The Impact of Digital Transformation on Supply Chain Procurement for Creating Competitive Advantage: An Empirical Study

Abstract

:1. Introduction

2. Literature Review

2.1. Digital Transformation (DT)

2.2. Supply Chain Procurement (SCP)

2.3. Competitive Advantage (CAD)

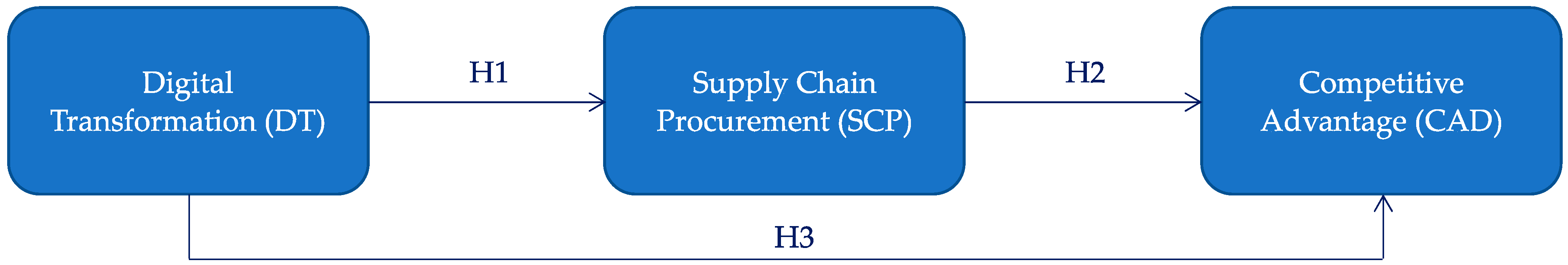

3. Conceptual Model

Theoretical Foundation

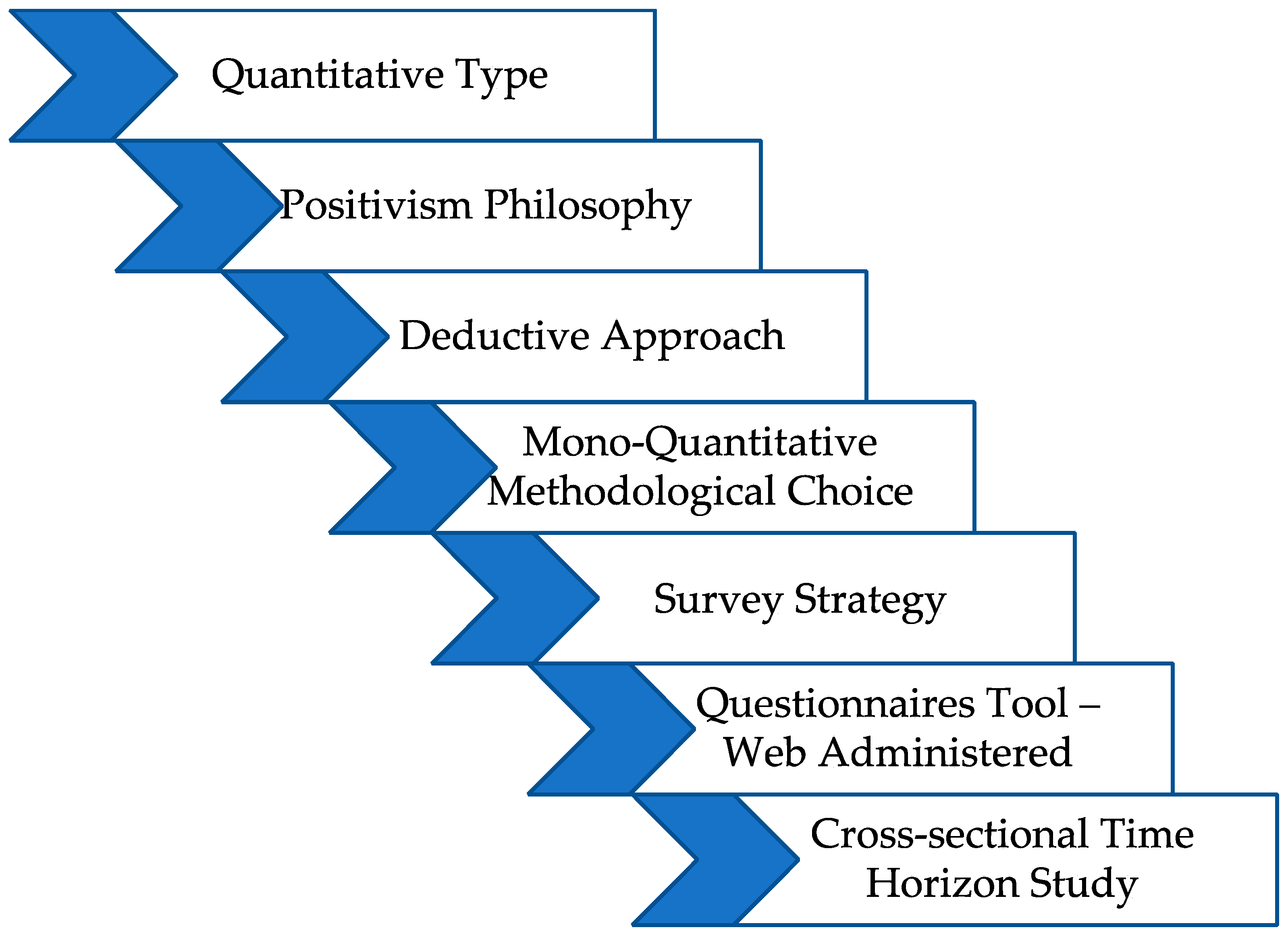

4. Research Methodology

4.1. Sampling

4.2. Instrument Development

4.3. Pretesting and Pilot Study

4.4. Final Survey Procedures

5. Results

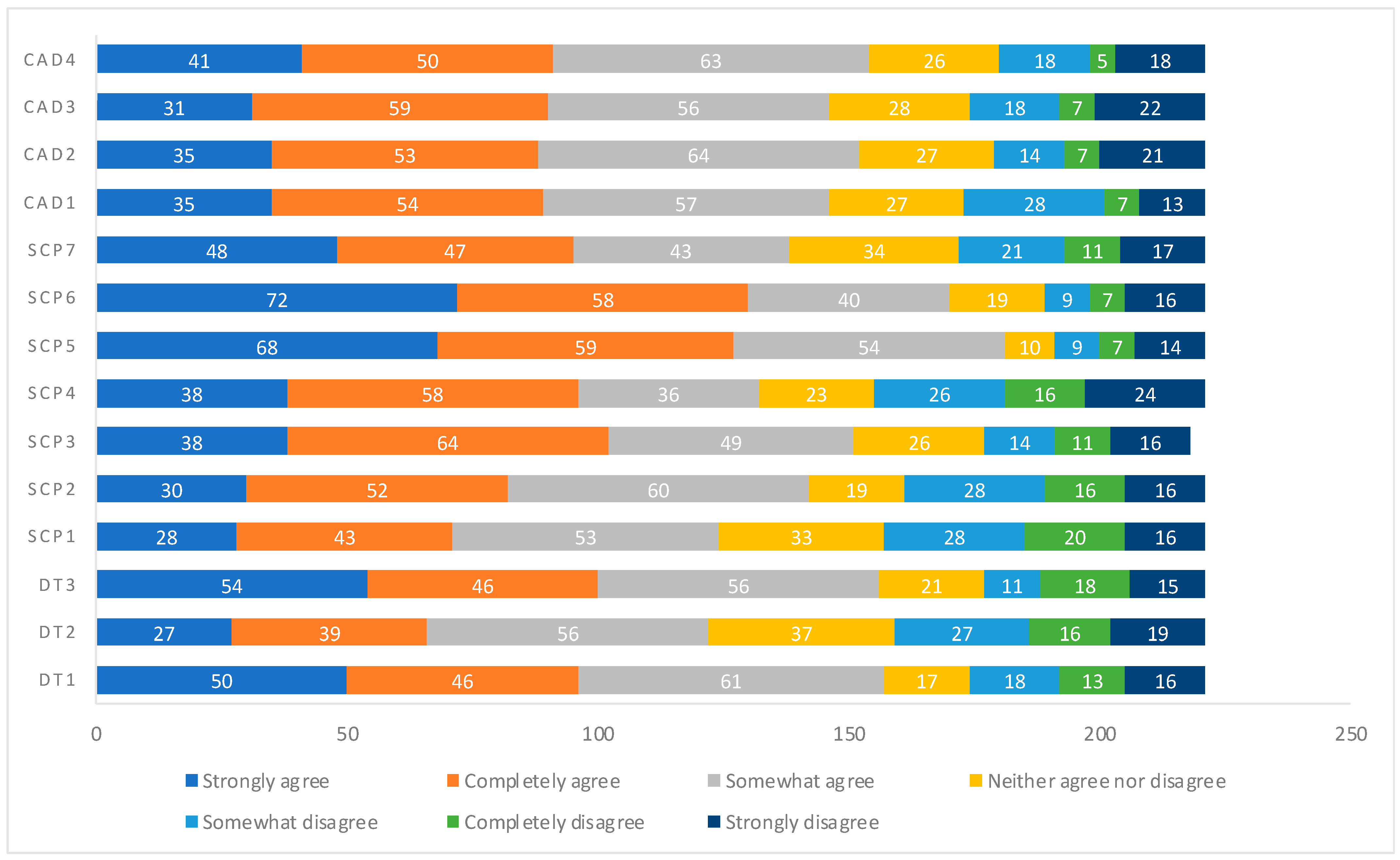

5.1. Descriptive Analysis

5.2. Common Method Bias/Variance (CMB/CMV)

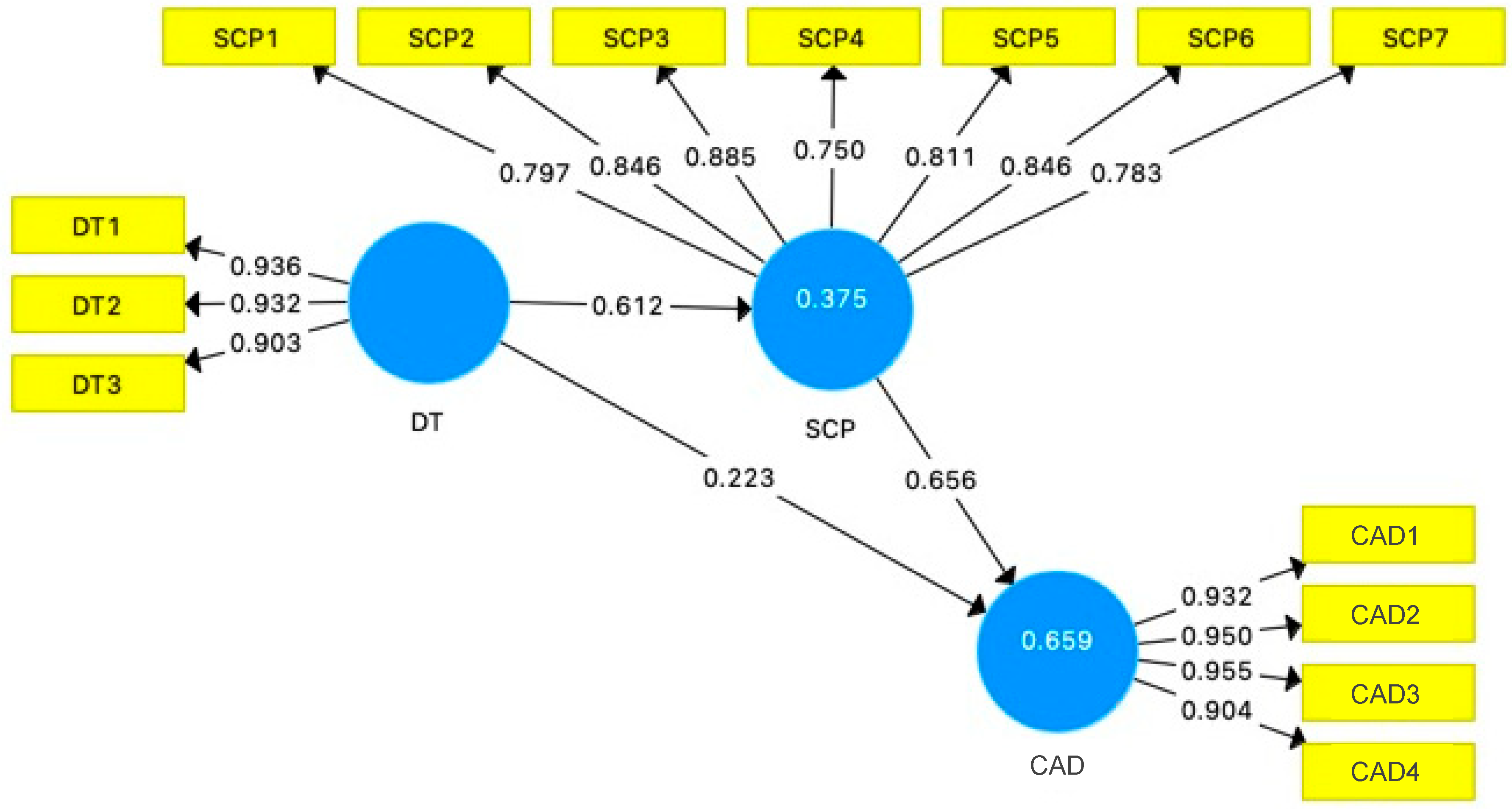

5.3. Measurement Model

5.3.1. Convergent Validity

5.3.2. Discriminant Validity

5.3.3. Structural Model

5.4. The Indirect Effect and SCP Mediation Analysis

6. Discussion

6.1. Theoretical and Practical Implications/Contributions (Implications for Theory and Practice)

6.2. Limitations and Future Research Recommendations

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Item | Source |

|---|---|

| Digital Transformation (DT) DT1: Our firm is driving new business processes built on technologies such as big data, analytics, cloud, mobile, and social media platform. DT2: Our firm is integrating digital technologies such as social media, big data, analytics, cloud, and mobile technologies to drive change. DT3: Our business operations are shifting toward making use of digital technologies such as big data, analytics, cloud, mobile, and social media platform. | Aral and Weill [62] |

| Supply Chain Procurement (SCP) SCP1. Our company selects the most appropriate supplier through the information system. SCP2. Our company gathers the demand proposals about procurement information or related information through the information system. SCP3. Our company releases the company requirements or rules via the information system. SCP4. Our company notifies the supplier on the arrival of an authorized procurement contract via the information system. SCP5. Our company documents past purchasing information in an electronic form. SCP6. Our company sets up a database about procurement and utilizes it in the purchasing process. SCP7 Our company evaluates the performance of suppliers from past purchasing information in the information system. | Croom [54]; Croom and Johnson [55] |

| Competitive Advantage (CAD) Our supply chain has … CAD1 competitive advantage in the efficient procurement operations. CAD2 competitive advantage in the effective procurement operations. CAD3 competitive advantage in differentiating our procurement operations. CAD4 competitive advantage in the reputation of our excellent procurement operations. | Kwak et al. [21] |

References

- Bouncken, R.B.; Kraus, S.; Roig-Tierno, N. Knowledge-and innovation-based business models for future growth: Digitalized business models and portfolio considerations. Rev. Manag. Sci. 2021, 15, 1–14. [Google Scholar] [CrossRef]

- Kraus, S.; Jones, P.; Kailer, N.; Weinmann, A.; Chaparro-Banegas, N.; Roig-Tierno, N. Digital transformation: An overview of the current state of the art of research. SAGE Open 2021, 11, 1–15. [Google Scholar] [CrossRef]

- Tabrizi, B.; Lam, E.; Girard, K.; Irvin, V. Digital transformation is not about technology. Harv. Bus. Rev. 2019, 13, 1–6. [Google Scholar]

- Loonam, J.; Eaves, S.; Kumar, V.; Parry, G. Towards digital transformation: Lessons learned from traditional organizations. Strat. Chang. 2018, 27, 101–109. [Google Scholar] [CrossRef]

- Hartley, J.L.; Sawaya, W.J. Tortoise, not the hare: Digital transformation of supply chain business processes. Bus. Horiz. 2019, 62, 707–715. [Google Scholar] [CrossRef]

- Hallikas, J.; Immonen, M.; Brax, S. Digitalizing procurement: The impact of data analytics on supply chain performance. Supply Chain. Manag. Int. J. 2021, 26, 629–646. [Google Scholar] [CrossRef]

- Viale, L.; Zouari, D. Impact of digitalization on procurement: The case of robotic process automation. Supply Chain Forum Int. J. 2020, 21, 185–195. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.T.; Neely, A.; Martinez, V. Digital transforming capability and performance: A microfoundational perspective. Int. J. Oper. Prod. Manag. 2020, 40, 1095–1128. [Google Scholar] [CrossRef]

- Scuotto, V.; Caputo, F.; Villasalero, M.; Del Giudice, M. A multiple buyer–supplier relationship in the context of SMEs’ digital supply chain management. Prod. Plan. Control 2017, 28, 1378–1388. [Google Scholar] [CrossRef]

- Sarkis, J. Supply chain sustainability: Learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2020, 21, 63–73. [Google Scholar] [CrossRef]

- Salam, M.A.; Bajaba, S. The role of supply chain resilience and absorptive capacity in the relationship between marketing–supply chain management alignment and firm performance: A moderated-mediation analysis. J. Bus. Ind. Mark. 2022. ahead-of-print. [Google Scholar]

- Li, G.; Liu, M.; Zheng, H. Subsidization or Diversification? Mitigating Supply Disruption with Manufacturer Information Sharing. Omega 2022, 112, 102670. [Google Scholar] [CrossRef]

- Li, G.; Xue, J.; Li, N.; Ivanov, D. Blockchain-Supported Business Model Design, Supply Chain Resilience, and Firm Performance. Transp. Res. Part E Logist. Transp. Rev. 2022, 163, 102773. [Google Scholar] [CrossRef]

- Barney, J.B. Purchasing, supply chain management and sustained competitive advantage: The relevance of resource-based theory. J. Supply Chain. Manag. 2012, 48, 3–6. [Google Scholar] [CrossRef]

- Kosmol, T.; Reimann, F.; Kaufmann, L. You’ll never walk alone: Why we need a supply chain practice view on digital procurement. J. Purch. Supply Manag. 2019, 25, 100553. [Google Scholar] [CrossRef]

- Malhotra, A.; Gosain, S.; Sawy, O.A.E. Absorptive capacity configurations in supply chains: Gearing for partner-enabled market knowledge creation. MIS Quart. 2005, 29, 145–187. [Google Scholar] [CrossRef]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, maturity and research agenda. Supply Chain. Manag. Int. J. 2019, 25, 262–282. [Google Scholar] [CrossRef]

- Soto-Acosta, P. COVID-19 pandemic: Shifting digital transformation to a high-speed gear. Inf. Syst. Manag. 2020, 37, 260–266. [Google Scholar] [CrossRef]

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Dong, J.Q.; Fabian, N.; Haenlein, M. Digital transformation: A multidisciplinary reflection and research agenda. J. Bus. Res. 2021, 122, 889–901. [Google Scholar] [CrossRef]

- Weerabahu, W.S.K.; Samaranayake, P.; Nakandala, D.; Hurriyet, H. Digital supply chain research trends: A systematic review and a maturity model for adoption. Benchmarking Int. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Kwak, D.W.; Seo, Y.J.; Mason, R. Investigating the relationship between supply chain innovation, risk management capabilities and competitive advantage in global supply chains. Int. J. Oper. Prod. Manag. 2018, 38, 2–21. [Google Scholar] [CrossRef]

- Gold, A.H.; Malhotra, A.; Segars, A.H. Knowledge management: An organizational capabilities perspective. J. Manag. Inf. Syst. 2001, 18, 185–214. [Google Scholar] [CrossRef]

- Bowersox, D.J.; Closs, D.J.; Drayer, R.W. The digital transformation: Technology and beyond. Supply Chain Manag. Rev. 2005, 9, 22–29. [Google Scholar]

- Hahn, G.J. Industry 4.0: A supply chain innovation perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Jahani, N.; Sepehri, A.; Vandchali, H.R.; Tirkolaee, E.B. Application of industry 4.0 in the procurement processes of supply chains: A systematic literature review. Sustainability 2021, 13, 7520. [Google Scholar] [CrossRef]

- Grant, R.M. Toward a knowledge-based theory of the firm. Strat. Manag. J. 1996, 17, 109–122. [Google Scholar] [CrossRef]

- Barney, J.B. Resource-based theories of competitive advantage: A ten-year retrospective on the resource-based view. J. Manag. 2001, 27, 643–650. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strat. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Malhotra, A.; Gosain, S.; El Sawy, O.A. Leveraging standard electronic business interfaces to enable adaptive supply chain partnerships. Inf. Syst. Res. 2007, 18, 260–279. [Google Scholar] [CrossRef]

- Ye, F.; Liu, K.; Li, L.; Lai, K.H.; Zhan, Y.; Kumar, A. Digital supply chain management in the COVID-19 crisis: An asset orchestration perspective. Int. J. Prod. Econ. 2022, 245, 108396. [Google Scholar] [CrossRef]

- Bonnet, D.; Westerman, G. The new elements of digital transformation. MIT Sloan Manag. Rev. 2021, 62, 82–89. [Google Scholar]

- Leonhardt, D.; Haffke, I.; Kranz, J.; Benlian, A. Reinventing the IT function: The Role of IT Agility and IT Ambidexterity in Supporting Digital Business Transformation. ECIS 2017, 63, 968–984. [Google Scholar]

- Seyedghorban, Z.; Samson, D.; Tahernejad, H. Digitalization opportunities for the procurement function: Pathways to maturity. Int. J. Oper. Prod. Manag. 2020, 40, 1685–1693. [Google Scholar] [CrossRef]

- Koh, L.; Orzes, G.; Jia, F. The fourth industrial revolution (Industry 4.0): Technologies’ disruption on operations and supply chain management. Int. J. Oper. Prod. Manag. 2019, 39, 817–828. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Giglio, R.; Van Dun, D.H. Industry 4.0 adoption as a moderator of the impact of lean production practices on operational performance improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Schrauf, S.; Berttram, P. Industry 4.0: How digitization makes the supply chain more efficient, agile, and customer-focused. Strat. Tech. 2016, 1–32. Available online: https://www.strategyand.pwc.com/gx/en/insights/2016/industry-4-digitization/industry40.pdf (accessed on 19 June 2022).

- Rubbio, I.; Bruccoleri, M.; Pietrosi, A.; Ragonese, B. Digital health technology enhances resilient behaviour: Evidence from the ward. Int. J. Oper. Prod. Manag. 2019, 40, 34–67. [Google Scholar] [CrossRef]

- Hastig, G.M.; Sodhi, M.S. Blockchain for supply chain traceability: Business requirements and critical success factors. Prod. Oper. Manag. 2020, 29, 935–954. [Google Scholar] [CrossRef]

- Martinez, V.; Zhao, M.; Blujdea, C.; Han, X.; Neely, A.; Albores, P. Blockchain-driven customer order management. Int. J. Oper. Prod. Manag. 2019, 39, 993–1022. [Google Scholar] [CrossRef]

- Kumar, N.; Ganguly, K.K. External diffusion of B2B e-procurement and firm financial performance: Role of information transparency and supply chain coordination. J. Enterp. Inf. Manag. 2020, 34, 1037–1060. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Ali, A.; Jehangir, M.; Hassan, N.; Bae, J. A Model for Understanding the Mediating Association of Transparency between Emerging Technologies and Humanitarian Logistics Sustainability. Sustainability 2022, 14, 6917. [Google Scholar] [CrossRef]

- Khan, M.; Khan, M.; Ali, A.; Khan, M.I.; Ullah, I.; Iqbal, M. Digitalization for Fast, Fair, and Safe Humanitarian Logistics. Logistics 2022, 6, 31. [Google Scholar] [CrossRef]

- Bienhaus, F.; Haddud, A. Procurement 4.0: Factors influencing the digitisation of procurement and supply chains. Bus. Process Manag. J. 2018, 24, 965–984. [Google Scholar] [CrossRef]

- Chen, S.S.; Chuang, Y.W.; Chen, P.Y. Behavioral intention formation in knowledge sharing: Examining the roles of KMS quality, KMS self-efficacy, and organizational climate. Knowl. Based Syst. 2012, 31, 106–118. [Google Scholar] [CrossRef]

- Preindl, R.; Nikolopoulos, K.; Litsiou, K. Transformation strategies for the supply chain: The impact of industry 4.0 and digital transformation. Supply Chain Forum Int. J. 2020, 21, 26–34. [Google Scholar] [CrossRef]

- Ghadge, A.; Kidd, E.; Bhattacharjee, A.; Tiwari, M.K. Sustainable procurement performance of large enterprises across supply chain tiers and geographic regions. Int. J. Prod. Res. 2019, 57, 764–778. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Mangla, S.K.; Luthra, S. Procurement 4.0 and its implications on business process performance in a circular economy. Resourc. Cons. Recyc. 2020, 152, 104502. [Google Scholar] [CrossRef]

- Accenture.com. The Future of Procurement|Accenture. Available online: https://www.accenture.com/us-en/insights/operations/future-procurement (accessed on 13 April 2022).

- Mehrabian, A.; Russell, J.A. An Approach to Environmental Psychology; MIT Press: Cambridge, MA, USA, 1974. [Google Scholar]

- Eroglu, S.A.; Machleit, K.A.; Davis, L.M. Atmospheric qualities of online retailing: A conceptual model and implications. J. Bus. Res. 2001, 54, 177–184. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Hall, R. A framework linking intangible resources and capabilities to sustainable competitive advantage. Strat. Manag. J. 1993, 14, 607–618. [Google Scholar] [CrossRef]

- Yang, C.C.; Marlow, P.B.; Lu, C.S. Assessing resources, logistics service capabilities, innovation capabilities and the performance of container shipping services in Taiwan. Int. J. Prod. Econ. 2009, 122, 4–20. [Google Scholar] [CrossRef]

- Croom, S. The impact of web-based procurement on the management of operating resources supply. J. Supply Chain Manag. 2000, 36, 4–13. [Google Scholar] [CrossRef]

- Croom, S.; Johnson, R. E-service: Enhancing internal customer service through e-procurement. Int. J. Serv. Ind. Manag. 2003, 14, 539–555. [Google Scholar] [CrossRef]

- David, R.J.; Han, S.-K. A systematic assessment of the empirical support for transaction cost economics. Strat. Manag. J. 2004, 25, 39–58. [Google Scholar] [CrossRef]

- Creswell, J.W. Research Design: Qualitative, Quantitative, and Mixed Methods Approach, 3rd ed.; Sage Publications, Inc.: London, UK, 2009. [Google Scholar]

- Saunders, M.L.; Lewis, P.P.; Thornhill, A. Research Methods for Business Students; Pearson: London, UK, 2019. [Google Scholar]

- Remenyi, D.; Williams, B.; Money, A.; Swartz, E. Doing Research in Business and Management: An Introduction to Process and Method; Sage Publications Ltd.: London, UK, 1998. [Google Scholar]

- Taherdoost, H. Sampling methods in research methodology: How to choose a sampling technique for research. Soc. Sci. Res. Net. 2016. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Aral, S.; Weill, P. IT assets, organizational capabilities, and firm performance: How resource allocations and organizational differences explain performance variation. Org. Sci. 2007, 18, 763–780. [Google Scholar] [CrossRef]

- Li, L.; Su, F.; Zhang, W.; Mao, J.Y. Digital transformation by SME entrepreneurs: A capability perspective. Inf. Syst. J. 2018, 28, 1129–1157. [Google Scholar] [CrossRef]

- Anim-Yeboah, S.; Boateng, R.; Odoom, R.; Kolog, E.A. Digital transformation process and the capability and capacity implications for small and medium enterprises. Int. J. E Entrep. Innovat. 2020, 10, 26–44. [Google Scholar] [CrossRef]

- Chang, H.H.; Tsai, Y.C.; Hsu, C.H. E-procurement and supply chain performance. Supply Chain Manag. Int. J. 2013, 18, 34–51. [Google Scholar] [CrossRef]

- Afraz, M.F.; Bhatti, S.H.; Ferraris, A.; Couturier, J. The impact of supply chain innovation on competitive advantage in the construction industry: Evidence from a moderated multi-mediation model. Tech. Forecast. Soc. Chang. 2021, 162, 120370. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Roubaud, D.; Foropon, C. Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int. J. Prod. Res. 2021, 59, 110–128. [Google Scholar] [CrossRef]

- Brislin, R.W. Back-translation for cross-cultural research. J. Cross Cult. Psych. 1970, 1, 185–216. [Google Scholar] [CrossRef]

- Dawes, J. Do data characteristics change according to the number of scale points used? An experiment using 5-point, 7-point and 10-point scales. Int. J. Market Res. 2008, 50, 61–104. [Google Scholar] [CrossRef]

- Vagias, W.M. Clemson International Institute for Tourism Research Development, Department of Parks, Recreation and Tourism Management; Clemson University: Clemson, SC, USA, 2006. [Google Scholar]

- Joshi, A.; Kale, S.; Chandel, S.; Pal, D.K. Likert scale: Explored and explained. Br. J. Appl. Sci. Technol. 2015, 7, 396–403. [Google Scholar] [CrossRef]

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill-Building Approach; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Yew, W.C.; Kong, S.M.; Awang, A.H.; Yi, G.R. Developing a Conceptual Model for the Causal Effects of Outdoor Play in Preschools Using PLS-SEM. Sustainability 2022, 14, 3365. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: London, UK, 2021. [Google Scholar]

- Logistics Bureau. Women in Supply Chain: Why So Few? Available online: https://www.logisticsbureau.com/women-in-supply-chain-why-so-few (accessed on 20 April 2022).

- Gartner. Gartner Survey Finds Women Comprise 41% of the Supply Chain Workforce. Available online: https://www.gartner.com/en/newsroom/press-releases/2021-06-16-gartner-survey-finds-women-comprise-41-percent-of-the-supply-chain-workforce (accessed on 30 April 2022).

- Sarstedt, M.; Radomir, L.; Moisescu, O.I.; Ringle, C.M. Latent class analysis in PLS-SEM: A review and recommendations for future applications. J. Bus. Res. 2022, 138, 398–407. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psych. 2003, 88, 879. [Google Scholar] [CrossRef]

- Chin, W.W.; Thatcher, J.B.; Wright, R.T.; Steel, D. Controlling for common method variance in PLS analysis: The measured latent marker variable approach. In New Perspectives in Partial Least Squares and Related Methods; Springer: New York, NY, USA, 2013; pp. 231–239. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson: London, UK, 2017. [Google Scholar]

- Nunnally, J.C. An overview of psychological measurement. In Clinical Diagnosis of Mental Disorders; Springer: Berlin/Heidelberg, Germany, 1978; pp. 97–146. [Google Scholar]

- Franke, G.; Sarstedt, M. Heuristics versus statistics in discriminant validity testing: A comparison of four procedures. Internet Research. 2019, 29, 430–447. [Google Scholar] [CrossRef]

- Narzary, S. Anthony Larsson and Robin Teigland (Eds.), The Digital Transformation of Labor: Automation, The Gig Economy, and Welfare. NHRD Netw. J. 2022, 15, 124–126. [Google Scholar] [CrossRef]

- Stone, M. Cross-validatory choice and assessment of statistical predictions. J. R. Stat. Soc. Ser. B Methodol. 1974, 36, 111–133. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modelling; Guilford Press: New York, NY, USA, 2005. [Google Scholar]

- Cohen, L.J. The Probable and the Provable (Vol. 384); Clarendon Library of Logic and Philosophy, Oxford University Press: Northants, UK, 1977; (accessed on 8 April 2022). [Google Scholar] [CrossRef]

| Participants’ Details (n = 221) | Frequency | Percentage |

|---|---|---|

| Region | ||

| Saudi Arabia | 214 | 97% |

| Other | 7 | 3% |

| Gender | ||

| Male | 191 | 86% |

| Female | 30 | 14% |

| Age (years) | ||

| <22 | 1 | 0.5% |

| 23–28 | 2 | 0.9% |

| 29–35 | 32 | 14.5% |

| 36–45 | 74 | 33.5% |

| 46–55 | 80 | 36.2% |

| 56–60 | 28 | 12.7% |

| 61+ | 4 | 1.8% |

| Year of Experience (years) | ||

| ≤1 | 5 | 2% |

| 2–5 | 43 | 19% |

| 6–10 | 53 | 24% |

| 11–15 | 47 | 21% |

| 16–20 | 36 | 16% |

| 21–25 | 25 | 11% |

| 26+ | 12 | 5% |

| Education Level | ||

| High school or less | 2 | 1% |

| Diploma | 7 | 3% |

| Bachelor | 142 | 64% |

| Higher education | 70 | 32% |

| Occupational Level | ||

| Entry | 12 | 5% |

| Specialist/supervisor | 66 | 30% |

| Manager/senior | 77 | 35% |

| Director | 52 | 24% |

| Leadership | 14 | 6% |

| Supply Chain Speciality | ||

| Planning | 33 | 15% |

| Procurement | 56 | 25% |

| Warehousing | 11 | 5% |

| Log and Trans | 40 | 18% |

| General supply chain | 81 | 37% |

| Items | Mean | SD | Kurtosis | Skewness |

|---|---|---|---|---|

| DT1 | 4.955 | 1.789 | −0.281 | −0.790 |

| DT2 | 4.448 | 1.745 | −0.664 | −0.425 |

| DT3 | 4.986 | 1.816 | −0.341 | −0.796 |

| SCP1 | 4.484 | 1.75 | −0.769 | −0.404 |

| SCP2 | 4.661 | 1.751 | −0.600 | −0.601 |

| SCP3 | 4.95 | 1.73 | −0.055 | −0.885 |

| SCP4 | 4.615 | 1.941 | −0.929 | −0.539 |

| SCP5 | 5.407 | 1.685 | 0.987 | −1.282 |

| SCP6 | 5.362 | 1.768 | 0.538 | −1.179 |

| SCP7 | 4.846 | 1.808 | −0.523 | −0.633 |

| CAD1 | 4.855 | 1.647 | −0.199 | −0.691 |

| CAD2 | 4.833 | 1.74 | 0.003 | −0.867 |

| CAD3 | 4.765 | 1.762 | −0.193 | −0.813 |

| CAD4 | 4.923 | 1.707 | 0.082 | −0.853 |

| R2 Without Marker Variable | R2 With Marker Variable | |

|---|---|---|

| SCP | 0.736 | 0.736 |

| CAD | 0.445 | 0.448 |

| Construct | Item | Loading | CA | rho_A | CR | AVE |

|---|---|---|---|---|---|---|

| DT | DT1 | 0.938 | 0.914 | 0.918 | 0.946 | 0.853 |

| DT2 | 0.932 | |||||

| DT3 | 0.900 | |||||

| SCP | SCP1 | 0.797 | 0.917 | 0.919 | 0.934 | 0.669 |

| SCP2 | 0.846 | |||||

| SCP3 | 0.885 | |||||

| SCP4 | 0.750 | |||||

| SCP5 | 0.811 | |||||

| SCP6 | 0.846 | |||||

| SCP7 | 0.783 | |||||

| CAD | CAD1 | 0.932 | 0.952 | 0.953 | 0.966 | 0.875 |

| CAD2 | 0.951 | |||||

| CAD3 | 0.955 | |||||

| CAD4 | 0.904 |

| CAD | DT | SCP | |

|---|---|---|---|

| CAD | 0.936 | 0.669 h | 0.847 h |

| DT | 0.624 | 0.924 | 0.666 h |

| SCP | 0.792 | 0.613 | 0.818 |

| CAD | DT | SCP | |

|---|---|---|---|

| CAD1 | 0.932 | 0.570 | 0.755 |

| CAD2 | 0.950 | 0.563 | 0.744 |

| CAD3 | 0.955 | 0.628 | 0.756 |

| CAD4 | 0.904 | 0.574 | 0.709 |

| DT1 | 0.578 | 0.936 | 0.604 |

| DT2 | 0.575 | 0.932 | 0.558 |

| DT3 | 0.577 | 0.903 | 0.532 |

| SCP1 | 0.570 | 0.505 | 0.797 |

| SCP2 | 0.680 | 0.543 | 0.846 |

| SCP3 | 0.645 | 0.532 | 0.885 |

| SCP4 | 0.628 | 0.399 | 0.750 |

| SCP5 | 0.625 | 0.488 | 0.811 |

| SCP6 | 0.703 | 0.496 | 0.846 |

| SCP7 | 0.674 | 0.529 | 0.783 |

| CAD | SCP | |

|---|---|---|

| DT | 1.599 | 1.000 |

| SCP | 1.599 |

| Relationship | Std Beta | Std Error | |t-value|^ | f2 | p-Value | CI 2.5% | CI 97.5% | Decision |

|---|---|---|---|---|---|---|---|---|

| DT → SCP | 0.615 | 0.057 | 10.759 | 0.803 | 0.000 *** | 0.097 | 0.342 | Supported |

| SCP → CAD | 0.793 | 0.03 | 26.615 | 0.788 | 0.000 *** | 0.49 | 0.706 | Supported |

| DT → CAD | 0.489 | 0.057 | 8.476 | 0.091 | 0.000 *** | 0.562 | 0.752 | Supported |

| Indirect relationship | ||||||||

| DT → SCP → CAD | 0.487 | 0.070 | 6.894 | 0.000 *** | 0.367 | 0.639 | Supported | |

| Saturated Model | 95% | 99% | Estimated Model | 95% | 99% | |

|---|---|---|---|---|---|---|

| SRMR | 0.037 | 0.044 | 0.048 | 0.037 | 0.044 | 0.048 |

| dULS | 0.147 | 0.206 | 0.240 | 0.147 | 0.206 | 0.240 |

| dG | 0.162 | 0.215 | 0.245 | 0.162 | 0.215 | 0.246 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alabdali, M.A.; Salam, M.A. The Impact of Digital Transformation on Supply Chain Procurement for Creating Competitive Advantage: An Empirical Study. Sustainability 2022, 14, 12269. https://doi.org/10.3390/su141912269

Alabdali MA, Salam MA. The Impact of Digital Transformation on Supply Chain Procurement for Creating Competitive Advantage: An Empirical Study. Sustainability. 2022; 14(19):12269. https://doi.org/10.3390/su141912269

Chicago/Turabian StyleAlabdali, Mahmoud Abdulhadi, and Mohammad Asif Salam. 2022. "The Impact of Digital Transformation on Supply Chain Procurement for Creating Competitive Advantage: An Empirical Study" Sustainability 14, no. 19: 12269. https://doi.org/10.3390/su141912269

APA StyleAlabdali, M. A., & Salam, M. A. (2022). The Impact of Digital Transformation on Supply Chain Procurement for Creating Competitive Advantage: An Empirical Study. Sustainability, 14(19), 12269. https://doi.org/10.3390/su141912269