Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System

Abstract

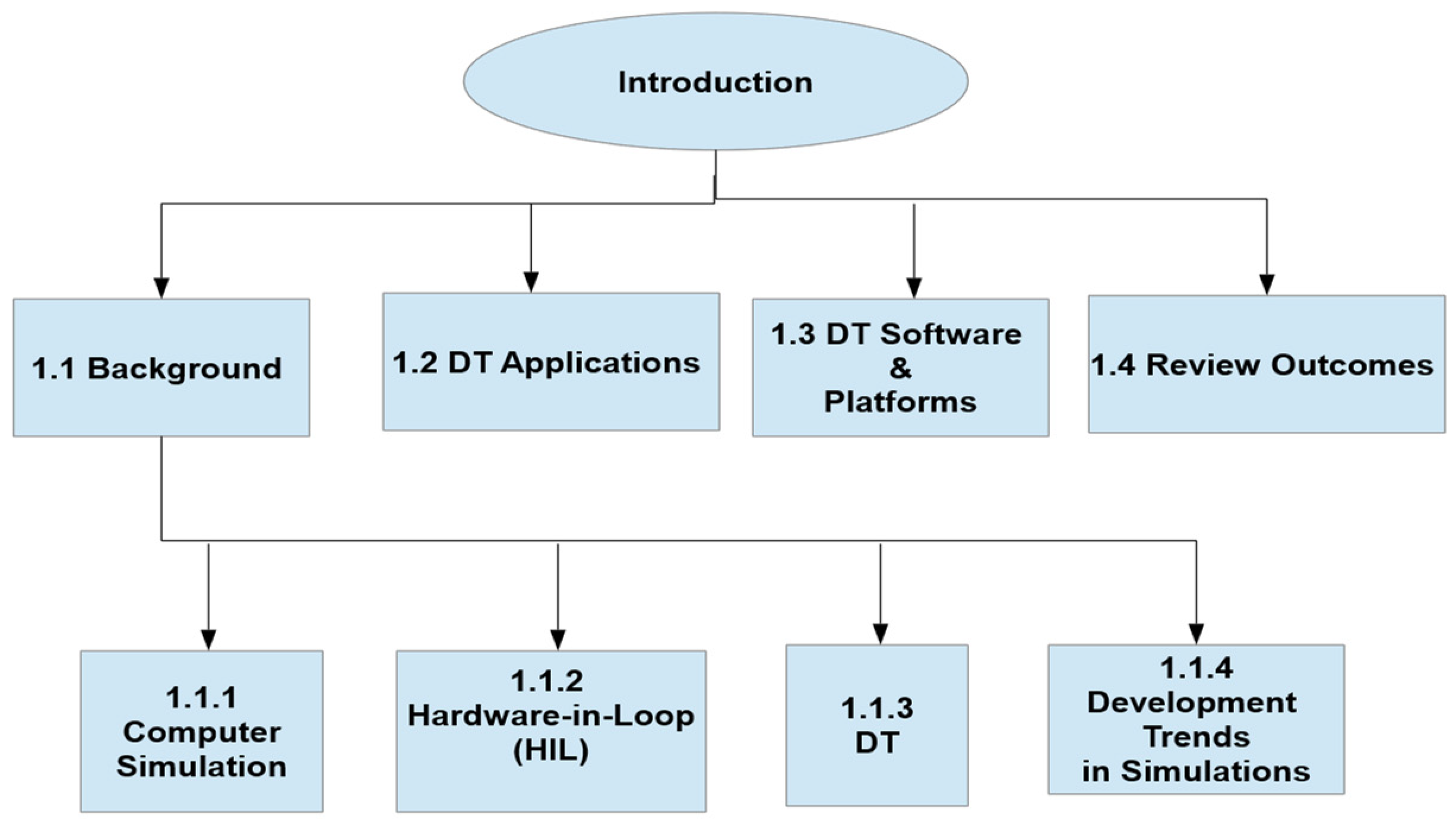

1. Introduction

1.1. Background

1.1.1. Computer Simulation

- Mistakes may be made in the programming or rules of the simulation or model.

- Time may be needed to make sense of the results.

- No data exchange occurs between the real and the simulation models, which might limit the effectiveness of the results.

- People’s reactions to the model or simulation might not be realistic or reliable.

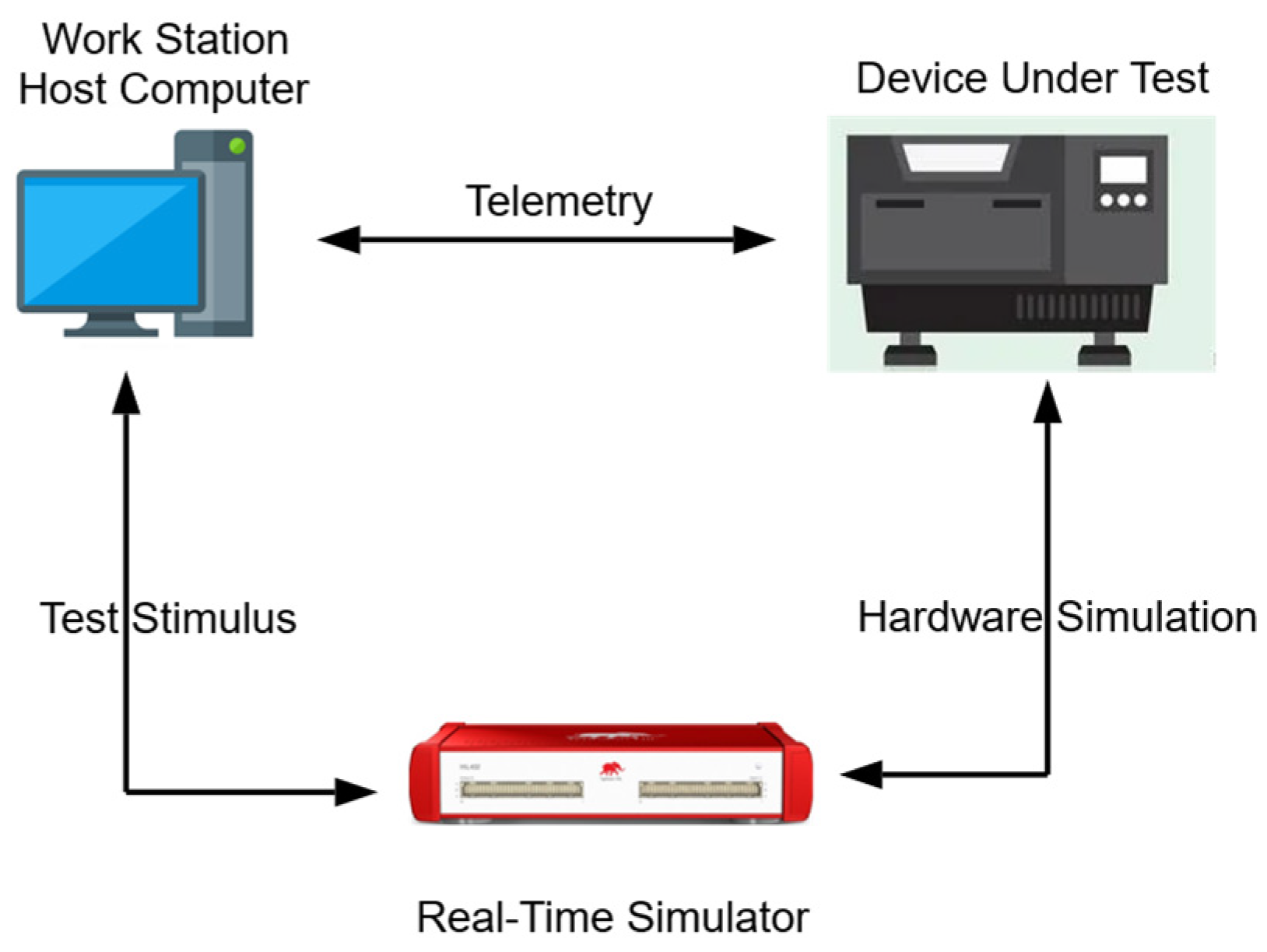

1.1.2. Hardware-in-the-Loop (HIL)

1.1.3. Digital Twins

1.1.4. Types of Digital Twins

1.1.5. Development Trends in Simulations

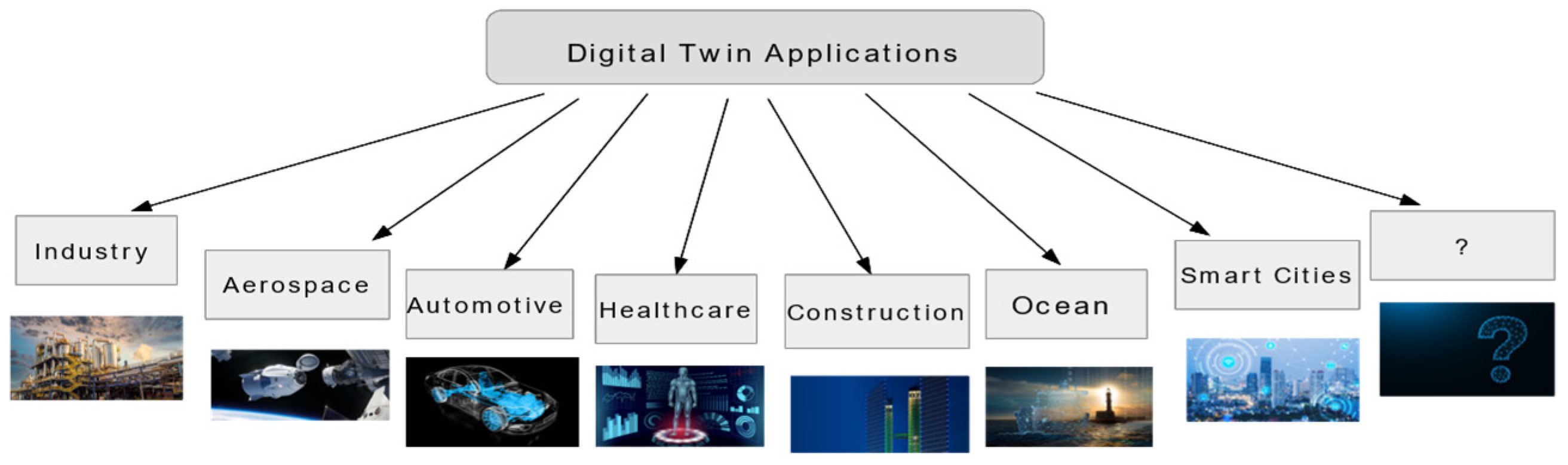

1.2. Applications of Digital Twins

1.3. Digital Twins Software and Platforms

1.4. Review Outcomes

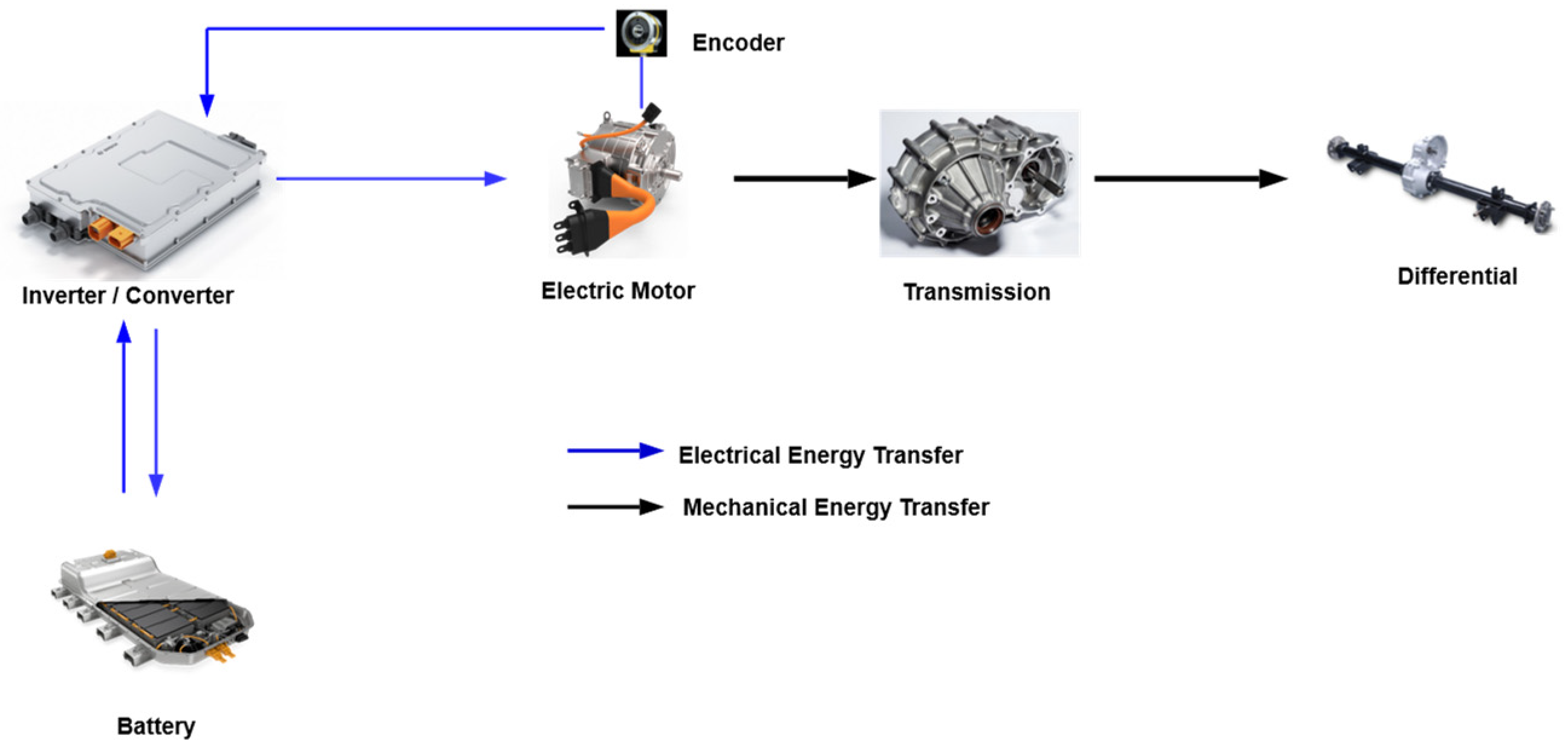

2. Overview of Recent Trends in EV Drive Systems

2.1. Background

2.2. Problem Definition

2.3. Hardware in the Loop Simulation for EV Drive Systems

2.4. Digital Twin (DT) for EV Drive System

3. Conclusions and Future Work

3.1. Conclusions

3.2. Future Works

- For EV propulsion drive system design, the first stage is to build simulation models of different system components;

- Verifying different models using HIL simulation tests;

- Building EV propulsion drive system physical models (test bench);

- Building DT models of the EV drive system starting with components, then assets, and finally the entire system model. DT models will be built based on previously collected data from HIL simulation tests and the current exchanged data with the physical model.

- Various datasets from the physical EV drive system can be obtained by the implementation of different sensors and data acquisition platforms. The DT model may include regulation for both virtual and physical entities that can be used for maintenance, diagnostic, optimization, and system development.

Author Contributions

Funding

Conflicts of Interest

References

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Mandolla, C.; Petruzzelli, A.M.; Percoco, G.; Urbinati, A. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Comput. Ind. 2019, 109, 134–152. [Google Scholar] [CrossRef]

- Raja, H.A.; Vaimann, T.; Rassolkin, A.; Kallaste, A.; Belahcen, A. IoT Based Tools for Data Acquisition in Electrical Machines and Robotics. In Proceedings of the 2021 IEEE 19th International Power Electronics and Motion Control Conference, PEMC, Gliwice, Poland, 25–29 April 2021; pp. 737–742. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human–robot collaborative assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Goldsman, D.; Nance, R.E.; Wilson, J.R. A brief history of simulation. In Proceedings of the Winter Simulation Conference, Austin, TX, USA, 13–16 December 2009; pp. 310–313. [Google Scholar] [CrossRef]

- Wimo, A.; Handels, R.; Jönsson, L. The art of simulation. Lancet Healthy Longev. 2020, 1, e2–e3. [Google Scholar] [CrossRef]

- Lahiri, S.K. Offline Simulation. Multivariable Predict. Control 2017, 167–182. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Tran, Q.T.; Guillo-Sansano, E.; Kotsampopoulos, P.; Gavriluta, C.; Lauss, G.; Strasser, T.I.; Jensen, T.V.; Heussen, K.; Gehrke, O.; et al. Hardware-in-the-Loop Assessment Methods. In European Guide to Power System Testing; Springer: Cham, Switzerland, 2020; pp. 51–66. [Google Scholar] [CrossRef]

- Nabi, S.; Balike, M.; Allen, J.; Rzemien, K. An overview of hardware-in-The-loop testing systems at Visteon. SAE Tech. Pap. 2004. [Google Scholar] [CrossRef]

- San, O. The digital twin revolution. Nat. Comput. Sci. 2021, 1, 307–308. [Google Scholar] [CrossRef]

- Glaessgen, E.H.; Stargel, D.S. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Chen, Z.; Huang, L. Digital twins for information-sharing in remanufacturing supply chain: A review. Energy 2020, 220, 119712. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient Intell. Humaniz. Comput. 2018, 10, 1141–1153. [Google Scholar] [CrossRef]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Cheng, X.; Zuo, H.; Cheng, Z. The Development of Digital Twin Technology Review. In Proceedings of the 2020 Chinese Automation Congress, CAC, Shanghai, China, 6–8 November 2020; pp. 4901–4906. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Weyer, S.; Meyer, T.; Ohmer, M.; Gorecky, D.; Zühlke, D. Future Modeling and Simulation of CPS-based Factories: An Example from the Automotive Industry. IFAC-PapersOnLine 2016, 49, 97–102. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2020, 58, 346–361. [Google Scholar] [CrossRef]

- Wagner, S.; Milde, M.; Barhebwa-Mushamuka, F.; Reinhart, G. Digital Twin Design in Production; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.-K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of Digital Twins for technical systems and services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Elsbach, K.D.; Stigliani, I. Design Thinking and Organizational Culture: A Review and Framework for Future Research. J. Manag. 2018, 44, 2274–2306. [Google Scholar] [CrossRef]

- Jiang, Y.; Yin, S.; Li, K.; Luo, H.; Kaynak, O. Industrial applications of digital twins. Philos. Trans. R. Soc. A 2021, 379, 20200360. [Google Scholar] [CrossRef]

- Centomo, S.; Dall’Ora, N.; Fummi, F. The Design of a Digital-Twin for Predictive Maintenance. In Proceedings of the IEEE Symposium on Emerging Technologies and Factory Automation, ETFA, Vienna, Austria, 8–11 September 2020; pp. 1781–1788. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. A Reconfigurable Modeling Approach for Digital Twin-based Manufacturing System. Procedia CIRP 2019, 83, 118–125. [Google Scholar] [CrossRef]

- Phanden, R.K.; Sharma, P.; Dubey, A. A review on simulation in digital twin for aerospace, manufacturing and robotics. Mater. Today Proc. 2021, 38, 174–178. [Google Scholar] [CrossRef]

- Yin, H.; Wang, L. Application and Development Prospect of Digital Twin Technology in Aerospace. IFAC-PapersOnLine 2020, 53, 732–737. [Google Scholar] [CrossRef]

- Gyimesi, K.; Berman, S. IBM Global Business Services Digital Transformation in the Automotive Industry Creating New Business Models where Digital Meets Physical. May 2011. Available online: https://www.ibm.com/downloads/cas/LVDZDXOA. (accessed on 2 January 2022).

- Rahman, I.; Tadayoni, R. Digital Transformation of Automobiles-From product to service. In Proceedings of the 11th CMI International Conference: Prospects and Challenges Towards Developing a Digital Economy within the EU, PCTDDE, Copenhagen, Denmark, 29–30 November 2018; pp. 7–13. [Google Scholar] [CrossRef]

- White, G.; Zink, A.; Codecá, L.; Clarke, S. A digital twin smart city for citizen feedback. Cities 2021, 110, 103064. [Google Scholar] [CrossRef]

- Mohammadi, N.; Taylor, J.E. Smart city digital twins. In Proceedings of the 2017 IEEE Symposium Series on Computational Intelligence, SSCI, Honolulu, HI, USA, 27 November–1 December 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Karakra, A.; Fontanili, F.; Lamine, E.; Lamothe, J. HospiT’Win: A predictive simulation-based digital twin for patients pathways in hospital. In Proceedings of the 2019 IEEE EMBS International Conference on Biomedical and Health Informatics, BHI, Chicago, IL, USA, 19–22 May 2019. [Google Scholar] [CrossRef]

- Erol, T.; Mendi, A.F.; Dogan, D. The Digital Twin Revolution in Healthcare. In Proceedings of the 4th International Symposium on Multidisciplinary Studies and Innovative Technologies, ISMSIT, Istanbul, Turkey, 22–24 October 2020. [Google Scholar] [CrossRef]

- Barbie, A.; Pech, N.; Hasselbring, W.; Flogel, S.; Wenzhofer, F.; Walter, M.; Shchekinova, E.; Busse, M.; Turk, M.; Hofbauer, M.; et al. Developing an Underwater Network of Ocean Observation Systems with Digital Twin Prototypes-A Field Report from the Baltic Sea. IEEE Internet Comput. 2021. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Orosz, T.; Gadó, K.; Katona, M.; Rassõlkin, A. Automatic Tolerance Analysis of Permanent Magnet Machines with Encapsuled FEM Models Using Digital-Twin-Distiller. Processes 2021, 9, 2077. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Anosike, A.; Loomes, H.; Udokporo, C.K.; Garza-Reyes, J.A. Exploring the challenges of electric vehicle adoption in final mile parcel delivery. Int. J. Logist. Res. Appl. 2021, 1–25. [Google Scholar] [CrossRef]

- Kumar, L.; Jain, S. Electric propulsion system for electric vehicular technology: A review. Renew. Sustain. Energy Rev. 2014, 29, 924–940. [Google Scholar] [CrossRef]

- Vaideeswaran, V.; Bhuvanesh, S.; Devasena, M. Battery Management Systems for Electric Vehicles using Lithium-Ion Batteries. In Proceedings of the 2019 Innovations in Power and Advanced Computing Technologies, i-PACT, Vellore, India, 22–23 March 2019. [Google Scholar] [CrossRef]

- Salgado, R.M.; Danzi, F.; Oliveira, J.E.; El-Azab, A.; Camanho, P.P.; Braga, M.H. The Latest Trends in Electric Vehicles Batteries. Molecules 2021, 26, 3188. [Google Scholar] [CrossRef]

- Katari, J.S.; Sneha, R.; Vinayaka, K.U.; Rana, K. A Concise review of different standards for performance testing of Lithium-ion Batteries for Electric Vehicle applications. In Proceedings of the 2020 IEEE International Conference on Power Systems Technology, POWERCON, Bangalore, India, 14–16 September 2020. [Google Scholar] [CrossRef]

- Reimers, J.; Dorn-Gomba, L.; Mak, C.; Emadi, A. Automotive Traction Inverters: Current Status and Future Trends. IEEE Trans. Veh. Technol. 2019, 68, 3337–3350. [Google Scholar] [CrossRef]

- Chi-Lan, C.; Xiao-Gang, W.; Yue-Wei, B.; Yan-Chun, X.; Kai, L. Key Technologies of EV Motor Drive System Design. Procedia Eng. 2011, 16, 356–362. [Google Scholar] [CrossRef][Green Version]

- Ji, S.; Zhang, Z.; Wang, F. Overview of high voltage sic power semiconductor devices: Development and application. CES Trans. Electr. Mach. Syst. 2020, 1, 254–264. [Google Scholar] [CrossRef]

- Bhatt, P.; Mehar, H.; Sahajwani, M. Electrical Motors for Electric Vehicle–A Comparative Study. SSRN Electron. J. 2019. [Google Scholar] [CrossRef]

- Momen, F.; Rahman, K.M.; Son, Y.; Savagian, P. Electric Motor Design of General Motors’ Chevrolet Bolt Electric Vehicle. SAE Int. J. Altern. Powertrains 2016, 5, 286–293. [Google Scholar] [CrossRef]

- Sieklucki, G. An investigation into the induction motor of tesla model S vehicle. In Proceedings of the 2018 International Symposium on Electrical Machines, SME, Andrychow, Poland, 10–13 June 2018. [Google Scholar] [CrossRef]

- Goli, C.S.; Manjrekar, M.; Essakiappan, S.; Sahu, P.; Shah, N. Landscaping and review of traction motors for electric vehicle applications. In Proceedings of the 2021 IEEE Transportation Electrification Conference and Expo, ITEC, Chicago, IL, USA, 21–25 June 2021; pp. 162–168. [Google Scholar] [CrossRef]

- Mudrov, M.; Ziuzev, A.; Nesterov, K.; Valtchev, S. Power electrical drive Power-Hardware-in-the-Loop system: 2018 X International Conference on Electrical Power Drive Systems (ICEPDS). In Proceedings of the 2018 X International Conference on Electrical Power Drive Systems (ICEPDS), Novocherkassk, Russia, 3–6 October 2018. [Google Scholar] [CrossRef]

- Mudrov, M.; Klimov, G.; Tecle, S.I.; Ziuzev, A. Experience in Using Real Time Simulators in Variable-Frequency Drives. In Proceedings of the 2020 XI International Conference on Electrical Power Drive Systems (ICEPDS), St. Petersburg, Russia, 4–7 October 2020. [Google Scholar] [CrossRef]

- Poon, J.J.; Kinsy, M.A.; Pallo, N.A.; Devadas, S.; Čelanović, I.L. Hardware-in-the-loop testing for electric vehicle drive applications. In Proceedings of the 2012 Twenty-Seventh Annual IEEE Applied Power Electronics Conference and Exposition-APEC, Orlando, FL, USA, 5–9 February 2012; pp. 2576–2582. [Google Scholar] [CrossRef]

- Berry, D.J.; Gu, E. FPGA based hardware in the loop inverter loss and thermal model for electric vehicles. In Proceedings of the 2020 IEEE Transportation Electrification Conference and Expo, ITEC, Chicago, IL, USA, 23–26 June 2020; pp. 75–80. [Google Scholar] [CrossRef]

- Collin, R.; Stephens, M.; von Jouanne, A. Development of SiC-Based Motor Drive Using Typhoon HIL 402 as System-Level Controller. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition, Detroit, MI, USA, 11–15 October 2020; pp. 2689–2695. [Google Scholar] [CrossRef]

- Mishra, I.; Nath Tripathi, R.N.; Kumar Singh, V.K.; Hanamoto, T. A Hardware-in-the-Loop Simulation Approach for Analysis of Permanent Magnet Synchronous Motor Drive. In Proceedings of the 2019 10th International Conference on Power Electronics and ECCE Asia (ICPE 2019-ECCE Asia), Busan, Korea, 27–30 May 2019. [Google Scholar]

- Amitkumar, K.S.; Pillay, P.; Belanger, J. Hardware-in-the-loop Simulations of Inverter Faults in an Electric Drive System. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition, ECCE, Baltimore, MD, USA, 29 September–3 October 2019; pp. 353–358. [Google Scholar] [CrossRef]

- Wunderlich, A.; Santi, E. Digital twin models of power electronic converters using dynamic neural networks. In Proceedings of the 2021 IEEE Applied Power Electronics Conference and Exposition-APEC, Phoenix, AZ, USA, 14–17 June 2021; pp. 2369–2376. [Google Scholar] [CrossRef]

- Rjabtsikov, V.; Rassolkin, A.; Asad, B.; Vaimann, T.; Kallaste, A.; Kuts, V.; Jegorov, S.; Stepien, M.; Krawczyk, M. Digital Twin Service Unit for AC Motor Stator Inter-Turn Short Circuit Fault Detection. In Proceedings of the 2021 28th International Workshop on Electric Drives: Improving Reliability of Electric Drives (IWED), Moscow, Russia, 27–29 January 2021. [Google Scholar] [CrossRef]

- Toso, F.; Torchio, R.; Favato, A.; Carlet, P.G.; Bolognani, S.; Alotto, P. Digital twins as electric motor soft-sensors in the automotive industry. In Proceedings of the 2021 IEEE International Workshop on Metrology for Automotive, MetroAutomotive, Bologna, Italy, 1–2 July 2021; pp. 13–18. [Google Scholar] [CrossRef]

- Tshoombe, B.K.; Dos Santos, J.F.; Araujo, R.C.F.; Fonseca, W.D.S. Implementation of DT-based monitoring system of induction motors. In Proceedings of the 2021 14th IEEE International Conference on Industry Applications (INDUSCON), São Paulo, Brazil, 15–18 August 2021; pp. 161–166. [Google Scholar] [CrossRef]

- Rassolkin, A.; Rjabtsikov, V.; Vaimann, T.; Kallaste, A.; Kuts, V.; Partyshev, A. Digital Twin of an Electrical Motor Based on Empirical Performance Model. In Proceedings of the 2020 XI International Conference on Electrical Power Drive Systems (ICEPDS), St. Petersburg, Russia, 4–7 October 2020. [Google Scholar] [CrossRef]

- Brandtstaedter, H.; Hübner, L.; Jungiewicz, A.; Ludwig, C.; Tsouchnika, E.; Wever, U. DIGITAL TWINS FOR LARGE ELECTRIC DRIVE TRAINS. In Proceedings of the 2018 Petroleum and Chemical Industry Conference Europe (PCIC Europe), Antwerp, Belgium, 5–7 June 2018. [Google Scholar]

- Jitong, X.; Lin, W.; Yan, Z. Design and Development of Digital Twin System for Intelligent Motor. In Proceedings of the 2020 IEEE International Conference on Advances in Electrical Engineering and Computer Applications, AEECA, Dalian, China, 25–27 August 2020; pp. 991–996. [Google Scholar] [CrossRef]

- Venkatesan, S.; Manickavasagam, K.; Tengenkai, N.; Vijayalakshmi, N. Health monitoring and prognosis of electric vehicle motor using intelligent-digital twin. IET Electr. Power Appl. 2019, 13, 1328–1335. [Google Scholar] [CrossRef]

| Computer Simulation | HIL | DT | |

|---|---|---|---|

| Data element and interaction | Static | Active | Active |

| Simulation Basis | Potential parameters | Real time feedback | Real time feed back |

| Scope | Narrow-Primary design | Narrow-Advanced | Wide-Advanced |

| Points of Comparison | Hardware-in-Loop (HIL) | Digital Twin (DT) |

|---|---|---|

| Simulation | Real-time (Online) | Real-time (Online) |

| Applications | Design; Testing; Optimization; Fault Detection | Design; Diagnosis; Optimization; Predictive Maintenance; Fault Detection; Health Monitoring; Life Time Prediction |

| Areas of Applications | Component; Subsystem | Component Subsystem; Whole System |

| Cost | High | Moderate |

| Reliability | High | Very High |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, M.; Rassõlkin, A.; Vaimann, T.; Kallaste, A. Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System. Sustainability 2022, 14, 601. https://doi.org/10.3390/su14020601

Ibrahim M, Rassõlkin A, Vaimann T, Kallaste A. Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System. Sustainability. 2022; 14(2):601. https://doi.org/10.3390/su14020601

Chicago/Turabian StyleIbrahim, Mahmoud, Anton Rassõlkin, Toomas Vaimann, and Ants Kallaste. 2022. "Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System" Sustainability 14, no. 2: 601. https://doi.org/10.3390/su14020601

APA StyleIbrahim, M., Rassõlkin, A., Vaimann, T., & Kallaste, A. (2022). Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System. Sustainability, 14(2), 601. https://doi.org/10.3390/su14020601