Abstract

Performance evaluation in logistics is crucial in identifying improvement opportunities. This study assessed performance indicators (PIs) for import–export logistics chains, including transport, dry ports, transhipment and warehouses, focusing on Ethiopia. PIs were identified by means of a literature review. An expert survey based on the analytical hierarchy process (AHP) was used to obtain weightings for the indicators to allow an evaluation of the overall performance of the country’s import–export chains. Key challenges faced in the sector were also identified. Indicators such as turnaround time and damage frequency were given high weightings by experts for dry port PIs, security was given the highest weighting for transport PIs, and order lead time was given the highest weighting for warehouse PIs. Technological advancements, human resource capacity building and government policies were found to be the main areas that could improve the performance of logistics operations and address the challenges faced by the sector. These findings could provide a new and comprehensive picture of the key performance indicators of Ethiopian import–export logistics chains.

1. Introduction

Logistics connects suppliers and customers internationally, making it critical for global trade [1]. It is, therefore, a crucial component in economic development that enables the delivery of the right product, at the right place, at the right time, in the right condition, at the right cost and in the right quantity to the right customer. A high standard of logistics performance increases profitability, advances the national economy and improves competitiveness [2], while also easing business transactions, making countries attractive places in which to conduct international trade. Thus, organisations can improve their logistics performance by identifying bottlenecks in their operations, optimising processes, building better infrastructures, improving policies and training workforces.

The overall quality of a logistics chain depends on the performance of logistics components. A typical import–export corridor involves the components of port activities, transport, warehousing and customs checks [3,4]. Dry ports are also integral parts of the import–export chain, particularly in landlocked countries, and are defined as ports that are located inland where the temporary storage of cargo, inspection and customs clearance take place [5]. The purpose of dry ports is to improve accessibility between seaports and inland trade zones, while also relieving constraints at seaports [6]. Transport provides a link between seaports, dry ports and warehouses, adding both time and space utilities to the goods being transported. Inefficiencies in transportation in the import–export sector cause major losses in terms of efficiency and profitability. Inefficiencies in transportation usually take place due to incompetent drivers, aged trucks, issues related to loading and unloading, availability of trucks, traffic accidents and security threats. Warehousing is another important activity in the import–export chain. Warehouses are used to store raw, partially assembled or finished products, accumulate and consolidate products, and receive, pick and ship products to customers [1]. The way goods are handled, tracked and stored in warehouses has a huge impact on the import–export chain. Companies that have effective warehouse and inventory management make major cost savings due to lower levels of damage and loss.

The occurrence of logistics inefficiencies and bottlenecks affects the performance of the import–export chain. One method for addressing logistics bottlenecks in the import–export chain is through the application of enabling technologies. Bottlenecks due to inefficiency, lack of integration and poor responsiveness have been addressed by previous studies following the increased use of enabling technologies [7,8,9,10]. Visibility of port operations can be improved through the use of tracking technologies [11], while automation technologies are used to improve throughput and port accessibility [7,8,9]. In transport, information and communication technology (ICT) solutions have been used to make transport choices and goods movements less costly and more efficient [12]. Using virtual clustering in transport, which is a temporary virtual cooperation network, logistic companies can choose cost-effective transport services, while at the same time reducing their environmental impact by increasing the load factor [13]. Furthermore, technologies have also been implemented in warehouses to reduce loading and unloading time, costs and damage rate [14,15].

The measurement of logistics performance is a critical step in logistics management. Logistics performance has been evaluated by many researchers at both a national and international level [3,16,17]. The World Bank has also been measuring and ranking the logistics performance of nations since 2007. This ranking is based on the logistics performance index (LPI), which comprises customs, infrastructures, ease of arranging shipments, quality of logistics services, timeliness, and tracking and tracing. A report by Arvis et al. [18] revealed that, based on the World Bank’s LPI, the top logistics performers were from high-income countries, whereas low-income countries were the least effective performers.

Numerous studies have measured logistics performance, but few have assigned weightings to indicators using the multi-criteria method. One of the most common multi-criteria methods used in the literature is the analytical hierarchy process (AHP). Bolat et al. [19] used AHP to identify factors affecting port congestion, while Chiu et al. [20] used this method to analyse factors that contribute to green ports, applying the weightings they obtained to evaluate the green performance of three ports in Taiwan. The application of AHP has also been extended to measure the performance of transportation. For instance, Hanaoka and Kunadhamraks [21] evaluated the performance of intermodal transportation using a fuzzy AHP method. This method also has a wide range of applications in warehouse management. Lam et al. [22] applied it to rank the risk factors in warehouse order fulfilment and develop a logistics operation strategy. Srisawat et al. [23] used fuzzy AHP to prioritise performance indicators (PIs) related to logistics efficiency.

According to UN-OHRLLS [5], compared with coastal countries, it costs landlocked countries double the amount and takes them almost twice as long to import or export goods. Thus, the high costs and long lead times incurred by landlocked countries reduce their competitive advantage in the international market. In addition to being a landlocked country, Ethiopia is a low-income country with limited infrastructures, causing the country’s logistics performance to become poor. Its aggregated ranking in terms of the World Bank’s LPI is 131 out of 160 countries [18]. In contrast, countries such as Botswana, Rwanda and Uganda are also landlocked countries in the region but have better logistics performances, with aggregate LPI rankings of 58, 65 and 72, respectively [18]. One of the reasons for Ethiopia’s poor logistics performance is its lack of access to seaports, while another is the lack of technological advancement in logistics components [24,25,26]. Inefficiencies during customs operations, poor road infrastructures, deficient storage and material handling techniques, and inadequate freight vehicles have led to a deterioration in the country’s logistics system [25].

When looking at the import–export chain in Ethiopia, previous research has focused on different aspects of the chain. For instance, Nitsche [27] mapped current challenges faced by the Ethiopian import–export chain and recommended strategies to address them; Gebrewahid and Wald [28] evaluated the export barriers confronting the Ethiopian leather industry; and Amentae and Gebresenbet [3] assessed intermodal freight transport services in Ethiopia. However, none of the above studies identified PIs for the Ethiopian import–export chain considering different weightings for these PIs. Studies argue that criteria should be provided with weightings because not all criteria are equally important to the overall performance of the chain [29,30].

In low-income countries with a poor logistics performance similar to that of Ethiopia, major costs arise from port handling, transport and warehousing [31]. Therefore, it is important to understand the performance of these sectors and identify the bottlenecks within them. The aim of this study was, therefore, to develop PIs for dry ports, transportation and warehouse operation, and to weight their importance in terms of the overall performance of the Ethiopian import–export chain. The most important challenges faced by the sector were also assessed.

2. Materials and Methods

2.1. Overview

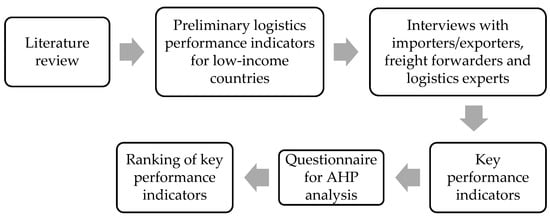

To identify the key PIs for dry ports, transportation and warehousing, first of all, a review was undertaken of earlier studies in these areas. The literature was categorised into low-income countries and high-income countries based on the study area on which they focused. The literature on the two categories was then compared to identify sets of PIs that are relevant for low-income countries. These sets were then presented to experts working in government offices influencing logistics activities in Ethiopia to check their relevance and the need for additional indicators. The offices contacted included the Ethiopian Shipping and Logistics Services Enterprise (ESLSE), the Ethiopian Maritime Authority (EMA) and the Ministry of Transport (MoT). The experts contacted from these organisations were team leaders and operation managers with a minimum experience of 7 years. The final set of indicators were then presented to customers and service providers in order for them to weight each indicator. Using the analytical hierarchy process (AHP), the weighting for each indicator was determined. The overall methodology followed in the study is depicted in Figure 1.

Figure 1.

Methodology followed in this study.

2.2. Literature Review

An extensive review of previous studies was conducted by evaluating journals and reports from around the world focusing on import–export chains, which allowed the major activities affecting their efficiency to be identified, along with criteria for measuring the performance for each of these activities. Thus, indicators were obtained for dry port operations, transportation and warehouse management.

2.3. Expert Survey

A survey was carried out in two stages in the study. The first stage was interviews with logistics experts working in government offices. The purpose of this interview was to assure the relevance and adequacy of the indicators gathered from the literature for the case of Ethiopia (Appendix A). After the completion of this step, lists of performance indicators that were to be weighted in the following stage were obtained. In the second stage of the survey, paper-based questionnaires were distributed to customers and service providers (Table 1). The questionnaire is presented in Appendix B. The purpose of this was to weight the PIs according to their importance. The experts required for the survey were divided into two categories, service providers and customers, because it was assumed that the importance of each criterion might be different for stakeholders in the respective groups.

Table 1.

Stakeholders approached in the survey.

The experts in the survey were selected using a purposive sampling technique. This is a type of non-probability sampling technique where respondents are deliberately selected for the information they can provide that cannot be obtained from other sources [32]. When using the AHP method for conducting pairwise comparisons and obtaining weights, a large sample size is not required as long as the consistency ratio (CR) is within the acceptable limits [33]. Hence, using the purposive sampling technique, interviews were conducted with 53 customers and 9 service providers. The customers interviewed included importers, exporters and freight forwarders that had significant experience in the field of logistics. The service providers interviewed included staff working in the Ethiopian Shipping and Logistics Service Enterprise (ESLSE), the Ethiopian Maritime Authority (EMA) and the Ministry of Transportation (MoT) (Table 1). The experts that were interviewed represented the views of their organisations and not their personal views.

Importers and exporters were asked to undertake pairwise comparisons for port operations, transport and warehouse management. The reason for this is that these experts are involved in all three stages of the operation (i.e., dry port operation, transportation and warehousing). In contrast, freight forwarders were only asked to conduct pairwise comparisons for port operations and transport, as these two aspects fall within the scope of their responsibilities. Staff at ESLSE, EMA and MOT were only asked to conduct pairwise comparisons for the dry port PIs, as they are responsible for providing dry port services.

The questionnaire used in the study comprised three sections. The first section asked respondents to provide general information. The second section provided lists of PIs for the respondents to provide their opinion on their importance level using the scale provided by Saaty [34], which is based on a Likert scale with values ranging from 1 to 9. According to Saaty [34], the values 1, 3, 5, 7 and 9 on the Likert scale represent equally important, slightly important, moderately important, very important and extremely important, respectively, while 2, 4, 6 and 8 are intermediate values between two adjacent scales. This section was required to conduct pairwise comparisons using the AHP method. Finally, the last section required respondents to list the challenges they faced in the sector.

2.4. Analysis

The AHP method is a type of multi-criteria decision-making (MCDM) framework that is used for making pairwise decisions when faced with several competing choices [35]. According to Brunelli [36], the main objective of AHP is to assign weights to a set of alternatives using pairwise comparisons. The method is useful for the analysis of both qualitative and quantitative attributes [37]. The method assumes that the decision makers are rational and that they can assign weights to each criteria using positive real numbers [35].

The other common MCDM methods include Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) [21], the Best Worst Method (BWM) [30] and Decision-Making Trial and Evaluation Laboratory (DEMATEL) [35]. Table 2 summarises the strengths and limitations of these MCDM methods. However, the AHP method is preferred over the other methods as it is one of the highly accepted MCDM methods [21] with a wide range of applications. Additionally, the AHP method integrates the judgments of multiple stakeholders and quantifies their judgments [33].

Table 2.

Some of the common MCDM methods along with their strengths and weaknesses.

AHP has been used for the identification of potential risk factors in warehouse management [22], the selection of appropriate locations for intermodal freight logistics centres [42], the selection of the location of a manufacturing plant [37] and the identification of the most important criteria for implementing digitalised logistics in low-income countries [43].

The main steps in the AHP method, according to Chang and Lin [37], are: (1) identification of criteria for comparison, (2) pairwise comparisons based on the scale outlined by Saaty [34], (3) calculation of the weightings for each criterion and (4) calculation of the consistency ratio (CR). The CR is obtained from the maximum eigenvalue by first calculating the consistency index (CI) using Equations (1) and (2):

where n is the number of criteria and RI is the random consistency index. The value for RI depends on the number of criteria and is obtained from Saaty [34]. The weightings obtained in step (3) are acceptable if the CR calculated in step (4) is less than 10%. If the CR is greater than 10%, the weights should be revised and the participants should be consulted to check whether they agree with the newly assigned weightings.

CI = (λ_max − n)/(n − 1)

CR = CI/RI

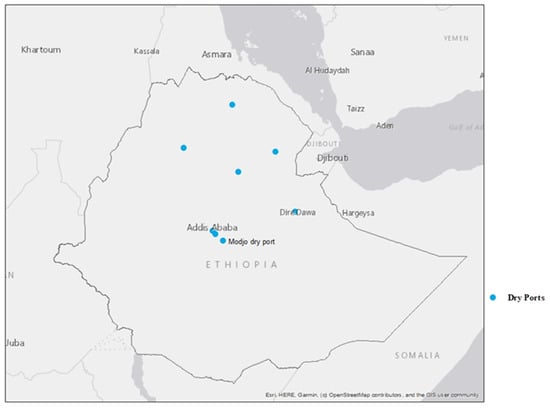

2.5. Study Area

Ethiopia’s main access to the sea is through the port of Djibouti, and over 90% of trade in Ethiopia is conducted through the Ethio-Djibouti corridor [44]. Ethiopia also has eight dry ports located in different parts of the country (Figure 2). The focus of this research was on the Modjo dry port located approximately 73 km from the capital city, Addis Ababa. The Modjo dry port is also the country’s largest dry port, with an operational capacity of 17,539 Twenty-foot Equivalent Unit (TEU) at a time, and it handles 78% of the country’s imports [45].

Figure 2.

Location of the eight dry ports in Ethiopia.

3. Results

3.1. Preliminary Sets of Logistics Performance Indicators

The identification of logistics PIs enables areas in the supply chain that need improvement to be established. Several authors have measured the performance of various aspects of it. Table 3 summarises the contributions of selected authors on logistics performance.

Table 3.

Selected literature focusing on logistics performance.

Although the aforementioned literature in Table 3 has shed light on various aspects of logistics performance, studies that develop logistics PIs and assigned weightings for the context of low-income countries are still lacking. On the other hand, several authors have taken an interest in measuring the performance of specific logistics activities. The sections below discuss the literature that focuses on logistics PIs for dry port operation, transportation and warehouse management.

3.1.1. Performance Indicators for Dry Ports

There is a considerable amount of literature on the performance of dry ports. Some studies have suggested key PIs that should be used to evaluate dry ports. Others have applied the indicators to evaluate certain ports, compare different ports and model how interventions in port operations affect port performance. Ha et al. [54] classified port PIs considering the goals and objectives of stakeholders in port operations. Accordingly, the indicators were classified into core activities, supporting activities, financial strength, user satisfaction, terminal supply chain integration and sustainability goals. The authors considered human capital, including the knowledge, skill and work ethics of human resources, as port PIs, which were not included in most of the literature. Operational, finance, quality, environmental and safety aspects were recommended as port PIs by Martin et al. [55]. Carboni and Deflorio [56] studied the effect of technologies on environmental and operational PIs, including time-related indicators, loss and damage frequency, utilisation rate and delays. Overall throughput, time aspects and financial aspects were considered in many studies. The indicators shown in Table 4 were found in most of the articles.

Table 4.

PIs for dry ports obtained from the literature.

Similar to the global indicators, the financial and time aspects of dry port PIs have attracted a great deal of attention in low-income countries (Table 4).

3.1.2. Performance Indicators for Transport

Transportation provides vast and multi-dimensional services. Several studies have measured the performance of transport. For instance, Hanaoka and Kunadhamraks [21] measured the logistics performance of intermodal transport using the fuzzy AHP method. Lai et al. [62] developed a performance measurement system for measuring the performance of transport logistics that reflected the performance of shippers, transport logistics service providers and consignees. Stoilova et al. [63] used infrastructural, economic and technological criteria to assess the performance of railway transport. Šakalys et al. [64] identified the main indicators influencing synchro-modality and used multi-criteria to obtain the weightings of each indicator. Studies conducted in the area have focused on infrastructural service quality and its impact on the environmental aspects of transport performance [65]. Table 5 summarises the categories of these indicators.

Table 5.

PIs for transport obtained from the literature.

Transport PIs in low-income countries were also identified from the literature focusing on low-income countries. The studies on low-income countries focused mainly on safety, infrastructure and vehicle condition, as shown in Table 5.

3.1.3. Performance Indicators for Warehouses

Warehousing is the other value-adding activity in supply chain management that facilitates activities involved in the availability of inventory, customisation of products and consolidation [1]. A number of researchers have measured the performance of warehouses. For instance, Chen et al. [72] conducted case studies to identify the critical functions and operations involved in warehouse management and then used their findings to develop key performance indicators (KPIs) focusing on quality, accuracy, costs, security and timeliness of warehouse operations. Karim et al. [73] developed warehouse KPIs by focusing on the productivity dimension, while Kusrini et al. [74] identified warehouse KPIs by conducting a case study in a construction materials warehouse. The global PIs obtained from the literature for warehousing are presented in Table 6.

Table 6.

PIs for warehousing obtained from the literature.

Few studies have focused on identifying and evaluating warehouse PIs for low-income countries. The PIs obtained from the literature for warehousing are presented in Table 6.

The initial evaluation of the indicators by experts developed a suitable list of indicators at a regional level that are representative of local conditions [23]. Thus, taking into consideration the global indicators in the first part of Table 4, Table 5 and Table 6 and indicators focusing on low-income countries in the second part of Table 4, Table 5 and Table 6, a preliminary list of PIs depicted in Table 7 were presented to experts from government offices.

Table 7.

Preliminary list of PIs for the three sectors.

Responses from the experts showed that the given indicators were relevant for the evaluation of performance in dry ports, transportation and warehousing for the case of Ethiopia. Feedback, for example, on combining indicators representing similar aspects, was also provided and, based on this, transhipment time and cut-off time were combined to give the turnaround time as a dry port PI. Indicators that comprised economic aspects were put into financial PIs, as shown in Figure 3. Based on the perspectives of transport users, indicators such as number of trips per month were removed from the list. Finally, the PIs depicted in Figure 3 were analysed further.

Figure 3.

Final list of PIs presented to experts for pairwise comparisons.

3.2. Assessment of Weightings for Each PI

Following the identification of suitable indicators, the experts in the two categories of service providers and customers were asked to perform a pairwise comparison, based on a Likert scale, with values ranging from 1 to 9. The weightings of the PIs shown in Figure 3 were then assessed using the AHP method.

3.2.1. Dry Port PIs

The criteria for the PIs of dry ports were divided into two categories: operational port PIs and financial port PIs. Customers were asked to perform pairwise comparisons for the operational port PIs, while service providers were requested to perform pairwise comparisons for both the operational and financial port PIs.

Operational Dry Port PIs

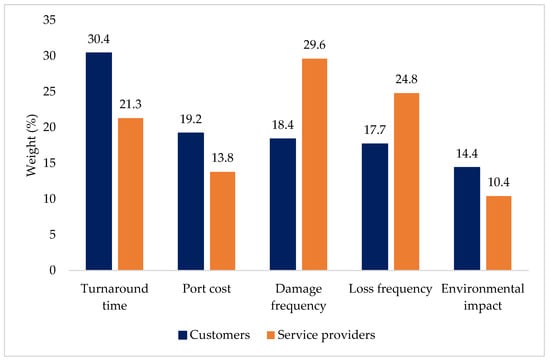

To obtain the operational dry port PIs, customers (importers/exporters and freight forwarders) and service providers were asked to conduct pairwise comparisons. The results of the pairwise comparison showed that customers gave the highest weighting to turnaround time, with a value of 30.4%. In contrast, service providers gave the highest weighting to damage frequency, with a value of 29.6%. Both customers and service providers gave the lowest weighting to environmental impact, with values of 14.4% and 10.4%, respectively (Figure 4). The CR obtained was 10% for the customers and 7% for service providers. Since the CRs were within the acceptable limits, the calculated weightings were accepted.

Figure 4.

Weightings given by experts for operational dry port performance.

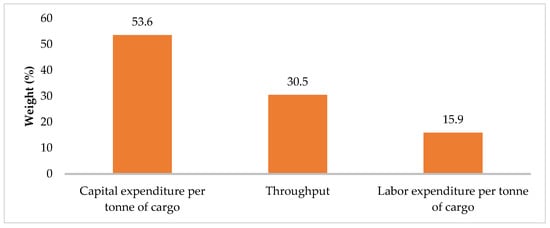

Financial Dry Port PIs

To obtain the weightings for dry port financial PIs, service providers were asked to conduct pairwise comparisons. They gave the highest weighting to capital expenditure per tonne of cargo (53.6%) and the lowest weighting to labour expenditure per tonne of cargo (15.9%) (Figure 5). The CR for financial dry port PIs was 0.2%, making the weightings obtained accepted, as they were within the acceptable range.

Figure 5.

Weightings given by service providers for financial dry port performance.

3.2.2. Transport PIs

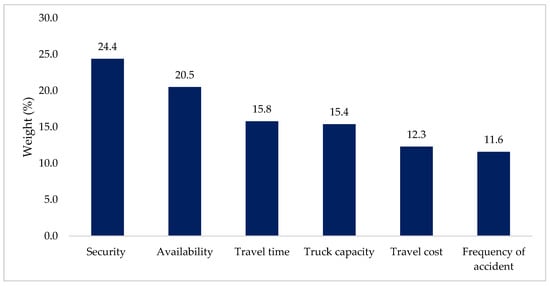

Customers of transport services in the import–export chain, including freight forwarders, importers and exporters, gave their opinion about the importance of each criterion. Accordingly, the experts gave the highest weighting to security (24.4%), followed by availability (20.5%). Frequency of accident was found to be the least important criterion, with a weighting of 11.6% (Figure 6). The CR obtained for transport PIs was 9.7%, resulting in the weightings being accepted.

Figure 6.

Weightings given by experts for transport performance.

3.2.3. Warehouse PIs

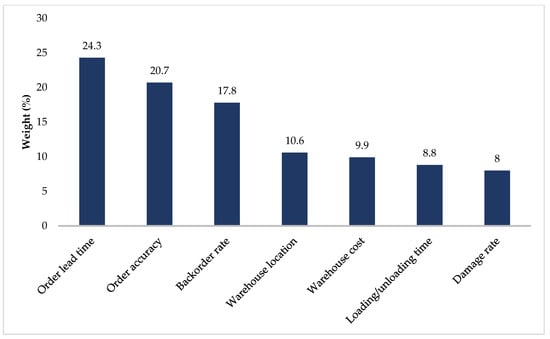

Importers and exporters conducted pairwise comparisons to obtain the weightings of warehouse PIs. The results of the AHP analysis showed that importers and exporters weighted order lead time as the most important criterion, at 24.3%, followed by order accuracy, with a weighting of 20.7%. The analysis also showed that the respondents gave the lowest weighting to damage rate, with a weighting of 8% (Figure 7). The CR obtained for warehouse PIs was 1.3%, resulting in the weights being accepted.

Figure 7.

Weightings given by experts for warehouse performance.

3.3. Challenges in the Import–Export Sector

The import–export sector faces a number of challenges related to dry ports, transportation and warehouse management. In response to the question about the challenges faced in the elements of the import–export chain, the respondents’ answers are summarised in Table 8.

Table 8.

Main challenges faced in the import–export chain.

4. Discussion

4.1. PIs for Low-Income Countries

Results from the literature review showed that, in contrast to high-income countries, the literature focusing on low-income countries used dry port PIs that mainly consider financial aspects. This is likely because dry port services need to be sustained before there can be any focus on providing a quality service and, therefore, operations focus on financial performance. Dry port PIs related to service quality, human resources and their environmental impact are given less attention in low-income countries. This could possibly be because the system is still developing and the priority is on basic indicators.

The literature on transport performance showed that there is a great similarity in the indicators used for both high-income and low-income countries. The limited infrastructure in low-income countries has led to less emphasis being placed on interconnectivity and the traceability aspect of PIs. Indicators related to sustainability are lacking in the literature on low-income countries. This is something that needs attention given the large impact of the transport system on the environment.

For the warehouse PIs, the literature from high-income countries mainly focused on improving quality by reducing damage to the inventory. Furthermore, the literature also focused on improving the productivity of warehouses by increasing throughput and improving the utilisation of storage spaces. However, adequate literature covering the performance of warehouses in low-income countries is lacking. The available literature from low-income countries focused on order lead time and inventory turnover ratio.

4.2. Importance Level of the PIs

For dry port operations, customers from the expert survey gave the highest weighting to turnaround time, with a value of 30.4% (Figure 4). This shows that customers prefer to have their customs and clearance processes handled as soon as possible to avoid incurring high port fees due to the prolonged stay of their shipment in the dry port. A longer turnaround time also poses a risk for customers’ importing/exporting time for sensitive or seasonal products. Turnaround time is a critical factor affecting logistics performance in landlocked countries, as outlined by Arvis et al. [82]. The timeliness of logistics service, which is in the World Bank’s LPI, can be reflected by reduced turnaround times in ports.

Service providers gave the highest weighting to damage frequency, with a value of 29.6% for dry port operations (Figure 4). The amount of goods damaged or lost during port operations reflects the quality of service provided by the agencies. This is also a measure of the reliability of the service provided. Reliable services ensure predictability and certainty in the supply chain [18] and thus help improve customer satisfaction. This, in turn, likely results in more customers using the port services, thereby increasing the throughput in the port. Hence, port operations in low-income countries should focus on improving the quality of their service to achieve greater reliability [46].

From the financial dry port PIs, service providers gave the highest weighting to capital expenditure per tonne of cargo, with a value of 53.6% (Figure 5). This shows that service providers want to reduce the expenditure that results from investing in port equipment. However, investing in technological advancements and increasing the number of cranes can improve the throughput in the port and increase the efficiency and profitability of the dry port. In contrast, labour expenditure per tonne of cargo was given the lowest weighting, implying that labour is readily available and not costly in port operations, especially in low-income countries.

For both customers and service providers, the environmental impact was given the lowest weighting, with values of 14.4% and 10.4%, respectively (Figure 4). Although there have been some initiatives in Ethiopia to reduce the impacts of climate change [83], the results of the survey showed that this issue has not gained much traction in dry port operations. This might be because the impact that dry port operations can have on the environment has not been well addressed and awareness of their consequences has not been raised. Instead, both customers and service providers are looking for options that boost their profit, mostly at the expense of the environment. Nath and Behera [84] state that low-income countries have fewer initiatives to combat climate impacts, and this is not a priority for governments in these countries. However, strong initiatives and policies should be in place to reduce the impact of climate change in low-income countries to create a sustainable environment. Additionally, seminars and training courses can be provided to learn how other more environmentally friendly ports are operated [20].

From the transport PIs, customers gave the highest weighting to security, with a weighting of 24.4% (Figure 6). The respondents also stated that one of the biggest challenges they face in the transport of containers from dry ports to warehouses is issues related to security. Security threats can arise in the import–export corridor due to political instability, theft and robbery. The issue with security is also a recurring problem in other low-income countries. For instance, it has hindered efficient port operations in Ghana [85]. Security threats due to political instability might cause loaded trucks to be stuck either in the dry port or along the corridor. This leads to delays in delivering products to end users, resulting in supply shortages. Furthermore, if the goods that are to be transported are time sensitive, such as food or medicine, then the products might be spoiled or expire due to poor storage conditions in trucks.

For warehouse management, importers/exporters gave the highest weighting to lead time, with a value of 24.3% (Figure 7). Lead times are generally longer for landlocked countries such as Ethiopia, where imported products have to cross borders and pass through long and bureaucratic customs clearance processes. This could explain the highest weighting given to lead time by importers/exporters. Furthermore, longer lead times also cause stock-outs due to unmet demands. Organisations in countries such as Ghana, Kenya, Uganda and Nigeria also have problems controlling and holding inventory [86]. In addition to improved customs services, lead times in low-income countries can be improved by having effective inventory management systems. Thus, schemes that can enable them to manage their inventories effectively and efficiently are recommended.

4.3. Challenges in the Import–Export Sector

The experts reported that they faced challenges such as long waiting times, high port fees and bureaucracy (Table 8). A survey of ESLSE customers conducted by Amentae and Gebresenbet [3] on the efficiency of services given by the service provider also showed that customers experienced cumbersome customs clearance processes and long waiting times. According to UN-OHRLLS [5], extensive documentation during customs and border clearance is an issue in other landlocked, less developed countries such as Botswana. Challenges faced by respondents, such as long waiting times, high port charges and bureaucracy in dry port operations, are captured by the identified PIs (Figure 4). Measurement and evaluation of these PIs enables progressive improvement to be monitored in areas that present challenges. Interventions related to improvement of these indicators should be given priority, since, based on the survey results, customers gave these a high weighting. One type of intervention that can help in addressing the challenges and improve PIs is the adoption of technologies.

The experts also reported that there is a lack of skilled and professional staff (Table 8). According to the case study of Ansah et al. [85], issues related to shortages of skilled staff have been observed in Ghana’s dry port operations. The lack of skilled staff hinders the smooth operation of dry ports, transportation and warehouses, leading to customers receiving a poor service, and delays and inefficiencies in how they are run. To address this issue, training courses and capacity-building programmes should be provided for employees so that they can become more competent at their jobs. There are different alternatives to carry out training and capacity building. One way is by formulating collaboration with higher education institutions. Applying for funding in interested organisations is another way of financing budgets. For big organisations, allocating a specific budget for capacity building is also an alternative. Government policies should also address issues associated with human capital [10]. In addition, the challenges related to skilled staff performance in dry port, transportation and warehouse operations are not included in the identified PIs. Few studies have considered employee performance as an indicator. Therefore, indicators focusing on the performance of human resources, including those working in dry port operations, as truck drivers and in warehouse operations, should be formulated.

The other challenge the experts mentioned was poor technological advancements in port operations (Table 8). They also stated that they experienced delays in receiving services due to poor network or system failures. Poor network availability is a recurring issue in other low-income countries as well, resulting in inefficiencies during port operation [87]. Although advances in information technology can improve information flow and facilitate customs clearance, a low level of technology implementation is an issue in other dry ports, such as in Ghana [85]. UN-OHRLLS [5] also state that landlocked, less developed countries face challenges related to technological advances in their ports. The report states that drawbacks for most landlocked countries in relation to the adoption and implementation of information technologies are related to accessibility, affordability and skills.

Improvement in government policies can help reduce the high documentation requirements for import and export. According to the interview with the experts, the Ethiopian government has commenced the implementation of a single-window service. This service facilities the submission of documents and information required for import/export through a single entry point, thereby reducing delays, facilitating clearances and improving transparency [87]. Trade portals are implemented in dry ports for customs declaration and verification [88], yet the integration with customers and other actors is low because of their lack of use of digital technologies. By providing visibility and control over goods in ports, tracking technologies such as RFID ensure the safety of goods [11]. Automation of equipment in ports results in low environmental impacts, short turnaround times and high equipment utilisation, and increases throughput and port accessibility [7,8,9]. Smart ports are the next emerging technologies with minimal human involvement in carrying out tasks, thus ensuring accurate and rapid port operations. To guarantee the effectiveness of these technologies, PIs measuring the implementation of technologies should also be in place. This enables an audit of the technologies addressing the challenges faced in the sector.

A commonly observed challenge during the transportation of containers from dry ports to warehouses is the extensive use of aged trucks (Table 8). Freight transportation services in Ethiopia are marked by a prevalence of aged trucks and lack of traceability [28]. According to Kine et al. [89], the use of aged trucks is a common problem in other low-income countries as well. They are not only a cause of traffic accidents along the route, but also a huge contributor to the emission of pollutants to the environment. Furthermore, drivers of these trucks are mostly inexperienced, making them a threat not only to the security of the goods being transported, but also to other road users. Thus, to counteract the risk posed to the environment and society by aged trucks and incompetent drivers, fleet modernisation is important. Fleet modernsation could occur by implementing technologies on the existing trucks or replacing the aged trucks with new ones. The cost of replacing aged trucks is not cost intensive, as the cost of buying new trucks is compensated by avoiding the huge cost encountered in maintaining and running old trucks. In addition, government intervention could be crucial, as government policies could allow the use of aged trucks to be limited and regulate the minimum number of years’ experience required by drivers before they are able to drive heavy trucks.

The experts also stated that they faced challenges in finding trucks that can transport their containers from the dry port to warehouses, particularly during peak seasons (Table 8). This explains the high weighting given by the experts to availability when conducting the pairwise comparisons (Figure 6). Using ICT solutions, transport choice and goods movement become less costly and more efficient [12]. Using virtual clustering in transportation, logistic companies choose less costly transport services and at the same time reduce their environmental impact by increasing the load factor [13]. Behrends et al. [90] discuss how installing telematics in railways can improve their share of use by increasing responsiveness, reliability and wagon efficiency. Hence, implementation of truck telematics and other ICT solutions can alleviate the challenges faced by experts in relation to truck availability. The cost for the implementation of telematics for trucks and other ICT solutions depends on the degree of implementation of the technologies. The government could subsidise some of the encountered costs to promote technology implementation. The cost also depends on a number of factors, including type of truck, specific solutions required, type and amount of data that needs to be collected and installations of tools.

In terms of warehouse management, the experts stated that there were few or no technologies in place for handling and/or managing inventory (Table 8). Warehouse operations lack integration with selling points and visibility, and are highly reliable on manpower [29,30]. This causes damage to goods during loading/unloading and loss of inventory due to theft, as there are few or no means for tracking inventories. Digital technologies make management of warehouses and inventories efficient. The use of digital technologies significantly reduces loading time, costs and damage rates in warehouses [14,15].

To improve the performance of dry ports, warehousing and transportation, technology adoption plays a vital role. However, the adoption of new technologies, particularly in low-income countries, is dependent on the economic advantages of the technologies, the presence of necessary infrastructure and the affordability of the technologies [43]. Thus, detailed studies regarding the technologies and ways on how to implement them is important.

5. Conclusions

This study developed PIs for dry ports, transportation and warehouse operations, and the importance of these indicators were weighted. The results of the study show that customers in the expert survey considered time-related PIs such as turnaround time important for dry port operations and order lead time important for warehouse activities. For transportation, customers considered security and availability as the most important PIs. Service providers considered damage frequency as the most important PI. The survey results also show that both customers and service providers gave a low weighting for environmental impact.

The PIs identified in this study could be adopted by other low-income countries to improve the performance of their dry port operation, transportation and warehouse management by taking local conditions into account. Moreover, the approach and methodology used to obtain the PIs in this paper could be used by other low-income countries to assess areas of logistics activities that require improvement.

The study showed that the logistics-related challenges faced in the import–export chain included high costs, low utilisation level of digital technologies, scarcity of skilled and professional workforce, aged trucks and the lack of integrated systems. To address these challenges, implementation of digitalisation and automation technologies, together with appropriate policy, could be recommended. These technologies could improve the performance of dry ports, transportation and warehouse management by increasing throughput, improving accessibility, boosting efficiency, lowering costs and reducing damage and losses. In addition to technological interventions, capacity-building programmes are recommended to develop skilled workers to make services efficient. The public institutions could play an important role in improving logistics services by making systems more transparent, better coordinated and less bureaucratic.

Although this study developed and weighted the performance indicators of dry ports, transportation and warehousing, seaports are also seen as a critical part of the import–export chain. Thus, further research studies could be recommended for the seaports. Furthermore, measuring the impact of the performance of dry ports, transportation and warehouse operations on supply chains and the required improvement of performance from the perspective of low-income countries could be recommended.

Author Contributions

Conceptualization: M.D.T., H.Z.K. and G.G.; methodology: M.D.T. and H.Z.K.; analysis: M.D.T. and H.Z.K.; original draft preparation and editing: M.D.T. and H.Z.K.; review and supervision: G.G., L.T. and D.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the CBP-Ethiolog project (project No. NICHE-ETH-285) funded by Netherlands Initiative for Capacity Development in Higher Education (NICHE).

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank all stakeholders that participated in the survey, including ESLSE, EMA and MOT.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. The First Round Questionnaire Deployed in the Study

Appendix A.1. Introduction

The purpose of this survey is to identify key logistic performance indicators in the import–export chain of Ethiopia. For this, logistics performance indicators for the main import–export components, including dry ports, transport and warehouses, are collected from the literature and presented. Please provide your responses for the following questions.

Appendix A.2. General Information

- What is the name of the company?

__________________________________

- b.

- What is your position in the company?

___________________________________

- c.

- What is your education level?

____________________________________

- d.

- How many years of experience do you have?

____________________________________

Appendix A.3. Dry Port

The table below shows the performance indicators of dry ports that are found from the literature. The indicators suitable for low-income countries are selected and presented here. Please rate the relevance of the performance indicators to measure dry port performance in Ethiopia.

Table A1.

Dry port PIs.

Table A1.

Dry port PIs.

| Performance Indicators | Not Important | Important |

|---|---|---|

| Distance from commercial areas | ||

| Transhipment time | ||

| Transhipment costs | ||

| Cut-off time | ||

| Turnaround time | ||

| Damage frequency | ||

| Loss frequency | ||

| Process utilisation rate | ||

| Environmental impacts | ||

| Throughput |

- Are there any dry port performance indicators other than the ones mentioned above?

__________________________________________________________________________

- b.

- If your response to part a is yes, please provide the indicators in the space provided below.

__________________________________________________________________________

- c.

- Do you perform performance evaluation in your company?

__________

- d.

- What performance indicators do you implement in your company (can be from the list above or any different indicators?)

__________________________________________________________________________

Appendix A.4. Transport

The following table shows the performance indicators of transport that are gathered from the literature. The indicators suitable to low-income countries are selected and presented here. Please rate the relevance of the performance indicators to measure transport performance in Ethiopia.

Table A2.

Transport PIs.

Table A2.

Transport PIs.

| Performance Indicators | Not Important | Important |

|---|---|---|

| Availability | ||

| Travel time | ||

| Travel costs | ||

| Integration with other means of transport | ||

| Frequency of accident | ||

| Security | ||

| Number of trips per month | ||

| Truck capacity |

- Are there any transport performance indicators other than the ones mentioned above?

__________________________________________________________________________

- b.

- If your response to part a is yes, please provide the indicators in the space provided below.

__________________________________________________________________________

- c.

- Do you perform performance evaluation in your company?

__________

- d.

- If yes, what performance indicators do you implement in your company (can be from the list above or any different indicators?)

__________________________________________________________________________

Appendix A.5. Warehouse

The following table shows the performance indicators of warehouses that are gathered from the literature. The indicators suitable to low-income countries are selected and presented here. Please rate the relevance of the performance indicators to measure warehouse performance in Ethiopia.

Table A3.

Warehouse PIs.

Table A3.

Warehouse PIs.

| Performance Indicators | Not Important | Important |

|---|---|---|

| Loading/unloading time | ||

| Inventory turnover rate | ||

| Damage rate | ||

| Inventory carrying costs | ||

| Order accuracy | ||

| Backorder rate | ||

| Order lead time | ||

| On-time delivery rate | ||

| Total warehouse costs | ||

| Accessibility from road | ||

| Quantity error rate | ||

| Stock accuracy | ||

| Excess inventory rate |

- Are there any warehouse performance indicators other than the ones mentioned above?

__________________________________________________________________________

- b.

- If your response to part a is yes, please provide the indicators in the space provided below.

__________________________________________________________________________

__________________________________________________________________________

- c.

- Do you perform performance evaluation in your company?

__________

- d.

- What performance indicators do you implement in your company (can be from the list above or any different indicators?)

__________________________________________________________________________

__________________________________________________________________________

Appendix B. The Second Round Questionnaire Deployed in the Study

Appendix B.1. Introduction

The research aims to develop logistics and supply chain management performance indicators for low-income countries, focusing on the export and import chain.

Accordingly, a multi-criteria decision framework is used in this questionnaire to identify the key performance indicators where a set of factors is given to you, and you rate the relative importance of each factor compared to its corresponding alternative. The relative importance is measured on a scale of 1 to 9. The meaning of each number value can be found in Table A4 below.

Table A4.

Legend for performance indicator rating numbers.

Table A4.

Legend for performance indicator rating numbers.

| Importance Scale | Definition of Importance Scale |

|---|---|

| 1 | Equally important preferred |

| 2 | Equally to moderately important preferred |

| 3 | Moderately important preferred |

| 4 | Moderately to strongly important preferred |

| 5 | Strongly important preferred |

| 6 | Strongly to very strongly important preferred |

| 7 | Very strongly important preferred |

| 8 | Very strongly to extremely important preferred |

| 9 | Extremely important preferred |

Appendix B.2. Respondent’s Information

- What is the name of the company?

__________________________________

- b.

- What is your position in the company?

__________________________________

- c.

- What is your education level?

__________________________________

- d.

- How many years of experience do you have?

___________________________________

- e.

- Do you own a truck? If yes, how many

_____________________________________

- f.

- Do you own a warehouse? If yes, how many?

_____________________________________

Appendix B.3. Performance Indicators of Dry Ports

The following performance indicators are related to the dry port performance. Please rate the relative importance of each performance indicators in the row to the performance indicators along the column on a scale of 1 to 9. Please find the meaning of each number value in Table A4.

- Operational Performance Indicators

Table A5.

Pairwise comparisons for operational dry port PIs.

Table A5.

Pairwise comparisons for operational dry port PIs.

| Factors | Turnaround Time | Port Cost | Damage Frequency | Loss Frequency | Environmental Impact |

|---|---|---|---|---|---|

| Turnaround time | |||||

| Port cost | |||||

| Damage frequency | |||||

| Loss frequency | |||||

| Environmental impact |

- 2.

- Financial Performance Indicators

Table A6.

Pairwise comparisons for financial dry port PIs.

Table A6.

Pairwise comparisons for financial dry port PIs.

| Factors | Capital Expenditure Per Tonne of Cargo | Throughput | Labour Expenditure Per Tonne of Cargo |

|---|---|---|---|

| Capital expenditure per tonne of cargo | |||

| Throughput | |||

| Labour expenditure per tonne of cargo |

- What are the main challenges you face in port operations?

__________________________________________________________________________

- b.

- Are there any forms of digitisation or automation implemented in your company?

__________

If yes, please list them?

__________________________________________________________________________

Appendix B.4. Performance Indicators for Transport Services

The following performance indicators are related to transport performance. Please rate the relative importance of each performance indicator in the row to the performance indicators along the column on a scale of 1 to 9. Please find the meaning of each number value in Table A4.

Table A7.

Pairwise comparisons for transport PIs.

Table A7.

Pairwise comparisons for transport PIs.

| Factors | Security | Availability | Travel Time | Truck Capacity | Travel Cost | Frequency of Accident |

|---|---|---|---|---|---|---|

| Security | ||||||

| Availability | ||||||

| Travel time | ||||||

| Truck capacity | ||||||

| Travel cost | ||||||

| Frequency of accidents |

- What are the main challenges you face in transport operations?

__________________________________________________________________________

- b.

- Are there any forms of digitisation or automation implemented in your company?

__________

If yes, please list them?

__________________________________________________________________________

Appendix B.5. Performance Indicators for Warehousing

The following performance indicators are related to warehouse performance. Please rate the relative importance of each performance indicator in the row to the performance indicators along the column on a scale of 1 to 9. Please find the meaning of each number value in Table A4.

Table A8.

Pairwise comparisons for warehousing PIs.

Table A8.

Pairwise comparisons for warehousing PIs.

| Factors | Order Lead Time | Order Accuracy | Backorder Rate | Warehouse Location | Total Warehouse Cost | Loading/Unloading Time | Damage Rate |

|---|---|---|---|---|---|---|---|

| Order lead time | |||||||

| Order accuracy | |||||||

| Backorder rate | |||||||

| Warehouse location | |||||||

| Total warehouse cost | |||||||

| Loading/unloading time | |||||||

| Damage rate |

- What are the main challenges you face in warehouse operations?

__________________________________________________________________________

- b.

- Are there any forms of digitisation or automation implemented in your company?

__________

If yes, please list them?

__________________________________________________________________________

References

- Frazelle, E.H. World-Class Warehousing and Material Handling; McGraw-Hill Education: New York, NY, USA, 2016. [Google Scholar]

- Heaver, T.D. Perspectives on global performance issues. In Handbook of Logistics and Supply Chain Management; Brewer, A.M., Button, K.J., Hensher, D.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Amentae, T.K.; Gebresenbet, G. Evaluation of Performances of Intermodal Import-Export Freight Transport System in Ethiopia. J. Serv. Sci. Manag. 2015, 8, 57–70. [Google Scholar] [CrossRef][Green Version]

- UNCTAD. The Djibouti City—Addis Ababa Transit and Transport Corridor: Turning Diagnostics into Action. Geneva, Switzerland. 2018. Available online: https://unctad.org/webflyer/djibouti-city-addis-ababa-transit-and-transport-corridor-turning-diagnostics-action (accessed on 29 December 2021).

- UN-OHRLLS. Achieving the Sustainable Development Goals in Landlocked Developing Countries through Connectivity and Trade Facilitation. 2018. Available online: https://www.un.org/ohrlls/sites/www.un.org.ohrlls/files/achieving_the_sdgs_in_landlocked_developing_countries_through_connectivity_and_trade_facilitation_2018.pdf (accessed on 10 February 2022).

- Nguyen, L.C.; Notteboom, T. The relations between dry port characteristics and regional port-hinterland settings: Findings for a global sample of dry ports. Marit. Policy Manag. 2019, 46, 24–42. [Google Scholar] [CrossRef]

- Bontekoning, Y.M. The Importance of New-Generation Freight Terminals For Intermodal Transport. J. Adv. Transp. 2000, 34, 391–413. [Google Scholar] [CrossRef]

- Philipp, R.; Gerlitz, L.; Moldabekova, A. Small and Medium-Sized Seaports on the Digital Track: Tracing Digitalisation Across the South Baltic Region by Innovative Auditing Procedures; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2020; Volume 117, pp. 351–362. [Google Scholar] [CrossRef]

- Jacobsson, S.; Arnäs, P.O.; Stefansson, G. Automatic information exchange between interoperable information systems: Potential improvement of access management in a seaport terminal. Res. Transp. Bus. Manag. 2020, 35, 100429. [Google Scholar] [CrossRef]

- Moldabekova, A.; Philipp, R.; Reimers, H.-E.; Alikozhayev, B. Digital technologies for improving logistics performance of countries. Transp. Telecommun. 2021, 22, 1019. [Google Scholar] [CrossRef]

- Scholliers, J.; Permala, A.; Toivonen, S.; Salmela, H. Improving the Security of Containers in Port Related Supply Chains. Transp. Res. Procedia 2016, 14, 1374–1383. [Google Scholar] [CrossRef]

- Corriere, F.; Di Vincenzo, D.; Corriere, R. A Logistics Pattern For Fruit And Vegetable Transportation From Island Region: The Case Of Sicily. ARPN J. Eng. Appl. Sci. 2014, 9, 2279–2285. [Google Scholar]

- Golińska, P. Information management supporting multimodal transport utilization in virtual clusters. Manag. Prod. Eng. Rev. 2013, 4, 20–29. [Google Scholar] [CrossRef]

- Wang, H.; Chen, S.; Xie, Y. An RFID-based digital warehouse management system in the tobacco industry: A case study. Int. J. Prod. Res. 2010, 48, 2513–2548. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Narwane, V.S.; Narkhede, B.E.; Muduli, K. Implementation barriers of smart technology in Indian sustainable warehouse by using a Delphi-ISM-ANP approach. Int. J. Prod. Perform. Manag. 2021, 71, 696–721. [Google Scholar] [CrossRef]

- Ojala, L.; Çelebi, D. The World Bank’s Logistics Performance Index (LPI) and Drivers of Logistics Performance; OECD: Paris, France, 2005. [Google Scholar]

- RFC Rhine-Alpine. Performance Measurement in the Intermodal Transport Chain RFC Rhine-Alpine Study; EEIG Corridor Rhine Alpine EWIV: Frankfurt, Germany, 2019; pp. 1–12. Available online: https://www.corridor-rhine-alpine.eu/downloads.html (accessed on 14 May 2021).

- Arvis, J.-F.; Ojala, L.; Wiederer, C.; Shepherd, B.; Raj, A.; Dairabayeva, K.; Kiiski, T. Connecting to Compete 2018: Trade Logistics in the Global Economy: The Logistics Performance Index and Its Indicators; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Bolat, P.; Kayisoglu, G.; Gunes, E.; Kızılay, F.E.; Ozsogut, S. Weighting Key Factors for Port Congestion by AHP Method. J. ETA Marit. Sci. 2020, 8, 252–273. [Google Scholar] [CrossRef]

- Chiu, R.-H.; Lin, L.-H.; Ting, S.-C. Evaluation of Green Port Factors and Performance: A Fuzzy AHP Analysis. Math. Probl. Eng. 2014, 2014, 802976. [Google Scholar] [CrossRef]

- Hanaoka, S.; Kunadhamraks, P. Multiple criteria and fuzzy based evaluation of logistics performance for intermodal transportation. J. Adv. Transp. 2009, 43, 123–153. [Google Scholar] [CrossRef]

- Lam, H.Y.; Choy, K.L.; Ho, G.T.S.; Cheng, S.W.Y.; Lee, C.K.M. A knowledge-based logistics operations planning system for mitigating risk in warehouse order fulfillment. Int. J. Prod. Econ. 2015, 170, 763–779. [Google Scholar] [CrossRef]

- Srisawat, P.; Kronprasert, N.; Arunotayanun, K. Development of Decision Support System for Evaluating Spatial Efficiency of Regional Transport Logistics. Transp. Res. Procedia 2017, 25, 4832–4851. [Google Scholar] [CrossRef]

- Reda, A.; Noble, B. Tackling vehicular fraud in Ethiopia: From technology to business. In Proceedings of the 2nd ACM Symposium on Computing for Development 2012, Atlanta, GA, USA, 11–12 March 2012. [Google Scholar] [CrossRef]

- Debela, F.M. Logistics Practices in Ethiopia; Swedish University of Agricultural Sciences: Uppsala, Sweden, 2013; ISSN 1654-9392. [Google Scholar]

- Georgise, F.B.; Heramo, A.H.; Bekele, H. Improving automotive service through e-logistics: A case of Moenco Hawassa, Ethiopia. Int. J. Econ. Manag. Syst. 2020, 5, 21–40. Available online: https://www.iaras.org/iaras/home/caijems/improving-automotive-service-through-e-logistics-a-case-of-moenco-hawassa-ethiopia (accessed on 11 February 2022).

- Nitsche, B. Embracing the Potentials of Intermodal Transport in Ethiopia: Strategies to Facilitate Export-Led Growth. Sustainability 2021, 13, 2208. [Google Scholar] [CrossRef]

- Gebrewahid, G.G.; Wald, A. Export Barriers and Competitiveness of Developing Economies: The Case of the Ethiopian Leather Footwear Industry. J. Afr. Bus. 2017, 18, 396–416. [Google Scholar] [CrossRef]

- Gogas, M.; Adamos, G.; Nathanail, E. Assessing the performance of intermodal city logistics terminals in Thessaloniki. Transp. Res. Procedia 2017, 24, 17–24. [Google Scholar] [CrossRef]

- Rezaei, J.; van Roekel, W.S.; Tavasszy, L. Measuring the relative importance of the logistics performance index indicators using Best Worst Method. Transp. Policy 2018, 68, 158–169. [Google Scholar] [CrossRef]

- Ministry of Transport. Federal Democratic Republic of Ethiopia National Logistics Strategy (2018–2028); Ministry of Transport: Addis Ababa, Ethiopia, 2019. [Google Scholar]

- Maxwell, J.A. Designing a Qualitative Study. In The SAGE Handbook of Applied Social Research Methods; Bickman, L., Rog, D.J., Eds.; SAGE Publications, Inc.: New York, NY, USA.

- Sambasivan, M.; Fei, N.Y. Evaluation of critical success factors of implementation of ISO 14001 using analytic hierarchy process (AHP): A case study from Malaysia. J. Clean. Prod. 2008, 16, 1424–1433. [Google Scholar] [CrossRef]

- Saaty, T. How to make a decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 2009, 48, 9–26. [Google Scholar] [CrossRef]

- Jamshidi, A.; Jamshidi, F.; Ait-Kadi, D.; Ramudhin, A. A review of priority criteria and decision-making methods applied in selection of sustainable city logistics initiatives and collaboration partners. Int. J. Prod. Res. 2019, 57, 5175–5193. [Google Scholar] [CrossRef]

- Brunelli, M. Introduction to the Analytic Hierarchy Process; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Chang, P.-Y.; Lin, H.-Y. Manufacturing plant location selection in logistics network using Analytic Hierarchy Process. J. Ind. Eng. Manag. 2015, 8, 1547–1575. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Analytic Hierarchy Process and Expert Choice: Benefits and limitations. OR Insight 2009, 22, 201–220. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Kraujalienė, L. Comparative analysis of multicriteria decision-making methods evaluating the efficiency of technology transfer. Bus. Manag. Educ. 2019, 17, 72–93. [Google Scholar] [CrossRef]

- Si, S.-L.; You, X.-Y.; Liu, H.-C.; Zhang, P. DEMATEL Technique: A Systematic Review of the State-of-the-Art Literature on Methodologies and Applications. Math. Probl. Eng. 2018, 2018, 3696457. [Google Scholar] [CrossRef]

- Kayikci, Y. A conceptual model for intermodal freight logistics centre location decisions. Procedia Soc. Behav. Sci. 2010, 2, 6297–6311. [Google Scholar] [CrossRef]

- Tadesse, M.D.; Gebresenbet, G.; Tavasszy, L.; Ljungberg, D. Assessment of Digitalized Logistics for Implementation in Low-Income Countries. Future Transp. 2021, 1, 227–247. [Google Scholar] [CrossRef]

- Bekele, R. Determinants of throughput performance of Modjo dry port, Ethiopia. J. Bus. Adm. Stud. 2019, 11, 1–35. [Google Scholar]

- ESLSE. Dry Ports of ESLSE. 2021. Available online: https://www.eslse.et/dryport.html (accessed on 3 February 2022).

- Çelebi, D. The role of logistics performance in promoting trade. Marit. Econ. Logist. 2019, 21, 307–323. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; Tirtiroglu, E. Performance measures and metrics in a supply chain environment. Int. J. Oper. Prod. Manag. 2001, 21, 71–87. [Google Scholar] [CrossRef]

- Jin, M.; Wang, H. System Performance Measures for Intermodal Transportation with a Case Study and Industrial Application; National Center for Intermodal Transportation: Denver, CO, USA, 2004. [Google Scholar]

- Kabak, Ö.; Ülengin, F.; Önsel Ekici, Ş. Connecting logistics performance to export: A scenario-based approach. Res. Transp. Econ. 2018, 70, 69–82. [Google Scholar] [CrossRef]

- Liebetruth, T. Sustainability in Performance Measurement and Management Systems for Supply Chains. Procedia Eng. 2017, 192, 539–544. [Google Scholar] [CrossRef]

- Lin, C.-Y. Supply chain performance and the adoption of new logistics technologies for logistics service providers in Taiwan. J. Stat. Manag. Syst. 2007, 10, 519–543. [Google Scholar] [CrossRef]

- Rashidi, K.; Cullinane, K. Evaluating the sustainability of national logistics performance using Data Envelopment Analysis. Transp. Policy 2019, 74, 35–46. [Google Scholar] [CrossRef]

- Özceylan, E.; Çetinkaya, C.; Erbaş, M.; Kabak, M. Logistic performance evaluation of provinces in Turkey: A GIS-based multi-criteria decision analysis. Transp. Res. Part A Policy Pract. 2016, 94, 323–337. [Google Scholar] [CrossRef]

- Ha, M.H.; Yang, Z.; Notteboom, T.; Ng, A.K.Y.; Heo, M.W. Revisiting port performance measurement: A hybrid multi-stakeholder framework for the modelling of port performance indicators. Transp. Res. Part E Logist. Transp. Rev. 2017, 103, 1–16. [Google Scholar] [CrossRef]

- Martin, E.; Dombriz, M.A.; Soley, G. Study of the State of the Art and Description of KPI and KRI of Terminals, Hinterland Mobility and Rail Network. 2017. Available online: https://vdocument.in/reader/full/d31-state-of-the-art-and-description-of-kpis-d31-study-of-the-state-of-the (accessed on 27 February 2022).

- Carboni, A.; Deflorio, F. Performance indicators and automatic identification systems in inland freight terminals for intermodal transport. IET Intell. Transp. Syst. 2018, 12, 309–318. [Google Scholar] [CrossRef]

- UNCTAD. Port Performance Indicators, 76th ed.; United Nations: New York, NY, USA, 1976. [Google Scholar]

- De Langen, P.W.; Sharypova, K. Intermodal connectivity as a port performance indicator. Res. Transp. Bus. Manag. 2013, 8, 97–102. [Google Scholar] [CrossRef]

- Cezar-Gabriel, C. Performance assessment in operating dry ports. Ann. Fac. Econ. 2010, 1, 934–938. [Google Scholar]

- Nathnail, E.; Gogas, M.; Adamos, G. Urban Freight Terminals: A Sustainability Cross-case Analysis. Transp. Res. Procedia 2016, 16, 394–402. [Google Scholar] [CrossRef]

- Onwuegbuchunam, D. Assessing Port Governance, Devolution and Terminal Performance in Nigeria. Logistics 2018, 2, 6. [Google Scholar] [CrossRef]

- Lai, K.-H.; Ngai, E.W.T.; Cheng, T.C.E. Measures for evaluating supply chain performance in transport logistics. Transp. Res. Part E Logist. Transp. Rev. 2002, 38, 439–456. [Google Scholar] [CrossRef]

- Stoilova, S.; Munier, N.; Kendra, M.; Skrúcaný, T. Multi-Criteria Evaluation of Railway Network Performance in Countries of the TEN-T Orient–East Med Corridor. Sustainability 2020, 12, 1482. [Google Scholar] [CrossRef]

- Šakalys, R.; Sivilevičius, H.; Miliauskaitė, L.; Šakaly, A. Investigation and evaluation of main indicators impacting synchromodality using ARTIW and AHP methods. Transport 2019, 34, 300–311. [Google Scholar] [CrossRef]

- Easley, R.; Katsikides, N.; Kucharek, K.; Shamo, D.; Tiedeman, J. Freight Performance Measure Primer; Federal Highway Administration: New York, NY, USA, 2017. [Google Scholar]

- Varma, A. Measurement Sources for Freight Performance Measures and Indicators. 2008. Available online: http://www.lrrb.org/PDF/200812.pdf (accessed on 28 February 2022).

- Hagler Bailly Services. Measuring Improvements in the Movement of Highway and Intermodal Freight—FHWA Freight Management and Operations. Available online: https://ops.fhwa.dot.gov/freight/freight_analysis/measure_rpt.htm#travel_time (accessed on 5 May 2021).

- Domingues, M.L.; Reis, V.; Macário, R. A comprehensive framework for measuring performance in a third-party logistics provider. Transp. Res. Procedia 2015, 10, 662–672. [Google Scholar] [CrossRef]

- Stein, N.; Blair, A.; Weisbrod, G. Freight Performance Measures: Measuring Freight Accessibility. 2018. Available online: https://www.researchgate.net/publication/336615388_Freight_Performance_Measures_Measuring_Freight_Accessibility (accessed on 28 February 2022).

- Khan, S.A.R.; Yu, Z. The Impact of Terrorism on Economics and Logistics Performance: An Empirical Study from the Perspective of Saarc Member States. Rom. J. Econ. Forecast. 2020, 23, 99–117. [Google Scholar]

- Oye, A.; Aderinlewo, O.; Croope, S. Urban transport safety assessment in akure based on corresponding performance indicators. Open Eng. 2013, 3, 113–120. [Google Scholar] [CrossRef]

- Chen, P.-S.; Huang, C.-Y.; Yu, C.-C.; Hung, C.-C. The examination of key performance indicators of warehouse operation systems based on detailed case studies. J. Inf. Optim. Sci. 2017, 38, 367–389. [Google Scholar] [CrossRef]

- Karim, N.H.; Abdul Rahman, N.S.F.; Md Hanafiah, R.; Abdul Hamid, S.; Ismail, A.; Abd Kader, A.S.; Muda, M.S. Revising the warehouse productivity measurement indicators: Ratio-based benchmark. Marit. Bus. Rev. 2021, 6, 49–71. [Google Scholar] [CrossRef]

- Kusrini, E.; Novendri, F.; Helia, V.N. Determining key performance indicators for warehouse performance measurement—A case study in construction materials warehouse. MATEC Web Conf. 2018, 154, 01058. [Google Scholar] [CrossRef][Green Version]

- Salhieh, L.; Alswaer, W. A proposed maturity model to improve warehouse performance. Int. J. Product. Perform. Manag. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Torabizadeh, M.; Yusof, N.M.; Ma’Aram, A.; Shaharoun, A.M. Identifying sustainable warehouse management system indicators and proposing new weighting method. J. Clean. Prod. 2020, 248, 119190. [Google Scholar] [CrossRef]

- De Marco, A.; Ruffa, S.; Mangano, G. Strategic factors affecting warehouse maintenance costs. J. Facil. Manag. 2010, 8, 104–113. [Google Scholar] [CrossRef]

- Vrat, P. Storage and Warehousing. In Materials Management: An Integrated Systems Approach; Texts in Business and Economics; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Abdul Rahman, N.S.F.; Karim, N.H.; Md Hanafiah, R.; Abdul Hamid, S.; Mohammed, A. Decision analysis of warehouse productivity performance indicators to enhance logistics operational efficiency. Int. J. Prod. Perform. Manag. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Ribino, P.; Cossentino, M.; Lodato, C.; Lopes, S. Agent-based simulation study for improving logistic warehouse performance. J. Simul. 2018, 12, 23–41. [Google Scholar] [CrossRef]

- Spisak, C.; Morgan, L.; Eichler, R.; Rosen, J.; Serumaga, B.; Wang, A. Results-Based Financing in Mozambique’s Central Medical Store: A Review After 1 Year. Glob. Health Sci. Pract. 2016, 4, 165–177. [Google Scholar] [CrossRef]

- Arvis, J.-F.; Raballand, G.; Marteau, J.-F. The Cost of Being Landlocked: Logistics Costs and Supply Chain Reliability; World Bank: Washington, DC, USA, 2010; Available online: https://openknowledge.worldbank.org/handle/10986/2489 (accessed on 20 January 2022).

- FDRE. Updated Nationally Determined Contribution. Environment, Forest, and Climate Change Commission of the Federal Democratic Republic of Ethiopia: Ethiopia. 2021. Available online: https://unfccc.int/sites/default/files/NDC/2022-06/Ethiopia%27s%20updated%20NDC%20JULY%202021%20Submission_.pdf: (accessed on 15 February 2022).

- Nath, P.K.; Behera, B. A critical review of impact of and adaptation to climate change in developed and developing economies. Environ. Dev. Sustain. 2011, 13, 141–162. [Google Scholar] [CrossRef]

- Ansah, R.K.; Obiri-Yeboah, K.; Akipelu, G. Improving the freight transport of a developing economy: A case of Boankra inland port. J. Shipp. Trade 2020, 5, 10. [Google Scholar] [CrossRef]

- Ngugi, E.N.; Kimutai, G.; Kibet, Y. Effects of inventory management systems on performance of manufacturing companies in Eldoret town, Kenya. J. Bus. Change Manag. 2019, 6, 1431–1445. [Google Scholar]

- UNECE. Recommendation and Guidelines on Establishing a Single Window to Enhance the Effiient Exchange of Information between Trade and Government: Recommendation No. 33; United Nations: New York, NY, USA; Geneva, Switzerland, 2005. [Google Scholar]

- FDRE. Digital Ethiopia 2025: A Digital Strategy for Ethiopia Inclusive Prosperity. 2020. Available online: https://www.pmo.gov.et/media/other/b2329861-f9d7-4c4b-9f05-d5bc2c8b33b6.pdf (accessed on 26 November 2021).

- Kine, H.Z.; Gebresenbet, G.; Tavasszy, L.; Ljungberg, D. Digitalization and Automation in Intermodal Freight Transport and Their Potential Application for Low-Income Countries. Future Transp. 2022, 2, 41–54. [Google Scholar] [CrossRef]

- Behrends, V.; Haunschild, M.; Galonske, N. Smart Telematics Enabling Efficient Rail Transport—Development of the ViWaS Research and Development Project. Transp. Res. Procedia 2016, 14, 4430–4439. [Google Scholar] [CrossRef][Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).