Abstract

Given the current scenario of increasing environmental problems associated with the need for rapid energy transition, this article aimed to investigate the implementation of Cynara cardunculus L. (cardoon), a plant with high environmental performance, as a source of energy resources. This study presented thLife Cycle Assessment of two energy production chains—for the polygeneration of power, heat, and cooling; and to produce biodiesel—fed with cardoon seeds, in addition to comparing these chains with the use of the traditional Italian grids (power and gas) and with the production of diesel based on palm, soybean, and rapeseed. Approximately 49 t of seeds were cultivated and processed, yielding 8.5 t of oil. The system boundaries encompass three main macro-phases, cardoon production, oil extraction, and, depending on the application, energy generation (polygeneration) or transesterification (biodiesel). The models were developed using the software SimaPro V9.3.0.2, and the inventory was based on the database ecoinvent V3.8. The Life Cycle Impact Assessment was performed using the ReCiPe V1.06 method at the midpoint (H) and endpoint (H/A) levels. Crude cardoon oil showed a global warming of 20–55% lower than other vegetable oils (palm, soybean, and rapeseed). In the case of biodiesel production, cardoon-based biodiesel presented a reduction in the impact burden by 12–57% compared to biodiesel based on palm, soybean, and rapeseed. With the use of oil in Polygeneration, a subtle increase in the impact burden was observed, with 13% more impact than the use of Italian power and gas grids.

1. Introduction

The need for researching and implementing alternative energy sources with high levels of sustainability has grown in the current context of population expansion, growing energy consumption, energy resource depletion, and the increased consequences of climate change as effects on human health and degradation of the ecosystem [1,2]. World consumption reached 13.86 billion metric tons of oil equivalent, with fossil fuels accounting for about three-quarters of total demand. The prediction is that the global demand for primary energy will increase to 35.5 million barrels in 2040 [3,4,5,6,7,8,9,10].

Recently, bioenergy from energy crops has gained the attention of researchers as an alternative to conventional fossil fuel resources for addressing the current demand and environmental needs [8,11,12]. The production of energy from non-food crops, particularly those grown on marginal lands, in addition to the use of residual biomass, would be an alternative. Even more, the use of marginal lands would avoid possible competition for fertile soils destined for food crops and vegetable fibres [13,14]. This would reduce the issue of boosting their worldwide food market prices [15]. Another relevant aspect of the biomasses is that their production occurs by emitting CO2, which is reabsorbed in the regrowth cycles of the plant in the cultivation phase, i.e., it is a carbon-neutral energy alternative [2,13,16,17].

Considering this perspective, Cynara cardunculus L., commonly known as cardoon, stands out for its high level of sustainability, which has been proven by various studies over the last 30 years. Gominho et al. [16] show that this species is a highly productive crop that can thrive in Mediterranean regions with poor edaphoclimatic conditions [2,18,19,20,21,22]. This plant, commonly known as cardoon, stands out through a low level of management. It possesses a perennial life form, an annual growth cycle, rapid regrowth, attractive flowers for bees, and water stress tolerance [23,24], i.e., an attractive choice for degraded and marginal lands [12,16].

The plant is composed of two fractions: the lignocellulosic material (90–92% of the plant’s weight), and seeds (8–10%). Even though the seeds present a reduced proportion, they are the fraction with the highest added value given their oil content, around 20–32% of the seed’s weight [16,25]. This oil consists of glycerine and fatty acids with chain lengths ranging between C8 and C20 of which 16, 18, and 20 carbon are the most common [26,27].

Different studies approach the use of cardoon for different purposes. Among the applications is the use to produce liquid, solid, and gaseous biofuels [28,29,30], bioplastics [13], bio-oil (pyrolysis) [31], animal feed [32], bio-lubricants [30], active films [33], therapeutic products [22], adhesives [34], and fertilisers [35]. Several thermochemical and mechanical techniques are available for extracting oil from oilseeds [35]. Solvent extraction and mechanical extraction are the two most used techniques in oil seed extraction. The most efficient technique is solvent extraction. However, using solvents has a high operational cost, a significant environmental effect, and complicated processing steps. On the other hand, mechanical extraction is the widely used technique for oil seed extraction [11]. The benefits of mechanical extraction include a simplified production chain, reduced environmental impact load, improved oil quality, and the possibility to use the oilcake for other uses such as animal feed or fertilizer because it is not contaminated by solvents [11,36,37,38,39]. In mechanical extraction, essentially, the seeds are placed between barriers and compressed by a press, separating the oil from the solid fraction of the seeds [11,40]. The most frequent mechanical extraction procedures are the use of the screw press, which offers advantages because it is more effective in extracting oil, in addition to being used in continuous processes [11,41].

Cardoon oil is made up of triglycerides that are made up of three long hydrocarbon chains connected to a single glycerol molecule. This molecular structure is similar to that of crude oil, making cardoon oil an interesting alternative to petroleum [42,43,44].

The objective of this study, considering the current energetic demands, was to investigate the environmental performance of the oil obtained and its use in two applications: for the polygeneration of power, heating and cooling by a combustion cogeneration engine; and for the use of oil for biodiesel production through transesterification. The solid fraction of the seeds, i.e., oilcake, was considered to be applied as animal feed or fertilising agent, this was considered a by-product of the oil extraction process, with its respective added value. Other potential uses could be the production of bioplastics [45], biogas [46,47], or direct use as solid fuel.

The two hypotheses for the use of cardoon oil (polygeneration and biodiesel) were analysed through the Life Cycle Assessment and compared with traditional systems (Italian power and gas grids, and traditional biodiesel) producing the same resources. Polygeneration was confronted with the use of Italian power and gas grids providing power, heat, and cooling. Additionally, cardoon biodiesel was compared with biodiesel from palm, soybean, and rapeseed oils. It is expected that this article will be a contribution at the level of propositional policies to diversification and energy transition, in addition to the economic valorisation of territories, in addition to improving the energy resilience of these places.

2. Materials and Methods

2.1. Life Cycle Assessment Methodology

The Life Cycle Assessment was developed under the requirements of ISO 14040:2006a [48] and 14044:2006b [49], allowing the assessment of environmental impacts through the compilation and evaluation of inputs (energy and material) and outputs (products, by-products, pollutants, and emissions) [50]. These frameworks comprehend the steps of goal and scope definition, life cycle inventory analysis, life cycle impact assessment, and interpretation of results. The life cycle models were developed using the commercial software SimaPro V9.3.0.2 [51].

2.2. Goal and Scope Definition

The study aims to estimate and evaluate the environmental impact loads for the entire production chain for the production and use of cardoon oil, starting from agricultural production to the final application (polygeneration of power, heating, and cooling through a cogeneration engine and chiller system; and biodiesel production through transesterification). The analysis of the two hypotheses was carried out by comparing them with traditional systems that provide the same resources. In the case of the polygeneration chain with the Italian power and gas grids. Additionally, in the case of the biodiesel chain, biodiesel production is based on other oils (palm, soybean, and rapeseed).

The expected outcome of this study is to obtain a better understanding of the multiple application of cardoon oil, in particular for energy sources supply. Then, verify the feasibility of these systems as an alternative to traditional production and distribution energy systems.

2.3. Functional Unit and Allocation Strategy

The functional unit was considered 1 MJ of energy obtained from the polygeneration and 1 kg obtained from biodiesel. In the case of polygeneration, the total energy output (power, heat, and cooling) was considered. The allocation of the burden of environmental impacts on intermediate products (plant, seeds, and oil) until obtaining the final energy resources was based on their energy content.

2.4. System Boundary

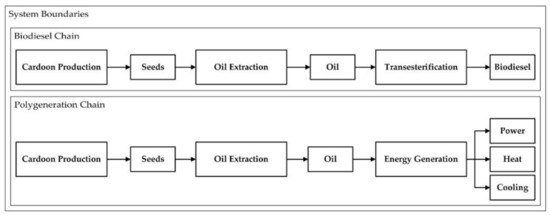

The definition of the system boundaries was done in accordance with ISO 14040 and 14044. A cradle-to-gate approach was chosen in its definition. The phases included in the analysed system were the production of cardoon, the extraction of oil, and the obtaining of the final products and energy sources (power, heat, and cooling; and biodiesel). The time boundary was one year of operations. The scheme of the system boundaries is shown in Figure 1.

Figure 1.

Boundaries of the System for Biodiesel and Polygeneration Chains.

2.5. Life Cycle Inventory

The proposed production chains were divided into three main phases, which were called macro-level categories. They were cardoon production, oil extraction, transesterification, and energy generation. The inventories were developed based on the material and process flows of each one of the macro-level categories and modelled based on the ecoinvent V3.8 [52].

2.5.1. Raw Material Production

The metadata required to develop the cardoon production inventory was gathered from a production field in Porto Torres, Sardinia (Appendix A—Table A1). As assumed by the supplier, the use of marginal lands was adopted as a good practice to overcome the problems attributed to the competition with food crops. Data on cardoon fractions characteristics, and input amounts were available on experimental metadata. Based on investigations of the cardoon cultivation developed by Gominho et al. [16], Deligios et al. [53], and Angelini et al. [23], data on the machinery and its usage were hypothesized. The use of each machinery was calculated based on the flow of inputs and outputs (fertilisers and yields of cardoon production) and the area cultivated.

During the cardoon growing cycle, the first activities were harrowing, ploughing, and fertilisation. The fertilisation was carried out employing chemical fertilisers and compost materials. Then sowing of seeds was carried out with an automatic transplanter.

The region where the cultivation was carried out has a range of 400–600 mm of seasonal precipitation [53,54], respecting the rainfall requirements of the plant of about 500 mm. Given these conditions and the fact that cardoon is resistant to dry climates, irrigation was not required which was an advantage in terms of environmental impacts. Irrigation systems are unsustainable as long as they use the limited freshwater resources required for human consumption and other activities, in addition to the high energy demand. Even without the use of irrigation, the crop showed a yield of 18 t/ha, close to the maximum of 20 t/ha reported by other authors [23,25]. Another advantage from an environmental point of view was the absence of pesticide use, improving environmental performance.

The harvest process was carried out by a combined harvester. It was done annually in the spring season, and for this reason, the dry matter content of the collected biomass was around 90%. The underground fraction of the plant was left in the field apportioning nitrogen to the soil supporting the nutrition of the next crop cycle. This material was considered cultivated in fields 20 km from the oil extraction plant, and the seeds were transported by road in trucks with a capacity of 30 tons.

The energy content of the cardoon fractions (seeds, epigean, and hypogeum fractions) was used to allocate emissions of this phase.

2.5.2. Layout and Operations of the Oil Extraction Plant

The oil extraction phase comprises the stages of seed storage, transportation, remotion of impurities, mechanical oil extraction, and filtration. The prototype plant is located in Sant’Apollinare’s Fortress, Central Italy. The experimental plant of mechanical oil extraction was dimensioned by the Biomass Research Centre (CRB) and the Interuniversity Research Centre on Pollution and the Environment “Mauro Felli” (CIRIAF), financially supported by the Italian Ministry of Agriculture.

The first stage is the transport and storage of the raw material. The seeds arrive by truck, and it is weighed in the weighbridge before unloading in a hopper (2 m3). From the hopper, these seeds are transported by a conveyor system composed of belts and a bucket elevator toward the silos with a 180 m3 of capacity. Following, seeds are extracted from the silos by the conveyor system to be cleaned. The cleaning system consisted of three levels of sieving, composed of a coarse sieve mesh size 7–8 mm, a fluidised bed to remove the lightest impurities such as bark and leaves through a blowing air process, and a final sieve mesh size of 3 mm. Then, in the extraction set, cleaned seeds are transported through a screw conveyor to the press, where a continuous process extracted the oil. This press system works with the seeds’ compression between an internal chamber, forced by a squeezing screw. The raw oil (rich in suspended solids) flows out through some apertures in the cylindrical chamber and finally passes through a filter set, to separate the rich-press cake and the crude cardoon oil. The filtered oil is stored in tanks with 100 m3. All the machinery operates with a set of fourteen electric engines, with 3 to 22 kW.

Representative samples were taken at all stages of the process chain and were analysed at the University of Perugia, Biomass Research Canter’s laboratories in terms of moisture, oil content, and energy content. Moisture was measured by a moisture analyser (model Mettler Toledo HB43-S) [55]. The energy content was measured using a calorimeter (LECO AC-350) [56]. The oil content in the seeds was determined based on the procedure of the National Renewable Energy Laboratory National, Determination of Extractives in Biomass [57]. All analyses were performed in triplicate.

2.5.3. Polygeneration

The polygeneration hypothesis was tested considering that all the oil extracted was used for the polygeneration of energy, heat, and cooling through the combustion of the oil in a cogeneration engine with a power of 100 kW of electric energy and consumption of 25 L/h. Residual energy from combustion was recovered to produce heat and cooling. The recovered energy provided a power of 60 kW of heat and the chiller provided a power of 75 kW of cooling. The process of producing heat and cooling operates alternately, when the residual energy was not used directly for heating, it was addressed to the chiller to produce cooling. The power demands of the oil extraction plant were supplied by the polygeneration plant.

2.5.4. Biodiesel

Alternatively, the oil was considered to be used for the production of biodiesel through transesterification. The oil was considered to be composed of 11% palmitic, 4% stearic, 25% oleic, and 60% linoleic fatty acids, as cited in other studies, which is similar to other energy crops that are traditionally used for biodiesel production, in particular the soybean oil [20,54]. Therefore, to model the transesterification, a model was developed based on the flows of materials and processes reported in other studies on the production of cardoon-based biodiesel [16,30,58], using methanol and sodium methoxide, and by modifying the transesterification model of soybean oil from the database ecoinvent v3.8, gives the physio-chemical similarities of both.

The transesterification technique was chosen because it is the most common procedure for producing standard biodiesel from vegetable oils [59,60,61], and in accordance with UNE-EN 14214 standard. It is performed in the following steps: triglycerides react with alcohol and produce fatty acid alkyl esters (FAAE) and diglyceride. Following diglycerides react with alcohol again and produce FAAE and monoglyceride. Additionally, finally, monoglyceride reacts with alcohol and produces FAAE and monoglyceride [11]. The transesterification of the oil was simulated based on the yields calculated by other studies, which is around 98% [62]. The biodiesel obtained was considered to have a LHV of about 39.73 MJ/kg, and a density of about 0.881 kg/L [62,63,64].

2.6. Life Cycle Impact Assessment and Interpretation

The method used to translate the life cycle inventory’s elementary flows into environmental impact scores was the ReCiPe 2016 V1.1 [65]. The method was applied at the Hierarchist Midpoint Level, since this perspective is based on scientific consensus with regard to the time frame and plausibility of impact mechanisms, besides being valid for the European region. The ReCiPe midpoint translates the elementary flows into 18 midpoint impact categories, including the GWP [66]. The results obtained in the characterisation were normalised to report on the relative magnitude of each of the scores for the different impact categories, expressing them to a common set of reference impacts. Additionally, the ReCiPe Endpoint (H/A) was used, aiming to show the total burden of environmental impacts avoiding the burden-shifting. The results are shown in terms of 3 endpoint areas of protection (“human health”, “ecosystems”, and “resources”), calculated based on midpoint characterization factors to endpoints through the midpoint-to-endpoint factor [65].

Aiming to simplify and be more comprehensive in the visualization of the results, the following methodology was adopted. After modelling the entire chain (for polygeneration and biodiesel) the midpoint level scores were directly normalised. With the normalisation, it was possible to identify and isolate the impact categories (ICs) that contributed most to the total burden of impact. By focusing only on the most prominent impacts, it was possible to have a more focused view of the critical points of the proposed chains. Once the main ICs were identified, they were characterised for detailed analysise

Pointing a more in-depth analysis, to visualise the core elements responsible for the emissions, the results were investigated at three levels: production chain (polygeneration and biodiesel); macro-level categories of the chains, which cardoon production, oil extraction, energy generation, and transesterification; and mid-level categories, that is, the sectioning of the macro-level categories: cardoon production (fertilising, illage, sowing, swath, harvesting, and others), oil extraction (storage, transportation, selection, oil extraction, and filtration), energy generation (power production, heat production, and cooling production), and transesterification (reaction and purification).,

3. Results

3.1. Mass Flows and Characterisation

A total of 49 tons of seeds, with a total impurity of about 7%, 2.39% of moisture, and 20.64% of oil content, were processed obtaining 8.5 tons of crude oil with LHV of 37.80 MJ/kg; and 39.4 tons of oilcake with 3.21% of moisture, 5.11% of oil content, and an LHV of 16.92 MJ/kg. The oil extraction efficiency of about 85% was slightly higher than that reported by other studies [37]. The unextracted oil that remained in the oilcake gave it greater added value for animal feed [67].

3.2. Life Cycle Inventory Analysis

The inventory was developed based on the resources, materials, and processes in input and output required for all steps of both chains: cardoon cultivation, oil extraction, energy generation, and transesterification.

3.2.1. Cardoon Production

The cardoon production inventory was carried out based on the mass flow metadata declared by the supplier (Appendix A—Table A1). The use of machinery for operations was hypothesized based on investigations of cardoon cultivation. The cardoon cultivation phase required nitrogen and phosphate fertilizers, in addition to compost, which was used to improve production performance. The modelling of the machinery used for soil preparation and maintenance was calculated based on the cultivated area and yields. For this purpose, the ecoinvent database processes were used, comprising the materials and manufacture of the machinery, in addition to the fuel consumption. The main materials and processes used for modelling the Cardoon Production are shown in Appendix A—Table A2.

3.2.2. Oil Extraction Plant

The oil extraction plant inventory was developed based on energy demand, weight and material composition of the machinery used, and building. In the calculation, a lifespan of 20–30 years was considered for the industrial park. The inventory can be seen in Table 1.

Table 1.

Oil Extraction Plant Inventory.

The power demand was estimated based on machinery operations as reported by Ramoon et al. [67]. The annual operations consumed around 18 GJ of electricity. At the beginning of the experimental campaign, the necessary energy was consumed from the grid. After obtaining the first batch of oil, the plant operated in a self-sufficient way through the production of energy provided using oil in the cogeneration engine. On the other hand, in the oil extraction model adopted for the production of biodiesel, energy was supplied by the Italian grid. The construction of the polygeneration plant would only have a positive impact if they were used more intensively, spreading the impact related to its construction in a higher amount of energy in output. The plant building occupies an area of about 240 m2. The main materials and processes used for modelling the oil extraction plant are shown in Appendix A—Table A2.

3.2.3. Polygeneration

The polygeneration plant was composed of a cogeneration engine and chiller. Both were modelled based on a modification of ecoinvent V3.8 database machinery. As a comparative reference, the use of the Italian power grid for the supply of electricity and cooling, and the use of the gas grid to supply heat was adopted. The main materials and processes used for modelling the polygeneration plant are shown in Appendix A—Table A2.

3.2.4. Biodiesel

The modelling of the transesterification plant was carried out based on the modification of a model of a soybean oil transesterification plant. This method was adopted since cardoon and soybean oils have physicochemical similarities. The comparative reference was obtained from the biodiesel models available in the ecoinvent V3.8 database, which are biodiesel based on soybean, palm, rapeseed oils, and standard biodiesel (a blend of biodiesel from different raw materials). The main materials and processes used for modelling the transesterification plant are shown in Appendix A—Table A2.

3.3. Life Cycle Impact Assessment

3.3.1. Definition and Characterisation of the Main Impact Categories

Initially, to visualize the impact categories that most contributed to the total burden of environmental impacts, the results of the ReCiPe Midpoint method were normalised for both chains. The normalised results for the 18 impact categories are shown in Table 2.

Table 2.

ReCiPe Midpoint level normalised results for the Biodiesel and Polygeneration Chains.

Normalizing the results, it was possible to simplify the analysis of environmental impacts by focusing on the most affected ICs. In both proposed chains around 90% of the burden of environmental impacts was concentrated in six ICs: Ozone Formation, Human Health (OF_HH); Ozone Formation, Terrestrial Ecosystem (OF_TE); Terrestrial Ecotoxicity (TE); Marine Ecotoxicity (ME); Human Carcinogenic Toxicity (HCT) and Fossil Resource Scarcity (FRS). Additionally, Global Warming (GW) was included as a reference indicator for comparison with other similar systems.

The characterization of Polygeneration and Biodiesel Chains, in addition to the reference systems, are shown in Table 3.

Table 3.

ReCiPe Midpoint level characterisation result for Biodiesel and Polygeneration Chains.

3.3.2. Polygeneration and Biodiesel Chains

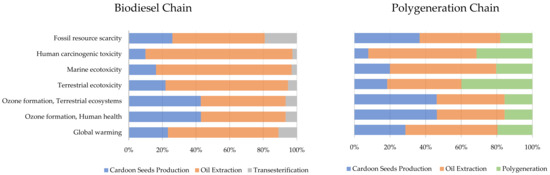

Both Polygeneration and Biodiesel chains were allocated into three macro-level categories: cardoon production, oil extraction, and depending on the use of the oil, nergy Generation or transesterification. The results in terms of the macro-level categories can be seen in Figure 2.

Figure 2.

ReCiPe Midpoint level characterization—Biodiesel and Polygeneration’s macro-level categories.

The macro-level category of cardoon production was the same in both chains. The macro-level category of oil extraction differentiated itself since in the production of biodiesel the energy demand was supplied by the Italian grid. Alternatively, in the polygeneration chain, the energy generated was used to supply the energy demand of oil xtraction. For the polygeneration chain, a plant composed of a cogeneration engine and a chiller was modelled, and for the production of biodiesel, was modelled a transesterification plant.

Cardoon production and oil extraction accounted for more than 90% of the impact burden in the biodiesel chain. The mid-level category transesterification had a relatively low impact of 3–10%. In the polygeneration chain, about 80% of the burden of impact was concentrated in cardoon production and oil extraction, except for the ICs HCT and TE, where the macro-level category energy production was more evident.

3.3.3. Cardoon Production

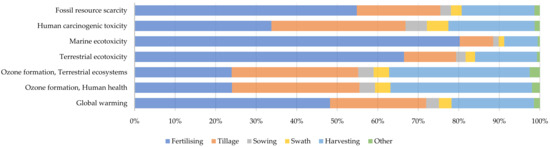

The macro-level category cardoon production was the same for the two proposed chains. It was divided into five main mid-level categories referring to the main stages of the production process (fertilising, tillage, sowing, swath, and harvesting). The mid-level category “Other” clustered the categories that had a minor impact (balling, loading, and compost). The characterization of this macro-level category can be seen in Figure 3.

Figure 3.

ReCiPe Midpoint level characterization—biodiesel and polygeneration’s cardoon production mid-level categories.

The mid-level categories with the most prominent impacts were fertilizing, tillage, and harvesting, accounting for more than 90% of the burden of impact across all ICs. In the mid-level category of fertilisation, the use of phosphate and nitrogen fertilizers accounted for almost 80–99% of all Ics in this mid-level category. The other mid-level categories dealt with machinery, which was composed of the material used to manufacture the machinery and the use of diesel. These inputs were the main impacting factors on the Ics HCT, OF (both), and GW.

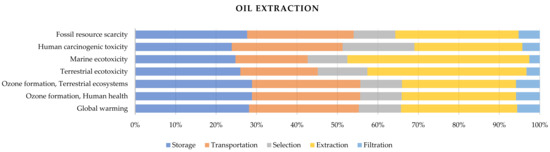

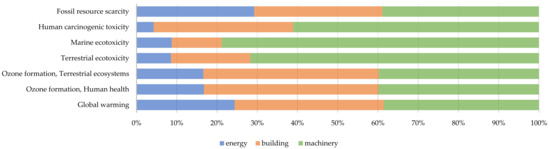

3.3.4. Oil Extraction

The macro-level category of ol extraction was divided into the following mid-level categories: storage, transportation, selection, extraction, and filtering. The percentage distribution of impacts in each of the mid-level categories, for both biodiesel and polygeneration chains, were similar. As a reference for both chains, the results for the polygeneration are shown in Figure 4.

Figure 4.

ReCiPe Midpoint level characterisation—Polygeneration’s Oil Extraction mid-level categories.

Figure 2 shows that the macro-level category of oil extraction has the highest weight in the burden of impact in both chains. In fact, in this phase, many infrastructures such as buildings and machinery are concentrated, which are complex and demand a wide variety of processes and materials for their construction and maintenance, in addition to the energy demand for their operation.

According to Figure 4, the mid-level category of Oil Extraction was the most impactful, since it was the mid-level category with the most complex machinery and the highest total weight, demanding large amounts of materials. As a result, the mid-level categories storage, transportation, selection, and filter were the most impactful, respectively.

Particularity, storage and transportation, which are composed of silos and well systems for the transport and storage of seeds, contributed to more than 50% of the burden of impact in all Ics, except ME and TE. About 60% of the total area of the plant was covered by the infrastructure of these two mid-level categories. The other categories are characterised by a greater impact due to the use of materials for the manufacture of machinery. In practice, all mid-level categories were characterized by three main elements, materials for infrastructure construction, machinery materials, and electricity consumption.

Targeting a more detailed view, the macro-level oil extraction was regrouped into three alternative mid-level categories: energy, including the total energy consumed by the machinery; machinery, including the materials and manufacturing processes of the equipment; and building, including the occupied area, infrastructure, and buildings for the oil extraction plant, Appendix A—Figure A1. In the mid-level category of machinery, all Ics were affected (39–70%), in particular Ics TE, ME, and HCT due to the use of large amounts of steel, use of electronic components, and to a lesser extent by the embodied energy. The electronic components were particularly impactful because of the use of gold and the large amounts of embodied energy which most affected the ICs TE and ME. On the other hand, the mid-category building (12–44%) had its impacts mostly caused by the intensive use of materials, in order of impact level, concrete, steel, aluminium, bricks, and diesel, were responsible for more than 70% of the impacts of all ICs. The mid-category Energy (4–29%) mainly affected the ICs FRS and GW. In fact, the Italian grid is mainly powered by the use of fossil sources, directly impacting the FRS and GW.

The only mid-category that changed in the polygeneration chain was the energy since the energy needed was supplied internally by the polygeneration unit. This macro-level category was examined in the section on energy generation.

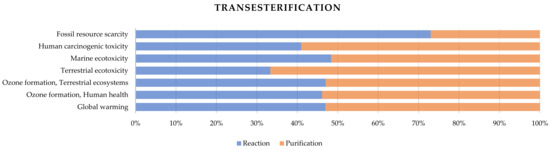

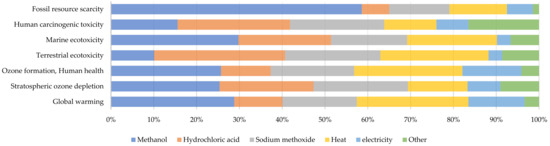

3.3.5. Transesterification

The macro-level category transesterification was divided into two mid-level categories: reaction, where biodiesel is produced; and purification, where biodiesel is separated from by-products and other chemicals used at the moment of the reaction. The results can be seen in Figure 5.

Figure 5.

ReCiPe Midpoint level characterisation—biodiesel’s transesterification mid-level categories.

The participation of the mid-level categories homogeneously affected the ICs, being subtly more affected by purification, except for the ICs FRS and TE, where approximately 70% of the impact load was caused by the reaction. The mid-level category reaction was characterized by the intense use of chemicals for the transesterification reaction, in particular methanol which was responsible for most of the burden of impact in all ICs (56–80%), except for the TE. Following the use of the base catalyser, sodium methoxide was responsible for 19–67% of the burden of impact in all ICs.

The mid-level category of purification, on the other hand, was intensive in terms of energy use. The most demanded energy resource was the use of heat which contribute on average of 40% in all ICs. The electricity was used in the processes of distillation of biodiesel and heating water to remove glycerine. Following, the use of electricity affected considerably this mid-level on the ICs OF (both), GWP, and FRS due to the use of fossil sources to supply the Italian power grid. Finally, the use of acids was impactfully in all the ICs, particularly in TE, ME, and HCT.

Because the transesterification process is very demanding in terms of chemical and energy inputs, the use of these inputs, particularly methanol, hydrochloric acid, sodium methoxide, and energy demand (heat and electricity), had a significant effect on all of the ICs investigated. These five inputs accounted for 83–99% of all CIs. Particularly, the use of methanol was what most impacted the macro-phase of biodiesel production, being the most critical input in the production of biodiesel. The individual chemical catalysts had a milder impact. From an energy point of view, the supply of heat to catalyse the process was more impactful than the use of electricity. The results can be seen in Appendix A—Figure A2.

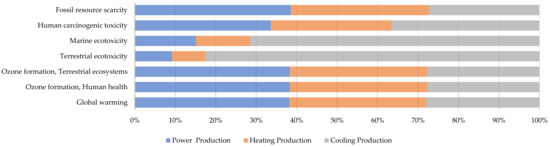

3.3.6. Energy Generation

The results of the macro-level category of Energy Generation were grouped into three mid-level categories referring to the production of each one of the energy resources in the output: power production, heat production, and cooling production. The results are shown in Figure 6.

Figure 6.

ReCiPe Midpoint level characterisation—polygeneration’s nergy generation mid-level categories.

The Energy Production presented a relatively homogeneous distribution for the ICs GWP, OF (both), HCT, and FRS, with a subtle concentration in the mid-level category of power production. The mid-level category cooling production impacted more than 70% in the ME and TE.

Aiming for the simplification and cohesion of the results, the mid-level categories Power production and Heat production were combined in this analysis since they have a common infrastructure and both energy resources are produced together by the cogeneration engine. In this combined mid-level category, the impact loads were mostly caused using materials and machinery maintenance, which are highly steel intensive. Around 80–95% of the ICs were affected by this material, the rest was caused by infrastructure construction.

The mid-level category cooling production showed the same pattern as the mid-level categories of power production and heat production; about 83–97% of the impact load was caused by the chiller manufacturing materials. There were four main materials, which aluminium, steel, copper, and electronic components. Steel and copper were the main materials to contribute practically to all ICs. It is worth noting that the TE and ME were respectively impacted by 71% and 85% by copper use.

4. Discussion

4.1. Life Cycle Interpretation

4.1.1. Macro-Level Categories

The macro-level categories of oil extraction and cardoon roduction most contributed to the burden of environmental impacts in both proposed chains (polygeneration and biodiesel), respectively. In fact, studies have pointed to agricultural production as a major contributor to the burden of impact in the biodiesel production chain [62]. In addition to the oil extraction process, which demands high amounts of energy [67] and materials. In the case of the biodiesel chain, transesterification had a much lower impact than the other phases. Still, in the case of biodiesel, cardoon production, oil extraction, and transesterification were responsible for 10–43%, 50–87%, and 3–19%, respectively. In the case of the polygeneration chain, the impacts were more distributed in the mid-level categories. Cardoon production, oil extraction, and transesterification accounted for 8–46%, 38–61%, and 16–40%.

The macro-level category of cardoon production was mostly impacted by the use of chemical fertilizers, which are nitrogen and phosphate fertilizers based on diammonium phosphate. These two inputs alone accounted for approximately half of the impact burden in the GW, TE, ME, and FRS categories. This input typically contributed to emissions in all environmental fields: air, water, and soil. Chemical fertilizers are significant sources of phosphorus and nitrogen emissions in the form of phosphates and nitrates, which mainly affect groundwater and surface water through runoff and leaching processes. This results in impacts on sweet water bodies close to the cultivation region and, finally, oceans and seas. Therefore, the demand for these inputs directly contributes to ME [68], i.e., releasing toxic substances into the marine environment, and ultimately causing damage to species in this environment [54,68]. Furthermore, phosphorus is derived from phosphate rocks, a non-renewable resource [69]. The other ICs (GWP, OF, and HCT) were mainly affected by the materials and energy resources used in machinery, particularly steel, and by the demand for diesel.

The macro-level category of oil extraction was mostly impacted by infrastructure and machinery materials. In both chains, these materials were responsible for more than 70% of the burden of impact in all ICs. In the case of machinery, the main material was steel; while in the construction of the oil extraction plant, the most intensively used materials were concrete, steel, aluminium and bricks. In the case of the biodiesel chain, since the extraction plant was fed by the Italian power grid, the impacts related to the use of electricity were not negligible, impacting the FRS and GW, being responsible for around 30% of the burden of impact in these ICs.

The macro-level category of Transesterification, as reported by several studies [62], had a high demand for chemicals which contributed between 60–80% of all ICs. The most impacting chemical inputs were methanol, hydrochloric acid, and sodium methoxide. The second biggest cause of impact was the use of energy resources, which were electricity and mostly the production of heat.

The macro-level category of energy generation was composed of two main types of machinery, the cogeneration engine, and the chiller, which contributed most of the impact load due to their material composition. The most intensively used materials were steel, aluminium, copper, and electronic components. The use of copper was responsible for 50% and 71% of the impact load on ICs TE and ME. For the other CIs, the main contributor to the impact load was the use of steel.

4.1.2. Biodiesel and Polygeneration Chains

The GWP in the Biodiesel Chain hypothesis, similar to the Polygeneration hypothesis, was primarily affected by the usage of steel, electronic components, and power, since the oil extraction process was supplied by the Italian grid. In this case, a long-term solution would be the adoption of renewable sources of primary energy by the Italian grid, in addition to increasing the use of more sustainable materials, such as alternative materials or metals and components obtained from recycling. In the OF (both), as well as in the polygeneration chain, the most impacting inputs were steel, electronic components, and diesel. The TE and ME ICs were mostly affected by the use of phosphoric acid, steel, copper, and electronic components. The impacts related to HCT were affected by the use of steel. Finally, the FRS was impacted by the use of methanol in the transesterification process, steel, electronic components, and the use of electricity and diesel. As in the case of polygeneration, there was intense demand for phosphoric acid, steel, copper, electronic components, and energy resources.

Regarding other similar systems, the cardoon-based biodiesel performed better with a large advantage on the Ics GWP compared to all other reference systems. However, regarding TE, HCT, and FRS the environmental performance was inferior to all reference systems. On ME, cardoon-based biodiesel only presented a lower performance than palm oil-based biodiesel. Regarding OF (both) it was noticed that cardoon-based biodiesel was less impactful in comparison with rapeseed-based biodiesel. The ICs with the highest percentage differences, and where cardoon-based biodiesel was significantly more impacting, were HCT followed by TE. These two most critical ICs, compared to other systems, were directly associated with the intense use of steel by the oil extraction machinery, and by the copper used in electronic systems. On the other hand, considering the endpoint level analysis, the proposed biodiesel was better placed in the “Human Health” and “Ecosystems” damage categories, only in “Resources”, its impact was more impactful. In the endpoint-level overall analysis, the cardoon-based biodiesel had a better environmental performance compared to all other reference systems.

Considering published studies, the biodiesel obtained by transesterification of other oils (palm, soybean, and rapeseed) covers a wide range of GHG emissions, ranging from 0.65–3.36 kg CO2 eq/kg of biodiesel produced. This wide variation can be explained by the fact that different input supply chains from different geographical regions are related to large-scale biodiesel production [70,71,72,73,74]. In this context, thistle-based biodiesel stands out as a potential biofuel with the possibility of having a positive impact not only from an environmental point of view but also socially and economically, as demonstrated by other authors [30].

The inputs that most affected the GWP, in the hypothesis of the use of oil in the polygeneration chain, were the use of steel used in the manufacture of industrial and agricultural machinery, and the use of anhydrous ammonia and phosphoric acid in the production of fertilizers. The OF (both) were affected by two key inputs, which were the use of concrete in the construction of facilities (extraction and polygeneration plant) and the use of diesel in agricultural machinery. The TE and ME were mostly affected by using copper, mainly present in the chiller body, the electronic component of machinery, the use of phosphoric acid, and the use of steel. HCT was mainly affected by steel production. Finally, the FRS was impacted by the use of steel, anhydrous ammonia, phosphoric acid, diesel, and electronic components. It is worth noting that the inputs that most contributed to the total impact load considering all ICs were phosphoric acid, steel, copper, electronic components, concrete, and diesel.

The polygeneration hypothesis presented a better performance in the ICs GWP and FRS in comparison to the supply of the same energy resources by the Italian power and gas grids. In fact, the proposed polygeneration chain was self-sufficient in terms of energy demands. No grid energy was used, which is characterised by the intensive use of fossil resources. In the remaining ICs, the polygeneration system was more impactful. In particular, in the ICs HCT, TE, and ME, the olygeneration chain was much more impactful than the Italian grids, respectively. Similar to the cardoon-based biodiesel, this was mainly due to the intense use of steel in the machinery, copper, and gold used in the electronic systems. In the endpoint level analysis, the polygeneration system was better in the ecosystems and resources damage categories and more impactful in human health. The final balance of the proposed polygeneration chain system was subtly lower than the use of Italian power and gas grids.

Unlike other studies using cardoon lignocellulosic material for polygeneration [69], in this study, using oil, a lower performance was observed due to its low intensity of machinery use. The energy generation phase presented considerable impacts linked to the cogeneration motor and the chiller, which were highly impactful, and was underused in the oil production scale of our proposal.

Finally, it is worth noting that the potential for using these technologies studied here depends only on the possibility of cultivating cardoon. This plant has the potential to be cultivated in several countries where cardoon is native or adapted for. In fact, the implementation of this plant has taken place in several Mediterranean countries such as Spain, France, Italy, and Portugal, where 2000 to 3000 ha have been cultivated with yields of 9 to 28 t/ha [75,76]. In addition to the European Mediterranean countries, the North African countries, in addition to China, California, Mexico, and West Africa could benefit from the implantation of this plant because they present suitable climatic conditions for cardoon [18,19,20,21,77].

5. Conclusions

The objectives of this study were to analyse the environmental performance of a prototype oil extraction plant fed with cardoon oil, in addition to testing the use of this oil for two different applications: polygeneration of power, heat, and cooling; and biodiesel production.

Considering the life cycle model developed and the database ecoinvent V3.8, the cardoon-based biodiesel chain showed a higher environmental performance compared with traditional systems of biodiesel production based on palm, rapeseed, and soybean oils. Cardoon-based biodiesel showed reduced impacts compared to other biodiesels in the midpoint impact categories of global warming and ozone formation, and in the endpoint damage categories of human health and ecosystems. The final result presented a reduction in the overall burden of impact (endpoint—single score) of 12–57% compared with the biodiesel base on palm, soybean, and rapeseed oils.

The polygeneration chain presented a lower performance compared to the use of Italian power and gas grids. The polygeneration chain was less impactful in the midpoint impact categories of global arming and fossil resource scarcity, and endpoint damage ategory resources. In the final result, polygeneration was around 13% more polluting considering the overall burden of impacts (endpoint—single score) compared with the Italian power and gas grids. Even with lower environmental performance, it is worth highlighting the potential positive impacts at a social and economic level. With the implementation of the polygeneration system, the local populations were able to benefit from the economic valorisation of the territory and the consequent generation of wealth, in addition to greater energy resilience.

Oil extraction and cardoon production were the critical phases in both proposed chains (biodiesel and polygeneration). The main inputs that contributed to the total burden of impact were the use of phosphoric acid in fertiliser production; steel, copper, and electronic components in the manufacture of machinery; and the consumption of electricity and diesel to maintain machinery operations.

Limitations of the Study and Future Perspectives

Even though the polygeneration plant demonstrated a lesser environmental performance when compared to the delivery of the same resources by Italian grids, it would be interesting to assess the increase in production size required to reach the same Italian grid’s performance. This would provide a better understanding of the ideal size of a potential polygeneration plant.

Furthermore, evaluating only the environmental performance does not meet all aspects to support the decision to implement or not a proposed technology. As a result, a deeper examination of this study in terms of social and economic aspects would be essential to better examine the entire sustainable potential of the solutions proposed.

Author Contributions

Conceptualization, R.B.L.T., A.N., G.C., A.P. and V.C.; supervision, A.N. and F.C.; writing—original draft, R.B.L.T.; writing—review and editing, R.B.L.T. All authors have read and agreed to the published version of the manuscript.

Funding

Project PRIN (BIO-CHEAPER): Biomass Circular Holistic Economy Approach to Energy equipment, Prot. 20175TXJER. MIUR.AOODGRIC.REGISTRO_PRIN2017.0000749.27-03-2018.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in Appendix A and the data regarding to the reference systems are part of the ecoinvent V3.8 database.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Cardoon Production Metadata.

Table A1.

Cardoon Production Metadata.

| Input/Output | Value |

|---|---|

| Seed production | 1.5 t/ha |

| Seed moisture | 8% |

| Seed oil content | 25% |

| Epigean fraction | 15 t/ha |

| Moisture epigean fraction | 15% |

| Hypogeum fraction | 3 t/ha |

| Moisture hypogeum fraction | 50% |

| Nitrogen fertilizer as N | 57.5 kg/ha |

| Phosphate fertilizer as P2O5 | 146.9 kg/ha |

| Compost | 20 kg/ha |

| Cultivated field | 36 ha |

Table A2.

Ecoinvent’s Materials and Processes.

Table A2.

Ecoinvent’s Materials and Processes.

| Cardoon Production |

|---|

| Nitrogen fertiliser, as N {RoW}|diammonium phosphate production|APOS, S |

| Phosphate fertiliser, as P2O5 {RoW}|diammonium phosphate production|APOS, S |

| Fertilising, by broadcaster {RoW}|processing|APOS, S |

| Tillage, harrowing, by rotary harrow {RoW}|processing|APOS, S |

| Tillage, ploughing {RoW}|processing|APOS, S |

| Swath, by rotary windrower {RoW}|processing|APOS, S |

| Baling {RoW}|processing|APOS, S |

| Bale loading {RoW}|processing|APOS, S |

| Sowing {RoW}|processing|APOS, S |

| Combine harvesting {RoW}|processing|APOS, S |

| Compost {GLO}|market for|APOS, S |

| Electricity, medium voltage {IT}|market for|APOS, S |

| Oil Extraction |

| Metal working, average for steel product manufacturing {GLO}|market for|APOS, S |

| Steel, unalloyed {GLO}|market for|APOS, S |

| Electric motor, vehicle {RER}|Production|APOS, S |

| Dust collector, multicyclone {GLO}|market for|APOS, S |

| Building, hall {GLO}|market for|APOS, S |

| Building, hall, steel construction {RoW}|building construction, hall, steel construction|APOS, S |

| Polygeneration |

| Heat and power co-generation unit, 200 kW electrical, diesel SCR, common components for heat + electricity {RER}|construction|APOS, U |

| Absorption chiller, 100 kW {RoW}|production|APOS, U |

| Biodiesel |

| Fatty acid methyl ester {RoW}|esterification of soybean oil|APOS, U (modified) |

| Polygeneration References |

| Electricity, medium voltage {IT}|market for|APOS, S |

| Heat, district or industrial, natural gas {RER}|market group for|APOS, S |

| Biodiesel References |

| Fatty acid methyl ester {RoW}|market for fatty acid methyl ester|APOS, U |

| Fatty acid methyl ester {RoW}|esterification of palm oil|APOS, U |

| Fatty acid methyl ester {RoW}|esterification of rape oil|APOS, U |

| Fatty acid methyl ester {RoW}|esterification of soybean oil|APOS, U (modified) |

| Oil References |

| Palm kernel oil, crude {GLO}|market for|APOS, U |

| Palm oil, crude {GLO}|market for|APOS, U |

| Rape oil, crude {RoW}|market for|APOS, U |

| Soybean oil, crude {GLO}|market for|APOS, U |

Figure A1.

ReCiPe Midpoint level characterization—Biodiesel’s Oil Extraction mid-level categories.

Figure A2.

ReCiPe Midpoint level characterization—Biodiesel’s Transesterification mid-level categories.

References

- Edenhofer, O. (Ed.) Climate Change 2014: Mitigation of Climate Change; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- Ottaiano, L.; di Mola, I.; Impagliazzo, A.; Cozzolino, E.; Masucci, F.; Mori, M.; Fagnano, M. Yields and Quality of Biomasses and Grain in Cynara cardunculus L. Grown in Southern Italy, as Affected by Genotype and Environmental Conditions. Ital. J. Agron. 2017, 11, 375–382. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, J.; Zhao, J. Thermochemical Conversion of Triglycerides for Production of Drop-in Liquid Fuels. Renew. Sustain. Energy Rev. 2016, 58, 331–340. [Google Scholar] [CrossRef]

- Gerland, P.; Raftery, A.E.; Ševčíková, H.; Li, N.; Gu, D.; Spoorenberg, T.; Alkema, L.; Fosdick, B.K.; Chunn, J.; Lalic, N.; et al. World Population Stabilization Unlikely This Century. Science (1979) 2014, 346, 234–237. [Google Scholar] [CrossRef]

- Statista OPEC Primary Energy Demand Worldwide in 2020, with a Forecast until 2045, by Fuel Type. Available online: https://woo.opec.org/chapter.php?chapterNr=206 (accessed on 14 October 2022).

- Fawzy, S.; Osman, A.I.; Doran, J.; Rooney, D.W. Strategies for Mitigation of Climate Change: A Review. Environ. Chem. Lett. 2020, 18, 2069–2094. [Google Scholar] [CrossRef]

- Osman, A.I.; Hefny, M.; Abdel Maksoud, M.I.A.; Elgarahy, A.M.; Rooney, D.W. Recent Advances in Carbon Capture Storage and Utilisation Technologies: A Review. Environ. Chem. Lett. 2021, 19, 797–849. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Conversion of Biomass to Biofuels and Life Cycle Assessment: A Review. Environ. Chem. Lett. 2021, 19, 4075–4118. [Google Scholar] [CrossRef]

- Moore, J.E.; Mascarenhas, A.; Bain, J.; Straus, S.E. Developing a Comprehensive Definition of Sustainability. Implement. Sci. 2017, 12, 110. [Google Scholar] [CrossRef]

- IEA—International Energy Agency—World Energy Outlook. Available online: https://iea.blob.core.windows.net/assets/e6f58562-203e-474c-97a3-486f409aa7ff/WEO2014.pdf (accessed on 14 October 2022).

- Yaashikaa, P.R.; Kumar, P.S.; Karishma, S. Bio-Derived Catalysts for Production of Biodiesel: A Review on Feedstock, Oil Extraction Methodologies, Reactors and Lifecycle Assessment of Biodiesel. Fuel 2022, 316, 123379. [Google Scholar] [CrossRef]

- Mehmood, M.A.; Ibrahim, M.; Rashid, U.; Nawaz, M.; Ali, S.; Hussain, A.; Gull, M. Biomass Production for Bioenergy Using Marginal Lands. Sustain. Prod. Consum. 2017, 9, 3–21. [Google Scholar] [CrossRef]

- Turco, R.; Tesser, R.; Cucciolito, M.E.; Fagnano, M.; Ottaiano, L.; Mallardo, S.; Malinconico, M.; Santagata, G.; di Serio, M. Cynara Cardunculus Biomass Recovery: An Eco-Sustainable, Nonedible Resource of Vegetable Oil for the Production of Poly(Lactic Acid) Bioplasticizers. ACS Sustain. Chem. Eng. 2019, 7, 4069–4077. [Google Scholar] [CrossRef]

- Bureau, J.-C.; Swinnen, J. EU Policies and Global Food Security. Glob. Food Sec. 2018, 16, 106–115. [Google Scholar] [CrossRef]

- McKendry, P. Energy Production from Biomass (Part 1): Overview of Biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Gominho, J.; Curt, M.D.; Lourenço, A.; Fernández, J.; Pereira, H. Cynara cardunculus L. as a Biomass and Multi-Purpose Crop: A Review of 30 Years of Research. Biomass Bioenergy 2018, 109, 257–275. [Google Scholar] [CrossRef]

- Abt, R.C.; Abt, K.L.; Cubbage, F.W.; Henderson, J.D. Effect of Policy-Based Bioenergy Demand on Southern Timber Markets: A Case Study of North Carolina. Biomass Bioenergy 2010, 34, 1679–1686. [Google Scholar] [CrossRef]

- Archontoulis, S.V.; Struik, P.C.; Vos, J.; Danalatos, N.G. Phenological Growth Stages of Cynara Cardunculus: Codification and Description According to the BBCH Scale. Ann. Appl. Biol. 2010, 156, 253–270. [Google Scholar] [CrossRef]

- Bolohan, C.; Marin, D.I.; Mihalache, M.; Ilie, L.; Oprea, A.C. Oprea Research on Cynara cardunculus L. Species under the Conditions of Southeastern Romania Area. Geography 2013, 56, 429–432. [Google Scholar]

- Fernández, J.; Curt, M.D.; Aguado, P.L. Industrial Applications of Cynara cardunculus L. for Energy and Other Uses. Ind. Crop. Prod. 2006, 24, 222–229. [Google Scholar] [CrossRef]

- Raccuia, S.A.; Melilli, M.G. Biomass and Grain Oil Yields in Cynara cardunculus L. Genotypes Grown in a Mediterranean Environment. Field Crop. Res. 2007, 101, 187–197. [Google Scholar] [CrossRef]

- Zayed, A.; Serag, A.; Farag, M.A. Cynara cardunculus L.: Outgoing and Potential Trends of Phytochemical, Industrial, Nutritive and Medicinal Merits. J. Funct. Foods 2020, 69, 103937. [Google Scholar] [CrossRef]

- Angelini, L.G.; Ceccarini, L.; Nassi o Di Nasso, N.; Bonari, E. Long-Term Evaluation of Biomass Production and Quality of Two Cardoon (Cynara cardunculus L.) Cultivars for Energy Use. Biomass Bioenergy 2009, 33, 810–816. [Google Scholar] [CrossRef]

- Fernández, J.; Hidalgo, M.; del Monte, J.P.; Curt, M.D. Cynara cardunculus L. as a Perennial Crop for Non-Irrigated Lands: Yields and Applications. Acta Hortic. 2005, 681, 109–116. [Google Scholar] [CrossRef]

- Curt, M.D.; Sánchez, G.; Fernández, J. The Potential of Cynara cardunculus L. for Seed Oil Production in a Perennial Cultivation System. Biomass Bioenergy 2002, 23, 33–46. [Google Scholar] [CrossRef]

- Hill, K. Industrial Development and Application of Biobased Oleochemicals. In Biorefineries-Industrial Processes and Products. Wiley-VCH Verlag GmbH: Weinheim, Germany; pp. 291–314.

- Cherubini, F. The Biorefinery Concept: Using Biomass Instead of Oil for Producing Energy and Chemicals. Energy Convers Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Gil, M.; Arauzo, I.; Teruel, E.; Bartolomé, C. Milling and Handling Cynara cardunculus L. for Use as Solid Biofuel: Experimental Tests. Biomass Bioenergy 2012, 41, 145–156. [Google Scholar] [CrossRef]

- Cavalaglio, G.; Petrozzi, A.; Coccia, V.; D’Antonio, S.; Cotana, S. Mass and Energy Flows of Cardoon Oil in a Prototype System for Seeds Milling and Vegetable Oil Treatment and Cogeneration. Energy Procedia 2015, 82, 681–686. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Sánchez, N.; Encinar, J.M. Valorization of Cynara cardunculus L. Oil as the Basis of a Biorefinery for Biodiesel and Biolubricant Production. Energies 2020, 13, 5085. [Google Scholar] [CrossRef]

- Coulson, M.; Bridgwater, A.V. Fast Pyrolysis of Annually Harvested Crops for Bioenergy Applications. Bio.-Energy Res. Group 2004, 1098, 10–14. [Google Scholar]

- Genovese, C.; Platania, C.; Venticinque, M.; Calderaro, P.; Argento, S.; Scandurra, S.; Raccuia, S.A. Evaluation of Cardoon Seeds Presscake for Animal Feeding. Acta Hortic. 2016, 1147, 323–328. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Varriale, S.; Porta, R.; Naviglio, D.; Spennato, M.; Gardossi, L.; Giosafatto, C.V.L.; Pezzella, C. A Biorefinery Approach for the Conversion of Cynara cardunculus Biomass to Active Films. Food Hydrocoll. 2022, 122, 107099. [Google Scholar] [CrossRef]

- Turco, R.; Tesser, R.; Russo, V.; Vitiello, R.; Fagnano, M.; di Serio, M. Comparison of Different Possible Technologies for Epoxidation of Cynara cardunculus Seed Oil. Eur. J. Lipid Sci. Technol. 2020, 122, 1900100. [Google Scholar] [CrossRef]

- Baskar, G.; Kalavathy, G.; Aiswarya, R.; Abarnaebenezer Selvakumari, I. Advances in Bio-Oil Extraction from Nonedible Oil Seeds and Algal Biomass. In Advances in Eco-Fuels for a Sustainable Environment; Elsevier: Amsterdam, The Netherlands, 2019; pp. 187–210. [Google Scholar]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumar Sharma, P.; Jhalani, A. A Review on Feedstocks, Production Processes, and Yield for Different Generations of Biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Petropoulos, S.A.; Fernandes, Â.; Calhelha, R.C.; Danalatos, N.; Barros, L.; Ferreira, I.C.F.R. How Extraction Method Affects Yield, Fatty Acids Composition and Bioactive Properties of Cardoon Seed Oil? Ind. Crop. Prod. 2018, 124, 459–465. [Google Scholar] [CrossRef]

- Azadmard-Damirchi, S.; Habibi-Nodeh, F.; Hesari, J.; Nemati, M.; Achachlouei, B.F. Effect of Pretreatment with Microwaves on Oxidative Stability and Nutraceuticals Content of Oil from Rapeseed. Food Chem. 2010, 121, 1211–1215. [Google Scholar] [CrossRef]

- Subroto, E.; Manurung, R.; Heeres, H.J.; Broekhuis, A.A. Optimization of Mechanical Oil Extraction from Jatropha curcas L. Kernel Using Response Surface Method. Ind. Crop. Prod. 2015, 63, 294–302. [Google Scholar] [CrossRef]

- Nde, D.; Foncha, A. Optimization Methods for the Extraction of Vegetable Oils: A Review. Processes 2020, 8, 209. [Google Scholar] [CrossRef]

- Guédé, S.S.; Soro, Y.R.; Kouamé, A.F.; Brou, K. Optimization of Screw Press Extraction of Citrillus Lanatus Seed Oil and Physicochemical Characterization. Eur. J. Food Sci. Technol. 2017, 5, 35–46. [Google Scholar]

- Long, F.; Zhang, X.; Cao, X.; Zhai, Q.; Song, Y.; Wang, F.; Jiang, J.; Xu, J. Mechanism Investigation on the Formation of Olefins and Paraffin from the Thermochemical Catalytic Conversion of Triglycerides Catalyzed by Alkali Metal Catalysts. Fuel Process. Technol. 2020, 200, 106312. [Google Scholar] [CrossRef]

- Khan, S.; Kay Lup, A.N.; Qureshi, K.M.; Abnisa, F.; Wan Daud, W.M.A.; Patah, M.F.A. A Review on Deoxygenation of Triglycerides for Jet Fuel Range Hydrocarbons. J. Anal. Appl. Pyrolysis 2019, 140, 1–24. [Google Scholar] [CrossRef]

- Athar, M.; Zaidi, S. A Review of the Feedstocks, Catalysts, and Intensification Techniques for Sustainable Biodiesel Production. J. Environ. Chem. Eng. 2020, 8, 104523. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Giosafatto, C.V.L.; Porta, R. Biorefining of Seed Oil Cakes as Industrial Co-Streams for Production of Innovative Bioplastics. A Review. Trends Food Sci. Technol. 2021, 109, 259–270. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A Technological and Economic Review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Cotana, F.; Cavalaglio, G.; Petrozzi, A.; Coccia, V. Lignocellulosic Biomass Feeding in Biogas Pathway: State of the Art and Plant Layouts. Energy Procedia 2015, 81, 1231–1237. [Google Scholar] [CrossRef]

- ISO. Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040); International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- ISO. Environmental Management—Life Cycle Assessment: Requirements and Guidelines (ISO 14044); International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Letcher, T. Comprehensive Renewable Energy, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Sustainability SimaPro. Available online: https://simapro.com/ (accessed on 14 October 2022).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E. Bo Weidema. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Deligios, P.A.; Sulas, L.; Spissu, E.; Re, G.A.; Farci, R.; Ledda, L. Effect of Input Management on Yield and Energy Balance of Cardoon Crop Systems in Mediterranean Environment. Eur. J. Agron. 2017, 82, 173–181. [Google Scholar] [CrossRef]

- Mancini, M.; Lanza Volpe, M.; Gatti, B.; Malik, Y.; Moreno, A.C.; Leskovar, D.; Cravero, V. Characterization of Cardoon Accessions as Feedstock for Biodiesel Production. Fuel 2019, 235, 1287–1293. [Google Scholar] [CrossRef]

- Mettler Toledo Instruments Moisture Analyzer HB43-S. Available online: https://Www.Mt.Com/Dam/P5/Labtec/05_Moisture_Analyzer/02_Advanced_Line/03_Documents/03_Operating_Instructions/HB43-S_OI_en.Pdf (accessed on 14 October 2022).

- LECO Instruments Calorimeter AC-350. Available online: http://Www.Zycon.Com/Literature/128173/62890/Ac-350%20flyer%20203-968.Pdf (accessed on 14 October 2022).

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Torres, C.M.; Ríos, S.D.; Torras, C.; Salvadó, J.; Mateo-Sanz, J.M.; Jiménez, L. Sustainability Analysis of Biodiesel Production from Cynara cardunculus Crop. Fuel 2013, 111, 535–542. [Google Scholar] [CrossRef]

- Ganesan, R.; Manigandan, S.; Shanmugam, S.; Chandramohan, V.P.; Sindhu, R.; Kim, S.-H.; Brindhadevi, K.; Pugazhendhi, A. A Detailed Scrutinize on Panorama of Catalysts in Biodiesel Synthesis. Sci. Total Environ. 2021, 777, 145683. [Google Scholar] [CrossRef]

- Li, D.; Feng, W.; Chen, C.; Chen, S.; Fan, G.; Liao, S.; Wu, G.; Wang, Z. Transesterification of Litsea Cubeba Kernel Oil to Biodiesel over Zinc Supported on Zirconia Heterogeneous Catalysts. Renew. Energy 2021, 177, 13–22. [Google Scholar] [CrossRef]

- Kant Bhatia, S.; Kant Bhatia, R.; Jeon, J.-M.; Pugazhendhi, A.; Kumar Awasthi, M.; Kumar, D.; Kumar, G.; Yoon, J.-J.; Yang, Y.-H. An Overview on Advancements in Biobased Transesterification Methods for Biodiesel Production: Oil Resources, Extraction, Biocatalysts, and Process Intensification Technologies. Fuel 2021, 285, 119117. [Google Scholar] [CrossRef]

- Long, F.; Liu, W.; Jiang, X.; Zhai, Q.; Cao, X.; Jiang, J.; Xu, J. State-of-the-Art Technologies for Biofuel Production from Triglycerides: A Review. Renew. Sustain. Energy Rev. 2021, 148, 111269. [Google Scholar] [CrossRef]

- Guo, S.; Yang, Z.; Gao, Y. Effect of Adding Biodiesel to Diesel on the Physical and Chemical Properties and Engine Performance of Fuel Blends. J. Biobased. Mater. Bioenergy 2016, 10, 34–43. [Google Scholar] [CrossRef]

- Ambat, I.; Srivastava, V.; Sillanpää, M. Recent Advancement in Biodiesel Production Methodologies Using Various Feedstock: A Review. Renew. Sustain. Energy Rev. 2018, 90, 356–369. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; Schryver, A.; Struijs, J.; Zelm, R. ReCiPE 2008: A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level. Natl. Inst. Public Health Environ. 2008. Available online: https://web.universiteitleiden.nl/cml/ssp/publications/recipe_characterisation.pdf (accessed on 14 October 2022).

- Krug, T.; Tanabe, K.; Srivastava, N.; Jamsranjav, B.; Fukuda, M.; Troxler, T. Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol; Intergovernmental Panel on Climate Change: Cham, Switzerland, 2004. [Google Scholar]

- Temporim, R.B.L.; Petrozzi, A.; Coccia, V.; Cotana, F.; Cavalaglio, G. A Prototype Plant for Oilseed Extraction: Analysis of Mass and Energy Flows. Sustainability 2020, 12, 9786. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. (Eds.) Life Cycle Assessment—Theory and Practice; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-56474-6. [Google Scholar]

- Barros Lovate Temporim, R.; Cavalaglio, G.; Petrozzi, A.; Coccia, V.; Iodice, P.; Nicolini, A.; Cotana, F. Life Cycle Assessment and Energy Balance of a Polygeneration Plant Fed with Lignocellulosic Biomass of Cynara cardunculus L. Energies 2022, 15, 2397. [Google Scholar] [CrossRef]

- Cespi, D.; Passarini, F.; Mastragostino, G.; Vassura, I.; Larocca, S.; Iaconi, A.; Chieregato, A.; Dubois, J.-L.; Cavani, F. Glycerol as Feedstock in the Synthesis of Chemicals: A Life Cycle Analysis for Acrolein Production. Green Chem. 2015, 17, 343–355. [Google Scholar] [CrossRef]

- Burnham, A.; Han, J.; Clark, C.E.; Wang, M.; Dunn, J.B.; Palou-Rivera, I. Life-Cycle Greenhouse Gas Emissions of Shale Gas, Natural Gas, Coal, and Petroleum. Environ. Sci. Technol. 2012, 46, 619–627. [Google Scholar] [CrossRef]

- Carvalho, M.; da Silva, E.S.; Andersen, S.L.F.; Abrahão, R. Life Cycle Assessment of the Transesterification Double Step Process for Biodiesel Production from Refined Soybean Oil in Brazil. Environ. Sci. Pollut. Res. 2016, 23, 11025–11033. [Google Scholar] [CrossRef]

- González-García, S.; García-Rey, D.; Hospido, A. Environmental Life Cycle Assessment for Rapeseed-Derived Biodiesel. Int. J. Life Cycle Assess. 2013, 18, 61–76. [Google Scholar] [CrossRef]

- de Souza, S.P.; Pacca, S.; de Ávila, M.T.; Borges, J.L.B. Greenhouse Gas Emissions and Energy Balance of Palm Oil Biofuel. Renew. Energy 2010, 35, 2552–2561. [Google Scholar] [CrossRef]

- Al-attab, K.A.; Zainal, Z.A. Performance of High-Temperature Heat Exchangers in Biomass Fuel Powered Externally Fired Gas Turbine Systems. Renew. Energy 2010, 35, 913–920. [Google Scholar] [CrossRef]

- Haes, U.; Finnveden, G.; Goedkoop, M.; Hauschild, M.; Hertwich, E.; Hofstetter, P.; Jolliet, O.; Klöpffer, W.; Krewitt, W.; Lindeijer, E.; et al. Life-Cycle Impact Assessment: Striving Towards Best Practice. In Brussels: Society of Environmental Toxicology and Chemistry (SETAC); SETAC Press: Pensacola, FL, USA, 2002; ISBN 1-880611-54-6. [Google Scholar]

- Vergara, P.; Ladero, M.; García-Ochoa, F.; Villar, J.C. Valorization of Cynara cardunculus Crops by Ethanol-Water Treatment: Optimization of Operating Conditions. Ind. Crop. Prod. 2018, 124, 856–862. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).