC. Relatório Annual. 2020. Available online: http://snic.org.br/assets/pdf/relatorio_anual/rel_anual_2020.pdf (accessed on 14 December 2021).

- Silva, V.U.; Nascimento, M.F.; Oliveira, P.R.; Panzera, T.H.; Rezende, M.O.; Silva, D.A.L.; de Moura Aquino, V.B.; Lahr, F.A.R.; Christoforo, A.L. Circular vs. Linear Economy of Building Materials: A Case Study for Particleboards Made of Recycled Wood and Biopolymer vs. Conventional Particleboards. Constr. Build. Mater. 2021, 285, 122906. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Tosun, K.; Baradan, B.; Altun, A.; Uyulgan, B. The Effect of Fly Ash and Limestone Fillers on the Viscosity and Compressive Strength of Self-Compacting Repair Mortars. Cem. Concr. Res. 2006, 36, 1719–1726. [Google Scholar] [CrossRef]

- Turk, K. Viscosity and Hardened Properties of Self-Compacting Mortars with Binary and Ternary Cementitious Blends of Fly Ash and Silica Fume. Constr. Build. Mater. 2012, 37, 326–334. [Google Scholar] [CrossRef]

- Karataş, M.; Benli, A.; Ergin, A. Influence of Ground Pumice Powder on the Mechanical Properties and Durability of Self-Compacting Mortars. Constr. Build. Mater. 2017, 150, 467–479. [Google Scholar] [CrossRef]

- Khoshkbijari, R.K.; Samimi, M.F.; Mohammadi, F.; Talebitaher, P. Effects of Mica and Feldspar as Partial Cement Replacement on the Rheological, Mechanical and Thermal Durability of Self-Compacting Mortars. Constr. Build. Mater. 2020, 263, 120149. [Google Scholar] [CrossRef]

- Rao, S.; Silva, P.; de Brito, J. Experimental Study of the Mechanical Properties and Durability of Self-Compacting Mortars with Nano Materials (SiO2 and TiO2). Constr. Build. Mater. 2015, 96, 508–517. [Google Scholar] [CrossRef]

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of Nano-Silica on Rheology and Fresh Properties of Cement Pastes and Mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Pereira, V.M.; Camarini, G. Fresh and Hardened Properties of Self-Leveling Mortars with Porcelain and Red Ceramic Wastes. Adv. Civ. Eng. 2018, 2018, 6378643. [Google Scholar] [CrossRef]

- Barluenga, G.; Hernández-Olivares, F. Self-Levelling Cement Mortar Containing Grounded Slate from Quarrying Waste. Constr. Build. Mater. 2010, 24, 1601–1607. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Jamil, M.; Karim, M.R.; Zain, M.F.M.; Kaish, A.B.M.A. Filler Effect of Pozzolanic Materials on the Strength and Microstructure Development of Mortar. KSCE J. Civ. Eng. 2017, 21, 274–284. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Zawawi, R.; Abu Hassan, Z.F. Introducing an Effective Curing Method for Mortar Containing High Volume Cementitious Materials. Constr. Build. Mater. 2016, 107, 365–377. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S. Strength and Chloride Resistance of the Blended Portland Cement Mortar Containing Rice Husk Ash and Ground River Sand. Mater. Struct. 2015, 48, 3771–3777. [Google Scholar] [CrossRef]

- Joshaghani, A.; Moeini, M.A. Evaluating the Effects of Sugar Cane Bagasse Ash (SCBA) and Nanosilica on the Mechanical and Durability Properties of Mortar. Constr. Build. Mater. 2017, 152, 818–831. [Google Scholar] [CrossRef]

- Miyandehi, B.M.; Feizbakhsh, A.; Yazdi, M.A.; Liu, Q.; Yang, J.; Alipour, P. Performance and Properties of Mortar Mixed with Nano-CuO and Rice Husk Ash. Cem. Concr. Compos. 2016, 74, 225–235. [Google Scholar] [CrossRef]

- Cao, Z.; Shen, L.; Zhao, J.; Liu, L.; Zhong, S.; Yang, Y. Modeling the Dynamic Mechanism between Cement CO2 Emissions and Clinker Quality to Realize Low-Carbon Cement. Resour. Conserv. Recycl. 2016, 113, 116–126. [Google Scholar] [CrossRef]

- Zhang, C.-Y.; Han, R.; Yu, B.; Wei, Y.-M. Accounting Process-Related CO2 Emissions from Global Cement Production under Shared Socioeconomic Pathways. J. Clean. Prod. 2018, 184, 451–465. [Google Scholar] [CrossRef]

- Asadollahfardi, G.; Katebi, A.; Taherian, P.; Panahandeh, A. Environmental Life Cycle Assessment of Concrete with Different Mixed Designs. Int. J. Constr. Manag. 2021, 21, 665–676. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Dong, Y.H.; Xuan, D. Evaluation of Environmental Impact Distribution Methods for Supplementary Cementitious Materials. Renew. Sustain. Energy Rev. 2018, 82, 597–608. [Google Scholar] [CrossRef]

- Toniolo, S.; Mazzi, A.; Pieretto, C.; Scipioni, A. Allocation Strategies in Comparative Life Cycle Assessment for Recycling: Considerations from Case Studies. Resour. Conserv. Recycl. 2017, 117, 249–261. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Dong, L.; Gebremariam, A.; Miranda-Xicotencatl, B.; di Maio, F.; Tukker, A. Eco-Efficiency Assessment of Technological Innovations in High-Grade Concrete Recycling. Resour. Conserv. Recycl. 2019, 149, 649–663. [Google Scholar] [CrossRef]

- Garcia, C.A.; Hora, G. State-of-the-Art of Waste Wood Supply Chain in Germany and Selected European Countries. Waste Manag. 2017, 70, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Klein, D.; Wolf, C.; Schulz, C.; Weber-Blaschke, G. Environmental Impacts of Various Biomass Supply Chains for the Provision of Raw Wood in Bavaria, Germany, with Focus on Climate Change. Sci. Total Environ. 2016, 539, 45–60. [Google Scholar] [CrossRef] [PubMed]

- Caldas, L.R.; da Gloria, M.Y.R.; Pittau, F.; Andreola, V.M.; Habert, G.; Toledo Filho, R.D. Environmental Impact Assessment of Wood Bio-Concretes: Evaluation of the Influence of Different Supplementary Cementitious Materials. Constr. Build. Mater. 2021, 268, 121146. [Google Scholar] [CrossRef]

- Shakantu, W.; Tookey, J.E.; Bowen, P.A. The Hidden Cost of Transportation of Construction Materials: An Overview. J. Eng. Des. Technol. 2003, 1, 103–118. [Google Scholar] [CrossRef]

- El Moussaoui, S.; Lafhaj, Z.; Leite, F.; Laqdid, Y.; BuHamdan, S.; Brunet, F.; Fléchard, J.; Linéatte, B. The Assessment of Pollutant Emissions from Transportation of Construction Materials and the Impact of Construction Logistics Centers. J. Manag. Eng. 2022, 38, 4022038. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; do Freitas, C.D.M.; Tavares, S.F. Circular Economy in the Construction Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- La Rovere, E.L.; Wills, W.; Pereira, A.O., Jr.; Dubeux, C.B.S.; Cunha, S.H.F.; Oliveira, B.C.P.; Moreira, M.M.R.; Watanabe, S.; Loureiro, S.M.; Moreira, L.S.S.C.; et al. Implicações Econômicas e Sociais de Cenários de Mitigação de Gases de Efeito Estufa No Brasil Até 2030; Projeto IES-Brasil, Forum Brasileiro de Mudanças Climáticas—FBMC.COPPE/UFRJ: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- Imazon, Desmatamento Acumulado até Setembro Passa dos 9 Mil km² em 2022, Pior Marca em 15 Anos. 2022. Available online: https://imazon.org.br/imprensa/desmatamento-acumulado-ate-setembro-passa-dos-9-mil-km%C2%B2-em-2022-pior-marca-em-15-anos/ (accessed on 25 October 2022).

- There’s Only One Choice in Brazil’s Election—For the Country and the World. Nature 2022, 610, 606. [CrossRef]

- Freitas, M.A.B.; Magalhães, J.L.L.; Carmona, C.P.; Arroyo-Rodríguez, V.; Vieira, I.C.G.; Tabarelli, M. Intensification of açaí palm management largely impoverishes tree assemblages in the Amazon estuarine forest. Biol. Conserv. 2021, 261, 109251. [Google Scholar] [CrossRef]

- Lopes, E.; Soares-Filho, B.; Souza, F.; Rajão, R.; Merry, F.; Ribeiro, S.C. Mapping the socio-ecology of Non Timber Forest Products (NTFP) extraction in the Brazilian Amazon: The case of açaí (Euterpe precatoria Mart) in Acre. Landsc. Urban Plan. 2019, 188, 110–117. [Google Scholar] [CrossRef]

| Oxide | ASA | CP II-E-32 |

|---|---|---|

| CaO | 17.8 | 65.5 |

| SiO2 | 10.3 | 12.6 |

| Al2O3 | 3.7 | 4.4 |

| Fe2O3 | 2.2 | 4.7 |

| K2O | 28.8 | 0.5 |

| P2O5 | 8.8 | - |

| SO3 | 5 | 3.1 |

| Cl | 3.1 | - |

| MnO | 1.3 | 0.2 |

| TiO2 | 0.7 | 0.4 |

| Loss on Ignition (LOI) | 18.3 | 8.6 |

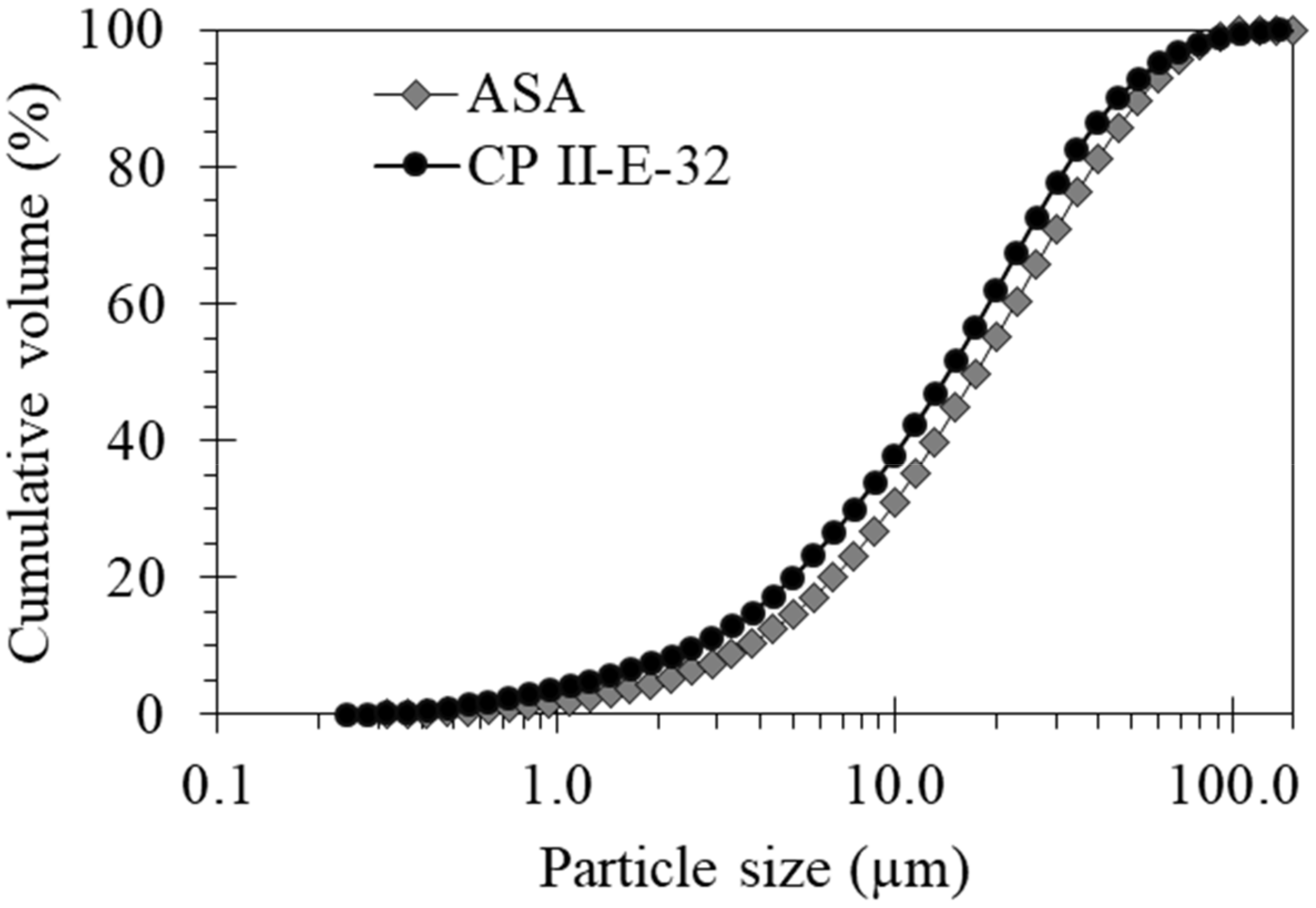

| Parameter | ASA | CP II-E-32 |

|---|---|---|

| D10 (µm) | 3.65 | 2.62 |

| D50 (µm) | 17.47 | 14.49 |

| D90 (µm) | 53.18 | 45.53 |

| Specific gravity (g/cm³) | 2.49 | 3.06 |

| Specific surface area (cm2/g) | 5080.24 | 3975.15 |

| Nomenclature | Cement | ASA | Sand | Water | Superplasticizer | ||

|---|---|---|---|---|---|---|---|

| (kg/m³) | (%) | (kg/m³) | (kg/m³) | (kg/m³) | (%) | (kg/m³) | |

| REF | 617.3 | - | - | 1234.6 | 308.6 | 0.65% | 4.01 |

| 5ASA-0.55 | 586.4 | 5% | 30.86 | 1234.6 | 293.2 | 0.55% | 3.40 |

| 5ASA-0.65 | 586.4 | 5% | 30.86 | 1234.6 | 293.2 | 0.65% | 4.01 |

| 10ASA-0.80 | 555.6 | 10% | 61.73 | 1234.6 | 277.8 | 0.80% | 4.94 |

| 10ASA-0.85 | 555.6 | 10% | 61.73 | 1234.6 | 277.8 | 0.85% | 5.25 |

| 10ASA-0.95 | 555.6 | 10% | 61.73 | 1234.6 | 277.8 | 0.95% | 5.86 |

| Materials | |

|---|---|

| Portland Cement | Cement, blast furnace slag 6–34% {BR}|cement production, blast furnace slag 6–34%|Cut-off, U |

| Sand | Sand {BR}| sand quarry operation, open pit mine|Cut-off, U |

| Water | Tap water {BR}|tap water production, conventional treatment|Cut-off, U |

| Superplasticizer | Plasticizer, for concrete, based on sulfonated melamine formaldehyde {GLO}|production|Cut-off, U |

| Transportation | |

| Scenario 1 | Transport, truck 10–20 t, EURO3, 100%LF, default/GLO Mass |

| Scenario 2 | Transport, truck 10–20 t, EURO3, 50%LF, empty return/GLO Mass |

| Production | |

| Mortar production | Concrete, 25 MPa {BR}| concrete production—Only plant processes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rocha, J.H.A.; de Siqueira, A.A.; de Oliveira, M.A.B.; Castro, L.d.S.; Caldas, L.R.; Monteiro, N.B.R.; Toledo Filho, R.D. Circular Bioeconomy in the Amazon Rainforest: Evaluation of Açaí Seed Ash as a Regional Solution for Partial Cement Replacement. Sustainability 2022, 14, 14436. https://doi.org/10.3390/su142114436

Rocha JHA, de Siqueira AA, de Oliveira MAB, Castro LdS, Caldas LR, Monteiro NBR, Toledo Filho RD. Circular Bioeconomy in the Amazon Rainforest: Evaluation of Açaí Seed Ash as a Regional Solution for Partial Cement Replacement. Sustainability. 2022; 14(21):14436. https://doi.org/10.3390/su142114436

Chicago/Turabian StyleRocha, Joaquin Humberto Aquino, Andréia Arenari de Siqueira, Marco Antonio Barbosa de Oliveira, Lucas da Silva Castro, Lucas Rosse Caldas, Nathalie Barbosa Reis Monteiro, and Romildo Dias Toledo Filho. 2022. "Circular Bioeconomy in the Amazon Rainforest: Evaluation of Açaí Seed Ash as a Regional Solution for Partial Cement Replacement" Sustainability 14, no. 21: 14436. https://doi.org/10.3390/su142114436

APA StyleRocha, J. H. A., de Siqueira, A. A., de Oliveira, M. A. B., Castro, L. d. S., Caldas, L. R., Monteiro, N. B. R., & Toledo Filho, R. D. (2022). Circular Bioeconomy in the Amazon Rainforest: Evaluation of Açaí Seed Ash as a Regional Solution for Partial Cement Replacement. Sustainability, 14(21), 14436. https://doi.org/10.3390/su142114436