Abstract

Safety 4.0 is a new stage of safety science coincident with the development of Industry 4.0. In Safety 4.0, safety researchers and professionals attach importance to the perspective of safety information and emerging technologies in safety management, and thus promote a new concept: smart safety management (SSM). However, there are still many gaps in its fundamental theory, and there are few fundamental studies on the concept and essence of SSM. In order to fill these gaps, this paper introduces a theoretical study on the method of SSM. Firstly, in order to clarify the concept of smartness in the era of information, we elaborate the smartness performance of artificial entities and the essence of smart safety capability on the basis of analyzing the smartness performance of smart safety entities (SSEs). Then, we review the new characteristics and requirements of organizational safety management research and practice in the era of Safety 4.0; on this basis, we propose the definition and connotation of SSM in the era of Safety 4.0, and elaborate the specific content of the SSM method. Specifically, we divide SSM into four modules, safety information processing, safety action, inspiring awareness of safety and internal optimization, and thus build the content model of SSM. By expounding the contents and steps of the four modules, we further elaborate how to conduct SSM in industrial organizations. Then, we propose a SSM ecosystem for realizing sustainable safety in industrial organizations and analyze the approaches to realizing SSM in coal mine safety production. Finally, we analyze the significance of SSM in supporting sustainable safety and discuss the practical challenges that SSM may encounter in the future. The results show that SSM is a method based on safety intelligence, and it can support sustainable safety through the four aspects of comprehensive function, safety predictability, safety awareness and continuous optimalization.

1. Introduction

Safety 4.0 is a new stage of safety science coincident with the development of Industry 4.0 and the era of information [1,2]. In recent years, some data processing technologies, such as data analysis, data mining and statistical analysis based on big data, have been attached more and more importance in safety science research and activity [3,4,5]. These technologies can be used by safety researchers and practitioners (or consultants) to analyze safety issues and discover new safety laws [3,4,5]. To this end, emerging technologies especially are considered by safety consultants to build smart safety systems through which safety data processing could be technically supported. Furthermore, smart safety management and smart safety conditions for sustainable safety could also be established [6,7,8,9].

Safety management has always been an important part of organization safety practice. In recent years, many technical solutions have been proposed to improve safety management performance, and these solutions share a common feature of realizing automation and digitalization in safety management systems. Moreover, various emerging technologies such as the new generation of information technology and intelligence technology are introduced in these technical solutions, such as the safety monitoring system based on CPS (Cyber-Physical Systems) and ICT (information and communication technology) [7], a smart safety system with incorporating smart entities that can self-adjust according to real-time safety requirements in the workplace [10], and a smart warning system based on wireless sensor networks for the coal mine [11]. In these technical solutions, the safety entity systems with emerging technology are generally regarded as smart, because they generally use interconnected devices to flexibly handle risks and crises in safety workplaces, and thus to achieve smart safety management (SSM).

However, due to the lack of basic research on SSM, some fundamental issues about SSM have not been solved, such as the essence of SSM. More specifically, the smartness capability of SSM is still a vague concept, and there is a lack of methods and standards to clearly judge whether a safety entity system is smart. For example, Podgorski et al. [10] regard the smartness of the safety entity system as a kind of adaptive capability. However, Chen et al. [11] hold the opinion that the smartness of an early warning safety system is brought about by real-time sensing capability and real-time communication capability.

In organizational safety management, the safety entity system is just a part of the safety management system, and it does not conform to scientific logic or common sense to regard the capability for smartness of a part as a capability of the overall system. Therefore, the existing technical solution is strictly a technical method to build smart entity system, rather than a method to achieve SSM in industrial organizations.

For the above reasons, we mainly focus on the essence and connotation of SSM and discuss the method of realizing SSM in the background of Safety 4.0 in this paper. Our contribution mainly includes four aspects. The essence and specific performance of artificial smart entities and smart safety entities under the technical background are elaborated in Section 2; then, based on the status and purpose of organizational safety management in the era of Safety 4.0, the essence and connotation of SSM are analyzed and the content of the SSM method is discussed in Section 3. In Section 4, four aspects and specific contents of SSM method are described. On this basis, we furtherly propose a SSM ecosystem for industrial organization and elaborate how to conduct SSM to realize sustainable safety in the era of Safety 4.0; finally, the benefits of SSM to sustainable safety are discussed and the practical challenges of applying SSM are elaborated in Section 5. The conclusions and our future work are given in Section 6.

2. Artificial Smart Entity and Smart Safety

The safety management system has always been a systematic method for conducting safety management. Therefore, as a part of safety management systems, smart safety entity (SSE) systems are a necessary systematic tool to achieve SSM. Furthermore, SSE system supports the realizing of smart safety capability of safety management system, and its smart safety performance is one of the important preconditions for naming a kind of safety management method as a smart one. In this Section, we analyze the essence of smart safety capability. To this end, we first discuss the essence of artificial smartness in the technical background. Secondly, by reviewing the construction method of smart safety systems, we clarify the source and specific performance of smart safety capability, and further identify the essence of smart safety capability.

2.1. Artificial Smartness in the Era of Information

Smart-X has become a ubiquitous term which is frequently used in almost all media such as newspapers and websites [12]. In recent years, Smart-X has also attracted the interest of researchers and practitioners of traditional fields, which promotes the emergence of many research themes on Smart-X, such as the smart city [13], smart factory [1,14,15], smart community [16] and smart regulation [17]. In these studies, the functional entities are created based on emerging technologies that form the basic aspects of realizing smartness. For example, the self-organized system of the smart factory is built based on AI [15], the home networking system of the smart community is built based on the virtual machines [16] and the real-time monitoring system of smart regulation is built based on CPS [17].

Therefore, in the research and practice of Smart-X, artificial smart entities are devices or components created through technical measures, which together constitute a functional entity system and participate in the realization of the system’s smartness capabilities. Here, we adopt the definition of smartness proposed by Alter [18].

Purposefully designed entity X is smart to the extent to which it performs and controls functions that attempt to produce useful results through activities that apply automated capabilities and other physical, informational, technical, and intellectual resources for processing information, interpreting information, and/or learning from information that may or may not be specified by its designers.

Based on this definition, the smartness of artificial entities is a kind of artificial smartness and exists as a product of human smartness. On the one hand, artificial entities are purposefully designed and created to automatically perform preset tasks. Therefore, artificial entities can replace workers in some simple and repetitive work, and have anthropomorphic smartness. For example, smart industrial robots in manufacturing can determine the best operation and perform specific tasks based on the context and their experience of the past [19]. Based on the definition proposed by Alter [18], the information processing capability of artificial entities is another basic aspect of smartness capability. Specifically, artificial entities can conduct information collecting, information cleaning, information processing and information analysis through automatic technology, perception technology and information processing technology; then, they can learn and obtain available knowledge from information processing and perform tasks according to the results of the information processing and learning. In a word, artificial smartness is a kind of action ability of artificial entities which are created by technical means (such as information technology and automatic technology), and smartness includes two basic aspects: automation and information processing.

For a long time, seeing, thinking and acting have been recognized as the three elements of smartness of smart machines [19]. For example, “see-think-act” has become the principle of designing and creating smart industrial robots (essentially a kind of smart machine) [19]. From the perspective of philosophy, a machine is a kind of entity. Therefore, if we review the concept of a smart entity proposed by Alter [18] according to the principle of “see-think-act”, this principle should be applicable to the design and creation of all artificial smart entities. In other words, all artificial entities with automation and information processing capabilities can see, think and act. To be more specific: (i) an artificial smart entity has the ability of perception (the ability to see). Artificial smart entities can collect, understand and interpret information. (ii) an artificial smart entity has the ability to learn from information (the ability to think). In other words, artificial smart entities can learn from information and the interpretation of results, and discover useful information and knowledge. (iii) an artificial smart entity has the ability of automatic action and adaptive ability (action ability), so artificial smart entities can automatically perform preset tasks based on useful information and knowledge.

2.2. The Smartness Performance of Smart Safety Entity

It is worth noting that information technology and intelligence technology have al-ways been introduced with the aim of realizing smartness in research focused on smart safety. New technologies are used for building smart safety entity systems and for the promotion of various methods of building smart safety systems. Therefore, reviewing the smartness performance of SSE is a precondition of understanding the essence of smart safety capability. With regard to this, we review some typical research and practical cases related to SSM such as the fundamental research, technical solutions, and research on cases. In these papers, SSEs form the core of smart safety systems. The themes of these papers include but are not limited to smart safety management, smart safety systems, intelligent safety systems, smart early warning, smart safety evaluation, smart safety prediction, and smart risk management. Following the principle of “see-think-act”, after a systematic review, we find that SSE not only has the basic capability of seeing, thinking and acting, but also has the attributes of tools and conditions. Based on this, we divide the smartness capability of SSE into five aspects:

(a) SSE has the capability of seeing, i.e., perception. Various safety sensors and perception devices are interconnected, communicate with each other and promote safety information sharing [20]. Through these approaches, SSE has the ability of real-time perception, i.e., seeing. This capability helps SSE to collect and grasp safety information in the organization and understand the real-time organizational safety status.

(b) SSE has the ability to think. Its thinking ability is reflected in that SSE can determine the best safety solutions and the safest course of action, and acquire new safety knowledge in this process. In addition, safety information is used as a basic resource in safety management. There are several forms of safety information, such as safety data, safety information, safety knowledge (or safety experience) and safety intelligence, and different forms of safety information could be used in different safety management stages and different safety tasks. We provide two examples. One example is the application of safety data. A safety database which is used for recording a system’s safety state and dynamic state could also be used for analyzing the safety laws of system dynamics and discovering risks and hazards in the safety system [21,22]. The other example is the application of safety intelligence. Safety intelligence is obtained by safety information processing [1], and it could be used in many safety activities such as safety decision making and safety plan making [23].

(c) SSE has the ability of action. Some key words such as information sharing, resource sharing and safety accuracy are considered in the capability of SSE, such as real-time safety perception [11], accurate safety perception [8], information-based safety decision making [24] and flexible and effective safety action [13,14,15,25]. In the design of SSE in recent years, action capabilities also include adaptability and self-regulation capabilities. These capabilities enable SSE to consider the constraints of specific safety scenarios and determine the best available action according to the history of safety decisions and real-time safety information, and to flexibly adjust action according to changes in safety scenarios and safety requirements, thus it can complete the given safety tasks in an effective and successful way.

(d) SSE has the attribute of tools. In order to improve performance and capabilities of safety management system, emerging technologies such the new generation of information technology [26], automatic technologies [13,14,24] and intelligence technologies [15] are used in creating SSE or building SSE systems. Both SSE and SSE systems are used as important components of safety management systems and as tools for safety management work, thus helping to improve safety management performance and safety management ability.

(e) SSE has the attribute of conditions. SSE can participate in creating smart safety conditions, including promoting multi-level cooperation and safety information sharing, safety resource sharing and building a safety idea bank for safety organizations. Smart safety conditions can also bring benefits to the use and further optimization of SSE. Therefore, smart safety entities and smart safety conditions are interdependent and mutually reinforcing. For example, SSE could be used in analyzing the risk preference of every worker in the organization and thus build the risk picture of the organization [13], which could be taken as a context of SSE action, promoting full participation and encouraging safety practitioners to cooperate with each other. The sharing of safety experience could promote good safety culture in the organization, and safety experience could be used as safety knowledge for SSE action [14].

In summary, as a kind of artificial smart entity and on the basis of automation ability and information processing ability, the smartness ability of SSE includes five aspects: seeing, thinking, acting, forming tools and promoting conditions. These five aspects are connected and integrated to form a comprehensive performance of smart safety capabilities in the technical background. Following the sequence of “see-think-act-form tools-create conditions”, smart safety practices in the safety management system are closely related to safety information, including safety information perception, safety information processing and learning, information-based safety action, creating safety tools, promoting security conditions; this ultimately promotes the high performance and excellent capabilities of safety management systems, such as predictability, prevention ability, accuracy, automation, resilience and customizability.

3. Safety 4.0 and SSM

SSE and SSM are both new concepts that emerged in the stage of Safety 4.0. Based on the above, SSEs are interconnected to form an SSE system, but an SSE system is only a part of a greater safety management system. Therefore, although the essence and content of smart safety capability have been proposed, it is not enough to understand the essence of SSM and the method of SSM. Therefore, we elaborate the background of safety management development from a broader perspective in this section; that is, to clarify the needs and objectives of organizational safety management in the era of Safety 4.0 and further analyze and discuss the methods to achieve smart safety management in the industrial organization, so as to clarify and understand the essence of SSM.

3.1. Organizational Safety Management in the Era of Safety 4.0

Safety 4.0 is a new stage of safety science in the age of information and big data [27], and Safety 4.0 could be seen as a corresponding concept to Industry 4.0 from the perspective of safety deriving from industry. Therefore, the development of Safety 4.0 is inevitably closely related to the development of information technology. However, technological progress is often seen as a double-edged sword in the development of Safety 4.0. On the one hand, information technology is widely used to strengthen the connection between man-made systems, which promotes complex safety problems, giant system safety problems and even globalization safety problems. On the other hand, information technology provides new technical support for dealing with safety problems. Affected by technological progress, new safety science theories have emerged in safety science research, such as safety information theory and safety intelligence theory.

Organizational safety management has always been an important theme of safety science research and practice. In organizational safety management, the double-edged sword effect of information technology appears in a more profound and detailed way. We elaborate the effects of technology to organization safety management from four aspects: safety management elements, safety management methods, basic safety resources and organizational safety problems:

(a) safety system informatization and the progress of safety information processing have been greatly promoted by the development of the methods of information-based safety management [2,27]. Moreover, these kinds of safety management methods have been accorded more and more importance by safety management research and practice [28].

(b) organizational safety system issues have become more and more open, which promotes further expansion of the category of organizational safety problems. To be more specific, industrial organizations are threatened by safety and security risks [29], so the safety problems of industrial organizations are safety and security problems in the era of Safety 4.0.

(c) the term safety information displays the system’s safety state and its dynamic state [27], and many safety elements, such as safety substance, safety energy, and safety and security problems, could be expressed in the form of safety information [30,31]. Therefore, more and more safety researchers have admitted the importance of safety information in studying safety issues and have regarded it as one of the core safety elements of organizational safety systems [27].

(d) the development of system informatization has brought a large number of safety information resources. Thus, using safety information resources to achieve safety improvement has become an essential subject in organizational safety practice. To this end, based on the information technology and intelligence technology, some safety information-based methods have been proposed and applied in organizational safety management, such as safety management information system, safety support system for safety decision, the method of safety virtual reality, evidence-based safety management methods, the method of accident pattern recognition and the method of computer-aided safety management [32].

In short, organizational safety management in the era of Safety 4.0 is developing towards information-based safety management. Moreover, because safety information displays the safety state and dynamic state of the safety system, safety management is a process in which the safety practitioner obtains, understands, and analyzes safety information pertaining to the safety system and uses the analysis results to control safety factors, thus controlling the system’s safety state within a safe range. In this process, every stage in safety information processing, such as the safety information input, storage, analysis, output and feedback, is perfectly integrated with the safety management process. In other words, safety activities of the safety system are driven by safety information communication among safety factors of the system. Therefore, through the analyzing of safety information processing in the safety system, safety practitioners could grasp new safety knowledge such as the real function of safety factors, the relationships among safety factors, the safety laws of safety systems, and thus conduct correct safety strategies. As a result, whether based on the trend of organizational safety management research and practice or the new understanding of safety management, the core elements of organizational safety management must contain safety information, and information-based safety management can also promote a variety of new safety management methods in Safety 4.0 and the information age.

3.2. Essence of SSM in the Era of Safety 4.0

From the perspective of term, SSM belongs to the category of Smart-X. Therefore, the essence of SSM is also a form of technology application, and it is also a new organizational safety management method in the information age and Safety 4.0. In this method, SSEs become the basic tools of management practice. A large number of SSEs are connected to each other and form a smart safety entity system, thus becoming a smart module and an important component of the organizational safety management system. Therefore, the smart capability of smart safety entities is the basis for safety practice in safety management, and supports the realization of partly smart to systematic smart components in the safety management system. Furthermore, the SSM method includes methods of creating SSEs and is committed to applying SSEs to each safety management work.

In the era of Safety 4.0, the application of information technology and the smartness capabilities of smart safety entities (closely related to safety information) constitute the technical basis and capability basis of smart safety management. Therefore, safety information is undoubtedly the basic element of SSM. In the application of SSEs, the implementation of safety actions is based on the results of thinking, that is, the results of safety information processing and analysis. Therefore, the basis of various safety actions in smart safety management is not raw safety information but valuable safety information (generally called safety intelligence) obtained through safety information processing.

Based on the above, we regard SSM as a method of safety management based on safety intelligence. It uses the purposefully designed smart safety entities as the essential tools to process, interpret, and learn from safety information and use basic safety resources conveniently, lawfully, and reasonably. Based on this, it performs useful results from safety information processing in a connected, cooperated, and negotiated way, and finally, it keeps the safety state in an acceptable range.

Specific aspects of the definition should be noted:

‘Purposefully designed smart safety entities.’ Smart safety entity (SSE) works as a necessary tool in the process of SSM. SSM could be a smart safety device such as safety robot, or it could be a safety system or a safety information platform with a specific function, such as safety evaluation information system, safety prediction system or safety smart analysis system. To this end, SSE should be designed and created with the automatic capability of performing safety management activities, such as safety perception, safety recognition, safety communication and safety action.

‘Process, interpret, and learn from safety information.’ In the process of SSM, the value of safety information is in the basic function of safety information in safety management, and the parts of safety information processing such as safety information analysis, interpretation, learning, are integrated with every part of safety management such as safety prediction, safety decision, safety action and safety regulation [33]. Specifically speaking, the process of safety information analysis includes acquisition, transmission, cleaning, storage, and visualization of safety information. Furthermore, interpreting safety information is defined as the process of understanding and concluding safety information, including data representation, data simulation, data modeling, context processing and semantic analysis [3]. In addition, learning from safety information is a process of discovering knowledge from safety information [30], including mining safety laws and discovering new safety knowledge.

‘Use basic safety resources conveniently, lawfully, and reasonably.’ Before the establishment of basic safety resources and promoting safety resources sharing, it is necessary for the organization to build a standard and open platform for sharing safety resources and various matched approaches for sharing such resources. Moreover, there is no doubt that the establishment of a safety resource sharing system is a long-term project; thus, the multi-level cooperation of safety practitioners is indispensable. To this end, the method of building various safety systems and regulations is viable, such as the safety regulation of full participation, reward and punishment, safety training and education. Some soft means could also be considered, such as building a safety culture of sharing safety resources. Furthermore, in terms of security issues of safety information especially security issues related to privacy and legality, laws are required to build legal restraint and power for the accumulation, sharing and application of safety resources, and standards are also required to ensure the scientific characteristic and validity of safety works.

‘Performs useful results from safety information processing in a connected, cooperated, and negotiated way.’ SSE is not only an action tool, but also a tool for safety information processing and communication. On this basis, safety practitioners and smart safety entities conduct safety management activities based on the results of safety information processing. Furthermore, safety practitioners cooperate with each other and with smart safety entities to conduct safety management through various approaches, such as safety information communication, cooperating with each other in safety action and performing safety negotiation before safety decision-making and safety planning.

‘Keeps the safety state in an acceptable range.’ Safety is freedom from unacceptable consequences [33]. Therefore, SSM is a process or a series of activities to realize safety, and its ultimate purpose is to protect people’s physical health, mental health, and property from damage, as well as to protect the expected realization of target functions, just as general safety methods do [34].

3.3. Content of SSM

In the age of information which emphasizes resource sharing and the internet of things, safety management systems should be semi-open, not only because safety system state is affected by safety factors from inside and outside the system, but also because safety resources inside and outside could be used in safety management.

Specifically, the environment in which the production organization is located constitutes the external environment of the organizational safety management system, which makes the operation of such systems subject to the constraints and influences of the external environment, such as the impacts of technological change and safety policies. In addition, because the internal environment of the industrial organization and the external environment always maintain the flow of personnel, economy, material and energy, there are many links between the organizational safety management system and the external environment, such as safety material flow, safety people flow, safety energy flow, safety information flow and safety knowledge flow.

The basic safety resources inside and outside could be divided into four aspects: (i) physical safety resources are all safety substances with entities, such as safety equipment, safety materials and safety management funds; (ii) technical safety resources are the technologies and strategies that can be used to implement safety management and optimize safety management performance, such as specific safety technology, specific safety management methods, information technologies and smart technologies; (iii) Safety information resources are the safety data, safety information and safety smart elements generated in various safety activities, such as daily safety management records, accident records, real-time safety information, safety laws and safety regulations; (iv) Safety intellect resources are an important aspect of affecting the smartness ability of SSM. Safety intellect resources consists of safety professionals, safety practitioners and safety entities with smart safety capabilities.

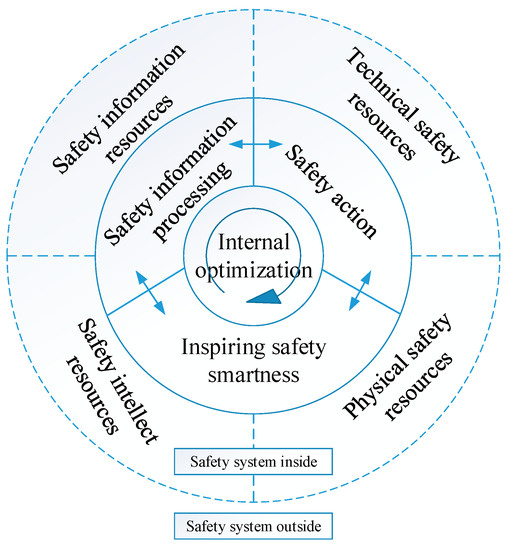

As we have discussed on the above, based on automation and information processing, smart safety entities have five aspects of smart safety performance: safety information perception, safety information processing and analysis, safety actions based on safety information, safety tool creation, and promoting safety conditions. From the perspective of organizational safety management process, safety information perception and safety information processing and analysis actually belong to safety information processing. Therefore, the five aspects of smartness can be summarized into four aspects, including safety information processing, safety action, inspiring safety smartness and internal optimization, thus forming the main content of smart safety management. Based on this and the four aspects of safety resources, we build the content model of SSM, as shown in Figure 1.

Figure 1.

Content model of SSM.

We elaborate the four parts of SSM: (i) safety information processing is a process based on safety information collection, transmission, and processing. Safety information processing aims to provide useful safety information for the other parts. (ii) Safety action is the process in which safety practitioners and SSEs perform useful results of safety information processing. The results of every safety action should be recorded and studied to accumulate safety knowledge and experience. (iii) Inspiring safety smartness is a process of acquiring safety knowledge and safety smartness capability from safety information processing and safety action. Safety knowledge and experience can be used for safety education and training, and can also be used in safety management for the generation of new safety knowledge and new SSEs. (iv) Internal optimization is the process of adjusting and optimizing smartness capability and safety system structure. Internal optimization also undertakes the task of promoting smart safety conditions. Its purpose is to ensure that SSM systems can consistently accomplish safety tasks over time, especially when complex safety problems are emerging and the safety environment is changing dynamically.

4. Process and Content of SSM

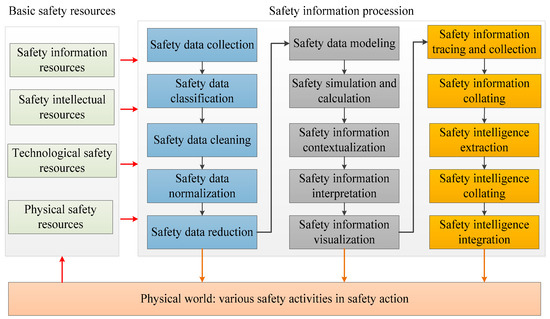

4.1. Process of Safety Information Processing

In the process of SSM, safety information processing is based on basic safety resources, while the source of safety information and the extent of safety information processing are determined according to safety tasks and safety requirements. For example, the raw safety information (or safety data) comes from workplaces such as safety sensor networks and real-time safety action feedback [3]. Although safety data is the raw form of safety information and sometimes contains information noise, it is valued by emergence management for its strong real-time and indicative nature. According to the evolution law of safety information [30], safety information processing follows the sequence of safety data, safety information, and safety smart elements. On this basis, we divide safety information processing into three stages: first safety data processing, then safety information analysis, and finally safety smart analysis. The content of safety information processing is shown in Figure 2.

Figure 2.

Content of safety information processing.

We would like to elaborate the process according to the stages of safety information processing:

First, safety data which is well-organized and clear could be better understood by safety practitioners and help them to quickly understand the safety state of the system. Therefore, safety data processing consists of safety data collecting, classifying, cleaning, standardizing, and simplifying. The purpose of this stage is to obtain real-time and valuable safety data to meet the requirement of some emergency tasks, such as real-time safety tasks and emergence management.

Second, safety information is essentially a kind of safety data that people can understand [20]. Therefore, safety information analysis is a process of understanding safety data. The process consists of five steps: (i) safety data modeling; (ii) safety contextualization; (iii) safety simulation and calculation; (iv) safety information interpretation; (v) safety information visualization. Furthermore, safety information analysis aims to help safety practitioners understand safety states and master safety dynamics as comprehensively as possible to understand safety problems and appropriate actions.

Third, safety smart is a kind of valuable safety information. In other words, safety smart is a kind of safety information which is able to affect safety decision-making and can only be obtained by safety information processing. Moreover, safety smart can only be used for a specific safety task, which means that it is necessary for safety practitioners to use safety smart in the matching safety tasks. For these reasons, safety smart analysis is suitable for safety decisions that must consider multiple factors, such as making safety plans. To be more specific, safety smart analysis is a process of sorting out safety smart from safety information groups and producing safety smart products. This process consists of five steps: (i) safety information tracing and collection; (ii) safety information collation; (iii) safety smart extraction; (iv) safety smart collation; (v) safety smart integration.

In addition, we would like to explain the difference between safety smart and safety smart products. Safety smart for a specific safety task could be a sentence of words or a group of safety data obtained through safety data processing or safety information analysis; it has value only for a specific task and in a given period of time. Safety smart products are obtained though the processing of safety smart based on safety knowledge, and it could be a report or a series of analysis papers. Therefore, safety smart products have the attributes of smart products and knowledge products, and have relatively long-term availability compared with safety smart.

4.2. Process and Content of Safety Action

Safety actions are implemented by the cooperation and communication of safety practitioners with SSEs, and safety actions are also implemented through the whole life cycle and the whole process of safety management. Therefore, according to the general process of safety management, safety actions are divided into safety actions focusing on risk, safety actions for controlling incidents and accidents, and safety actions for accident post-processing. Moreover, different tasks have different means of acquiring safety information.

To be more specific: (i) the main tasks of safety actions focusing on risks are eliminating risks and preventing risk development. To this end, according to the principles of advanced prevention, precise control, and intrinsic safety, safety actions focusing on risks consists of four aspects including safety anomaly elimination, risk control, risk elimination and risk reviewing. The safety anomaly elimination requires safety sensing information that can reflect real-time safety status. Risk control requires risk identification information to indicate the risk objectives that need to be suppressed. Risk elimination requires risk assessment information to help determine the risk elimination method and plan. Risk reviewing requires risk status information to review whether the risk level in the organization is acceptable. (ii) When an incident or accident occurs, safety actions should be carried out based on the principle of safety first, regardless of whether any loss has occurred. Therefore, safety actions for controlling incidents and accidents should include emergency warnings, emergency control and emergency rescue. The emergency warning is based on crisis state information, because this information indicates the type and state of the crisis and emergency control needs crisis assessment information to determine a safety control method, while emergency rescue needs emergency rescue information to determine the emergency rescue plan. (iii) Safety actions for accident post-processing are implemented to prevent derived accidents and restore a state of safety. To this end, these kinds of safety actions consist of safety checks after incidents and accidents, restoration, and safety reinforcement. Safety checks after incidents and accidents require real-time safety information to understand the current safety status of the accident site. Restoration requires safety loss information to create statistics and determine the repair plan. Safety reinforcement is intended to develop the organization’s safety optimization plan and implement the safety optimization strategy based on the comprehensive information of the accident report.

Furthermore, we propose a model of safety action in order to show its process and various types of safety information applied in every stage of safety action, as shown in Figure 3. Table 1 shows the content of every type of safety information applied in safety action.

Figure 3.

Process of safety action.

Table 1.

The contents of safety information in safety actions.

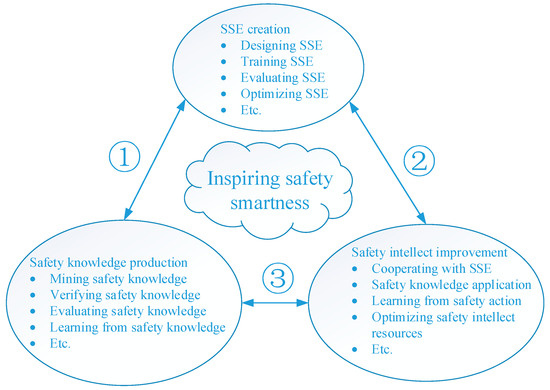

4.3. Inspiring Safety Smartness

From the perspective of capability, safety smartness is a collection of safety capabilities based on the smartness capability of SSE and human intelligence, such as the cognition ability of safety practitioners for safety objects, the ability to predict safety events, and the ability to develop safety laws. Moreover, technical smartness is generated from the application of SSEs, and their automatic capability and safety information processing capability promote the technical smartness of SSEs. Therefore, the process of inspiring safety smartness consists of three aspects.

The first aspect is to improve the safety smartness of safety practitioners. This aspect not only includes some traditional safety activities, such as safety knowledge education and safety skill training, but also includes the activities for forming smart scenarios, such as enhancing the understanding safety practitioners on SSEs and establishing channels for cooperation between safety practitioners and SSEs.

The second one is the creation of SSEs. SSEs should have at least one smartness capability, such as safety perception, safety information processing and analysis and safety action. Furthermore, SSE should undergo sufficient capability testing and effect evaluation before being put to use. The creation of SSE is an engineering technology issue, and we will not conduct in-depth research on it in this paper.

The third aspect is the production of safety knowledge because the accumulation of safety knowledge is a premise condition for inspiring safety smartness. Specifically, safety knowledge can not only be applied to safety education and safety training, but can also be used to create SSEs such as mathematical formulas for designing safety programs.

We have built a content model of inspiring safety smartness to show the specific contents of this aspect, shown in Figure 4.

Figure 4.

Content of inspiring safety smartness.

In addition, the relationships among the three aspects need to be illustrated: ① SSE creation provides tools for safety knowledge production, such as the safety smart mining system and the safety simulation system. Correspondingly, safety knowledge production provides a knowledge base to support and guide the creation of SSEs. ② SSE creation provides tools for improving the safety smartness of safety practitioners. Specifically, safety practitioners use SSEs as aid tools in safety management and thus gain safety experience (or safety knowledge) in safety practice. Correspondingly, safety practitioners can participate in SSE creation and their safety knowledge and safety requirements could be considered by designers and engineers of SSE. ③ Safety knowledge production provides safety smart products and safety knowledge products to help improve safety smartness. Correspondingly, safety practitioners can participate in the safety knowledge production by sharing knowledge, while their practical safety knowledge is useful for testing the scientificity and availability of new safety knowledge.

4.4. Content of Internal Optimization

The main purpose of internal optimization is to review and optimize the performance of SSM systems. On the one hand, the SSM system is a system composed of multiple elements, and its smartness ability is generated from the mutual effort and interaction of various elements. Therefore, the main task of internal optimization is to improve the cooperation of safety practitioners and SSEs. On the other hand, SSE systems also have some safety service functions, such as safety information services, safety smart services, safety knowledge services and safety decision services. Therefore, all basic elements of a typical service system should be considered in internal optimization, such as interoperability, availability, convenience, runtime monitoring, transaction services, principles and standards [35]. Based on the above, we listed the main contents of internal optimization, as shown in Table 2.

Table 2.

Main contents of internal optimization.

5. Significance and Challenges of SSM

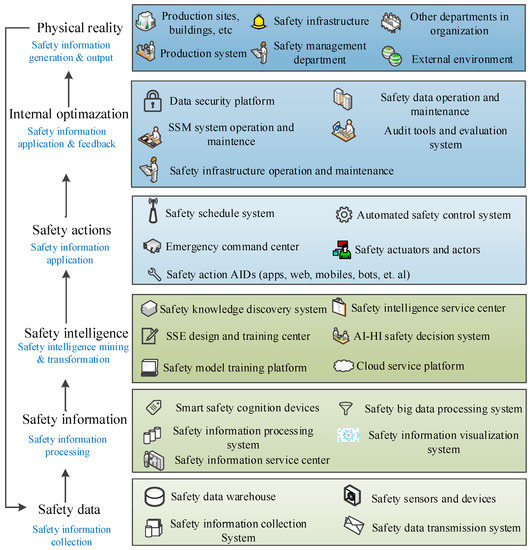

5.1. Framework of a SSM Ecosystem

In the process of SSM, every safety activity is related to safety information and safety information constitutes the basis of an SSM system. In order to realize sustainable security in an organizational safety management system, a stable safety information ecology is necessary. Based on the information ecology theory [36], an SSM ecosystem which can operate continuously and stably must have some basic characteristics of a typical information ecosystem, such as unblocked information channels, rapid information flow, accurate information transformation, and equal information input and output. Therefore, from the perspective of safety information flow, we built an SSM ecosystem of an industrial organization, in which we demonstrated some smart systems or platforms composed by SSEs corresponding to each process of safety information flow. As shown in Figure 5.

Figure 5.

Model of SSM ecosystem.

Based on the contents of SSM and the theory of safety information flow, we divided the SSM ecosystem into six layers as follows:

(a) Safety data layer. This layer performs safety information collection by using a safety information collection system (which is comprised by safety sensors and devices, usable apps, platforms and mobile devices, etc.) to collect safety data and information from physical reality; this layer also includes the storage and transmission of safety information.

(b) Safety information layer. This layer performs safety information processing. Details of risks and hazards can be identified by smart safety cognition devices, and structured safety data can be transformed into nonstructured safety information by a safety information processing system or safety big data processing system; thus, safety information can be visualized to make it more comprehensible for safety actors. A safety information service center provides safety information to safety actors based on their safety demands, safety behavior characteristics, safety psychology characteristics, etc.

(c) Safety intelligence layer. This layer performs safety intelligence mining and transformation by the cooperation of safety actors, SSEs, and technical aids. Concrete tasks include safety knowledge discovery, safety intelligence service, SSE design and training, safety model training, safety decision making, a cloud service (cloud service platforms provide cloud services with safety intelligence products, safety knowledge products, safety management assistance and others), etc.

(d) Safety actions layer. This layer performs safety information application, which includes various safety actions implemented by safety actors and various smart systems, such as safety schedule system, automated safety control system and safety action aids. In the future, with the iteration of SSEs, safety information application may also include safety actions dominated by SSEs.

(e) Internal optimization layer. In this layer, based on the audit and evaluation results, safety professionals maintain the operation of SSM system and the storage and application of safety data. Specifically, concrete tasks also include the integration and optimization of safety resources, the upgrade, migration, expansion, installation and deployment of SSEs, configuration change of networks, diagnosis and troubleshooting of system operation, as well as the data security of SSM ecosystem.

(f) Physical reality layer. In this layer, new safety information is generated from feedback after safety actions in the production sites, safety infrastructure, safety management department and other departments of the organization. Further, new safety information outputs from physical reality are collected by safety data layer. Thus, a loop of safety information flow is completed.

5.2. Realizaing SSM in Coal Mine Safety Production Organization

In coal mine safety production, the mine is not only the resource of production, but also the working environment of production organization. In order to improve the visualization of mine safety status information, coal mine spatial safety data have become the most important data resource in coal mine safety management. Therefore, information technology (especially GIS technology) has been widely used in building mine safety information system, and further promotes the popularity of mine GIS safety systems in mine safety management and even in China’s land and resources management.

In China, because the mine space safety information system usually displays the real-time safety data of the corresponding safety business in the modules and nodes on the 2D and 3D maps, the mine GIS safety system is also called the “One Map” system [37]. The “One Map” system has the recognized advantages of low construction cost and diverse functions, so it has been widely used in China’s coal industry.

Generally speaking, mine safety production includes many businesses and processes such as geological safety, mining safety, machinery safety, transportation safety, ventilation safety, etc. [38] Therefore, mine GIS safety system works based on sensor networks and monitoring systems to monitor various safety production businesses and processes and record real-time safety data. After the completion of safety data processing, the data and data processing results are automatically displayed through data visualization technology so that safety managers can quickly obtain the safety information they need. Therefore, the mine GIS safety system is a smart safety entity system for mine safety management. Its smart safety capabilities mainly include safety perception and safety information processing capabilities.

There is no doubt that a mine GIS safety system is necessary for realizing SSM in mine safety production. The wide use of mine GIS safety systems has proven the feasibility of realizing comprehensive safety perception and safety status information visualization in mine safety production. However, the existing mine GIS safety system lacks the capability of knowledge learning and intelligence analysis, which makes it lack smart safety capabilities in the safety management process except for safety information collection and safety information processing in the process of mine safety management.

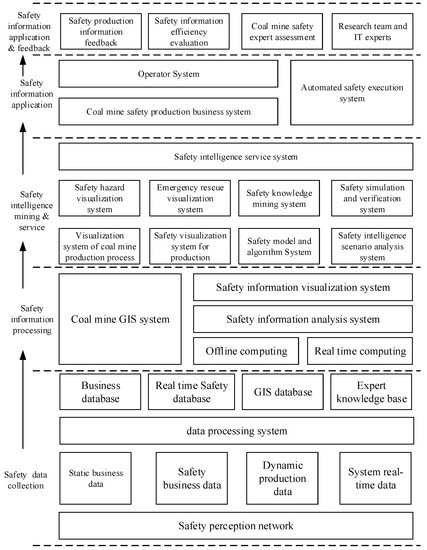

Considering that the mine GIS safety system has been widely used in mine safety production, it is a low-cost and realizable method to transform and optimize the mine GIS safety system to realize the smart mine safety management. According to the main contents of SSM, we have built a smart mine safety management system with comprehensive smart safety capability on the basis of the mine GIS system. The functions and construction methods of smart mine safety management system are shown in Table 3. The model of smart mine safety management system is shown in Figure 6.

Table 3.

Main approaches and functions of coal mine SSM system.

Figure 6.

Model of coal mine SSM system.

5.3. Significance of SSM in Promoting Sustainable Safety

Minimizing latent errors from behavior and technology is an important aspect of sustainability [39]. There are many kinds of latent errors in the safety system, such as the dangerous actions of safety practitioners, psychological precursors of dangerous actions and failures of safety components [38,40,41]. To avoid these latent errors, some traditional safety methods are still being used, such as safety decision making based on experience and safety management based on safety technology. There is no doubt that traditional safety methods are useful on specific occasions, but the misuse of these methods could promote accidents. We provide three examples: when safety decision making only relies on subjective intuition and safety experience rather than objective fact, it may lead to wrong safety decisions and result in dangerous actions; the errors and failures of safety devices may lead to a more serious problems in the case of using only safety technology to conduct safety management; the safety management method which takes human as the core has exposed more unsafe human factors such as low safety awareness, wrong safety attitude, and job burnout [35].

From the perspective of safety information, errors come from safety information distortion, safety information gaps, and cognitive errors [12,13,40]. In other words, errors come from a lack of safety intelligence. For example, dangerous actions of a safety practitioner may result from his misjudgment of a safety state (wrong safety cognition) and the failure of safety equipment may be due to some previous problems which had not been found by workers (safety information gap). In SSM, real-time safety perception ensures the correctness and integrity of the original safety information, and provides safety practitioners with safety intelligence and safety knowledge they need. In this way, safety practitioners could not only obtain all correct safety information they need, they could also make wise safety decision and perform safety actions.

In addition, SSM does not deny the effectiveness of traditional safety methods in safety management; instead, it attaches importance to the flexible use of traditional safety methods in safety management. Furthermore, it is committed to taking full advantage of safety information in the whole process of safety management through emerging technical measures and promoting cooperation and communication between SSEs and safety practitioners. In other words, it aims to provide a safety occasion for safety practitioners to show human safety smartness and SSE to express technical smartness.

To sum up, SSM is conducive to achieving sustainable safety from four aspects:

- (1)

- SSM has comprehensive functions. SSM encourages ubiquitous information connection, general human–machine cooperation, real-time decision-making consultation, continuous information flow and feedback in the organization, thus maximizing the advantages of each safety elements to achieve automatic task performance and sustainable safety. Moreover, SSE is composed of several functional safety components, and it can have automatic performance in multiple tasks.

- (2)

- SSM supports safety prediction. In the process of SSM, all safety actions are based on the results of safety information processing. SSM systems collect original safety information from all aspects and the whole process of safety management, including all safety information before, during and after the event. Safety prediction and advance prevention are conducted based on real-time safety information.

- (3)

- SSM supports safety state awareness. In SSM, safety information is shared and used as a basic resource. On this basis, the SSM system is a comprehensive and integrated system composed of interconnected SSEs and safety practitioners. SSEs can provide real-time safety information to safety practitioners, help them to understand the real-time safety state and make wise safety decisions. Safety practitioners can give feedback on behavior results to help SSEs optimize their functions

- (4)

- SSM supports the continuous improvement of safety smartness. The development of emerging technologies, as well as the internal optimization of SM systems, are conducive to the improvement of the smartness capability of SSM systems and thus realize a more intelligent safety management paradigm, featuring higher digitization, more unmanned elements, high automation and high autonomy. To be more specific and to look forward to the future, various SSEs are enabled in the safety management system in a more intelligent safety management paradigm, such as safety sensors, safety actuators, computing devices. Each safety element is related to each other, shares basic safety resources in the organization and performs information processing to support safety actions.

5.4. Challenges of Promoting SSM

When an SSM system is introduced in safety practices, practical experience and performance evaluation are crucial. However, the existing practice of SSM is still lacking, and most SSEs are used as additional tools in safety management. Moreover, we cannot accurately predict specific effects or performance of SSE. Therefore, it must be clear that SSM is a theoretical concept and could be realized gradually with the development of technology and the application of safety information theory, and necessary caution is needed to prevent new technical safety problems. We would like to discuss some challenges and possible solutions in promoting SSM.

Development and use of SSEs. The development of SSEs involves the use of multiple disciplinary knowledge and expertise. For example, developing a high-altitude danger warning system involves the use of ultra-wideband technology, sensing technology, virtual fence logic, and algorithm optimization. Therefore, technological barriers can be resolved through active cross-disciplinary cooperation. In addition, it should be considered to develop a manual intervention mechanism and monitor the operation status and history of SSEs to prevent the failure or error of SSEs.

Safety information service. The wide use of information technology would bring a large number of safety information resources, so it should be clear what kind of safety information is needed in safety practice, how to express the safety information, and how to use it. Some approaches may be helpful, such as mapping individual risk preferences and identifying all types of safety information that might be required for specific safety tasks.

Smart safety decision-making and negotiation mechanism. In order to establish a negotiation mechanism between SSEs and safety practitioners, SSEs should have a certain degree of autonomy. That means not all SSEs can only accept and follow instructions, and some of them can make their own decisions. Therefore, the roles of SSEs and safety practitioners should be flexibly arranged according to their capabilities. The establishment and operation of negotiation mechanism also require trust of safety practitioners in SSEs. Their trust may come from the high accuracy, stability, and efficiency brought by SSEs, or come from safety practitioners’ understanding of the working principle, logical principle, system structure, advantages, and disadvantages of SSEs. To this end, in addition to ensuring sufficient capabilities of SSEs, it is also essential to enhance safety practitioners’ understanding of SSEs.

Ubiquitous connections and real-time safety data. This means that the volume of data transmission is huge, and advanced communication technologies such as wireless sensor networks and ultra-high bandwidth can be considered.

Network and data security. Without data and privacy guarantees, ubiquitous connectivity can only be a slogan. It is necessary to clarify the differences between private information and safety information resources that can be open and shared, and both of them should be stored and used separately so it is better to establish a reliable information protection mechanism

6. Conclusions and Future Works

Safety 4.0 is a new stage of safety science research and practice which is currently emerging in the era of Industry 4.0 and information technology. In the stage of Safety 4.0, the method of information-based safety management has attained wide attention from safety researchers and safety practitioners. SSM is a new method based on safety intelligence and it takes SSE as its basic tool. Based on the typical safety methods of realizing SSM and the essence of smartness, we define SSM and elaborate its content and application from four aspects: safety information processing, safety action, inspiring safety smartness, and internal optimization. Finally, we propose a SSM ecosystem and discuss the approaches of realizing SSM in coal mine safety production.

SSM is undoubtedly interesting. In particular, SSM strives to achieve early prevention, accurate control, highly efficient execution and continuous improvement through ubiquitous information connection, early safety actions, general human-machine cooperation, real-time safety decision-making and safety negotiation, information flow and continuous feedback. However, as a frontier method of safety management, SSM is still a theoretical concept, which is also one of the starting points of our research. We hope to study the basic theory of SSM from the perspective of development, so as to help the further research and implementation of this new method. The application of SSM could be realized in a gradual way through the application of technology and multi-level cooperation. To this end, we will focus on the specific functions of emerging technologies in the establishment of SSM system and the application of SSM method for a complex safety system with multiple factors as well as promoting sustainable safety.

Author Contributions

Conceptualization, X.H. and C.W.; methodology, C.W.; validation, X.H., B.W. and C.W.; investigation, X.H.; resources, B.W.; writing—original draft preparation, X.H.; writing—review and editing, X.H. and C.W.; supervision, C.W.; project administration, C.W.; funding acquisition, C.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was founded by the Major Program of National Social Science Fund of China (Grant No. 22ZDA121).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are openly available in a public repository.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industry 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Wang, B. Safety intelligence as an essential perspective for safety management in the era of Safety 4.0: From a theoretical to a practical framework. Process Saf. Environ. Prot. 2021, 148, 189–199. [Google Scholar] [CrossRef]

- Ouyang, Q.; Wu, C.; Huang, L. Methodologies, principles and prospects of applying big data in safety science research. Saf. Sci. 2018, 101, 60–71. [Google Scholar] [CrossRef]

- Ghasri, M.; Maghrebi, M. Factors affecting unmanned aerial vehicles’ safety: A post-occurrence exploratory data analysis of drones’ accidents and incidents in Australia. Saf. Sci. 2021, 139, 105273. [Google Scholar] [CrossRef]

- Xu, X.; Zou, P.X.W. Discovery of new safety knowledge from mining large injury dataset in construction. Saf. Sci. 2021, 144, 105481. [Google Scholar] [CrossRef]

- Tokody, D.; Flammini, F. Smart systems for the protection of individuals. Key Eng. Mater. 2017, 755, 190–197. [Google Scholar] [CrossRef]

- Teimourikia, M.; Fugini, M. Ontology development for run-time safety management methodology in Smart Work Environments using ambient knowledge. Future Gener. Comput. Syst. 2017, 68, 428–441. [Google Scholar] [CrossRef]

- Xu, R.; Nikouei, S.Y.; Nagothu, D.; Fitwi, A.; Chen, Y. Blendsps: A blockchain-enabled decentralized smart public safety system. Smart Cities 2020, 3, 928–951. [Google Scholar] [CrossRef]

- Wu, F.; Wu, T.; Yuce, M.R. An internet-of-things (IoT) network system for connected safety and health monitoring applications. Sensors 2019, 19, 21. [Google Scholar] [CrossRef]

- Podgorski, D.; Majchrzycka, K.; Dąbrowska, A.; Gralewicz, G.; Okrasa, M. Towards a conceptual framework of OSH risk management in smart working environments based on smart PPE, ambient intelligence and the Internet of Things technologies. Int. J. Occup. Saf. Ergon. 2017, 23, 1–20. [Google Scholar] [CrossRef]

- Chen, K.; Wang, C.; Chen, L.; Niu, X.; Zhang, Y.; Wan, J. Smart safety early warning system of coal mine production based on WSNs. Saf. Sci. 2020, 124, 104609. [Google Scholar] [CrossRef]

- Alazawi, Z.; Alani, O.; Abdljabar, M.B.; Altowaijri, S.; Mehmood, R. A smart disaster management system for future cities. In Proceedings of the 2014 ACM International Workshop on Wireless and Mobile Technologies for Smart Cities, Philadelphia, PA, USA, 11 August 2014; Association for Computing Machinery: New York, NY, USA, 2014; pp. 1–10. [Google Scholar]

- Nihan, C.E. Ubiquitous computing in the workplace: Ethical issues identified by the interdisciplinary IWE and HRM Research Group. In Ubiquitous Computing in the Workplace; Kinder, K.K., Ehrwein, N.C., Eds.; Springer: Cham, Switzerland, 2015; pp. 75–95. [Google Scholar]

- Li, R.Y.M. Smart working environments using the Internet of Things and construction site safety. In An Economic Analysis on Automated Construction Safety; Li, R.Y.M., Ed.; Springer: Singapore, 2018; pp. 137–153. [Google Scholar]

- Camero, A.; Alba, E. Smart City and information technology: A review. Cities 2019, 93, 84–94. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data-based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C.; Li, J.; Zhang, L.; Huang, L.; Kang, L. Certified Safety Engineer (CSE) as a new official profession in China: A brief review. Saf. Sci. 2019, 116, 108–115. [Google Scholar] [CrossRef]

- Alter, S. Making sense of smartness in the context of smart devices and smart systems. Inf. Syst. Front. 2020, 22, 381–393. [Google Scholar] [CrossRef]

- Arents, J.; Greitans, M. Smart industrial robot control trends, challenges and opportunities within manufacturing. Appl. Sci. 2022, 12, 937. [Google Scholar] [CrossRef]

- Aanandh, S.B.; Kar, C.; Siddiqqui, N. Safety Information Modeling: Smart Safety Device & Internet of Everything. Int. J. Intell. Syst. Appl. 2015, 7, 41–49. [Google Scholar]

- Drahos, P. Regulatory Theory: Foundations and Applications; ANU Press: Canberra, Australia, 2017; pp. 133–148. [Google Scholar]

- Nesheim, T.; Gressgård, L.J. Knowledge sharing in a complex organization: Antecedents and safety effects. Saf. Sci. 2014, 62, 28–36. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C. Thoughts about the Three Key Questions of Safety Management Informatization on the Science Level: Basic Connotation, Theoretical Motives and Focus Changes. J. Intell. 2018, 37, 15–23. (In Chinese) [Google Scholar]

- Huang, L.; Wu, C.; Wang, B.; Ouyang, Q. Big-data-driven safety decision-making: A conceptual framework and its influencing factors. Saf. Sci. 2018, 109, 46–56. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Carbonari, A.; Giretti, A.; Naticchia, B. A proactive system for real-time safety management in construction sites. Autom. Constr. 2011, 20, 686–698. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C. Safety informatics as a new, promising and sustainable area of safety science in the information age. J. Clean Prod. 2020, 252, 119852. [Google Scholar] [CrossRef]

- Le Coze, J.C. Ideas for the future of safety science. Saf. Sci. 2020, 132, 104966. [Google Scholar] [CrossRef]

- Piètre-Cambacédès, L.; Chaudet, C. The SEMA referential framework: Avoiding ambiguities in the terms “security” and “safety”. Int. J. Crit. Infrastruct. Prot. 2010, 3, 55–66. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C. Demystifying safety-related intelligence in safety management: Some key questions answered from a theoretical perspective. Saf. Sci. 2019, 120, 932–940. [Google Scholar] [CrossRef]

- Ajayi, A.; Oyedele, L.; Delgado, J.M.D.; Akanbi, L.; Bilal, M.; Akinade, O.; Olawale, O. Big data platform for health and safety accident prediction. World J. Sci. Technol. Sustain. Dev. 2019, 6, 2–21. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C.; Shi, B.; Huang, L. Evidence-based safety (EBS) management: A new approach to teaching the practice of safety management (SM). J. Saf. Res. 2017, 63, 21–28. [Google Scholar] [CrossRef]

- Li, Y.; Guldenmund, F.W. Safety management systems: A broad overview of the literature. Saf. Sci. 2018, 103, 94–123. [Google Scholar] [CrossRef]

- Hollnagel, L.F.E. Safety management–looking back or looking forward. Resil. Eng. Perspect. 2016, 1, 77–92. [Google Scholar]

- Mont, O.K. Clarifying the concept of product–Service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Eryomin, A.L. Information ecology—A viewpoint. Int. J. Environ. Stud. 1998, 54, 241–253. [Google Scholar] [CrossRef]

- Li, H.L.; Xiao, J. The concept of coal mine“One Map”and the study of its system structure. Geomat. Spat. Inf. Technol. 2014, 37, 168–171. [Google Scholar]

- Peeters, J.F.W.; Basten, R.; Tinga, T. Improving failure analysis efficiency by combining FTA and FMEA in a recursive manner. Reliab. Eng. Syst. Saf. 2018, 172, 36–44. [Google Scholar] [CrossRef]

- Mao, S.J.; Yang, N.S.; Gao, Y.Q.; Zhang, P.P.; Wu, D.Z. Research and application on big data integration analysis platform for intelligent mine safety production. Coal Sci. Technol. 2018, 46, 169–176. [Google Scholar]

- Baiburin, A.K. Errors, defects and safety control at construction stage. Procedia Eng. 2017, 206, 807–813. [Google Scholar] [CrossRef]

- Nahrgang, J.D.; Morgeson, F.P.; Hofmann, D.A. Safety at work: A meta-analytic investigation of the link between job demands, job resources, burnout, engagement, and safety outcomes. J. Appl. Psychol. 2011, 96, 71–94. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).