Disintegration Resistance of Steep-Rocky-Slope Wall-Hanging Soil Based on High-Performance Ester Materials

Abstract

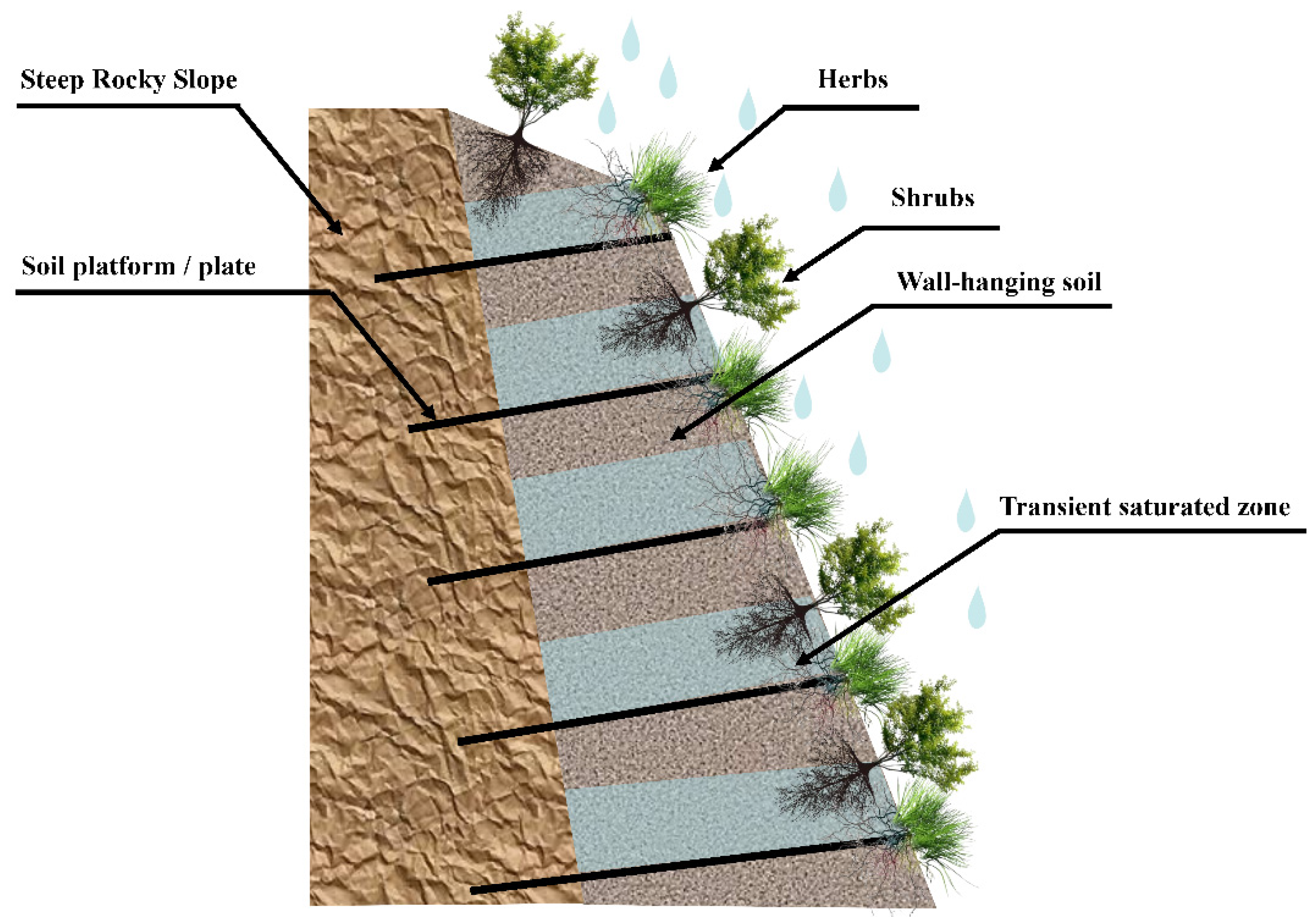

:1. Introduction

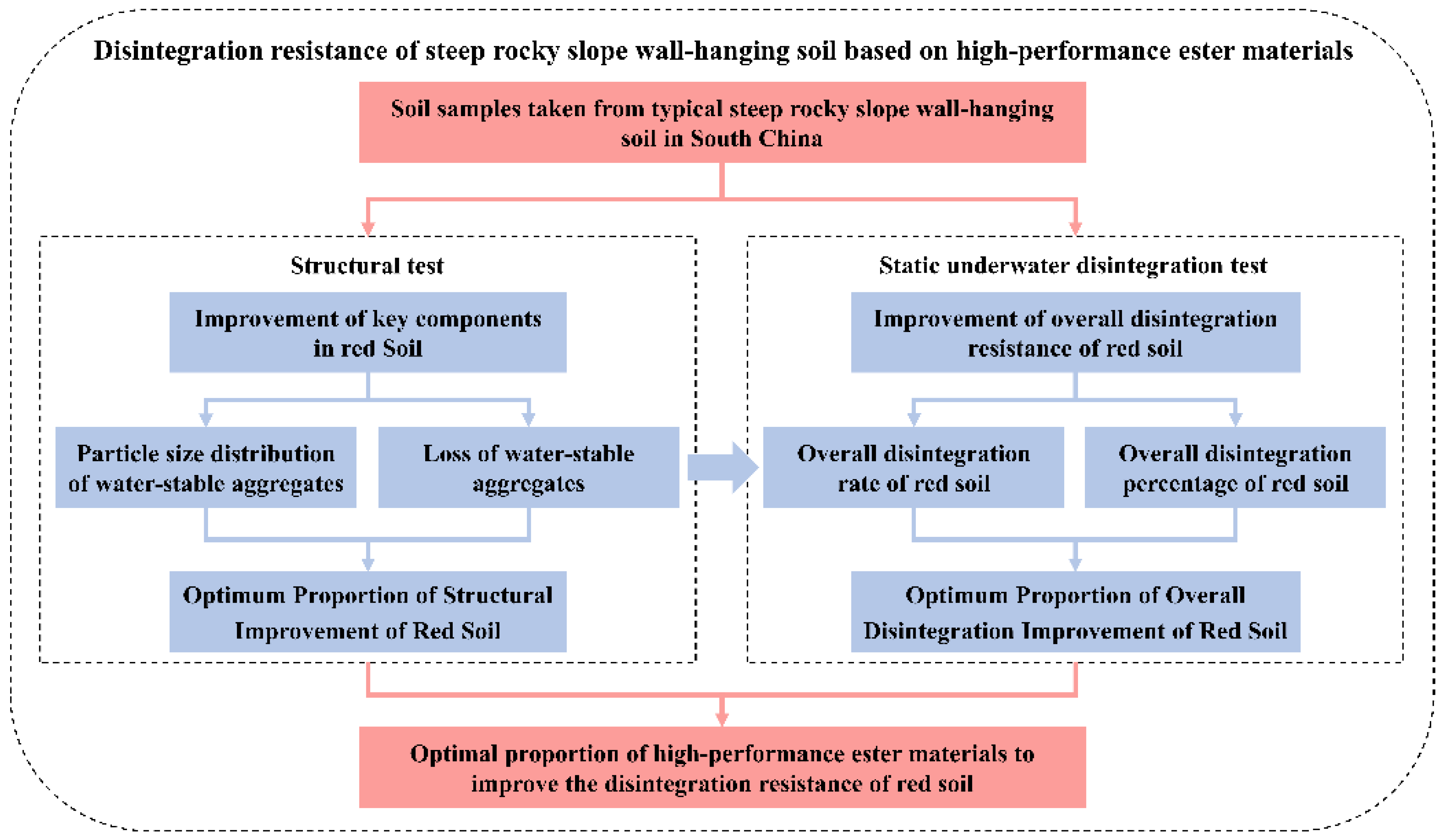

2. Test and Method

2.1. Test Purpose

2.2. Test Material

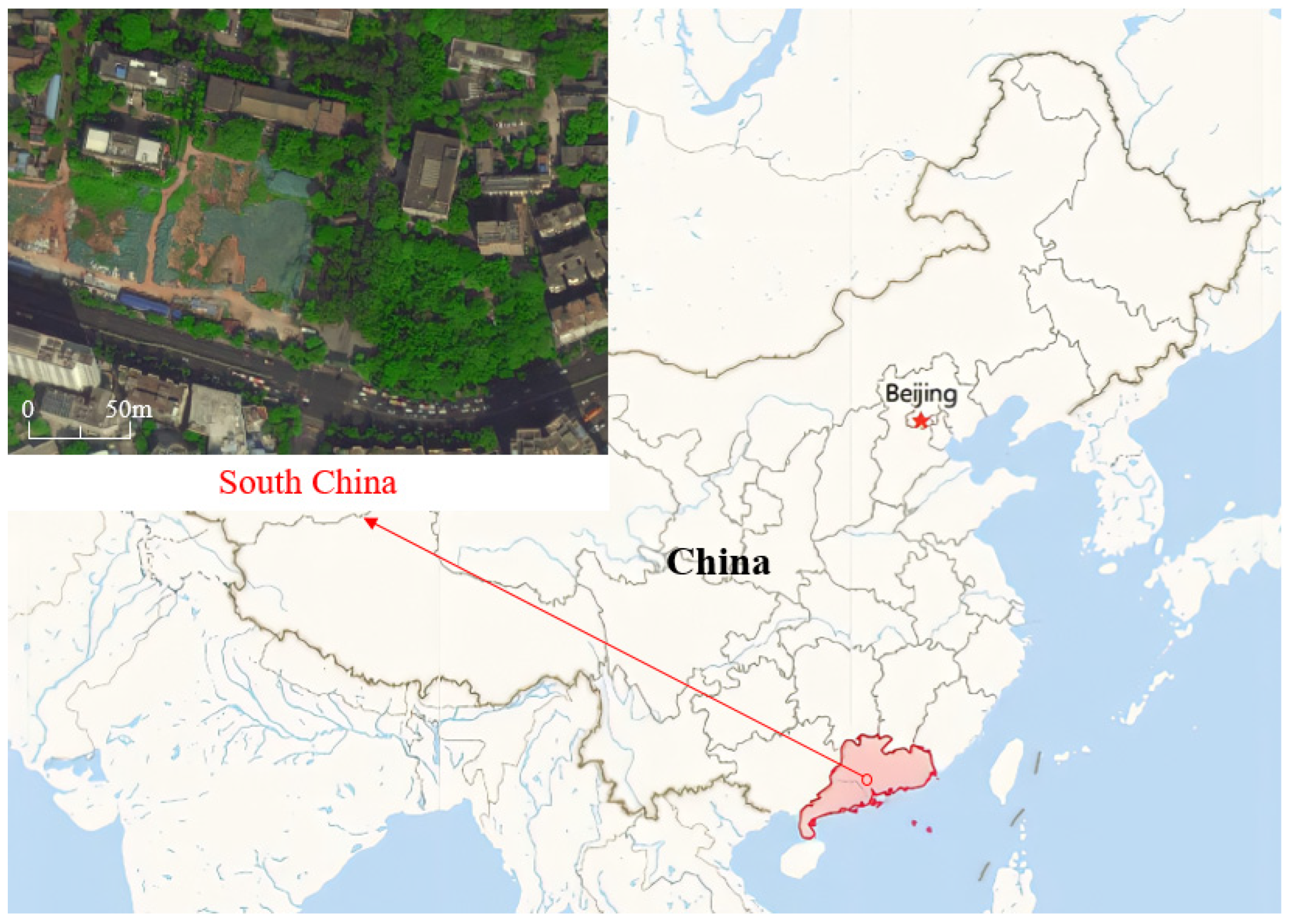

2.2.1. Soil Sample

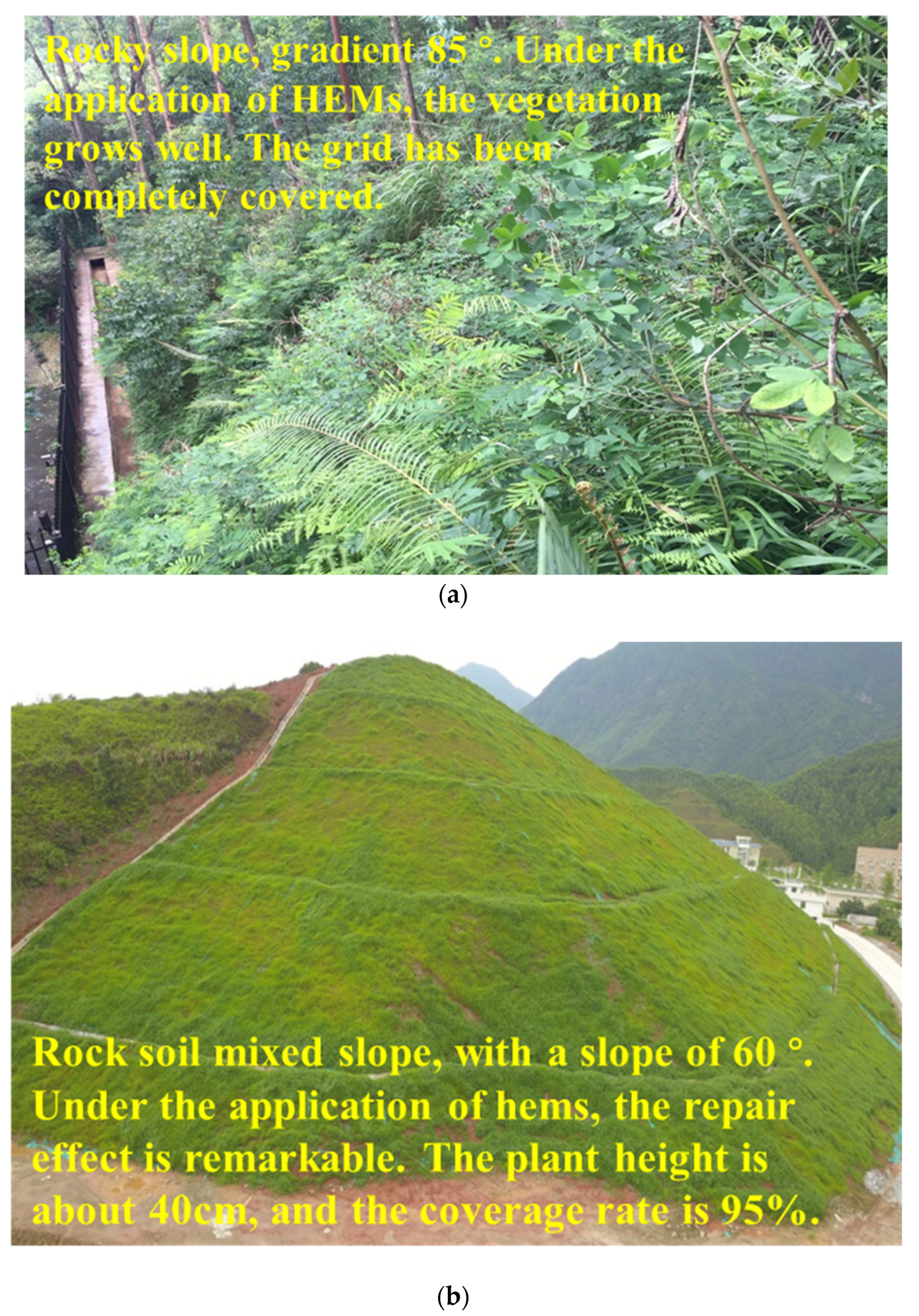

2.2.2. Introduction to High-Performance Ester Materials (HEMs)

2.3. Test Proportions

2.4. Test Method

2.4.1. Soil Structural Test

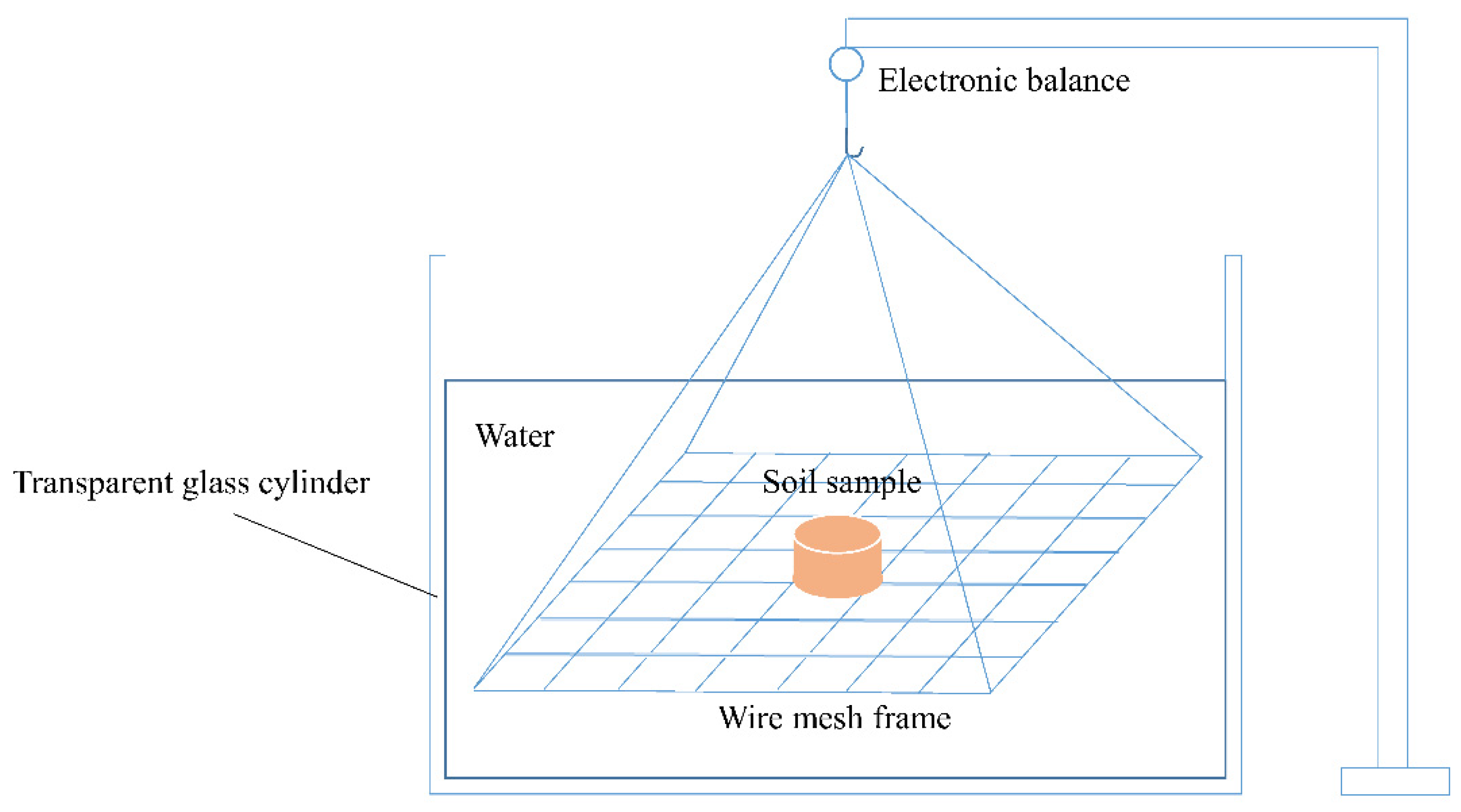

2.4.2. Static Underwater Disintegration Test

3. Test Results and Discussion

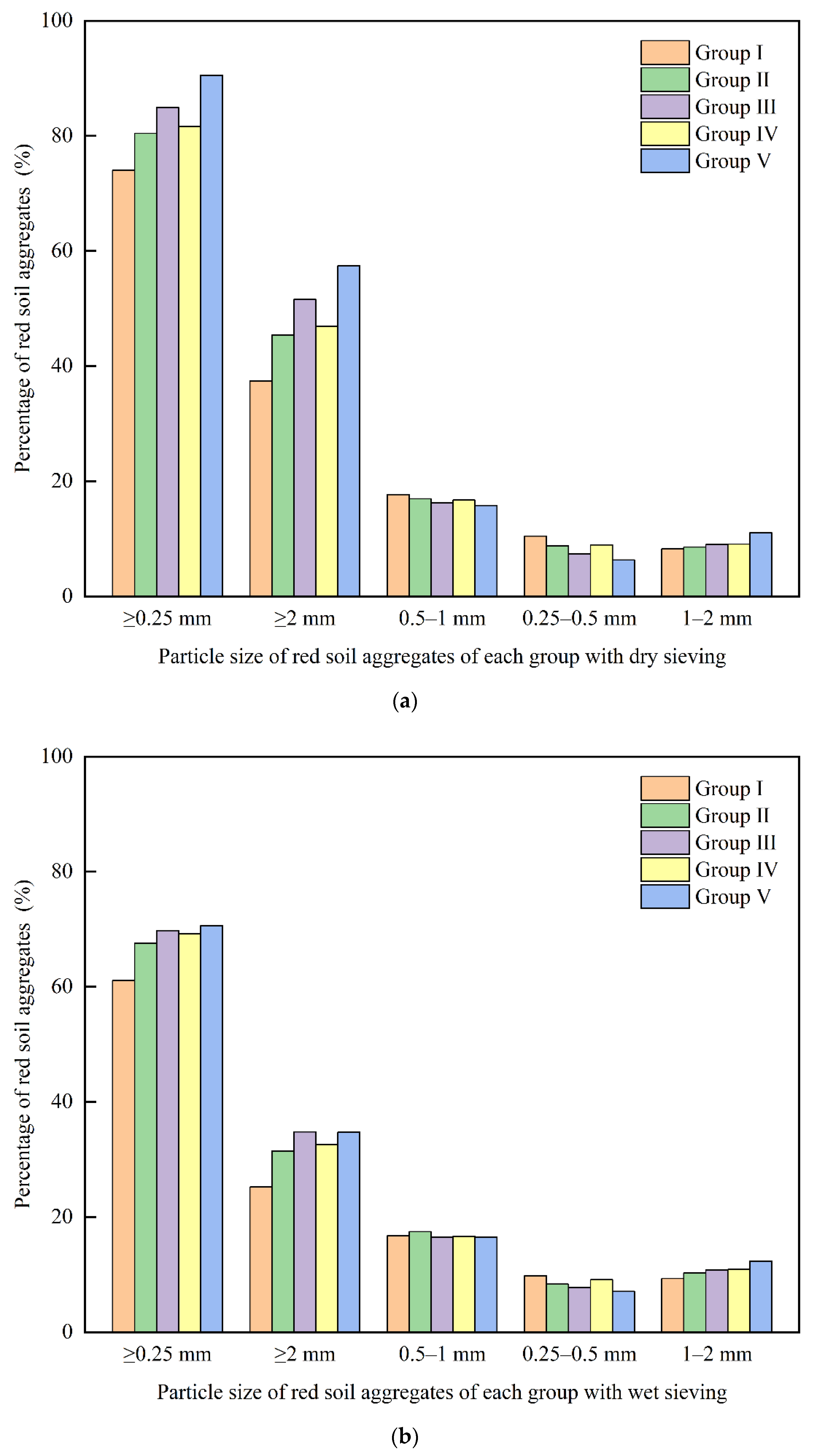

3.1. Effects of High-Performance Ester Materials (HEMs) on Water-Stable Aggregates (WAs) Content in Red Soil

3.2. Characterization of Red-Soil Aggregate Water Stability

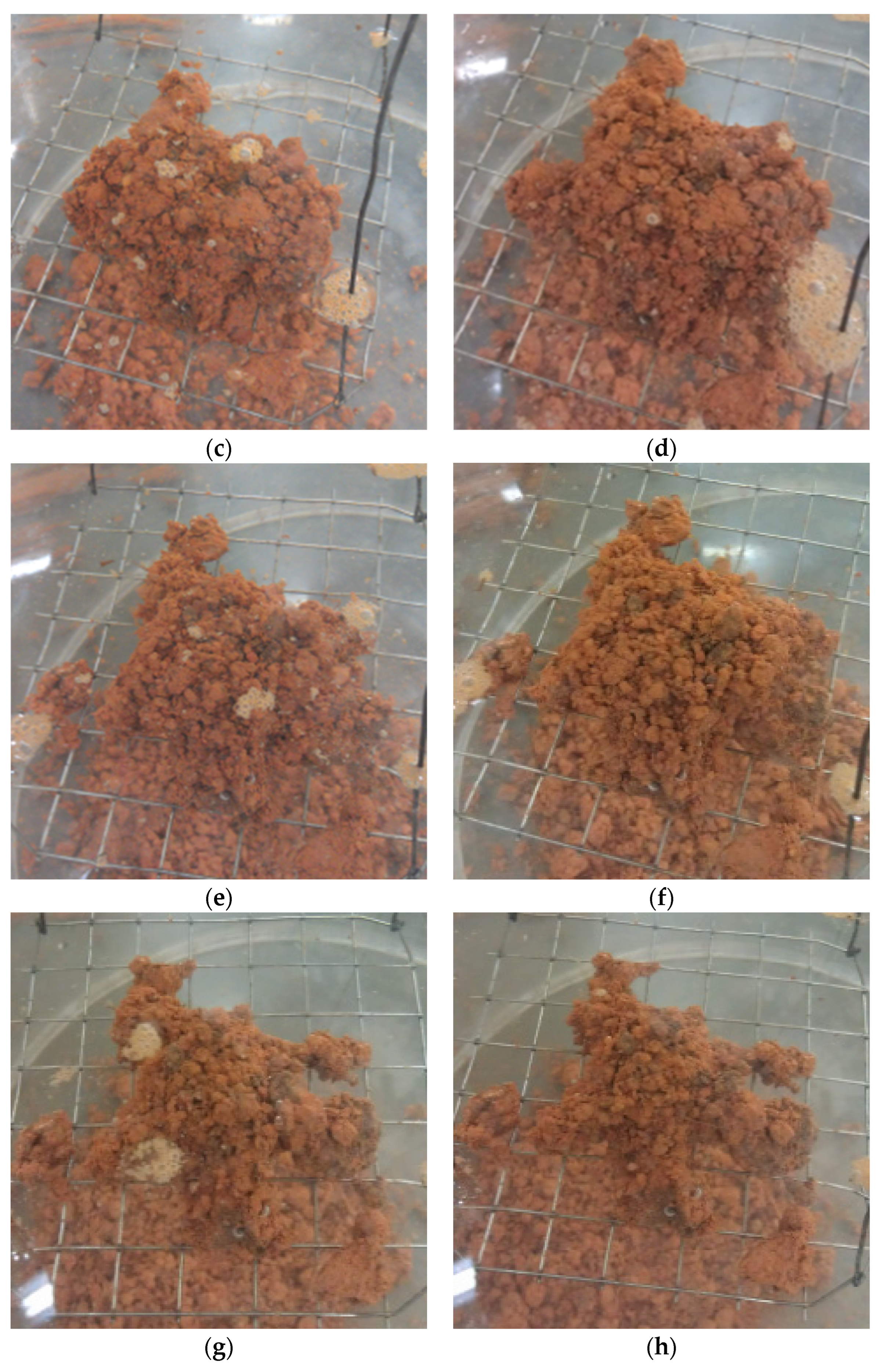

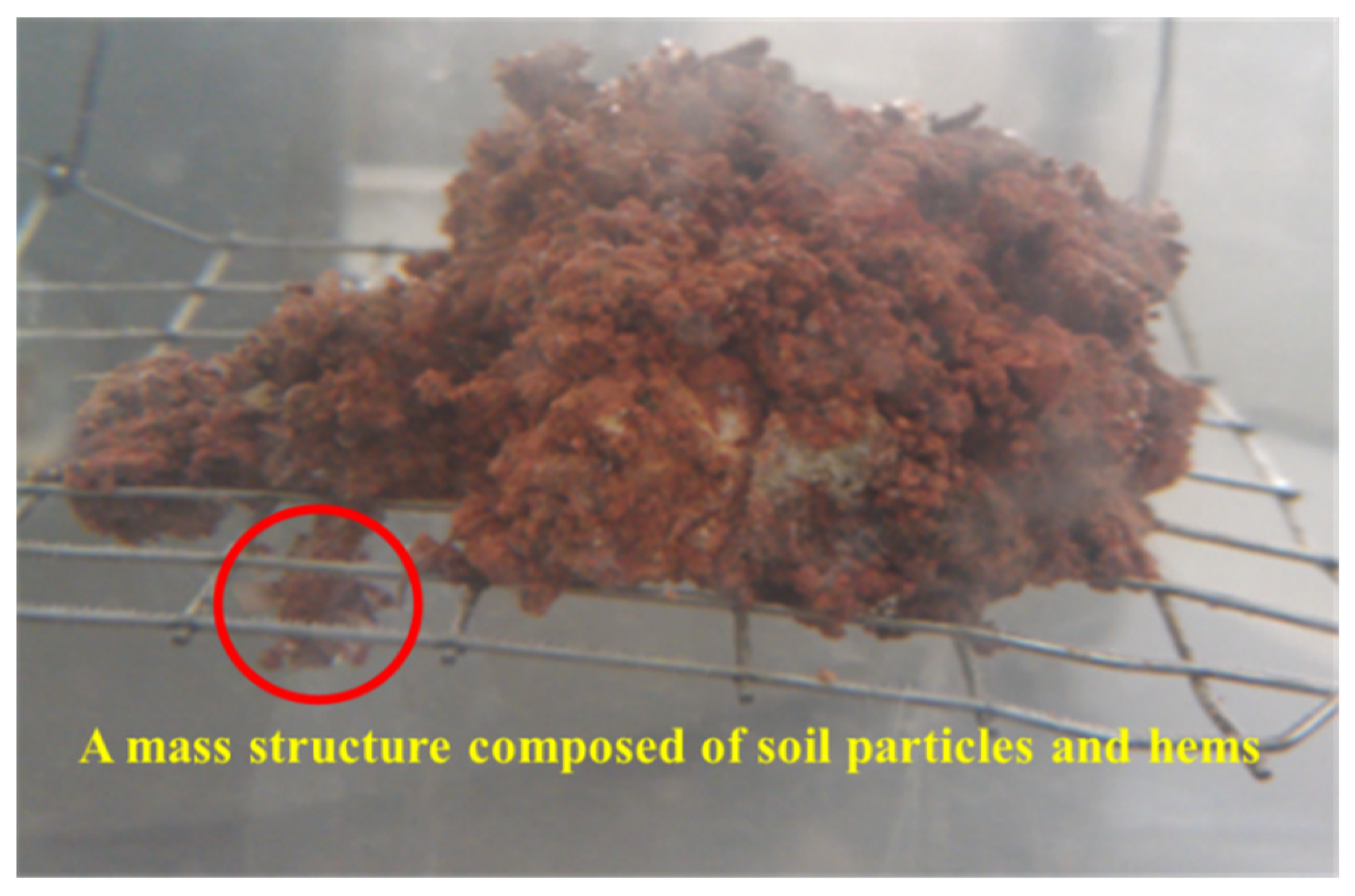

3.3. Effects of High-Performance Ester Materials (HEMs) on Overall Disintegration of Red Soil

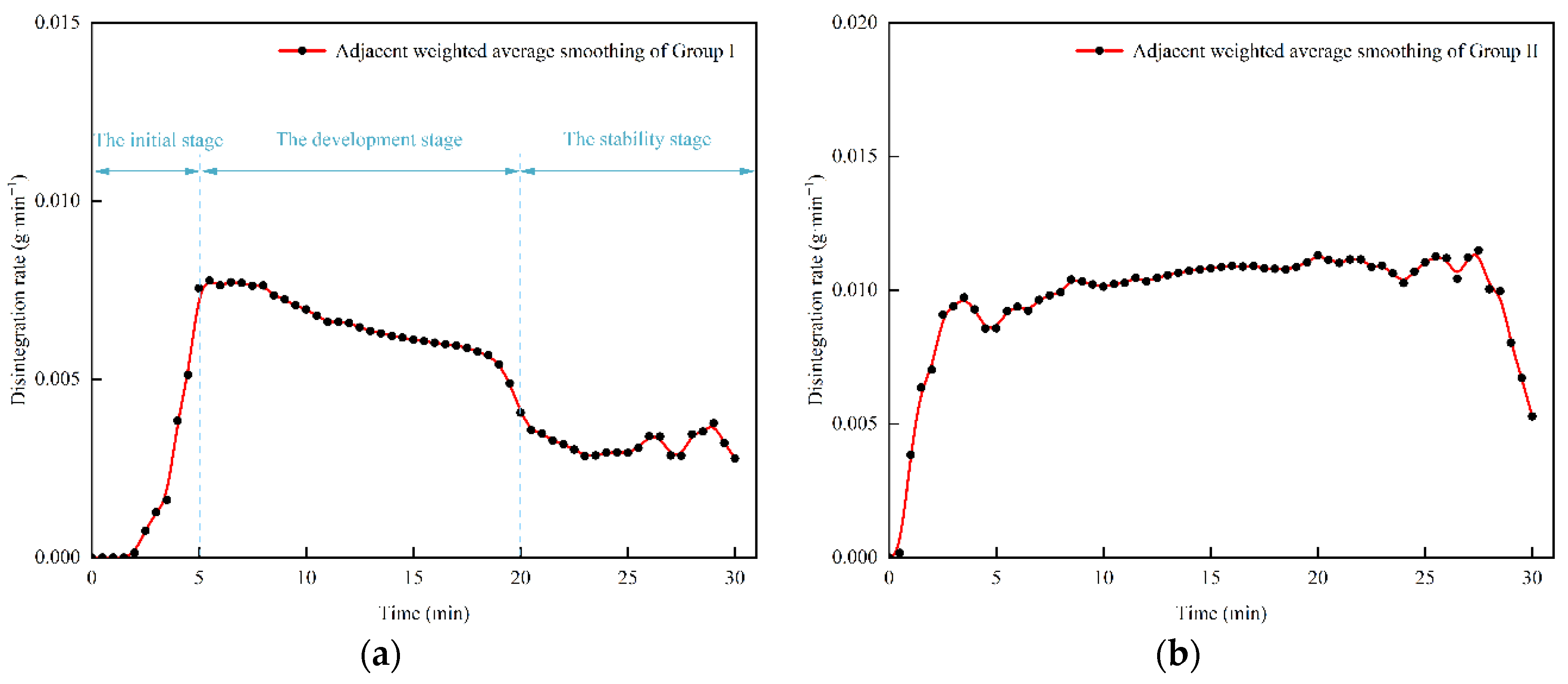

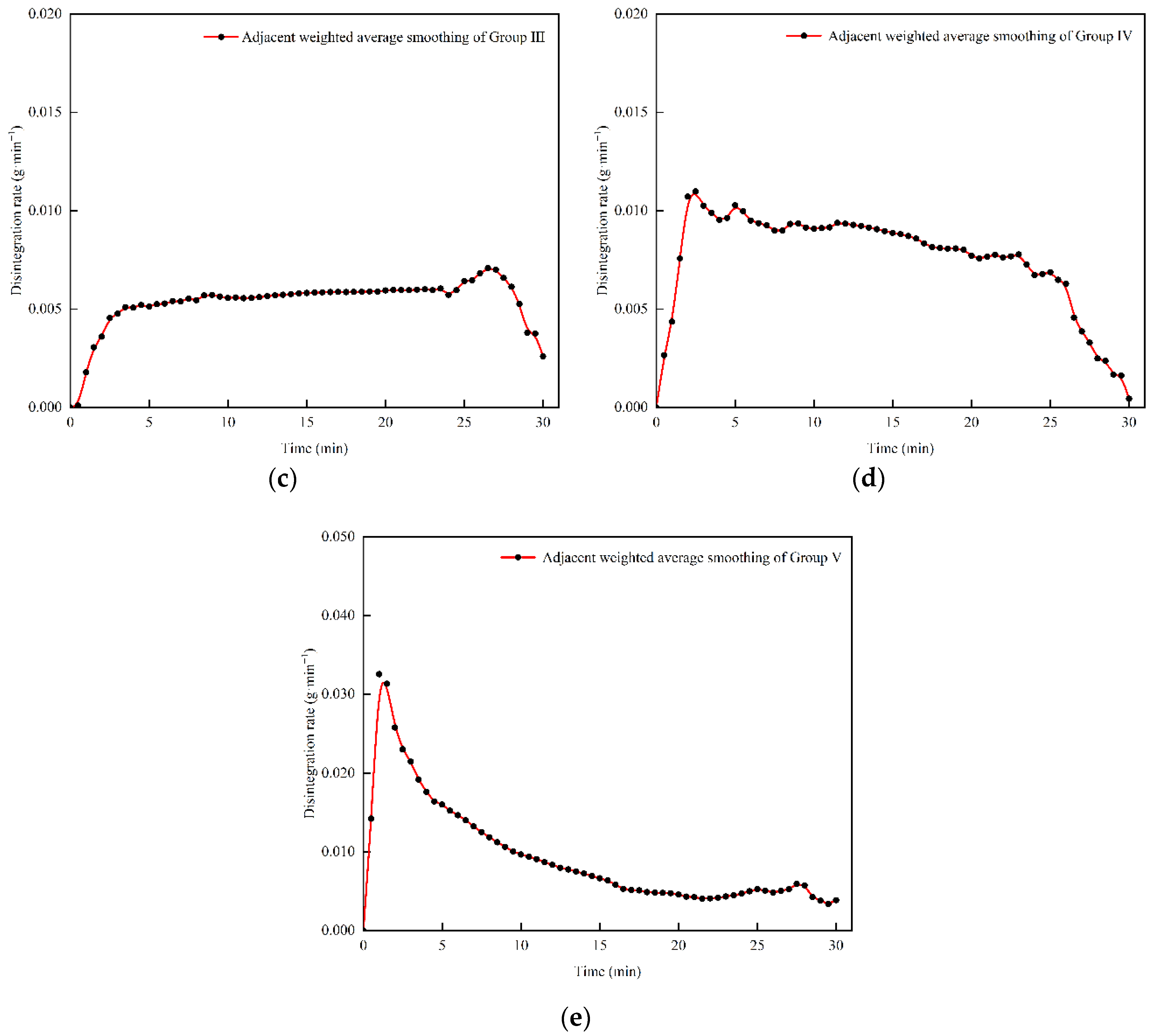

3.4. Effect of High-Performance Ester Materials (HEMs) on Red-Soil Disintegration Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mostafa, A.A.; Hafez, R.M.; Hegazy, A.K.; Fattah, A.M.A.; Mohamed, N.H.; Mustafa, Y.M.; Gobouri, A.A.; Azab, E. Variations of Structural and Functional Traits of Azolla pinnata R. Br. in Response to Crude Oil Pollution in Arid Regions. Sustainability 2021, 13, 2142. [Google Scholar] [CrossRef]

- Xerdiman, D.; Zhou, H.X.; Li, S.C.; Sun, H.L.; Xin, K.W.; Sun, D.Y.; Li, C.Y. Effects of Water-Retaining Agent Dosages on Slope-Protection Plants and Soil Nutrients on Rocky Slopes. Sustainability 2022, 14, 3615. [Google Scholar] [CrossRef]

- Wang, Z.H.; Luo, D.; Xiong, K.N.; Gu, X.; Zhu, Z.Z. Studies on Hydrological Processes on Karst Slopes for Control of Soil and Water Loss. Sustainability 2022, 14, 5789. [Google Scholar] [CrossRef]

- Gou, H.; Liao, J.; Du, F.; Tang, C.L.; Lin, Y.L.; Li, D.J.; Zhang, Y.L.; Ning, Y.Y.; Ye, Z.H.; Xu, Z.Y.; et al. Soil Remediation of Subtropical Garden Grasses and Shrubs Using High-Performance Ester Materials. Sustainability 2022, 14, 3228. [Google Scholar] [CrossRef]

- Yang, Z.C.; Zhang, J.Y.; Zhou, D.P. Study on fast weathering characteristics of red bed mudstone slope. Chin. J. Rock Mech. Eng. 2006, 25, 275–283. [Google Scholar]

- Gu, W.; Shao, Q.; Xu, Y. Experimental Study on Drainage with the Application of Plastic Blind Drains at the Bottom of the External Soil on Side Slopes. J. Basic Sci. Eng. 2010, 18, 379–389. [Google Scholar]

- Wu, Z.; Liu, J.; He, Y.; Wei, J.; Song, Z.; Sun, S. Erosion resistance characteristics of surface sand soil improved by polymer curing agent and vegetation. Adv. Sci. Technol. Water Resour. 2021, 41, 28–33, 70. [Google Scholar]

- Li, J.; Wang, X.; Zhang, Y.; Jiang, D.; Liu, D.; Ma, X.; Wang, J. Experimental study on strength and microstructure of loess reinforced with F1 ionic soil stabilizer. J. Southeast Univ. (Nat. Sci. Ed.) 2021, 51, 618–624. [Google Scholar]

- Ghanim, I.R.; Ebrahim, S.E. Solidification/stabilization of Heavy Metals Ions Using biocement Matrix. Biochem. Cell. Arch. 2021, 21, 703–714. [Google Scholar]

- Peng, E.; Hu, X.; Chou, Y.; Sheng, Y.; Liu, S.; Zhou, F.; Wu, J.; Cao, W. Study of microbially-induced carbonate precipitation for improving coarse-grained salty soil. J. Clean. Prod. 2022, 365, 132788. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Hago, A.W.; Al-Sarmi, H. Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman. Build. Environ. 2005, 40, 681–687. [Google Scholar] [CrossRef]

- Khatami, H.R.; O’Kelly, B.C. Improving Mechanical Properties of Sand Using Biopolymers. J. Geotech. Geoenvironmental Eng. 2013, 139, 1402–1406. [Google Scholar] [CrossRef] [Green Version]

- Cazzuffi, D.; Cardile, G.; Gioffrè, D. Geosynthetic Engineering and Vegetation Growth in Soil Reinforcement Applications. Transp. Infrastruct. Geotechnol. 2014, 1, 262–300. [Google Scholar] [CrossRef]

- Han, J.; Guo, J. Geosynthetics used to stabilize vegetated surfaces for environmental sustainability in civil engineering. Front. Struct. Civ. Eng. 2017, 11, 56–65. [Google Scholar] [CrossRef]

- Syahril, S.; Suyono, A.; Prajudi, I.R. Study of Soft Soil Stabilization on Slope Using Volcanic Ash and Phosphoric Acid Concerning of Plasticity Index. In International Seminar of Science and Applied Technology (ISSAT 2020); Advances in Engineering Research; Atlantis Press: Paris, France, 2020. [Google Scholar]

- Zhang, J.; Yi, W.; Yuan, W.; Liu, Y.; Sui, Z. Research on the Ecological Protection of Coal Gangue Slope Based on a Polymer Curing Agent. Adv. Mater. Sci. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Zhou, K.; Su, S.; Liu, F.; Gao, F.; Yang, Z. Experimental research on applicability of soil stabilizer in dry-tailing stacking. J. Saf. Sci. Technol. 2015, 11, 36–42. [Google Scholar]

- Zhang, Y.M.; Hu, X.Q.; Li, Z. Experimental Study on Reinforcement of Biological Enzyme for Road Soil. In Proceedings of the 6th International Conference on Energy and Environmental Protection (ICEEP), Zhuhai, China, 29–30 June 2017; pp. 1209–1213. [Google Scholar]

- Kushwaha, S.S.; Kishan, D.; Dindorkar, N. Stabilization of Expansive Soil Using Eko Soil Enzyme for Highway Embankment. In Proceedings of the 8th International Conference on Materials Processing and Characterization (ICMPC), Hyderabad, India, 16–18 March 2018; pp. 19667–19679. [Google Scholar]

- Divya, V.; Asha, M.N. Evaluation of sustainable methods for embankment stabilization. IOP Conf. Ser. Earth Environ. Sci. 2020, 573, 012008. [Google Scholar] [CrossRef]

- Zhou, C.Y.; Li, D.X.; Liu, Z. Quantitative Characterization of the Aqua-Dispersing Nano-Binder Effects on the Slip Resistance of Borrowed Soil of a Rock Slope. Appl. Sci. 2019, 9, 3618. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.Y.; Zhao, S.S.; Yang, X.; Liu, Z. Improvement of eco-ester materials on sandy soils and engineering slope protection. Rock Soil Mech. 2019, 40, 4828–4837. [Google Scholar]

- Huang, W.; Liu, Z.; Zhou, C.Y.; Yang, X. Enhancement of soil ecological self-repair using a polymer composite material. Catena 2020, 188, 104443. [Google Scholar] [CrossRef]

- Huang, W.; Du, J.X.; Sun, H.; Zhou, C.Y.; Liu, Z.; Zhang, L.H. New polymer composites improve silty clay soil microstructure: An evaluation using NMR. Land Degrad. Dev. 2021, 32, 3272–3281. [Google Scholar] [CrossRef]

- Huang, W.; Zhou, C.Y.; Liu, Z.; Sun, H.; Du, J.X.; Zhang, L.H. Improving Soil-Water Characteristics and Pore Structure of Silty Soil Using Nano-aqueous Polymer Stabilisers. Ksce J. Civ. Eng. 2021, 25, 3298–3305. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, H.; Lin, K.; Zhou, C.Y.; Huang, W. Occurrence Regularity of Silt-Clay Minerals in Wind Eroded Deserts of Northwest China. Sustainability 2021, 13, 2998. [Google Scholar] [CrossRef]

- Huang, W.; Lin, K.; Du, J.; Zhou, C.; Liu, Z.; Zhang, L. Application of New Polymer Composite Materials in Rock Slope Ecological. IOP Conf. Ser. Earth Environ. Sci. 2021, 861, 042092. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, W.; Huang, Y.; Qiu, X.; Wu, J. Analysis of durability performance of ionic soil stabilizer improving soil. Key Eng. Mater. 2016, 667, 335–340. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, Y.; Wang, H. Application and curing mechanism of soil stabilizer. Adv. Mater. Res. 2012, 557–559, 809–812. [Google Scholar] [CrossRef]

- Lin, J.; Mou, G.; Yang, X. Agricultural Application Study of Super Absorbent Resin. Bull. Soil Water Conserv. 2010, 30, 167–170. [Google Scholar]

- Liu, L.; Qiu, W.; Xu, W.; Sun, C.; Guo, P. Discussion on traditional slope protection and ecological slope protection technology. J. China Three Gorges Univ. 2007, 29, 528–532. [Google Scholar]

- Qin, X.C.; Ni, A.C.; Zhang, N.; Chen, Z.H. Erosion Control and Growth Promotion of W-OH Material on Red Clay Highway Slopes: A Case Study in South China. Sustainability 2021, 13, 1144. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Jiang, B.; Liu, J.; Li, M.; Li, W.; Song, Z. An experimental study of the ecological restoration of rock slope based on polyurethane composite-based materials. Hydrogeol. Eng. Geol. 2021, 48, 174–181. [Google Scholar]

- Zhou, C.Y.; Zhao, S.S.; Huang, W.; Li, D.X.; Liu, Z. Study on the Stabilization Mechanisms of Clayey Slope Surfaces Treated by Spraying with a New Soil Additive. Appl. Sci. 2019, 9, 1245. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.Y.; Huang, W.; Qiu, S.Y.; Liu, Z. A quantitative study on the amount of water-retaining agent based on adhesive-modified red bed weathered soil. Bull. Eng. Geol. Environ. 2021, 80, 3139–3150. [Google Scholar] [CrossRef]

- Zhou, C.; Ge, X.; Huang, W.; Li, D.; Liu, Z. Effects of Aqua-Dispersing Nano-Binder on Clay Conductivity at Different Temperatures. Sustainability 2019, 11, 4859. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, X. Effect of EN-1 Ionic Stabilizer on Moisture Characteristics of Loess Soil. Chin. J. Soil Sci. 2014, 45, 24–31. [Google Scholar]

- Wang, Y.; Liu, J.; Wang, Q.; Kong, F.; Wang, Y.; Li, D. Study on the Permeability Characteristics of Sand Reinforced with Polymer Soil Stabilizers. J. Disaster Prev. Mitig. Eng. 2020, 40, 243–250. [Google Scholar]

- Guo, Y.; Geng, Y.; Zhang, Y.; Zhang, L. Effects of EN-1Stabilizer on Soil Anti-collapse Ability. Bull. Soil Water Conserv. 2015, 35, 214. [Google Scholar]

- Lu, J.; Zheng, F.; An, J.; Li, G. An experimental study of Mollisol aggregate loss characteristics during rainfall erosion processes. Acta Ecol. Sin. 2016, 36, 2264–2273. [Google Scholar]

- Ramos, M.C.; Nacci, S.; Pla, I. Effect of raindrop impact and its relationship with aggregate stability to different disaggregation forces. Catena 2003, 53, 365–376. [Google Scholar] [CrossRef]

- Angers, D.A.; Bullock, M.; Mehuys, G. Aggregate stability to water. Soil Sampl. Methods Anal. 2008, 2, 811–819. [Google Scholar]

- Wuddivira, M.N.; Ekwue, E.I.; Stone, R.J. Modelling slaking sensitivity to assess the degradation potential of humid tropic soils under intense rainfall. Land Degrad. Dev. 2010, 21, 48–57. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, E.; Chen, X. Effect of mechanical compaction on soil micro-aggregate composition and stability of black soil. Trans. Chin. Soc. Agric. Eng. 2015, 31, 54–59. [Google Scholar]

- Zhang, Z.; Zhu, Z.; Wen, Z. Compositional Characteristics of Soil Micro-aggregates and Its Relationship with Soil Properties in Karst Mountain. J. Soil Water Conserv. 2014, 28, 123. [Google Scholar]

- Xu, X.T.; Wang, Y.B.; Bai, R.Q.; Fan, C.X.; Hua, S.G. Comparative studies on mechanical behavior of frozen natural saline silty sand and frozen desalted silty sand. Cold Reg. Sci. Technol. 2016, 132, 81–88. [Google Scholar] [CrossRef]

- Zhang, X.; Kong, L.; Chen, C.; Yin, S. Experimental investigation on relative contribution of hot and humid weather and heavy rainfall in disintegration of basalt residual soil. Sci. Sin. Technol. 2016, 46, 1175–1184. [Google Scholar] [CrossRef]

- He, Z.Q.; Fan, H.H.; Wang, J.Q.; Liu, G.; Wang, Z.N.; Yu, J.H. Experimental study of engineering properties of loess reinforced by lignosulfonate. Rock Soil Mech. 2017, 38, 731–739. [Google Scholar]

- Li, S.; Shou, K.; Liu, Z.; Meng, J. Water Absorption of Red Clay and its Influence on the Slaking Test. J. Guilin Univ. Technol. 2011, 41, 804–809. (In Chinese) [Google Scholar]

- Zhang, W.; Chen, J. Experimental Studies of Reinforced Fibers in All Recycled Material Mixtures. Soil Eng. Found. 2020, 34, 732–735. (In Chinese) [Google Scholar]

- Qin, W.; Zuo, C.; Yan, Q.; Wang, Z.; Du, P.; Yan, N. Regularity of individual rainfall soil erosion in bare slope land of red soil. Trans. Chin. Soc. Agric. Eng. 2015, 31, 124–132. [Google Scholar]

| Soil | Volumetric Weight (g·cm−3) | Water Content (%) | Grain Size Distribution | ||||

|---|---|---|---|---|---|---|---|

| ≥2 mm | 2–1 mm | 1–0.5 mm | 0.5–0.25 mm | ≥0.25 mm | |||

| Red soil | 1.42 | 9.32 | 40.16 | 3.86 | 5.75 | 8.98 | 58.75 |

| Group Number | Adhesive High-Performance Ester Materials (hems) (g·m−3) | Absorbent High-Performance Ester Materials (hems) (g·m−3) |

|---|---|---|

| I | 10 | 0 |

| II | 10 | 40 |

| III | 10 | 60 |

| IV | 10 | 80 |

| V | 10 | 100 |

| VI | 10 | 120 |

| Group Number | wd(i≥0.25 mm) | ww(i≥0.25 mm) | FR (%) | Amplitude of Variation (%) |

|---|---|---|---|---|

| Ⅰ | 61.1 | 74.03 | 21.16 | / |

| Ⅱ | 67.55 | 80.42 | 19.05 | −9.97% |

| Ⅲ | 69.76 | 84.94 | 21.76 | 2.84% |

| Ⅳ | 69.21 | 81.62 | 17.93 | −15.26% |

| Ⅴ | 70.63 | 90.54 | 28.19 | 33.22% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, J.; Liu, Z.; Zhou, C.; Zhang, Q. Disintegration Resistance of Steep-Rocky-Slope Wall-Hanging Soil Based on High-Performance Ester Materials. Sustainability 2022, 14, 8850. https://doi.org/10.3390/su14148850

Liao J, Liu Z, Zhou C, Zhang Q. Disintegration Resistance of Steep-Rocky-Slope Wall-Hanging Soil Based on High-Performance Ester Materials. Sustainability. 2022; 14(14):8850. https://doi.org/10.3390/su14148850

Chicago/Turabian StyleLiao, Jin, Zhen Liu, Cuiying Zhou, and Qingxiu Zhang. 2022. "Disintegration Resistance of Steep-Rocky-Slope Wall-Hanging Soil Based on High-Performance Ester Materials" Sustainability 14, no. 14: 8850. https://doi.org/10.3390/su14148850

APA StyleLiao, J., Liu, Z., Zhou, C., & Zhang, Q. (2022). Disintegration Resistance of Steep-Rocky-Slope Wall-Hanging Soil Based on High-Performance Ester Materials. Sustainability, 14(14), 8850. https://doi.org/10.3390/su14148850