Abstract

The aim of this study is to draw a comprehensive image of the relationship between life cycle sustainability assessment (LCSA) impact using the three dimensions, namely life cycle costing (LCC), life cycle assessment (LCA), and social life cycle (SLC), and solid oxide fuel cells (SOFCs). By systematically reviewing and analyzing 43 articles from 17 different peer-reviewed journals between 1998 and 2021, the analysis shows that SOFC-related applications may substantially contribute to a cleaner energy sector in the future via high-level temperature power generation. The result indicated that SOFCs have better implications for environmental performance, as well as being the least cost-effective option for commercially competitive purposes. The review revealed several gaps in the literature; several studies assessed LCA using particular or very few indicators, and the few indicators may not sufficiently assess the environmental impact of SOFCs. Further, limited studies shed the light on the association between SLC and SOFCs. Future LCSA studies ought to adopt dynamic criteria, especially environmental impact analysis considering social and economic factors, to enable a feasible comparison of results. Future studies should also target various industrial sectors in developing countries.

1. Introduction

Over the last decade, large electrical energy consumption globally has increased electricity price fees. It has also negatively impacted the environment, causing global warming, acid rain, and urban smog [1]. Extensive efforts have been carried out to improve renewable energy source (RES) utilization and cost-efficiency strategy whilst meeting environmental goals [2]. Biomass resources have the potential to provide over 25% of worldwide primary energy in the year 2050 [3]. Biomass resources consist of solid biomass, biogas, and organic municipal solid waste (MSW). Electricity is generated from biomass resources by directly firing or co-firing in either electricity alone or a combined high degree of heat and power (CHP) [1]. A high-temperature fuel cell generates high-quality heat [4], especially from the developed version, the SOFC [3].

The SOFC is an efficient renewable energy technology that generates electrical voltage from the chemical reaction between hydrogen and oxygen [5]. SOFCs reduce methane gas emission pollution and use the biogas captured for fuel substitution, electricity production, and revenue generation [6]. An SOFC is economically feasible due to its steam pre-reforming catalyst and the creative design of internal recycling [7]. Furthermore, it has greater temperature scores and efficiency, which are optimal for hybrid power and power generation applications, while producing less pollutants, including NOx, SOx, CO, and particulate matter [8].

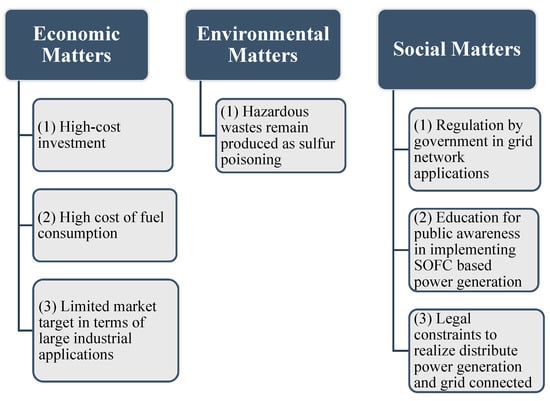

Despite the numerous benefits of the SOFC as a sustainable technology, it is mainly used in developed countries, especially European ones. The application of SOFCs across developing countries is scarce [9] due to the common thought about the high investment cost of new sustainable technology. In addition, transferring SOFC technology from laboratory scale to public scale can cause numerous issues (i.e., economic, environmental, and social opinions) [5] without any tangible benefits except being environmentally and socially compatible. Figure 1 shows the economic, environmental, and social issues in applying SOFCs.

Figure 1.

Issues in SOFC application adoption [5].

Tackling these issues requires a systematic assessment, which provides accurate data for policymakers and consumers based on life cycle impacts and their effect on economic, environmental, and social sustainability, and feasible solutions [7]. The life cycle sustainability assessment approach (LCSA) can provide sustainability evaluation during the life cycle. It comprises three principal pillars, namely life cycle costing (or LCC), life cycle assessment (or LCA), and social life cycle (or SLC). The LCSA was applied to gather several aspects from the related research on SOFCs, such as scope and goals, the life cycle inventory (or LCI) modeling, and the assessment of impact [7]. The major purposes of LCSA research on SOFCs are (1) identifying the materials and processes that can motivate the economic and environmental influences of an SOFC application and the impact improvement opportunity options and (2) sustainability comparison involving economic and environmental assets of other alternative energy supply in reducing cost-effective option and environmental impacts [9,10].

LCSA is a comprehensive model aiming to achieve the product’s highest performance [11]. LCSA calculates and estimates the raw material, final products, and environmental impacts of a product in its full life cycle, “i.e., manufacture, use, maintenance, and disposal”, including the resource inputs used for manufacturing the product. It provides numerous criteria that describe various strategic choices to improve decision-making and align with economic, environmental, and social sustainability [12]. LCC, LCA, and SLC measured the LCSA for this study. Prior studies utilized different tools to evaluate the SOFC economically, such as the current cash flow net present value or economic criteria [6,8]. Most of these studies found that the SOFC was scored as the least cost-effective technology [9]. However, LCC is the most reliable economic assessment of design alternatives [7]. LCC provides valuable information for relevant decision-making, such as assessing and choosing alternatives during the product design phase [13]. It evaluates the total costs during the financial lifetime of products. LCC can calculate aggregate costs of alternative products and processes, including investment, capital, operating, energy, maintenance, and disposal costs across the project lifetime or the product with present value indicators [14].

Similarly, LCA is an analytical methodology used to analyze the environmental effect through the whole product life cycle, service, or process [13]. LCA analyzes the entire or individual process from raw material consumption through manufacturing, usage, and disposal/recycling [8]. The LCA process comprises the “definition of a goal and scope”, “inventory analysis”, “impact assessment”, and “interpretation of the results” [14]. It aims to facilitate and quantify the environmental issues across the life cycle of resource-based SOFC systems [15]. LCA provides comprehensive information on resource usage, emissions, and waste generation from different technologies used for generating electricity [16]. LCA in SOFC is used to identify the material environmental assessment effects, the potential influence of mitigation of these effects, and the assessment of energy sources [17]. SLC is established according to the United Nations (UN) environmental program to investigate the sociological and social factors of products and their effect across the entire life cycle. SLC generally consists of a group of stages for socially calculating a product's impacts. It uses data from dedicated databases on countries and sectors, utilizing both general and site-specific data. SLC uses approaches and systems to collect and manipulate the data [18]. While LCA involves physical quantities associated with the product system, SLC includes quantitative and qualitative information on organization-related aspects [19].

Despite the rising trend of research on the usage of LCA on SOFCs, there are a few substantial gaps identified in this research [9]. Most studies focused on the environmental impact assessment [6], whereas the studies assessing the economic and social impact associated with SOFC are rarely reported. The authors of [14,15] conducted a review study focused on LCA usage on SOFCs consisting of 55 articles during the period from 1999 to 2018. Thirty-five of those articles focused merely on environmental LCA. Whereas 15 focused on implementing a combined environmental data and economic analysis, the remaining studies concentrated on the socio-economic efficiency by means of LCC evaluation. While identifying indicators for the environmental assessment using LCA is crucial for providing relevant and reliable data to the stakeholders for environment and biodiversity evaluation [9], identifying indicators associated with economic and social impact assessment utilizing LCC and SLC can improve decision-making. An indicator derived from the LCC model provides in-depth cost analysis, comparison, and commercial level contrast between the SOFC and a conventional system [7]. Further, indicators designed for SLC can show the benefits of the SOFC for people, such as job creation [20].

Second, previous studies assessed LCA using single or very few indicators. Few indicators may not sufficiently assess the sustainability impact of SOFCs, since products and processes might have a small influence on certain indicators such as climate change impacts (less CO2 emission). Still, they may have a harmful or high influence on acidification impacts due to the increased emission of SO2 and NOX [9]. Accordingly, developing a framework based on the LCSA methodology is recommended to integrate the environmental impact assessment alongside the economy and society into the work for better sustainability evaluation [16,17]. More specifically, a wide-ranging dynamic multi-criteria sustainability impact analysis, consisting of environmental, economic, and social indicators, is required to make a robust comparison of sustainability assessment results of SOFC applications. This work offers an in-depth review of the situation of LCSA methodology during the past two decades and provides valuable insights on the sustainability impact of SOFCs and their implications on environmental, economic, and social performance using LCSA.

This study is structured as follows: Section 2 summarizes the literature review of the SOFCs, and describes the methodology adopted to conduct the systematic review. Section 3 highlights the results in various tables and detailed analysis and discussion. Lastly, Section 4 concludes the study and discusses limitations, implications, and some recommendations for future work.

2. Systematic Review Methodology

A systematic literature review offers an in-depth and comprehensive perception through theoretical synthesis into fields and sub-fields (to collectively synthesize and establish research on a specific question, using replicable procedures during every stage of the process) [21] (p. 1). A review creates a reliable knowledge base and increases methodological rigor, assisting academic and practitioner communities [19]. A systematic review pursues a detailed plan (a protocol) that identifies and carefully documents its key objectives, concepts, and methods in advance.

A recent study adopted the review methodology from four main studies as a basis for design and structure [9,22,23,24]. This study developed a model based on LCS methodology to assess the sustainability impacts of SOFCs throughout their life cycle stages. New insight for evaluating the sustainability impacts (economic, environmental, and social) of SOFCs was established to gain more relevant results. This study consisted of two parts: The first part includes the reviews from 1999–2015 adopted by [9], which were based on the comprehensive guidance on conducting LCA based on “ISO 14040 and 14044 standards” for FC technologies as provided by the original manual. The second part reviews works between 2016 and 2021 and employs the review methodology of [19] as a general guideline structure of the systematic review. It is complemented by the detailed process proposed by [22] for an adequate systematic review.

The methodology of [19] comprises three key stages: (i) planning, (ii) conducting, and (iii) reporting. The approach of [22] includes six steps: (1) choosing relevant research questions, (2) choosing search keywords, (3) choosing appropriate bibliographic articles and contemporary electronic databases to manage a great amount of data, (4) using salient screening factors, (5) using methodological screening factors, and (6) analyzing and synthesizing the results. This appropriate flow has been successfully adopted in various studies, allowing the categorization of the studies and results of the research structure based on emerging themes.

2.1. Plan of the Review

The initial step of planning a review is to create a review protocol, which aids in protecting an objective view by providing explicit descriptions of the steps to be taken. This involves the research questions of this study, the study’s population (or sample), search keywords and strategy for identifying relevant articles, and the criteria for inclusion and exclusion of the articles [19].

2.1.1. Choosing Research Questions, Appropriate Search Keywords, and Contemporary Electronic Databases

The primary research question is as follows: what are the potential indicators and metrics for measuring sustainability assessment (i.e., economic, environmental, social) of SOFCs using the life cycle sustainability approach? Keywords such as “SOFC”, “life cycle assessment”, “life cycle analysis”, “life cycle sustainability”, “life cycle costing”, “social life cycle”, “environmental impact”, “economic impact”, and “social impact” were used to search for articles on SOFCs using the life cycle method. The database search tools were adjusted to find articles relevant to these search keywords. It is preferable to not limit the search tools to bibliographic databases [19]. Accordingly, the articles specified by the above keywords were collected from both the Scopus and the ISI databases, considering the full text of the documents from Google Scholar, Taylor & Francis, Emerald, Springer, Science Direct, Wiley Online Library, and MDPI to ensure wider data coverage [24,25].

2.1.2. Applying Practical Screening Criteria

The decision on inclusion and exclusion criteria was made by identifying eligibility criteria formulation. These criteria provide limitations to allow others to extend this review [24]. There are two screening types for article selection: practical screening and methodological screening. Practical screening criteria comprise the publications’ content, language, date of publication, methods, research setting, and publication type [22]. The search was limited to English articles to remove a preference for a certain language [25]. Therefore, empirical publications, review articles, and academic books published in English were considered as related literature. Conference proceedings, books, presentations, and comments were discarded. The dimension of quality standards (e.g., journal rankings) was not considered [26]. This review aims to understand the life cycle sustainability assessment of SOFCs comprehensively. Thus, publications that merely addressed SOFCs or in which SOFCs were of only secondary significance were excluded. Articles that addressed the association between life cycle sustainability and other renewable energy sources or chemical processes were excluded.

2.1.3. Methodological Screening Criteria

Methodological screening criteria are used in a quality appraisal that assesses the article’s validity and the extent to which its analysis and design have diminished errors [22]. In this step, a protocol was established for the content analysis of the considered articles. A review protocol describes the outcome and collects data on particular questions the study addresses. The categories for investigating the considered studies were extracted from prior work. The protocol comprised three main categories. The first reviewed the reference section of each study, including the author names, year of publication, title, type, and publishing journal’s name. This category involved describing the life cycle sustainability evaluation of SOFCs from 1999 to 2021 and identifying articles that focused on this study. The second category analyzed the background of the articles, the investigated object, the description of LCS and SOFCs, and the alternatively used terms other life cycle terms. More specifically, the new term ‘LCS’ involves economic, environmental, and social aspects. Therefore, it is focused on the definition of alternative life cycle terms used to assess SOFCs. The third category sheds light on the article’s content, clarifying the indicator(s) adopted for the sustainability assessment of SOFCs. This section was intended to answer the research questions and to understand how LCS was conducted for SOFCs in prior studies.

2.2. Conducting the Review

2.2.1. The Review from 1999 to 2015

The authors of [9] analyzed the environmental effect classes for LCA in research articles published between 1999 and 2015. The classes selected were already listed. Further indicators in the ReCiPe approach were not indicated; the wide range of selected environmental impact classes encompasses the majority of the required areas [6]. In this study, 46 articles (about 75%) concerning LCA studies on SOFCs focused only on environmental impact categories. Sixteen articles included the economic criteria (e.g., net present value (NPV), the least cost-effective option approach, and LCC for sustainable technology adoption). The LCA approach comprises four main phases, namely scope and goal definition, inventory analysis of life cycle, assessment of impact, and interpretation process. However, most of those articles used the cradle-to-gate (C-GT) or the cradle-to-grave (C-G) approach. However, the majority did not examine the full life cycle of the SOFC model due to simplification needs [7], poor end-of-life strategy definition [9], or lack of data for the disposal of SOFCs [7].

The authors of [27] conducted a life cycle evaluation of a fuel cell model during the manufacturing stage, excluding end-of-life material recycling and recovery. The authors of [28,29] do not include the manufacturing, maintenance, and decommissioning stages of the SOFC system, assuming that the ecological issues originated from fuel energy production and SOFC processing activities. A large number of articles [20,30,31] analyzed a single indicator concept, either the global warming potential (or GWP) or the acidification potential (or AP), in considering the environmental impact. However, merely relying on individual indicators may not reflect the actual environmental impact since the product or process might have a low impact on climate change (fewer CO2 emissions) in comparison to the rival product or process but a higher impact in relation to acidification effects due to great SO2 and NOX emissions [9]. Accordingly, this study selected only 13 articles from the [9] review involving more than three indicators to formulate more comprehensive sustainability assessment (i.e., economic, environmental, social) impact categories related to SOFC application.

2.2.2. The Review from 2016 to 2021

The search results using the above keywords from eight databases between 2016 and 2021 generated 12,850 related publications. In addition to exclusion and inclusion criteria, other screening processes were applied to obtain relevant articles: (a) elimination of repeated or duplicate articles, (b) alignment of the titles with the theme, (c) alignment of abstracts with the theme, and (d) availability of full-text publications in the databases. Accordingly, after the screening process (i.e., due to lack of availability and criteria not being fulfilled), only 34 relevant articles were included. On the other hand, four articles analyzed very few indicators. As a result, 30 relevant articles with full text were selected.

2.3. Analysis of Reported Results

In this review, 43 articles selected were published between 1999 and 2021. The low number of articles is due to the inclusion and exclusion criteria adopted. However, there was a remarkable growth in the number of publications in 2015 [31]. In 2021, the number of yearly publications reached its peak, accounting for 15% of total publications. The rising trend is due to the awareness of conducting a study using sustainability impact assessment (i.e., economic, environmental, social) on SOFCs using a life cycle approach in different industrial sectors across various developing countries [32]. The majority of articles (in total, 43) were from high-ranked journals, and the remaining two were book chapters from [33,34]. In total, 28 articles were from journals that are related to the discipline of energy (Applied Energy, Energy, Energies, Energy Conversion and Management, International Journal of Hydrogen Energy, Sustainability in Energy and Buildings, Energy Reports, Journal of Energy Storage). Fifteen articles were published in environment and sustainability journals (The Journal of Cleaner Production, The International Journal of Life Cycle Assessment, Science of the Total Environment, Sustainability). The distribution of journal articles is presented in Table 1. Notably, journals related to energy applications have the highest number of articles on the sustainability impact assessment of SOFCs.

Table 1.

Life cycle sustainability assessment of SOFCs by journals.

3. Result

3.1. Environmental Impact Assessment Indicators Using LCA

The impact categories, consisting of endpoint and midpoint LCA indicators, reflect the environmental aspects of SOFC technology in electricity generation [7]. Midpoint categories are closely related to low uncertainty and environmental flows. Categorization indicators at the midpoint level are available across the pathway of impact, reducing the correlation between uncertainties and assessing the potential environmental damages [34]. On the other hand, endpoint categories provide direct data on the environmental flows’ environmental significance but are less clear than the midpoint characterization factors [35]. Characterization elements at the endpoint level consist of three zones of protection, which are ecosystem quality, health, and natural resources [36]. The key variances between the two levels are “comprehensiveness and gaps, uncertainty (model and parameter), relevance (or scenario uncertainty), transparency, value-choices, and an understanding of the limited panel-based weighting methods across impact categories comparison” [37].

As shown in Table 2, most prior studies have used certain midpoint impact categories to assess the environmental impacts of SOFC application. Few studies used the endpoint level [38]. Nevertheless, midpoint and endpoint indicators should be applied together within a consistent framework [37]. The transparency level related to midpoint indicators may be regarded as greater than endpoint methods. However, when comparing the impact categories, the indirect associations among the midpoint and endpoint effects remain unclear or represented in an unorganized way. This may affect the overall quality of the results and weighting exercise [37].

Table 2.

A literature survey of multiple environmental impact categories for SOFC applications.

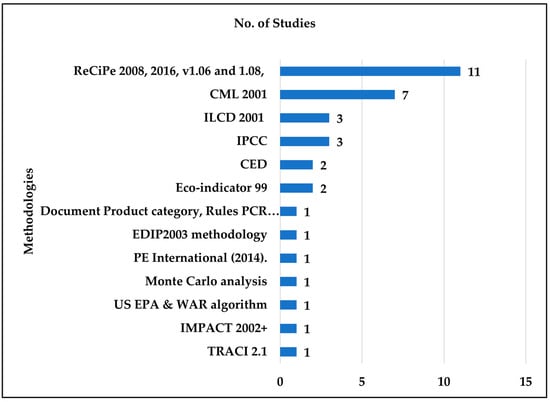

In terms of the methodologies for the environmental impact, 13 different methods and approaches were used in the prior studies, as shown in Figure 2. Eleven articles used ReCiPe approaches, seven used CML methods, three used both IPCC factors and ILCD methods, and two used Eco-indicator 99 and CED methods. Only one article used the CED, TRACI, Impact 2002+ US EPA & WAR algorithm, Monte Carlo analysis, PE International (2014), EPID2003 and document product category, Rules PCR 2007:08 method [6,7,8,39,40]. Detailed information about these methodologies is discussed in the following subsection.

Figure 2.

Environmental impact approaches used in LCA SOFC-related applications.

Each method assesses specific impact categories shown with particular environment indicators and measured by specific categorization, normalization, characterization, and weighting techniques [39]. These methodologies have been applied in numerous studies and for a broad range of products in services and manufacturing industry sector, such as transportation [41,42], construction [34], agriculture [43,44], oil and gas [32], and other sectors and activities to realize green growth. On the other hand, a logical question comes to mind: “which method is more relevant for authors to choose?”

3.1.1. CML Methodology

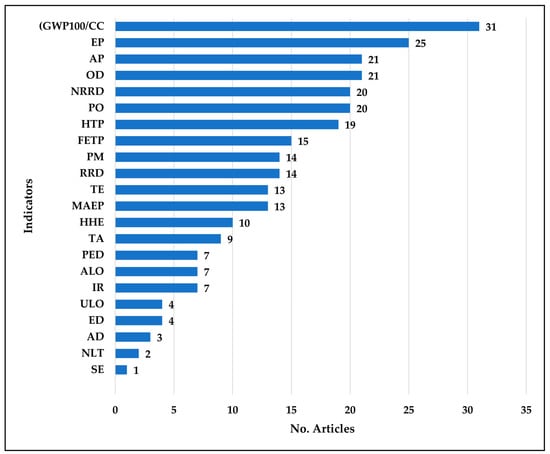

The CML style methodology has been widely utilized in practice due to its adequate robustness and reliability [44]. CML commonly uses the midpoint indicator level [9] and contains seven key indicators, namely the global warming potential, the acidification potential, the eutrophication potential, the abiotic depletion potential, the ozone depletion potential, the photochemical ozone, and the primary energy demand. As shown in Figure 3, GWP, EP, ODP, AP, and PO were the indicators most broadly analyzed across prior studies. CML is widely used in studies on SOFCs fueled by various energy sources, such as natural gas, hydrogen, methanol, ammonia, synthesis gas, and renewable biogas [7,13,33,45,46,47,48], due to its flexibility, correctness and transparency.

Figure 3.

Indicators employed in LCA SOFC systems.

The authors of [13] evaluated Norway-sourced liquefied natural gas, LNG from imports, in-house LNG, and sulfur-free engine diesel as settings for an SOFC along with a gas turbine. Generally, SOFC/GT technology has enhanced performance, but this depends on the kind of fuel used, in the range of 35 to 93% in all the considered indicators, namely, GWP, POCP, and AP. The authors of [7] assessed the LCA of a solid oxide fuel cell model (230 kW) and reported that the biogas offered a better environmental impact than the natural gases (NG) in terms of GWP, ADP, ODP, EP, as well as PED. It is also found that the NG layout is more desirable than the biogas configuration from the viewpoint of AP. A H2-fueled PO SOFC from electrolysis demonstrates higher performance in GWP and ODP compared to NG and biogas but slightly higher performance concerning PO, EP, and AP. The result of [44] supported the result of [7], in which generating a considerable share of electrical energy (about 25%) through biogas-fed SOFC-related applications can decrease the environmental harm correlated with wastewater treatment plant (WWTP) operations in AP, EP, GWP, PO, and PED. The authors of [47] assessed the environmental impact using micro-tubular SOFC LCA for the auxiliary power units fueled by liquefied propane gas, transformed into hydrogen by a catalytic partial oxidation (CPOx) reformer. An electrical supply is required for a camping vehicle besides the consumption of the tractor. There is a 45% decrease in CO2 emission and an 88% decrease in primary energy consumption as compared to traditional diesel APU models. In total, 54% of the GWP was impacted by the production stage of the traditional model. This can be reduced by changing the fabrication process.

Few studies used the CML approach with other methodologies to use midpoint and endpoint impact assessment, as shown in Table 2. Utilizing multiple approaches is recommended to obtain more accurate results. Using only one method could provide poor indications due to inconsistencies in the life cycle impact assessment (LCIA) approach [32]. The authors of [49] used combined CML and ReCiPe methodologies to assess the feasibility of using new material structures in an SOFC to minimize its temperatures. It was found that the main energy requirements decreased in comparison to SOFC production material with the usage of novel material combinations. The lowest explored environmental impact offers the best environmentally safe opportunity for upcoming intermediate temperature level SOFCs. Reference [46], EF3.0 was combined with CML to obtain appropriate data on materials most frequently utilized in hydrogen and fuel cell technology. It is reported that the lowest effects are detected in alkaline-based water electrolyzers. Both polymer electrolyte membrane fuel cells and SOFCs have a lower impact. The highest environmental impacts were from polymer electrolyte membrane water electrolyzers.

Hence, not all studies that adopted the CML approach used all seven indicators. Ref. [45] adopted CML with 10 indicators and added 3 more indicators (human-toxicity potential, marine aquatic ecotoxicity potential (MAEP), and terrestrial ecotoxicity (TE)). It was found that GWP was the most concerning parameter, and GHG emissions were at a high level due to the large contribution from the storage and transportation processes.

3.1.2. ReCiPe Methodology

ReCiPe was initially introduced in 2008 in prior work [62]. It consists of 18 midpoint indicators and 3 endpoint indicators. The method was modified to ReCiPe 2016 to provide characterization factors that represent the global scale instead of the European scale [62]. Eleven studies [6,8,10,17,37,41,53,54,55,61,64] used the ReCiPe 2008 or 2016 or v1.06 or 1.08, particularly using a hierarchic perspective to classify indicator categories at midpoint and endpoint levels [9]. As shown in Table 3, Ref. [8,10] reflect the highest number of impact categories, including 17 midpoint indicators.

Table 3.

Environmental impact category indicators used in LCA SOFC-related applications.

The ReCiPe approach has been used to study SOFCs that are also powered by several energy sources with both renewable and non-renewable sources [6]. Reference [8] evaluated various electricity source inputs (i.e., natural gas, coal, and others) in the SOFC manufacturing systems. Among all the impact classes, climate change and fossil fuel reduction are the two main ones, including 94.4% of the environmental impact from primary operation steps. However, manufacturing and disposal steps do not significantly contribute to the total impacts. Reference [52] performed two different LCA analyses for large-scale solid oxide power plants that are fueled by natural gas and gasified coal. The initial work presents a comprehensive LCA analysis of a large-scale power plant using SOFCs fueled by coal gasification. Combining carbon capture and sequestration with the NG as fuel supplying SOFCs minimized GWP by a total of 93%, and coal-fueled SOFCs minimized GWP by a total of 87.6%.

In endpoint impacts, ecosystem diversity, human health, and resource depletion were reduced by 35% with CCS and 20% without CCS. The second work by [53] utilizes NG as fuel feeding SOFCs. The results reported that 1 kW of SOFC generation in the manufacturing phase significantly influences fossil depletion, climate change, and metal depletion impact classes. Reference [6] revealed that applying NG directly in SOFCs generates a smaller climate change impact than other fuels such as hydrogen and methanol. Applying an SOFC fueled fed by biogas demonstrates higher efficiency than NG across all emissions and lower SO2, CO2, and PM than an SOFC fueled with hydrogen from co-electrolysis. Likewise, Reference [38] performed an LCA for an SOFC supplied with biogas and a CO2 recovery system. The results suggest that the effect of the climate change category for NG is about 0.4 kg CO2. Eq. per kWh of electricity production, whereas biogas was decreased to 0.2 kg CO2. Eq. per kWh. Despite the positive results that biogas provided, Reference [7] explained that biogas needs to be highly dependent on local conditions and accessibility. Reference [40] reported that SOFC vehicles may be a promising solution for effect reduction in 2030, if hydrogen is produced according to specific conditions. It is stated that the fuel cell is not the major contributor to any environmental impact category except for mineral resource scarcity, reducing the impact via weight decline or mass production.

3.1.3. Other Environmental Impact Assessment Methodologies

Other environmental impact assessment methods were selected besides the CML and ReCiPe approaches. TRACI assesses and minimizes chemical impacts. It consists of several indicators of potential environmental impact, such as the human health particulate air (or HHPA), the human toxicity cancer (or HTC), and the human toxicity non-cancer (or HTNC), as well as seven other categories of CML. TRACI is more optimal for evaluating the impact of valuable earth products [65]. HTC and GWA reflected the dominant impacts caused by every procedure, where Fe separation (II) and oxalic acid precipitation processes account for 38% and 15% and 48% and 14%, respectively. Reference [43] used Monte Carlo experiments and scenario analysis to evaluate the environmental effect of sewage sludge systems and micro-electricity generation analysis for agriculture. GWP, AP, and PO had the highest environmental performance footprint and the most cost-effectiveness when using the PEM FC micro-generation as well as Micro GT distributed models in comparison to other natural-gas-based models.

References [60,62,65] used the ILCD approach with 7 midpoint indicators or 15 midpoint indicators. Reference [38] showed that SOFC application significantly improved climate change, acidification, photochemical ozone development, terrestrial eutrophication, and particulate matter. SOFC applications performed better than ORCs due to greater exergy efficiencies as well as no particulate emissions. Reference [64] reported that the operation phase gives the highest impact (63.3–98.8%) associated with HT, Fe, IR-E, ME, WRD, and FEtox, followed by manufacturing phases (38–66.1%) related to IR-E and HT non-cancer effect and maintenance phases (20–30%) associated with HT, IR, FE, FEtox, and WRD. The finding regarding process phases agreed with [8]. Reference [57] used Eco-indicator 99 (the endpoint LCIA approach) originally used for decision-making in environment protection. It assesses the environmental issue by adopting real impacts and modifications on human health, ecosystem quality, and resources. Reference [50] used combined Eco-indicator 99, IPCC factors and CED methods. IPCC is primarily focused on GHGs emissions such as CO2, CH4, and N2O, as a function of the GWP indicator. CED is a parameter which forms the starting point for further energy assessment values (energy payback time or amortization time).

Based on [57], all thermal biomass gasification was integrated with a high-temperature SOFC. An integration model between exergy analysis with cost analysis using LCA was designed to report information for optimal design and cost-effective conversion techniques. The result showed that SOFC was the most relevant process component. Reference [50] summarized that, in the case of carcinogen emissions, the potential recycling of 70% of weight could reduce the overall life-cycle impacts by 7.5%. This study observed that the Eco-indicator 99 method had not been used since 2013 for articles with more than singular indicators. In addition, IPCC and CED have not been applied individually in previous studies. Reference [60] combined IPCC and CED methods to perform an SOFC-based comparative analysis of combined heat and power (CHP) models with storage of thermal energy and fueling with hydrogen storage and natural gas using LCA. Reference [61] used the combination of IPCC and ILCD 2.0 midpoint 2018 to evaluate the environmental impact assessment of three water electrolysis technologies, using similar tubing for a solid oxide fuel cell (SOFC, 300 kg, 100 kW). It has been found that the technology has the smallest potential environmental effect for energy settings in 2019 as well as 2030.

Reference [28] used EDIP 2003 and IMPACT 2002+ methodologies. IMPACT 2002+ applies midpoint and endpoint approaches linking 14 midpoint and 4 endpoint categories [66]. It is found that three studies, namely [35,50,57], did not directly determine particular environmental impact categories. Instead, they indicated selected indicators according to their needs. Multiple approaches without direct determination were applied in a unique work to assess the environmental effect of an SOFC stack created with 3D printing [34]. The 3D printing procedure has a small environmental effect in all categories, mainly due to the modifications needed for the manufacturing procedure by using 3D printing to create the SOFC stack, decreasing the impact by 95% in terms of GWP, AD Elements, AD Fossil, EP, and HTP.

3.2. Economic Impact Assessment Indicators Using LCC

For optimal strategy, various objectives must be considered in SOFC applications. Economic aspects are one of these objectives that ought to be considered [5]. Most of the customers in energy technology acquisition often build up their decision based on profit-driven, cost-effective analysis [67]. Accordingly, identifying the economic feasibility of the entire system is necessary for all stakeholders to make their correct choices [68]. Prior studies used different economic impact assessment methodologies for calculating the feasibility of the SOFC application, such as the LCC, the net present value, the net present cost, environmental cost, payback period, profitability index, and gross operative margins (GOM) [5,6,7,69,70].

The LCC method is chosen as the focus in this review. The LCC system comprises capital, fuel, operating, salvage value, and maintenance. Additionally, it comprises the utility expenses in the case utilities offer a building electricity and thermal energy [69]. Effective LCC usage of a system is necessary for a complicated decision-making process. Reference [7] identified that the cost of natural gas fuel feed is a major contribution to the life cycle. SOFC application shows a smaller overall LCC than microturbines in home applications. SOFC is a good alternative to the traditional system when the sustainability of investment costs is determined. On the contrary, [70] revealed that wind power plants make up 68.35% of total capital investment of GBP 2,468,093. SOFC/gas turbine (GT) technology costs about 50% of power to gas (P2G), with 67.1% electrical efficiency operation through multiple safety constraints. Accordingly, SOFC/GT technology shows financial and technical feasibility options for investors in a renewable-powered P2G model.

Apart from that, investors are concerned about recovering the investment cost or “payback period” [71], which influences their decision on SOFC investment. The payback period occurs once the actual capitalized expense and the yearly saving amounts are more than the lifespan of the overall installation [67]. From the economic perspective, the acceptable payback period is preferred to be between 7 and 10 years [72] or 10 and 15 years [57], Reference [73] as the lifespan of an SOFC is 40,000–80,000 h. Reference [74] analyzed the impact of recovering the key energy in municipal solid waste produced in Port Harcourt through the SOFC system in a single platform. It is found that the cost stands evaluated at USD 227.8 million. The cost of energy and recovery of the initial investment were 0.018 USD/kWh and 7.5 years, respectively. In [75], it was found that the capital investment for integrated gasification and anaerobic digestion to transform waste from agricultural to refrigeration and electrical power in a combined multiple generation plan could be repaid after 7.5 years and was USD 3.75 million.

On the other hand, the recommended payback period for commercially competitive purposes is 3–5 years. Government subsidization at half of the system costs for a trigeneration model is enough for the break-even point to be less than 6 years [72]. Reference [42] compares the economic impact of SOFC usage fueled with biogas among individual and centralized systems across Malaysian palm oil mills. The individual system required a lower cost than the central system with RM 2.56 per kWh and RM 7.04 per kWh, respectively, including incentives and government financial support. Reference [76] emphasized financial satisfaction with a small payback period in the presence of subsidization reaching less than 12 months. The period may need to be 36.46 months in the deficiency of any subsidy. The reduced operation costs increase the cash inflows and the likelihood of ideal payback, as shown in Equation (1).

Payback period = Investment Cost

Annual cash inflows

Annual cash inflows

Reduced operating costs or relevant cost-effective demand promote the development of advanced SOFC technology which could hybridize with other technologies. Reference [69] emphasized that the operation costs of the hybrid model were lower than those of the individual model through the baseline phase. When the systems become more optimized in the cogeneration process, the individual system show more privilege in cost saving compared to the hybrid system with about USD 24,000 in favor of a stand-alone system. Nevertheless, hybrid systems should be further researched and developed. Reference [77] revealed that a hybrid energy storage system with supercapacitors saves costs substantially more than battery energy storage for microgrid (MG) applications. It is found that Li-ion batteries are more cost-efficient than lead–acid batteries. Reference [33] demonstrated that the hybrid SOFC/GT technology is economically feasible (lower fuel costs and system investment), highly efficient, and less polluting at all rates compared with the hybrid MCFC/GT technology.

3.3. Social Impact Assessment Indicators Using SLC

Social impact assessment is a model used to determine, manage, monitor, and reduce the impacts of policies, projects, and programs [78]. It is based on a policy technique that evaluates a scheme’s socio-cultural impacts and provides data to socio-political decision-makers on the scheme’s potential social acceptance. It also shows recommendations by the management to satisfy the policy’s opposing social impacts [79]. The Guidelines of SLC were issued under the structure of the UNEP/SETAC life-cycle in 2009. It proposes subcategories, which are assessment criteria [80], such as geographic locations and stakeholders (i.e., local community, workers, consumers, and value chain participants) [81]. Prior studies have addressed these categories in various fields such as mining, agriculture, and fisheries [21,82]. However, studies in advanced renewable energies such as SOFC are scarce [76]. Such scarce studies exclude many components related to stakeholder categories [83]. The articles do not offer complete life-cycle stages without taking into account relations and consumers among actors within the value chain [84].

The UNEP/SETAC sets a guideline for the SLC of products to give a holistic social impact assessment using the social life cycle on SOFC-related applications. This guideline includes 5 major stakeholder categories and 32 subcategories of socially important themes or attributes as follows: (I) workers, freedom of association and collective bargaining, child labor, fair salary, working hours, forced labor, equal opportunities/discrimination, health and safety, social benefits/social security; (II) local community, access to material resources, access to immaterial resources, delocalization and migration, cultural heritage, safe and healthy living conditions, respect of indigenous rights, community engagement, local employment, secure living conditions; (III) society, public commitments to sustainability issues, contribution to economic development, prevention and mitigation of armed conflicts, technology development, corruption; (IV) customer, health and safety, feedback mechanism, consumer privacy, transparency, end-of-life responsibility; (V) value chain actors, fair competition, promoting social responsibility, supplier relationships, respect for intellectual property rights.

These categories consist of stakeholders with mutual interests, primarily due to their association with the product that is being assessed [81]. Only a few articles did not consider the entire subcategories stated in the UNEP/SETAC Guidelines since the selection should be subjected to applicability and data availability. In addition, not all subcategories may reflect any suitability to the context of product technology social impacts [12]. Hence, the social impact categories proposed in this research can provide a solid foundation for future studies. However, further validation from professionals and academicians in the field of SOFCs is needed to assess their applicability in real case studies.

4. Conclusions

This review collected two decades of work on sustainability assessment (i.e., economic, environmental, social) of SOFCs using the life cycle sustainability approach. The review focused on LCA, LCC, and SLC on SOFCs and discussed the methodologies used. LCA impact consists of categories, indicators, and recommendations in developing a framework based on LCSA methodology using a quantitative method. LCA provides a wide-ranging dynamic multiple-criteria analysis of environmental impact that involves economic and social factors to present a reliable comparison of sustainability assessments of SOFC applications.

This review proved the superiority benefits of SOFCs from both environmental and economic perspectives because of the high electrical efficiency and capability to produce surplus electricity with minimum pollution. Accordingly, adopting such a system is a gateway to a greener energy future. The best formula for the environmental impact assessment is to integrate more than one methodology to obtain highly accurate results. The use of only one method could offer poor indications because of inconsistencies in the LCIA approach. On the other hand, data availability could hinder the implementation of such a formula, as manufacturers often classify the information regarding materials selected in SOFC production for privacy and market competitiveness [32]. Second, the manufacturing and operation phases were the key contributors to most environmental impacts. Third, start-up/shut-down cycles and maintenance do not cause environmental impact. It is preferable to conduct an economic and environmental impact assessment, as enhancing the environmental efficiency requires modification of a few SOFC configurations and tools, raising the cost [6,7].

There are several limitations related to prior studies. The results of this review are restricted and formulated using a scoping review of the searching strategy; other publications may be found related to a similar subject but are only discoverable outside of the searching strategy. Further, most studies mainly focused on environmental impact assessment, and very few address social impact assessment. Indicators designed for SLC are significant for showing what power can produce more benefits for the people, such as job creation. Apart from that, extensive geographical distribution focused on Europe or developed countries, while developing countries were found to be addressed in a very limited manner. Lastly, prior studies cover a widespread manufacturing and industrial sector (e.g., transportation, agriculture, oil and gas).

On the other hand, it is desirable to address some sectors, such as construction and services, particularly governmental sectors. For future studies, with sufficient data, it is worth combining multiple environmental impact assessment categories involving the 22 indicators revealed in Table 3. In addition, future studies should integrate the entire sustainability assessment (i.e., economic, environmental, social) of SOFCs using the life cycle approach. Furthermore, more studies need to be conducted, particularly in developing countries such as countries in East Asia, the Middle East, and Africa, as this will improve the natural environment and reduce pollution. Finally, future studies may investigate the sustainability impact assessment of SOFC-related applications across governmental sectors.

Author Contributions

Conceptualization, K.M.A.S.; methodology, K.M.A.S.; software, K.M.A.S.; validation, K.M.A.S., R.M., M.N.A.R., H.H. and A.M.A.; formal analysis, K.M.A.S.; investigation, K.M.A.S.; resources, K.M.A.S.; data curation, K.M.A.S.; writing—original draft preparation, K.M.A.S.; writing—review and editing, K.M.A.S., R.M., M.N.A.R., H.H. and A.M.A.; visualization, K.M.A.S.; supervision, R.M., M.N.A.R., H.H. and A.M.A.; project administration, R.M., H.H., A.M.A. and M.N.A.R.; funding acquisition, R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Higher Education, Malaysia through the Transdisciplinary Research Grant Scheme (TRGS) with code TRGS/1/2019/UKM/01/1/3.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pazheri, F.R.; Othman, M.F.; Malik, N.H. A review on global renewable electricity scenario. Renew. Sustain. Energy Rev. 2014, 31, 835–845. [Google Scholar] [CrossRef]

- Sternberg, R. Hydropower’s future, the environment, and global electricity systems. Renew. Sustain. Energy Rev. 2010, 14, 713–723. [Google Scholar] [CrossRef]

- Din, Z.U.; Zainal, Z.A. Biomass integrated gasification-SOFC systems: Technology overview. Renew. Sustain. Energy Rev. 2016, 53, 1356–1376. [Google Scholar] [CrossRef]

- Narasipuram, R. Analysis, identification and design of robust control techniques for ultra-lift Luo DC-DC converter powered by fuel cell. Int. J. Comput. Aided Eng. Technol. 2021, 14, 102–129. [Google Scholar] [CrossRef]

- Ramadhani, F.; Hussain, M.A.; Mokhlis, H.; Hajimolana, S. Optimization strategies for Solid Oxide Fuel Cell (SOFC) application: A literature survey. Renew. Sustain. Energy Rev. 2017, 76, 460–484. [Google Scholar] [CrossRef]

- Bicer, Y.; Khalid, F. Life cycle environmental impact comparison of solid oxide fuel cells fueled by natural gas, hydrogen, ammonia and methanol for combined heat and power generation. Int. J. Hydrogen Energy 2020, 45, 3670–3685. [Google Scholar] [CrossRef]

- Strazza, C.; del Borghi, A.; Costamagna, P.; Gallo, M.; Brignole, E.; Girdinio, P. Life Cycle Assessment and Life Cycle Costing of a SOFC system for distributed power generation. Energy Convers. Manag. 2015, 100, 64–77. [Google Scholar] [CrossRef]

- Lee, Y.D.; Ahn, K.Y.; Morosuk, T.; Tsatsaronis, G. Environmental impact assessment of a solid-oxide fuel-cell-based combined-heat-and-power-generation system. Energy 2015, 79, 455–466. [Google Scholar] [CrossRef]

- Mehmeti, A.; McPhail, S.J.; Pumiglia, D.; Carlini, M. Life cycle sustainability of solid oxide fuel cells: From methodological aspects to system implications. J. Power Sources 2016, 325, 772–785. [Google Scholar] [CrossRef]

- Atia, N.G.; Bassily, M.A.; Elamer, A.A. Do life-cycle costing and assessment integration support decision-making towards sustainable development? J. Clean. Prod. 2020, 267, 122056. [Google Scholar] [CrossRef]

- Westkämper, E. Life cycle management and assessment: Approaches and visions towards sustainable manufacturing (keynote paper). CIRP Ann. 2000, 49, 501–526. [Google Scholar] [CrossRef]

- Jing, R.; Wang, M.; Wang, W.; Brandon, N.; Li, N.; Chen, J.; Zhao, Y. Economic and environmental multi-optimal design and dispatch of solid oxide fuel cell based CCHP system. Energy Convers. Manag. 2017, 154, 365–379. [Google Scholar] [CrossRef]

- Hasanzadeh, A.; Chitsaz, A.; Mojaver, P.; Ghasemi, A. Stand-alone gas turbine and hybrid MCFC and SOFC-gas turbine systems: Comparative life cycle cost, environmental, and energy assessments. Energy Rep. 2021, 7, 4659–4680. [Google Scholar] [CrossRef]

- Smith, L.; Ibn-Mohammed, T.; Koh, L.; Reaney, I.M. Life cycle assessment of functional materials and devices: Opportunities, challenges, and current and future trends. J. Am. Ceram. Soc. 2019, 102, 7037–7064. [Google Scholar] [CrossRef]

- Tanveer, W.H.; Abdelkareem, M.A.; Kolosz, B.W.; Rezk, H.; Andresen, J.; Cha, S.W.; Sayed, E.T. The role of vacuum based technologies in solid oxide fuel cell development to utilize industrial waste carbon for power production. Renew. Sustain. Energy Rev. 2021, 142, 110803. [Google Scholar] [CrossRef]

- Gonçalves, F.d.; Lopes, E.S.; Lopes, M.S.; Filho, R.M. Evaluation of the feasibility of ethanol and gasoline in solid oxide fuel cell vehicles in Brazil. Int. J. Hydrogen Energy 2021, 46, 36381–36397. [Google Scholar] [CrossRef]

- Smith, L.; Ibn-Mohammed, T.; Yang, F.; Reaney, I.M.; Sinclair, D.C.; Koh, S.C.L. Comparative environmental profile assessments of commercial and novel material structures for solid oxide fuel cells. Appl. Energy 2019, 235, 1300–1313. [Google Scholar] [CrossRef]

- Naghshineh, B.; Lourenço, F.; Godina, R.; Jacinto, C.; Carvalho, H. A social life cycle assessment framework for additive manufacturing products. Appl. Sci. 2020, 10, 4459. [Google Scholar] [CrossRef]

- Mancini, L.; Sala, S. Social impact assessment in the mining sector: Review and comparison of indicators frameworks. Resour. Policy 2018, 57, 98–111. [Google Scholar] [CrossRef]

- Reenaas, M. Solid Oxide Fuel Cell Combined with Gas Turbine Versus Diesel Engine as Auxiliary Power Producing Unit Onboard a Passenger Ferry: A Comparative Life Cycle Assessment and Life Cycle Cost. Master’s Thesis, Norges Teknisk-naturvitenskapelige Universitet, Trondheim, Norway, 2005. [Google Scholar]

- Vattenfall’s, E.I.S. Life-Cycle Assessment, Vatenfall’s Electricity Generation in Sweden. 2005. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.205.5058&rep=rep1&type=pdf (accessed on 25 August 2022).

- Litte, J.H.; Corcoran, J.; Pillai, V. Systematic Review and Meta- Analysis, Pocket Guides to Social Work Research Methods. Resour. Policy 2008, 57, 98–111. [Google Scholar]

- Tranfield, D.; Denyer, D. Smart. Towards a methodology for developing evidence—Informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; Saga Publication: Saga, Japan, 2014; Volume 20. [Google Scholar]

- Salim, N.; Rahman, M.N.A.; Wahab, D.A. A systematic literature review of internal capabilities for enhancing eco-innovation performance of manufacturing firms. J. Clean. Prod. 2019, 209, 1445–1460. [Google Scholar] [CrossRef]

- Stechemesser, K.; Guenther, E. Carbon accounting: A systematic literature review. J. Clean. Prod. 2012, 36, 17–38. [Google Scholar] [CrossRef]

- Suhariyanto, T.T.; Wahab, D.A.; Rahman, M.N.A. Multi-Life Cycle Assessment for sustainable products: A systematic review. J. Clean. Prod. 2017, 165, 677–696. [Google Scholar] [CrossRef]

- Karakoussis, V.; Brandon, N.; Leach, M.; van der Vorst, R. The environmental impact of manufacturing planar and tubular solid oxide fuel cells. J. Power Sources 2001, 101, 10–26. [Google Scholar] [CrossRef]

- Lin, J.; Babbitt, C.W.; Trabold, T.A. Life cycle assessment integrated with thermodynamic analysis of bio-fuel options for solid oxide fuel cells. Bioresour. Technol. 2013, 128, 495–504. [Google Scholar] [CrossRef]

- Tonini, D.; Astru, T. LCA of biomass-based energy systems: A case study for Denmark. Appl. Energy 2012, 99, 234–246. [Google Scholar] [CrossRef]

- Staffell, I.; Ingram, A.; Kendall, K. Energy and carbon payback times for solid oxide fuel cell based domestic CHP. Int. J. Hydrogen Energy 2012, 37, 2509–2523. [Google Scholar] [CrossRef]

- Gantner, U.; Jakob, M.; Hirschberg, S. Total greenhouse gas emissions and costs of alternative Swiss energy supply strategies. Fifth International Conference on Greenhouse Gas Control Technologies. 2001, pp. 991–996. Available online: https://www.researchgate.net/profile/Martin-Jakob-2/publication/253789416_Total_greenhouse_gas_emissions_and_costs_of_alternative_Swiss_energy_supply_strategies/links/00b7d529e481e28e68000000/Total-greenhouse-gas-emissions-and-costs-of-alternative-Swiss-energy-supply-strategies.pdf (accessed on 25 August 2022).

- Knauer, T.; Möslang, K. The adoption and benefits of life cycle costing. J. Account. Organ. Chang. 2018, 14, 188–215. [Google Scholar] [CrossRef]

- Al-Khori, K.; Al-Ghamdi, S.G.; Boulfrad, S.; Koç, M. Life cycle assessment for integration of solid oxide fuel cells into gas processing operations. Energies 2021, 14, 4668. [Google Scholar] [CrossRef]

- Cánovas, A.; Zah, R.; Gassó, S. Comparative Life-Cycle Assessment of Residential Heating Systems, Focused on Solid Oxide Fuel Cells. In Sustainability in Energy and Buildings 22; Springer: Berlin/Heidelberg, Germany, 2013; pp. 659–668. [Google Scholar]

- Ferreira, V.J.; Wolff, D.; Hornés, A.; Morata, A.; Torrell, M.; Tarancón, A.; Corchero, C. 5 kW SOFC stack via 3D printing manufacturing: An evaluation of potential environmental benefits. Appl. Energy 2021, 291, 116803. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Rillo, E.; Gandiglio, M.; Lanzini, A.; Bobba, S.; Santarelli, M.; Blengini, G. Life Cycle Assessment (LCA) of biogas-fed Solid Oxide Fuel Cell (SOFC) plant. Energy 2017, 126, 585–602. [Google Scholar] [CrossRef]

- Moretti, C.; Corona, B.; Rühlin, V.; Götz, T.; Junginger, M.; Brunner, T.; Obernberger, I.; Shen, L. Combining biomass gasification and solid oxid fuel cell for heat and power generation: An early-stage life cycle assessment. Energies 2020, 13, 11. [Google Scholar] [CrossRef]

- Wang, L.; Wang, P.; Chen, W.Q.; Wang, Q.Q.; Lu, H.S. Environmental impacts of scandium oxide production from rare earths tailings of Bayan Obo Mine. J. Clean. Prod. 2020, 270, 122464. [Google Scholar] [CrossRef]

- Longo, S.; Cellura, M.; Guarino, F.; Ferraro, M.; Antonucci, V.; Squadrito, G. Life Cycle Assessment of Solid Oxide Fuel Cells and Polymer Electrolyte Membrane Fuel Cells: A Review. Hydrogen Econ. 2017, 685, 139–169. [Google Scholar] [CrossRef]

- Vargas, J.E.V.; Seabra, J.E.A. Fuel-cell technologies for private vehicles in Brazil: Environmental mirage or prospective romance? A comparative life cycle assessment of PEMFC and SOFC light-duty vehicles. Sci. Total Environ. 2021, 798, 149265. [Google Scholar] [CrossRef]

- Li, M.; Zhang, X.; Li, G. A comparative assessment of battery and fuel cell electric vehicles using a well-to-wheel analysis. Energy 2016, 94, 693–704. [Google Scholar] [CrossRef]

- SShafie, M.; Othman, Z.; Nu’man, A.H.; Yusuf, N.N.A.N. A Model of Life Cycle on Biogas Feed to Solid Oxide Fuel Cell in Malaysia: Economic and Environmental Perspective. J. Adv. Res. Fluid Mech. Therm. Sci. 2021, 86, 126–135. [Google Scholar] [CrossRef]

- Sadhukhan, J. Distributed and micro-generation from biogas and agricultural application of sewage sludge: Comparative environmental performance analysis using life cycle approaches. Appl. Energy 2014, 122, 196–206. [Google Scholar] [CrossRef]

- Gandiglio, M.; de Sario, F.; Lanzini, A.; Bobba, S.; Santarelli, M.; Blengini, G.A. Life cycle assessment of a biogas-fed solid oxide fuel cell (SOFC) integrated in awastewater treatment plant. Energies 2019, 12, 1611. [Google Scholar] [CrossRef]

- Shafie, S.M.; Othman, Z.; Hami, N.; Omar, S.; Nu’Man, A.H.; Yusoff, N.N.; Shaf, A. Biogas Fed-fuel Cell Based Electricity Generation: A Life Cycle Assessment Approach. Acad. J. Econ. Stud. 2020, 10, 498–502. [Google Scholar] [CrossRef]

- Mori, M.; Stropnik, R.; Sekavčnik, M.; Lotrič, A. Criticality and life-cycle assessment of materials used in fuel-cell and hydrogen technologies. Sustainability 2021, 13, 3565. [Google Scholar] [CrossRef]

- Kawajiri, K.; Inoue, T. Cradle-to-gate greenhouse gas impact of nanoscale thin-film solid oxide fuel cells considering scale effect. J. Clean. Prod. 2016, 112, 4065–4070. [Google Scholar] [CrossRef]

- Baratto, F.; Diwekar, U.M. Life cycle assessment of fuel cell-based APUs. J. Power Sources 2005, 139, 188–196. [Google Scholar] [CrossRef]

- Osman, A.; Ries, R. Life cycle assessment of electrical and thermal energy systems for commercial buildings. Int. J. Life Cycle Assess. 2007, 12, 308–316. [Google Scholar] [CrossRef]

- Meyer, L.; Castillo, R.; Buchgeister, J.; Tsatsaronis, G. Application of exergoeconomic and exergoenvironmental analysis to an SOFC system with an allothermal biomass gasifier. Int. J. Thermodyn. 2009, 12, 177–186. [Google Scholar]

- Strazza, C.; del Borghi, A.; Costamagna, P.; Traverso, A.; Santin, M. Comparative LCA of methanol-fuelled SOFCs as auxiliary power systems on-board ships. Appl. Energy 2010, 87, 1670–1678. [Google Scholar] [CrossRef]

- Nease, J.; Adams, T.A. Comparative life cycle analyses of bulk-scale coal-fueled solid oxide fuel cell power plants. Appl. Energy 2015, 150, 161–175. [Google Scholar] [CrossRef]

- Nease, J.; Adams, T.A. Life cycle analyses of bulk—Scale solid oxide fuel cell power plants and comparisons to the natural gas combined cycle. Can. J. Chem. Eng. 2015, 93, 1349–1363. [Google Scholar] [CrossRef]

- Rogers, J.G.; Cooper, S.J.G.; O’Grady, T.; McManus, M.C.; Howard, H.R.; Hammond, G. The 20% house—An integrated assessment of options for reducing net carbon emissions from existing UK houses. Appl. Energy 2015, 138, 108–120. [Google Scholar] [CrossRef]

- Benveniste, G.; Pucciarelli, M.; Torrell, M.; Kendall, M.; Tarancón, A. Life Cycle Assessment of microtubular solid oxide fuel cell based auxiliary power unit systems for recreational vehicles. J. Clean. Prod. 2017, 165, 312–322. [Google Scholar] [CrossRef]

- Evangelisti, S.; Clift, R.; Tagliaferri, C.; Lettieri, P. A life cycle assessment of distributed energy production from organic waste: Two case studies in Europe. Waste Manag. 2017, 64, 371–385. [Google Scholar] [CrossRef] [PubMed]

- Mehmeti, A.; Pérez-Trujillo, J.P.; Elizalde-Blancas, F.; Angelis-Dimakis, A.; McPhail, S.J. Exergetic, environmental and economic sustainability assessment of stationary Molten Carbonate Fuel Cells. Energy Convers. Manag. 2018, 168, 276–287. [Google Scholar] [CrossRef]

- Cortés, A.; Feijoo, G.; Chica, A.; da Costa-Serra, J.F.; Moreira, M.T. Environmental implications of biohydrogen based energy production from steam reforming of alcoholic waste. Ind. Crop. Prod. 2019, 138, 111465. [Google Scholar] [CrossRef]

- Longo, S.; Cellura, M.; Guarino, F.; Brunaccini, G.; Ferraro, M. Life cycle energy and environmental impacts of a solid oxide fuel cell micro-CHP system for residential application. Sci. Total Environ. 2019, 685. [Google Scholar] [CrossRef]

- Di Florio, G.; Macchi, E.G.; Mongibello, L.; Baratto, M.C.; Basosi, R.; Busi, E.; Caliano, M.; Cigolotti, V.; Testi, M.; Trini, M. Comparative life cycle assessment of two different SOFC-based cogeneration systems with thermal energy storage integrated into a single-family house nanogrid. Appl. Energy 2021, 285, 116378. [Google Scholar] [CrossRef]

- Gerloff, N. Comparative Life-Cycle-Assessment analysis of three major water electrolysis technologies while applying various energy scenarios for a greener hydrogen production. J. Energy Storage 2021, 43, 102759. [Google Scholar] [CrossRef]

- Mehmeti, A.; McPhail, S.J.; Ulgiati, S. Life cycle inventory data and metrics for high-temperature fuel cells: A streamlined decision-support tool and case study application. Energy 2018, 159, 1195–1205. [Google Scholar] [CrossRef]

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; de Haes, H.A.U. Life cycle impact assessment workshop summary. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000, 5, 319–326. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A New Life Cycle Impact Assessment Methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.D.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016—A harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Report I: Characterization. 2016. Available online: https://www.rivm.nl/bibliotheek/rapporten/2016-0104.html (accessed on 25 August 2022).

- Yan, J.; Broesicke, O.A.; Tong, X.; Wang, D.; Li, D.; Crittenden, J.C. Multidisciplinary design optimization of distributed energy generation systems: The trade-offs between life cycle environmental and economic impacts. Appl. Energy 2021, 284, 116197. [Google Scholar] [CrossRef]

- Caramanico, N.; di Florio, G.; Baratto, M.C.; Cigolotti, V.; Basosi, R.; Busi, E. Economic analysis of hydrogen household energy systems including incentives on energy communities and externalities: A case study in Italy. Energies 2021, 14, 5847. [Google Scholar] [CrossRef]

- Whiston, M.M.; Collinge, W.O.; Bilec, M.M.; Schaefer, L.A. Exergy and economic comparison between kW-scale hybrid and stand-alone solid oxide fuel cell systems. J. Power Sources 2017, 353, 152–166. [Google Scholar] [CrossRef]

- Ding, X.; Sun, W.; Harrison, G.; Lv, X.; Weng, Y. Multi-objective optimization for an integrated renewable, power-to-gas and solid oxide fuel cell/gas turbine hybrid system in microgrid. Energy 2020, 213, 118804. [Google Scholar] [CrossRef]

- Fong, K.F.; Lee, C.K. System analysis and appraisal of SOFC-primed micro cogeneration for residential application in subtropical region. Energy Build. 2016, 128, 819–826. [Google Scholar] [CrossRef]

- Golkhatmi, S.Z.; Asghar, M.I.; Lund, D. A review on solid oxide fuel cell durability: Latest progress, mechanisms, and study tools. Renew. Sustain. Energy Rev. 2022, 161, 112339. [Google Scholar] [CrossRef]

- Chen, J.M.; Ni, M. Economic Analysis of a Solid Oxide Fuel Cell Cogeneration / Trigeneration System for Hotels in Hong Kong. Energy Build. 2014, 75, 160–169. [Google Scholar] [CrossRef]

- Owebor, K.; Oko, C.O.C.; Diemuodeke, E.O.; Ogorure, O.J. Thermo-environmental and economic analysis of an integrated municipal waste-to-energy solid oxide fuel cell, gas-, steam-, organic fluid- and absorption refrigeration cycle thermal power plants. Appl. Energy 2019, 239, 1385–1401. [Google Scholar] [CrossRef]

- Ogorure, O.J.; Oko, C.O.C.; Diemuodeke, E.O.; Owebor, K. Energy, exergy, environmental and economic analysis of an agricultural waste-to-energy integrated multigeneration thermal power plant. Energy Convers. Manag. 2018, 171, 222–240. [Google Scholar] [CrossRef]

- Wang, Q.; Wei, H.H.; Xu, Q. A solid oxide fuel cell (SOFC)-based biogas-from-waste generation system for residential buildings in China: A feasibility study. Sustain. 2018, 10, 2395. [Google Scholar] [CrossRef]

- Torkashvand, M.; Khodadadi, A.; Sanjareh, M.B.; Nazary, M.H. A Life Cycle-Cost Analysis of Li-ion and Lead-Acid BESSs and Their Actively Hybridized ESSs with Supercapacitors for Islanded Microgrid Applications. IEEE Access 2020, 8, 153215–153225. [Google Scholar] [CrossRef]

- da Silva, G.D.; Diogo, G. Social Impact Assessment Practice for Hydroelectricity in Canada: A Review of Methods and Monitoring; 2021. Available online: http://hdl.handle.net/10222/80597 (accessed on 25 August 2022).

- Martinez, N.; Komendantova, N. The effectiveness of the social impact assessment (SIA) in energy transition management: Stakeholders’ insights from renewable energy projects in Mexico. Energy Policy 2020, 145, 111744. [Google Scholar] [CrossRef]

- Sureau, S.; Mazijn, B.; Garrido, S.R.; Achten, W.M.J. Social life-cycle assessment frameworks: A review of criteria and indicators proposed to assess social and socioeconomic impacts. Int. J. Life Cycle Assess. 2018, 23, 904–920. [Google Scholar] [CrossRef]

- Feeney, R.G. Evaluating the use of social impact assessment in Northeast US federal fisheries management. Impact Assess. Proj. Apprais. 2013, 31, 271–279. [Google Scholar] [CrossRef][Green Version]

- UNEP-SETAC. Guidelines for Social Life Cycle Assessment of Products; United Nations Environment Programme: Nairobi, Kenya, 2019; Volume 15. [Google Scholar]

- Hanna, K.; McGuigan, E.; Noble, B.; Parkins, J. An analysis of the state of impact assessment research for low carbon power production: Building a better understanding of information and knowledge gaps. Energy Res. Soc. Sci. 2019, 50, 116–128. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).