Uncovering Readiness Factors Influencing the Lean Six Sigma Pre-Implementation Phase in the Food Industry

Abstract

1. Introduction

- (1)

- What are the LSS readiness factors in Malaysia’s food manufacturing industry?

- (2)

- What are the critical LSS readiness factors in Malaysia’s food manufacturing industry?

2. Literature Review

2.1. LSS in The Food Industry

2.2. Creating Readiness For LSS in the Food Industry

2.3. LSS Readiness Factors in the Food Industry

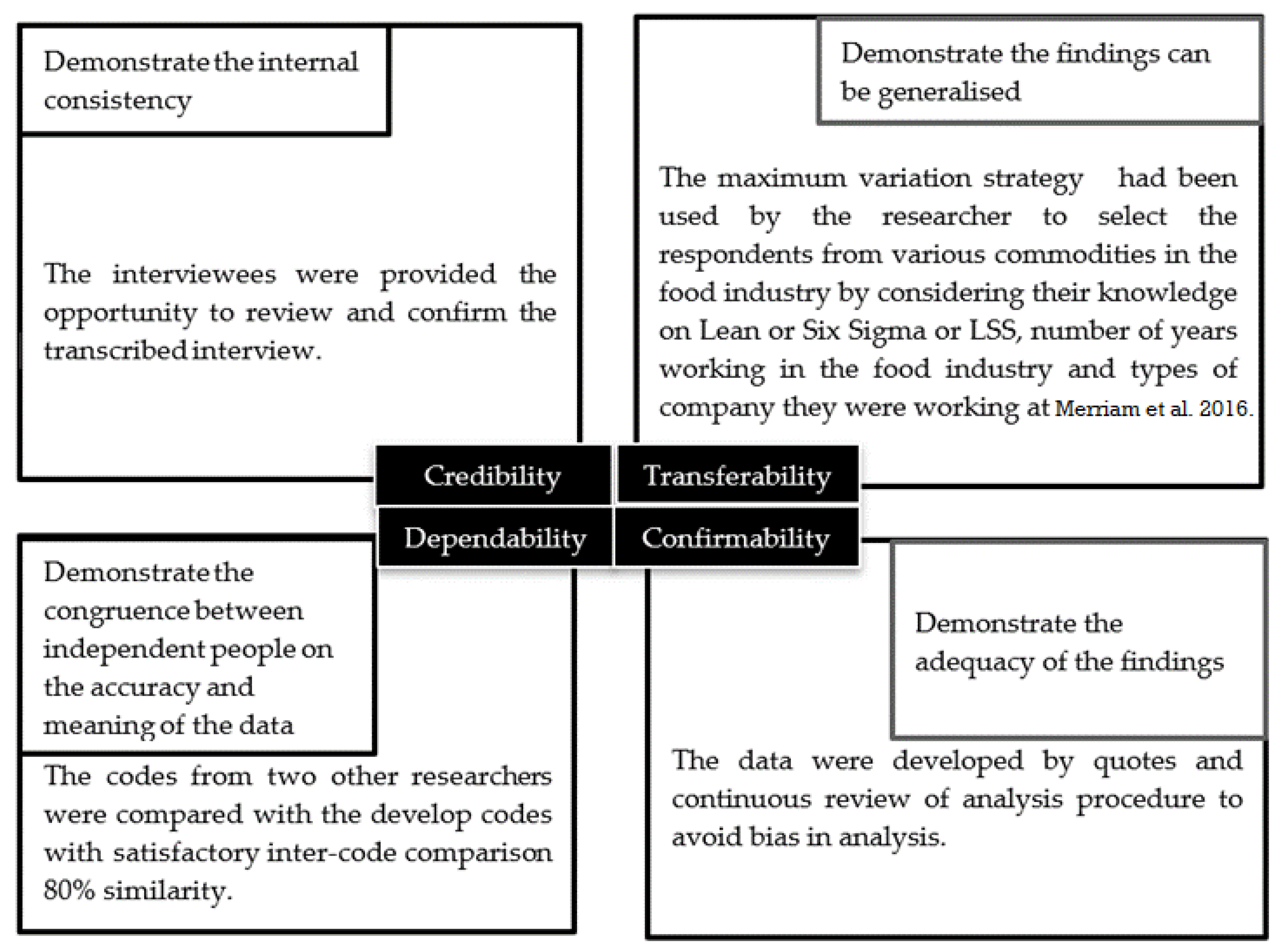

3. Research Methodology

3.1. Semi-Structured Interview

- (1)

- After reading the data multiple times for familiarisation, the data was descriptively coded.

- (2)

- The content of the coded data was thematically analysed to generate new notions as the basis of the development of a readiness to change theory.

- (3)

- The data were tabulated by comparing the themes and patterns that were identified and matched from the respondents’ answers.

- (4)

- The evaluation considered conceptual and theoretical grounds. The condensed and reduced data were analysed and interpreted to rationally govern earlier inferences and gain a better understanding of the data.

3.2. Case Study

4. Results and Discussions

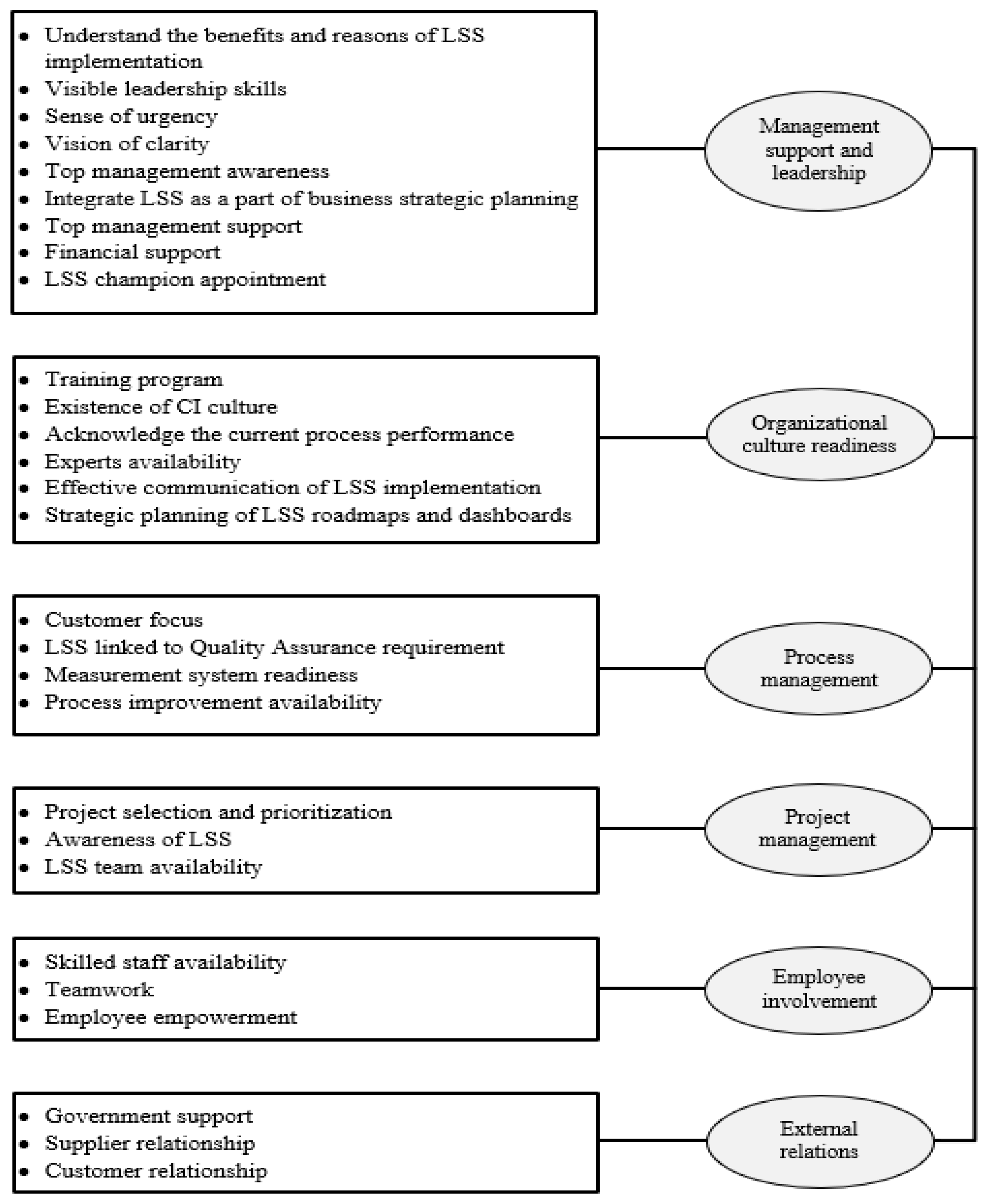

4.1. LSS Readiness Criteria in the Food Industry

4.1.1. Management Support and Leadership

4.1.2. Organisational Culture Readiness

4.1.3. Process Management

4.1.4. Project Management

4.1.5. Employee Involvement

4.1.6. External Relation

4.2. Validation Case Studies

| Dimensions | Company A | Company B | Company C |

|---|---|---|---|

| Management Support and Leadership |

|

|

|

| Organisational culture readiness |

|

|

|

| Process management |

|

|

|

| Project management |

|

|

|

| Employee involvement |

|

|

|

| External relations |

|

|

|

5. Conclusions and Future Research Agenda

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- What are factors that you think that may impact the readiness of LSS application in food manufacturing industry?

- How may those readiness factors mentioned impact LSS application in food manufacturing industry?

- Based on these readiness factors, which do you think affect the LSS readiness of your company?

- How may those readiness factors mentioned impact LSS application in your company?

- What do you think of the level of readiness of your company for LSS application?

References

- Li, H.; Li, D.; Jiang, D. Optimising the configuration of food supply chains. Int. J. Prod. Res. 2020, 59, 3722–3746. [Google Scholar] [CrossRef]

- Franceschelli, M.V.; Santoro, B.V.; Candelo, E. Business model innovation for sustainability: A food start-up case study. Br. Food J. 2018, 120, 2483–2494. [Google Scholar] [CrossRef]

- Muñoz-Villamizar, A.; Santos, J.; Grau, P.; Viles, E. Trends and gaps for integrating lean and green management in the agri-food sector. Br. Food J. 2019, 121, 1140–1153. [Google Scholar] [CrossRef]

- Sreedharan, V.R.; Raju, R.; Sunder, M.V.; Antony, J. Assessment of Lean Six Sigma Readiness (LESIRE) for manufacturing industries using fuzzy logic. Int. J. Qual. Reliab. Manag. 2019, 36, 137–161. [Google Scholar] [CrossRef]

- Abbess, N.; Sejri, N.; Xu, J.; Cheokhrouhou, M. New Lean six sigma readiness assessment model using fuzzy logic: Case study within clothing industry. Alex. Eng. J. 2022, 61, 9079–9094. [Google Scholar] [CrossRef]

- Barcia, K.F.; Garcia-Castro, L.; Abad-Moran, J. Lean Six Sigma Impact Analysis on Sustainability Using Partial Least Squares Structural Equation Modeling (PLS-SEM): A Literature Review. Sustainability 2022, 14, 3051. [Google Scholar] [CrossRef]

- Juliani, F.; Roe, O.J. Lean Six Sigma principles and practices under a management perspective. Prod. Plan. Control. 2020, 31, 1223–1244. [Google Scholar] [CrossRef]

- Costa, L.B.M.; Filho, M.G.; Fredendall, L.D.; Ganga, G.M.D. The effect of Lean Six Sigma practices on food industry performance: Implications of the Sector’s experience and typical characteristics. Food Control 2020, 112, 107110. [Google Scholar] [CrossRef]

- Dora, M.; Gellynck, X. Lean six sigma implementations in a food processing SME: A case study. Qual. Reliab. Eng. Int. 2015, 31, 1151–1159. [Google Scholar] [CrossRef]

- Kim-Soon, N.; Mostafa, S.A.; Nurunnabi, M.; Chin, L.H.; Kumar, N.M.; Ali, R.R.; Subramaniam, U. Quality Management Practices of Food Manufacturers: A Comparative Study between Small, Medium and Large Companies in Malaysia. Sustainability 2020, 12, 7725. [Google Scholar] [CrossRef]

- Lim, S.A.H.; Antony, J.; Arshed, N. A critical assessment on SPC implementation in the UK food industry. Syst. Cybern. Inform. 2016, 14, 37–42. [Google Scholar]

- Garousi Mokhtarzadedeh, N.; Jafarpanah, I.; Zamani Babgohari, A. Knowledge Management Capability, Entrepreneurial Creativity, Entrepreneurial Intensity and Firm Performance: The Mediating Role of Ambidexterity. Br. Food J. 2022, 124, 2179–2208. [Google Scholar] [CrossRef]

- Vaishnavi, V.; Suresh, M. Modelling of Readiness Factors for the Implementation of Lean Six Sigma in Healthcare Organizations. Int. J. Lean Six Sigma 2020, 11, 597–633. [Google Scholar] [CrossRef]

- Weiner, B.J. A Theory of Organizational Readiness for Change. Implement. Sci. 2009, 4, 1–9. [Google Scholar] [CrossRef]

- Gudergan, G.; Buschmeyer, A.; Krechting, D.; Feige, B. Evaluating the Readiness to Transform towards a Product-Service System Provider by a Capability Maturity Modelling Approach. Procedia CIRP 2015, 30, 384–389. [Google Scholar] [CrossRef][Green Version]

- Armenakis, A.A.; Harris, S.G.; Mossholder, K.W. Creating Readiness for Organizational Change. Hum. Relat. 1993, 46, 681–703. [Google Scholar] [CrossRef]

- Kochan, T.A.; Lansbury, R.D.; Macduffie, J.P. After Lean Production: Evolving Employment Practices in the World Auto Industry; Cornell University Press: New York, NY, USA, 1997. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Albliwi, S.A.; Antony, J.; Lim, S.A.H. A Systematic Review of Lean Six Sigma for the Manufacturing Industry. Bus. Process Manag. J. 2015, 21, 665–691. [Google Scholar] [CrossRef]

- Snee, R.D. Lean Six Sigma—Getting Better All the Time. Int. J. Lean Six Sigma 2010, 1, 9–29. [Google Scholar] [CrossRef]

- Letchumanan, L.T.; Gholami, H.; Yusof, N.M.; Ngadiman, N.H.A.B.; Salameh, A.A.; Štreimikienė, D.; Cavallaro, F. Analyzing the Factors Enabling Green Lean Six Sigma Implementation in the Industry 4.0 Era. Sustainability 2022, 14, 3450. [Google Scholar] [CrossRef]

- Powell, D.; Lundeby, S.; Chabada, L.; Dreyer, H. Lean Six Sigma and Environmental Sustainability: The Case of a Norwegian Dairy Producer. Int. J. Lean Six Sigma 2017, 8, 53–64. [Google Scholar] [CrossRef]

- Marrucci, L.; Marchi, M.; Daddi, T. Improving the Carbon Footprint of Food and Packaging Waste Management in a Supermarket of the Italian Retail Sector. Waste Manag. 2020, 105, 594–603. [Google Scholar] [CrossRef] [PubMed]

- Rabago, D.M. Statistical Quality Control and Process Capability Analysis for Variability Reduction of the Tomato Paste Filling Process. Ind. Eng. Manag. 2013, 3, e137. [Google Scholar] [CrossRef]

- Jacobson, E.H. The effect of changing industrial methods and automation on personnel. In Symposium on Preventive and Social Psychology, Washington, DC; Walter Reed Army Institute of Research: Silver Spring, MD, USA, 1957. [Google Scholar]

- Schein, E.H. Organizational Culture and Leadership, 4th ed.; Jossey-Bass: San Francisco, CA, USA, 1985. [Google Scholar]

- Cummings, S.; Bridgman, T.; Brown, K.G. Unfreezing Change as Three Steps: Rethinking Kurt Lewin’s Legacy for Change Management. Hum. Relat. 2015, 69, 33–60. [Google Scholar] [CrossRef]

- Al-Balushi, S.; Sohal, A.S.; Singh, P.J.; Al Hajri, A.; Al Farsi, Y.M.; Al Abri, R. Readiness Factors for Lean Implementation in Healthcare Settings—A Literature Review. J. Health Organ. Manag. 2014, 28, 135–153. [Google Scholar] [CrossRef] [PubMed]

- Yukl, G.A. Leadership in Organizations, 8th ed.; Harlow Pearson Education Limited: Harlow, UK, 2013. [Google Scholar]

- Laureani, A.; Antony, J. Leadership and Lean Six Sigma: A Systematic Literature Review. Total Qual. Manag. Bus. Excell. 2017, 30, 53–81. [Google Scholar] [CrossRef]

- Alnajem, M.; Reyes, J.A.G.; ElMelegy, A. Measuring the Lean Readiness of Kuwaiti Manufacturing Industries. Int. J. Bus. Perform. Manag. 2019, 20, 70. [Google Scholar] [CrossRef]

- Radnor, Z. Implementing lean in health care: Making the link between the approach, readiness and sustainability. Int. J. Ind. Eng. Manag. 2011, 2, 1–12. [Google Scholar]

- Antony, J. Readiness Factors for the Lean Six Sigma Journey in the Higher Education Sector. Int. J. Product. Perform. Manag. 2014, 63, 257–264. [Google Scholar] [CrossRef]

- Costa, L.B.M.; Godinho Filho, M.; Fredendall, L.D.; Gómez Paredes, F.J. Lean, Six Sigma and Lean Six Sigma in the Food Industry: A Systematic Literature Review. Trends Food Sci. Technol. 2018, 82, 122–133. [Google Scholar] [CrossRef]

- Shokri, A.; Waring, T.S.; Nabhani, F. Investigating the Readiness of People in Manufacturing SMEs to Embark on Lean Six Sigma Projects. Int. J. Oper. Prod. Manag. 2016, 36, 850–878. [Google Scholar] [CrossRef]

- Douglas, J.; Muturi, D.; Douglas, A.; Ochieng, J. The Role of Organisational Climate in Readiness for Change to Lean Six Sigma. TQM J. 2017, 29, 666–676. [Google Scholar] [CrossRef]

- Uluskan, M.; McCreery, J.K.; Rothenberg, L. Impact of Quality Management Practices on Change Readiness due to New Quality Implementations. Int. J. Lean Six Sigma 2018, 9, 351–373. [Google Scholar] [CrossRef]

- Robson, C.; Mccartan, K. Real World Research: A Resource for Users of Social Research Methods in Applied Settings, 4th ed.; John Wiley & Sons Ltd: Chichester, UK, 2016. [Google Scholar]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; Sage Publications, Inc: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Dikko, M. Establishing Construct Validity and Reliability: Pilot Testing of a Qualitative Interview for Research in Takaful (Islamic Insurance). Qual. Rep. 2016, 21, 521–529. [Google Scholar] [CrossRef]

- Charmaz, K. Constructing Grounded Theory: A Practical Guide through Qualitative Analysis; Sage: London, UK, 2006. [Google Scholar]

- Miles, M.B. A Michael Huberman. Qualitative Data Analysis an Expanded Sourcebook; Sage: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Guba, E.G. Criteria for Assessing the Trustworthiness of Naturalistic Inquiries. ECTJ 1981, 29, 75. [Google Scholar] [CrossRef]

- Merriam, S.B.; Tisdell, E.J. Qualitative Research: A Guide to Design and Implementation, 4th ed.; Jossey-Bass, Cop: San Francisco, CA, USA, 2016. [Google Scholar]

- Al-Haddad, S.; Kotnour, T. Integrating the Organizational Change Literature: A Model for Successful Change. J. Organ. Chang. Manag. 2015, 28, 234–262. [Google Scholar] [CrossRef]

- Holt, D.T.; Armenakis, A.A.; Feild, H.S.; Harris, S.G. Readiness for Organizational Change. J. Appl. Behav. Sci. 2007, 43, 232–255. [Google Scholar] [CrossRef]

- Lim, S.A.H.; Priyono, A.; Mohamad, S.F. Introducing a Six Sigma Process Control Technique in a Food Production Line: Step-by-step Guideline and Critical Elements of the Implementation. In Proceedings of the IEEE 6th International Conference on Industrial Engineering and Applications (ICIEA), Tokyo, Japan, 12–15 April 2019; pp. 338–342. [Google Scholar]

- Lagrosen, Y.; Chebl, R.; Rios Tuesta, M. Organisational Learning and Six Sigma Deployment Readiness Evaluation: A Case Study. Int. J. Lean Six Sigma 2011, 2, 23–40. [Google Scholar] [CrossRef]

- Mureşan, C.C.; Marc, R.A.; Jimborean, M.; Rusu, I.; Mureşan, A.; Nistor, A.; Cozma, A.; Suharoschi, R. Food Safety System (HACCP) as Quality Checkpoints in a Spin-off Small-Scale Yogurt Processing Plant. Sustainability 2020, 12, 9472. [Google Scholar] [CrossRef]

- Abdul Halim Lim, S.; Antony, J.; He, Z.; Arshed, N. Critical Observations on the Statistical Process Control Implementation in the UK Food Industry. Int. J. Qual. Reliab. Manag. 2017, 34, 684–700. [Google Scholar] [CrossRef]

- Wang, S. Assessing the Food Safety and Quality Assurance System during the COVID-19 Pandemic. Sustainability 2022, 14, 1507. [Google Scholar] [CrossRef]

- Lim, S.A.H.; Antony, J.; Albliwi, S. Statistical Process Control (SPC) in the Food Industry—A Systematic Review and Future Research Agenda. Trends Food Sci. Technol. 2014, 37, 137–151. [Google Scholar] [CrossRef]

- Lim, S.A.H.; Antony, J. Statistical Process Control Readiness in the Food Industry: Development of a Self-Assessment Tool. Trends Food Sci. Technol. 2016, 58, 133–139. [Google Scholar] [CrossRef]

- Manville, G.; Greatbanks, R.; Krishnasamy, R.; Parker, D.W. Critical Success Factors for Lean Six Sigma Programmes: A View from Middle Management. Int. J. Qual. Reliab. Manag. 2012, 29, 7–20. [Google Scholar] [CrossRef]

- Gonzalez Aleu, F.; Van Aken, E.M. Systematic Literature Review of Critical Success Factors for Continuous Improvement Projects. Int. J. Lean Six Sigma 2016, 7, 214–232. [Google Scholar] [CrossRef]

- Antosz, K.; Stadnicka, D. Lean Philosophy Implementation in SMEs—Study Results. Procedia Eng. 2017, 182, 25–32. [Google Scholar] [CrossRef]

- Dora, M.; Van Goubergen, D.; Kumar, M.; Molnar, A.; Gellynck, X. Application of Lean Practices in Small and Medium-Sized Food Enterprises. Br. Food J. 2014, 116, 125–141. [Google Scholar] [CrossRef]

- Domínguez, R.A.; del Espinosa, M.M.; Domínguez, M.; Romero, L. Lean 6S in Food Production: HACCP as a Benchmark for the Sixth S “Safety”. Sustainability 2021, 13, 12577. [Google Scholar] [CrossRef]

- Lim, S.A.H. An Exploratory Study on Statistical Process Control in the UK Food Industry. Ph.D. Thesis, Herriot Watt University, Edinburgh, UK, 2016. [Google Scholar]

- Satolo, E.G.; de Hiraga, L.E.S.; Goes, G.A.; Lourenzani, W.L. Lean Production in Agribusiness Organizations: Multiple Case Studies in a Developing Country. Int. J. Lean Six Sigma 2017, 8, 335–358. [Google Scholar] [CrossRef]

- Abdulmalek, F.A.; Rajgopal, J.; Needy, K.L. A Classification Scheme for the Process Industry to Guide the Implementation of Lean. Eng. Manag. J. 2006, 18, 15–25. [Google Scholar] [CrossRef]

- Shah, S.R.; Naghi Ganji, E. Lean Production and Supply Chain Innovation in Baked Foods Supplier to Improve Performance. Br. Food J. 2017, 119, 2421–2447. [Google Scholar] [CrossRef]

- Moya, C.A.; Galvez, D.; Muller, L.; Camargo, M. A New Framework to Support Lean Six Sigma Deployment in SMEs. Int. J. Lean Six Sigma 2019, 10, 58–80. [Google Scholar] [CrossRef]

- Cox, A.; Chicksand, D.; Palmer, M. Stairways to Heaven or Treadmills to Oblivion? Br. Food J. 2007, 109, 689–720. [Google Scholar] [CrossRef]

- Belhadi, A.; Touriki, F.E.; El Fezazi, S. Prioritizing the Solutions of Lean Implementation in SMEs to Overcome Its Barriers. J. Manuf. Technol. Manag. 2017, 28, 1115–1139. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Lopez, C.; Chen, H.; Lu, H.; Mangla, S.K.; Elgueta, S. Risk Analysis of the Agri-Food Supply Chain: A Multi-Method Approach. Int. J. Prod. Res. 2020, 58, 4851–4876. [Google Scholar] [CrossRef]

| References | Theme/Purpose | Category of Readiness Frameworks/Factors | Industry |

|---|---|---|---|

| [33] | To reveal the LSS readiness factors which are required for the successful introduction and development for the higher education sector. |

| Service (Higher education industry) |

| [35] | Development of hypothesis model for German manufacturing SMEs to investigate the readiness of people in SME manufacturing to embark on LSS projects |

| Manufacturing (Food, automotive and aerospace industry) |

| [36] | Development of instrument for LSS organisational readiness for Kenya Institute of Management |

| Service (Non-profit organisation) |

| [37] | Structural path model on organisational readiness for change due to new quality implementations (LSS) |

| Manufacturing (Apparel and textile industry) |

| [4] | Development of LSS Readiness (LESIRE) evaluation model by using fuzzy approach |

| Manufacturing (Automotive and heavy machine industry) |

| [13] | Development of LSS readiness factors model in healthcare organizations |

| Service (Healthcare industry) |

| [5] | Development of LSS Readiness assessment model for the clothing industries using fuzzy logic |

| Manufacturing (Apparel industry) |

| Respondent Code | Type of Company (Commodities) | Years of Experience in Food Industry | Position |

|---|---|---|---|

| RA | Oil and Fats | 9 years | Operational Excellence Manager/LSS Black Belt |

| RB | Dairy Products | 14 years | Production Manager/Six Sigma Green Belt and Lean Black Belt |

| RC | Dairy Products | 7 years | Process Engineer/LSS Green Belt |

| RD | Oil and Fats | 9 years | Assistant Manager Quality |

| RE | Beverages | 7 years | Production Engineer |

| RF | Bakeries | 2 years | Quality Assurance Executive |

| RG | Oil and Fats | 1 year | Continuous Improvement Manager/LSS Black Belt |

| RH | Dairy Products | 15 years | Operation Manager/LSS Black Belt |

| RI | Beverages | 2 years | Quality Assurance Executive/Certified Quality Engineer |

| RJ | Confectionery | 13 years | Value Stream Manager |

| RK | Oil and Fats | 9 years | Supply Chain Manager |

| RL | Meat and Poultry | 10 years | Quality Assurance Manager/Six Sigma Green Belt |

| Company | Type of Products Produced | Year Established | Annual Profit | Food Safety Certifications | Process Involved |

|---|---|---|---|---|---|

| A | Packed vegetables and fruits | 2013 | 17.2 million | ISO 22000 GMP HACCP | Receiving raw materials, cleaning, sorting and grading, weighing, packaging, labelling, cartoning, storing, loading and delivery |

| B | Condiments | 1975 | 14 million | ISO 22000 GMP HACCP | Receiving raw materials, weighing, mixing, cooking, filtering, filling, capping and sealing, labelling, cartoning, storing, loading and delivery. |

| C | Instant coffee | 2001 | 5.6 million | GMP | Receiving raw materials, dispensing, sieving, blending, filling, bottling, packing, storing and delivery. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azalanzazllay, N.N.; Lim, S.A.H.; Abidin, U.F.U.Z.; Anass, C. Uncovering Readiness Factors Influencing the Lean Six Sigma Pre-Implementation Phase in the Food Industry. Sustainability 2022, 14, 8941. https://doi.org/10.3390/su14148941

Azalanzazllay NN, Lim SAH, Abidin UFUZ, Anass C. Uncovering Readiness Factors Influencing the Lean Six Sigma Pre-Implementation Phase in the Food Industry. Sustainability. 2022; 14(14):8941. https://doi.org/10.3390/su14148941

Chicago/Turabian StyleAzalanzazllay, Nurul Najihah, Sarina Abdul Halim Lim, Ungku Fatimah Ungku Zainal Abidin, and Cherrafi Anass. 2022. "Uncovering Readiness Factors Influencing the Lean Six Sigma Pre-Implementation Phase in the Food Industry" Sustainability 14, no. 14: 8941. https://doi.org/10.3390/su14148941

APA StyleAzalanzazllay, N. N., Lim, S. A. H., Abidin, U. F. U. Z., & Anass, C. (2022). Uncovering Readiness Factors Influencing the Lean Six Sigma Pre-Implementation Phase in the Food Industry. Sustainability, 14(14), 8941. https://doi.org/10.3390/su14148941