1. Introduction

Since entering the 21st century, China’s municipal solid waste output has always been maintained at 100 million tons and presented an increasing trend year by year. The Chinese government introduced several regulations about waste classification (

http://www.gov.cn/zhengce/content/2017-03/30/content_5182124.htm (accessed on 15 June 2022)) to protect the environment and save resources. By November 2019, there had been 237 prefecture-level cities in China that began to classify waste, among which Shanghai took the lead in implementing the compulsory waste classification policy [

1] and classified the solid waste into wet waste, dry waste, recyclable waste, and hazardous waste [

2].

According to the field investigation, the waste collection in Shanghai is mainly undertaken by local sanitation companies in various districts. At the beginning, many wet waste trucks were converted from dry waste ones, inevitably bringing on an adverse impact to the environment, such as exuding unpleasant gas, spreading diseases in high-temperature weather, and causing a leakage problem during transportation [

3]. Moreover, implementing classified collection requires more human resources, whereas the personnel of the company does not increase on a large scale. Thus, the existing employees need to take on heavier tasks than before. The employees’ satisfaction will directly influence their motivation to work [

4], so balancing the workload of employees has become one of the urgent problems to be solved.

With consideration of the above environmental and workload balancing issues, this paper constructs a vehicle routing optimization model for waste collection and transportation, so as to provide some guidance and suggestions for the practical decision making. To the best of our knowledge, there are relatively few studies that consider both waste leakage and workload balance among employees under the premise of considering the economy. Therefore, it is necessary to conduct more in-depth research for this problem. In addition, China needs to deal with a large amount of domestic waste every year, and the collection and transportation costs account for more than half of the total cost. Therefore, optimizing the vehicle route and personnel allocation of the waste collection system can improve the recycling and utilization efficiency of waste resources, which is of great significance for the construction of resource-saving and environment-friendly cities.

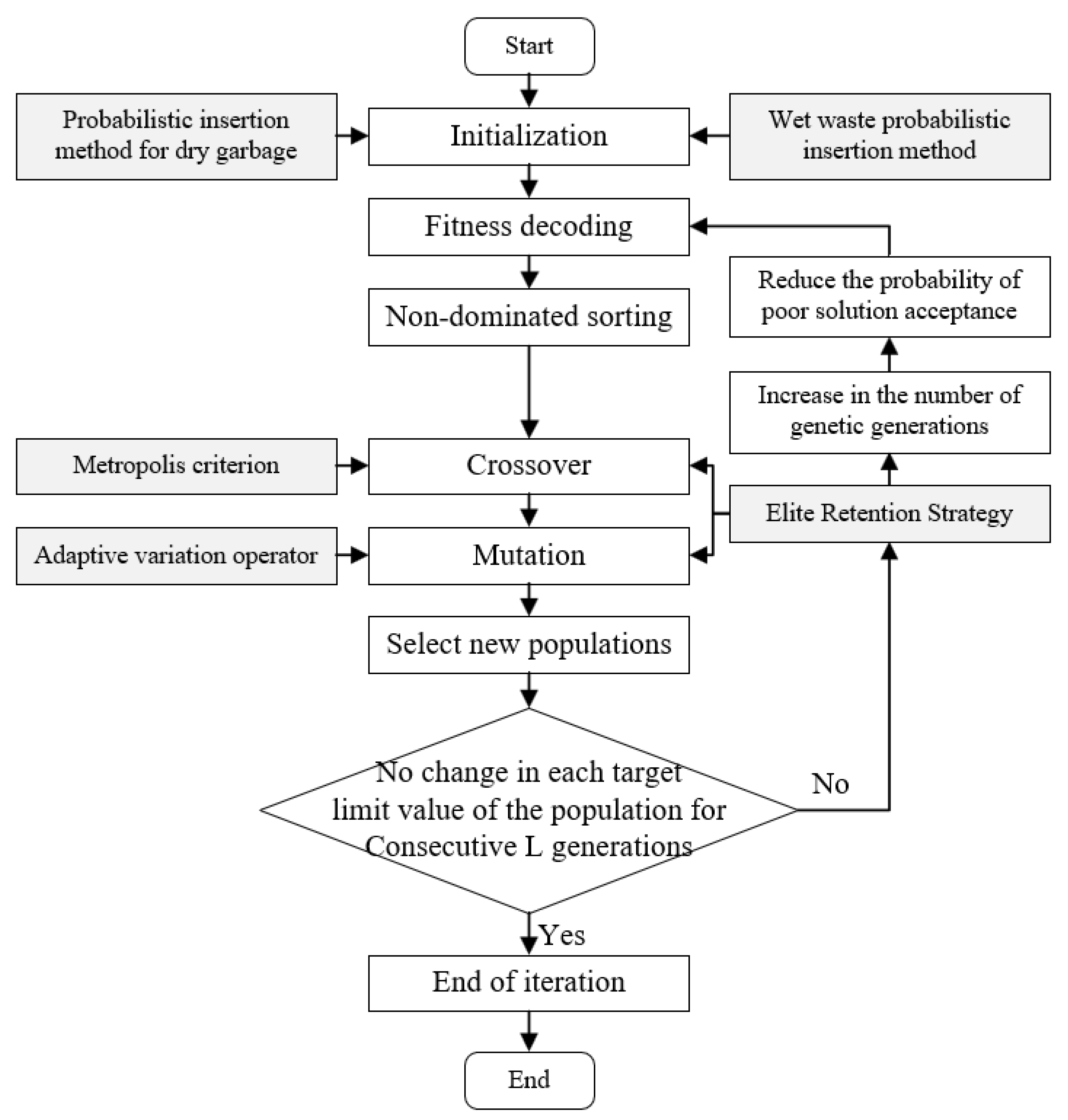

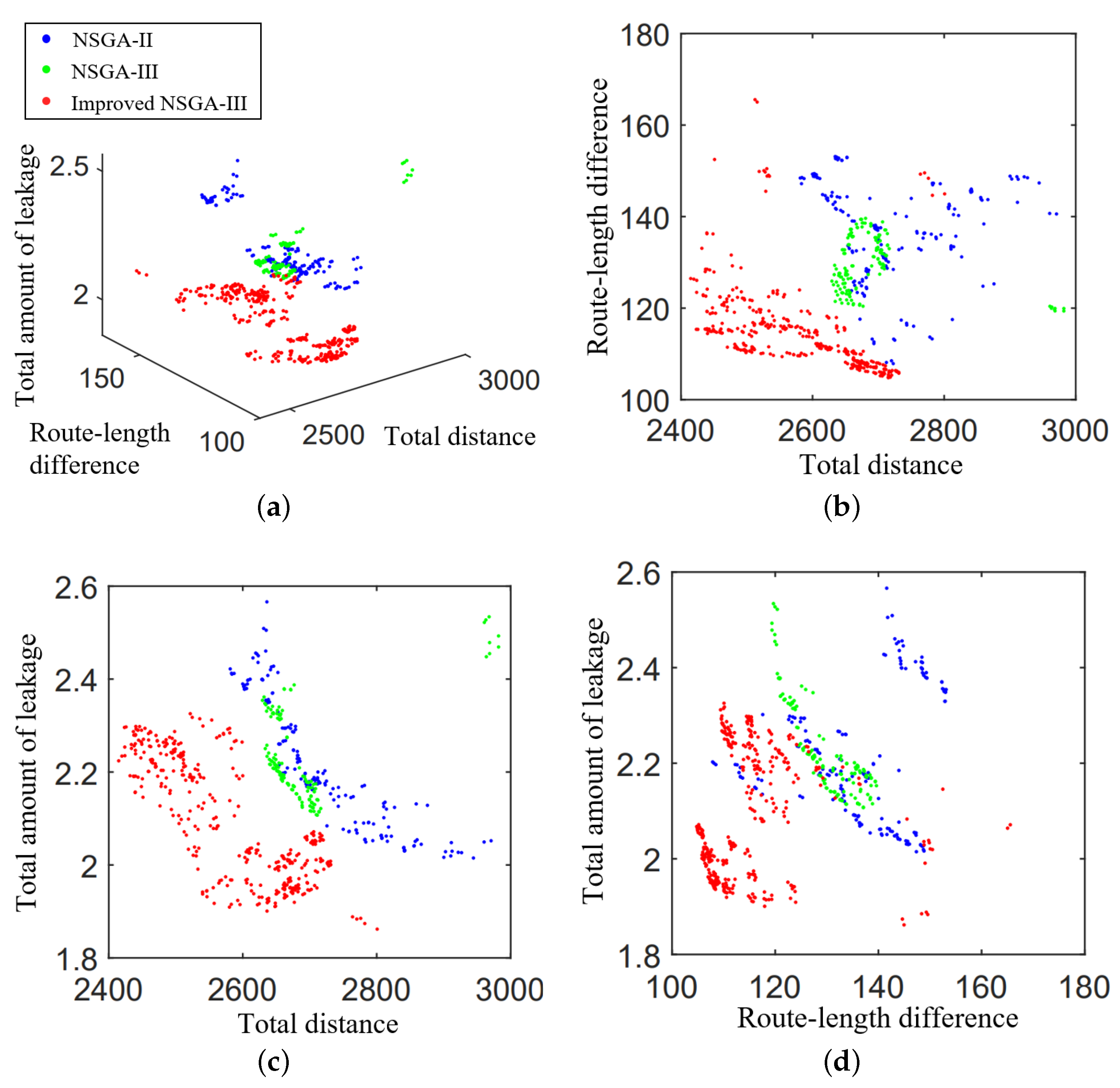

The contributions of this research are as follows: First, from the perspective of practice, taking into account the three factors of sustainable development, the multi-objective vehicle routing optimization model for collecting two kinds of waste is constructed. Second, combining the non-dominated sorting genetic algorithm III (NSGA-III) with the probabilistic insertion method, the Metropolis criterion of the simulated annealing algorithm, and the adaptive mutation operator, an effective improved NSGA-III algorithm is designed. Third, the real case of waste collection in the Xuhui District of Shanghai is carried out, and some management insights are given to propose a comprehensive waste collection program, which can ensure a certain market share and enhance the core competitiveness of the sanitation company.

The remainder of this paper is organized as follows.

Section 2 reviews the research related to the vehicle routing problem (VRP) with route balancing and reverse logistics.

Section 3 presents the mathematical model of the VRP for classified waste collection.

Section 4 specifies the improved NASG-III algorithm.

Section 5 compares the performance of the proposed algorithm with the non-dominated sorting genetic algorithm II (NSGA-II) and the classic NSGA-III.

Section 6 studies the case of Xuhui, Shanghai, and provides some management insights.

Section 7 gives the conclusion and future research direction.

3. Problem Formulation

3.1. Problem Description

The waste classification policy by the Shanghai Municipal Government requires dry and wet wastes to be collected separately, and the sanitation companies face a daunting challenge with purchasing new vehicles, adjusting staff scheduling, the reformulation of routes, and a host of other issues that need to be reconsidered.

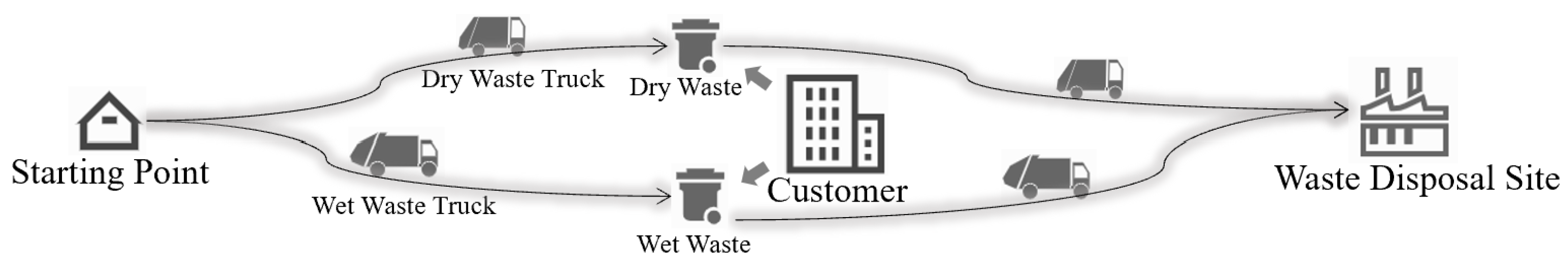

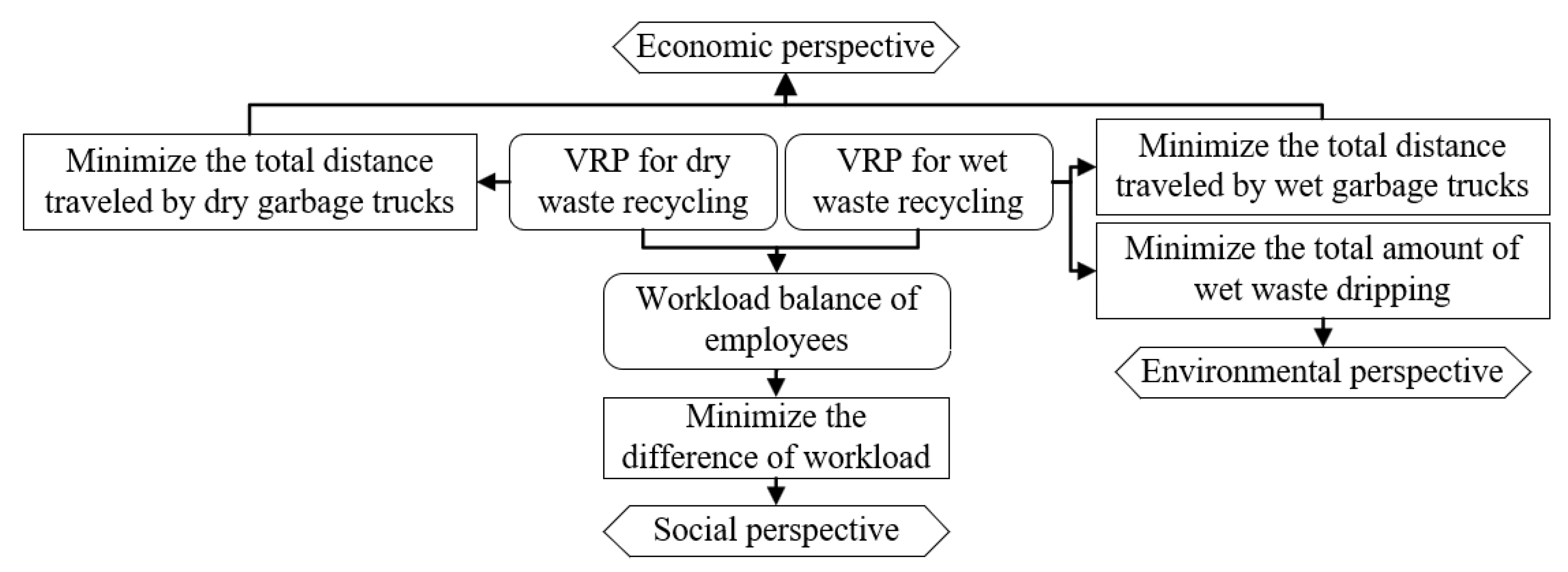

This paper investigates the problem of routing optimization and collection of dry and wet waste, which is considered in an integrated manner from the three pillars of sustainable development, first discussing the two types of products separately from the economic and environmental aspects and integrating the transportation problems of the two types of products from the social aspect. From an economic point of view, the objective of minimizing the collection routes of dry and wet waste is considered. In addition, from an environmental point of view, the objective of minimizing the leakage of wet waste is considered. Finally, from the social perspective, the workload balance between employees handling different types of waste is considered. The transportation process is shown in

Figure 1, and its model description diagram is shown in

Figure 2.

In this scenario, the waste trucks depart from the starting point and arrive at the waste disposal site after passing a number of customers in a day, and each customer needs to be served once by a dry and a wet waste truck. The journey of a truck from the starting point to the waste disposal site is taken as a route, and there is no limit to the number of routes traveled by each truck per day. Through the optimal combination of different routes, the effective allocation of vehicle resources is achieved while reducing the amount of leakage. In addition, it is necessary to consider the workload balance between employees with different work, and this paper analyzes the length of the routes to derive the optimization of the employee’s efficiency.

3.2. Assumptions and Indices

This paper abstracts and simplifies certain mathematical problems, among which the specific assumptions are as follows:

Assumption 1. The locations of the starting point, customer, and waste disposal site are known, and there is only one starting point and one waste disposal site.

Assumption 2. The dry and wet wastes are, respectively, transported by a fleet of fixed-size waste trucks, and the two types of vehicles are sufficient and there is no shortage problem.

Assumption 3. The employees collecting dry and wet wastes are independent, and there is a fixed upper limit for the employees’ daily working hours.

Assumption 4. As long as the workload does not exceed the upper limit, the trucks can return to the starting point and start again after reaching the waste disposal site.

Assumption 5. An employee works with only one truck on a single day, and the employee’s workload can be measured by the route length of the truck.

Assumption 6. Wet waste may leak, and the degree of leakage is related to the leakage probability, amount of waste carried, and travel distance.

The sets, parameters, and decision variables are defined as in

Table 2.

Based on the above problem description and assumptions, we need to construct the intermediate variables measuring the length of each route and workload of each employee, so as to facilitate the subsequent analysis and construction of the objective function.

From the starting point, the total distance contains the distances of both wet and dry waste trucks. The expressions for each vehicle’s travel distance is as follows:

where

is the distance between

i and

j,

is the distance traveled by vehicle

k.

According to Assumption 5, an employee follows only one truck throughout the day, and the workload of the employee can be measured by the running time of the truck. The expression is as follows:

where

is the total length of the route traveled by vehicle

k.

According to Assumption 6, the current load weight of the vehicle as it passes through each vertex needs to be considered for calculating the degree of leakage. The amount of wet waste when the vehicle passes through point

i is

where

denotes the amount of wet waste at point

j. Adding up the amount of wet waste at all eligible points is the current load of the wet waste truck when it reaches point

i.

3.3. Mathematical Model

Based on the above problem description, this paper considers the separate collection and transportation process of dry and wet wastes; proposes the three objectives of minimizing the total distance, balancing the workload, and minimizing the total amount of leakage from the economic, social, and environmental perspectives; and proposes the constraints in terms of vehicle transportation route selection, the employee working time, and vehicle load. The mathematical model is expressed as follows:

Subject to

Equation (

4) is to minimize the total travel distance; Equation (

5) is to balance the workload of employees, minimizing the maximum distance difference between the vehicles driven by the employees responsible for the two types of waste in a day; and Equation (

6) is to minimize the total leakage, which is related to the amount of wet waste carried and length of the route.

Equations (

7)–(

10) are constraints on the vehicle route, Equation (

11) is the capacity constraint, and Equation (

12) limits the maximal working hour an employee can work in a single day. Equations (

13)–(

16) state the interconnections and constraints between decision variables.

The model constructed in this paper is a multi-objective 0–1 integer nonlinear programming, and the commonly used software, such as CPLEX, cannot directly solve it. Additionally, in practical waste collection problems, the number of customer points are relatively huge in size, which will increase the dimensionality and constraints of the decision variables and the computational complexity, and the traditional algorithms, such as branch-and-bound and cut-plane, are not suitable for solving such large-scale problems. Therefore, a multi-objective evolutionary algorithm needs to be designed for solving the problem.

6. Case Study of Shanghai City

In this section, the improved NSGA-III is applied to solve and analyze the real case of the Xujiahui subdistrict in the Xuhui District, Shanghai. The data are preprocessed first, and the final solution is selected from the resulting Pareto solution set. Then, the route before and after waste classification are compared, and the parameters sensitivity analyses of the maximum working hour, vehicle load capacity, and weight of waste are conducted. Finally, the management insights are given to ensure that the company has a high level of competition.

6.1. Background Description

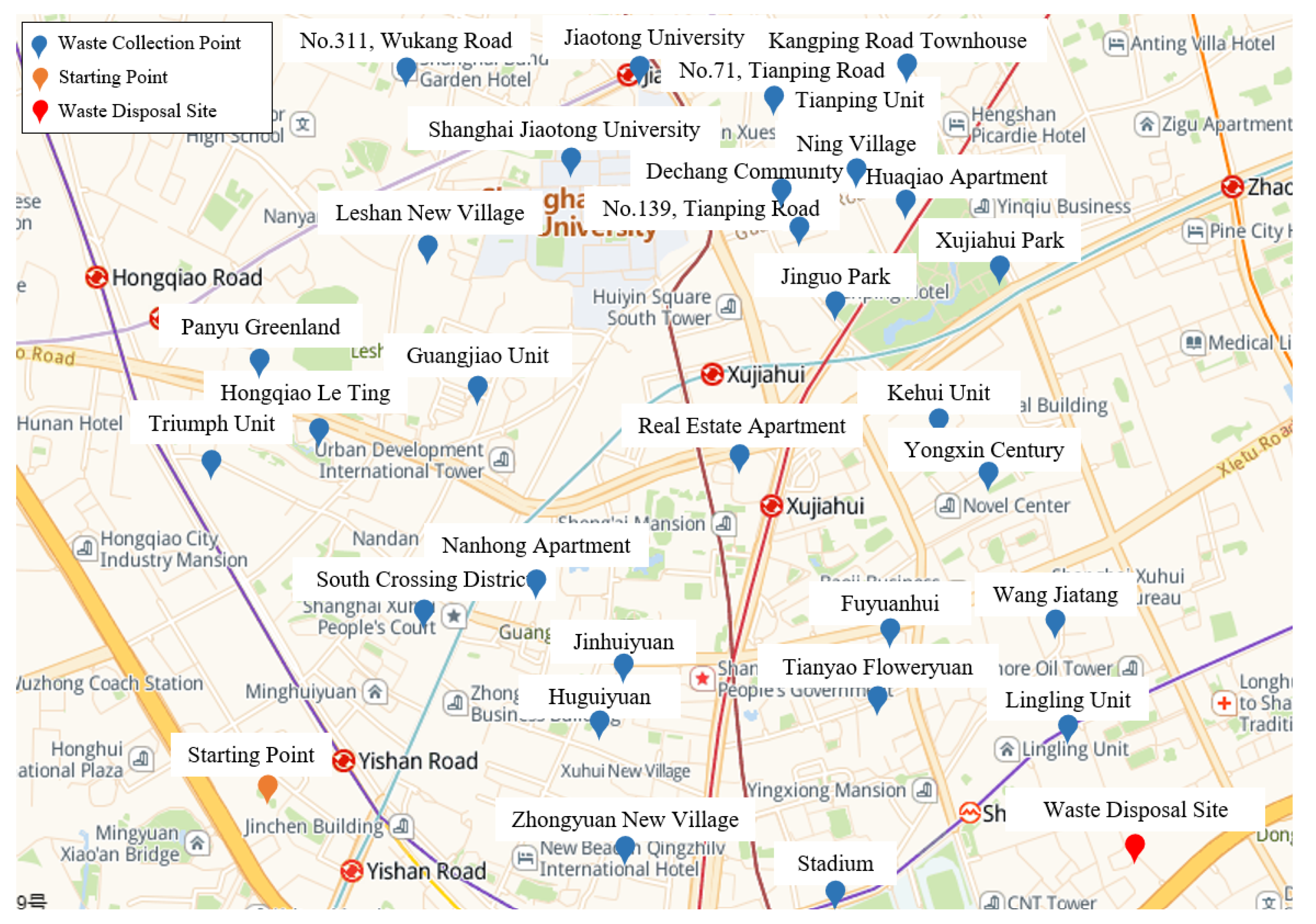

Xujiahui Street is a subdistrict located in the central and western part of the Xuhui District. There are currently 248 customer points in this area, and some of them are close to each other. Hence, the gravity method is utilized to merge the adjacent customer points into a collection point, and a set of 30 barycenters with their coordinates are obtained. The geographic locations of the collection points, starting point, and waste disposal site are shown in

Figure 6. Three sanitation companies are responsible for collection in this area, and there are a total of 128 dry waste trucks with a load capacity of 5 tons and 50 wet waste trucks with a capacity of 3 tons.

Assume that the maximum working hour of employees is 8 h, and the average speed of the trucks is 50 km per hour. Then, we apply the proposed model and algorithm to find the Pareto set and select the optimal solution, comparing the differences between the results before and after waste classification.

6.2. Optimal Solution Selection

Before the specific routing optimization, the distances between each two points are calculated according to Equation (

19),

where

km is the radius of the earth, and

are the latitude and longitude coordinates of points 1 and 2.

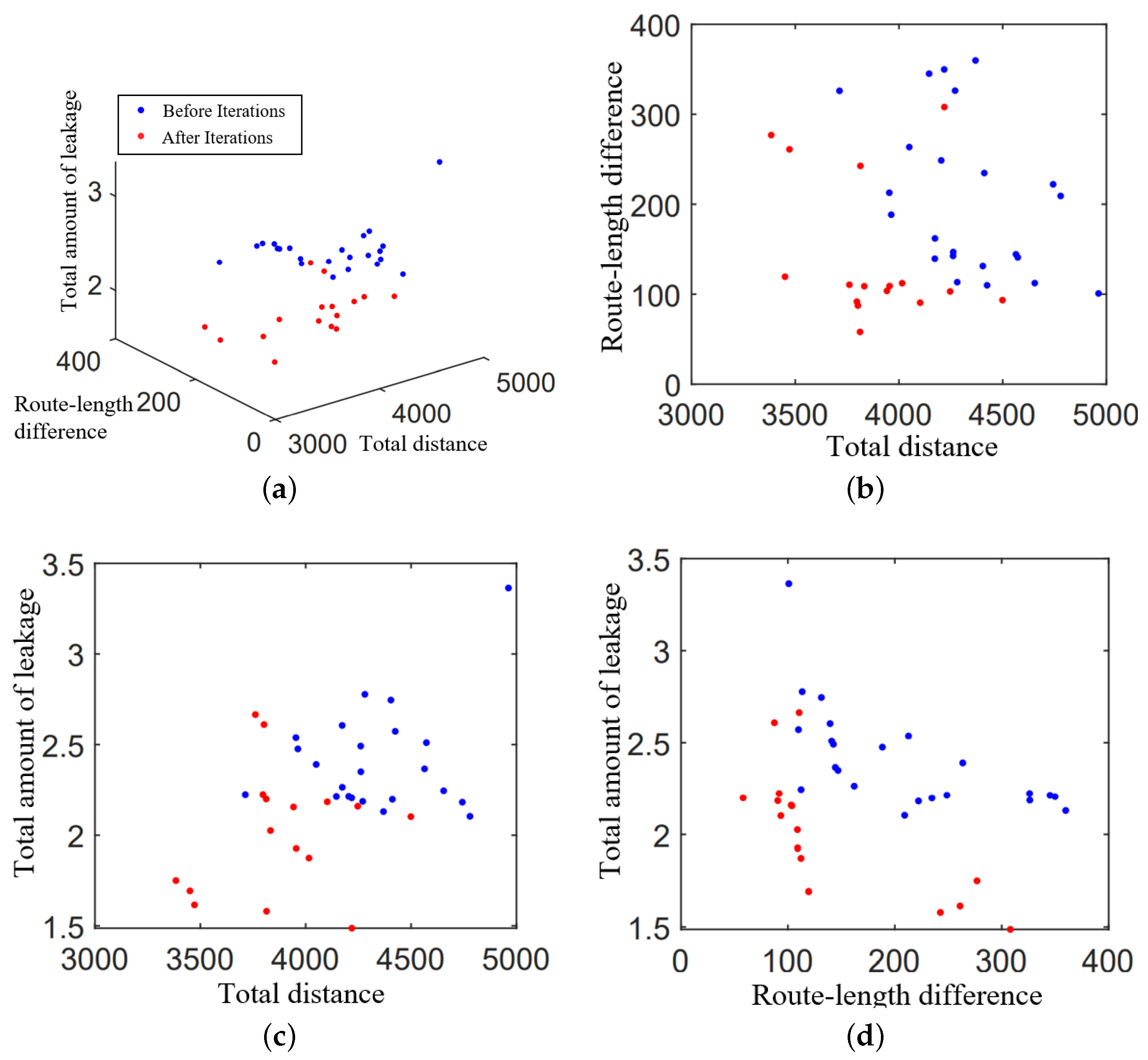

In the process of solving with the improved NSGA-III, the initial and final Pareto sets can be obtained, and the spatial distribution and two-dimensional projections are shown in

Figure 7, where the blue and red dots represent the Pareto sets before and after the iterations, respectively.

The comparison shows that in terms of the total amount of leakage, the quality of the final solutions are mostly significantly better than that of the initial solutions. In terms of the route-length difference, the overall quality of the final Pareto set has improved significantly, with smaller values than at the initial one. A large improvement is also achieved in terms of the total distance, with only two of the optimal solutions taking closer values to the initial solution set. The above results further demonstrate that the iteration process can significantly improve the overall quality of the Pareto solution set.

After combining all the Pareto solutions in each generation, the final 127 Pareto optimal solutions are obtained, and the final collection routing scheme can be decided according to the decision maker’s preference.

As an economically prosperous area, the government of the Xuhui District is more concerned about the impact of waste collection on the environment than the economic cost and personnel balance of waste collection and hopes that the total amount of leakage in the transportation process will be as small as possible. Therefore, the decision maker can first sort the Pareto solution set and divide it into different intervals according to the total amount of leakage. Subsequently, assume that the decision maker attaches equal importance to the total distance and route-length difference and normalize the values of these two objective functions of each solution in the same interval. Then, add the sum of the three objective function values, as shown in

Table 8.

As we can see, among the 127 scenarios, the total amount of leakage ranges from 1.49 to 3.46 tons. According to the numerical results in

Table 5 and

Table 6, if the government’s allowed range for the total amount of leakage is 1.4–1.8 tons, then the optimal should be selected from the first interval, and Scheme 4 with the minimal normalized sum is the optimal option, of which the total distance and route-length difference are both significantly smaller than other schemes. If the allowable range is 1.8–2.0 tons, then Scheme 8 is the optimal solution, and if the allowable range is 3.0–3.5 tons, option 123 is the optimal solution.

Note that the solution in this paper only provides a reference for companies to select the optimal solution. If the company’s most important goal is not the total amount of leakage, or if the total distance and the route-length difference are not equally important, the method of selecting the optimal solution can be adjusted.

6.3. Comparison of Routing Optimization Results

This section compares the routing results of the changes for sanitation companies in terms of routes, personnel, and vehicles, before and after waste classification.

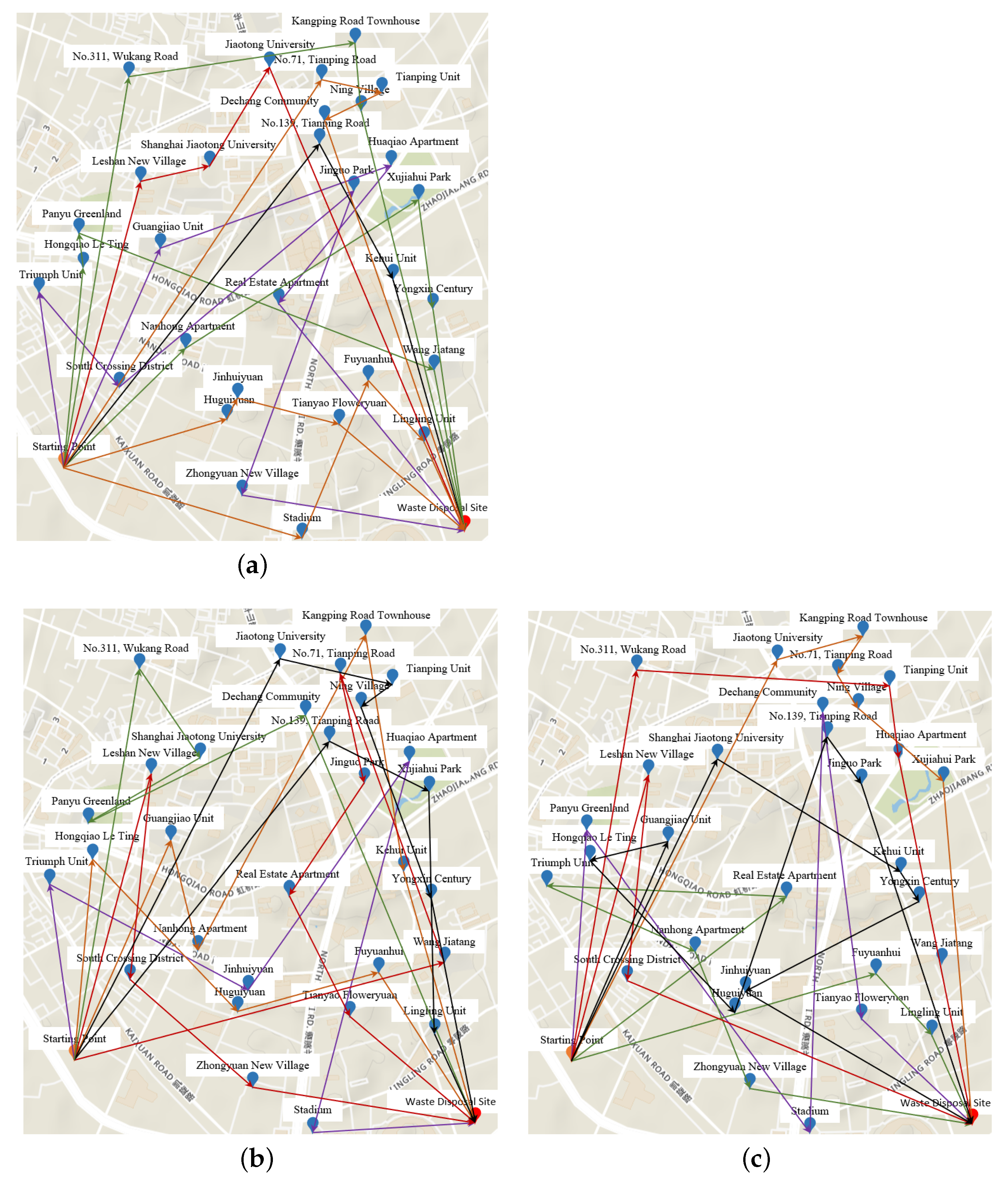

Figure 8 presents the routes before waste classification and the separate dry and wet waste collection routes after classification, where the lines in the same color represent the routes of the same vehicle. Before the waste classification, the weight of the waste at each point is the sum of the dry and wet wastes weight, and the load capacity of each vehicle is 5 tons. The solution that meets the load capacity and maximum working hour of employees with the smallest total distance is found in the routing arrangement, and the solution after the classification is Scheme 4 in

Table 8. To make the map readable, all routes from the waste disposal site back to the starting point are omitted here.

By comparison, it can be found that the route before the classification is a collection of some points close to each other because only the total distance and vehicle capacity are considered. However, because of the mixed loading of the dry and wet waste, the weight of the waste at each collection point is heavier; thus, the number of collection points on a single route is less than the number after the waste classification, and some points farther apart than others with less weight of waste appear in some routes. In contrast, the routes after the classification are results of the trade-off between multiple objectives, and thus the spatial distribution of points on the same route are more dispersed.

The comparative results of the optimal solutions before and after the classification are shown in

Table 9, from which we can see that before the classification, only economic factors are considered, and the total distance is 1803, nearly half less than that after the classification. By substituting 1803 into the objective function of workload balance, a route-length difference of 410 can be derived, which is far more than the result after the classification. Because of a more detailed division of labor among employees, the workload balance after classification was optimized by 276%.

In addition, with regard to manpower and material resources, only five employees and five trucks are needed for waste collection before the classification. After the classification, however, collecting dry and wet wastes requires 10 employees, 5 dry waste trucks, and 5 wet waste trucks, meaning that the company needs to purchase 5 wet waste trucks and recruit 5 new employees. Given that the cost of wet waste trucks is roughly 70,000 CNY each and the monthly salary of employees is about 5000 CNY, then the company’s operating cost doubles.

In order to analyze the influence of the route-length difference and total amount of leakage on the route selection, this section also considers three models with different objective functions, the results of which are shown in

Table 10.

As we can see, without considering social factors, Model 2 performs poorly in terms of the workload balance, which will cause a great injustice in real life and interfere with company operations. And if the environmental impact is not considered, Model 3 performs poorly in terms of the total amount of leakage, which can have a large impact on the environment and thus affect the company’s operations. For sanitation companies, the priority is not economic factors but social and environment factors, so the biggest advantage of Model 1 is that it starts from the actual situation and balances the operations from multiple aspects.

6.4. Sensitivity Analyses

Based on actual data, the sensitivity analyses of three parameters, maximum employee working time, vehicle load, and waste weight, are conducted in this section.

By plus or minus 10 and 20% of the initial setting of the maximum working hour of 8 h, we obtain five values between 6.4 and 9.6 h, and show its effect on the optimization routing scheme in

Figure 9. It can be seen that with the growth of the maximum working hour of employees, the route-length difference increases, yet the total distance and wet waste leakage change irregularly. The reason is that when arranging the driving routes, it is always desired that employees work as long as possible, but some employees will not be able to approach the maximum working hour limited to the vehicle load capacity and number of waste collection points. According to the results, the sanitation company should specify a reasonable maximum working hour for employees, ensure a relatively reasonable workload distribution, and give corresponding remuneration to the employees, so as to better motivate them.

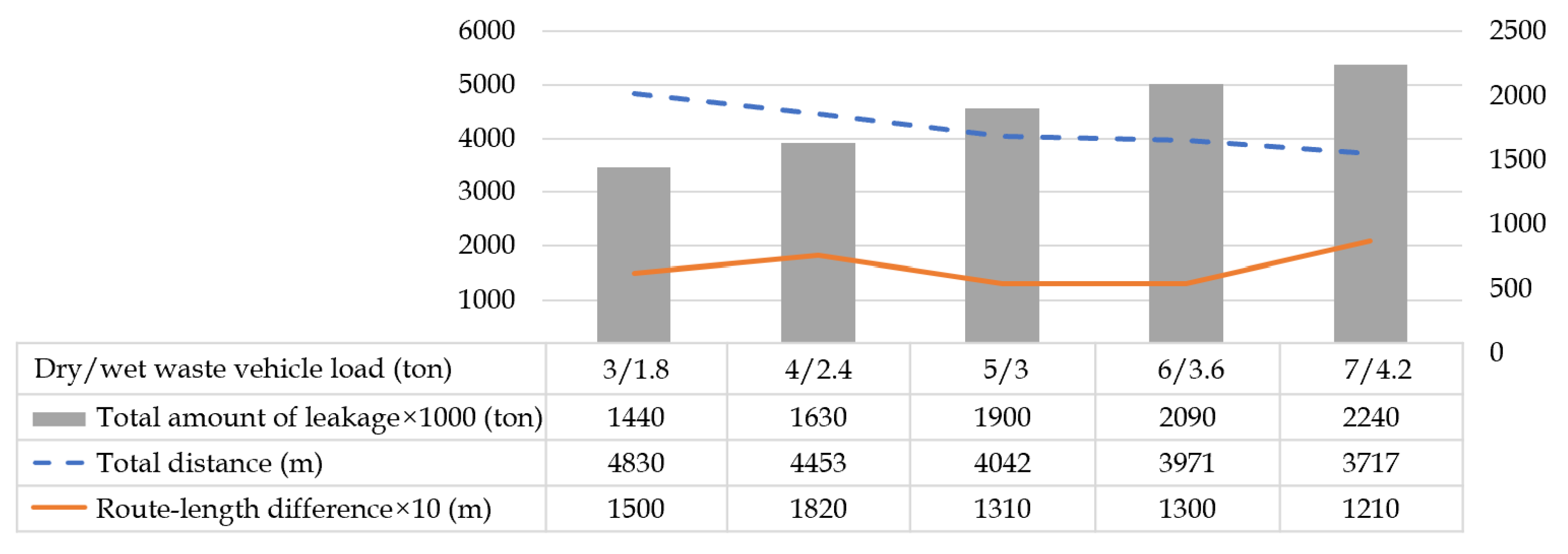

Figure 10 shows the effect of the maximum vehicle load capacity on the final optimization scheme, which is set to 5 and 3 tons initially. Here, the ratio of dry and wet waste load capacity is kept constant, and 3/1.8, 4/2.4, 5/3, 6/3.6, and 7/4.2 tons are selected for the sensitivity analyses. It can be seen that the total distance and wet waste leakage increases with the increase in vehicle load capacity, whereas the route-length difference is not significantly correlated. It may be because with the vehicle load capacity increases, one vehicle can travel to more waste collection points and accordingly reduce the total number of trucks going to and departing from the starting point and waste disposal site. In addition, the increase in leakage is caused by the increasing load during a single route and a smaller change in the distance traveled between points. Therefore, the sanitation companies can consider using some heavy-duty vehicles for transportation. At the same time, in order to protect the environment, they shall purchase wet waste trucks with stronger sealing properties.

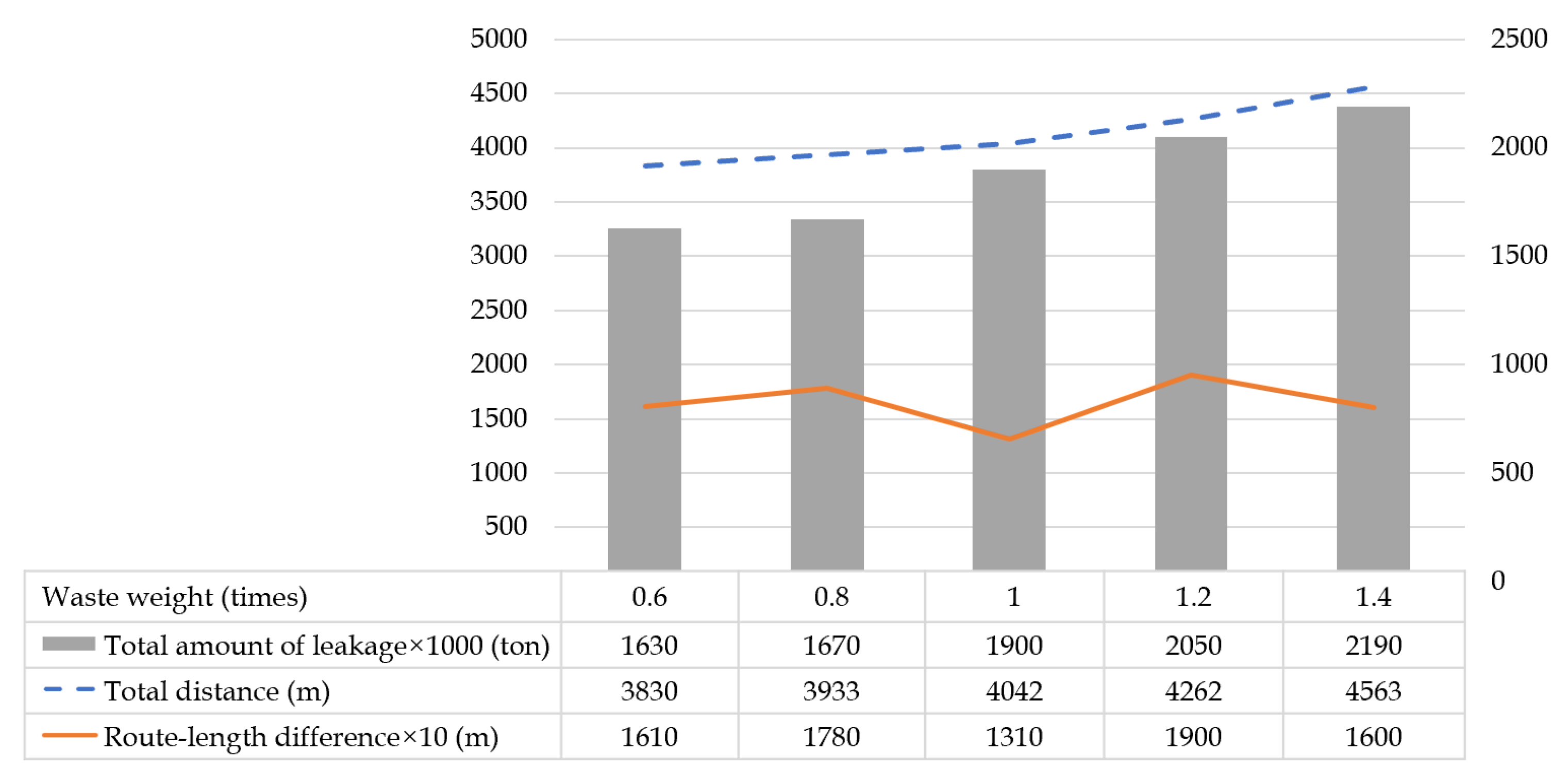

The influence of the waste weight on the routing scheme is shown in

Figure 11. For comparison, 0.6, 0.8, 1, 1.2, and 1.4 times of the initial weight of 1 are taken. As we can see, the total distance and total amount of leakage both increase with the waste weight, while there is no significant relationship between the difference in the route-length and the change in the waste weight. As the waste weight increases, the average load of the vehicle during transportation will rise, and accordingly, the vehicle will travel to less waste collection points on a single route due to the load limitation, resulting in a greater total distance. Both of these factors will increase the total amount of wet waste leakage. Henceforth, the sanitation companies should consider using vehicles with a larger load capacity and ensure that the total driving distance is as small as possible by rationally arranging vehicle routes.

We use the objective values as the dependent variable and perform a one-way ANOVA for each of the above three scenarios. The results show that the significance level p-values are 1, 0.999, and 0.992, respectively, all greater than 0.05, indicating that there is no significant difference between the results, which means the maximum working time, the waste vehicle load, and the waste weight will not affect the results.

6.5. Discussion and Management Insights

The results of the numerical analysis above show that the company’s actual transport routes change significantly after the waste classification, more waste collection points are served on a single route, and the distribution on the same route is more dispersed. The total distance nearly doubled after the classification, and most of the subsidies received by the company were used to purchase new vehicles. If there were not enough funds to recruit new employees, this would result in a significant increase in the number of hours worked by the employees and reduce their job satisfaction. Therefore, the company needs to take into account the change in the employee workload and solve the problem of employee satisfaction by increasing the salary performance or recruiting new employees.

From the comparison before and after the waste classification, we have found that the routes after the classification are more chaotic than before, because it is necessary to obtain a more suitable route scheme while keeping the total distance as small as possible and taking into account the route-length difference in employees and total amount of leakage. The company is balancing the workload of the wet and dry waste collection employees, because it is difficult to balance the route-length difference on a single day (from

Table 10, we can see that the average value of the employee-distance difference is 131 km, which is about 2.6 h of working-hour difference), the company can try to introduce a shift scheduling system, so that the employees can travel different routes every day and ensure a workload balance over a longer period.

The leakage coefficient in this paper is set to 0.0001, which is relatively small, but the leakage is still a considerable amount, which will aggravate the pressure of road cleaning along the transportation process in the long run. From a long-term perspective, companies should try to choose wet waste trucks with better enclosures and better treatment for leakage prevention, but perhaps at a higher unit cost, in order to reduce the risk of leakage in daily operations and help the sustainable development of the city.

In addition, although the employees responsible for dry and wet waste may have a closer driving time during transportation, the workload will be different when loading and unloading waste, and there is a significant difference in the feeling of waste handling because the smell of wet waste is heavier, which will make the employees more uncomfortable. Companies shall consider from the perspective of a performance system and rotate the employees of dry and wet wastes in a certain cycle, so as to improve the satisfaction as well as the work skills of the employees.

Apart from better servicing to the society, sanitation companies also need to compete with companies in the same industry, so in addition to considering from the perspective of route optimization, companies can also improve their competitiveness from the perspective of service. First, the company can try to refine the collection and transportation of the waste. Because the wet waste contains a large amount of liquid, it is easy to cause liquid leakage and produce odors when the weather is hot. The company can try to increase the frequency of wet waste collection and transportation at night in some areas on the basis of the comprehensive protection of collection and transportation, and effectively reduce the residence time of wet waste in residential areas. Second, the company can try to develop different cleaning programs according to local conditions and create various cleaning work modes, such as chain cleaning and three-dimensional cleaning, for each region. Third, the company can also make improvements in terms of waste trunks. From the company’s long-term planning, it is necessary to fully consider the damage caused by the increase in the weight of waste to the trunk, as well as the load capacity and sealing performance of the new trunk. In addition, the waste trunk can be modified to grasp the vehicle position, running trajectory, and load capacity in real time and connect with the street grid management platform to achieve data interoperability. Through the real-time sharing of information, the perfect docking between the waste trunk and the waste can is realized.

7. Conclusions

The implementation of a waste classification and collection policy plays a very important role in protecting the environment. In order to further promote the policy, Shanghai took the lead in adopting waste classification and collection. However, in the process of implementing the policy, there will undoubtedly be many problems. Environmental protection, employee mentality, and company interests are all factors that need to be considered. Based on the above background, this paper proposes a multi-objective VRP model of waste collection and transportation and an improved NSGA-III algorithm to solve this problem.

First, in this paper, the actual driving route is obtained with consideration of classified waste collection. Although this scheme will increase the driving cost, it can also ensure the workload balance among employees to a certain extent, thus improving the job satisfaction of employees. In addition, this paper considers the leakage of wet waste; the employee has to recycle the waste with as little leakage of wet waste as possible.

Second, in the process of designing the improved NSGA-III, the probabilistic insertion method is mainly used to generate the initial solution, and the effectiveness of the method is verified by comparing it with the greedy algorithm and the nearest insertion method. Then, the quality of the solution is improved by the probability acceptance operator of the simulated annealing algorithm, and the population diversity is further increased by the adaptive mutation operator.

In addition, in order to verify the solution efficiency of the proposed model and algorithm, numerical experiments are illustrated using Solomon datasets, and it can be seen from the experimental results that the algorithm outperforms the other algorithms in terms of the convergence speed and ideal values. In addition, this paper compares the routes before and after waste classification with the real case of the Xuhui District and performs a sensitivity analysis on the parameters so as to provide references for the actual operations of sanitation companies.

Although this paper provides a set of methods that can be used for reference by sanitation companies for waste collection and obtains some research results with theoretical and practical significance, there are still some limitations in this study. Firstly, all the input parameters considered in this paper are definite values, yet there may be uncertain factors in practice. Secondly, the limiting factors of customers’ time windows are not taken into account in this paper. In addition, we assume that there is only one distribution center, in the practical waste collection problem; however, this may be more complex with multiple starting points and waste disposal sites. In the future work, we will model fuzzy or uncertain programming to deal with the indeterminate factors in the transportation process. In addition, the customers can be divided into different areas and then we will derive a more realistic transportation route scheme.