The Logistics Aspect in Research on the Reduction of Carbon Dioxide Emissions from Agricultural Biogas

Abstract

:1. Introduction

- −

- Type of biomass;

- −

- Physical, chemical and mechanical properties of biomass;

- −

- Raw material availability;

- −

- Technical possibilities of transport;

- −

- The possibility of pre-treatment before the conversion process;

- −

- Location of energy production sites.

- −

- Complete supply chain management (CSCM) with solid and liquid biomass as an energy source;

- −

2. Materials and Methods

2.1. Purpose and Methodology of Research

2.2. Description of General Assumptions

- −

- Variant I—agricultural biogas production is based only on the use of maize silage.

- −

- Variant II—agricultural biogas production based on a substrate mix consisting of a mixture of maize and cattle slurry in the ratio of 70:30 [42].

3. Results

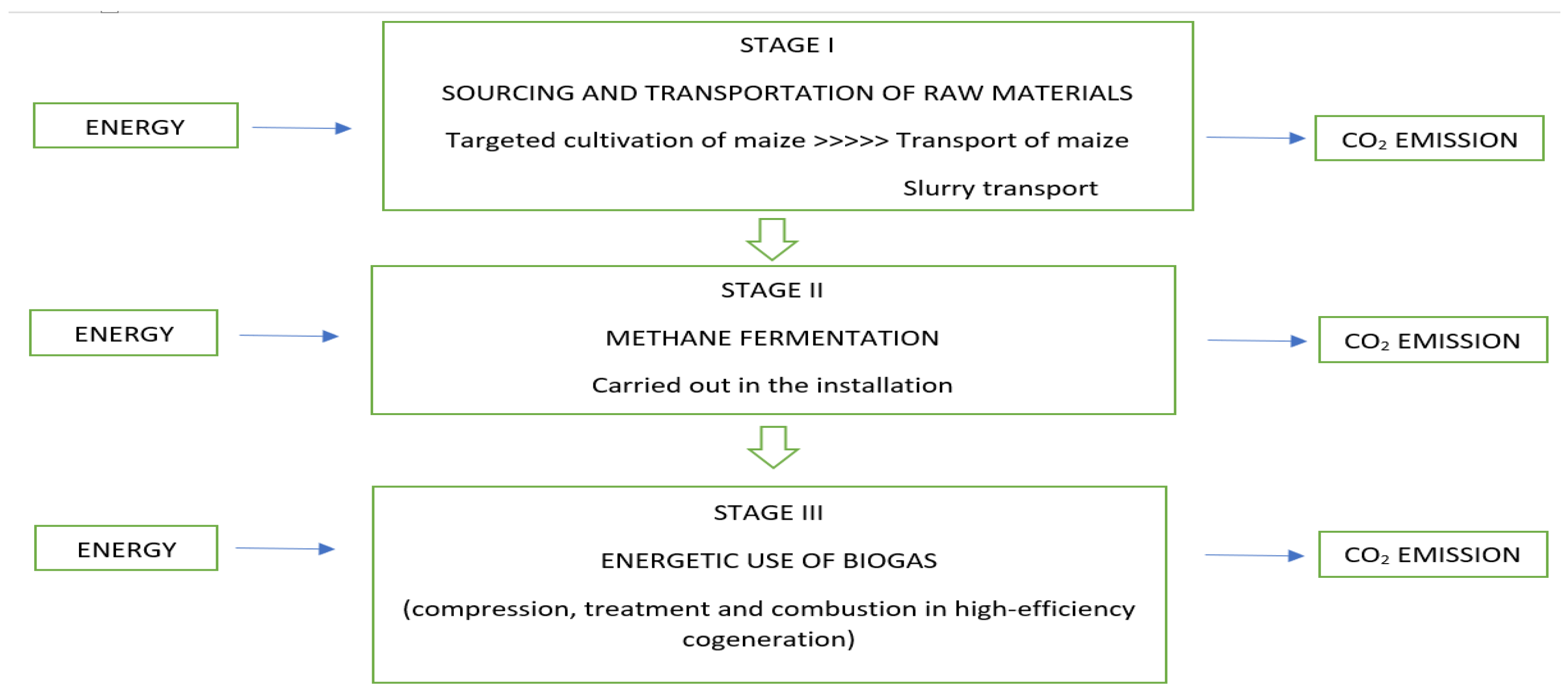

3.1. Calculation of CO2 Emission Reduction for Variant I (Maize Silage)

- −

- Mass of the substrate—1 t.;

- −

- Dry matter content—32.5%;

- −

- Content of dry organic matter—90.8%.

3.1.1. Calculation of the Value for Stage I

- −

- Synthetic nitrogen fertilizer: 169 kg N/ha/year;

- −

- Calcium fertilizer: 780 kg CaO/ha/year;

- −

- Potassium fertilizer: 90 kg K2O/ha/year;

- −

- Phosphorus fertilizer: 60 kg P2O5/ha/year.

3.1.2. Calculation of the Value for Stage II

3.1.3. Calculation of the Value for Stage III—The Energetic Use of Biogas

3.2. Calculation of CO2 Emission Reduction for Variant II (Substrate Mix—70% Maize Silage and 30% Slurry)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Muradin, M.; Foltynowicz, Z. Potential for Producing Biogas from Agricultural Waste in Rural Plants in Poland. Sustainability 2014, 6, 5065–5074. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Szymańska, M. Poferment Nawozem dla Rolnictwa (Digestate as Fertilizer for Agriculture). 2015. Available online: https://ksow.pl/files/Bazy/Biblioteka/files/Poferment_nawozem_dla_rolnictwa_01.pdf (accessed on 19 June 2022).

- Powałka, M.; Klepacka, A.; Skudlarski, J.; Golisz, E. Aktualny stan sektora biogazu rolniczego w Polsce na tle krajów Unii Europejskiej. The current state of the agricultural biogas sector in Poland compared to the European Union countries). Zesz. Nauk. Szk. Gł. Gospod. Wiej. Warszawie Probl. Rol. Świat. 2013, 13, 203–212. [Google Scholar] [CrossRef]

- Florkowski, W.; Us, A.; Klepacka, A. Food waste in rural households support for local biogas production in Lubelskie Voivodship (Poland). Resour. Conserv. Recycl. 2018, 136, 46–52. [Google Scholar] [CrossRef]

- Ginalski, Z. Substraty dla Biogazowi Rolniczych (Substrates for Agricultural Biogas Plants). Available online: https://cdr.gov.pl/pol/OZE/substraty.pdf (accessed on 19 June 2022).

- Rosińska-Bukowska, M.; Janiszewska, A.; Mordwa, S. Potential of Poland. Introduction to Socio-Economic Geography of Poland for Foreigners; Department of Spatial Economy and Spatial Planning: Warsaw, Poland, 2012. [Google Scholar]

- Jasiulewicz, M. Possibility of liquid bio-fuels, electric and heat energy production from biomass in Polish agriculture. Pol. J. Environ. Stud. 2010, 19, 479–483. [Google Scholar]

- Statistics Poland. Agriculture in Poland in 2019; Statistics Poland: Warsaw, Poland, 2020.

- Romaniuk, W.; Łukaszuk, M.; Karbowy, A. Potencjalne możliwości rozwoju biogazowni w gospodarstwach rolnych w Polsce. (Potential possibilities for the development of biogas plants on farms in Poland). Probl. Inż. Rol. 2010, 4, 129–139. [Google Scholar]

- Gradziuk, P. Potencjał i prognozy wykorzystania biogazu rolniczego w Polsce (Potential and forecasts for the use of agricultural biogas in Poland). Rocz. Nauk. Stowarzyszenia Ekon. Rol. Agrobiz. 2017, 19, 64–70. [Google Scholar]

- Weiland, P.; Rieger, C.; Ehrmann, T. Evaluation of the newest biogas plants in Germany with respect to renewable energy production, green house, gas reduction and nutrient management. In The Future of Biogas in Europe II; European Biogas Workshop: Esbjerg, Denmark, 2003. [Google Scholar]

- Pochwatka, P.; Pulka, J. Biogaz Rolniczy-Nowe Otwarcie (Agricultural Biogas-New Opening); Technika: Vilnius, Lithuania, 2020; pp. 72–74. [Google Scholar]

- Budzianowski, W.M.; Chasiak, I. The expansion of biogas power plants in Germany during the 2001–2010 decade: Main sustainable conclusions for Poland. J. Power Technol. 2011, 91, 102–113. [Google Scholar]

- European Environment Agency. Trends and Projections in Europe 2021; European Environment Agency: Copenhagen, Denmark, 2021.

- Gołasa, P.; Gradziuk, P.; Gradziuk, B.; Golonko, M.; Gromada, A.; Bieńkowska-Gołasa, W.; Siedlecka, A. Źródła emisji gazów cieplarnianych w rolnictwie, ze szczególnym uwzględnieniem emisji ze zużytej energii (Sources of greenhouse gas emissions in agriculture, with particular emphasis on emissions from the energy used). Energies 2021, 14, 3784. [Google Scholar] [CrossRef]

- Piechota, G.; Igliński, B. Biomethane in Poland—Current Status, Potential, Perspective and Development. Energies 2021, 14, 1517. [Google Scholar] [CrossRef]

- Sztekler, K.; Komorowski, M.; Wal-Agh, K. Modelowanie procesu ograniczania emisji CO2 z układów energetycznych (Modeling the process of reducing CO2 emissions from energy systems). Energetyka 2020, 11, 740–747. [Google Scholar]

- International Energy Agency (IEA). Net Zero by 2050. A Global Roadmap for the Energy Sector. Available online: https://iea.blob.core.windows.net/assets/deebef5d-0c34-4539-9d0c10b13d840027/NetZeroby2050-ARoadmapfortheGlobalEnergySector_CORR.pdf (accessed on 19 June 2022).

- Krajowy Ośrodek Bilansowania i Zarządzania Emisjami (KOBIZE). Krajowy Raport Inwentaryzacyjny; Krajowy Ośrodek Bilansowania i Zarządzania Emisjami (KOBIZE): Warszawa, Poland, 2016. [Google Scholar]

- Budzianowski, W.M. Sustainable biogas energy in Poland: Prospects and challenges. Renew. Sustain. Energy Rev. 2012, 16, 342–349. [Google Scholar] [CrossRef]

- IPCC. Managing the Risks of Extreme Events and Disasters to Advance Climate Change Adaptation: Special Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Pawlita-Posmyk, M.; Wzorek, M. Biogas production from the perspective of sustainable development. Econ. Environ. Stud. 2018, 18, 1043–1057. [Google Scholar] [CrossRef]

- Sołtysik, M. Zarządzanie Logistyczne, III Wydanie, Zmienione i Rozszerzone; Wydawnictwo AE: Katowice, Poland, 2003; p. 11. [Google Scholar]

- Beier, F.J.; Rutkowski, K. Strategia Zarządzania Dystrybucją; Placet: Warszawa, Poland, 1996. [Google Scholar]

- Witkowski, J. Strategia Logistyczna Przedsiębiorstw Przemysłowych; Wyd. AE: Wrocław, Poland, 1995. [Google Scholar]

- Oniszk-Popławska, A.; Matyka, M.; Dagny-Ryńska, E. Evaluation of a long-term potential for the development of agricultural biogas plants: A case study for the Lubelskie Province, Poland. Renew. Sustain. Energy Rev. 2014, 36, 329–349. [Google Scholar] [CrossRef]

- Osiak, J.; Dwórznik, M. System Storage, Distribution and Sale of Biomass; Amicus Society: Warsaw, Poland, 2016. [Google Scholar]

- Krupnik, D. Bezpieczeństwo zarządzania łańcuchem dostaw biomasy. Ekon. Organ. Logistyki 2019, 4, 41–53. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R.; Iglińska, A.; Cichosz, M.; Piechota, G.; Kujawski, W. Agricultural biogas plants in Poland: Investment proces, economic and environmental aspects, biogas potential. Renew. Sustain. Energy Rev. 2012, 16, 4890–4900. [Google Scholar] [CrossRef]

- Murphy, J.D.; McKoegh, E. The benefits of integrated treatment of waste for the analysis production of energy. Energy 2006, 31, 294–310. [Google Scholar] [CrossRef]

- Davis, T. Effective supply chain management. Sloan Manag. Rev. 1993, 34, 35–46. [Google Scholar]

- Curran, M.A. Life Cycle Assessment: Principles and Practice; United States Environmental Protection Agency: Washington, DC, USA, 2006.

- Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H.; Ismail, H. Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector. Sustainability 2020, 12, 3213. [Google Scholar] [CrossRef]

- Jürgensen, L.; Ehimen, E.A.; Born, J.; Holm-Nielsen, J.B. A combination anaerobic digestion scheme for biogas production from dairy effluent—CSTR and ABR, and biogas upgrading. Biomass Bioenergy 2018, 111, 241–247. [Google Scholar] [CrossRef]

- Kwaśny, J.; Banach, M.; Kowalski, Z. Technologies of biogas production from various sources—A review. Chem. Technol. Trans. 2012, 17, 83–102. [Google Scholar]

- Hennecke, A.M.; Faist, M.; Reinhardt, J.; Junquera, V.; Neeft, J.; Fehrenbach, H. Biofuel greenhouse gas calculations under the European Renewable Energy Directive-a comparison of the Biogracee tool vs. the tool of the Roundtable on Sustainable Biofuels. Appl. Energy 2013, 102, 55–62. [Google Scholar] [CrossRef]

- Żmuda, K. Biomass Potential in the Production of Agricultural Biogas in Poland. In Renewable Energy Sources as a New Challenge for Rural Areas in Poland; Kucharska, B., Ed.; Foundation of Assistance Programme for Agriculture (FAPA): Opole, Poland, 2009; pp. 17–20. [Google Scholar]

- Borowski, S.; Domański, J.; Weatherley, L. Anaerobic co-digestion of swine and poultry manure with municipal sewage sludge. Waste Manag. 2014, 34, 513–521. [Google Scholar] [CrossRef] [PubMed]

- Fugol, M.; Szlachta, J. Feasibility of using maize silage and pig slurry for biogas production. Agric. Eng. 2010, 119, 169–174. [Google Scholar]

- Kutera, J.; Hus, S. Agricultural Treatment and Use of Sewage and Slurry; Agricultural University in Wrocław: Warszawa, Poland, 1998. [Google Scholar]

- Murphy, J.D.; McKeoghb, E.; Kiely, G. Technical/economic/environmental analysis of biogas utilization. Appl. Energy 2004, 77, 407–427. [Google Scholar] [CrossRef]

- Gołembska, E. Logistyka Jako Zarządzanie Łańcuchem Dostaw; AE: Poznan, Poland, 1994. [Google Scholar]

- Kowalczyk-Juśko, A.; Kościk, B.; Jóźwiakowski, K.; Marczuk, A.; Zarajczyk, J.; Kowalczuk, J.; Szmigielski, M.; Sagan, A. Effects of biochemical and thermochemical conversion of sorghum biomass to usable energy. Przem. Chem. 2015, 94, 1838–1840. [Google Scholar]

- Księżak, J. Produkcja kukurydzy w różnych rejonach Polski (Maize production in various regions of Poland). Wieś Jutra 2009, 3, 16. [Google Scholar]

- Król, A. Kiszonki—Cenny substrat do produkcji biogazu (Silage—A valuable substrate for biogas production). Autobusy Technol. Eksploat. Syst. Transp. 2011, 10, 249–254. [Google Scholar]

- Romaniuk, W.; Domasiewicz, T. Substraty dla biogazowni rolniczych (Substrates for agricultural biogas plants). Agrotech. Porad. Rolnika 2014, 11, 74–75. [Google Scholar]

- Oslaj, M. Biogas production from maize hybrids. Biomass Bioenergy 2010, 34, 1538–1545. [Google Scholar] [CrossRef]

- Dołęga, W. Ekologia w Wytwarzaniu (Ecology in Production); Energia Gigawat: Poznan, Poland, 2016. [Google Scholar]

- Konieczna, A.; Borek, K.; Mazur, K.; Wardal, W. Emisje tlenku azotu (I) i ditlenku węgla z aplikacji nawozów nieorganicznych i naturalnych w wybranych technologiach upraw kukurydzy na kiszonkę (Emissions of nitrogen oxide (I) and carbon dioxide from the application of inorganic and natural fertilizers in selected technologies of maize cultivation for silage). Przem. Chem. 2019, 1, 901–906. [Google Scholar] [CrossRef]

- Jarosz, Z.; Faber, A. Możliwości ograniczenia emisji rolniczych z uprawy pszenicy przeznaczonej na cele paliwowe (Possibilities to reduce emissions agricultural with growing wheat intended for fuel purposes). Probl. Inż. Rol. Probl. Agric. Eng. 2015, 6, 75–83. [Google Scholar]

- Jarosz, Z.; Faber, A. Możliwości ograniczenia emisji rolniczych z uprawy kukurydzy przeznaczonej do produkcji bioetanolu (The p ossibility of agricultural emission limitations from corn cultivation on bioethanol). Stow. Ekon. Rol. Agrobiz. 2016, 6, 12–126. [Google Scholar]

- Rogowska, D. Ocena Wpływu Czynników Występujących na Etapie Uprawy na Emisję GHG w Cyklu Życia Bioetanolu (Assessment of the Influence of Factors Occurring at the Stage Crops for GHG Emissions in the Life Cycle of Bioethanol); Nafta-Gaz: Zug, Switzerland, 2017; pp. 119–125. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siudek, A.; Klepacka, A.M. The Logistics Aspect in Research on the Reduction of Carbon Dioxide Emissions from Agricultural Biogas. Sustainability 2022, 14, 10124. https://doi.org/10.3390/su141610124

Siudek A, Klepacka AM. The Logistics Aspect in Research on the Reduction of Carbon Dioxide Emissions from Agricultural Biogas. Sustainability. 2022; 14(16):10124. https://doi.org/10.3390/su141610124

Chicago/Turabian StyleSiudek, Aleksandra, and Anna M. Klepacka. 2022. "The Logistics Aspect in Research on the Reduction of Carbon Dioxide Emissions from Agricultural Biogas" Sustainability 14, no. 16: 10124. https://doi.org/10.3390/su141610124

APA StyleSiudek, A., & Klepacka, A. M. (2022). The Logistics Aspect in Research on the Reduction of Carbon Dioxide Emissions from Agricultural Biogas. Sustainability, 14(16), 10124. https://doi.org/10.3390/su141610124