Realizing Smart Safety Management in the Era of Safety 4.0: A New Method towards Sustainable Safety

Abstract

1. Introduction

2. Artificial Smart Entity and Smart Safety

2.1. Artificial Smartness in the Era of Information

2.2. The Smartness Performance of Smart Safety Entity

3. Safety 4.0 and SSM

3.1. Organizational Safety Management in the Era of Safety 4.0

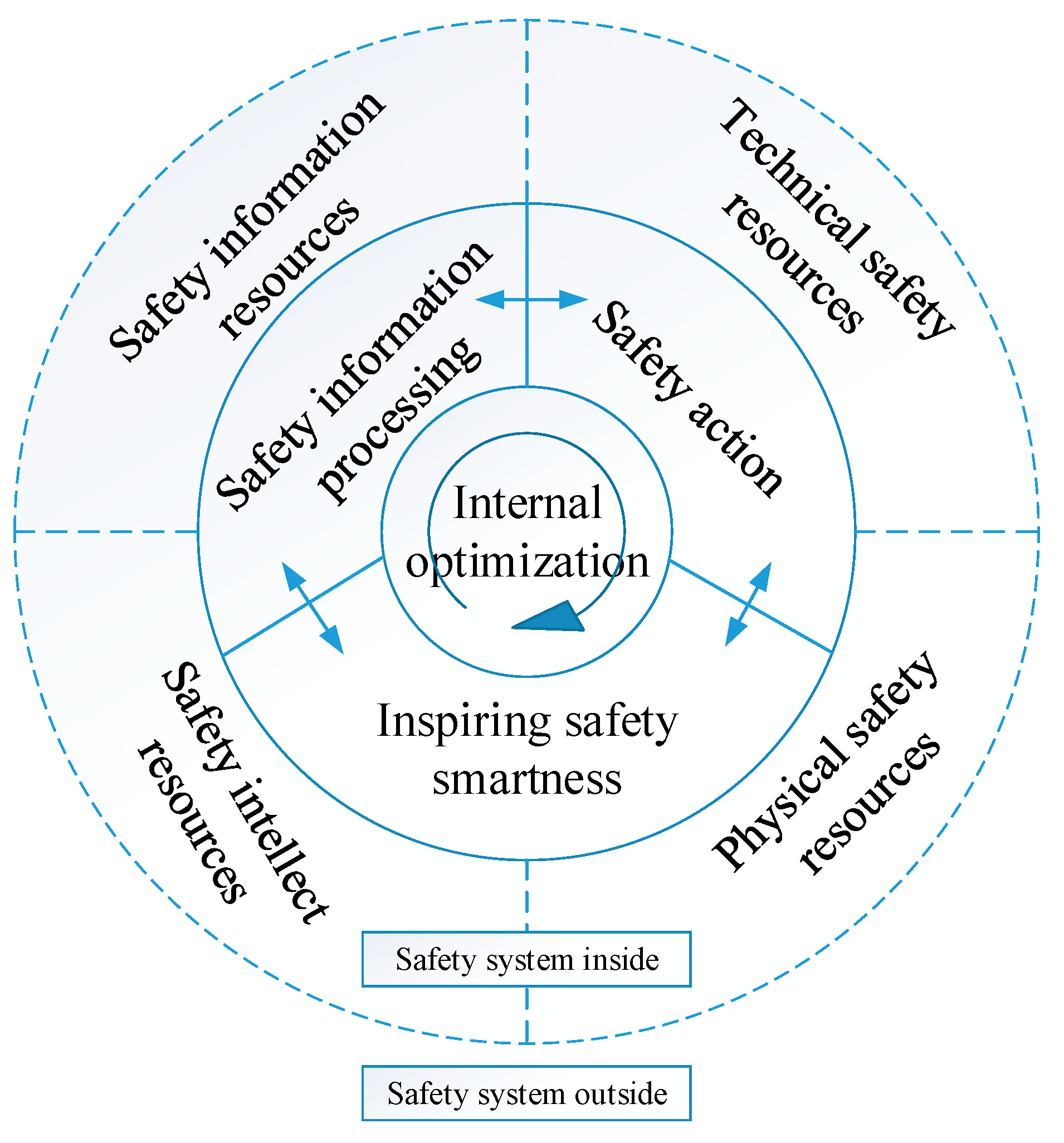

3.2. Essence of SSM in the Era of Safety 4.0

3.3. Content of SSM

4. Process and Content of SSM

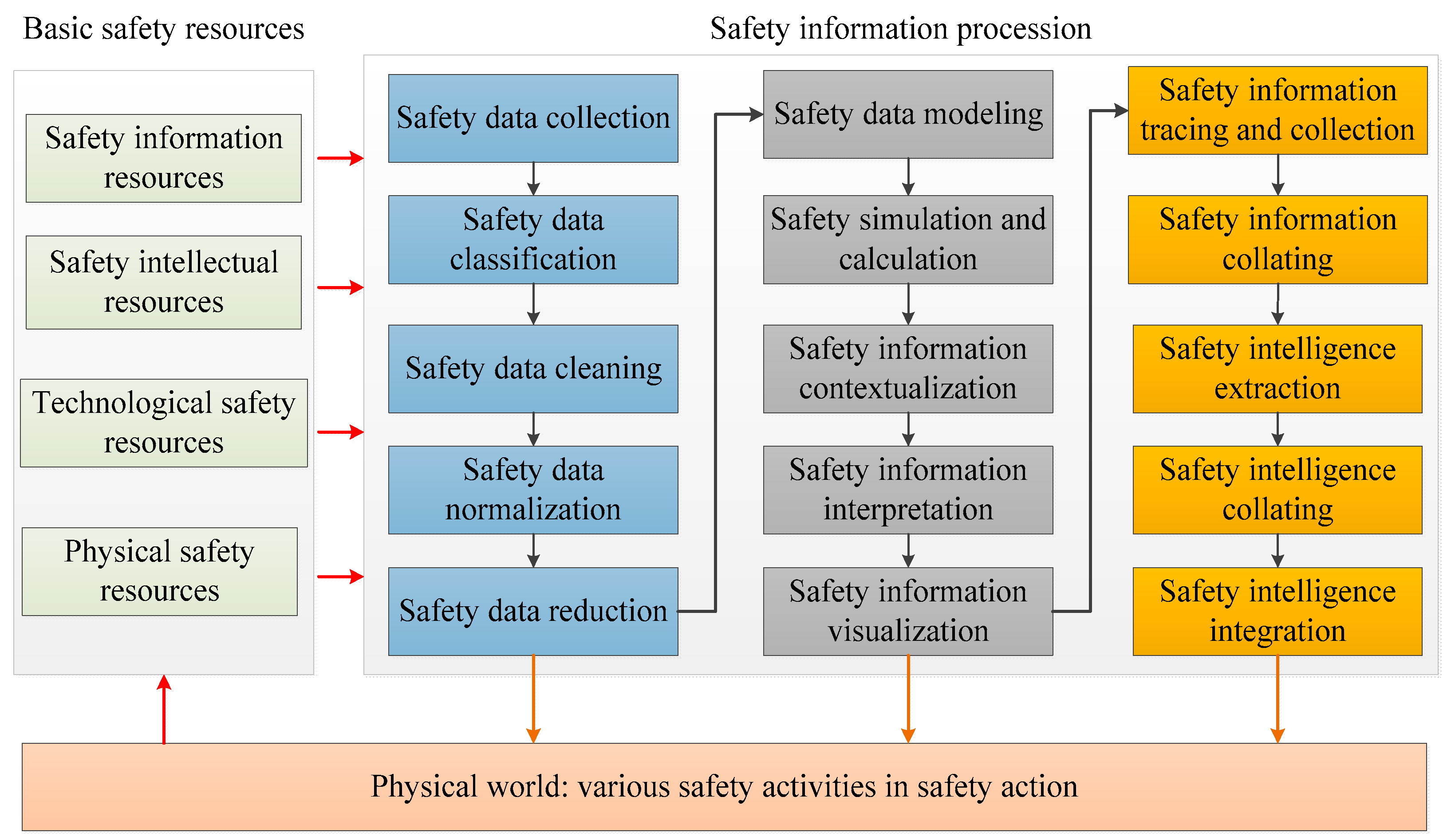

4.1. Process of Safety Information Processing

4.2. Process and Content of Safety Action

4.3. Inspiring Safety Smartness

4.4. Content of Internal Optimization

5. Significance and Challenges of SSM

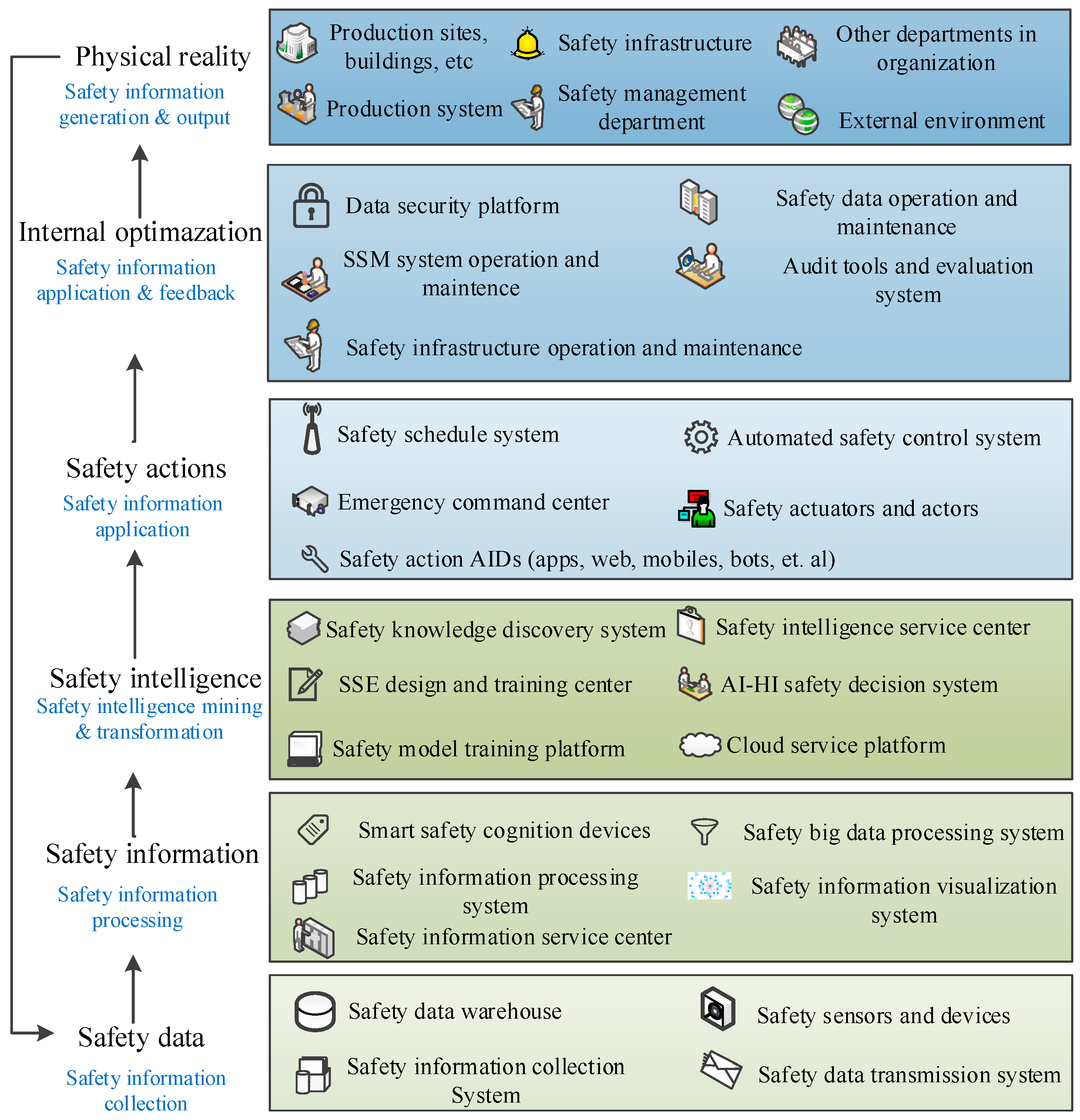

5.1. Framework of a SSM Ecosystem

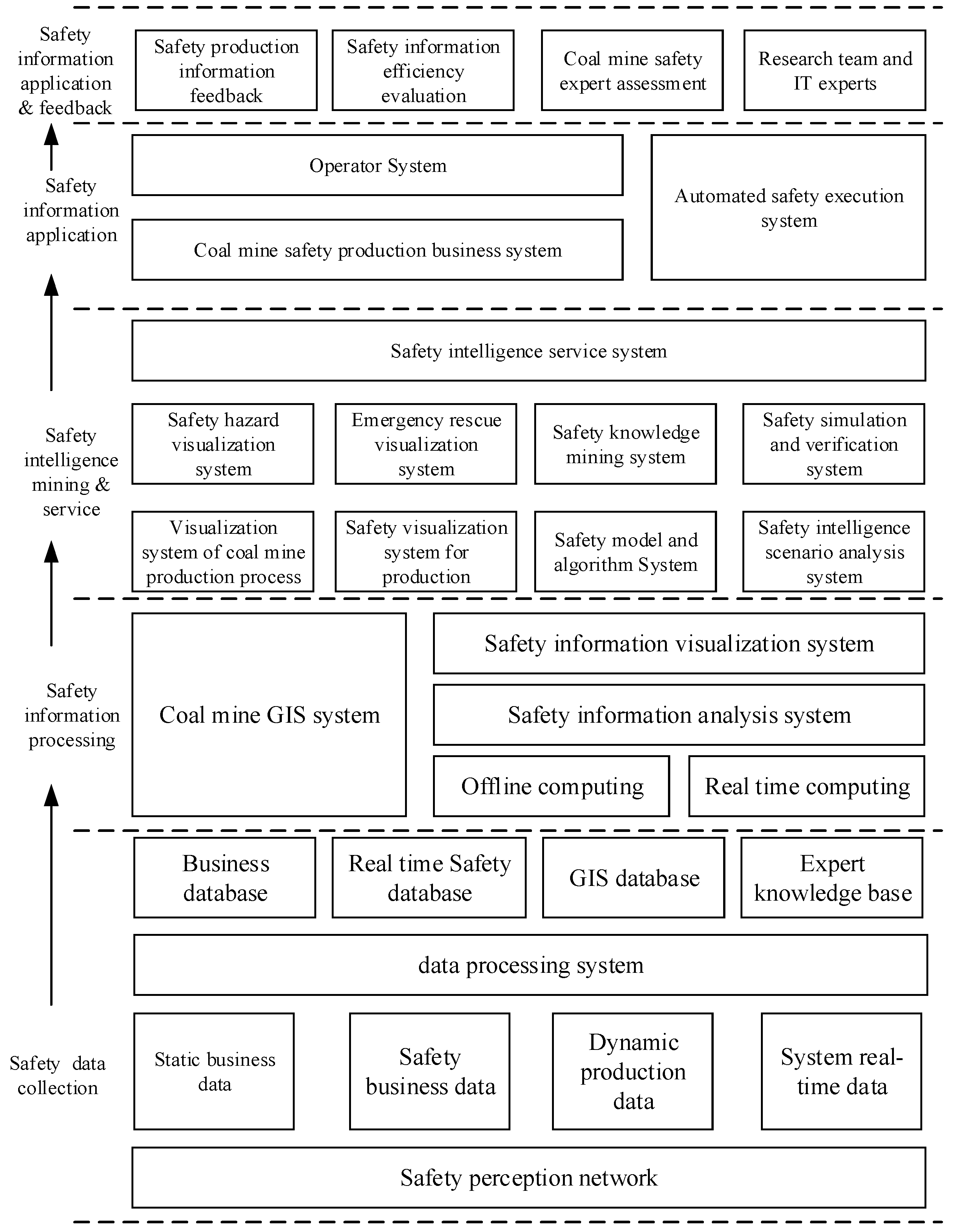

5.2. Realizaing SSM in Coal Mine Safety Production Organization

5.3. Significance of SSM in Promoting Sustainable Safety

- (1)

- SSM has comprehensive functions. SSM encourages ubiquitous information connection, general human–machine cooperation, real-time decision-making consultation, continuous information flow and feedback in the organization, thus maximizing the advantages of each safety elements to achieve automatic task performance and sustainable safety. Moreover, SSE is composed of several functional safety components, and it can have automatic performance in multiple tasks.

- (2)

- SSM supports safety prediction. In the process of SSM, all safety actions are based on the results of safety information processing. SSM systems collect original safety information from all aspects and the whole process of safety management, including all safety information before, during and after the event. Safety prediction and advance prevention are conducted based on real-time safety information.

- (3)

- SSM supports safety state awareness. In SSM, safety information is shared and used as a basic resource. On this basis, the SSM system is a comprehensive and integrated system composed of interconnected SSEs and safety practitioners. SSEs can provide real-time safety information to safety practitioners, help them to understand the real-time safety state and make wise safety decisions. Safety practitioners can give feedback on behavior results to help SSEs optimize their functions

- (4)

- SSM supports the continuous improvement of safety smartness. The development of emerging technologies, as well as the internal optimization of SM systems, are conducive to the improvement of the smartness capability of SSM systems and thus realize a more intelligent safety management paradigm, featuring higher digitization, more unmanned elements, high automation and high autonomy. To be more specific and to look forward to the future, various SSEs are enabled in the safety management system in a more intelligent safety management paradigm, such as safety sensors, safety actuators, computing devices. Each safety element is related to each other, shares basic safety resources in the organization and performs information processing to support safety actions.

5.4. Challenges of Promoting SSM

6. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industry 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Wang, B. Safety intelligence as an essential perspective for safety management in the era of Safety 4.0: From a theoretical to a practical framework. Process Saf. Environ. Prot. 2021, 148, 189–199. [Google Scholar] [CrossRef]

- Ouyang, Q.; Wu, C.; Huang, L. Methodologies, principles and prospects of applying big data in safety science research. Saf. Sci. 2018, 101, 60–71. [Google Scholar] [CrossRef]

- Ghasri, M.; Maghrebi, M. Factors affecting unmanned aerial vehicles’ safety: A post-occurrence exploratory data analysis of drones’ accidents and incidents in Australia. Saf. Sci. 2021, 139, 105273. [Google Scholar] [CrossRef]

- Xu, X.; Zou, P.X.W. Discovery of new safety knowledge from mining large injury dataset in construction. Saf. Sci. 2021, 144, 105481. [Google Scholar] [CrossRef]

- Tokody, D.; Flammini, F. Smart systems for the protection of individuals. Key Eng. Mater. 2017, 755, 190–197. [Google Scholar] [CrossRef]

- Teimourikia, M.; Fugini, M. Ontology development for run-time safety management methodology in Smart Work Environments using ambient knowledge. Future Gener. Comput. Syst. 2017, 68, 428–441. [Google Scholar] [CrossRef]

- Xu, R.; Nikouei, S.Y.; Nagothu, D.; Fitwi, A.; Chen, Y. Blendsps: A blockchain-enabled decentralized smart public safety system. Smart Cities 2020, 3, 928–951. [Google Scholar] [CrossRef]

- Wu, F.; Wu, T.; Yuce, M.R. An internet-of-things (IoT) network system for connected safety and health monitoring applications. Sensors 2019, 19, 21. [Google Scholar] [CrossRef]

- Podgorski, D.; Majchrzycka, K.; Dąbrowska, A.; Gralewicz, G.; Okrasa, M. Towards a conceptual framework of OSH risk management in smart working environments based on smart PPE, ambient intelligence and the Internet of Things technologies. Int. J. Occup. Saf. Ergon. 2017, 23, 1–20. [Google Scholar] [CrossRef]

- Chen, K.; Wang, C.; Chen, L.; Niu, X.; Zhang, Y.; Wan, J. Smart safety early warning system of coal mine production based on WSNs. Saf. Sci. 2020, 124, 104609. [Google Scholar] [CrossRef]

- Alazawi, Z.; Alani, O.; Abdljabar, M.B.; Altowaijri, S.; Mehmood, R. A smart disaster management system for future cities. In Proceedings of the 2014 ACM International Workshop on Wireless and Mobile Technologies for Smart Cities, Philadelphia, PA, USA, 11 August 2014; Association for Computing Machinery: New York, NY, USA, 2014; pp. 1–10. [Google Scholar]

- Nihan, C.E. Ubiquitous computing in the workplace: Ethical issues identified by the interdisciplinary IWE and HRM Research Group. In Ubiquitous Computing in the Workplace; Kinder, K.K., Ehrwein, N.C., Eds.; Springer: Cham, Switzerland, 2015; pp. 75–95. [Google Scholar]

- Li, R.Y.M. Smart working environments using the Internet of Things and construction site safety. In An Economic Analysis on Automated Construction Safety; Li, R.Y.M., Ed.; Springer: Singapore, 2018; pp. 137–153. [Google Scholar]

- Camero, A.; Alba, E. Smart City and information technology: A review. Cities 2019, 93, 84–94. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data-based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C.; Li, J.; Zhang, L.; Huang, L.; Kang, L. Certified Safety Engineer (CSE) as a new official profession in China: A brief review. Saf. Sci. 2019, 116, 108–115. [Google Scholar] [CrossRef]

- Alter, S. Making sense of smartness in the context of smart devices and smart systems. Inf. Syst. Front. 2020, 22, 381–393. [Google Scholar] [CrossRef]

- Arents, J.; Greitans, M. Smart industrial robot control trends, challenges and opportunities within manufacturing. Appl. Sci. 2022, 12, 937. [Google Scholar] [CrossRef]

- Aanandh, S.B.; Kar, C.; Siddiqqui, N. Safety Information Modeling: Smart Safety Device & Internet of Everything. Int. J. Intell. Syst. Appl. 2015, 7, 41–49. [Google Scholar]

- Drahos, P. Regulatory Theory: Foundations and Applications; ANU Press: Canberra, Australia, 2017; pp. 133–148. [Google Scholar]

- Nesheim, T.; Gressgård, L.J. Knowledge sharing in a complex organization: Antecedents and safety effects. Saf. Sci. 2014, 62, 28–36. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C. Thoughts about the Three Key Questions of Safety Management Informatization on the Science Level: Basic Connotation, Theoretical Motives and Focus Changes. J. Intell. 2018, 37, 15–23. (In Chinese) [Google Scholar]

- Huang, L.; Wu, C.; Wang, B.; Ouyang, Q. Big-data-driven safety decision-making: A conceptual framework and its influencing factors. Saf. Sci. 2018, 109, 46–56. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Carbonari, A.; Giretti, A.; Naticchia, B. A proactive system for real-time safety management in construction sites. Autom. Constr. 2011, 20, 686–698. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C. Safety informatics as a new, promising and sustainable area of safety science in the information age. J. Clean Prod. 2020, 252, 119852. [Google Scholar] [CrossRef]

- Le Coze, J.C. Ideas for the future of safety science. Saf. Sci. 2020, 132, 104966. [Google Scholar] [CrossRef]

- Piètre-Cambacédès, L.; Chaudet, C. The SEMA referential framework: Avoiding ambiguities in the terms “security” and “safety”. Int. J. Crit. Infrastruct. Prot. 2010, 3, 55–66. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C. Demystifying safety-related intelligence in safety management: Some key questions answered from a theoretical perspective. Saf. Sci. 2019, 120, 932–940. [Google Scholar] [CrossRef]

- Ajayi, A.; Oyedele, L.; Delgado, J.M.D.; Akanbi, L.; Bilal, M.; Akinade, O.; Olawale, O. Big data platform for health and safety accident prediction. World J. Sci. Technol. Sustain. Dev. 2019, 6, 2–21. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C.; Shi, B.; Huang, L. Evidence-based safety (EBS) management: A new approach to teaching the practice of safety management (SM). J. Saf. Res. 2017, 63, 21–28. [Google Scholar] [CrossRef]

- Li, Y.; Guldenmund, F.W. Safety management systems: A broad overview of the literature. Saf. Sci. 2018, 103, 94–123. [Google Scholar] [CrossRef]

- Hollnagel, L.F.E. Safety management–looking back or looking forward. Resil. Eng. Perspect. 2016, 1, 77–92. [Google Scholar]

- Mont, O.K. Clarifying the concept of product–Service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Eryomin, A.L. Information ecology—A viewpoint. Int. J. Environ. Stud. 1998, 54, 241–253. [Google Scholar] [CrossRef]

- Li, H.L.; Xiao, J. The concept of coal mine“One Map”and the study of its system structure. Geomat. Spat. Inf. Technol. 2014, 37, 168–171. [Google Scholar]

- Peeters, J.F.W.; Basten, R.; Tinga, T. Improving failure analysis efficiency by combining FTA and FMEA in a recursive manner. Reliab. Eng. Syst. Saf. 2018, 172, 36–44. [Google Scholar] [CrossRef]

- Mao, S.J.; Yang, N.S.; Gao, Y.Q.; Zhang, P.P.; Wu, D.Z. Research and application on big data integration analysis platform for intelligent mine safety production. Coal Sci. Technol. 2018, 46, 169–176. [Google Scholar]

- Baiburin, A.K. Errors, defects and safety control at construction stage. Procedia Eng. 2017, 206, 807–813. [Google Scholar] [CrossRef]

- Nahrgang, J.D.; Morgeson, F.P.; Hofmann, D.A. Safety at work: A meta-analytic investigation of the link between job demands, job resources, burnout, engagement, and safety outcomes. J. Appl. Psychol. 2011, 96, 71–94. [Google Scholar] [CrossRef]

| Category | Content |

|---|---|

| Safety information from sensors | This is the real-time safety data or information collected by safety monitoring systems and safety sensor networks. It reflects the actual safety status in specific safety scenarios and helps detect safety anomalies quickly. |

| Risk identification information | The risk identification information is the safety information processed by the safety perception system, the risk identification system, and other systems. It reflects the categories and characteristics of risks in a specific safety situation to help select risk control technologies and tools. |

| Risk assessment information | The risk assessment information is the safety information or safety smart processed by the risk assessment system and safety assessment experts. It reflects the current risk level, development forecast, and severity of consequences to help select risk treatment methods and strategies. |

| Real-time risk information | The real-time risk information is the safety data or information collected after the risk control complete. It reflects the safety status of a specific safety situation to ensure that the risk level has been reduced to an acceptable state. The risks and hazards are rechecked using the safety sensor network and the risk identification system. |

| Crisis information | The crisis information is the real-time safety status data and preliminary safety assessment information when the incident/accident occurs, which reflect the nature and development of the incident/accident, to help carry out emergency warning and evacuation. |

| Crisis assessment information | Crisis assessment information is safety assessment information and safety prediction information for a specific event/accident, which reflects the severity of the event/accident, crisis factors, etc., to help select emergency control methods and take emergency control measures. |

| Emergency information | The emergency information is comprehensive safety information of the accident site, which includes the nature, severity, safety situation, location, affected personnel, and core crisis factors to help rescue personnel and restore equipment function quickly. |

| Real-time safety information | The real-time safety information is the safety data/information obtained from the safety recheck after accident control. It reflects the safety state of the site and surrounding environment to ensure that there are no risks and hazards. |

| Safety loss information | The safety loss information is the safety assessment information of the loss caused by accidents; it reflects the specific losses to assist with loss statistics and compensation. |

| Incident/accident report | The incident/accident report is the safety analysis and safety evaluation to incident/accident. It reflects the causing factors, development process, loss, safety experience, and safety knowledge of the incident/accident to help optimize the safety reinforcement for the affected system/organization. |

| Task | Main Content |

|---|---|

| Structure optimization | Safety subsystem regulation (i.e., the upgrade, increase or decrease of safety subsystem), function adjustment, process optimization, application of new safety standards/regulations/laws, etc. |

| Resource optimization | The adjustment of basic safety resources contents, strengthen safety resources sharing, online-offline adjustment, evaluation of safety resources, etc. |

| SSE optimization | Functional optimization and adjustment, interoperability improvement, convenience enhancement, usability improvement, etc. |

| Safety education and training | Safety awareness improvement, enhancing safety knowledge and safety skills, improving understanding and application of SSE, the establishment of a new mode in safety action, etc. |

| Organizational safety culture | Building safety resource sharing culture, creating a better safety atmosphere and other helpful attempts for the application and optimization of SSM. |

| Safety & security protection | System data security protection, safety system protection barrier, safety system maintenance under harsh environment, etc. |

| Main Contents | Main Function | Approaches and Purposes |

|---|---|---|

| Safety information processing | Real-time safety data processing | Building a comprehensive safety perception network, obtaining all production safety data and using Kafka for data processing, building safety databases through a unified data access platform, etc. |

| Safety information analysis and visualization | Using offline computing and real-time computing to analyze static and dynamic safety data; using safety information visualization to realize safety data visualization system; etc. | |

| Safety intelligence analysis and services | Using real-time safety data and safety knowledge databases of coal mines to evaluate and predict the system safety status and safety development trend of related businesses according to the safety intelligence needs of users; supporting the continuous service of safety intelligence etc. | |

| Safety action | Supporting safety information for safety action | Constructing various safety information visualization systems; supporting perception of safety information needs, demand prediction and supporting corresponding information services in various safety businesses; etc. |

| Improving automate safety action capability | Connecting with various safety production automation systems, realizing automatic safety intervention and safety control under unmanned environments, etc. | |

| Inspiring safety smartness | Improving safety smartness of workers | Collecting the experience and theoretical knowledge of coal mine safety production, building an expert knowledge base which includes coal mine safety assessment standards, laws and regulations of coal mine production, coal mine disaster prevention methods and emergency plans, major hazard identification standards, and accident cases; promoting the sharing of a safety knowledge base; supporting safety education and training, etc. |

| Creation of SSEs | Designing and developing a safety knowledge inference engine to support knowledge mining and information analysis; designing and creating smart safety entities with specific functions to improve the automation capability of coal mine safety production; etc. | |

| Safety knowledge mining and accumulation | Building the classification system and meta database of coal mine safety knowledge; choosing scientific knowledge reasoning and expression methods based on the characteristics of coal mine safety knowledge; using safety knowledge inference engine to realize safety knowledge inference and discovery; etc. | |

| Internal optimization | System reviewing and evaluation | Building safety production information feedback system and safety information efficiency evaluation system; building coal mine safety expert evaluation system, and evaluating the efficiency of the safety management system; etc. |

| Function optimization and extension | Establishing an expert team of artificial intelligence and IT system to design and develop more types of smart safety equipment for coal mines; continuously optimizing the functions of the coal mine SSM system; explore more information service functions, such as mine virtual space simulation, personnel and equipment status display; etc. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Wang, B.; Wu, C. Realizing Smart Safety Management in the Era of Safety 4.0: A New Method towards Sustainable Safety. Sustainability 2022, 14, 13915. https://doi.org/10.3390/su142113915

Huang X, Wang B, Wu C. Realizing Smart Safety Management in the Era of Safety 4.0: A New Method towards Sustainable Safety. Sustainability. 2022; 14(21):13915. https://doi.org/10.3390/su142113915

Chicago/Turabian StyleHuang, Xi, Bing Wang, and Chao Wu. 2022. "Realizing Smart Safety Management in the Era of Safety 4.0: A New Method towards Sustainable Safety" Sustainability 14, no. 21: 13915. https://doi.org/10.3390/su142113915

APA StyleHuang, X., Wang, B., & Wu, C. (2022). Realizing Smart Safety Management in the Era of Safety 4.0: A New Method towards Sustainable Safety. Sustainability, 14(21), 13915. https://doi.org/10.3390/su142113915