A Two-Step Fuzzy MCDM Method for Implementation of Sustainable Precision Manufacturing: Evidence from China

Abstract

:1. Introduction

2. Literature Review

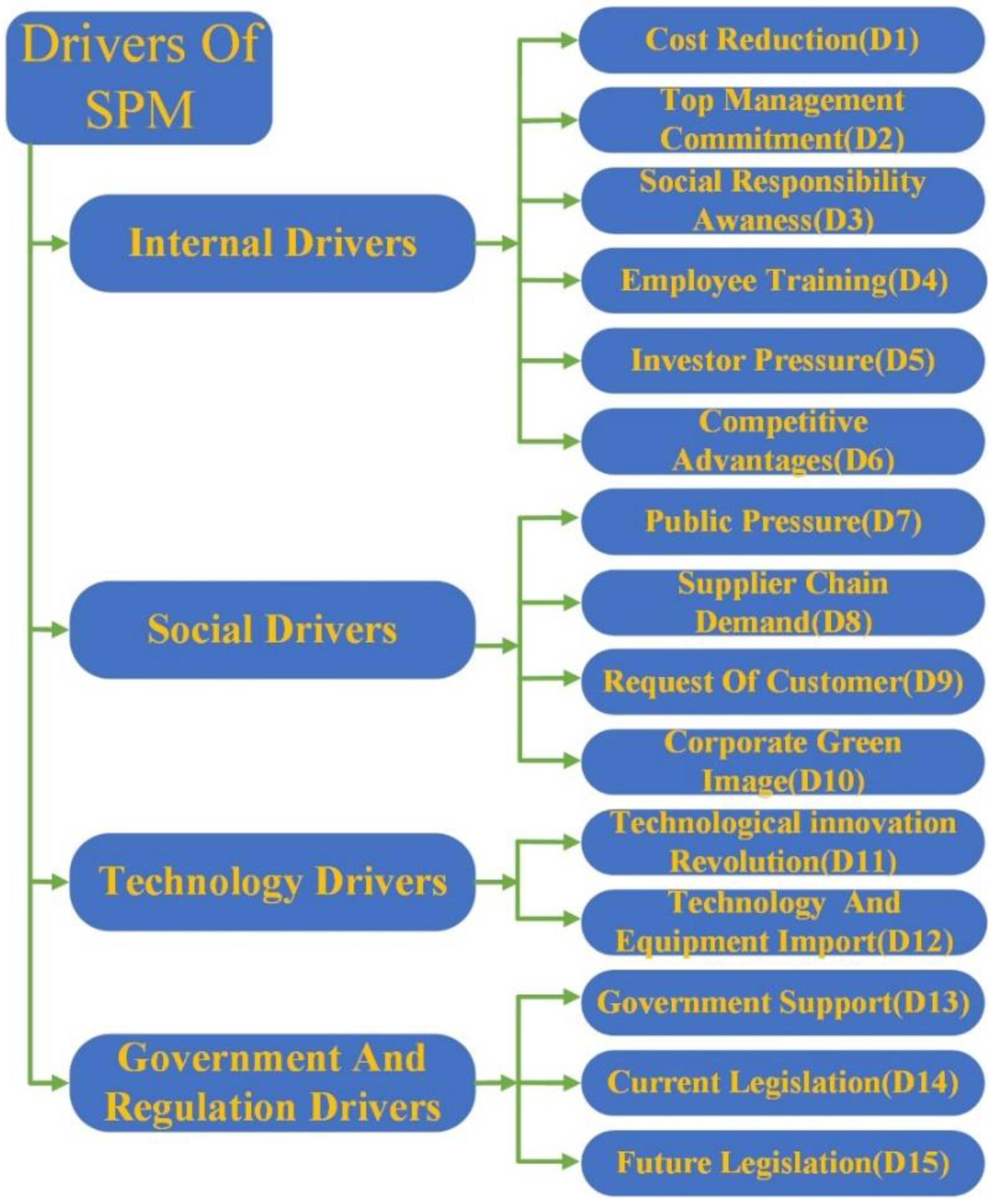

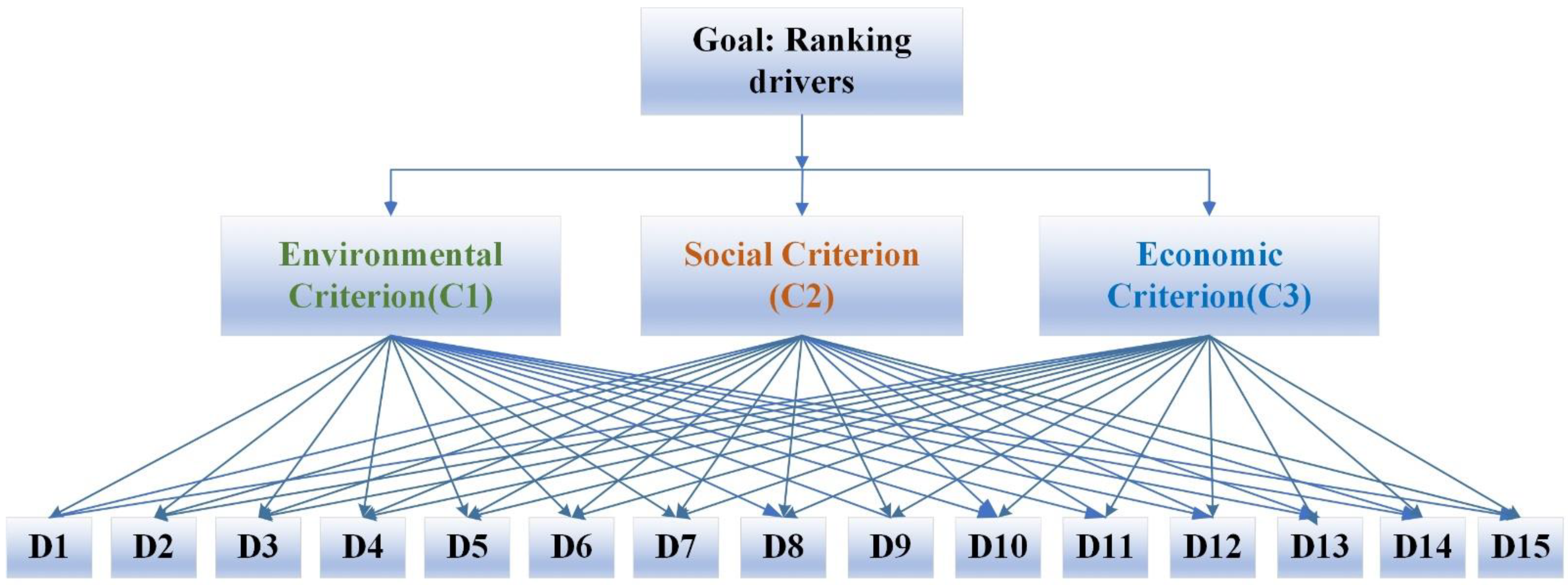

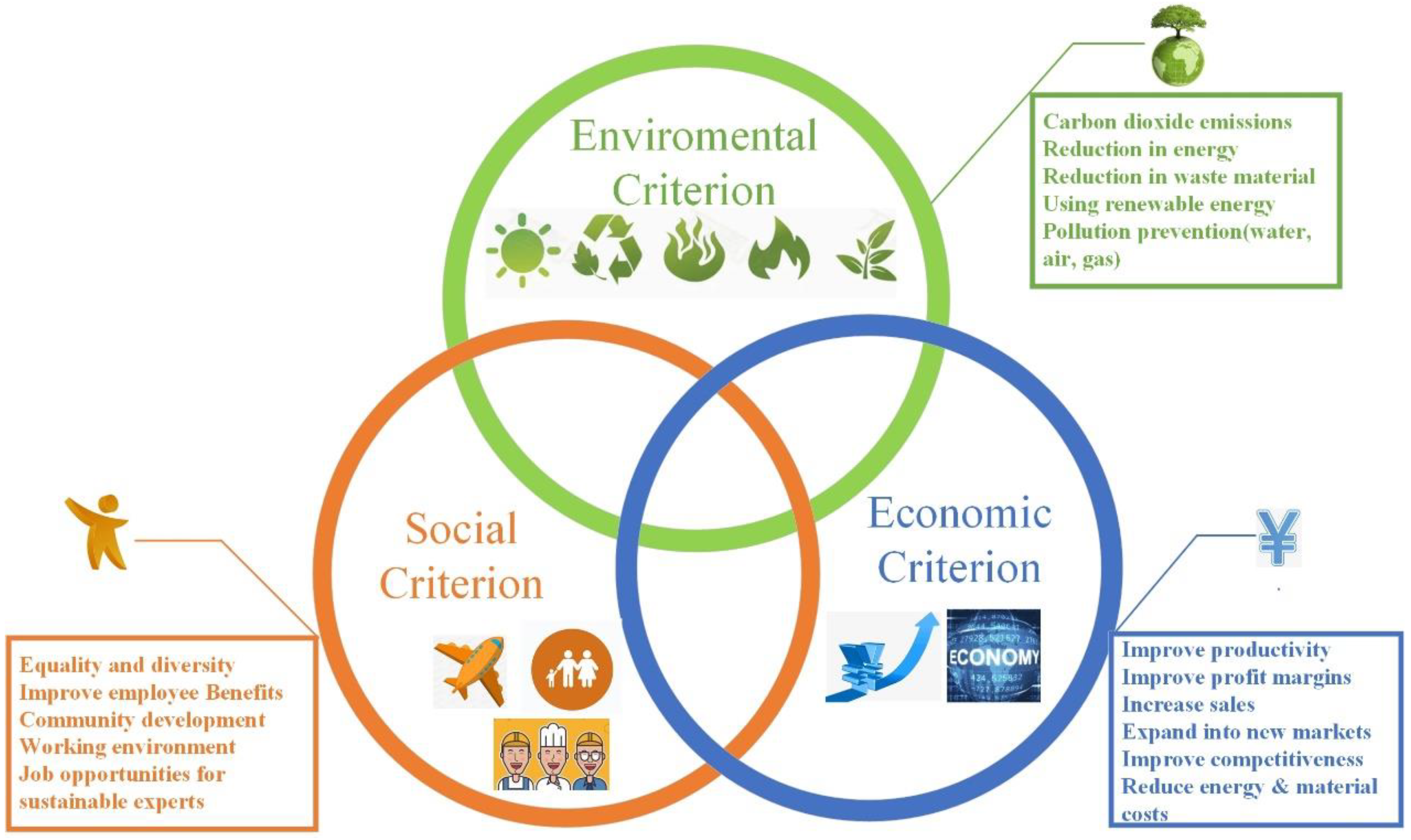

2.1. Drivers of Sustainable Precision Manufacturing

2.2. MCDM Methods

2.3. Gap Areas and Highlights

3. Methodology

3.1. Calculation of Drivers’ Weights Using Proposed Fuzzy AHP Method

3.2. Fuzzy TOPSIS Method

4. Application of the Two-Step Fuzzy MCMD Method

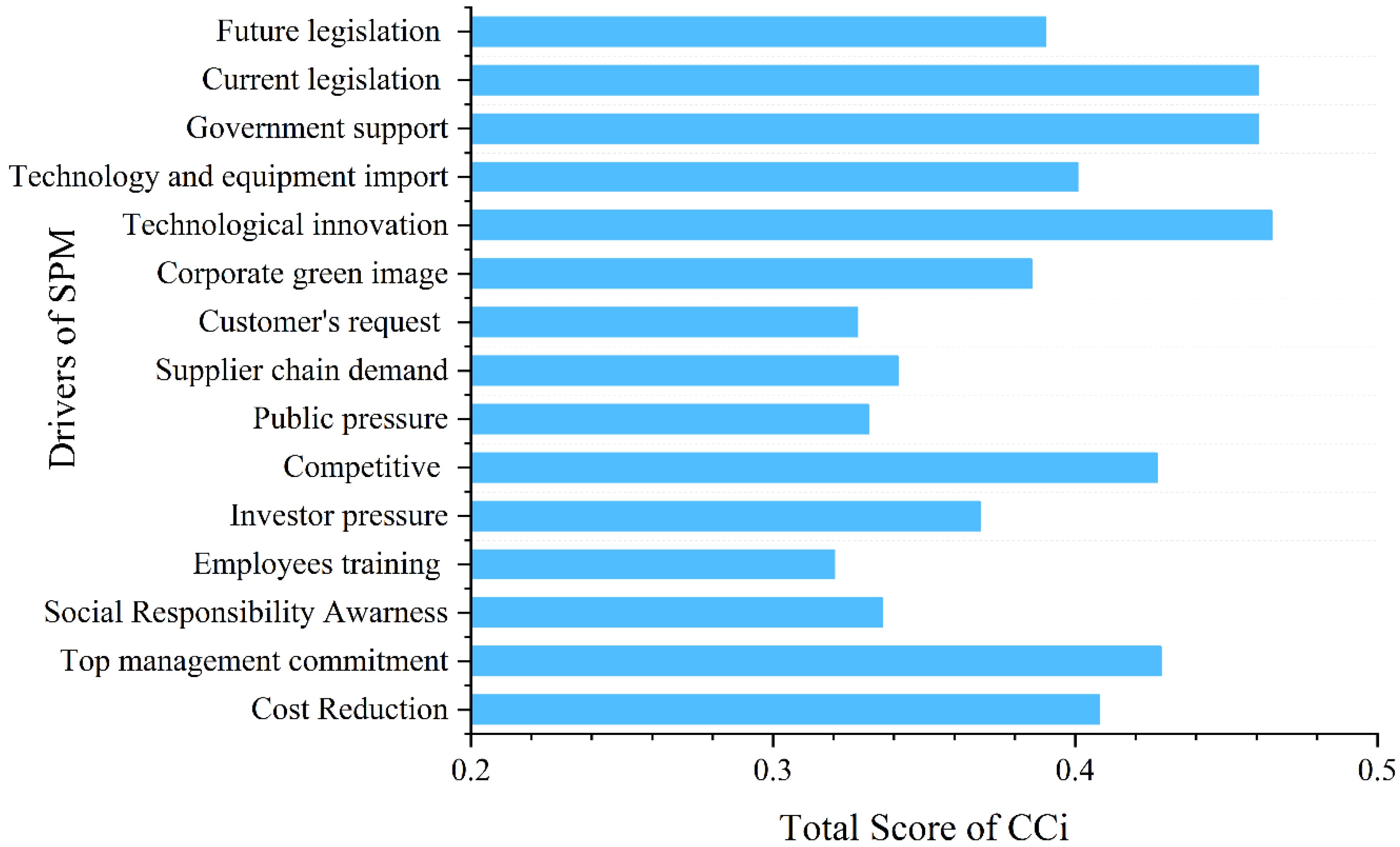

5. Results and Discussion

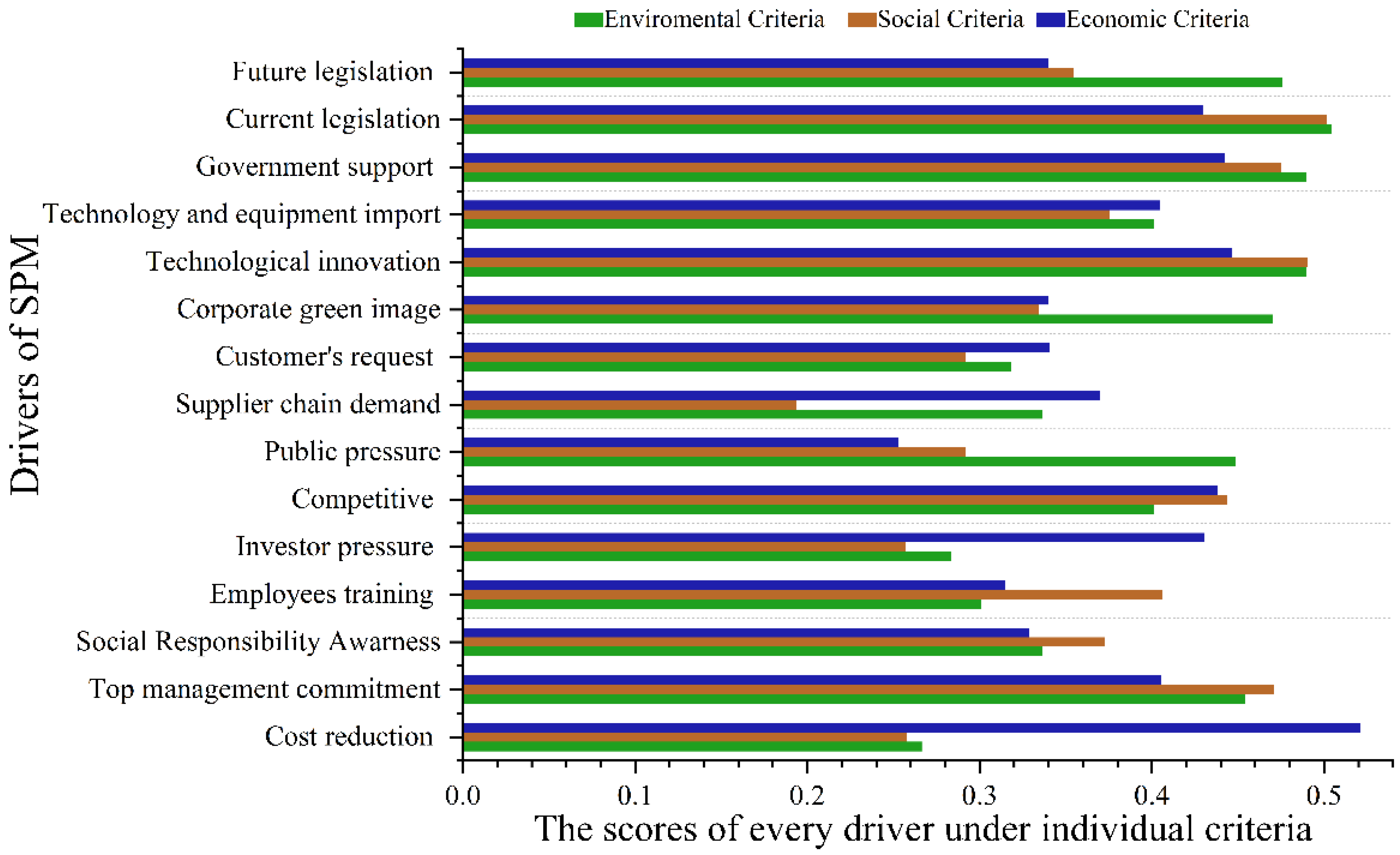

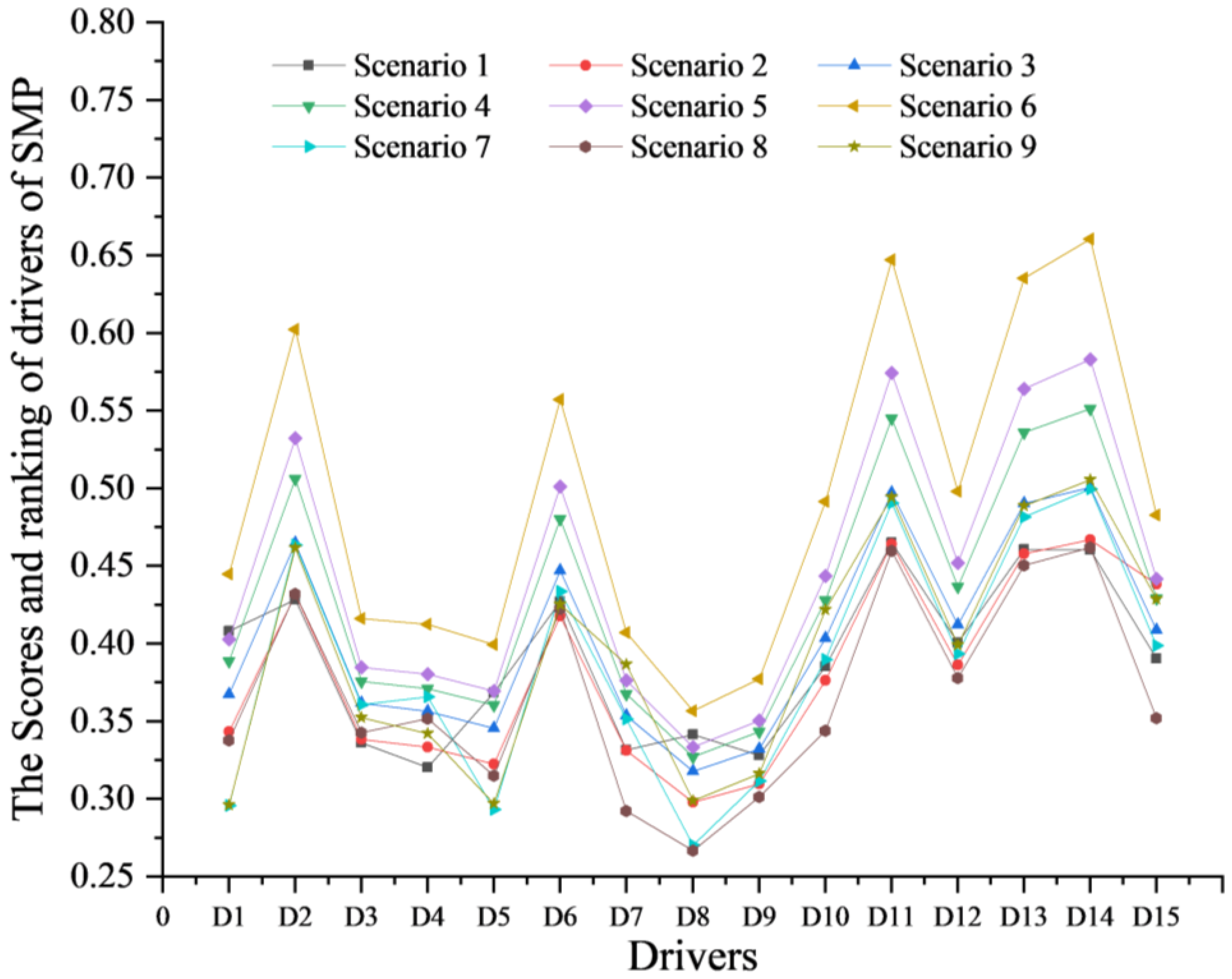

5.1. Results

5.2. Discussion

6. Implications of the Study

- Strengthening technological innovations of SPM.

- 2.

- Strengthen government support and policy supervision.

- 3.

- Accurately use the driver ranking from different perspectives.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World GDP 1960–2022. Available online: https://www.macrotrends.net/countries/WLD/world/gdp-gross-domestic-product (accessed on 6 April 2022).

- Emissions for Manufacturing. Available online: https://www.baux.com/sustainability/manufacturing (accessed on 6 April 2022).

- Yip, W.S.; To, S.; Zhou, H. Current status, challenges and opportunities of sustainable ultra-precision manufacturing. J. Intell. Manuf. 2021, 1–13. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, E.Y.; Qi, H.; Ji, S.M.; Chen, Z.Z. A novel polishing method for single-crystal silicon using the cavitation rotary abrasive flow. Precis. Eng. 2019, 61, 72–81. [Google Scholar] [CrossRef]

- Radetzky, M.; Grams, L.; Ulutas, B.; Bracke, S. Sustainability versus efficiency of manufacturing process: Structured comparisonof two high precision fine grinding processes. Procedia Manuf. 2019, 39, 859–867. [Google Scholar] [CrossRef]

- Garcia, M.V.; Lopes, J.C.; Diniz, A.E.; Rodrigues, A.R.; Volpato, R.S.; Sanchez, L.E.d.A.; Mello, H.J.d.M.; Aguiar, P.R.; Bianchi, E.C. Grinding performance of bearing steel using MQL under different dilutions and wheel cleaning for green manufacture. J. Clean. Prod. 2020, 257, 120376. [Google Scholar] [CrossRef]

- Li, M.; Xie, J.C. Green-chemical-jump-thickening polishing for silicon carbide. Ceram. Int. 2022, 48, 1107–1124. [Google Scholar] [CrossRef]

- Zhao, J.; Xiang, Y.C.; Fan, C. A new method for polishing the inner wall of a circular tube with a soft abrasive rotating jet. Powder Technol. 2021, 398, 117068. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2012, 24, 148–157. [Google Scholar] [CrossRef]

- Stisusman: About Sustainable Manufacturing and the Toolkit. Available online: https://www.oecd.org/innovation/green/toolkit/aboutsustainablemanufacturingandthetoolkit.htm (accessed on 6 April 2022).

- Jeurissen, R.; Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business. J. Bus. Ethics 2000, 23, 229–231. [Google Scholar] [CrossRef]

- Nezhad, H. World Energy Scenarios to 2050: Issues and Options; White Paper; Metropolitan State University: Minneapolis, MN, USA, 2009. [Google Scholar]

- Rosen, M.A.; Kishawy, H.A. Sustainable Manufacturing and Design: Concepts, Practices and Needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef] [Green Version]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Thirupathi, R.M.; Vinodh, S.; Dhanasekaran, S. Application of system dynamics modelling for a sustainable manufacturing system of an Indian automotive component manufacturing organisation: A case study. Clean Technol. Environ. Policy 2019, 21, 1055–1071. [Google Scholar] [CrossRef]

- Executive Office of the President’s Council of Advisors on Science and Technology. Report to the President on Capturing Domestic Competitive Advantage in Advanced Manufacturing. Available online: https://www.whitehouse.gov/sites/default/files/microsites/ostp/pcast_amp_steering_committee_report_final_july_27_2012.pdf (accessed on 6 April 2022).

- Horizon 2020. The EU Framework Programme for Research and Innovation. Available online: https://ec.europa.eu/programmes/horizon2020 (accessed on 6 April 2022).

- Notice of the State Council on Issuing “Made in China 2025”. Available online: http://www.gov.cn/zhengce/content/2015-05/19/content_9784.htm (accessed on 6 April 2022).

- Bilge, P.; Badurdeen, F.; Seliger, G.; Jawahir, I. A novel manufacturing architecture for sustainable value creation. CIRP Ann. 2016, 65, 455–458. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef] [Green Version]

- Qiu, L.; Jie, X.W.; Wang, Y.N.; Zhao, M.J. Green product innovation, green dynamic capability, and competitive advantage: Evidence form Chinese manufacturing enterprises. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 146–165. [Google Scholar] [CrossRef]

- Shankar, K.M.; Kumar, P.U.; Kannan, D. Analyzing the Drivers of Advanced Sustainable Manufacturing System Using AHP Approach. Sustainability 2016, 8, 824. [Google Scholar] [CrossRef] [Green Version]

- UN-CSD (The United Nations Committee on Sustainable Development). Indicators of Sustainable Development: Guidelines and Methodologies, 3rd ed.; The United Nations: New York, NY, USA, 2007; Available online: http://www.un.org/esa/sustdev/natlinfo/indicators/guidelines.pdf (accessed on 6 April 2022).

- US Department of Commerce. Sustainable Manufacturing Initiative (SMI): A True Public-Private Dialogue; International Trade Administration: Washington, DC, USA, 2011; pp. 1–16.

- Xia, X.Q.; Govindan, K.G.; Zhu, Q.H. Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Luo, Y.; Jie, X.W.; Li, X.P.; Yao, L.M. Ranking Chinese SMEs Green Manufacturing Drivers Using a Novel Hybrid Multi-Criterion Decision-Making Model. Sustainability 2018, 8, 824. [Google Scholar] [CrossRef] [Green Version]

- Gandhi, N.S.; Thanki, S.J.; Thakkar, J.J. Ranking of drivers for integrated lean-green manufacturing for Indian manufacturing SMEs. J. Clean. Prod. 2018, 171, 675–689. [Google Scholar] [CrossRef]

- Lin, C.J.; Belis, T.T.; Kuo, T.C. Ergonomics-Based Factors or Criteria for the Evaluation of Sustainable Product Manufacturing. Sustainability 2019, 11, 4955. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.G.; Ao, X.Y.; Jiang, Z.G.; Zhang, H. A sustainability evaluation method integrating the energy, economic and environment in remanufacturing systems. J. Clean. Prod. 2019, 239, 118100. [Google Scholar] [CrossRef]

- Singh, M.; Singh, K.; Sethi, A.S. Analytical hierarchy process and TOPSIS for selecting best parameters of green manufacturing. Meas. Bus. Excel. 2020, 24, 345–365. [Google Scholar] [CrossRef]

- Ali, H.; Chen, T.; Hao, Y.H. Sustainable Manufacturing Practices, Competitive Capabilities, and Sustainable Performance: Moderating Role of Environmental Regulations. Sustainability 2021, 13, 10051. [Google Scholar] [CrossRef]

- Ullah, S.; Khan, F.U.; Ahmad, N. Promoting sustainability through green innovation adoption:a case of manufacturing industry. Environ. Sci. Pollut. Res. 2021, 29, 21119–21139. [Google Scholar] [CrossRef] [PubMed]

- Moktadir, A.; Rahman, T.; Jabbour, C.J.C.; Ali, S.M.; Kabir, G. Prioritization of drivers of corporate social responsibility in the footwear industry in an emerging economy: A fuzzy AHP approach. J. Clean. Prod. 2018, 201, 369–381. [Google Scholar] [CrossRef]

- Ho, F.H.; Abdul-Rashid, S.H.; Ghazilla, R.A.; Sakundarini, N.; Woo, Y.L.; Ahmad, S.; Ghazali, I.; Haq, R.H.A. What Key Drivers Are Needed to Implement Material Efficiency Strategies? An Analysis of the Electrical and Electronic Industry in Malaysia and Its Implications to Practitioners. Sustainability 2021, 13, 2065. [Google Scholar] [CrossRef]

- Orji, I.J.; Liu, S.X. A dynamic perspective on the key drivers of innovation-led lean approaches to achieve sustainability in manufacturing supply chain. Int. J. Prod. Econ. 2020, 219, 480–496. [Google Scholar] [CrossRef]

- Misopoulos, F.; Michaelides, R.; Salehuddin, M.A.; Manthou, V.; Michaelides, Z. Addressing Organisational Pressures as Drivers towards Sustainability in Manufacturing Projects and Project Management Methodologies. Sustainability 2018, 10, 2098. [Google Scholar] [CrossRef] [Green Version]

- Qu, Y.; Li, M.R.; Jia, H.; Guo, L.L. Developing More Insights on Sustainable Consumption in China Based on Q Methodology. Sustainability 2015, 7, 14211–14229. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.Q.; Wang, Q.; Zhang, S.S.; Zhao, X.D. Effects of customer and cost drivers on green supply chain management practices and environmental performance. J. Clean. Prod. 2018, 189, 673–682. [Google Scholar] [CrossRef]

- Liu, C.H.; Cai, W.; Jia, S.; Zhang, M.Y.; Guo, H.Y.; Hu, L.K.; Jiang, Z.G. Emergy-based evaluation and improvement for sustainable manufacturing systems considering resource efficiency and environment performance. Energy Convers. Manag. 2018, 177, 176–189. [Google Scholar] [CrossRef]

- Seth, D.; Ahemad, M.; Rehman, A.; Shrivastava, R.L. Green manufacturing drivers and their relationships for small and medium (SME) and large industries. J. Clean. Prod. 2018, 198, 1381–1405. [Google Scholar] [CrossRef]

- Yi, H. Green businesses in a clean energy economy: Analyzing drivers of green business growth in U.S. states. Energy 2014, 68, 922–929. [Google Scholar] [CrossRef]

- Aboelmaged, M. The drivers of sustainable manufacturing practices in Egyptian SMEs and their impact on competitive capabilities: A PLS-SEM model. J. Clean. Prod. 2018, 175, 207–221. [Google Scholar] [CrossRef]

- Santolaria, M.; Oliver-Solà, J.; Gasol, C.M.; Morales-Pinzón, T.; Rieradevall, J. Eco-design in innovation driven companies: Perception, predictions and the main drivers of integration. The Spanish example. J. Clean. Prod. 2011, 19, 1315–1323. [Google Scholar] [CrossRef]

- Ososanmi, A.O.; Ojo, L.D.; Ogundimu, O.E.; Emmanuel, A. Drivers of green supply chain management: A close-up study. Environ. Sci. Pollut. Res. 2022, 29, 14705–14718. [Google Scholar] [CrossRef]

- Halili, Z. Identifying and ranking appropriate strategies for effective technology transfer in the automotive industry: Evidence from Iran. Technol. Soc. 2020, 62, 101264. [Google Scholar] [CrossRef]

- Sealy, M.P.; Liu, Z.Y.; Zhang, D.; Guo, Y.B.; Liu, Z.Q. Energy consumption and modeling in precision hard milling. J. Clean. Prod. 2016, 135, 1591–1601. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, R.; Huang, J.F.; Hu, B.W.; Ji, S.M. Micro ultrasonic machining hemispherical mold for MEMS resonator gyroscope using a novel ultraprecise ceramic entire-ball tool. J. Micromechan. Microeng. 2020, 30, 075007. [Google Scholar] [CrossRef]

- Goldhahn, L.; Eckardt, R. Sustainable Process Planning of Manufacturing Variants for High-precision Parts. Procedia CIRP 2016, 46, 344–347. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Huang, J.F.; Xiang, Y.C.; Wang, R.; Xu, X.Q.; Ji, S.M.; Hang, W. Effect of a protective coating on the surface integrity of a microchannel produced by microultrasonic machining. J. Manuf. Process. 2021, 61, 280–295. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, R.; Jiang, E.Y.; Ji, S.M. Research on a new method for optimizing surface roughness of cavitation abrasive flow polishing monocrystalline silicon. Int. J. Adv. Manuf. Technol. 2021, 113, 1649–1661. [Google Scholar] [CrossRef]

- Fan, C.; Liu, K.X.; Chen, Y.G.; Xue, Y.C.; Zhao, J.; Khudoley, A. A new modelling method of material removal profile for electrorheological polishing with a mini annular integrated electrode. J. Mater. Process. Technol. 2022, 305, 117589. [Google Scholar] [CrossRef]

- Ji, S.M.; Cao, H.Q.; Zhao, J.; Pan, Y.; Jiang, E.Y. Soft abrasive flow polishing based on the cavitation effect. Int. J. Adv. Manuf. Technol. 2019, 101, 1865–1878. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, J.F.; Wang, R.; Peng, H.R.; Ji, S.M. Investigation of the optimal parameters for the surface finish of K9 optical glass using a soft abrasive rotary flow polishing process. J. Manuf. Process. 2019, 49, 26–34. [Google Scholar] [CrossRef]

- Fan, C.; Hong, G.S.; Zhao, J.; Zhang, L.; Zhao, J.; Sun, L.N. The integral sliding mode control of a pneumatic force servo for the polishing process. Precis. Eng. 2018, 55, 154–170. [Google Scholar] [CrossRef]

- Schneider, F.; Das, J.; Kirsch, B.; Linke, B.; Aurich, J. Sustainability in Ultra Precision and Micro Machining: A Review. Int. J. Precis. Eng. Manuf. Technol. 2019, 6, 601–610. [Google Scholar] [CrossRef] [Green Version]

- Sharma, M.; Sehrawat, R. A hybrid multi-criteria decision-making method for cloud adoption: Evidence from the healthcare sector. Technol Soc. 2020, 61, 101258. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T. Prioritization of sustainable manufacturing barriers using Best Worst Method. J. Clean. Prod. 2019, 226, 589–600. [Google Scholar] [CrossRef]

- Ibáñez-Forés, V.; Bovea, M.D.; Pérez-Belis, V. A holistic review of applied methodologies for assessing and selecting the optimal technological alternative from a sustainability perspective. J. Clean. Prod. 2014, 70, 259–281. [Google Scholar] [CrossRef]

- Ocampo, L.A. Applying fuzzy AHP–TOPSIS technique in identifying the content strategy of sustainable manufacturing for food production. Environ. Dev. Sustain. 2019, 21, 2225–2251. [Google Scholar] [CrossRef]

- Liang, G.S. Fuzzy MCDM based on ideal and anti-ideal concepts. Eur. J. Oper. Res. 1999, 112, 682–691. [Google Scholar] [CrossRef]

- Ertuğrul, İ.; Karakaşoğlu, N. Comparison of fuzzy AHP and fuzzy TOPSIS methods for facility location selection. Int. J. Adv. Manuf. Technol. 2008, 39, 783–795. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, V. Review on multi-criteria decision analysis in sustainable manufacturing decision making. Int. J. Sustain. Eng. 2021, 14, 202–225. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making Methods and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Wang, T.C.; Lee, H.D. Developing a fuzzy TOPSIS approach based on subjective weights and objective weights. Expert. Syst. Appl. 2009, 36, 8980–8985. [Google Scholar] [CrossRef]

- Behzadian, M.; Otaghsara, S.K.; Yazdani, M.; Ignatius, J. A state-of the-art survey of TOPSIS applications. Expert. Syst. Appl. 2012, 39, 13051–13069. [Google Scholar] [CrossRef]

- Shyur, H.J.; Shih, H.S. A hybrid MCDM model for strategic vendor selection. Math. Comput. Model. 2006, 44, 749–761. [Google Scholar] [CrossRef]

- Rouhani, S.; Ghazanfari, M.; Jafari, M. Evaluation model of business intelligence for enterprise systems using fuzzy TOPSIS. Expert Syst. Appl. 2012, 39, 3764–3771. [Google Scholar] [CrossRef]

- Riaz, M.; Tanveer, S.; Pamucar, D.; Qin, D.-S. Topological Data Analysis with Spherical Fuzzy Soft AHP-TOPSIS for Environmental Mitigation System. Mathematics 2022, 10, 1826. [Google Scholar] [CrossRef]

- Riaz, M.; Smarandache, F.; Firdous, A.; Fakhar, A. On Soft Rough Topology with Multi-Attribute Group Decision Making. Mathematics 2019, 7, 67. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.C. A performance evaluation model by integrating fuzzy AHP and fuzzy TOPSIS methods. Expert Syst. Appl. 2010, 37, 7745–7754. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications. In Lecture notes in Economics and Mathematical Systems; Springer: Now York, NY, USA, 1981. [Google Scholar]

- Buckley, J.J. Fuzzy hierarchical analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Hsieh, T.Y.; Lu, S.T.; Tzeng, G.H. Fuzzy MCDM approach for planning and design tenders selection in public office buildings. Int. J. Proj. Manag. 2004, 22, 573–584. [Google Scholar] [CrossRef]

- Wang, T.C.; Chang, T.H. Application of TOPSIS in evaluating initial training aircraft under a fuzzy environment. Expert Syst. Appl. 2007, 33, 870–880. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S. Ranking of Drivers for Green Manufacturing Implementation Using Fuzzy Technique for Order of Preference by Similarity to Ideal Solution Method. J. Multi-Criteria Decis. Anal. 2015, 22, 119–130. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Trianni, A. Barriers and drivers for the adoption of industrial sustainability measures in European SMEs: Empirical evidence from chemical and metalworking sectors. Sustain. Prod. Consum. 2021, 28, 1433–1464. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, M.; Yan, W.; Liu, Y.; Jiang, Z.; Li, S. Analysis the Drivers of Environmental Responsibility of Chinese Auto Manufacturing Industry Based on Triple Bottom Line. Processes 2021, 9, 751. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. Investigating the role of sustainable manufacturing adoption in improving the organizational performance. Technol. Soc. 2022, 68, 101940. [Google Scholar] [CrossRef]

- Zhang, J.; Chang, Y.; Wang, C.; Zhang, L. The green efficiency of industrial sectors in China: A comparative analysis based on sectoral and supply-chain quantifications. Resour. Conserv. Recycl. 2018, 132, 269–277. [Google Scholar] [CrossRef]

| Fuzzy Number | Linguistic Terms for Criteria | Linguistic Terms for Alternatives | Scale of Fuzzy Number |

|---|---|---|---|

| 1 | Very low | Equally important (Eq) | (1,1,3) |

| 3 | Low | Weakly important (Wk) | (1,3,5) |

| 5 | Medium | Essentially important (Es) | (3,5,7) |

| 7 | High | Very strongly important (Vs) | (5,7,9) |

| 9 | Very high | Absolutely important (Ab) | (7,9,9) |

| S. No. | Drivers | Significance | References |

|---|---|---|---|

| 1 | Cost reduction (D1) | The reduction of cost in resource and energy consumption to gain more profits | Ullah et al. (2021) [32] Gandhi et al. (2018) [27] Orji et al. (2020) [35] |

| 2 | Top management commitment (D2) | The commitment of owner or manager or major investors towards SPM | Ullah et al. (2021) [32] Luo et al. (2018) [26] Gandhi et al. (2018) [27] Mittal et al. (2015) [75] Neri et al. (2021) [76] |

| 3 | Social responsibility awareness (D3) | Nonprofit activities and implementation of environmentally friendly and green initiatives | Moktadir et al. (2018) [33] Ullah et al. (2021) [32] Neri et al. (2021) [76] Zhang et al. (2021) [77] |

| 4 | Employee training (D4) | Improve SPM-related skills and awareness | Gandhi et al. (2018) [27] Shankar (2016) [22] Ullah et al. (2021) [32] Seth et al. (2018) [40] Neri et al. (2021) [76] |

| 5 | Investor pressure (D5) | The continuous pressure from stakeholders/investors pushes firms to become more sustainable | Orji et al. (2020) [35] Shankar (2016) [22] Ullah et al. (2021) [32] |

| 6 | Competitive (D6) | For new market opportunities and partnerships | Luo et al. (2016) [26] Moktadir et al. (2018) [33] Neri et al. (2021) [76] |

| 7 | Public pressure (D7) | Sustainability demand from local communities, politicians, NGOs, media | Luo et al. (2016) [26] Gandhi et al. (2018) [27] Mittal et al. (2015) [75] Seth et al. (2018) [40] |

| 8 | Supplier chain demand (D8) | SPM enhances green and lean supply chain for sustainability demand | Mittal et al. (2015) [75] Orji et al. (2020) [35] Shankar (2016) [22] Ullah et al. (2021) [32] |

| 9 | Customer’s request (D9) | Customers’ purchasing criteria and choices have changed due to sustainable awareness, which has translated into growing demand for products | Ullah et al. (2021) [32] Luo et al. (2018) [26] Shankar (2016) [22] Moktadir et al. (2018) [33] Seth et al. (2018) [40] |

| 10 | Corporate green image (D10) | Increase corporate image and reputation | Ososanmi et al. (2022) [44] Gandhi et al. (2018) [27] Ullah et al. (2021) [32] Seth et al. (2018) [40] |

| 11 | Technological innovation (D11) | New high-performance and low-cost products to replace similar functional products by realizing product revolution | Schneider et al. (2019) [55] Luo et al. (2018) [26] Yip et al. (2021) [3] Shankar (2016) [22] Neri et al. (2021) [76] Zhang et al. (2021) [77] |

| 12 | Technology andequipment import (D12) | Improve the total sustainable factor productivity for manufacturing enterprises, involving energy savings, emission reduction, resource reuse, cost savings, and so on | Schneider et al. (2019) [55] Luo et al. (2018) [26] Yip et al. (2021) [3] Ullah et al. (2021) [32] Neri et al. (2021) [76] |

| 13 | Government support (D13) | Government’s attention and policy guidance, financial support, R&D investment support, tax rebates, etc. | Ososanmi et al. (2022) [44] Orji et al. (2020) [35] Shankar (2016) [22] Ho et al. (2021) [34] Seth et al. (2018) [40] Neri et al. (2021) [76] |

| 14 | Current legislation (D14) | Pollution control, carbon emission requirements, eco-labels, stricter laws, and so on | Ullah et al. (2021) [32] Luo et al. (2018) [26] Schneider et al. (2019) [55] Gandhi et al. (2018) [27] Ososanmi et al. (2022) [44] Malek et al. (2022) [78] |

| 15 | Future legislation (D15) | Expected initiation of new laws, increased level of enforcement | Ososanmi et al. (2022) [44] Ullah et al. (2021) [32] Luo et al. (2018) [26] Gandhi et al. (2018) [27] |

| S. No | Position | Years of Experience | Education Level |

|---|---|---|---|

| 1 | CEO of precision manufacturing enterprise (PME) | 23 | Master’s |

| 2 | CTO of PME | 21 | PhD |

| 3 | General manager of PME | 12 | PhD |

| 4 | Former director of Key Laboratory of PM | 25 | PhD, professor |

| 5 | Chief engineer of PME | 28 | Bachelor’s |

| 6 | Chairman of PME | 13 | Master’s |

| C. No. | Group 1 of Experts | Group 2 of Experts | Group 3 of Experts | Group 4 of Experts | Group 5 of Experts | Group 6 of Experts | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | |

| C1 | 1 | 1 | 1 | 1 | 1 | 1 | ||||||||||||

| C2 | 1 | 1 | 1 | 1 | 1 | 1 | ||||||||||||

| C3 | 1 | 1 | 1 | 1 | 1 | 1 | ||||||||||||

| C. No. | C1 | C2 | C3 |

|---|---|---|---|

| C1 | 1 | (1.89, 2.84, 5.20) | (0.32, 0.44, 1.20) |

| C2 | (0.19, 0.35, 0.53) | 1 | (0.14, 0.19, 0.35) |

| C3 | (0.83, 2.26, 3.09) | (2.84, 5.20, 7.09) | 1 |

| Criteria | Weights | BNP | Rank |

|---|---|---|---|

| Environmental | (0.162, 0.287, 0.744) | 0.398 | 2 |

| Social | (0.057, 0.109, 0.231) | 0.132 | 3 |

| Economic | (0.260, 0.605, 1.131) | 0.664 | 1 |

| Drivers | C1 (Environmental) | C2 (Social) | C3 (Economic) |

|---|---|---|---|

| D1 | (1.7, 2.7, 4.7) | (1.3, 2.3, 4.3) | (6.0, 8.0, 9.0) |

| D2 | (6.3, 8.3, 9.0) | (4.7, 6.7, 8.0) | (5.0, 7.0, 7.7) |

| D3 | (2.0, 4.0, 6.0) | (2.3, 4.3, 6.3) | (2.3, 4.0, 6.0) |

| D4 | (2.0, 3.3, 5.3) | (3.0, 5.0, 7.0) | (2.0, 3.7, 5.7) |

| D5 | (1.0, 3.0, 5.0) | (1.0, 2.3, 4.3) | (6.0, 8.0, 8.7) |

| D6 | (3.3, 5.3, 7.3) | (4.0, 5.7, 7.7) | (6.3, 8.3, 9.0) |

| D7 | (4.3, 6.3, 8.3) | (1.0, 3.0, 5.0) | (1.0, 2.3, 4.3) |

| D8 | (2.0, 4.0, 6.0) | (1.0, 1.3, 3.3) | (3.3, 5.3, 7.0) |

| D9 | (1.7, 3.7, 5.7) | (1.0, 3.0, 5.0) | (3.3, 4.7, 6.0) |

| D10 | (5.3, 7.3, 8.7) | (2.0, 3.7, 5.7) | (2.3, 4.3, 6.3) |

| D11 | (6.0, 8.0, 9.0) | (4.7, 6.7, 8.7) | (7.0, 9.0, 9.0) |

| D12 | (3.3, 5.3, 7.3) | (3.0, 4.3, 6.3) | (4.3, 6.3, 8.3) |

| D13 | (6.0, 8.0, 9.0) | (4.3, 6.3, 8.3) | (6.7, 8.7, 9.0) |

| D14 | (7.0, 9.0, 9.0) | (5.3, 7.3, 8.7) | (5.7, 7.7, 9.0) |

| D15 | (5.0, 7.0, 9.0) | (2.3, 4.0, 6.0) | (2.3, 4.3, 6.3) |

| Drivers | C1 (Environmental) | C2 (Social) | C3 (Economic) |

|---|---|---|---|

| D1 | (0.19, 0.30, 0.52) | (0.15, 0.27, 0.50) | (0.67, 0.89, 1.00) |

| D2 | (0.70, 0.93, 1.00) | (0.54, 0.77, 0.92) | (0.56, 0.78, 0.85) |

| D3 | (0.22, 0.44, 0.67) | (0.27, 0.50, 0.73) | (0.26, 0.44, 0.67) |

| D4 | (0.22, 0.37, 0.59) | (0.34, 0.57, 0.80) | (0.22, 0.41, 0.63) |

| D5 | (0.11, 0.33, 0.56) | (0.11, 0.27, 0.50) | (0.67, 0.89, 0.96) |

| D6 | (0.37, 0.59, 0.81) | (0.46, 0.65, 0.88) | (0.70, 0.93, 1.00) |

| D7 | (0.48, 0.70, 0.93) | (0.11, 0.34, 0.57) | (0.11, 0.26, 0.48) |

| D8 | (0.22, 0.44, 0.67) | (0.11, 0.15, 0.38) | (0.37, 0.59, 0.78) |

| D9 | (0.19, 0.41, 0.63) | (0.11, 0.34, 0.57) | (0.37, 0.52, 0.67) |

| D10 | (0.59, 0.81, 0.96) | (0.23, 0.42, 0.65) | (0.26, 0.48, 0.70) |

| D11 | (0.67, 0.89, 1.00) | (0.54, 0.77, 1.00) | (0.78, 1.00, 1.00) |

| D12 | (0.37, 0.59, 0.81) | (0.34, 0.50, 0.73) | (0.48, 0.70, 0.93) |

| D13 | (0.67, 0.89, 1.00) | (0.50, 0.73, 0.96) | (0.74, 0.96, 1.00) |

| D14 | (0.78, 1.00, 1.00) | (0.61, 0.84, 1.00) | (0.63, 0.85, 1.00) |

| D15 | (0.56, 0.78, 1.00) | (0.27, 0.46, 0.69) | (0.26, 0.48, 0.70) |

| 9.0 | 8.7 | 9.0 |

| Drivers | C1 (Environmental) | C2 (Social) | C3 (Economic) |

|---|---|---|---|

| D1 | (0.031, 0.086, 0.387) | (0.009, 0.029, 0.116) | (0.174, 0.538, 1.131) |

| D2 | (0.087, 0.221, 0.684) | (0.031, 0.084, 0.213) | (0.375, 0.472, 0.961) |

| D3 | (0.036, 0.126, 0.498) | (0.015, 0.055, 0.169) | (0.146, 0.266, 0.758) |

| D4 | (0.036, 0.106, 0.439) | (0.019, 0.062, 0.185) | (0.057, 0.248, 0.713) |

| D5 | (0.018, 0.095, 0.417) | (0.006, 0.029, 0.116) | (0.147, 0.538, 1.086) |

| D6 | (0.060, 0.169, 0.603) | (0.026, 0.071, 0.203) | (0.469, 0.563, 1.131) |

| D7 | (0.078, 0.201, 0.692) | (0.006, 0.037, 0.132) | (0.077, 0.157, 0.543) |

| D8 | (0.036, 0.126, 0.498) | (0.006, 0.016, 0.088) | (0.041, 0.357, 0.882) |

| D9 | (0.031, 0.118, 0.469) | (0.006, 0.037, 0.132) | (0.137, 0.315, 0.785) |

| D10 | (0.096, 0.232, 0.714) | (0.013, 0.046, 0.150) | (0.096, 0.290, 0.792) |

| D11 | (0.109, 0.255, 0.744) | (0.031, 0.084, 0.231) | (0.203, 0.605, 1.131) |

| D12 | (0.060, 0.169, 0.60) | (0.019, 0.055, 0.169) | (0.374, 0.424, 1.052) |

| D13 | (0.109, 0.255, 0.744) | (0.029, 0.080, 0.222) | (0.355, 0.581, 1.131) |

| D14 | (0.126, 0.287, 0.744) | (0.035, 0.092, 0.231) | (0.466, 0.514, 1.131) |

| D15 | (0.091, 0.224, 0.744) | (0.015, 0.050, 0.159) | (0.164, 0.290, 0.792) |

| FPIS (A+) | (0.744, 0.744, 0.744) | (0.231, 0.231, 0.231) | (1.131, 1.131, 1.131) |

| FNIS (A−) | (0.018, 0.018, 0.018) | (0.006, 0.006, 0.006) | (0.029, 0.029, 0.029) |

| (0.162, 0.287, 0.744) | (0.057, 0.109, 0.231) | (0.260, 0.605, 1.131) |

| Distance | C1 | C2 | C3 | Distance | C1 | C2 | C3 |

|---|---|---|---|---|---|---|---|

| d(D1,D*) | 0.5970 | 0.1857 | 0.6498 | d(D1,D−) | 0.2168 | 0.0645 | 0.7063 |

| d(D2,D*) | 0.4858 | 0.1438 | 0.8020 | d(D2,D−) | 0.4044 | 0.1280 | 0.6001 |

| d(D3,D*) | 0.5608 | 0.1649 | 0.8743 | d(D3,D−) | 0.2847 | 0.0979 | 0.4433 |

| d(D4,D*) | 0.5778 | 0.1586 | 0.9019 | d(D4,D−) | 0.2487 | 0.1083 | 0.4150 |

| d(D5,D*) | 0.5933 | 0.1866 | 0.9124 | d(D5,D−) | 0.2345 | 0.0645 | 0.6828 |

| d(D6,D*) | 0.5222 | 0.1509 | 0.8247 | d(D6,D−) | 0.3496 | 0.1203 | 0.7127 |

| d(D7,D*) | 0.4972 | 0.1807 | 0.8858 | d(D7,D−) | 0.4048 | 0.0746 | 0.3061 |

| d(D8,D*) | 0.5608 | 0.1976 | 0.9249 | d(D8,D−) | 0.2847 | 0.0474 | 0.5295 |

| d(D9,D*) | 0.5706 | 0.1807 | 0.8620 | d(D9,D−) | 0.2667 | 0.0746 | 0.4539 |

| d(D10,D*) | 0.4771 | 0.1716 | 0.8952 | d(D10,D−) | 0.4231 | 0.0862 | 0.4663 |

| d(D11,D*) | 0.4628 | 0.1434 | 0.8977 | d(D11,D−) | 0.4442 | 0.1380 | 0.7252 |

| d(D12,D*) | 0.5222 | 0.1631 | 0.8523 | d(D12,D−) | 0.3496 | 0.0981 | 0.6357 |

| d(D13,D*) | 0.4628 | 0.1461 | 0.8532 | d(D13,D−) | 0.4442 | 0.1320 | 0.7181 |

| d(D14,D*) | 0.4436 | 0.1390 | 0.8370 | d(D14,D−) | 0.4515 | 0.1398 | 0.6999 |

| d(D15,D*) | 0.4821 | 0.1677 | 0.8696 | d(D15,D−) | 0.4378 | 0.0921 | 0.4663 |

| S. No. | di+ | di− | CCi | Rank |

|---|---|---|---|---|

| D1 | 1.4324 | 0.9876 | 0.4081 | 6 |

| D2 | 1.5109 | 1.1325 | 0.4284 | 4 |

| D3 | 1.6299 | 0.8259 | 0.3363 | 12 |

| D4 | 1.6383 | 0.7719 | 0.3203 | 15 |

| D5 | 1.6828 | 0.9818 | 0.3685 | 10 |

| D6 | 1.5865 | 1.1826 | 0.4271 | 5 |

| D7 | 1.5831 | 0.7854 | 0.3316 | 13 |

| D8 | 1.6618 | 0.8616 | 0.3414 | 11 |

| D9 | 1.6291 | 0.7952 | 0.3280 | 14 |

| D10 | 1.5550 | 0.9757 | 0.3855 | 9 |

| D11 | 1.5039 | 1.3075 | 0.4651 | 1 |

| D12 | 1.6198 | 1.0834 | 0.4008 | 7 |

| D13 | 1.5149 | 1.2944 | 0.4607 | 2 |

| D14 | 1.5126 | 1.2911 | 0.4605 | 3 |

| D15 | 1.5561 | 0.9963 | 0.3903 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, X.; Zhao, J. A Two-Step Fuzzy MCDM Method for Implementation of Sustainable Precision Manufacturing: Evidence from China. Sustainability 2022, 14, 8085. https://doi.org/10.3390/su14138085

Guan X, Zhao J. A Two-Step Fuzzy MCDM Method for Implementation of Sustainable Precision Manufacturing: Evidence from China. Sustainability. 2022; 14(13):8085. https://doi.org/10.3390/su14138085

Chicago/Turabian StyleGuan, Xiaowei, and Jun Zhao. 2022. "A Two-Step Fuzzy MCDM Method for Implementation of Sustainable Precision Manufacturing: Evidence from China" Sustainability 14, no. 13: 8085. https://doi.org/10.3390/su14138085

APA StyleGuan, X., & Zhao, J. (2022). A Two-Step Fuzzy MCDM Method for Implementation of Sustainable Precision Manufacturing: Evidence from China. Sustainability, 14(13), 8085. https://doi.org/10.3390/su14138085