Study on the Disintegration Characteristics and Mechanism of Modified Dispersive Soil Based on the C-S-H Synthesis Principle

Abstract

:1. Introduction

2. Materials and Methods

2.1. Soil

2.2. Materials

2.3. Methods

2.3.1. Test Design

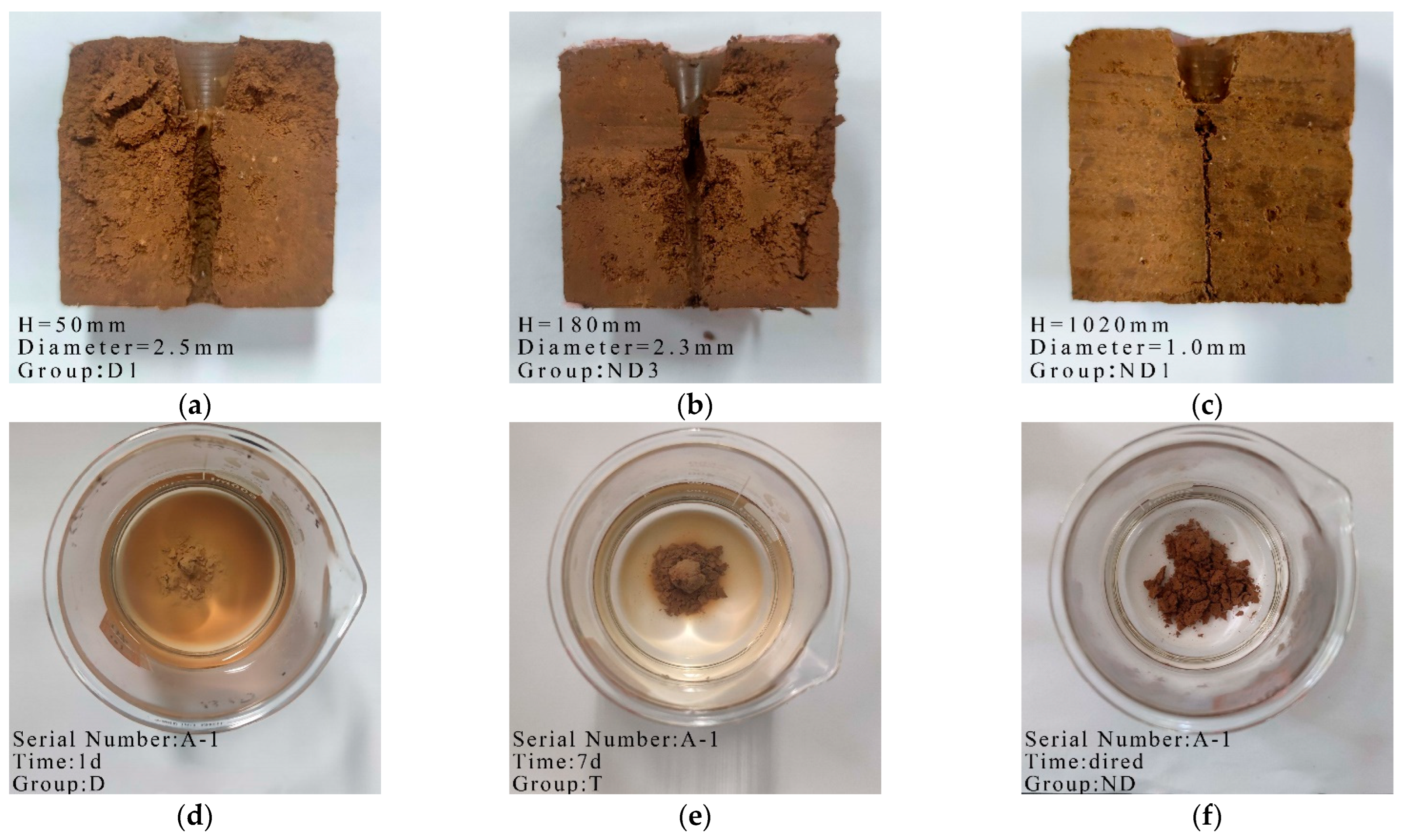

2.3.2. Dispersivity Discrimination Tests

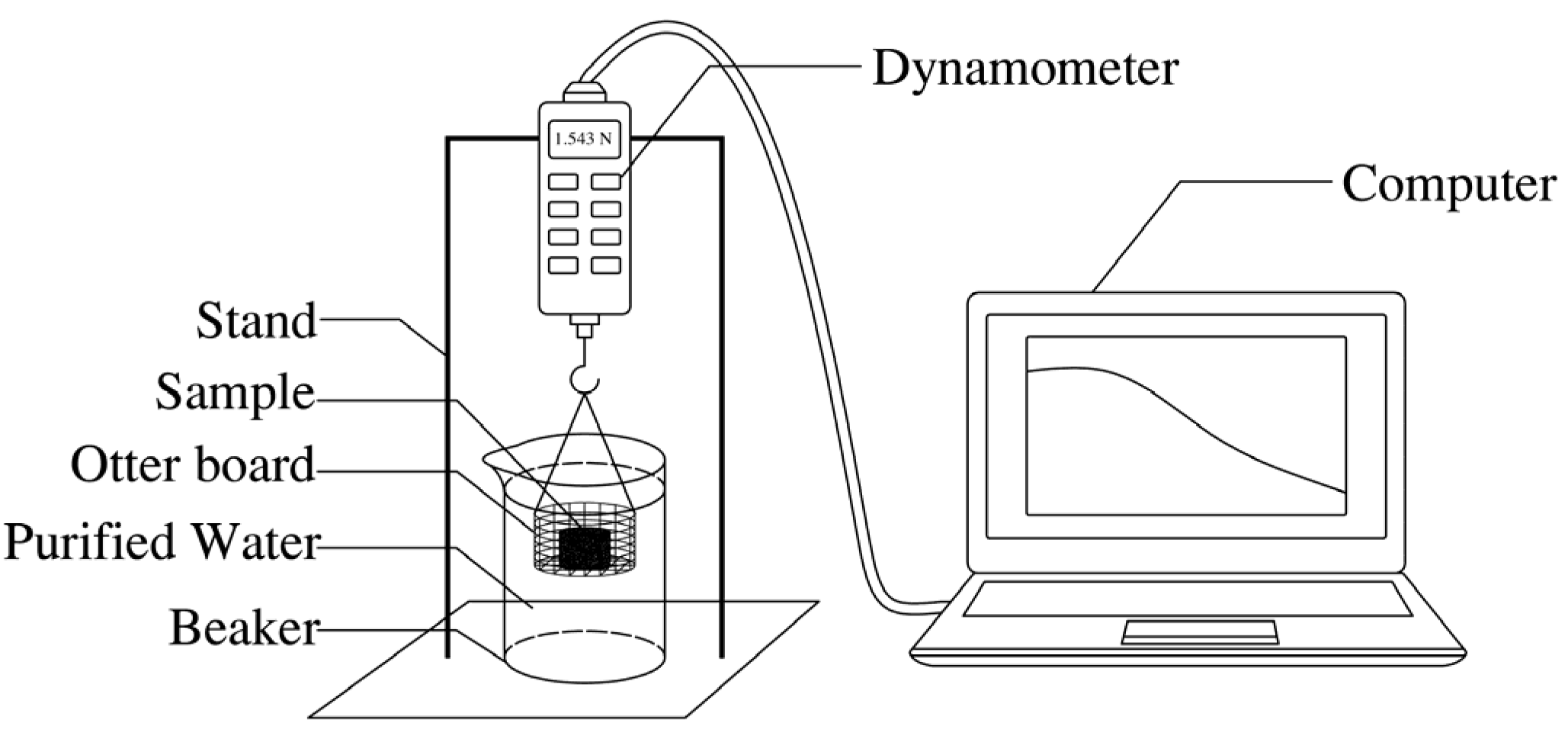

2.3.3. Dispersion and Disintegration Test

2.3.4. Mechanism Tests

3. Results and Discussion

3.1. Dispersivity Tests Result Analysis of Modified Soil

3.1.1. Effect of CaO on Soil Dispersivity

3.1.2. Effect of Nano-SiO2 on Soil Dispersivity

3.1.3. Effect of the C/S and Solid Dosage on Ca–Si-Treated Soil Dispersivity

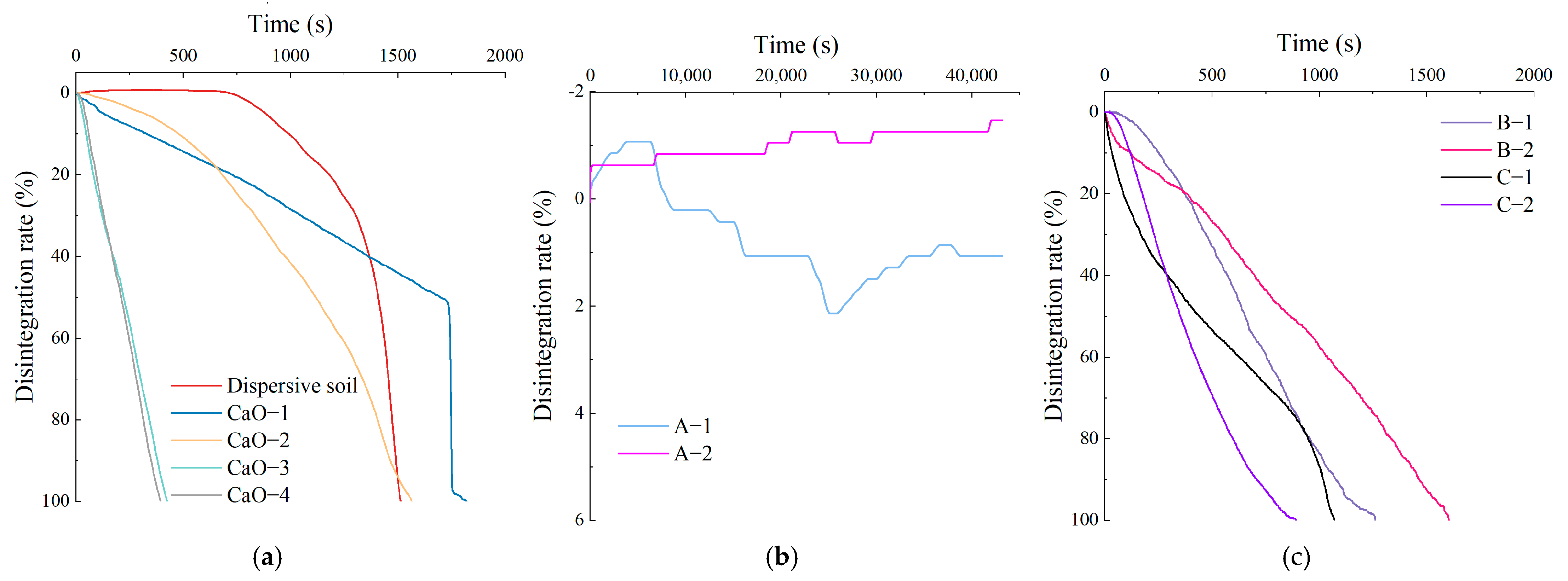

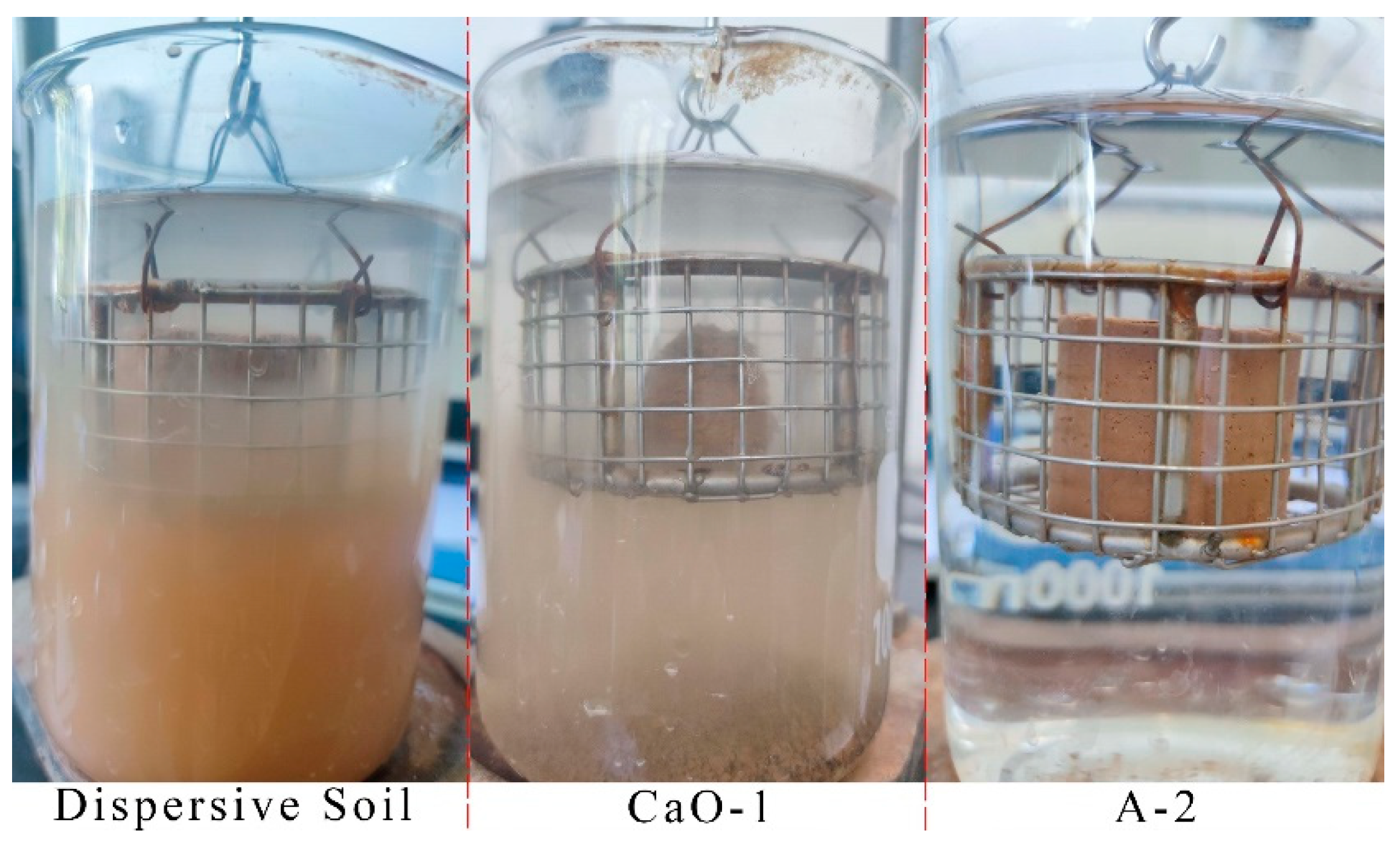

3.2. Dispersion and Disintegration Test Result Analysis of Modified Soil

3.3. Mechanism Tests Result Analysis

3.3.1. Results of the Laser Particle Analysis Test

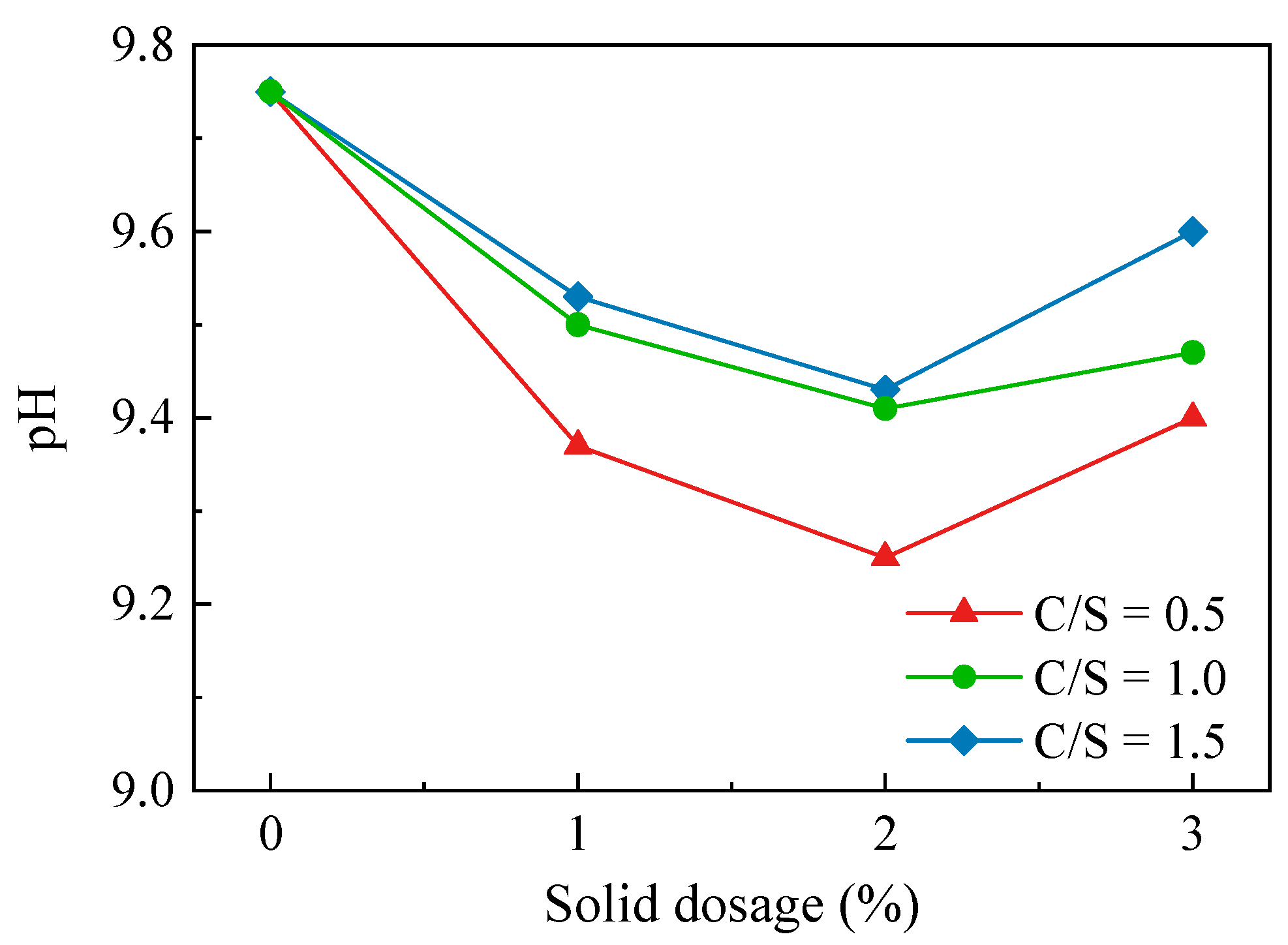

3.3.2. Results of the pH Test

3.3.3. Results of the Conductivity Test

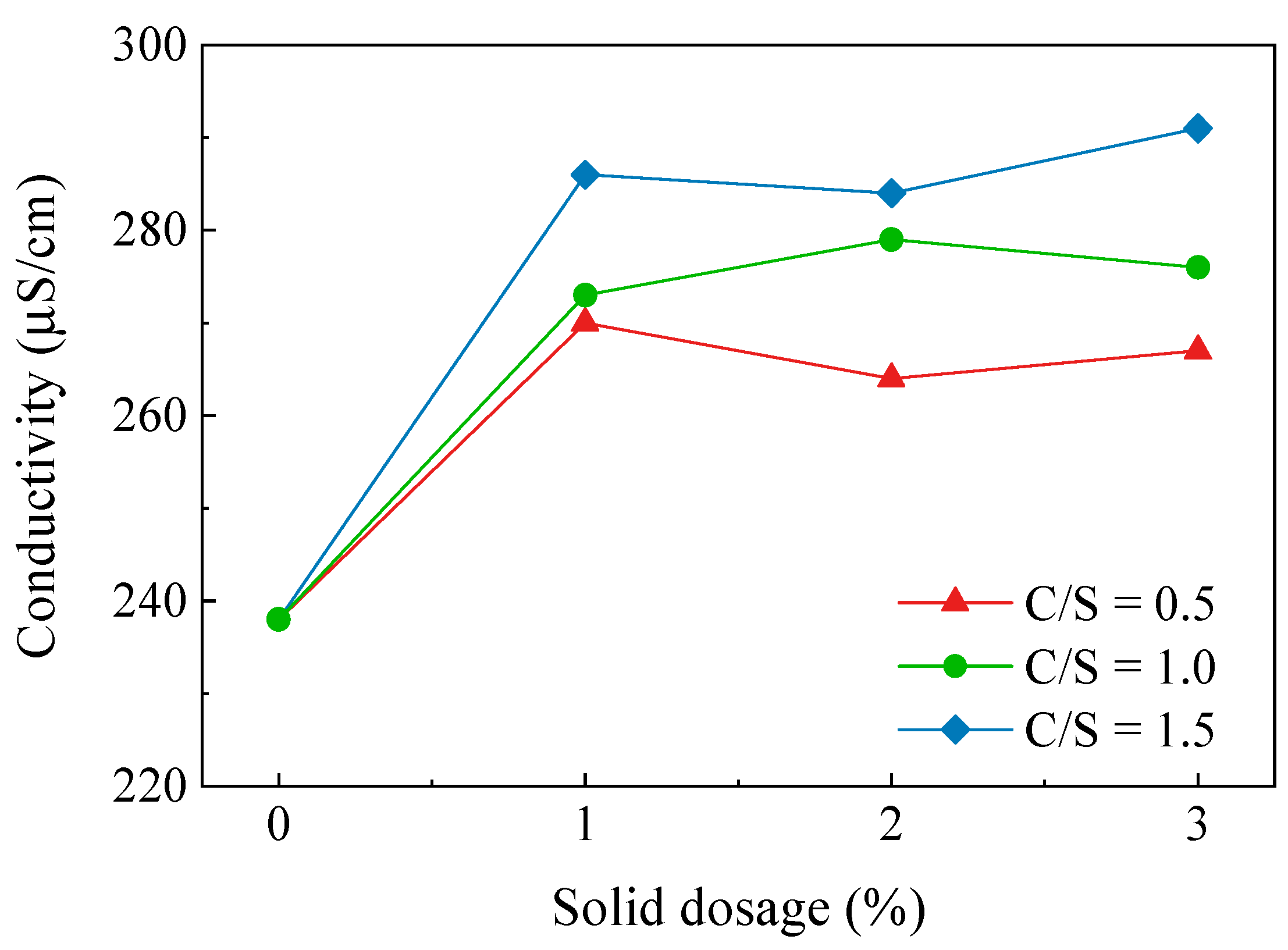

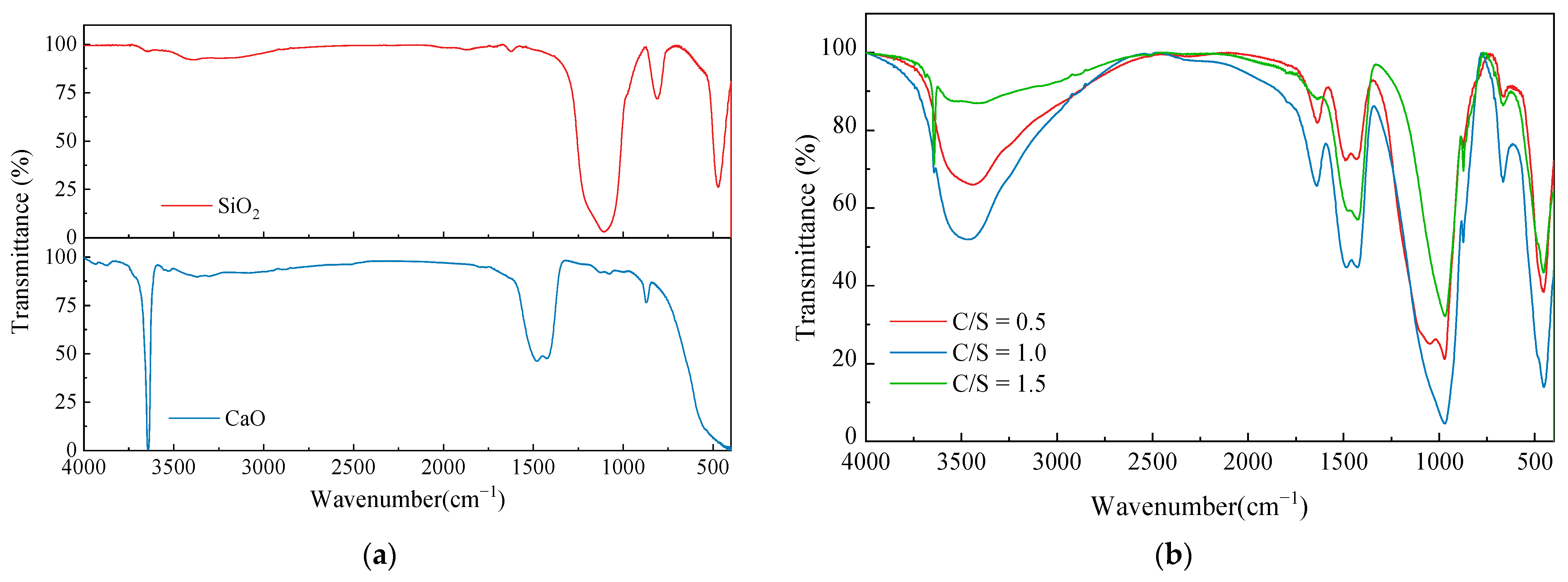

3.3.4. Results of the Exchangeable Sodium Percentage Test

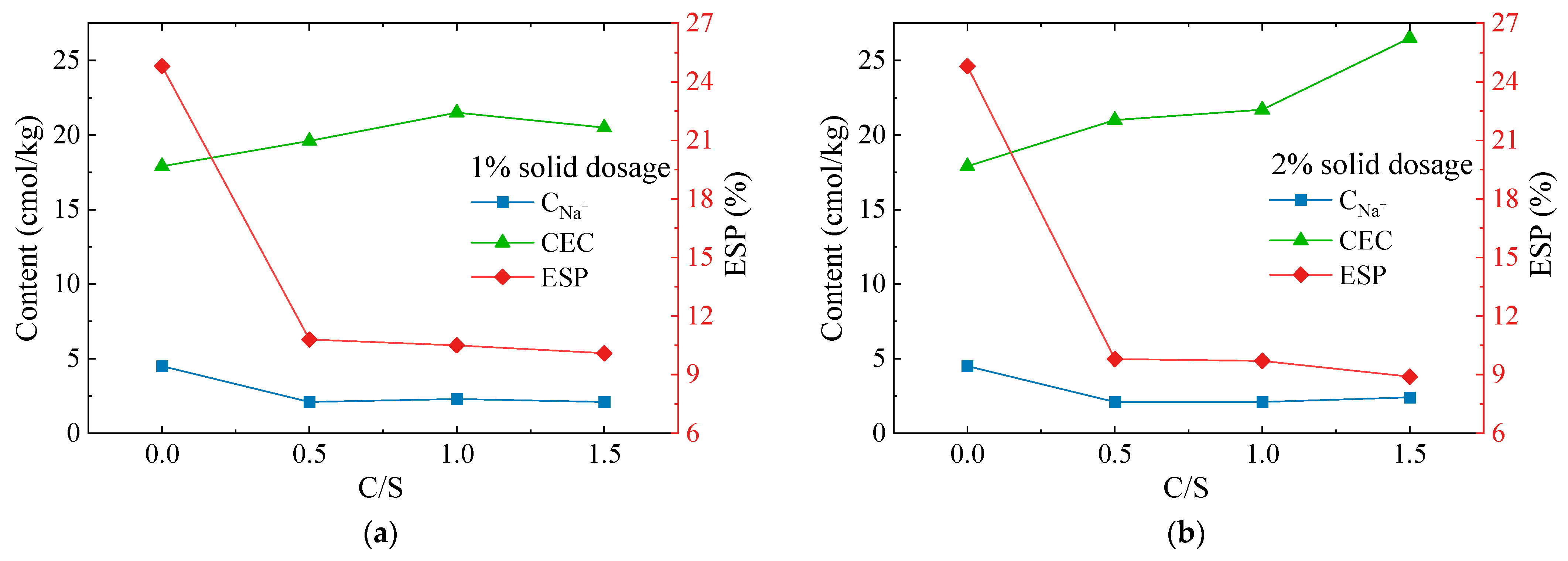

3.3.5. Results of the FT–IR Test

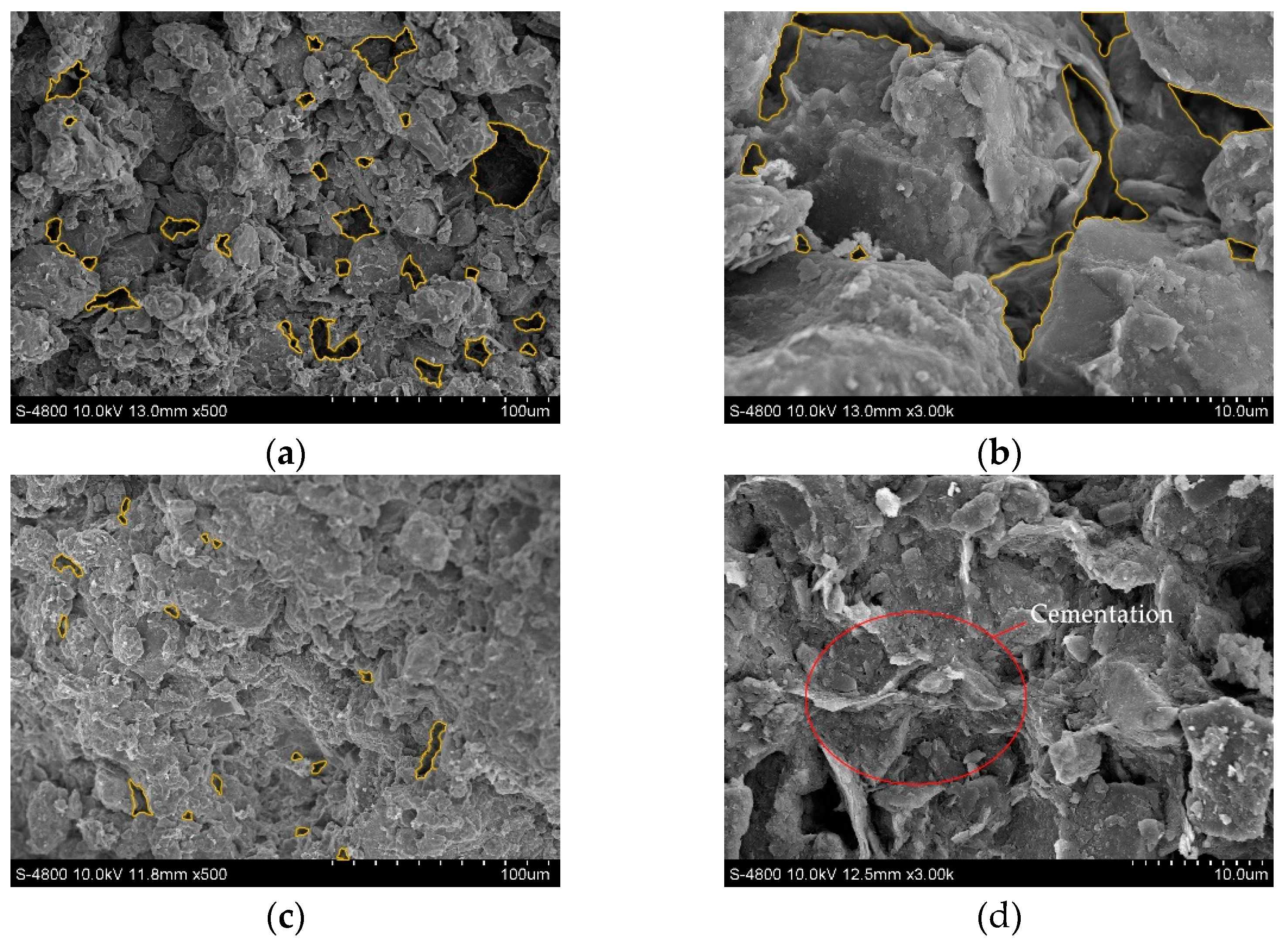

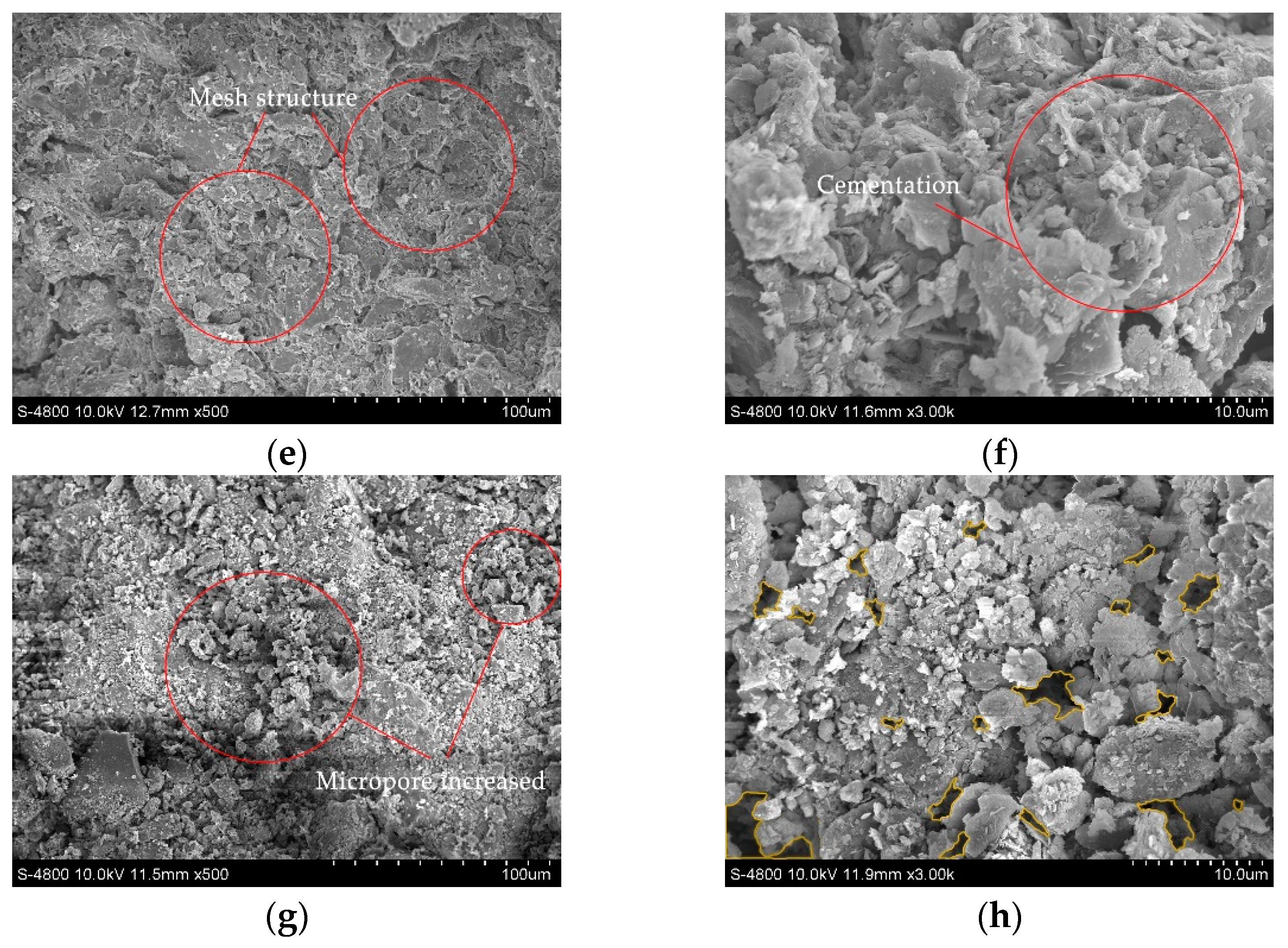

3.3.6. Results of the SEM Test

- (1)

- A serious chemical reaction occurred during the modification of the dispersive soil by Ca–Si, as shown in Equations (5)–(7).

- (2)

- Through chemical reactions, the OH− in the soil was depleted to a certain extent. As a result, the alkalinity of the dispersive soil decreased, and the adsorption of the Na+ by the clay particles was weakened.

- (3)

- During the CaO reaction, some free Ca2+ was generated within the soil pore fluid. As the ion exchange capacity of Ca2+ is stronger than that of Na+ [31], the Ca2+ underwent an ion replacement reaction with the exchangeable Na+ on the surface of the clay particles, effectively reducing the ESP value. This effectively reduced the thickness of the double electric layer of the clay particles, decreased the inter-particle repulsion, and eliminated the dispersivity.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petry, T.M. Identification of Dispersive Clay Soils by a Physical Test; Oklahoma State University: Stillwater, OK, USA, 1974. [Google Scholar]

- Gutiérrez, F.; Desir, G.; Gutiérrez, M. Causes of the catastrophic failure of an earth dam built on gypsiferous alluvium and dispersive clays (Altorricón, Huesca province, NE Spain). Environ. Geol. 2003, 43, 842–851. [Google Scholar] [CrossRef]

- Premkumar, S.; Piratheepan, J.; Arulrajah, A.; Disfani, M.M.; Rajeev, P. Experimental study on contact erosion failure in pavement embankment with dispersive clay. J. Mater. Civ. Eng. 2016, 28, 4015179. [Google Scholar] [CrossRef]

- Ingles, O.G.; Aitchison, G.D. Soil–water disequilibrium as a cause of subsidence in natural soils and earth embankments. In Proceedings of the Association Internationale d’Hydrologie Scientifique, Affaisement du Sol, Tokyo, Japan, September 1970; Volume 89, pp. 342–353. [Google Scholar]

- Sherard, J.L.; Decker, R.S.; Ryker, N.L. Piping in Earth Dams of Dispersive Clay, Performance of Earth and Earth–Supported Structures; ASCE: Reston, VA, USA, 1972; p. 589. [Google Scholar]

- Holmgren, G.G.S.; Flanagan, C.P. Factors affecting spontaneous dispersion of soil materials as evidenced by the crumb test. In Dispersive Clays, Related Piping, and Erosion in Geotechnical Projects; ASTM International: West Conshohocken, PA, USA, 1977; Volume 623, pp. 218–239. [Google Scholar]

- Tao, R.; Meng, M.Q.; Zhang, W.B.; Fan, H.H.; Wen, J.X.; Guo, H.D.; Yang, X.J. Study on the dispersivity discrimination methods of fine–grained soil based on dispersive mechanism. Chin. J. Geotech. Eng. 2022, 1–10. Available online: http://kns.cnki.net/kcms/detail/32.1124.TU.20220424.1635.002.html (accessed on 25 April 2022).

- Bhuvaneshwari, S.; Soundra, B.; Robinson, R.G.; Gandhi, S.R. Stabilization and microstructural modification of dispersive clayey soils. In Proceedings of the 1st International Conference on Soil and Rock Engineering, Srilankan Geotechnical Society, Columbo, Srilanka, 7–11 August 2007. [Google Scholar]

- Savaş, H.; Türköz, M.; Seyrek, E.; Ünver, E. Comparison of the effect of using class c and f fly ash on the stabilization of dispersive soils. Arab. J. Geosci. 2018, 11, 612. [Google Scholar] [CrossRef]

- Indraratna, B.; Nutalaya, P.; Kuganenthira, N. Stabilization of a dispersive soil by blending with fly ash. Q. J. Eng. Geol. Hydrogeol. 1991, 24, 275–290. [Google Scholar] [CrossRef]

- Turkoz, M.; Vural, P. The effects of cement and natural zeolite additives on problematic clay soils. Sci. Eng. Compos. Mater. 2013, 20, 395–405. [Google Scholar] [CrossRef]

- Umesha T, S.; Dinesh S, V.; Sivapullaiah, P.V. Control of dispersivity of soil using lime and cement. Int. J. Geol. 2009, 3, 8–16. [Google Scholar]

- Vakili, A.H.; Ghasemi, J.; Bin Selamat, M.R.; Salimi, M.; Farhadi, M.S. Internal erosional behaviour of dispersive clay stabilized with lignosulfonate and reinforced with polypropylene fiber. Constr. Build. Mater. 2018, 193, 405–415. [Google Scholar] [CrossRef]

- Türköz, M.; Umu, S.U.; Öztürk, O. Effect of silica fume as a waste material for sustainable environment on the stabilization and dynamic behavior of dispersive soil. Sustainability 2021, 13, 4321. [Google Scholar] [CrossRef]

- Vakili, A.H.; Shojaei, S.I.; Salimi, M.; Bin Selamat, M.R.; Farhadi, M.S. Contact erosional behaviour of foundation of pavement embankment constructed with nanosilica–treated dispersive soils. Soils Found. 2020, 60, 167–178. [Google Scholar] [CrossRef]

- Reddy, J.J.; Varaprasad, B. Long–term and durability properties of xanthan gum treated dispersive soils—An eco–friendly material. Mater. Today Proc. 2021, 44, 309–314. [Google Scholar] [CrossRef]

- Reddy, J.J.; Varaprasad, B. Effect of Xanthan Gum on Internal Erosion Characteristics of Dispersive Soils—As an Ecofriendly Additive. Int. J. Eng. Adv. Technol. 2020, 29, 4716–4724. [Google Scholar]

- Li, C.; Shi, G.Y.; Wu, H.M.; Wang, C.Y.; Gao, Y. Experimental study on bio–mineralization for dispersive soil improvement based on enzyme induced calcite precipitate technology. Rock Soil Mech. 2021, 42, 333–342. [Google Scholar]

- Li, X.A.; Huang, R.Q.; Peng, J.B. Experimental research on disintegration of loess. Chin. J. Rock Mech. Eng. 2009, 28, 3207–3213. [Google Scholar]

- Wang, J.; Gu, T.; Zhang, M.; Xu, Y.; Kong, J. Experimental study of loess disintegration characteristics. Earth Surf. Proc. Land. 2019, 44, 1317–1329. [Google Scholar] [CrossRef]

- Ze, Z.; Vadim, P.; Svetlana, N.; Zhongqiong, Z.; Junjie, W. Disintegration characteristics of a cryolithogenic clay loam with different water content: Moscow covering loam (prqiii), case study. Eng. Geol. 2019, 258, 105159. [Google Scholar] [CrossRef]

- Chen, H.; Fan, H.H.; Nie, Y.; He, Z.Q. Study on water stability of clayey soil under soil–water–electrolyte systems. J. Hydroelectr. Eng. 2015, 34, 128–138. [Google Scholar]

- Yu, L.C. Preparation of Calcium Silicate (C–S–H) and the Effect on the Cement Hydration Process. Master’s Thesis, East China University of Science and Technology, Shanghai, China, 2018. [Google Scholar]

- Zhao, X.G. Synthesis of Calcium Silicate Hydrate and Its Composition, Structure and Morphology. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2010. [Google Scholar]

- Abbasi, N.; Nazifi, M.H. Assessment and modification of Sherard chemical method for evaluation of dispersion potential of soils. Geotech. Geol. Eng. 2013, 31, 337–346. [Google Scholar] [CrossRef]

- The American Society for Testing and Material. D4647–2020 Standard Test Method for Dispersive Characteristics of Clay Soil by the Pinhole Test; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Fan, H.H.; Kong, L.W. Study of Dispersive Soil; Water & Power Press: Beijing, China, 2012. [Google Scholar]

- The American Society for Testing and Material. D6572–2020 Standard Test Method for Dispersive Characteristics of Clay Soil by the Crumb Test; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Ministry of Water Resources of the People’s Republic of China. GB/T 50123-2019 Standard for Geotechnical Testing Method; China Planning Press: Beijing, China, 2019.

- Kalinkin, A.M.; Kalinkina, E.V.; Zalkind, O.A.; Makarova, T.I. Chemical interaction of calcium oxide and calcium hydroxide with CO2 during mechanical activation. Inorg. Mater. 2005, 41, 1073–1079. [Google Scholar] [CrossRef]

- Gao, G.R. The Modern Soil Science; Southeast University Press: Nanjing, China, 1990. [Google Scholar]

| Properties | Value |

|---|---|

| Specific gravity of solid particles | 2.71 |

| Liquid limit (%) | 29.9 |

| Plastic limit (%) | 18.5 |

| Plastic index | 11.4 |

| Clay percentage (%) | 35.2 |

| Slit percentage (%) | 63.5 |

| Sand percentage (%) | 1.3 |

| Soil type | CL |

| Maximum dry density (g/cm3) | 1.77 |

| Optimum moisture content (%) | 16.5 |

| Soluble salt content (g/kg) | 1.7 |

| Organic content (g/kg) | 5.3 |

| pH | 9.75 |

| Result of mud ball test | Dispersive soil |

| Result of pinhole test | Dispersive soil |

| Dispersity (%) | 77.6 |

| Exchangeable sodium percentage (%) | 24.8 |

| Soil Sample No. | C/S | Solid Dosage (%) | Nano-SiO2 Dosage (%) | CaO Dosage (%) |

|---|---|---|---|---|

| D (dispersive soil) | / | / | / | / |

| A-1 | 0.5 | 1 | / | / |

| B-1 | 1.0 | 1 | / | / |

| C-1 | 1.5 | 1 | / | / |

| A-2 | 0.5 | 2 | / | / |

| B-2 | 1.0 | 2 | / | / |

| C-2 | 1.5 | 2 | / | / |

| A-3 | 0.5 | 3 | / | / |

| B-3 | 1.0 | 3 | / | / |

| C-3 | 1.5 | 3 | / | / |

| NS-1 | / | / | 1 | / |

| NS-2 | / | / | 2 | / |

| NS-3 | / | / | 3 | / |

| NS-4 | / | / | 4 | / |

| CaO-1 | / | / | / | 0.4 |

| CaO-2 | / | / | / | 0.6 |

| CaO-3 | / | / | / | 0.8 |

| CaO-4 | / | / | / | 1.0 |

| Soil Sample No. | C/S | Solid Dosage (%) | CaO Initial Ratio (%) | SiO2 Initial Ratio (%) |

|---|---|---|---|---|

| A-1 | 0.5 | 1 | 0.32 | 0.68 |

| B-1 | 1.0 | 1 | 0.48 | 0.52 |

| C-1 | 1.5 | 1 | 0.58 | 0.42 |

| A-2 | 0.5 | 2 | 0.64 | 1.36 |

| B-2 | 1.0 | 2 | 0.97 | 1.03 |

| C-2 | 1.5 | 2 | 1.17 | 0.83 |

| A-3 | 0.5 | 3 | 0.95 | 2.05 |

| B-3 | 1.0 | 3 | 1.45 | 1.55 |

| C-3 | 1.5 | 3 | 1.75 | 1.25 |

| Mud Ball Test | Pinhole Test | Result |

|---|---|---|

| Serious reactions between soil and water and the soil–water interface was completely blurred. | Cloudy water flowed under a 50 mm head and the pinhole was enlarged to more than 1.5 times. | Dispersive (D) |

| Slight reactions between soil and water and the soil–water interface was slightly blurred. | Cloudy water flowed under a 180 mm or 380 mm head and the pinhole was enlarged. | Transitional (T) |

| No reaction between soil and water and the soil–water interface was clear. | Clear water flowed under a 1020 mm head and the pinhole was unchanged. | Non-dispersive (N) |

| Soil No. | (Solid) Dosage (%) | Pinhole Test | Mud Ball Test | Discrimination | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H (mm) | C | R (mL/s) | PD (mm) | Result | 1 d | 3 d | 7 d | Air-Dried | |||

| D | / | 50 | cloudy | 0.29 | 2.5 | D | D | D | D | D | D |

| CaO-1 | 0.4 | 50 | cloudy | 0.60 | 2.2 | D | D | D | D | D | D |

| CaO-2 | 0.6 | 180 | cloudy | 0.38 | 2.3 | T | T | T | T | T | T |

| CaO-3 | 0.8 | 1020 | clear | 1.07 | 1.0 | N | N | N | N | N | N |

| CaO-4 | 1.0 | 1020 | clear | 1.70 | 1.0 | N | N | N | N | N | N |

| NS-1 | 1.0 | 50 | cloudy | 0.23 | 2.4 | D | D | D | D | D | D |

| NS-2 | 2.0 | 50 | cloudy | 0.32 | 2.1 | D | D | D | D | D | D |

| NS-3 | 3.0 | 180 | cloudy | 0.58 | 2.1 | T | D | D | T | T | T |

| NS-4 | 4.0 | 1020 | clear | 1.48 | 1.0 | N | D | T | N | N | N |

| A-1 | 1.0 | 1020 | clear | 1.37 | 1.0 | N | D | D | T | N | N |

| B-1 | 1.0 | 1020 | clear | 1.45 | 1.0 | N | D | T | T | N | N |

| C-1 | 1.0 | 1020 | clear | 1.65 | 1.0 | N | T | N | N | N | N |

| A-2 | 2.0 | 1020 | clear | 1.53 | 1.0 | N | N | N | N | N | N |

| B-2 | 2.0 | 1020 | clear | 1.28 | 1.0 | N | N | N | N | N | N |

| C-2 | 2.0 | 1020 | clear | 1.55 | 1.0 | N | N | N | N | N | N |

| A-3 | 3.0 | 1020 | clear | 1.61 | 1.0 | N | N | N | N | N | N |

| B-3 | 3.0 | 1020 | clear | 1.77 | 1.0 | N | N | N | N | N | N |

| C-3 | 3.0 | 1020 | clear | 1.23 | 1.0 | N | N | N | N | N | N |

| Soil Sample No. | Final Disintegration Rate (%) | Final Disintegration Time (s) | Average Disintegration Velocity (%/s) | Maximum Disintegration Velocity (%/s) |

|---|---|---|---|---|

| D | 100 | 1514 | 0.06 | 0.62 |

| CaO-1 | 100 | 1820 | 0.05 | 3.81 |

| CaO-2 | 100 | 1566 | 0.06 | 0.16 |

| CaO-3 | 100 | 425 | 0.23 | 0.31 |

| CaO-4 | 100 | 393 | 0.25 | 0.31 |

| A-1 | 1.07 | / | 2.4 × 10−5 | 0.03 |

| B-1 | 100 | 1260 | 0.08 | 0.11 |

| C-1 | 100 | 1069 | 0.09 | 0.29 |

| A-2 | −1.46 | / | −3.4 × 10−5 | 0.03 |

| B-2 | 100 | 1603 | 0.06 | 0.11 |

| C-2 | 100 | 892 | 0.11 | 0.18 |

| Soil Sample No. | Particle Volume Composition (%) | ||

|---|---|---|---|

| <5 μm | 5~75 μm | >75 μm | |

| D | 9.8 | 71.1 | 19.1 |

| CaO-3 | 2.6 | 38.3 | 59.1 |

| CaO-4 | 5.5 | 43.2 | 51.3 |

| A-1 | 9.9 | 47.0 | 43.2 |

| B-1 | 9.6 | 44.5 | 45.9 |

| C-1 | 7.8 | 44.6 | 47.6 |

| A-2 | 10.4 | 40.9 | 48.7 |

| B-2 | 9.9 | 38.3 | 51.8 |

| C-2 | 8.7 | 36.4 | 54.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Tang, C.; Fan, H.; Zhu, Z.; Jiang, S.; Zhang, B. Study on the Disintegration Characteristics and Mechanism of Modified Dispersive Soil Based on the C-S-H Synthesis Principle. Sustainability 2022, 14, 14370. https://doi.org/10.3390/su142114370

Liu Y, Tang C, Fan H, Zhu Z, Jiang S, Zhang B. Study on the Disintegration Characteristics and Mechanism of Modified Dispersive Soil Based on the C-S-H Synthesis Principle. Sustainability. 2022; 14(21):14370. https://doi.org/10.3390/su142114370

Chicago/Turabian StyleLiu, Yifei, Chaoxin Tang, Henghui Fan, Zhen Zhu, Shoufang Jiang, and Bo Zhang. 2022. "Study on the Disintegration Characteristics and Mechanism of Modified Dispersive Soil Based on the C-S-H Synthesis Principle" Sustainability 14, no. 21: 14370. https://doi.org/10.3390/su142114370

APA StyleLiu, Y., Tang, C., Fan, H., Zhu, Z., Jiang, S., & Zhang, B. (2022). Study on the Disintegration Characteristics and Mechanism of Modified Dispersive Soil Based on the C-S-H Synthesis Principle. Sustainability, 14(21), 14370. https://doi.org/10.3390/su142114370