Dynamic Mechanical Behaviors and Failure Mechanism of Lignite under SHPB Compression Test

Abstract

:1. Introduction

2. Methology

2.1. Sample Preparation

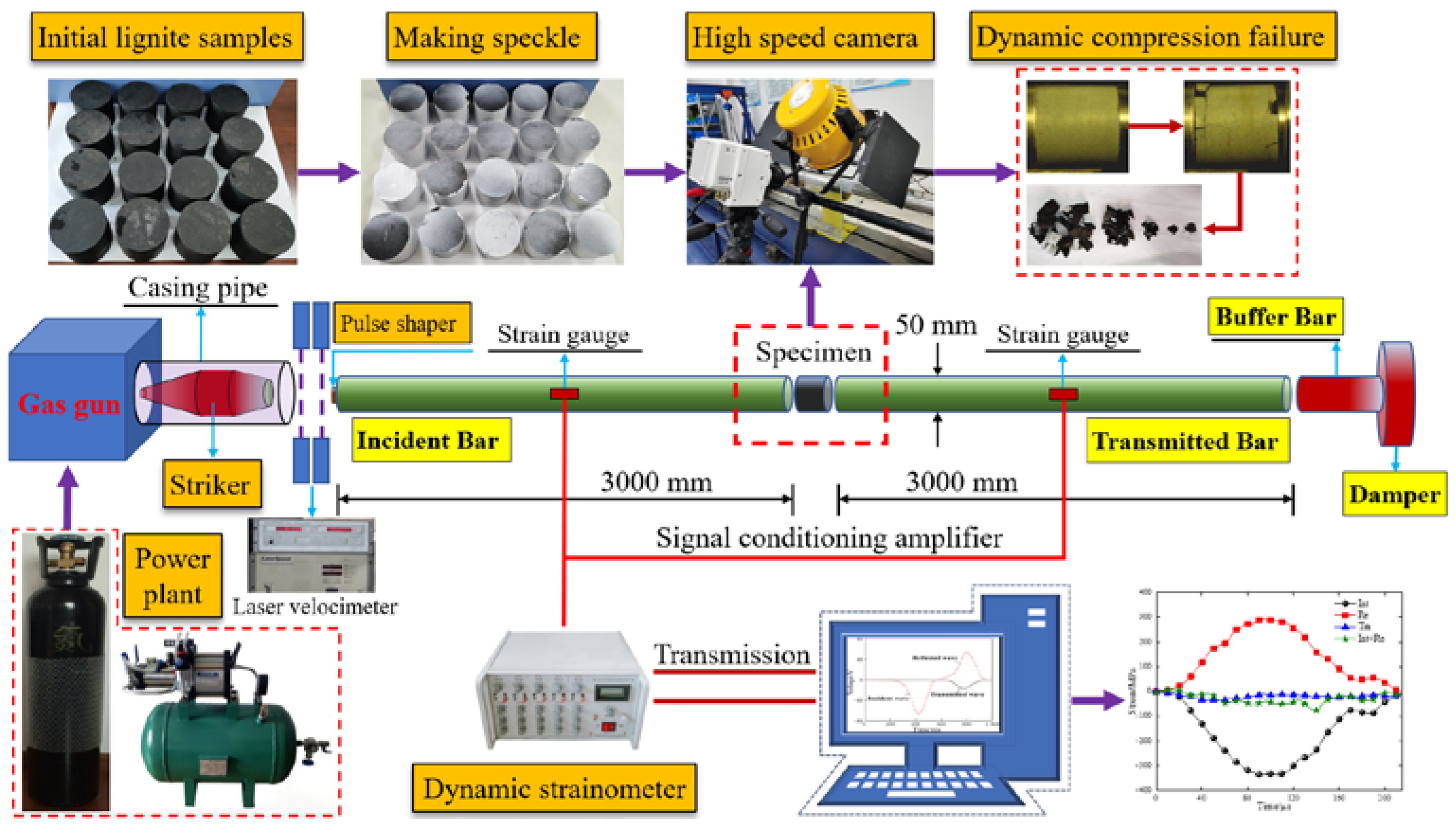

2.2. Test System

2.3. Test Method

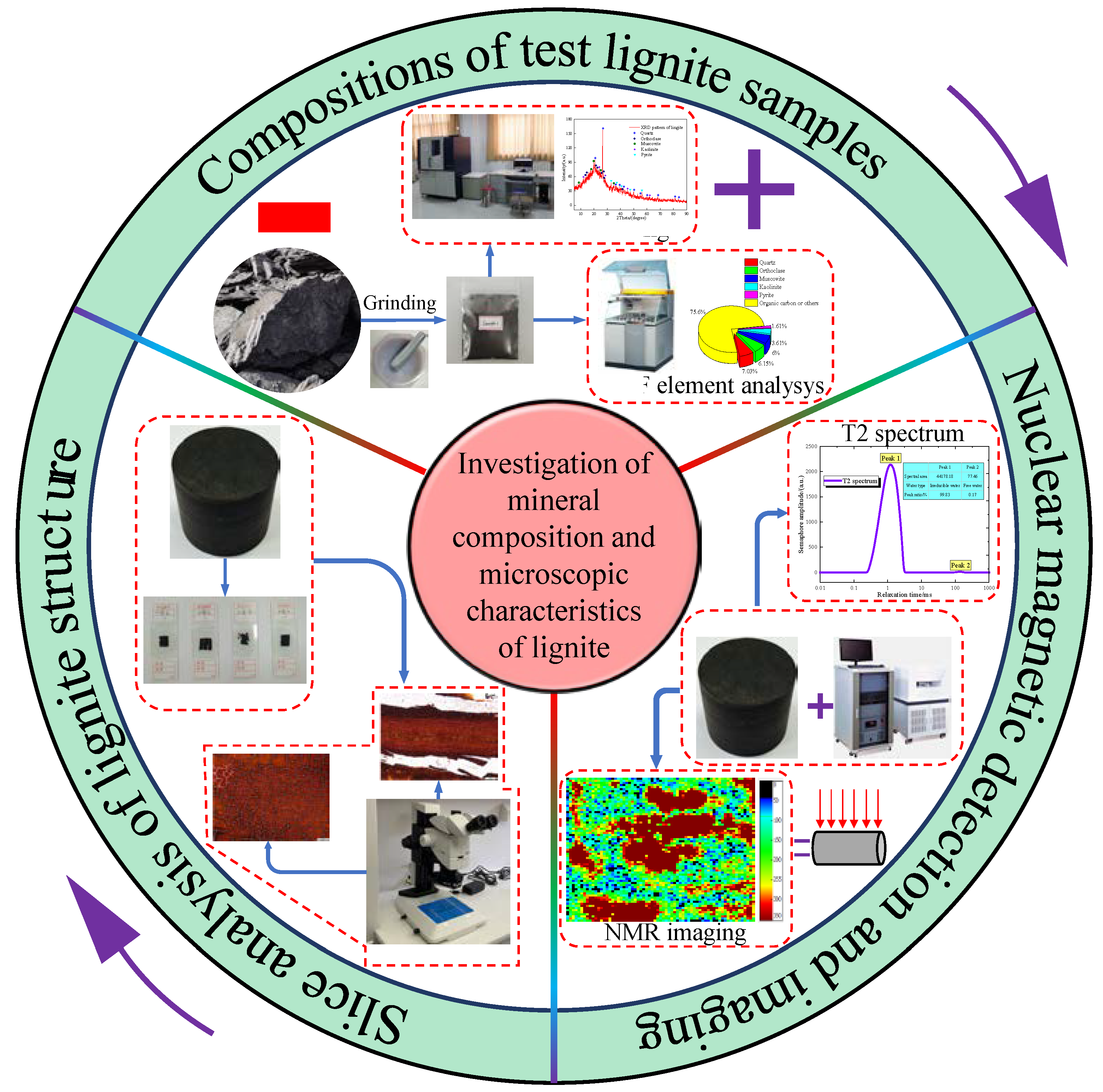

3. Composition and Microstructure

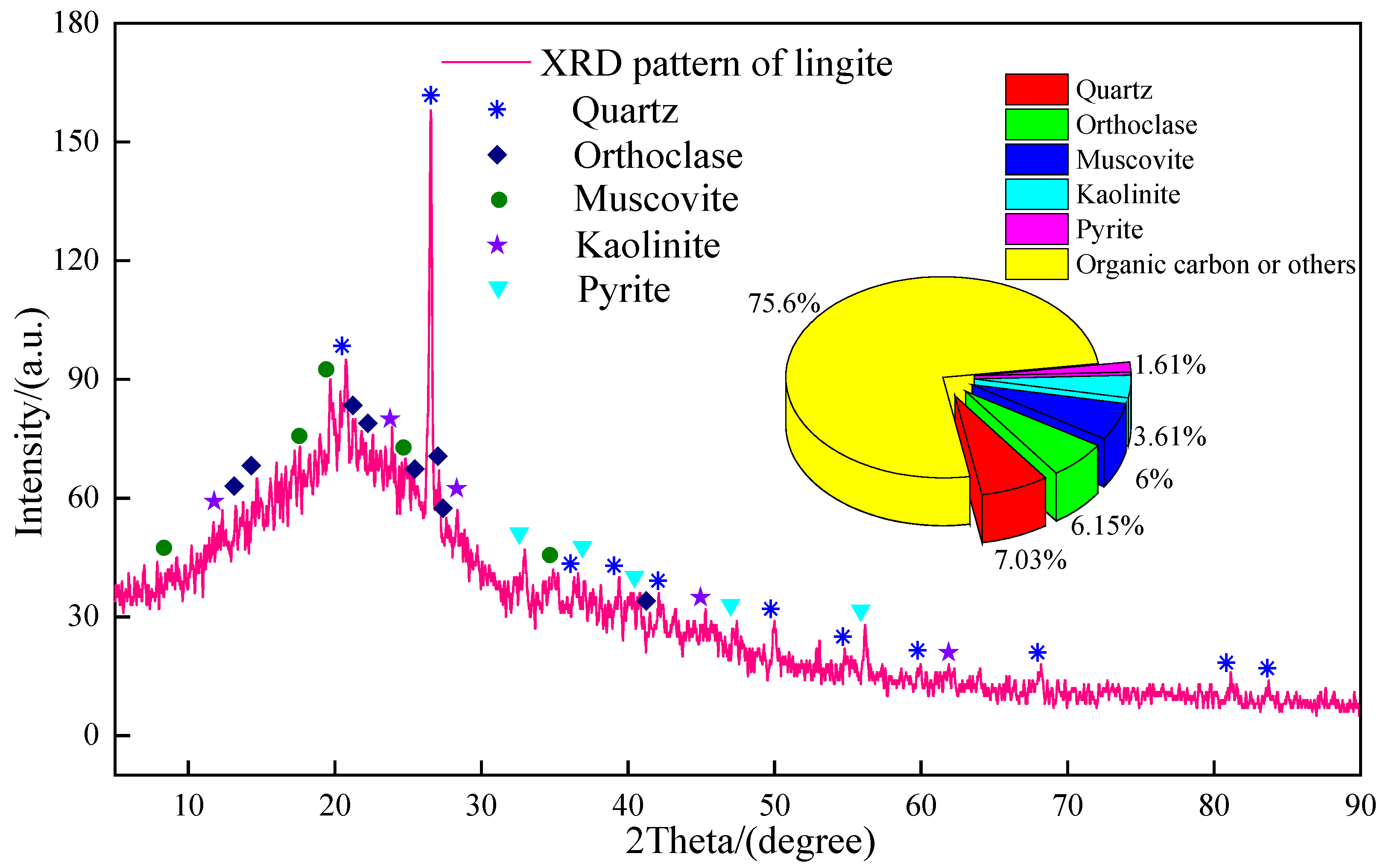

3.1. Composition

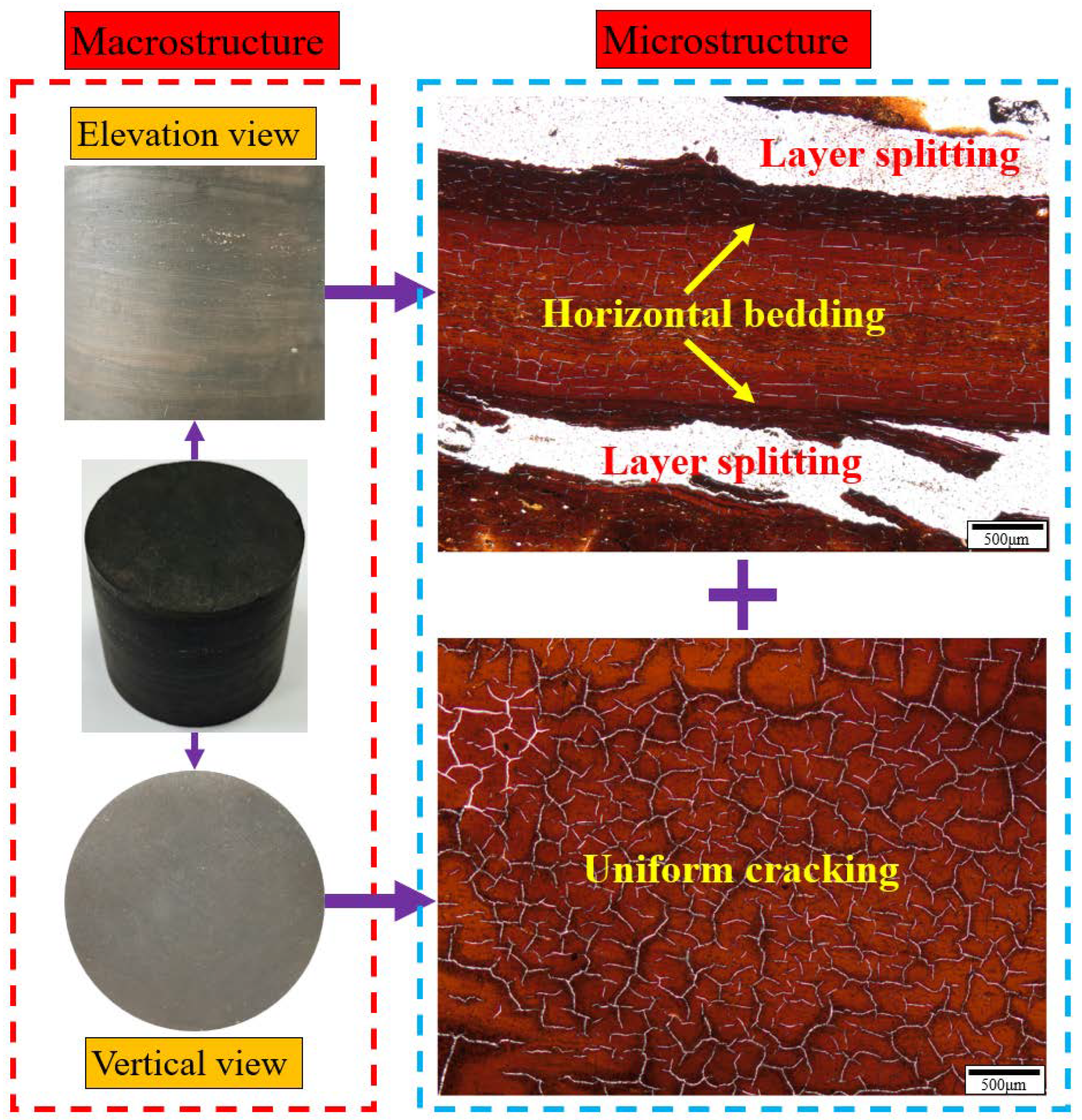

3.2. Thin Slice Analysis

3.3. NMR Analysis

4. Dynamic Mechanical Behaviors

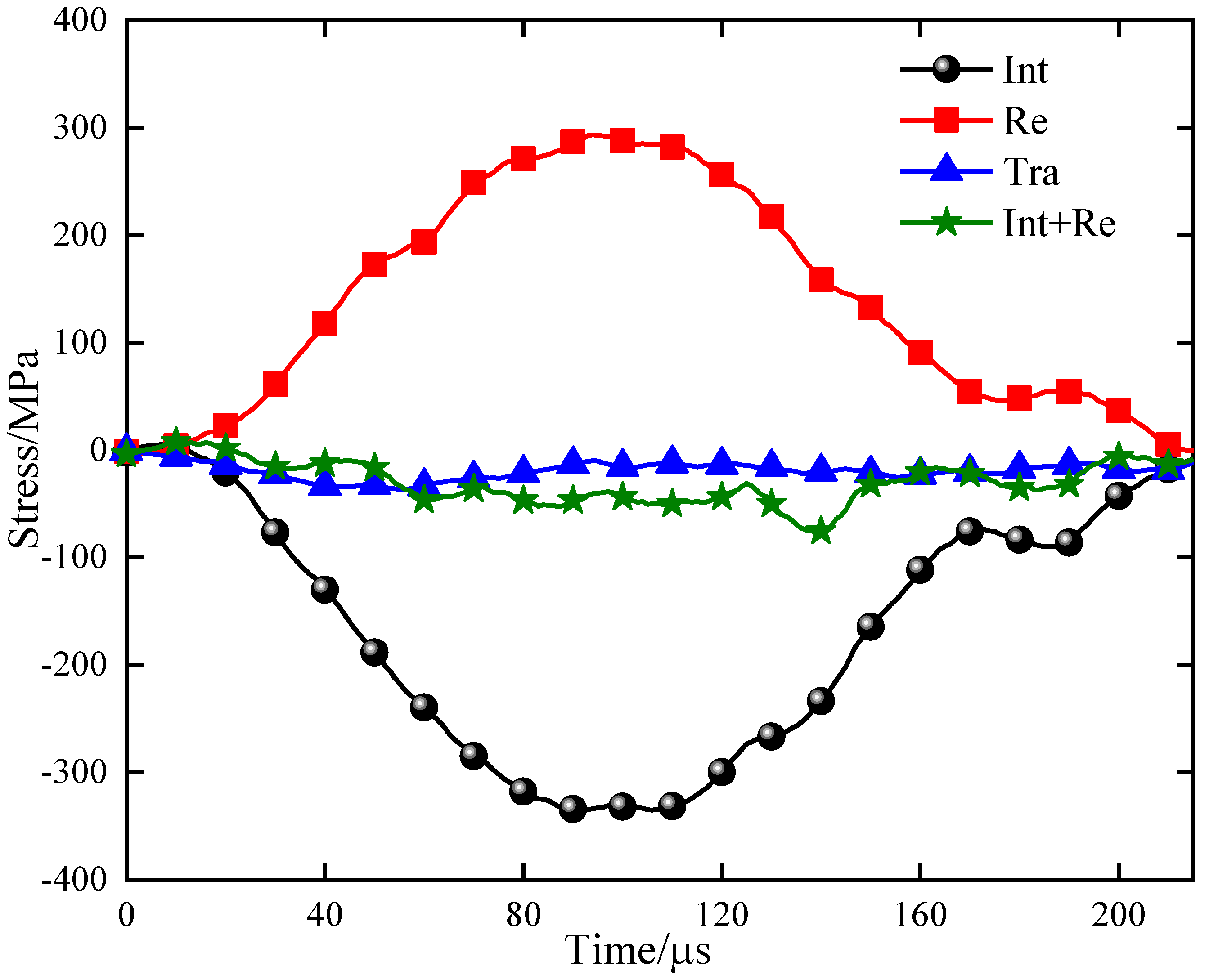

4.1. Calculation Criteria

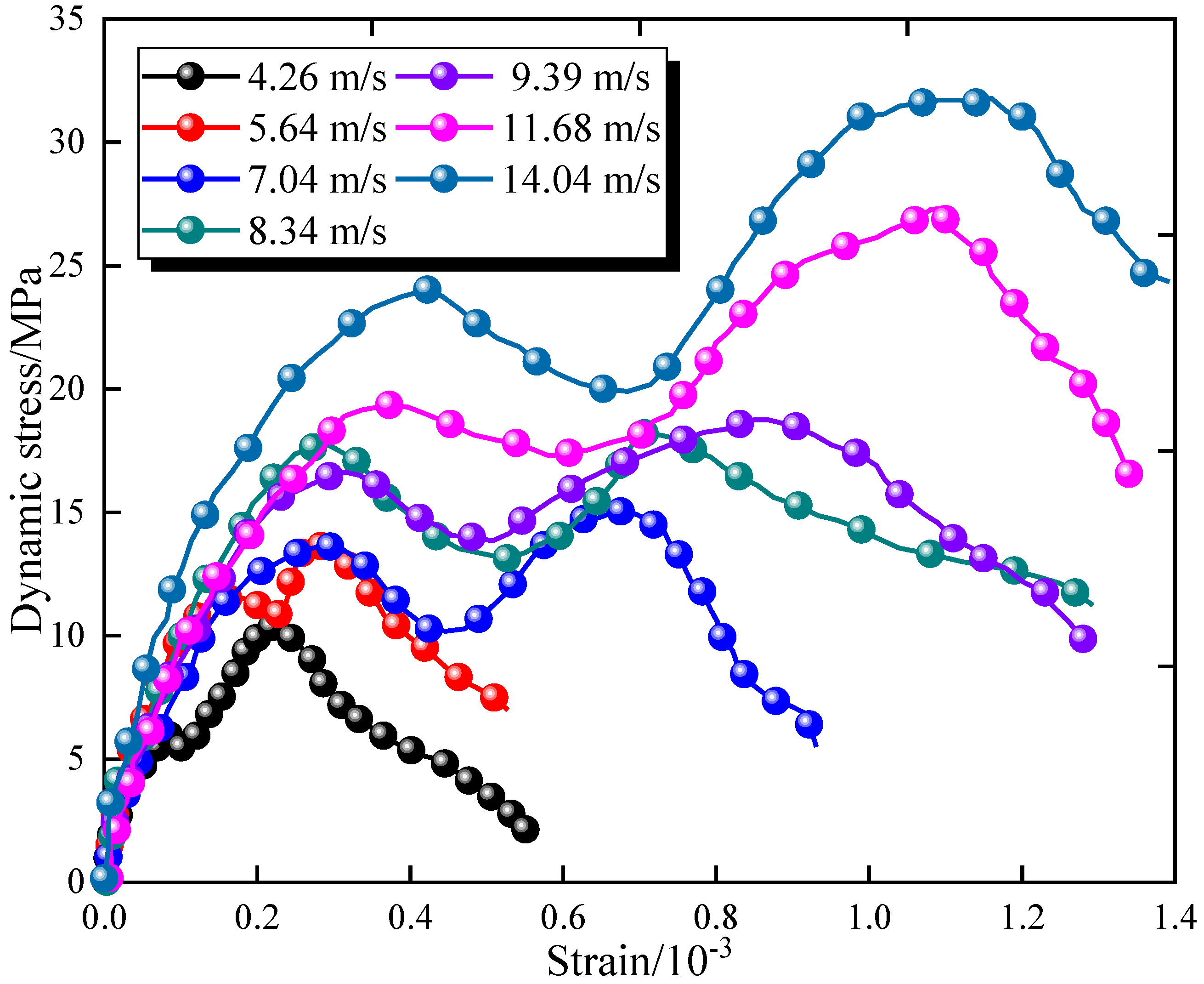

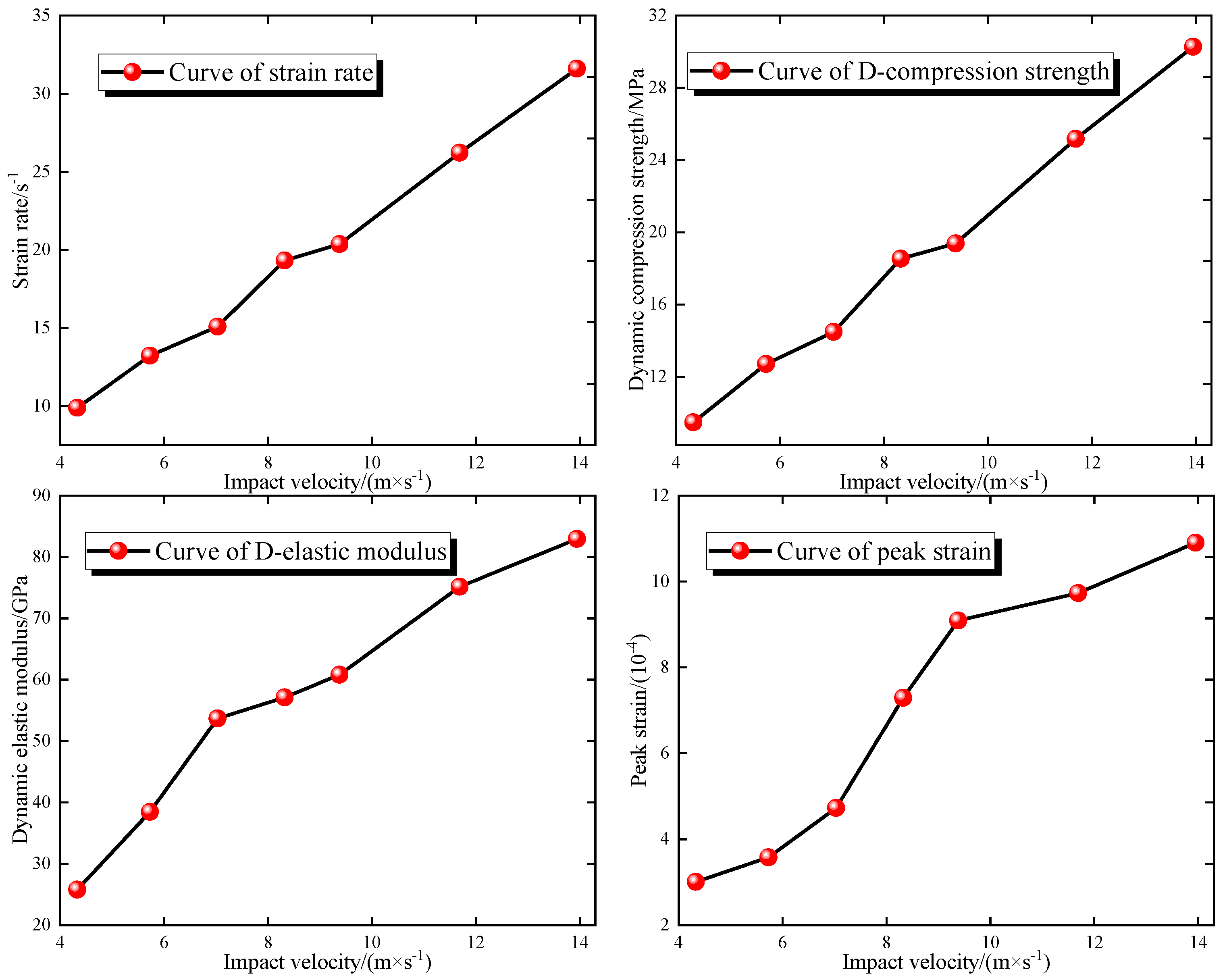

4.2. Dynamic Mechanical Parameters

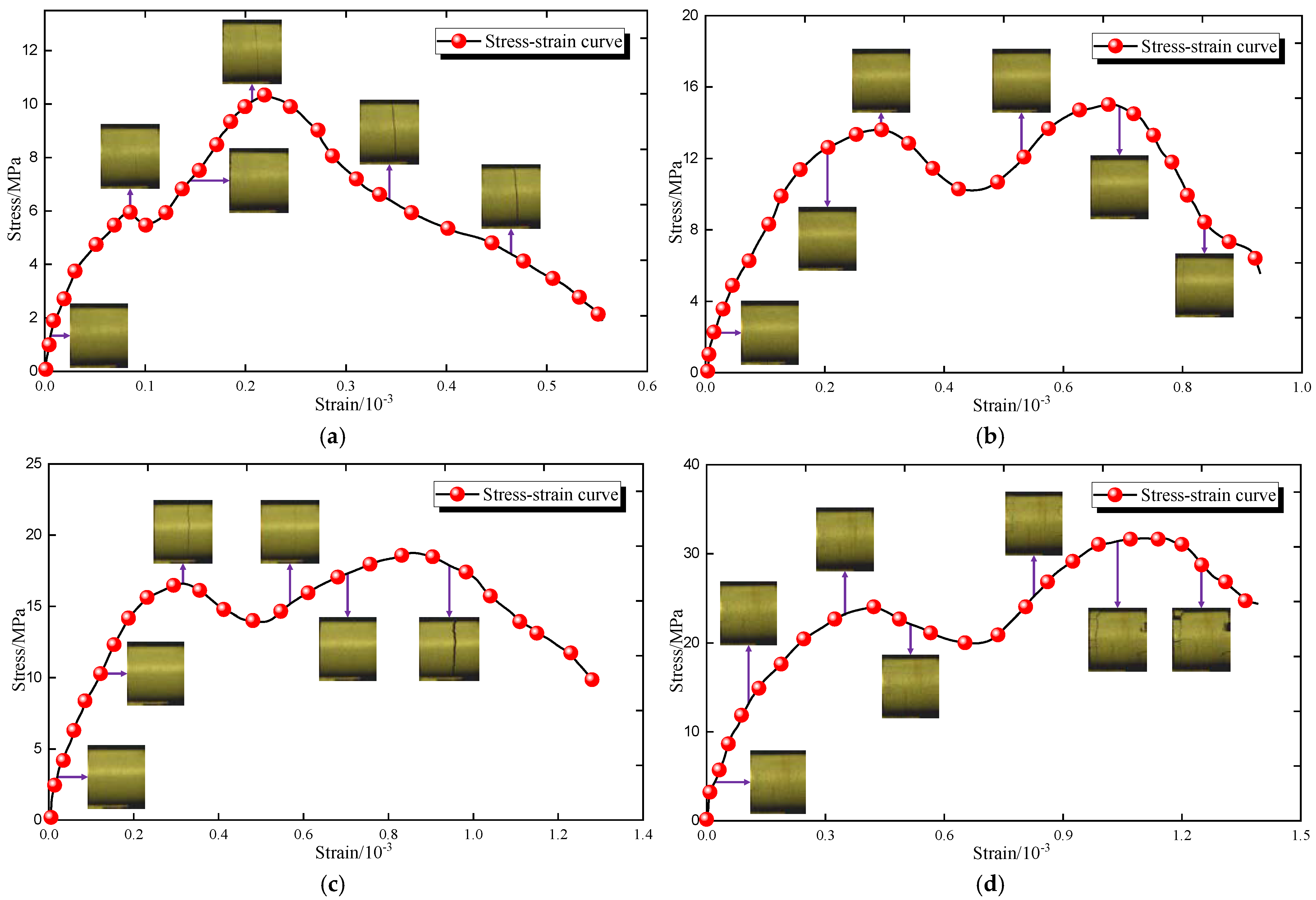

4.3. Progressive Failure and Fractal Characteristics

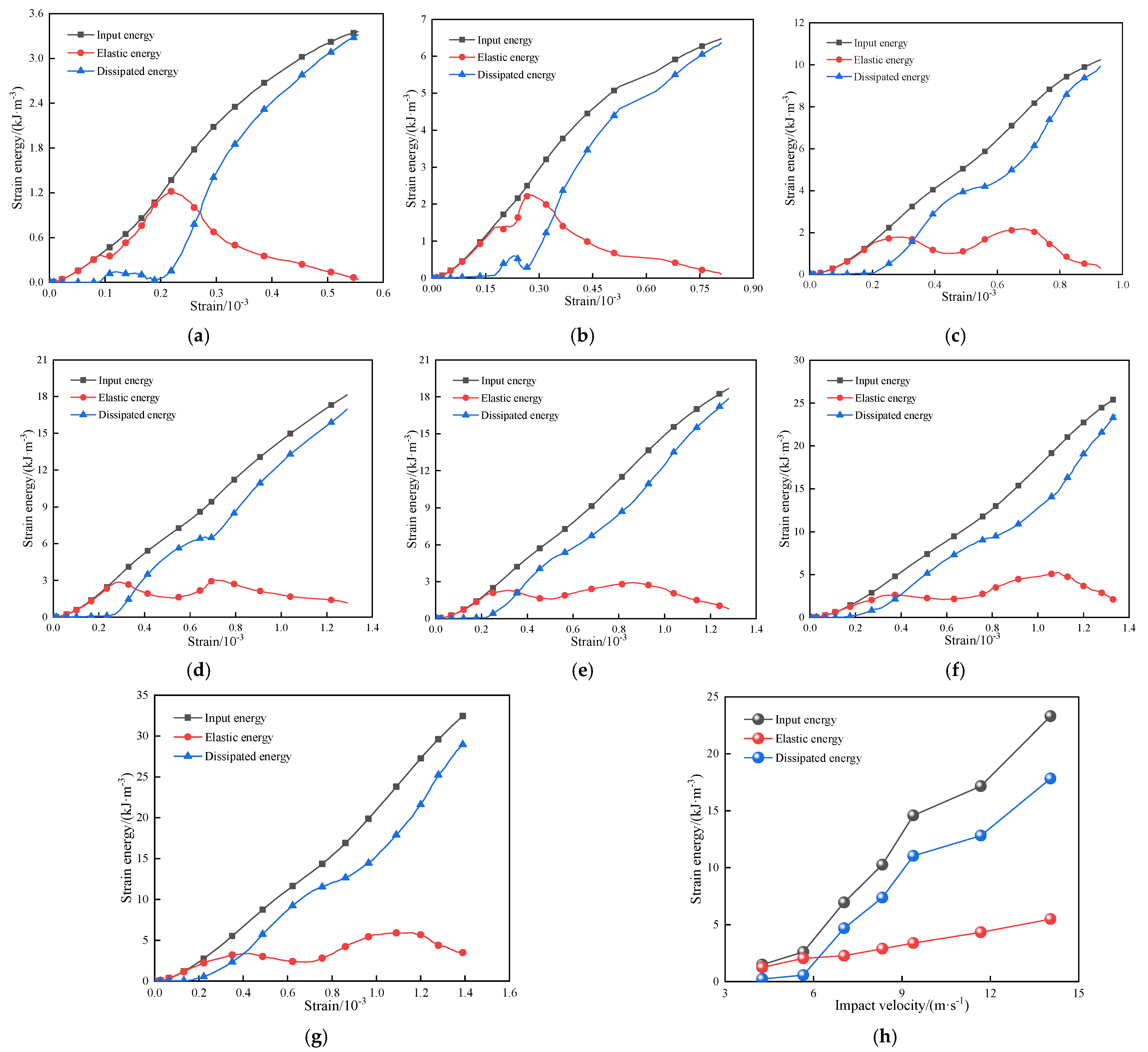

4.4. Evolution Law of Strain Energy

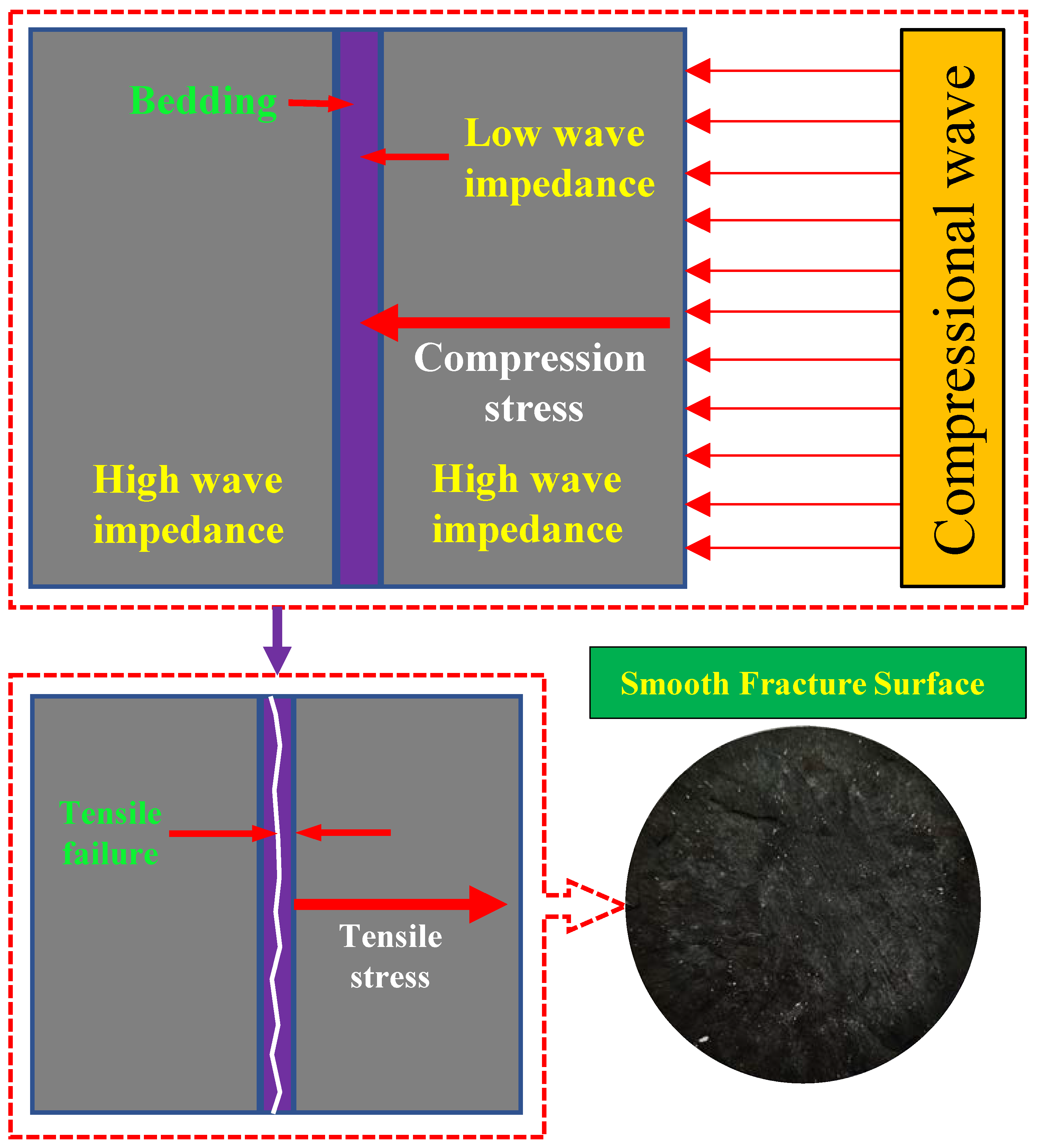

5. Interlayer Fracture Mechanism of Lignite under Dynamic Compression

6. Conclusions

- (1)

- The content of other impurities such as clay accounts for more than 24.40% of lignite; meanwhile, the axial direction of the cylindrical rock sample has obvious bedding characteristics, and the interlayer material has low strength; then, the interior of the rock sample is dominated by micropores and transition pores, with obvious internal water content characteristics, and there is a high-water content banded area in the rock, which is parallel to the bedding direction.

- (2)

- The stress–strain curve of impact lignite has obvious “double peak” characteristics; furthermore, the strain rate and dynamic compression strength increase linearly with the impact velocity, while the growth of dynamic elastic modulus and peak strain slows down in the later stage. In the process of impact loading, a macro crack appears at the first stress wave peak, and then is compressed until the interlayer fracture of the rock sample occurs; meanwhile, the fractal dimension of rock fragmentation increases linearly with the impact velocity, which reveals that the fragmentation degree of rock sample increases gradually.

- (3)

- The input energy and dissipated energy of impact lignite increase rapidly in stages with the impact velocity, and the elastic energy increases slowly at a low level. The interlaminar fracture mechanism of lignite samples can be explained as when the stress wave propagates from the high wave impedance rock medium to the low wave impedance medium, the stress wave reflection phenomenon will occur at the interface, and then a significant tensile stress wave will be generated, which contributes to the tensile failure of the rock along the beddings; in addition, the vibration effect of the incident bar during impact process will also aggravate the rock tensile failure.

- (4)

- Although we have obtained the mineral composition of the test lignite by using the advanced test techniques, in terms of the analysis of the mechanical behaviors and the failure mechanism of rock samples, we emphatically consider the influence of the microstructure, which can completely account for the test phenomenon. Although the influence of the mineral composition is not the key point of this paper, we will continue to carry out relevant research to fully explore its influence mechanism.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aler, J.; Mouza, J.D.; Arnould, M. Measurement of the fragmentation efficiency of rock mass blasting and its mining applications. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1996, 33, 125–139. [Google Scholar] [CrossRef]

- Xie, L.X.; Lu, W.B.; Zhang, Q.B. Damage evolution mechanisms of rock in deep tunnels induced by cut blasting. Tunn. Undergr. Space Technol. 2016, 58, 257–270. [Google Scholar] [CrossRef]

- Gong, F.Q.; Luo, Y.; Li, X.B. Experimental simulation investigation on rockburst induced by spalling failure in deep circular tunnels. Tunn. Undergr. Space Techol. 2018, 81, 413–427. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yang, J.X.; Yu, B. Rock-breaking mechanism and experimental analysis of confined blasting of borehole surrounding rock. Int. J. Min. Sci. Technol. 2017, 27, 795–801. [Google Scholar] [CrossRef]

- Wei, D.; Chen, M.; Ye, Z.W. Study on blasting failure zone based on rate-dependent dynamic characteristics of rock mass. Chin. J. Adv. Eng. Sci. 2021, 53, 67–74. [Google Scholar] [CrossRef]

- Ding, X.H.; Lu, X.; Zhou, W. Blasting impact simulation test and fragmentation distribution characteristics in an open-pit mine. Shock Vib. 2019, 2019, 4080274. [Google Scholar] [CrossRef]

- Shi, L.; Xu, J. Effect of strain rate on the dynamic compressive mechanical behaviors of rock material subjected to high temperatures. Mech. Mater. 2015, 82, 28–38. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Xia, K.; Li, X.B. Suggested methods for determining the dynamic strength parameters and mode-I fracture toughness of rock materials. Int. J. Rock Mech. Min. Sci. 2012, 49, 105–112. [Google Scholar] [CrossRef]

- Kawahara, S.; Muro, T. Effects of dry density and thickness of sandy soil on impact response due to rockfall. J. Terramechanics 2006, 43, 329–340. [Google Scholar] [CrossRef]

- He, M.C.; Gong, W.L.; Wang, J. Development of a novel energy-absorbing bolt with extraordinarily large elongation and constant resistance. Int. J. Rock Mech. Min. Sci. 2014, 67, 29–42. [Google Scholar] [CrossRef]

- Mishra, S.; Khetwal, A.; Chakraborty, T. Dynamic Characterisation of geniss. Rock Mech. Rock Eng. 2019, 52, 61–81. [Google Scholar] [CrossRef]

- Li, X.B.; Lok, T.S.; Zhao, J. Dynamic characteristics of granite subjected to intermediate loading rate. Rock Mech. Rock Eng. 2005, 38, 21–39. [Google Scholar] [CrossRef]

- Fakhimi, A.; Azhdari, P.; Kimberley, J. Physical and numerical evaluation of rock strength in Split Hopkinson Pressure Bar testing. Comput. Geotech. 2018, 102, 1–11. [Google Scholar] [CrossRef]

- Dai, F.; Huang, S.; Xia, K.W. Some fundamental issues in dynamic compression and tension tests of rocks using split Hopkinson pressure bar. Rock Mech. Rock Eng. 2010, 43, 657–666. [Google Scholar] [CrossRef]

- Mishra, S.; Chakraborty, T. Determination of high-strain-rate stress–strain response of granite for blast analysis of tunnels. J. Eng. Mech. 2019, 145, 04019057. [Google Scholar] [CrossRef]

- Ning, J.G.; Ren, H.L.; Guo, T.T. Dynamic response of alumina ceramics impacted by long tungsten projectile. Int. J. Impact Eng. 2013, 62, 60–74. [Google Scholar] [CrossRef]

- Yao, W.; Xia, K.W. Dynamic notched semi-circle bend (NSCB) method for measuring fracture properties of rocks: Fundamentals and applications. J. Rock Mech. Geotech. Eng. 2019, 11, 1066–1093. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.Y.; Liu, S. Static and dynamic mechanical properties of sedimentary rock after freeze-thaw or thermal shock weathering. Eng. Geol. 2016, 210, 148–157. [Google Scholar] [CrossRef] [Green Version]

- Gong, F.Q.; Shi, X.F.; Li, X.B. Dynamic triaxial compression tests on sandstone at high strain rates and low confining pressures with split Hopkinson pressure bar. Int. J. Rock Mech. Min. Sci. 2019, 113, 211–219. [Google Scholar] [CrossRef]

- Zhao, H.H.; Liu, C.; Zhang, J. Breakage behavior of gravel rock particles under impact force. Comput. Part. Mech. 2021, 8, 1075–1087. [Google Scholar] [CrossRef]

- Gong, F.Q.; Jia, H.Y.; Zhang, Z.X. Energy dissipation and particle size distribution of granite under different incident energies in SHPB compression tests. Shock Vib. 2020, 2020, 8899355. [Google Scholar] [CrossRef]

- Zhang, C.H.; He, X.W.; Zhu, S.Q. Distribution, character and utilization of lignite in China. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011. [Google Scholar] [CrossRef]

- Ma, H.F.; Song, Y.Q.; Chen, S.J. Experimental investigation on the mechanical behavior and damage evolution mechanism of water immersed gypsum rock. Rock Mech. Rock Eng. 2021, 54, 4929–4948. [Google Scholar] [CrossRef]

- Ma, H.F.; Chen, S.J.; Song, Y.Q. Experimental investigation into the effects of composition and microstructure on the tensile properties and failure characteristics of different gypsum rocks. Sci. Rep. 2021, 11, 14517. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Zang, C.W.; Ding, Z.W. Effects of confining pressure on deformation failure behavior of jointed rock. J. Cent. South Univ. 2022, 29, 1305–1319. [Google Scholar] [CrossRef]

- Chen, M.; Yang, S.Q.; Ranjith, P.G. Cracking behavior of rock containing non-persistent joints with various joints inclinations. Theor. Appl. Frac. Mec. 2020, 109, 102701. [Google Scholar] [CrossRef]

- Pikryl, R. Some microstructural aspects of strength variation in rocks. Int. J. Rock Mech. Min. Sci. 2001, 38, 671–682. [Google Scholar] [CrossRef]

- Song, Y.Q.; Ma, H.F.; Li, X.S. Experimental investigation on the influence of water content on mechanical properties and failure characteristics of tuff. Geotech. Geol. Eng. 2021, 39, 2871–2882. [Google Scholar] [CrossRef]

- Yang, J.U.; Wang, H.J.; Yang, Y.M. Numerical simulation of mechanisms of deformation, failure and energy dissipation in porous rock media subjected to wave stresses. Sci. China Technol. Sci. 2010, 53, 1098–1113. [Google Scholar] [CrossRef]

- Yu, L.Y.; Zhang, Z.Q.; Wu, J.Y. Experimental study on the dynamic fracture mechanical properties of limestone after chemical corrosion. Theor. Appl. Fract. Mec. 2020, 108, 102620. [Google Scholar] [CrossRef]

- Liu, X.H.; Dai, F.; Zhang, R. Static and dynamic uniaxial compression tests on coal rock considering the bedding directivity. Environ. Earth Sci. 2015, 73, 5933–5949. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Gong, S.; Hao, X.J. Effects of loading rate and bedding on the dynamic fracture toughness of coal: Laboratory experiments. Eng. Fract. Mec. 2017, 178, 375–391. [Google Scholar] [CrossRef]

- Han, J.; Zhang, L.; Kim, H.J. Fast pyrolysis and combustion characteristic of three different brown coals. Fuel Process. Technol. 2018, 176, 15–20. [Google Scholar] [CrossRef]

- Xin, F.D.; Xu, H.; Tang, D.Z. Experimental study on the change of reservoir characteristics of different lithotypes of lignite after dehydration and improvement of seepage capacity. Fuel 2020, 277, 118196. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M.; Xie, S.B. Quantitative characterization of methane adsorption on coal using a low-field NMR relaxation method. Int. J. Coal Geol. 2014, 131, 32–40. [Google Scholar] [CrossRef]

- Zhou, H.W.; Liu, Z.L.; Sun, X.T. Evolution characteristics of seepage channel during water infusion in deep coal samples. J. China Coal Soc. 2021, 46, 867–875. [Google Scholar] [CrossRef]

- Xia, K.; Nasseris, M.H.B.; Mohanty, B. Effects of microstructures on dynamic compression of Barre granite. Int. J. Rock Mec. Min. Sci. 2008, 45, 879–887. [Google Scholar] [CrossRef]

- Janach, W. The role of bulking in brittle failure of rocks under rapid compression. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1976, 13, 177–186. [Google Scholar] [CrossRef]

- Wang, D.R.; Hu, S.S. Influence of aggregate on the compression properties of concrete under impact. Chin. J. Exp. Mec. 2002, 17, 23–27. [Google Scholar]

- Liu, J.Z.; Xu, J.Y.; Lv, X.C. Experimental study on dynamic mechanical properties of amphibolites under impact compressive loading. Chin. J. Rock Mech. Eng. 2009, 28, 2113–2120. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.L.; Liu, X.S. Effect of coal thicknesses on energy evolution characteristics of roof rock-coal-floor rock sandwich composite structure and its damage constitutive model. Compos. Part B-Eng. 2020, 198, 108086. [Google Scholar] [CrossRef]

- Yang, R.S.; Li, W.Y.; Fang, S.Z. Experimental study on impact dynamic characteristics of layered composite rocks. Chin. J. Rock Mech. Eng. 2019, 38, 1747–1757. [Google Scholar] [CrossRef]

- Chai, S.B.; Wang, H.; Jing, Y.L. Experimental study on dynamic compression characteristics of rock with filled joints after cumulative damage. Chin. J. Rock Mech. Eng. 2020, 39, 2025–2037. [Google Scholar] [CrossRef]

| Group | Impact Velocity /(m/s) | Strain Rate /s−1 | Peak Strength /MPa | Dynamic Elastic Modulus /GPa | Peak Strain /10−4 |

|---|---|---|---|---|---|

| A | 4.26~4.73 | 9.21~10.80 | 8.28~10.30 | 24.14~28.42 | 3.01 |

| 4.33 | 9.90 | 9.47 | 25.78 | ||

| B | 5.65~6.17 | 12.08~14.32 | 11.60~13.72 | 35.98~41.48 | 3.58 |

| 5.73 | 13.23 | 12.70 | 38.47 | ||

| C | 6.96~7.10 | 12.80~16.62 | 12.32~15.92 | 51.86~55.20 | 4.73 |

| 7.03 | 15.10 | 14.47 | 53.67 | ||

| D | 8.28~8.35 | 18.79~19.74 | 18.04~18.95 | 54.81~58.80 | 7.29 |

| 8.32 | 19.33 | 18.53 | 57.11 | ||

| E | 9.30~9.45 | 19.63~22.74 | 19.32~21.74 | 60.24~61.09 | 9.09 |

| 9.38 | 20.73 | 19.83 | 60.80 | ||

| F | 11.50~11.89 | 24.80~29.41 | 23.32~27.24 | 70.99~79.95 | 9.73 |

| 11.69 | 26.23 | 25.17 | 75.13 | ||

| G | 13.88~14.04 | 30.94~33.28 | 29.61~31.94 | 75.69~88.05 | 10.90 |

| 13.95 | 31.60 | 30.27 | 82.94 |

| Group | Impact Velocity /(m × s−1) | Input Energy /(kJ/m3) | Elastic Energy /(kJ/m3) | Dissipated Energy /(kJ/m3) |

|---|---|---|---|---|

| A | 4.33 | 1.48 | 1.25 | 0.23 |

| B | 5.73 | 2.60 | 2.04 | 0.56 |

| C | 7.03 | 6.95 | 2.27 | 4.69 |

| D | 8.32 | 10.26 | 2.89 | 7.37 |

| E | 9.38 | 14.58 | 3.38 | 11.03 |

| F | 11.69 | 17.16 | 4.33 | 12.82 |

| G | 13.95 | 23.30 | 5.49 | 17.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Ma, H.; Yang, J.; Zheng, J.; Yang, J.; Bao, W. Dynamic Mechanical Behaviors and Failure Mechanism of Lignite under SHPB Compression Test. Sustainability 2022, 14, 10528. https://doi.org/10.3390/su141710528

Song Y, Ma H, Yang J, Zheng J, Yang J, Bao W. Dynamic Mechanical Behaviors and Failure Mechanism of Lignite under SHPB Compression Test. Sustainability. 2022; 14(17):10528. https://doi.org/10.3390/su141710528

Chicago/Turabian StyleSong, Yanqi, Hongfa Ma, Jiangkun Yang, Junjie Zheng, Juntao Yang, and Wei Bao. 2022. "Dynamic Mechanical Behaviors and Failure Mechanism of Lignite under SHPB Compression Test" Sustainability 14, no. 17: 10528. https://doi.org/10.3390/su141710528

APA StyleSong, Y., Ma, H., Yang, J., Zheng, J., Yang, J., & Bao, W. (2022). Dynamic Mechanical Behaviors and Failure Mechanism of Lignite under SHPB Compression Test. Sustainability, 14(17), 10528. https://doi.org/10.3390/su141710528