A Numerical Simulation of the Interaction of Aggregate and Rockfill in a Gangue Fluidized Filling Method

Abstract

1. Introduction

2. Test Background

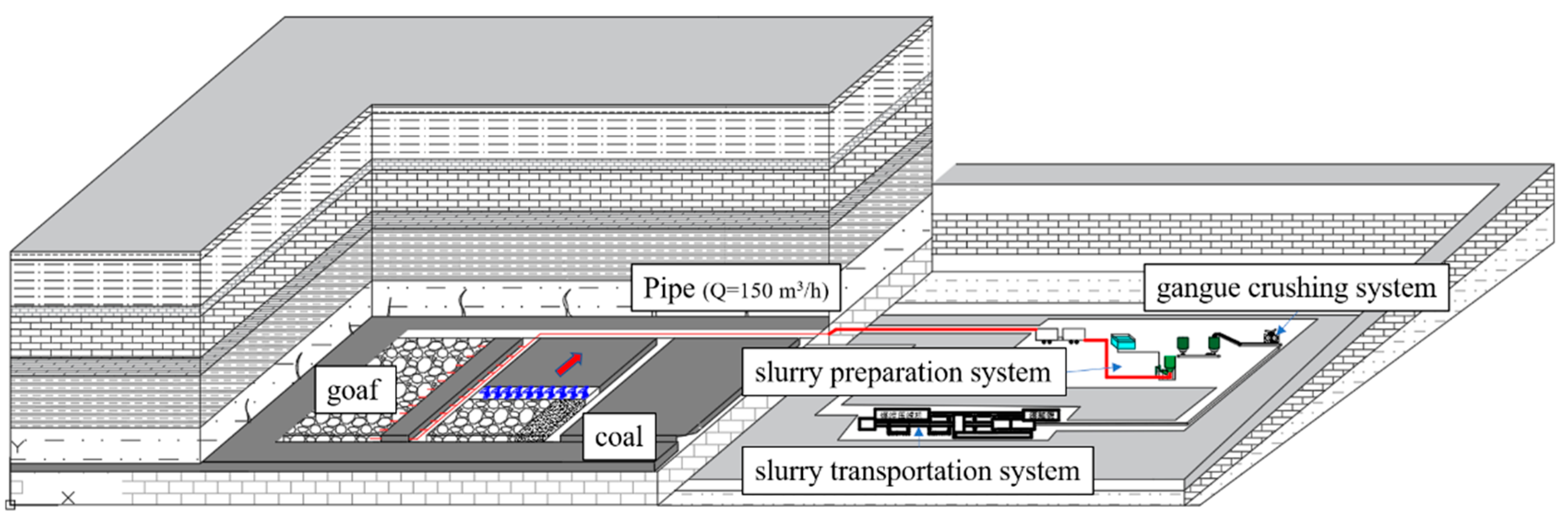

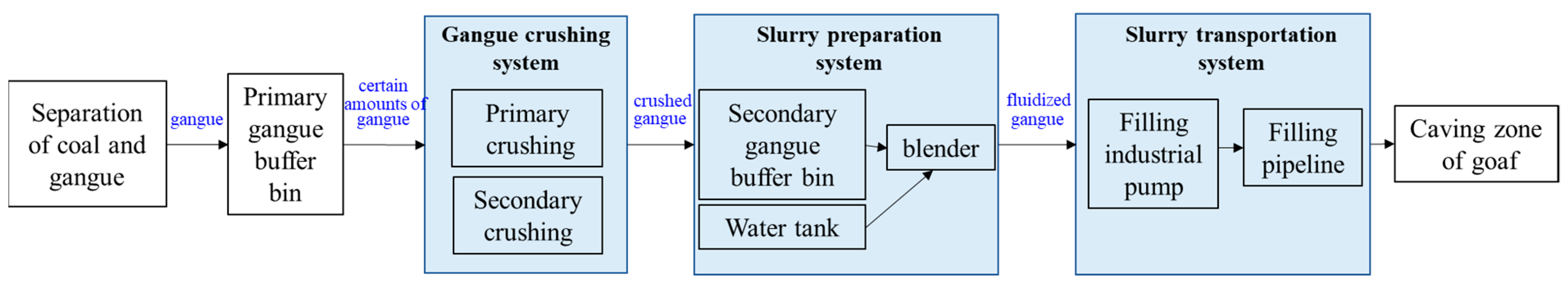

2.1. Fluidized Gangue Filling Method

2.2. Key Scientific Issues

3. Test Principle and Scheme

3.1. Simulation Method of Fluidized Gangue and Goaf

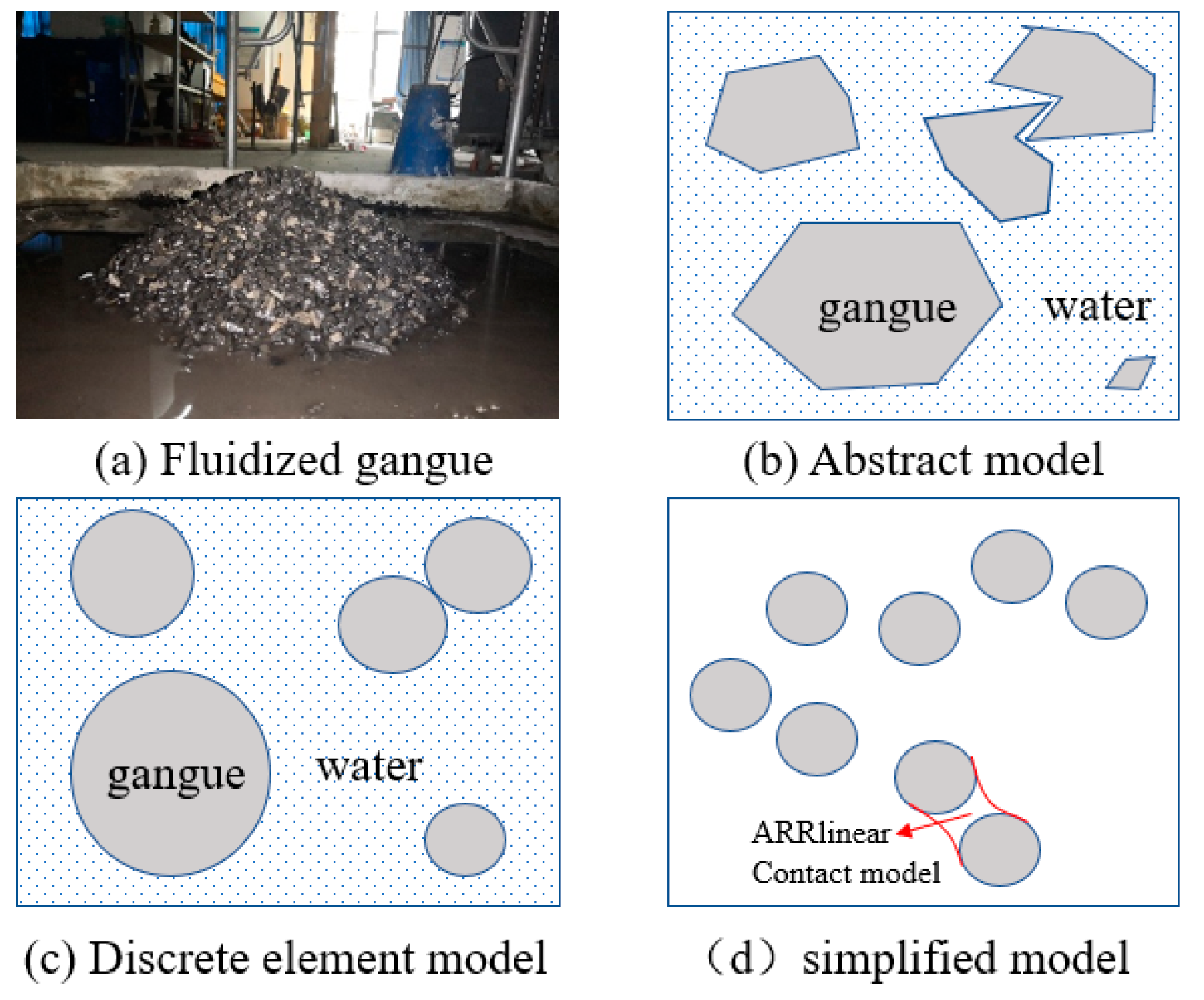

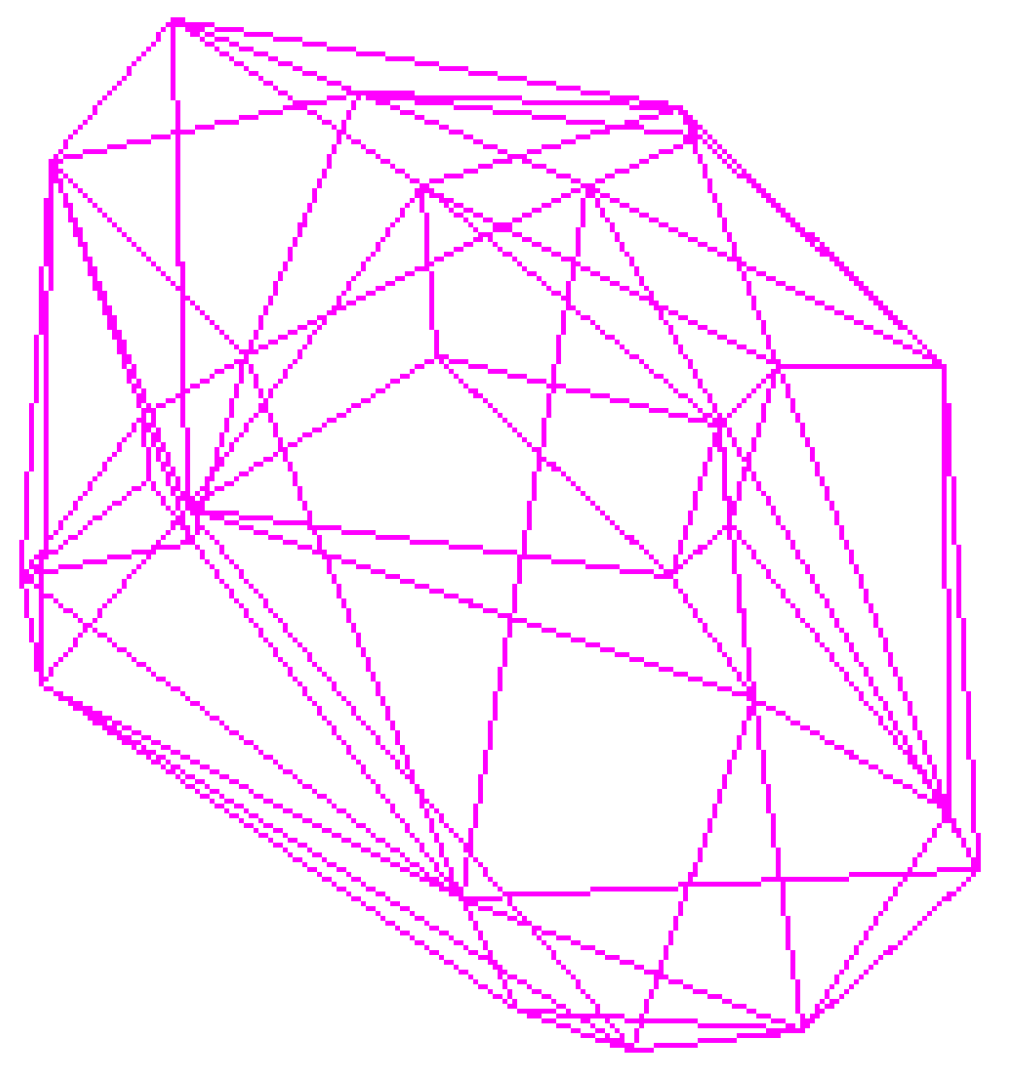

- Simulation method of fluidized gangue

- 2.

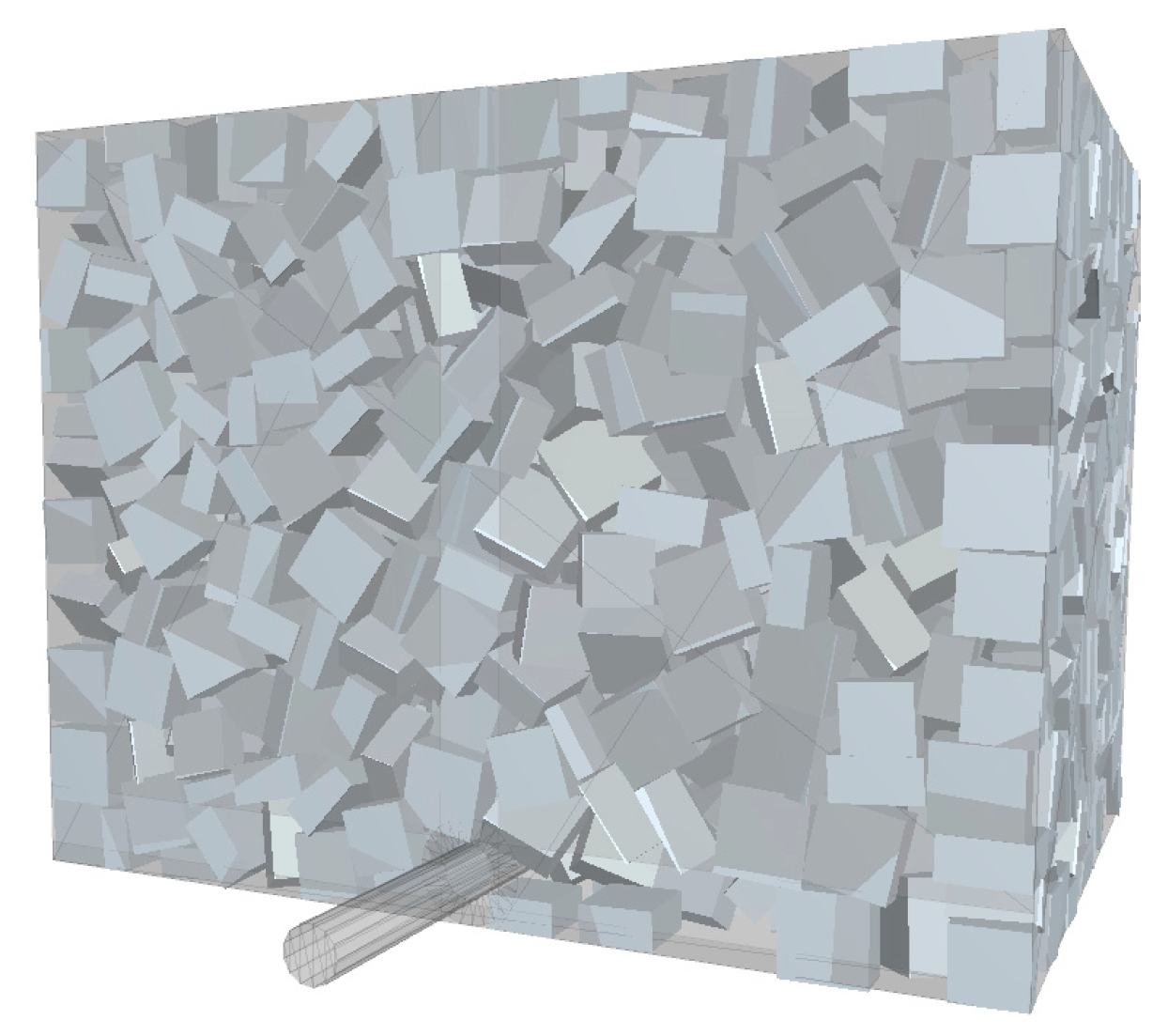

- Simulation method of goaf

3.2. Test Scheme

4. Model Parameter Calibration

4.1. Parameter Calibration Method

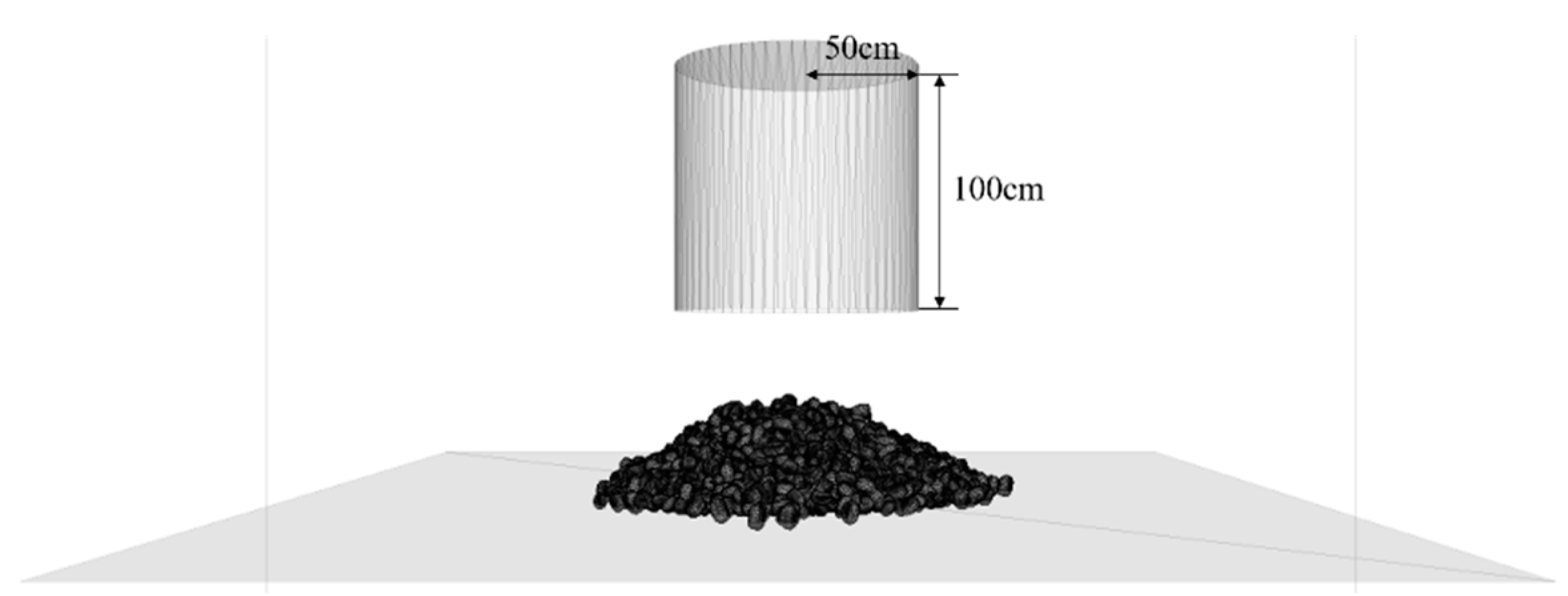

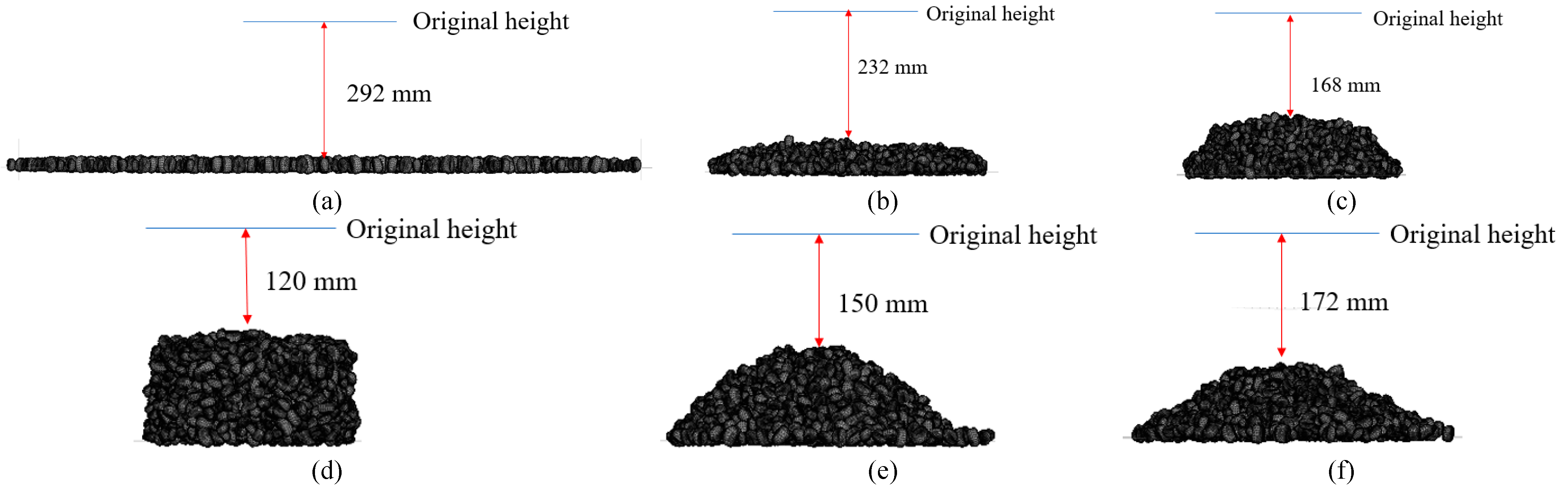

4.2. Calibration Results of Atacking Test

4.3. L Box Calibration Results

5. Model Establishment and Test

5.1. Model Establishment and Process

5.1.1. Goaf Construction

5.1.2. Construction of Fluid Gangue

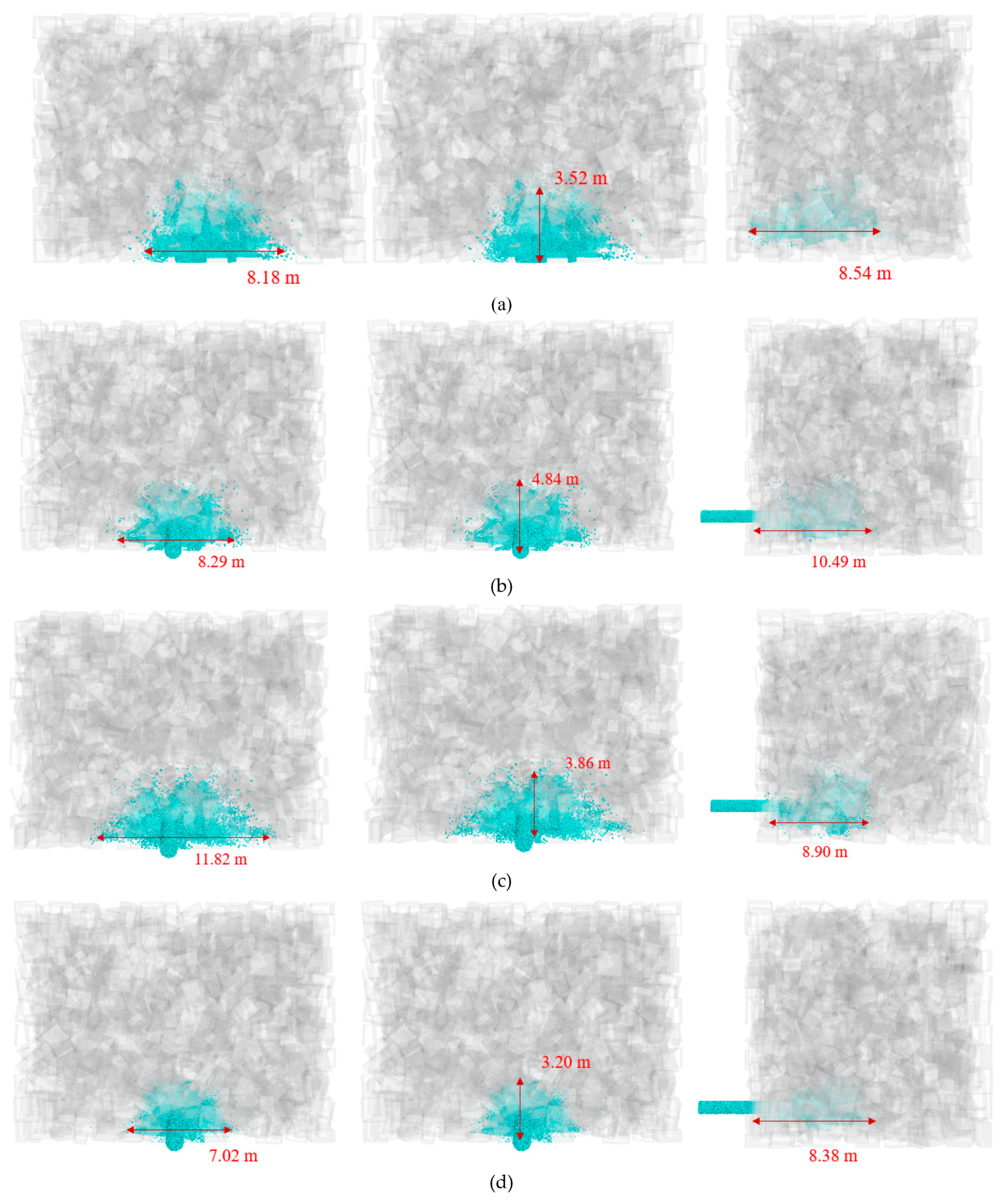

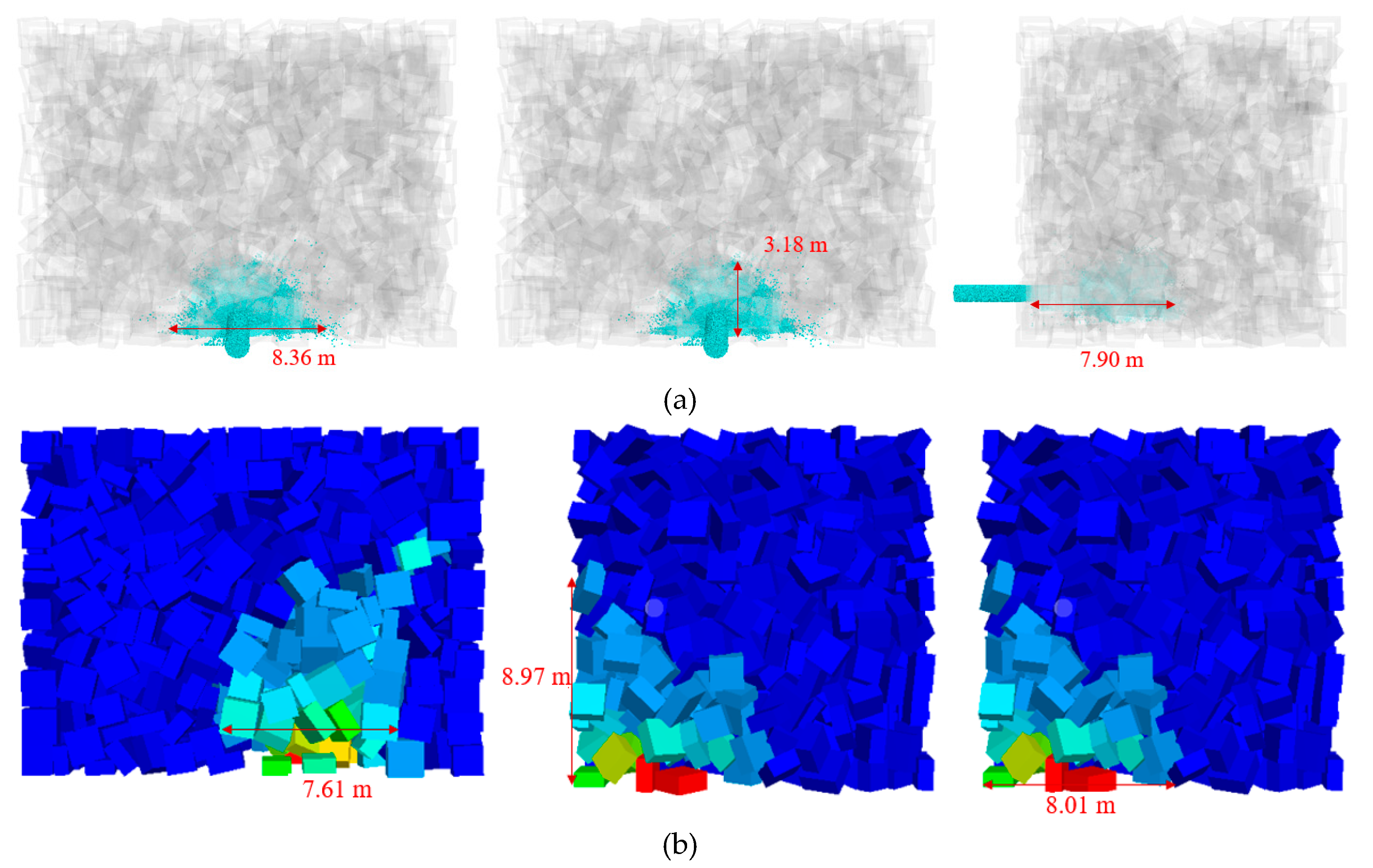

5.2. Slurry Diffusion Law

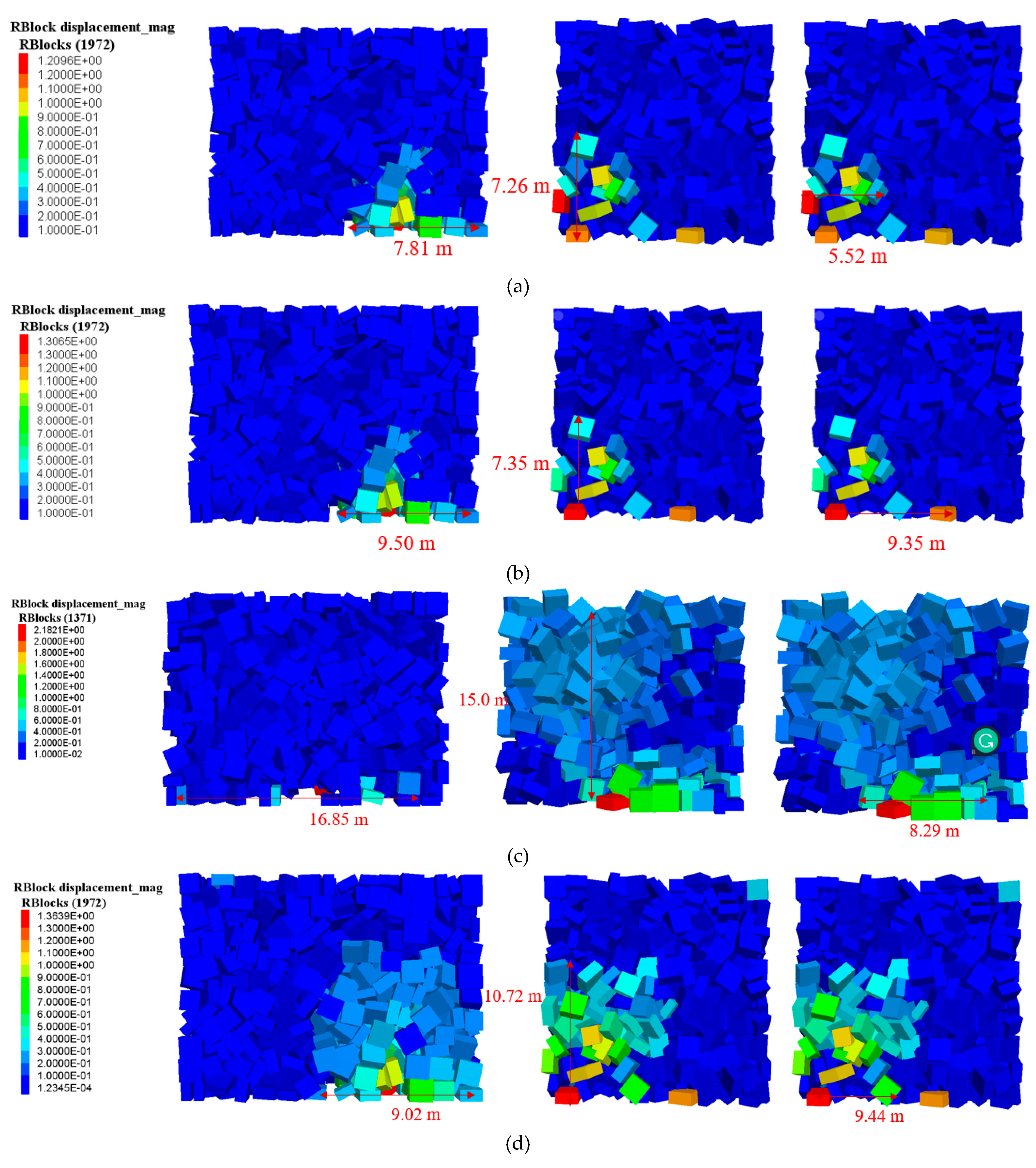

5.3. Law of Rock Movement in Goaf

6. Results Analysis and Discussion

6.1. Grouting Scale under Specific Conditions

6.2. Optimization and Adjustment of Grouting Technology

7. Conclusions

- The fluidization filling technology of gangue is developed. The interaction model between filling aggregate and goaf rock is constructed. The discrete element simulation method of Fluidized gangue is proposed, and the appropriate meso parameters of gangue are selected through a calibration test. The rock model of goaf based on Rblock structure is constructed.

- The diffusion range of fluidized gangue under the influence of different grouting speeds, porosity, and gangue particle sizes are analyzed. With the increase of porosity, the diffusion width increases significantly. Diffusion depth and diffusion height are greatly affected by grouting speed. With the rise of grouting speed, diffusion depth and diffusion height increase significantly.

- The influence range of rock displacement in goaf under the influence of different grouting speeds, porosity, and gangue particle size is analyzed. Porosity affects the maximum displacement of rock, and the range value is 1.194. The width and height of rock displacement are greatly affected by porosity, and the range values are 10.80 and 13.51. The influence depth of rock displacement is greatly affected by grouting speed, and the range value reaches 5.97.

- To facilitate grouting, improve grouting depth, increase grouting volume, and increase gangue treatment capacity, grouting speed should be increased. When the grouting time is 0.5 h, and the grouting speed is 5 m/s, the single hole grouting amount reaches 5.63 × 104 kg.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yuan, J. The future of coal in China. Resour. Conserv. Recycl. 2018, 129, 290–292. [Google Scholar] [CrossRef]

- Lin, B.Q.; Liu, J.H. Estimating coal production peak and trends of coal imports in China. Energy Policy 2010, 38, 512–519. [Google Scholar] [CrossRef]

- Chen, W.; Xu, R. Clean coal technology development in China. Energy Policy 2010, 38, 2123–2130. [Google Scholar] [CrossRef]

- You, C.A.; Xu, X.C. Coal combustion and its pollution control in China. Energy 2010, 35, 4467–4472. [Google Scholar] [CrossRef]

- Li, J.; Hu, S. History and future of the coal and coal chemical industry in China. Resources. Conserv. Recycl. 2017, 124, 13–24. [Google Scholar] [CrossRef]

- Xie, K.; Li, W.; Zhao, W. Coal chemical industry and its sustainable development in China. Energy 2010, 35, 4349–4355. [Google Scholar] [CrossRef]

- Chen, H.; Qi, H.; Long, R.; Zhang, M. Research on 10-year tendency of China coal mine accidents and the characteristics of human factors. Saf. Sci. 2012, 50, 745–750. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Pan, Y.S.; Jiang, F.X.; Dou, L.M.; Ju, Y. State of the art review on mechanism and prevention of coal bumps in China. J. China Coal Soc. 2014, 39, 205–213. [Google Scholar]

- Miao, X.X.; Qian, M.G. Research on green mining of coal resources in China: Current status and future prospects. J. Min. Saf. Eng. 2009, 26, 1–14. [Google Scholar]

- Yu, J.L.; Meng, F.R.; Li, X.C.; Tahmasebi, A. Power generation from coal gangue in China: Current status and development. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2012; Volume 550, pp. 443–446. [Google Scholar]

- Zhou, C.; Liu, G.; Wu, S.; Lam, P.K.S. The environmental characteristics of usage of coal gangue in bricking-making: A case study at Huainan, China. Chemosphere 2014, 95, 274–280. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ling, T.C. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials—A review. Constr. Build. Mater. 2020, 234, 117424. [Google Scholar] [CrossRef]

- Zhou, H.; Hou, C.; Sun, X.; Qu, Q.; Chen, D. Solid waste paste filling for none-village-relocation coal mining. J. China Univ. Min. Technol. 2004, 33, 154–158. [Google Scholar]

- Jian-gong, L.I.U. Solid-filling technology in fully mechanized coal mining. Coal Chem. Ind. 2013, 36, 1545–1551. [Google Scholar]

- Cao, L.; Sun, F.; Chen, T.; Teng, Z.; Tang, Y.; Liao, D. Numerical simulation of liquid-solid conversion affecting flow behavior during casting filling process. Acta Met. Sin 2017, 53, 1521–1531. [Google Scholar]

- Zhong, Z.; Ooi, J.Y.; Rotter, J.M. The sensitivity of silo flow and wall stresses to filling method. Eng. Struct. 2001, 23, 756–767. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Strength evolution and deformation behaviour of cemented paste backfill at early ages: Effect of curing stress, filling strategy and drainage. Int. J. Min. Sci. Technol. 2016, 26, 809–817. [Google Scholar] [CrossRef]

- Zhou, N.; Ma, H.; Ouyang, S.; Germain, D.; Hou, T. Influential factors in transportation and mechanical properties of aeolian sand-based cemented filling material. Minerals 2019, 9, 116. [Google Scholar] [CrossRef]

- Choudhary, B.S.; Kumar, S. Underground void filling by cemented mill tailings. Int. J. Min. Sci. Technol. 2013, 23, 893–900. [Google Scholar] [CrossRef]

- Yin, B.; Kang, T.; Kang, J.; Chen, Y.; Wu, L.; Du, M. Investigation of the hydration kinetics and microstructure formation mechanism of fresh fly ash cemented filling materials based on hydration heat and volume resistivity characteristics. Appl. Clay Sci. 2018, 166, 146–158. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Xu, J.; Qiu, P.; Wang, Y.; Han, G. Particle size distribution of cemented rockfill effects on strata stability in filling mining. Minerals 2018, 8, 407. [Google Scholar] [CrossRef]

- Wu, D.; Luo, F.; Li, M.; Diao, Y.; Guo, Y.; Xu, P. Macroscopic and microscopic study on the compression bearing characteristics and deformation failure mechanism of gangue with different particle sizes. Powder Technol. 2021, 383, 198–211. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Chen, Z.; Zhang, J.; Jiang, H.; Zhang, Y. Characterizations of macroscopic deformation and particle crushing of crushed gangue particle material under cyclic loading: In solid backfilling coal mining. Powder Technol. 2019, 343, 159–169. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Chen, Z.; Li, M.; Qiao, M.; Kizil, M. Particle-crushing characteristics and acoustic-emission patterns of crushing gangue backfilling material under cyclic loading. Minerals 2018, 8, 244. [Google Scholar] [CrossRef]

- Chang, Q.L.; Zhou, H.Q.; Hou, C.J. Using particle swarm optimization algorithm in an artificial neural network to forecast the strength of paste filling material. J. China Univ. Min. Technol. 2008, 18, 551–555. [Google Scholar] [CrossRef]

- Kong, D.; Pu, S.; Cheng, Z.; Wu, G.; Liu, Y. Coordinated deformation mechanism of the top coal and filling body of gob-side entry retaining in a fully mechanized caving face. Int. J. Geomech. 2021, 21, 04021030. [Google Scholar] [CrossRef]

- You, X.; Ren, F.Y.; He, R.X.; Ding, H.X. Research on compressive strength of cemented filling body in subsequent filling at the stage of open stope. J. Min. Saf. Eng 2017, 34, 163–169. [Google Scholar]

- Petlovanyi, M.; Malashkevych, D.; Sai, K.; Bulat, I.; Popovych, V. Granulometric composition research of mine rocks as a material for backfilling the mined-out area in coal mines. Min. Miner. Depos. 2021, 15, 122–129. [Google Scholar] [CrossRef]

- Pomykała, R.; Kępys, W. The properties of the backfill mixtures based on own fine-grained waste. In Minefill 2020–2021; CRC Press: Boca Raton, FL, USA, 2021; pp. 102–107. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Malashkevych, D.; Sai, K.; Zubko, S. Research into balance of rocks and underground cavities formation in the coal mine flowsheet when mining thin seams. Min. Miner. Depos. 2020, 14, 66–81. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Nakata, Y.; Bolton, M.D. Discrete element simulation of crushable soil. Geotechnique 2003, 53, 633–641. [Google Scholar] [CrossRef]

- Ng, T.T. Input parameters of discrete element methods. J. Eng. Mech. 2006, 132, 723–729. [Google Scholar] [CrossRef]

- Williams, J.R.; O’Connor, R. Discrete element simulation and the contact problem. Arch. Comput. Methods Eng. 1999, 6, 279–304. [Google Scholar] [CrossRef]

- Nannen, V.; Eiben, A.E. A method for parameter calibration and relevance estimation in evolutionary algorithms. In Proceedings of the 8th Annual Conference on Genetic and Evolutionary Computation, Seattle, WA, USA, 8–12 July 2006; pp. 183–190. [Google Scholar]

- Zhijia, L.; Penglei, X.; Jiahui, T. Study of the Xinanjiang model parameter calibration. J. Hydrol. Eng. 2013, 18, 1513–1521. [Google Scholar] [CrossRef]

- Hofmann, M. On the complexity of parameter calibration in simulation models. J. Def. Model. Simul. 2005, 2, 217–226. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Yang, H.; Liu, Q.; Tian, G. Experimental study on relationship between fracture propagation and pumping parameters under constant pressure injection conditions. Fuel 2021, 307, 121789. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Wang, C.; Liu, Q. Hydraulic fracturing characteristics and evaluation of fracturing effectiveness under different anisotropic angles and injection rates: An experimental investigation in absence of confining pressure. J. Nat. Gas Sci. Eng. 2022, 97, 104343. [Google Scholar] [CrossRef]

- Yu, Z.; Yongfa, Z.; Guodong, T.; Chaolin, W.; Jing, B. A new model for predicting hydraulic fracture penetration or termination at an orthogonal interface between dissimilar formations. Pet. Sci. 2022; in press. [Google Scholar] [CrossRef]

| Serial Number | Influence Factor | Grouting Speed m/s | Void Ratio | Particle Size /m |

|---|---|---|---|---|

| 1 | Grouting speed | 10 | 0.35 | 0.005 |

| 2 | 30 | |||

| 3 (Basic experiment) | 50 | |||

| 4 | 70 | |||

| 5 | 90 | |||

| 6 | Void ratio | 50 | 0.15 | 0.005 |

| 7 | 0.25 | |||

| 8 | 0.45 | |||

| 9 | 0.55 | |||

| 10 | Particle size | 50 | 0.35 | 0.001 |

| 11 | 0.003 | |||

| 12 | 0.007 | |||

| 13 | 0.009 |

| Factor | Fric | Rfric | F0/N | D0/m |

|---|---|---|---|---|

| Test 1 | 0 | 0 | 0 | 0 |

| Test 2 | 0 | 0.1 | 2.2 × 10−3 | 1.5 × 10−4 |

| Test 3 | 0 | 0.5 | 1.1 × 10−2 | 7.5 × 10−4 |

| Test 4 | 0.15 | 0 | 2.2 × 10−3 | 7.5 × 10−4 |

| Test 5 | 0.15 | 0.1 | 1.1 × 10−2 | 0 |

| Test 6 | 0.15 | 0.5 | 0 | 1.5 × 10−4 |

| Test 7 | 0.75 | 0 | 1.1 × 10−2 | 1.5 × 10−4 |

| Test 8 | 0.75 | 0.1 | 0 | 7.5 × 10−4 |

| Test 9 | 0.75 | 0.5 | 2.2 × 10−3 | 0 |

| Correction test | 0.75 | 0.1 | 2.2 × 10−3 | 7.5 × 10−4 |

| Test | Slump/mm | Test | Slump/mm |

|---|---|---|---|

| Test 1 | 292 | Test 6 | 250 |

| Test 2 | 292 | Test 7 | 120 |

| Test 3 | 232 | Test 8 | 180 |

| Test 4 | 223 | Test 9 | 150 |

| Test 5 | 168 | Correction test | 172 |

| Number | Factor | Slurry Diffusion Range (Width × Deep × High = m × m × m) | ||

|---|---|---|---|---|

| 1 | Grouting speed | 7.62 | 7.63 | 2.85 |

| 2 | 7.95 | 8.21 | 2.90 | |

| 3 | 8.18 | 8.54 | 3.52 | |

| 4 | 8.22 | 9.86 | 3.63 | |

| 5 | 8.29 | 10.49 | 4.84 | |

| 6 | Void ratio | 7.65 | 6.82 | 3.18 |

| 7 | 8.16 | 7.78 | 3.50 | |

| 8 | 9.50 | 8.81 | 3.54 | |

| 9 | 11.82 | 8.90 | 3.86 | |

| 10 | Particle size | 8.81 | 9.05 | 3.86 |

| 11 | 8.74 | 8.58 | 3.77 | |

| 12 | 7.41 | 8.50 | 3.48 | |

| 13 | 7.02 | 8.38 | 3.20 | |

| Number | Factor | Influence Range of Rock Movement (Width × Deep × High) | The Maximum Displacement of Rock | ||

|---|---|---|---|---|---|

| 1 | Grouting speed | 7.45 | 3.38 | 4.54 | 1.086 |

| 2 | 7.60 | 3.50 | 4.68 | 1.206 | |

| 3 | 7.81 | 5.52 | 7.26 | 1.210 | |

| 4 | 7.84 | 9.34 | 7.29 | 1.231 | |

| 5 | 9.50 | 9.35 | 7.35 | 1.307 | |

| 6 | Void ratio | 6.05 | 3.35 | 1.49 | 0.988 |

| 7 | 7.72 | 5.26 | 3.01 | 1.237 | |

| 8 | 8.62 | 7.44 | 10.10 | 1.728 | |

| 9 | 16.85 | 8.29 | 15.0 | 2.182 | |

| 10 | Particle size | 7.34 | 4.34 | 5.34 | 1.205 |

| 11 | 7.42 | 4.56 | 6.42 | 1.208 | |

| 12 | 8.91 | 8.96 | 9.73 | 1.243 | |

| 13 | 9.02 | 9.44 | 10.72 | 1.364 | |

| Factors | Range of Slurry Diffusion | Range of Influence of Rock Movement | Range Value of Maximum Displacement of Rock | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Width | Depth | Height | Range Sum | Width | Depth | Height | Range Sum | ||

| Grouting speed | 0.67 | 2.86 | 1.99 | 5.52 | 2.05 | 5.97 | 2.81 | 10.83 | 0.221 |

| Void ratio | 4.17 | 2.08 | 0.68 | 6.93 | 10.80 | 4.94 | 13.51 | 29.25 | 1.194 |

| Particle size | 1.79 | 0.67 | 0.66 | 3.12 | 1.68 | 5.10 | 5.38 | 12.16 | 0.159 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, J.; Li, M.; Sartaj, M.; Wang, Y. A Numerical Simulation of the Interaction of Aggregate and Rockfill in a Gangue Fluidized Filling Method. Sustainability 2022, 14, 12838. https://doi.org/10.3390/su141912838

Wang J, Zhang J, Li M, Sartaj M, Wang Y. A Numerical Simulation of the Interaction of Aggregate and Rockfill in a Gangue Fluidized Filling Method. Sustainability. 2022; 14(19):12838. https://doi.org/10.3390/su141912838

Chicago/Turabian StyleWang, Jiaqi, Jixiong Zhang, Meng Li, Majid Sartaj, and Yunbo Wang. 2022. "A Numerical Simulation of the Interaction of Aggregate and Rockfill in a Gangue Fluidized Filling Method" Sustainability 14, no. 19: 12838. https://doi.org/10.3390/su141912838

APA StyleWang, J., Zhang, J., Li, M., Sartaj, M., & Wang, Y. (2022). A Numerical Simulation of the Interaction of Aggregate and Rockfill in a Gangue Fluidized Filling Method. Sustainability, 14(19), 12838. https://doi.org/10.3390/su141912838