The Agro-Waste Production in Selected EUSAIR Regions and Its Potential Use for Building Applications: A Review

Abstract

1. Introduction

2. Materials and Methods

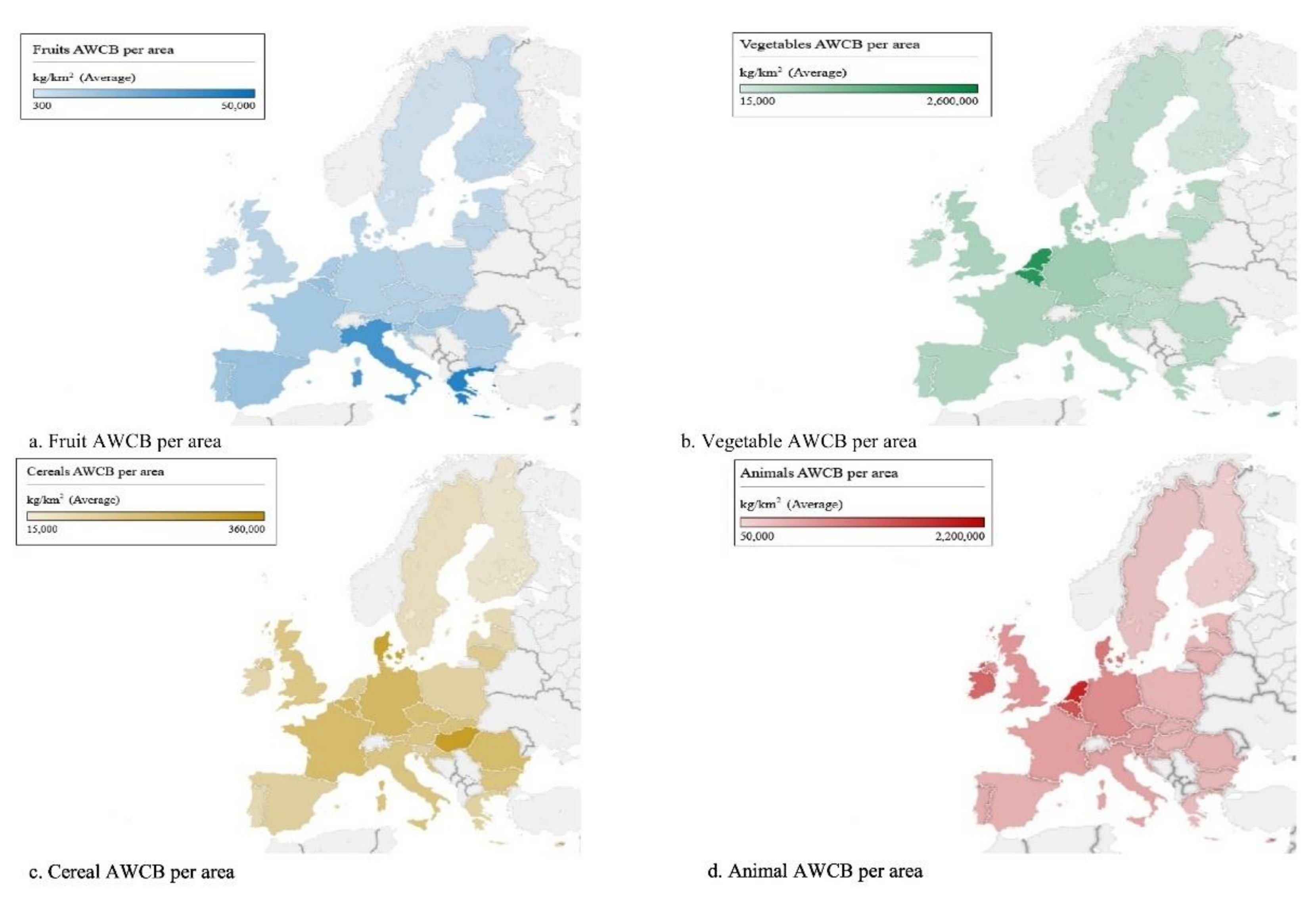

3. Agriculture and Agro-Waste

4. Re-Use and Recycle: Building Applications

5. Agro-Waste Production and Use in the Building Sector

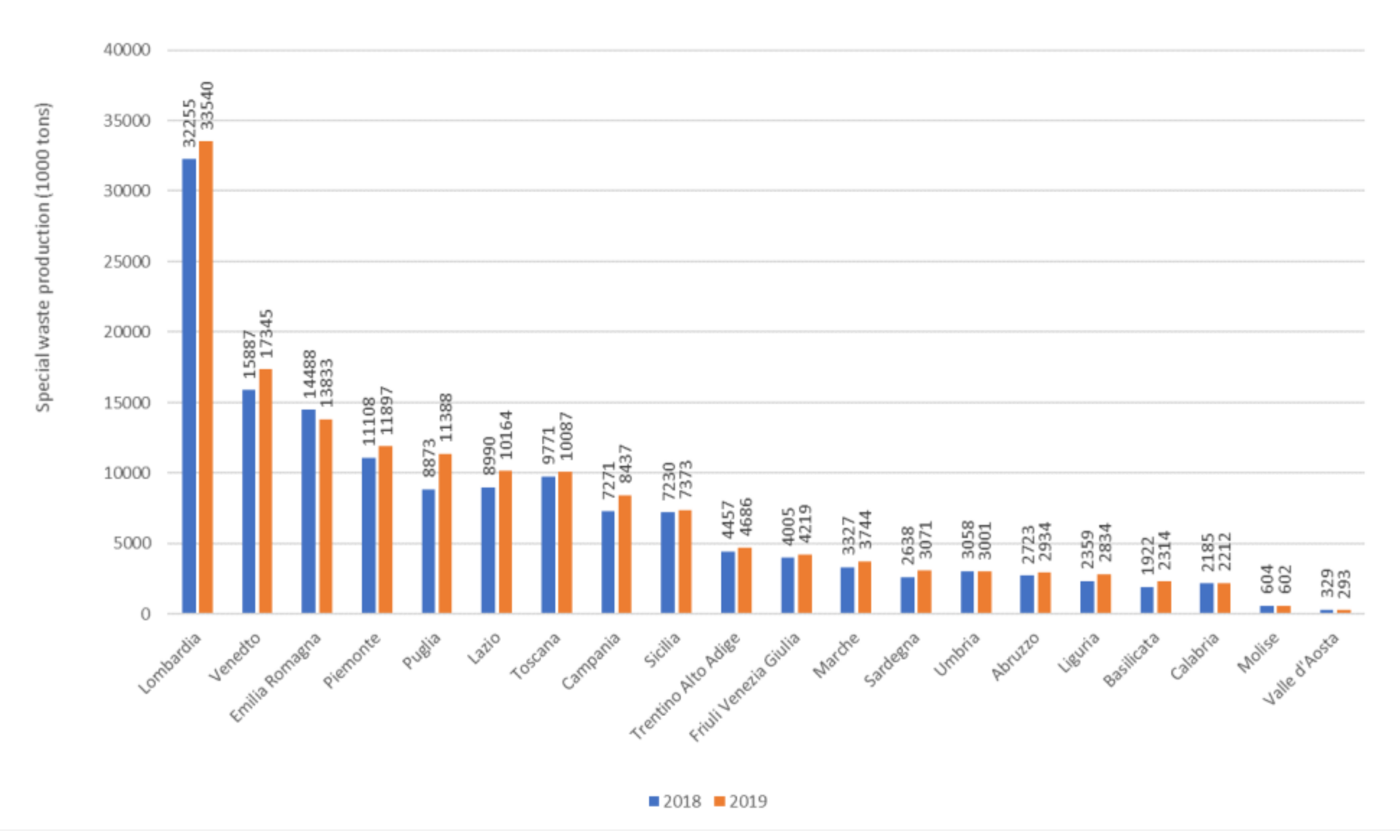

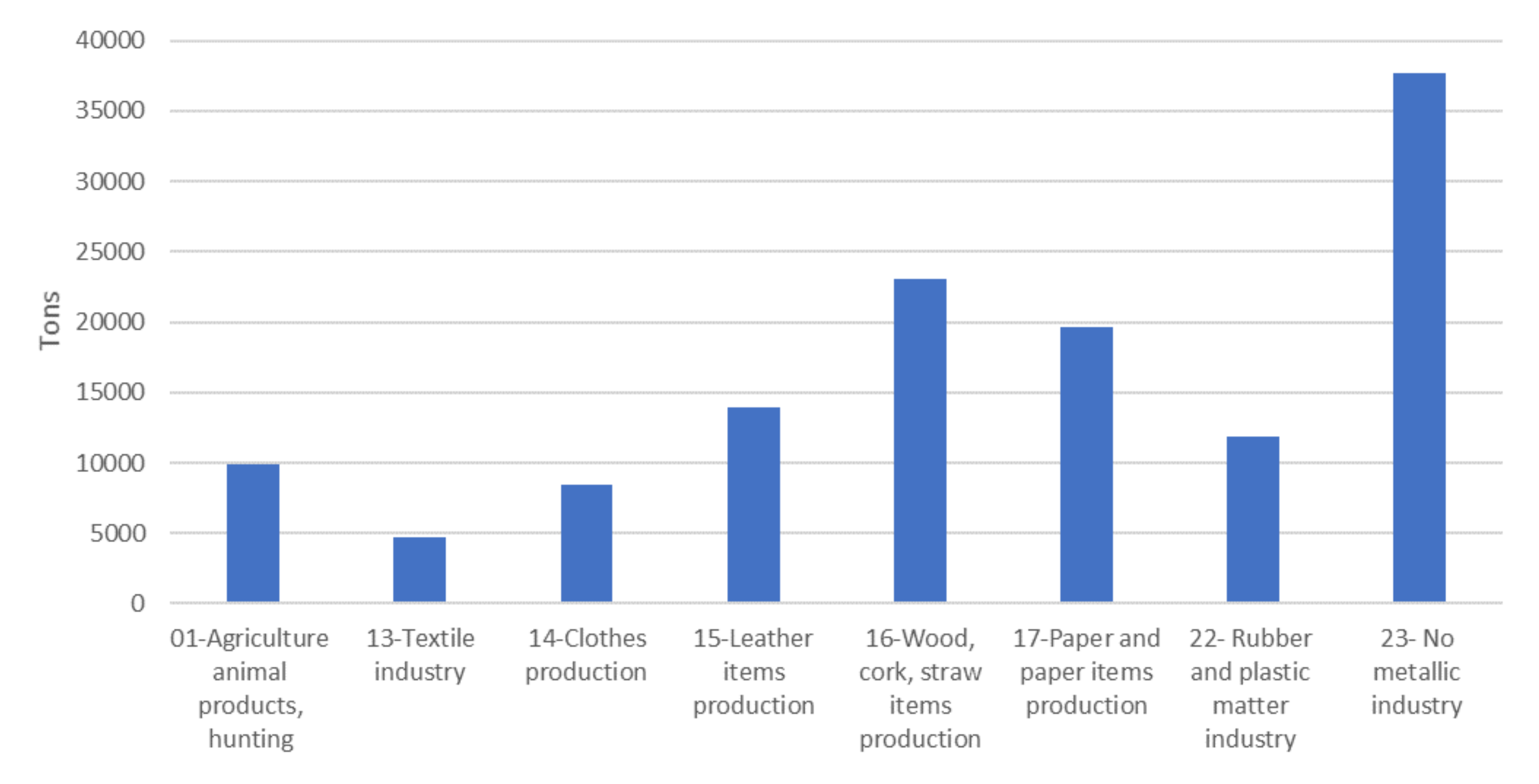

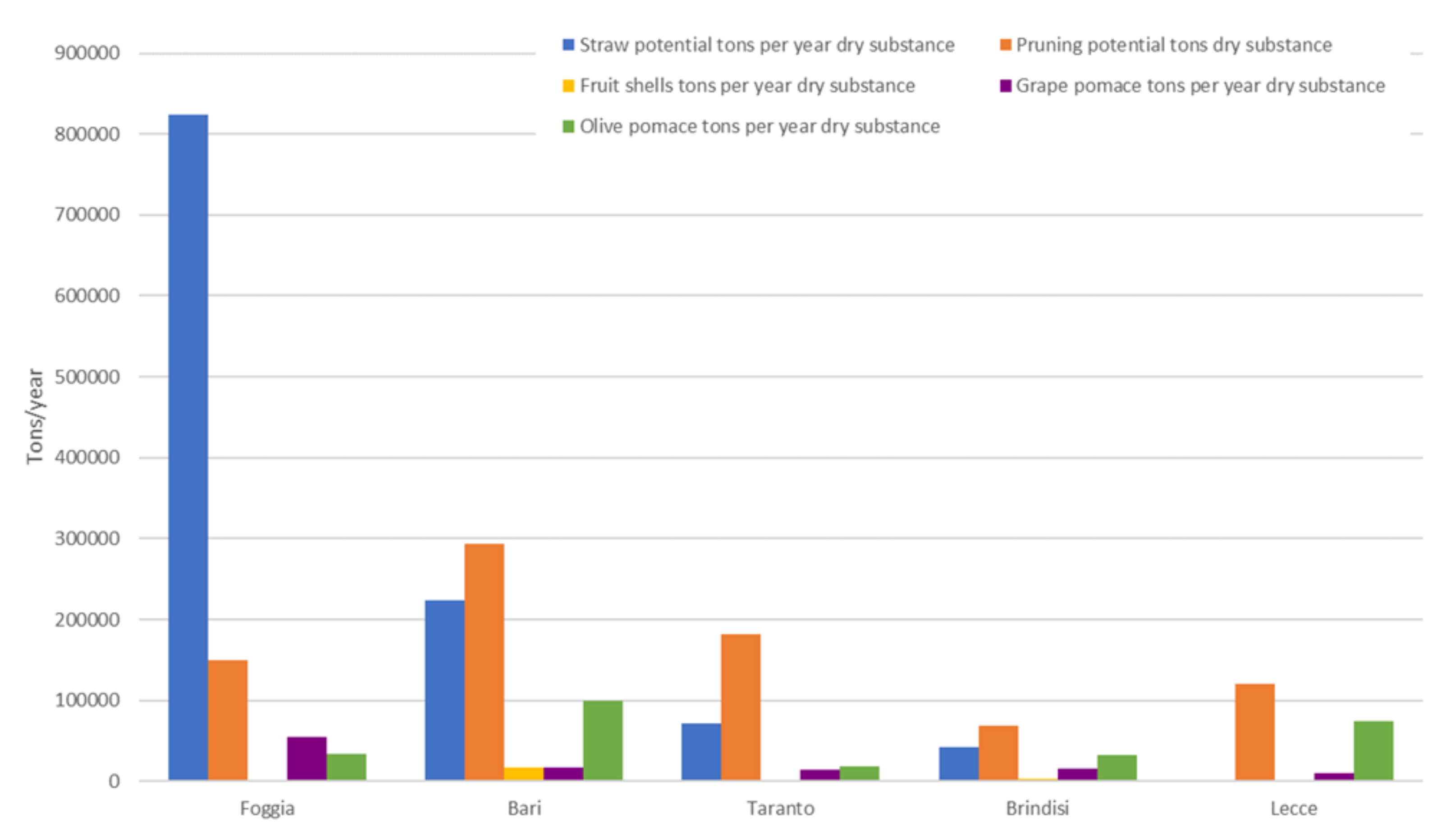

5.1. Puglia and Molise

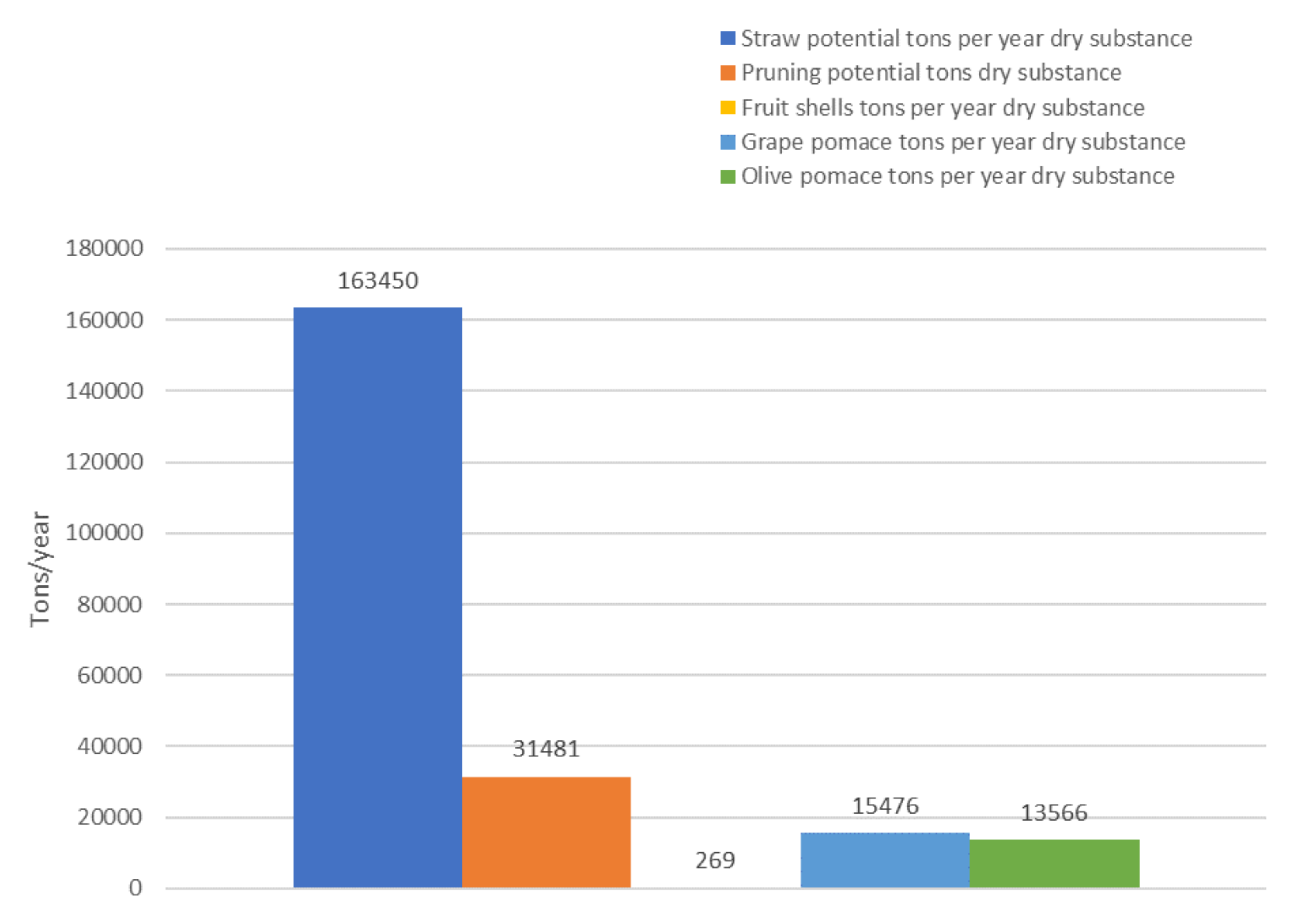

5.2. Montenegro

- the harvesting method;

- the moisture content;

- the demand of agricultural residues for other scopes (animal feeding or bedding);

- the need to store the residues on the soil as nutrients.

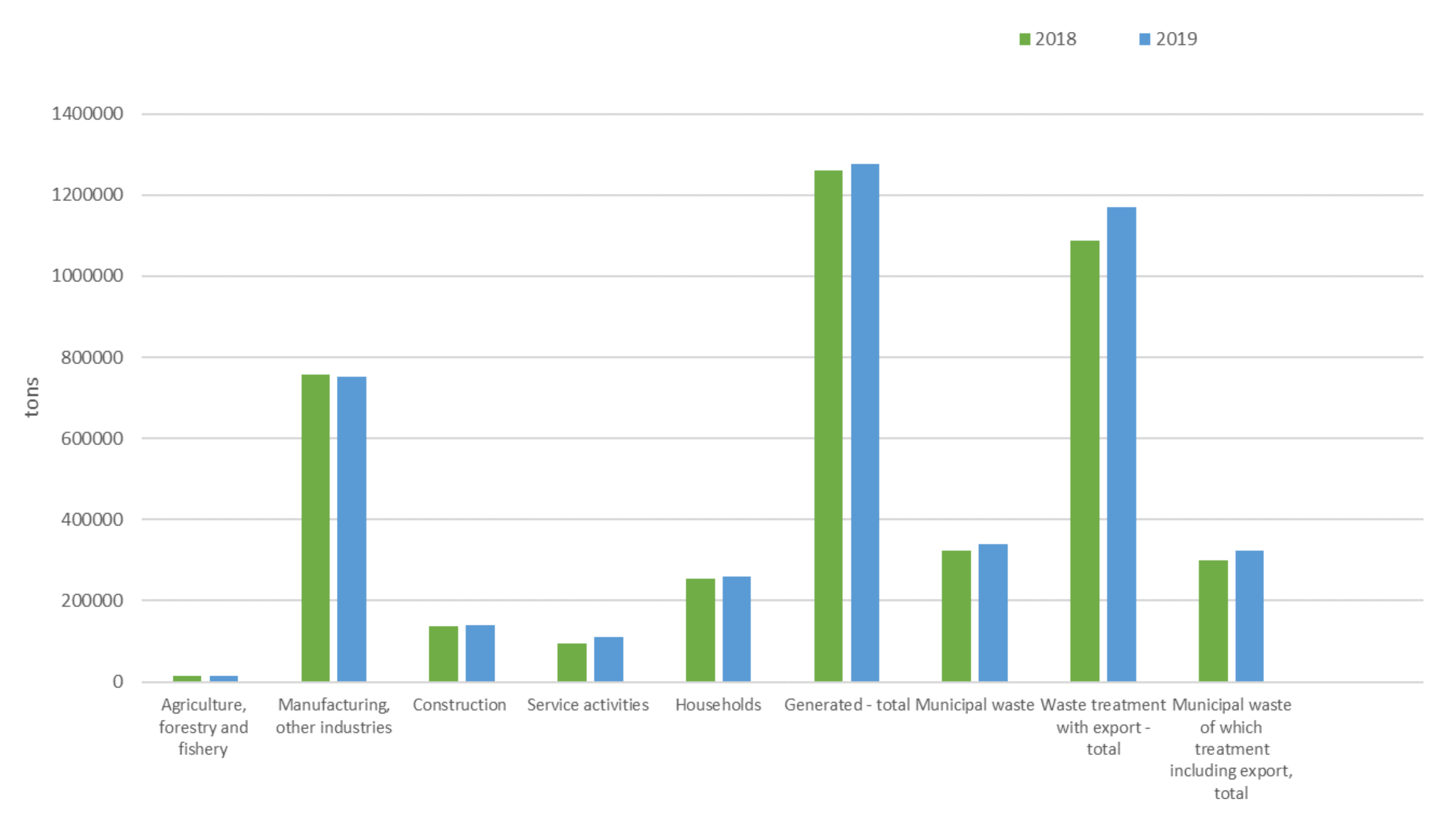

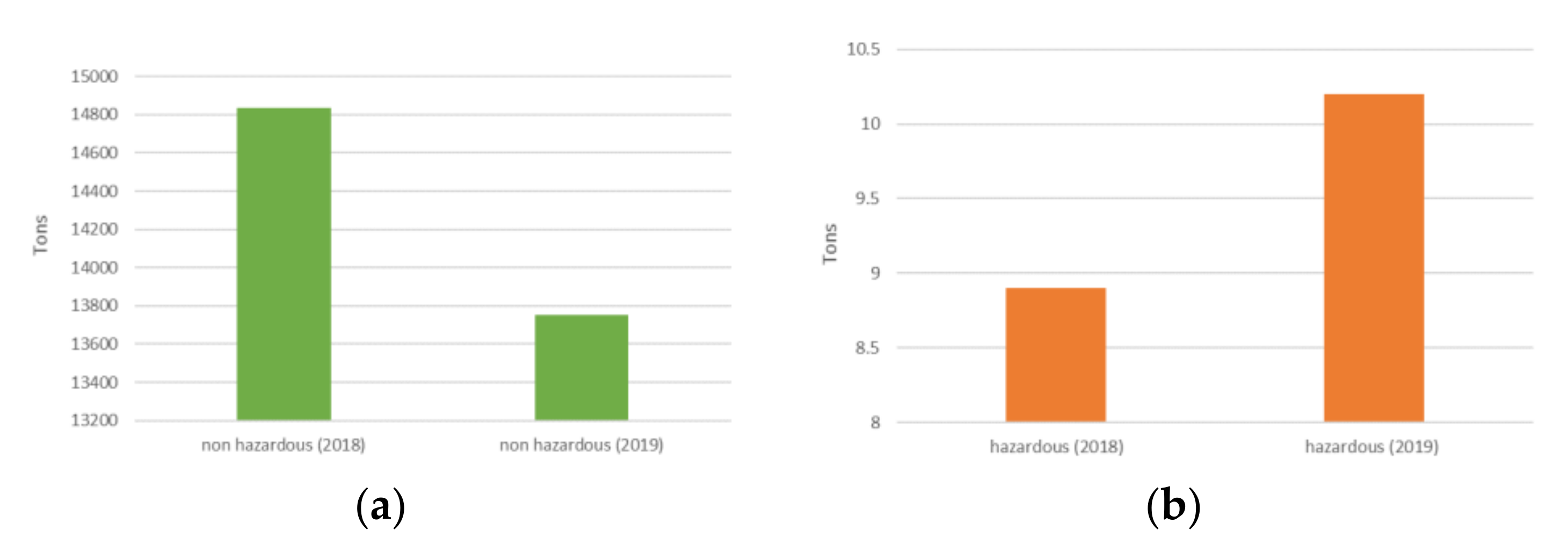

5.3. Albania

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Bank. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Circular Economy Action Plan. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2020:98:FIN (accessed on 30 September 2021).

- EU. 2013. Available online: https://ec.europa.eu/eurostat/web/main/home (accessed on 12 November 2021).

- Hernandez, G.A.A.; Dias, J.F.; Tukkera, R.A. Macroeconomic, social and environmental impacts of a circular economy up to 2050: A meta-analysis of prospective studies. J. Clean. Prod. 2021, 278, 123421. [Google Scholar] [CrossRef]

- Haiyuan Maa, H.; Guoa, Y.; Qina, Y.; Lia, Y.Y. Nutrient recovery technologies integrated with energy recovery by waste biomass anaerobic digestion. Bioresour. Technol. 2018, 269, 520–531. [Google Scholar]

- Khan, A.; De Jong, W.; Jansens, P.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Pereira, A.; Akasaki, J.L.; Melges, J.L.; Tashima, M.; Soriano, L.; Borrachero, M.V.; Monzó, J.; Payá, J. Mechanical and durability properties of alkali-activated mortar based on sugarcane bagasse ash and blast furnace slag. Ceram. Int. 2015, 41, 13012–13024. [Google Scholar] [CrossRef]

- Ismail, M.S.; Waliuddin, A. Effect of rice husk ash on high strength concrete. Constr. Build. Mater. 1996, 10, 521–526. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Saeting, T.; Jaturapitakkul, C.; Kiattikomol, K.; Siripanichgorn, A. Use of waste ash from palm oil industry in concrete. Waste Manag. 2007, 27, 81–88. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Köppen-Geiger Climate Map. Available online: http://koeppen-geiger.vu-wien.ac.at/present.htm (accessed on 12 November 2021).

- Jager, A.C. Exposure of Poultry Farm Workers to Ammonia, Particulate Matter and Microorganisms in the Otchefstroom District, South Africa. Master’s Dissertation, NorthWest University, Potchefstroom, South Africa, 2005. [Google Scholar]

- Lim, S.F.; Matu, S.U. Utilization of agro-wastes to produce biofertilizer. Int. J. Energy Envion. Eng. 2015, 6, 31–35. [Google Scholar] [CrossRef]

- Moshood, A.; NasirAni, A.F. Recent development in the production of activated carbon electrodes from agricultural waste biomass for supercapacitors: A review. Renew. Sustain. Energy Rev. 2015, 52, 1282–1293. [Google Scholar]

- Esparcia, J. Innovation and networks in rural areas. An analysis from European innovative projects. J. Rural Stud. 2014, 34, 1–14. [Google Scholar] [CrossRef]

- Bedoić, R.; Ćosić, B.; Duić, N. Technical potential and geographic distribution of agricultural residues, co- products and by-products in the European Union. Sci. Total Environ. 2019, 686, 568–579. [Google Scholar] [CrossRef] [PubMed]

- Sortino, O.; Montoneri, E.; Patanè, C.; Rosato, R.; Tabasso, S.; Ginepro, M. Benefits for agriculture and the environment from urban waste. Sci. Total Environ. 2014, 487, 443–451. [Google Scholar] [CrossRef] [PubMed]

- Malico, I.; Carrajola, J.; Pinto Gomes, C.; Lima, J.C. Biomass residues for energy production and habitat preservation. Case study in a montado area in Southwestern Europe. J. Clean. Prod. 2016, 112, 3676–3683. [Google Scholar] [CrossRef]

- Liuzzi, S.; Sanarica, S.; Stefanizzi, P. Use of agro-wastes in building materials in the Mediterranean area: A review. Energy Procedia 2017, 126, 242–249. [Google Scholar]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crop. Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. [Google Scholar]

- Barreca, F.; Ficheira, C.R. Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- Ashour, T.; Korjenic, A.; Korjenic, S.; Wu, W. Thermal conductivity of unfired earth bricks reinforced by agricultural wastes with cement and gypsum. Energy Build. 2015, 104, 139–146. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O. Eco-friendly insulation material production with waste olive seeds, ground PVC and wood chips. J. Build. Eng. 2016, 5, 260–266. [Google Scholar] [CrossRef]

- Liuzzi, S.; Stefanizzi, P. Experimental investigation on lightweight and lime stabilized earth composites. Key Eng. Mater. 2016, 666, 31–45. [Google Scholar] [CrossRef]

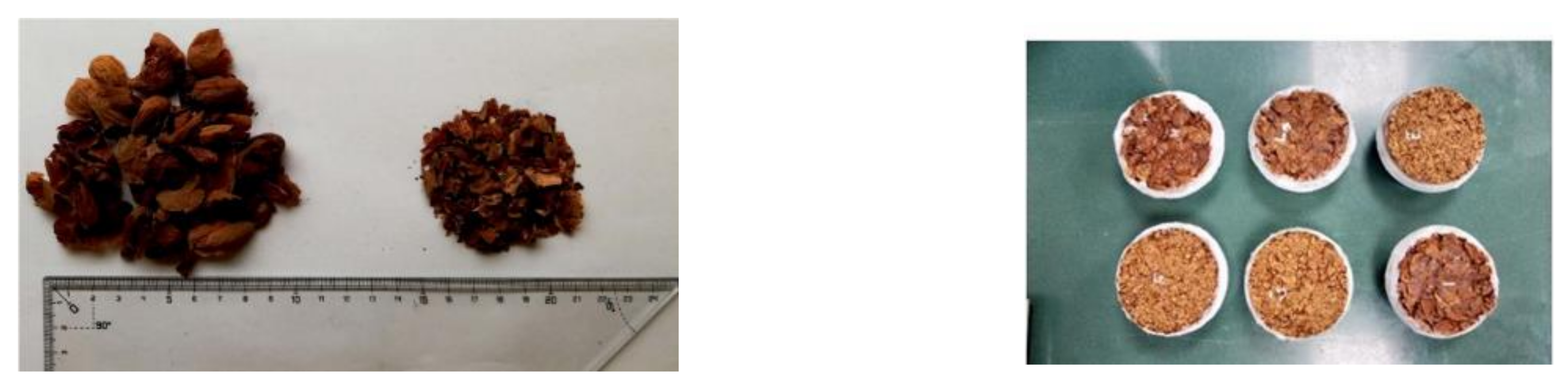

- Liuzzi, S.; Rubino, C.; Martellotta, F.; Casavola, C.; Pappalettera, G. Characterization of biomass-based materials for building applications: The case of straw and olive tree waste. Ind. Crops Prod. 2020, 147, 112229. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Navarro, A.; Avellaneda, J. Characterization of thermal insulation materials developed with crop wastes and natural binders. In Proceedings of the WSB14 World Sustainable Building Conference, GBC, Barcelona, Spain, 28–30 October 2014; pp. 1–10. [Google Scholar]

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The development history and prospects of biomass-based insulation materials for buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Prusty Kumar, J.; Kumar Patro, S.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment—A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Martellotta, F. Performance Characterization of Broad Band Sustainable Sound Absorbers Made of Almond Skins. Materials 2020, 13, 5474. [Google Scholar] [CrossRef] [PubMed]

- Balador, Z.; Gjerde, M.; Isaacs, N.; Whitburn, S. Research hotspots on agro-waste based building insulation products—A meta-review. In Proceedings of the International Conference on Advances on Sustainable Cities and Buildings Development, Green Lines Institute, Porto, Portugal, 1 November 2017. [Google Scholar]

- National Legislative Decree n. 397. Disposizioni Urgenti in Materia di Smaltimento dei Rifiuti Industrial; Governement Publication; Gazzetta Ufficiale: Rome, Italy, 1988.

- National Legislative Decree n. 475, Conversione in Legge, con Modificazioni, del Decreto-Legge 9 Settembre 1988, n. 397, Recante Disposizioni Urgenti in Materia di Smaltimento dei Rifiuti Industriali; Governement Publication; Gazzetta Ufficiale: Rome, Italy, 1988.

- National Legislative Decree 152/2006—Norme in Materia Ambientale; Gazzetta Ufficiale: Rome, Italy, 3 April 2006.

- Rapporto Rifiuti Speciali, Edizione. 2020. Available online: https://www.isprambiente.gov.it/files2020/pubblicazioni/rapporti/rapportorifiutispeciali_ed-2020_n-322_versionedati-di-sintesi_agg02_10_2020.pdf (accessed on 30 September 2021).

- GELSO (GEstione Locale SOstenibile). Available online: http://gelso.sinanet.isprambiente.it/ (accessed on 30 September 2021).

- EUROSTAT. Available online: https://ec.europa.eu/eurostat/371 (accessed on 30 September 2021).

- FAOSTAT. Available online: www.fao.org/faostat (accessed on 30 September 2021).

- Moliner, C.; Arato, E.; Marchelli, F. Current Status of Energy Production from Solid Biomass in Southern Italy. Energies 2021, 14, 2576. [Google Scholar] [CrossRef]

- Meleddu, M.; Pulina, M. Public spending on renewable energy in Italian regions. Renew. Energy 2018, 115, 1086–1098. [Google Scholar] [CrossRef]

- CORINE Land Cover. 2000. Available online: http://groupware.sinanet.isprambiente.it/uso-copertura-e-consumo-di-suolo/library/copertura-del-suolo/corine-land-cover (accessed on 30 September 2021).

- Motola, V.; Colonna, N.; Alfano, V.; Gaeta, M.; Sasso, S.; De Luca, V.; De Angelis, C.; Soda, A.; Braccio, G. Censimento Potenziale Energetico Biomasse, Metodo Indagine, Atlante Biomasse su WEBGIS, Report RSE/2009/167. 2009. Available online: http://aida.casaccia.enea.it/aida/file/RSE167.pdf (accessed on 30 September 2021).

- Spada, V.; Dipaola, M. Prospects of biomass energy use in Puglia (Italy). J. Commod. Sci. Technol. Qual. 2008, 47, 67–88. [Google Scholar]

- CAM Criteri Ambientali Minimi. Available online: https://www.mite.gov.it/pagina/i-criteri-ambientali-minimi (accessed on 12 November 2021).

- Itaca Protocol. Available online: https://www.itaca.org/valutazione_sostenibilita.asp (accessed on 12 November 2021).

- Puglia: Regional Decree 10 Giugno 2008, n. 13 Norme per l’abitare Sostenibile. Available online: https://www.anit.it/wp-content/uploads/2015/03/LR132.pdf (accessed on 12 November 2021).

- Puglia: Itaca Protocol. Available online: https://www.proitaca.com/puglia2017/residenziale/ (accessed on 12 November 2021).

- Molise: Regional Law 11 December 2009, n. 30. Available online: http://www.regione.molise.it/web/crm/lr.nsf/0/D27A5B8179C9506DC12576A2002D547E?OpenDocument (accessed on 12 November 2021).

- MONSTAT. Montenegro Statistical Office Release no. 117, Podgorica, 1 July 2020. Available online: https://www.monstat.org/eng/ (accessed on 15 July 2021).

- Čurovic, M.; Pavicevic, K.; Đokic, M.; Drobnjak, D. Analysis of the energy potential of agricultural biomass residues in Montenegro. Agric. For. 2016, 62, 277–284. [Google Scholar] [CrossRef][Green Version]

- MONSTAT. Montenegro Statistical Office Release No. 218, Podgorica, 29 December 2020. Available online: https://www.monstat.org/eng/ (accessed on 15 July 2021).

- Glavonjić, B. Opportunities, challenges and current progress with developing woody biomass fuels application in Montenegro. In Proceedings of the Regional Conference, Renewable Energy Sources and Their Application, Montenegrin Academy of Science and Arts, Podgorica, Montengro, 27–29 April 2010; pp. 149–157. [Google Scholar]

- Energy Policy of Montenegro until 2030. Available online: https://www.gov.me/en/documents/f0a01d7a-478d-4e57-93c8-afeb0375b591 (accessed on 12 November 2021).

- Energy Efficiency Law, Official Gazette of Montenegro, no. 057/14, 26 December 2014. Available online: https://www.gov.me/dokumenta/0637a545-c8dc-4ec6-8608-840cc9e7fe2f (accessed on 15 July 2021).

- Lushaj, B. Renewable Biomass: Suggestions and Proposed Alternatives. World J. Environ. Biosci. 2012, 1, 100–110. [Google Scholar]

- Available online:. Available online: https://www.eurofound.europa.eu/observatories/eurwork/industrial-relations-dictionary/acquis-communautaire (accessed on 12 November 2021).

- INSTAT. Press Release Urban Solid Waste. Institute of Statistics: Tirana, Albania, 2020. Available online: http://www.instat.gov.al/ (accessed on 30 September 2021).

- Oncioiu, I.; Căpuşneanu, S.; Topor, D.I.; Petrescu, M.; Petrescu, A.-G.; Toader, M.I. The Effective Management of Organic Waste Policy in Albania. Energies 2020, 13, 4217. [Google Scholar] [CrossRef]

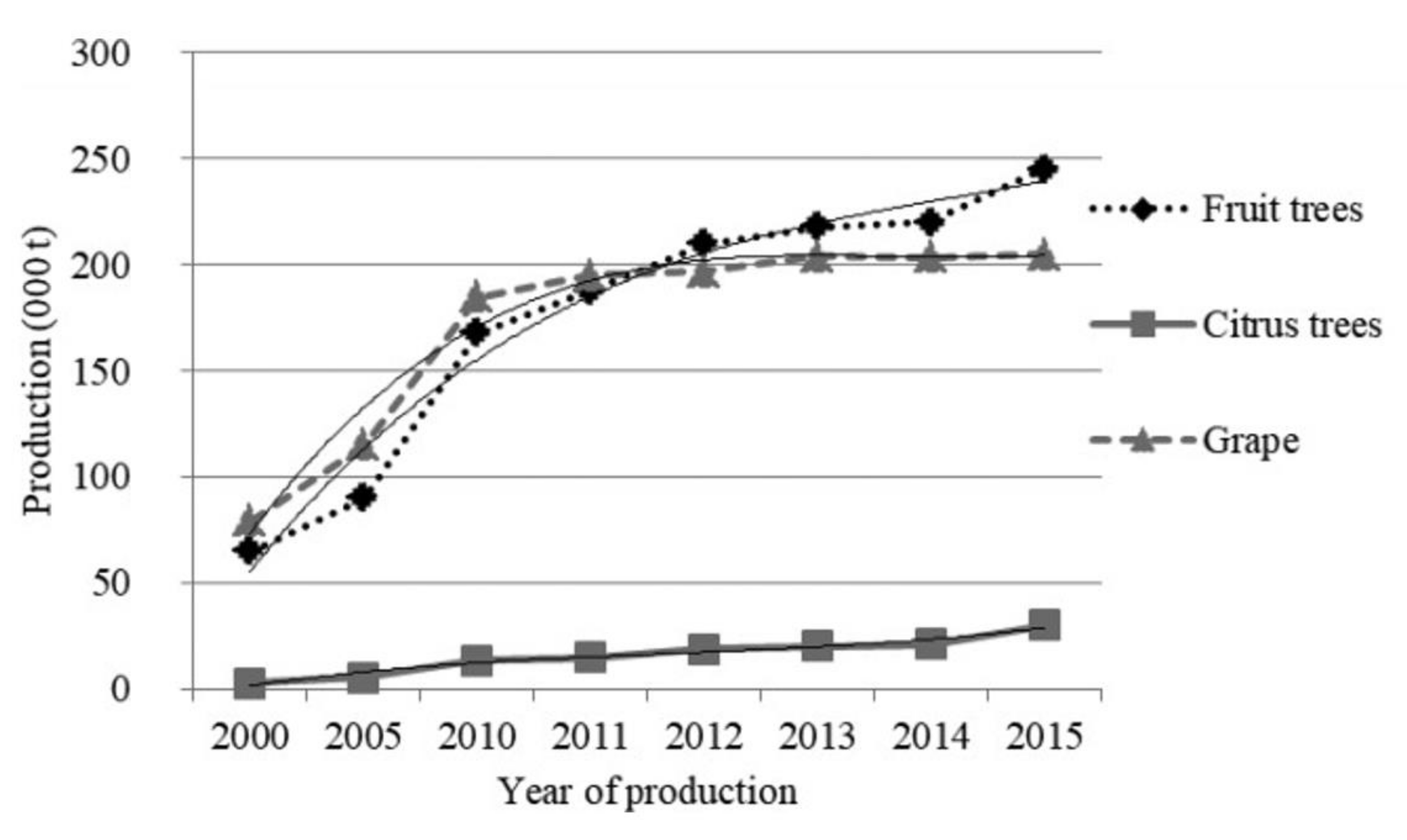

- Brahushi, F.; Alikaj, M.; Abeshi, P.; Draeck, M.; Geylan, O.; Hyso, H. Assessment of biomass potential as bio-energy source from fruit trees and grapes in Albania. Bulg. J. Agric. Sci. 2020, 26, 1143–1150. [Google Scholar]

- Albania: National Law n.124/2015 “On Energy Efficiency”. Available online: https://rise.esmap.org/data/files/library/albania/Energy%20Efficiency/Albania_Energy%20Efficiency%20Law.pdf (accessed on 12 November 2021).

- Albania: Law n. 116/2016 “On the Energy Performance of Buildings”. Available online: https://rise.esmap.org/data/files/library/albania/Energy%20Efficiency/Albania%20EE%20in%20Buildings.pdf (accessed on 12 November 2021).

| Material-Related Keywords | Application-Related Keywords |

|---|---|

| Agricultural components | Building components |

| Biobased material | Building material |

| Biomass | Sustainable architecture |

| Waste | Insulation panels |

| Raw matter | Building envelope |

| Thermal conductivity | Sustainable bricks |

| Thermal properties | Lightweight mortar |

| Acoustic properties | Agro-waste-based plaster |

| Laboratory tests | |

| High energy efficiency |

| Manufacturing Methods | Argumentation |

|---|---|

| Bonding | The method involves binder to join the single particles in order to create different mix design. |

| Pressing | The method involves the pressing at environmental temperature. |

| Hot-pressing | The method involves pressing at high temperature to change the chemical compositions of the particle and join them together. |

| Injection | The method involves the introduction of a liquid solution to join the particles. |

| Foaming | The method involves the use of foam to cover the internal pore. |

| Real form | The fibers are joined as they are in the real state (e.g., pruning waste bales). |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Martellotta, F. The Agro-Waste Production in Selected EUSAIR Regions and Its Potential Use for Building Applications: A Review. Sustainability 2022, 14, 670. https://doi.org/10.3390/su14020670

Liuzzi S, Rubino C, Stefanizzi P, Martellotta F. The Agro-Waste Production in Selected EUSAIR Regions and Its Potential Use for Building Applications: A Review. Sustainability. 2022; 14(2):670. https://doi.org/10.3390/su14020670

Chicago/Turabian StyleLiuzzi, Stefania, Chiara Rubino, Pietro Stefanizzi, and Francesco Martellotta. 2022. "The Agro-Waste Production in Selected EUSAIR Regions and Its Potential Use for Building Applications: A Review" Sustainability 14, no. 2: 670. https://doi.org/10.3390/su14020670

APA StyleLiuzzi, S., Rubino, C., Stefanizzi, P., & Martellotta, F. (2022). The Agro-Waste Production in Selected EUSAIR Regions and Its Potential Use for Building Applications: A Review. Sustainability, 14(2), 670. https://doi.org/10.3390/su14020670