Optimization of Biomass Fuel Composition for Rubber Glove Manufacturing in Thailand

Abstract

1. Introduction

- -

- Compared to coal fuels, biomass fuels generally contain more volatile components and oxygen. They have a low carbon content and heating value.

- -

- The pyrolysis process of biomass fuels starts at a lower temperature.

- -

- The heat content generated from the vaporization of biomass is about 70% as compared to about 30% for coal.

- -

- Biomass fuels such as rice straw and oil palm empty fruit branch contain more free alkali (K and Na, but mainly K) in the ash. This leads to more severe problems with ash melting, slagging, ash deposition on the heat exchanger surface, or fouling than coal.

- -

- Biomass charcoal has a better oxidation response than coal charcoal because it has a larger surface area and alkali is present in the charcoal as a catalyst (Blasi et al., 1999).

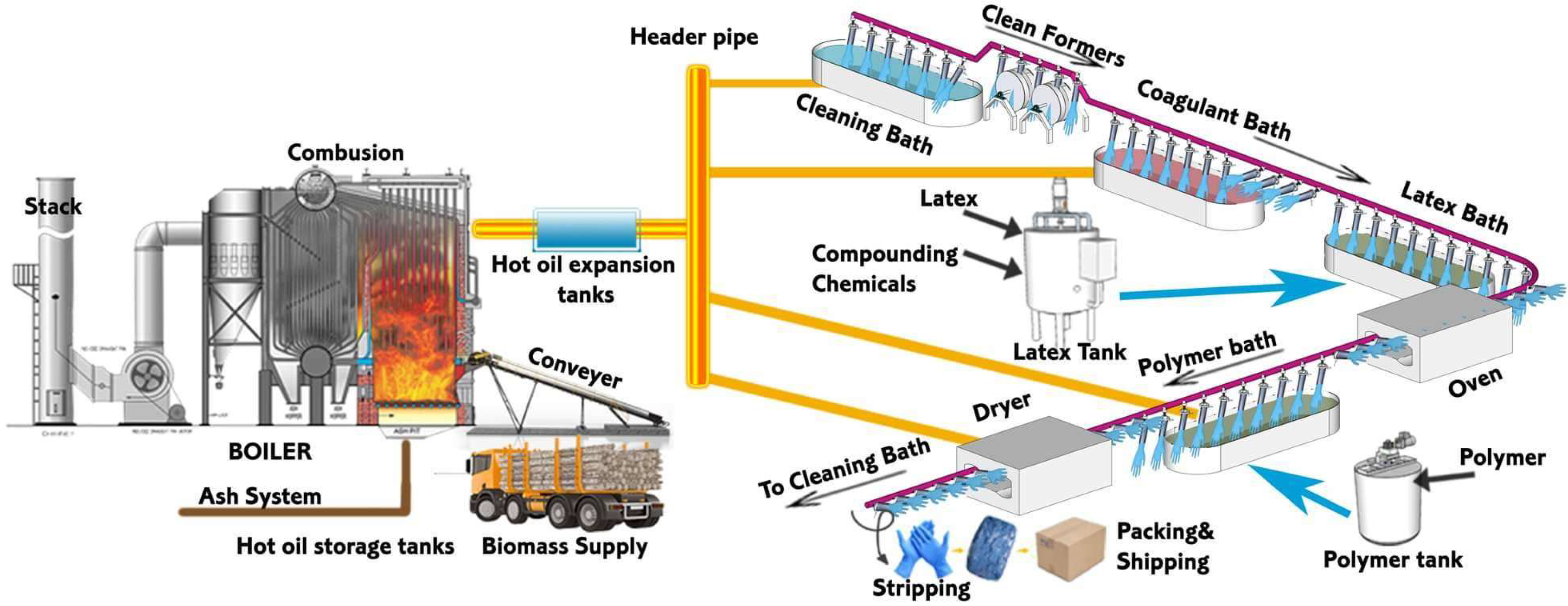

2. Materials and Methods

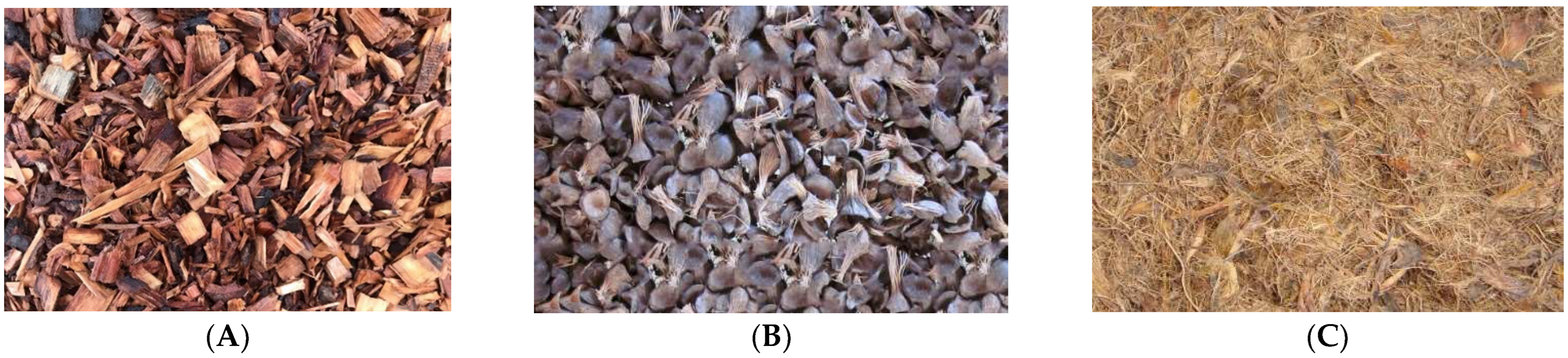

2.1. Sample Preparation

2.2. Experiment Set Up

2.3. Biomass Fuel Analytical Methods

- Moisture content of biomass fuel: Gravimetric method/ASTM D 3173.

- Proximate analysis: ASTM D 5468.

- Ultimate analysis

- Moisture content: ASTM D 7582.

- Volatile matter: ASTM D 7582.

- Fixed carbon: ASTM D 7582.

- Ash value: ASTM D 3174.

- Gross heating value (as received basis): Bomb Calorimeter/AC-350/BSEN 14918.

- Heat energy consumption: Read data from thermal hot oil machine and one-way ANOVA analysis.

- Moisture content of biomass fuel: Gravimetric method/ASTM D 3173.

- Heat energy consumption: Read data from thermal hot oil machine and one-way ANOVA analysis.

- Production cost: One-way ANOVA analysis

- Total suspension particulate: US.EPA Method 5.

- Sulfur dioxide: US.EPA Method 6C.

- Oxide of nitrogen: US.EPA Method 7E.

- Carbon monoxide: US.EPA Method 10.

- Carbon dioxide: US.EPA Method 3.

2.4. Experimentation and Observation of Boiler Performance Parameters

2.5. Performance Analysis of Boiler

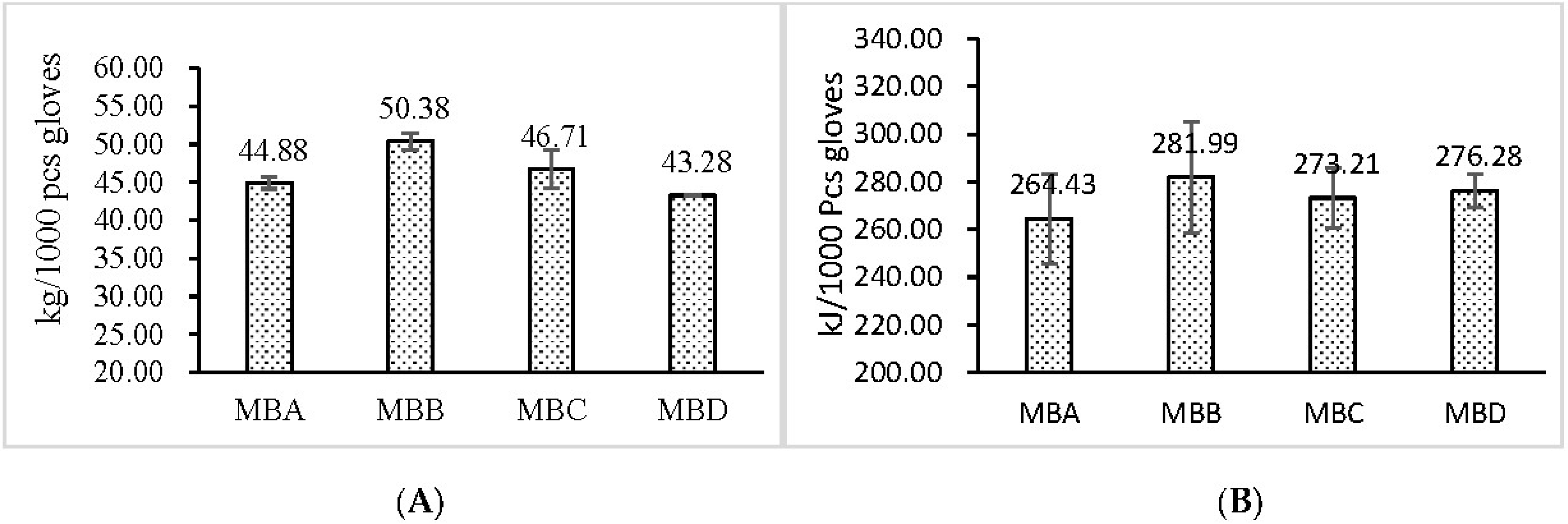

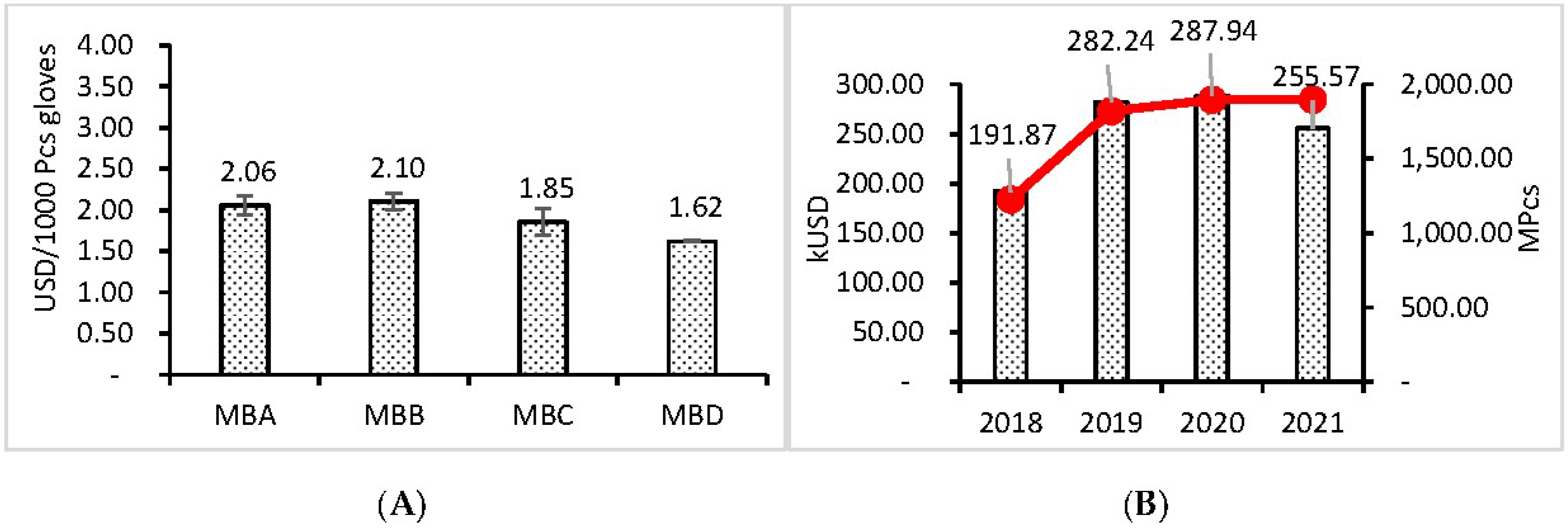

2.6. Economics of Biomass Utilization

2.7. Cost Analysis Calculation

2.8. Environmental Impact

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| WC | Wood chip |

| PKS | Palm kernel shells |

| OPMF | Oil palm mesocarp fiber |

| TOH | Thermal oil heater |

| CTN | Carton, or 1000 pieces of gloves |

| HHV | High heating value |

| LHV | Low heating value |

| GCV | Gross calorific value |

| NCE | Net calorific value |

| H | Hydrogen |

| C | Carbon |

| N | Nitrogen |

| O | Oxygen |

| S | Sulphur |

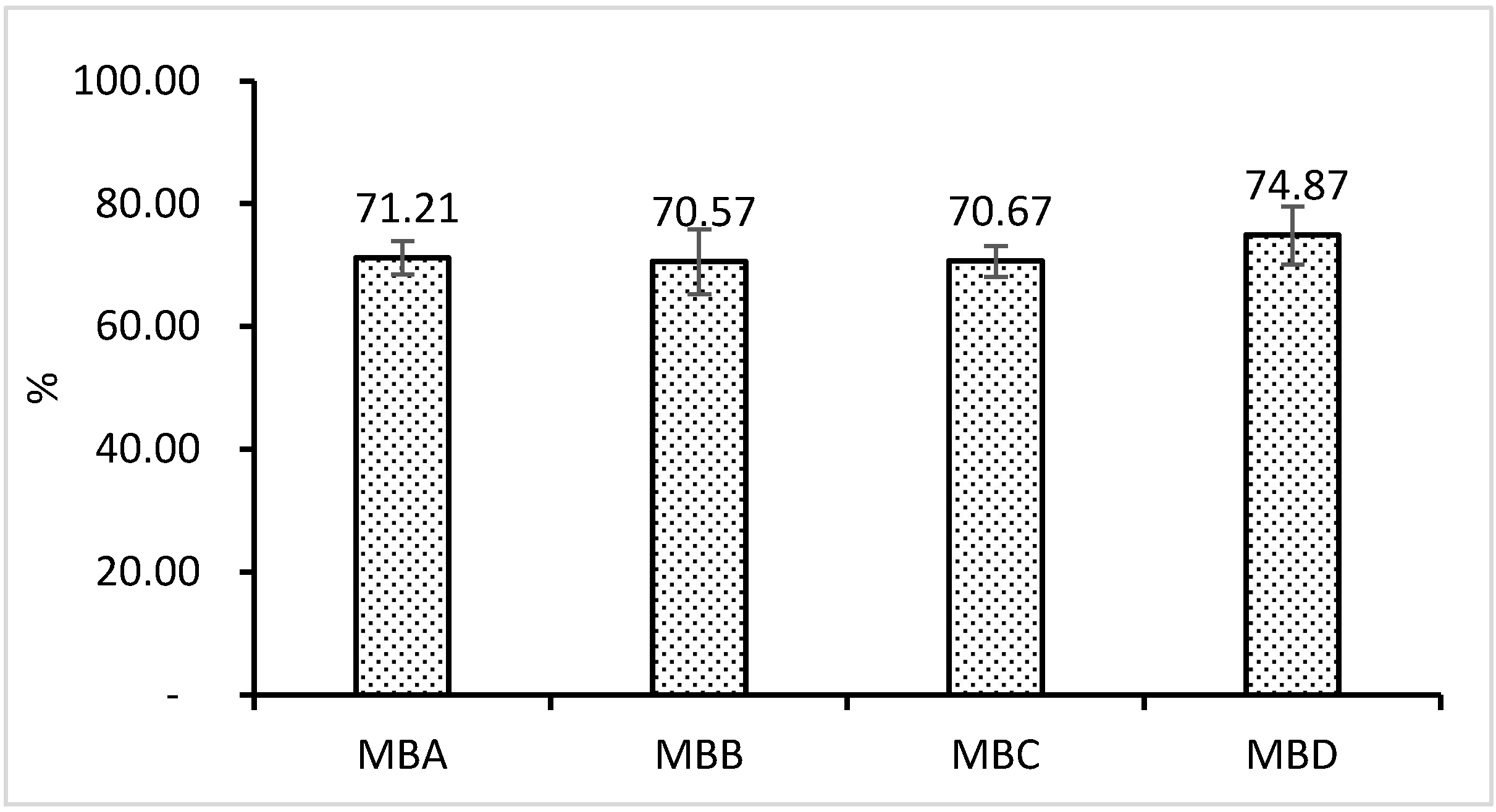

| MBA | Mixed biomass fuel sample A |

| MBB | Mixed biomass fuel sample B |

| MBC | Mixed biomass fuel sample C |

| MBD | Mixed biomass fuel sample D |

| η | Boiler efficiency (%) |

| Energy output (kJ/h), refer to Equation (2) | |

| Total energy input (kJ/h), refer to Equation (4) | |

| m | Flow rate (m3/h) |

| Cp | Specific heat (kJ/kg °C) |

| ∆T | Delta temperature (°C), refer to Equation (3) |

| Temperature inlet (°C) | |

| Temperature outlet (°C) | |

| Total energy input (kJ/h) | |

| Energy input of WC (kJ/h) | |

| Energy input of PKS (kJ/h) | |

| Energy input of OPMF (kJ/h) | |

| NPV | Net present value |

| PBP | Payback period |

| IRR | Internal rate of return |

| The cash benefit of the investment | |

| The cash cost of invertment | |

| The net cash flow in the year (t) | |

| n | The calculation period, which is equal to the project lifecycle |

| i | The cut-off discount rate |

| SO2 | Sulphur dioxide |

| NO2 | Nitrous oxide |

| CO | Carbon monoxide |

| TSP | Total suspended particulate |

| EPA | Environmental Protection Agency |

References

- Health Industry Distributors Association. A Lack Of Manufacturing Capacity Is Causing A Global Glove Shortage; Health Industry Distributors Association, 2022; Available online: http://cdn.boundtree.com/assets/btm/pdfs/Global-Glove-Shortage-Infographic.pdf (accessed on 8 May 2022).

- Arizton. Medical Gloves Market—Global Outlook & Forecast 2021–2026. Available online: https://www.researchandmarkets.com/reports/5403544/medical-gloves-market-global-outlook-and (accessed on 8 May 2022).

- Christoffersen, L.B.; Larsen, A.; Togeby, M. Empirical analysis of energy management in Danish industry. J. Clean. Prod. 2006, 14, 516–526. [Google Scholar] [CrossRef]

- Alazemi, A.S.K.R.; Ali, M.Y.; Daud, M.R.C. Preventive Maintenance of Boiler: A Case of Kuwait Industry. Int. J. Eng. Mater. Manuf. 2019, 4, 48–58. [Google Scholar] [CrossRef]

- Ranaraja, C.D.; Devasurendra, J.; Maduwantha, M.; Madhuwantha, G.; Hansa, R. Optimization of an industrial boiler operation. Jf Res. Technol. Eng. 2020, 1, 126–134. [Google Scholar]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Bapat, D.; Kulkarni, S.; Bhandarkar, V. Design and Operating Experience on Fluidized Bed Boiler Burning Biomass Fuels with High Alkali Ash; American Society of Mechanical Engineers: New York, NY, USA, 1997. [Google Scholar]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-firing of coal and biomass fuel blends. Prog. Energy Combust. Sci. 2001, 27, 171–214. [Google Scholar] [CrossRef]

- Hein, K.; Bemtgen, J. EU clean coal technology—co-combustion of coal and biomass. Fuel Processing Technol. 1998, 54, 159–169. [Google Scholar] [CrossRef]

- Glarborg, P.; Jensen, A.; Johnsson, J.E. Fuel nitrogen conversion in solid fuel fired systems. Prog. Energy Combust. Sci. 2003, 29, 89–113. [Google Scholar] [CrossRef]

- Williams, A.; Pourkashanian, M.; Jones, J. Combustion of pulverised coal and biomass. Prog. Energy Combust. Sci. 2001, 27, 587–610. [Google Scholar] [CrossRef]

- Madhiyanon, T.; Sathitruangsak, P.; Sungworagarn, S.; Pipatmanomai, S.; Tia, S. A pilot-scale investigation of ash and deposition formation during oil-palm empty-fruit-bunch (EFB) combustion. Fuel Processing Technol. 2012, 96, 250–264. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels—Significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Yin, C.; Rosendahl, L.A.; Kær, S.K. Grate-firing of biomass for heat and power production. Prog. Energy Combust. Sci. 2008, 34, 725–754. [Google Scholar] [CrossRef]

- Onoja, E.; Chandren, S.; Abdul Razak, F.I.; Mahat, N.A.; Wahab, R.A. Oil palm (Elaeis guineensis) biomass in Malaysia: The present and future prospects. Waste Biomass Valorization 2019, 10, 2099–2117. [Google Scholar] [CrossRef]

- Ahmad, F.B.; Zhang, Z.; Doherty, W.O.; O’Hara, I.M. The outlook of the production of advanced fuels and chemicals from integrated oil palm biomass biorefinery. Renew. Sustain. Energy Rev. 2019, 109, 386–411. [Google Scholar] [CrossRef]

- Sharma, H.B.; Sarmah, A.K.; Dubey, B. Hydrothermal carbonization of renewable waste biomass for solid biofuel production: A discussion on process mechanism, the influence of process parameters, environmental performance and fuel properties of hydrochar. Renew. Sustain. Energy Rev. 2020, 123, 109761. [Google Scholar] [CrossRef]

- Asadullah, M.; Adi, A.M.; Suhada, N.; Malek, N.H.; Saringat, M.I.; Azdarpour, A. Optimization of palm kernel shell torrefaction to produce energy densified bio-coal. Energy Convers. Manag. 2014, 88, 1086–1093. [Google Scholar] [CrossRef]

- Jaafar, A.A.; Ahmad, M.M. Torrefaction of Malaysian palm kernel shell into value-added solid fuels. Int. J. Chem. Mol. Eng. 2011, 5, 1120–1123. [Google Scholar]

- Onochie, U.; Obanor, A.; Aliu, S.; Igbodaro, O. Proximate and ultimate analysis of fuel pellets from oil palm residues. Niger. J. Technol. 2017, 36, 987–990. [Google Scholar] [CrossRef]

- Sukiran, M.A.; Abnisa, F.; Daud, W.M.A.W.; Bakar, N.A.; Loh, S.K. A review of torrefaction of oil palm solid wastes for biofuel production. Energy Convers. Manag. 2017, 149, 101–120. [Google Scholar] [CrossRef]

- Talero, G.; Rincón, S.; Gómez, A. Biomass torrefaction in a standard retort: A study on oil palm solid residues. Fuel 2019, 244, 366–378. [Google Scholar] [CrossRef]

- Kaewluan, S.; Pipatmanomai, S. Preliminary study of rubber wood chips gasification in a bubbling fluidised-bed reactor: Effect of air to fuel ratio. In Proceedings of the PSU-UNS International Conference on Engineering and Environment, Phuket, Thailand, 10–11 May 2007. [Google Scholar]

- Sriket, W.; Kaewjuea, W.; Kaosol, T. Improving fuel potential of para rubber wood bottom ash as charcoal briquette with co-extruded materials. Thai Environ. Eng. J. 2019, 33, 51–57. [Google Scholar]

- Horvat, I.; Dović, D. Combustion of agricultural biomass-issues and solutions. Trans. Famena 2018, 42, 75–86. [Google Scholar] [CrossRef]

- bp. Statistical Review of World Energy. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2020-full-report.pdf (accessed on 8 May 2022).

- Sukarta, I.N.; Sastrawidana, I.D.K.; Ayuni, N.P.S. Proximate Analysis and Calorific Value of Pellets in Biosolid Combined with Wood Waste Biomass. J. Ecol. Eng. 2018, 19, 185–190. [Google Scholar] [CrossRef]

- Carneiro, P.; Ferreira, P. The economic, environmental and strategic value of biomass. Renew. Energy 2012, 44, 17–22. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A review of technical and economic aspects of biomass briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Mehdizadeh, H.; Alishah, A.; Hojjati, A.S. Study on Performance and Methods to Optimize Thermal oil Boiler Efficiency in Cement Industry. Energy Equip. Syst. 2016, 4, 53–64. [Google Scholar]

- Williams, A.; Jones, J.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Martsri, A.; Yodpijit, N.; Jongprasithporn, M.; Junsupasen, S. Energy, Economic and Environmental (3E) Analysis for Sustainable Development: A Case Study of a 9.9 MW Biomass Power Plant in Thailand. Appl. Sci. Eng. Prog. 2021, 14, 378–386. [Google Scholar] [CrossRef]

| Biomass Type | Cellulose | Hemicellulose | Lignin | Ash | Reference |

|---|---|---|---|---|---|

| PKS | 28.8–27.2 | 21.6–22.7 | 44.0–50.7 | 8.6–16.3 | [16] |

| 27.70 | 21.60 | 44.0 | No data | [15] | |

| EFB | 34.0–40.4 | 17.2–22.4 | 23.1–29.6 | 5.0–6.5 | [16] |

| 23.70 | 21.60 | 29.20 | No data | [15] | |

| 26.0 | 43.0 | 24.0 | No data | [15] | |

| OPMF | 23.0–28.8 | 25.3–30.5 | 25.5–28.97 | 2.6–5.8 | [16] |

| 19.0 | 37.0 | 33.0 | No data | [17] | |

| OPF | 31.0–42.8 | 12.5–22.5 | 15.2–25.0 | 5.0–5.8 | [16] |

| OPT | 40.3–50.78 | 18.7–30.36 | 17.9–26.8 | 2.4–2.9 | [16] |

| Biomass | Proximate Analysis (wt, %) | Ultimate Analysis (wt, %) | HHV | LHV | References | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | FC | VM | Ash | C | H | O | N | S | (MJ/kg) | (MJ/kg) | ||

| PKS | 10.00 | 23.00 | 74.00 | 3.00 | 45.10 | 50.10 | 49.20 | 0.56 | 0.04 | 17.58 | - | [18] |

| 1.74 | 10.66 | 83.38 | 4.22 | 46.53 | 5.85 | 42.32 | 0.89 | 0.12 | 18.81 | - | [19] | |

| 11.00 | 19.70 | 67.20 | 2.10 | 49.74 | 5.32 | 44.86 | 0.08 | 0.16 | 16.30 | - | [15,16] | |

| 5.40 | 18.80 | 71.10 | 4.70 | 48.06 | 6.38 | 34.10 | 1.27 | 0.09 | - | - | [15] | |

| 10.23 | 1.42 | 85.11 | 3.24 | 47.88 | 5.15 | 42.69 | 0.94 | 0.10 | - | - | [20] | |

| EFB | 66.00–69.00 | 10.80–14.50 | 86.50–87.70 | 3.70–5.30 | 48.72 | 7.86 | 48.18 | 0.25 | - | 18.88 | [21] | |

| 8.78 | 8.60 | 79.65 | 3.00 | 48.79 | 7.33 | 40.18 | n.d. | 0.68 | 16.80 | - | [15] | |

| 54.10–56.50 | 8.0–8.2 | 34.3–34.7 | 2.04–2.16 | 21.00–22.80 | 2.70–2.90 | 16.70–18.30 | 0.41–0.42 | n.d. | 8.90–9.45 | 6.48–7.48 | [22] | |

| n/a | 27.90 | 67.50 | 4.60 | 40.70 | 5.40 | 47.80 | 0.30 | 1.20 | [23] | |||

| 15.01 | 0.98 | 79.58 | 4.48 | 43.89 | 5.33 | 54.32 | 0.52 | 0.10 | - | - | [20] | |

| OPF | 62.00–77.00 | 3.20–14.80 | 83.60–88.30 | 3.20–3.80 | 48.43 | 10.48 | 46.50 | 12.40 | - | 15.72 | [21] | |

| OPT | 67.00–81.00 | 4.90–7.80 | 68.30–88.30 | 2.90–3.70 | 51.41 | 11.82 | 51.16 | 0.17 | - | 17.47 | [21] | |

| OPMF | 30.40–33.40 | 14.10–14.70 | 51.10–51.70 | 2.24–2.36 | 33.10–36.10 | 3.40–3.80 | 25.20–27.60 | 1.16–1.20 | 0.09 | 13.87–17.87 | 11.57–13.37 | [22] |

| n/a | 16.13 | 73.03 | 10.83 | 51.52 | 5.45 | 40.91 | 1.89 | 0.23 | 19.00 | [15] | ||

| 11.10 | 1.01 | 80.08 | 7.90 | 42.20 | 5.21 | 42.34 | 2.21 | 0.14 | - | - | [20] | |

| WC | 8.50 | 14.75 | 83.09 | 0.83 | 46.39 | 5.75 | 14.71 | 0.02 | 0.00 | [23] | ||

| 6.40 | 3.90 | 15.30 | 74.5 | 19.30 | 4.60 | 22.40 | 0.10 | 0.10 | 9.13 | [24] | ||

| Sample | WC | PKS | OPMF |

|---|---|---|---|

| Mixed biomass sample A (MBA) | 88 | 12 | - |

| Mixed biomass sample B (MBB) | 85 | 15 | - |

| Mixed biomass sample C (MBC) | 85 | 13 | 2 |

| Mixed biomass sample D (MBD) | 85 | 10 | 5 |

| Biomass Type | Fuel Consumption (kg/day) | Ration (% w/w) | Price (THB/KG) | Cost (THB) |

|---|---|---|---|---|

| WC | 213,890.00 | 85 | 1.09 | 233,140.10 |

| PKS | 31,890.00 | 13 | 2.83 | 90,248.70 |

| OPMF | 4915.00 | 2 | 0.90 | 4423.50 |

| Total | 250,695.00 | 100 | 327,812.30 | |

| Cost per carton (THB/Carton) | 62.11 | |||

| Cost per carton (THB/Carton) | 35.43 | |||

| No. | Parameters | Units | WC | PKS | OPMF | MBA | MBB | MBC | MBD |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Moisture | % wt. | 9.76 ± 0.02 | 11.20 ± 0.02 | 42.71 ± 0.30 | 10.02 ± 0.05 | 9.97 ± 0.11 | 10.67 ± 0.01 | 10.28 ± 0.05 |

| 2 | Volatile matter | % wt. | 74.49 ± 0.44 | 66.80 ± 0.14 | 44.28 ± 0.13 | 73.21 ± 0.18 | 73.63 ± 0.26 | 73.30 ± 0.47 | 73.91 ± 0.13 |

| 3 | Fixed carbon | % wt. | 14.67 ± 0.44 | 18.93 ± 0.15 | 10.10 ± 0.17 | 15.98 ± 0.22 | 15.43 ± 0.24 | 15.04 ± 0.47 | 15.02 ± 0.18 |

| 4 | Ash content | % wt. | 1.08 ± 0.02 | 3.08 ± 0.06 | 2.90 ± 0.01 | 0.79 ± 0.02 | 0.97 ± 0.03 | 0.99 ± 0.02 | 0.78 ± 0.01 |

| 5 | HHV | kJ/kg | 16,850 ± 97 | 17,154 ± 376 | 11,196 ± 281 | 16,737 ± 53 | 16,422 ± 81 | 17,110 ± 57 | 17,249 ± 44 |

| 6 | Carbon (C) | % wt. | 44.74 ± 0.18 | 45.93 ± 0.12 | 30.90 ± 0.89 | 46.79 ± 0.25 | 44.55 ± 0.12 | 45.31 ± 0.11 | 46.23 ± 0.15 |

| 7 | Hydrogen (H) | % wt. | 6.05 ± 0.16 | 5.64 ± 0.01 | 6.11 ± 0.11 | 6.01 ± 0.07 | 6.01 ± 0.04 | 6.02 ± 0.21 | 5.96 ± 0.14 |

| 8 | Nitrogen (N) | % wt. | 0.28 ± 0.01 | 0.41 ± 0.01 | 0.76 ± 0.03 | 0.25 ± 0.01 | 0.49 ± 0.01 | 0.28 ± 0.02 | 0.31 ± 0.01 |

| 9 | Sulphur (S) | % wt. | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| 10 | Oxygen (O) | % wt. | 42.09 ± 0.70 | 36.80 ± 0.50 | 46.22 ± 0.36 | 42.73 ± 0.53 | 42.54 ± 0.54 | 41.73 ± 0.62 | 41.56 ± 0.22 |

| 11 | O: C ratio | - | 0.94 | 0.80 | 1.50 | 0.91 | 0.96 | 0.92 | 0.90 |

| 12 | H: C ratio | - | 0.14 | 0.12 | 0.20 | 0.13 | 0.14 | 0.13 | 0.13 |

| 13 | GHV | kJ/kg | 16,491 ± 173 | 17,266 ± 53 | 11,096 ± 342 | 17,022 ± 100 | 16,296 ± 9 | 16,717 ± 332 | 16,975 ± 153 |

| 14 | NHV | kJ/kg | 15,192 ± 139 | 16,054 ± 52 | 9783 ± 333 | 15,732 ± 92 | 15,004 ± 1 | 15,423 ± 287 | 15,694 ± 124 |

| Description | Unit | Method of Analysis | Results | Standard | Evaluation |

|---|---|---|---|---|---|

| Stack height | m. | Measuring tape | 30.00 | - | - |

| Diameter | cm. | Measuring tape | 120.00 | - | - |

| Cross-sectional area | m2 | Measuring tape | 1.13 | - | - |

| Atmospheric pressure | mm.Hg | U.S.EPA Method 2 | 749.00 | - | - |

| Temperature | °C | U.S.EPA Method 2 | 199.17 | - | - |

| Gas velocity | m/s | U.S.EPA Method 2 | 21.74 | - | - |

| Flow rate | m3/h | U.S.EPA Method 2 | 88,530.68 | - | - |

| Oxygen (%O2) | % | U.S.EPA Method 3 | 10.50 | - | - |

| Carbon dioxide (%CO2) | % | U.S.EPA Method 3 | 5.40 | - | - |

| Nitrogen and other (%N2) | % | U.S.EPA Method 3 | 84.10 | - | - |

| Moisture content | % | U.S.EPA Method 4 | 7.67 | - | - |

| Isokinetic | % | U.S.EPA Method 5 | 99.09 | - | - |

| Total suspended particulate (2) | mg/m3 | U.S.EPA Method 5 | 266.19 | ≤320 (1) | Pass |

| Sulfur dioxide (2) | ppm | U.S.EPA Method 6C | 1.34 | ≤60 (1) | Pass |

| Oxide of nitrogen (2) | ppm | U.S.EPA Method 7E | 66.83 | ≤200 (1) | Pass |

| Carbon monoxide (2) | ppm | U.S.EPA Method 10 | 634.86 | ≤690 (1) | Pass |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thep-On, L.; Chowdhury, S.; Taechato, K.-A.; Kumar, A.; Chanakaewsomboon, I. Optimization of Biomass Fuel Composition for Rubber Glove Manufacturing in Thailand. Sustainability 2022, 14, 12493. https://doi.org/10.3390/su141912493

Thep-On L, Chowdhury S, Taechato K-A, Kumar A, Chanakaewsomboon I. Optimization of Biomass Fuel Composition for Rubber Glove Manufacturing in Thailand. Sustainability. 2022; 14(19):12493. https://doi.org/10.3390/su141912493

Chicago/Turabian StyleThep-On, Laddawan, Shahariar Chowdhury, Kua-Anan Taechato, Anil Kumar, and Issara Chanakaewsomboon. 2022. "Optimization of Biomass Fuel Composition for Rubber Glove Manufacturing in Thailand" Sustainability 14, no. 19: 12493. https://doi.org/10.3390/su141912493

APA StyleThep-On, L., Chowdhury, S., Taechato, K.-A., Kumar, A., & Chanakaewsomboon, I. (2022). Optimization of Biomass Fuel Composition for Rubber Glove Manufacturing in Thailand. Sustainability, 14(19), 12493. https://doi.org/10.3390/su141912493