Abstract

Cement paste is an already well-known material used in ore mining. It is mainly used to fill excavation areas and the tailings from the surface return to underground mines. In this way, the amount of deposited material and degradation of the surface of the terrain are reduced. The paste itself can be used as an artificial barrier between mining works and underground watercourses. Significant economic and environmental benefits can be expected from using cement paste, which would contribute to sustainable development. The basic materials that make up cemented paste backfill (CPB) are flotation tailings, cement, and water. For CPB to be adequately and safely applied to the filling of excavation spaces and indirectly to the protection of the groundwater, environment, and sustainable development of the mining industry, it must meet certain physical–mechanical, physicochemical, and deformation properties. This paper presents the results of synthesized and analyzed samples of different compositions based on flotation tailings (from the production of ZiJin Copper in Bor, Serbia), cement, and water. The methods used for chemical and mineralogical tests include inductively coupled plasma atomic emission spectroscopy (ICP-AES), atomic absorption spectroscopy (AAS), X-ray diffraction analysis (XRD), and nephelometric turbidity units (NTUs; turbidimetry). The results prepared with CPB consisting of 5% cement, 24% water, and 71% flotation tailings were the most acceptable.

1. Introduction

The mining industry at the global level has a role in sustainable development through its impact on all three aspects of this concept—economic, social, and environmental [1]. There is a multiplier effect of the mining sector on the economy and society [2]. The growth of the mining industry has a positive influence on the economy through its large share in the gross domestic product (GDP) of countries [3,4,5]. Increased employment contributes to the achievement of economic and social goals of sustainable development. On the contrary, the exploitation of mineral raw materials generates large amounts of waste, pollutes and destroys natural habitats, and contributes to climate change and biodiversity loss, which negatively affects the achievement of sustainable development goals related to environmental protection [6]. Moreover, indirectly, in this way, the mining industry harms human health and, in this case, its negative impact on the social aspect is evident [7]. The impact on sustainability can also be observed from the point of the safety of employees in mining companies.

Many authors have researched the impact of the mining industry on sustainable development, environmental pollution, and groundwater. Fu et al. stated that the pressure of economic growth and social development causes excessive exploitation of natural resources, which leads to a large number of problems, called the “curse of natural resources” [8]. In their research, Singhal and Poonia pointed out that there is a huge difference in the environmental behavior of mining companies, with larger organizations proving to be more responsible than smaller ones [9]. According to Carvalho [10], mining activities are very diverse and can cause various environmental damages, but two issues are of particular importance worldwide, namely, tailings and acid mine drainage. Carvalho [10] concluded that the existing practices in the mining industry should be changed in accordance with the goals of sustainable development and that it is necessary to strengthen the procedures of environmental protection and public health when performing mining activities. Liu et al. [11] pointed to the problem of water pollution within the Asian Golden Belt, where heavy metals and radioactive elements are the predominant pollutants, all of which are a consequence of the mining industry. Pollution of surface and groundwater poses a risk to human health and damages the environment. In order to prevent further water pollution, the authors warned of the urgency of conducting joint monitoring of the quantity and quality of surface and groundwater throughout Central Asia [11].

In general, the conclusions of these authors boil down to the fact that the existing practices in the mining industry must change to protect the environment and preserve groundwater and human health with the goals of sustainable development. The change in the existing practices refers to the application of green technologies, development strategies, and new ways and methods of waste reduction in the mining sector. Technological innovations contribute to the reduction of ecological footprints and the reduction of the negative consequences of the mining industry on the environment [5].

Numerous studies point to the importance of green technologies and innovations in the mining industry. Green innovations, in addition to economic and environmental benefits, contribute to reducing the consumption of natural resources in the process of product production, such as Lončar et al., who presented an example of European countries [12]. In their research, Doulati Ardejani et al. [13] presented a conceptual framework for a green mining method for coal mines that took into account economic and social aspects and paid special attention to health, safety, and environmental requirements. Aron and Molina [14] investigated the internal and external factors of green innovation in the natural resources industry and pointed out the importance of highly specialized human capital, as well as research centers, in achieving these innovations. An important place in achieving the goals of environmental and sustainable development is occupied by the application of the circular economy in mining [15,16] and the reduction in the amount of waste generated by mining operations, the most famous of which is tailings. A useful solution for the utilization and reduction of waste in mining is the use of tailings for the preparation of cement paste.

Cement paste (CPB, cement paste filling) is one of the building materials for green mining and it is widely used for filling during excavations in underground mining around the world [17,18,19]. By applying CPB, clean, efficient, and safe underground exploitation in metal ore mines can be achieved, which would save groundwater from further pollution. Acidic drainage water from mining activities can seriously impair water quality. The severity and degree of the degradation of watercourses depend on many factors, such as the frequency, quantity, and use of chemicals.

Ma et al. [20] pointed out the positive effects of the method of filling underground mining premises and its direct impact on all three aspects of sustainable business: by contributing to ensuring the safety of employees (social facet) and equipment in underground exploitation, by increasing the ore utilization (economic aspect), and by minimizing the environmental problems caused by tailing disposal (ecological aspect).

The application of CPB has made an extraordinary transition from tailings as “waste” to recyclable material. The method of filling mining excavations with the help of CPB is one of the main development trends for efficient and economical underground exploitation of metal ore without pollution. CPB mainly consists of tailings, water, and binders. It is usually prepared on the surface of the terrain and transported to underground rooms by pumping or gravity. As Xiu et al. [21] pointed out, CPBs are gradually hardened and consolidated to achieve adequate strength. Sometimes a small amount of additive is added to CPB to achieve better physicochemical performance and mechanical properties, such as uniaxial compressive strength, abbreviated UCS, shear strength, and rheological behavior [22,23,24].

With the achieved desired physical–mechanical and deformation characteristics of CPB, it is possible to count on the reduction of deformations of the surrounding rock mass, which ensures the safety of underground mining and, thus, protection of groundwater from mining, which is a significant contribution to sustainable development in the mining industry. The strength indices of CPB (i.e., uniaxial compressive strength (UCS) and shear strength) can provide a basic reference for optimal design of the filling process.

Liu et al. [25] used PFC2D (Particle Flow Code in 2 Dimensions) software to reproduce the stress–strain curve of CPB and predicted its corresponding mechanical properties. Fall et al. [26] indicated that the maximum stress and stiffness of CPB during curing after more than 28 days are affected by flexural strength (σc).

The use of technogenic waste in the production of filling materials and/or as a potential source of minerals has recently been investigated in many countries around the world, which can be seen in published scientific papers in various journals. Some of the group authors engaged in the work and improvement of the use of waste material from the mining industry are observed in Russia [27,28,29,30,31], Czech Republic [32], Poland [33,34], China [8,11,35], Saudi Arabia [36], and Slovenia and Serbia [37]. The authors recognized the topicality of the problem created by mining waste and by using tailings, they are engaged in solving social, economic, and environmental problems.

The mining industry, in addition to the positive economic effects it has on economic growth, is known as a major polluter of the environment. Mining by-products pollute water, air, and land. One of these by-products is the tailings that are disposed of in the form of waste. Due to the harmful effects of this by-product, it is of great importance to find different methods of reducing and using this type of waste to protect the environment and to attain sustainable development of the mining industry. Although a large number of tests of the various types of cement paste have been conducted around the world, with different compositions of flotation tailings and combined with additives, there is still room to synthesize new materials to obtain cement paste of the highest quality with minimal material consumption, being economically acceptable and environmentally friendly, to expand its application to other areas of construction and groundwater protection. The proposed research in this paper focuses on examining the influence of hardening time for the period of 7, 14, 28, and 90 days, as well as the physicochemical and mechanical properties of CPB. The results of this research will help to understand the physicochemical properties and mechanical behavior of CPB under different curing conditions, as well as applications for the protection of groundwater from possible heavy metal pollution during mining activities.

2. Materials and Methods

2.1. Materials

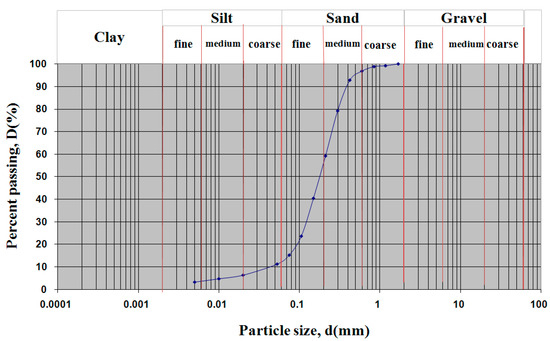

Flotation tailings, cement, and water are the basic materials used to prepare cement paste. Flotation tailings are treated as waste material obtained by processing copper ore in RTB Bor in Serbia, whose successor is the Chinese company Serbia ZiJin Copper Bor in Serbia, since 2019. Batch samples with different contents of flotation tailings, cement, and water were used. The granulometric composition of the flotation tailings was determined using a series of sieves according to the standard ISO 17892-4: 2016 [38], as shown in Figure 1.

Figure 1.

Grain size distribution of flotation tailings.

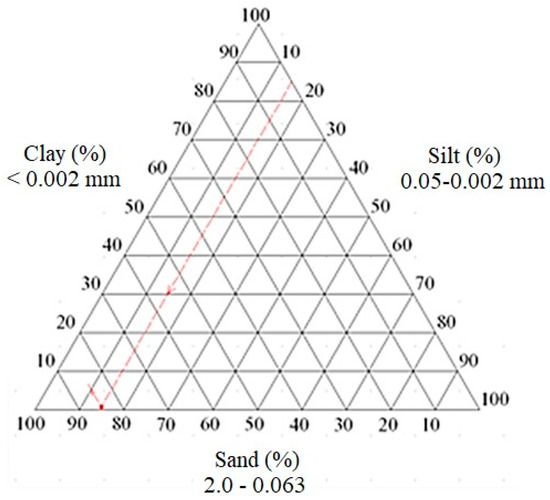

Table 1 and Table 2 show the results of granulometric composition. Table 1 provides data on grain size at 60%, 30%, and 10% of the cumulative sieve passage, as well as the uniformity coefficient (Cu) and curvature coefficient (Cc). It can be concluded that the flotation tailings were of uniform composition (Cu = 5.12). According to the triangular USBR diagram, from the determination of the soil texture [39] and the results in Table 2, where the fraction 2.0–0.063 (sand) is represented by 84.80% and the fraction 0.063–0.002 (silt) is represented by 15.20%, it can be concluded that flotation tailings belong to loamy sand, as shown graphically in Figure 2.

Table 1.

Values of grain size on 60%, 30%, and 10% of the cumulative passage through a sieve, uniformity coefficient (Cu), and curvature coefficient (Cc).

Table 2.

Grain size of flotation tailings.

Figure 2.

The triangular diagram of USBR confirms that the texture of flotation tailings belongs to loamy sand.

According to Formula (1) Hazen, the filtration coefficient for a given material can be calculated using data D10 (mm) from the granulometric curve:

kf = 0.016 × (D10)2 (m/s)

For flotation tailings, the value of the filtration coefficient is: kf = 2.8 × 10−5 (m/s).

Table 3 [39] shows the textural distribution of natural materials (clay and sand). According to Eggelsmann, the value of the filtration coefficient is expressed in m/day or (m/s) and the obtained results classify flotation tailings into a material with a high filtration coefficient (>2.5).

Table 3.

Filtration coefficient values by Eggelsmann. Reprinted with permission from Kolaković and Trajković, 2006, Copyright (2006) FTN Novi Sad, Serbia [39].

2.2. Characterization Methods

Tests have shown that a content of tailings of 71%, cement of 5%, and water of 24% classifies cement paste into materials with a liquid consistency, and therefore, the material is easily installed. Cement was used from the CRH Popovac cement plant, Serbia, while water from the city water supply was used for sample synthesis.

The degree of consistency, compressive strength after 7, 14, 28, and 90 days, and water permeability were determined by the prepared samples. To test individual properties, cube-shaped samples with dimensions of 15 × 15 × 15 cm were made for compressive strength determination. The untreated rock sample was poured with the prepared paste and after 90 days, it was processed for discontinuity shear testing. Shear testing was performed at the contact of these two materials.

The chemical analysis of the samples was performed by using the inductively coupled plasma atomic emission spectrometry (ICP-AES) model “Spectro Ciros Vision” and the atomic absorption spectrometry (AAS) model FIMS-100, manufactured by Perkin Elmer. Water permeability was determined according to the standard ISO 17892-11:2019. The permeability of heavy metals using ICP-AES to test the ability of the synthesized paste confirmed the possibility of their use in groundwater protection.

Turbidimetry and nephelometry are methods used to determine the concentration of particles in a suspension. The units of turbidity are expressed in nephelometric turbidity units (NTUs) based on the elastic scattering of electromagnetic radiation on suspended particles in a solution.

Diffraction analysis (XRD), a model of Explorer manufactured by GNR, was used to determine the mineralogical analysis.

A CONTROLS Milano press, type C44D2, capacity 2000 kN, was used to test the uniaxial compressive strength of the backfill paste. The loading rate was (0.6 ± 0.2) MPa/s (N/mm2) according to EN 12390-3: 2019 [40]. After application, with an initial load not exceeding approximately 30% of the fracture load, the specimen was subjected to a free load without concussion and was continuously increased by ±10% until the maximum load could be maintained.

2.3. Flotation Tailing Characterization Results

The results of the chemical analysis of the flotation tailings, using appropriate analysis techniques, are shown in Table 4. Table 4 shows that the highest representation of SiO2, which was 54.91% of the total content, was obtained by gravimetric analysis, while Al2O3 was 16.49%, which was obtained by ICP-AES. The percentages of S and Fe were 2.06% and 3.11%, respectively. The percentage of sulfur was obtained using elementary analysis, while iron was tested on AAS. Heavy metal traces were present, which indicates a high percentage of purity of this waste material from copper ore processing.

Table 4.

Results of the chemical analysis of flotation tailings.

The permissible limits of chloride and sulfate content in the concrete aggregate were up to 0.05% and 1.0% by weight, respectively, according to the construction standard CS3: 2013, [41], which also refers to the British Standard BS EN 1744-1:2009. The obtained results for chlorides (Table 4) were within the mentioned limits, while sulfates slightly exceeded the allowed value.

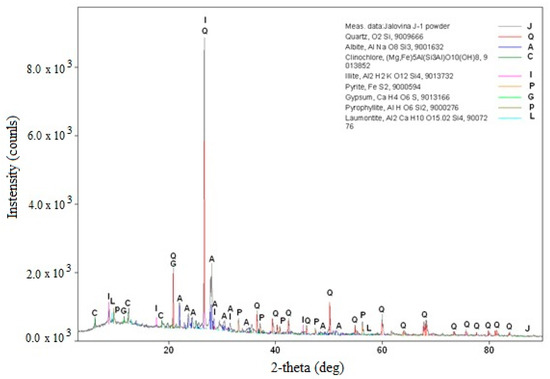

Figure 3 shows the mineralogical analysis of the flotation tailings. XRD analysis showed that the mineral composition included SiO2 (quartz), NaAlO8Si3 (plagioclase), (Mg, Fe) 5Al (Si3Al)O10(OH)8 (chlorite), Al2H2KO12Si4 (illite), Al2Si4O10(OH), Al2Si4O10(OH)2 (pyrophyllite), Ca(AlSi2O6)2 × 4H2O (laumontite), FeS2 (pyrite), and CaSO4 × 2H2O (gypsum).

Figure 3.

XRD mineralogical analysis of flotation tailings.

3. Experimental Design

The backfill paste was prepared with several different combinations of components. Finally, the experiment was limited to the preparation of pastes with a cement content of 3–9%, a flotation tailing content of 67–73%, and a constant water composition of 24%. After a series of experiments, in order to find the most optimal ratio of components for the production of backfill paste, it was concluded that the most favorable results were obtained with a paste synthesized with 5% cement, 71% flotation tailings, and 24% water. Particular attention was paid to the storage of test bodies, in order to better ensure realistic conditions, which means higher temperature and humidity.

The preparation of samples was carried out by first mixing the flotation tailings with the cement by hand, according to the established ratio, for 1 min. The mixture was transferred to a concrete mixer, model 190 LS Limex, Altrad–Limex, LTD Donji Miholjac, Croatia, power 850 W, volume 190 L. It was mixed with water in a mixer for another 3 min. After homogenization, the obtained paste was poured into plastic molds with dimensions of 150 × 150 × 150 mm, which were previously lubricated with silicone gel. Deaeration and consolidation of the poured paste were performed for 5 min on a vibrating table, whose dimensions were 100 × 160 × 96 cm, manufactured by SINEX INDUSTRIE, from France. After 48 h of curing, the samples were removed from the molds. The prepared samples were stored under conditions with increased humidity (95%) and at a temperature higher than 30 °C. The prepared samples were kept in a controlled atmosphere and tested for physical and mechanical properties.

4. Results and Discussion

The idea for the synthesis of new materials, suitable cement pastes for filling, with the appropriate physical and mechanical properties, was the use of waste material, flotation tailings, together with water and cement (without using additives). The advantage of using these materials is the ensuing environmental benefits and groundwater conservation.

The main component of cement paste is flotation tailings, obtained by processing copper ore by the ZiJin Bor company. Đurđevac Ignjatović et al. [42,43] examined flotation tailings by varying different parameters during the synthesis of cement paste materials, while the company was owned by RTB Bor, Serbia.

When using cement paste in underground mining, after ore exploitation, as a replacement for the supporting column in the chamber–column method, it is necessary to meet basic criteria such as compressive strength, modulus of elasticity, and other physical–mechanical properties, as shown by Mitchell in his work [44]. Lee et al. [45] showed a minimum required uniaxial compressive strength of 1.0–1.5 MPa, while the column application of filling uniaxial compressive strength (UCS) is usually lower than 1 MPa [46]. For this reason, one of the main requirements in our study was that the uniaxial compressive strength after 28 days must be 1.0–1.5 MPa. In addition to these criteria, the paste had to meet other physical and mechanical properties, which are listed in Section 2.2 and relate to the degree of consistency [47], compressive strength after 7, 14, 28, and 90 days, and water permeability. The degree of consistency of the paste was examined using the Abrams cone [47]. This test was performed on medium to poorly workable cement concretes.

The results obtained by the Abrams cone test were compared to the standard results. In terms of consistency, the measurements showed settlements in the range of 11–18 cm, which puts the backfill in the group of materials with a liquid consistency.

The constant water content was defined at the beginning of the synthesis of cement paste samples and it was 24%. Table 5 shows the mass ratio of cement and flotation tailings, expressed as percentages, for the observed synthesized samples of cement paste.

Table 5.

Cement and flotation tailings content at a constant water content of 24%.

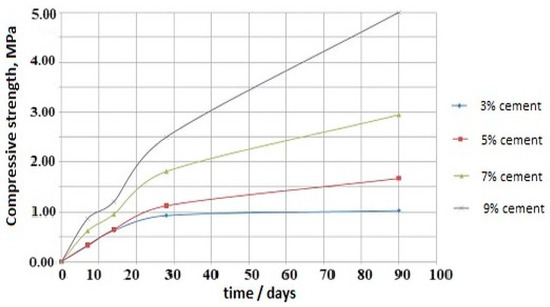

Figure 4 shows the dependence of compressive strength on time.

Figure 4.

Correlation between uniaxial compressive strength and time.

Table 6 shows the results of testing the compressive strength of cement paste as a function of time.

Table 6.

Uniaxial compressive strength results of CPB with a constant water content.

The water permeability of the cement paste was determined according to the standard EN ISO 17892-11:2019 [38] and the value was 8.3 × 10−6 m/s. According to Magalhäes Gomes et al. [48], the obtained value for kf classifies the synthesized cement paste into a material with an average filtration coefficient, which refers to the test of the standard permeability classification, from 1.0 × 10−3 to 1.0 × 10−4 mm/s.

According to the aforementioned physical, mechanical, and deformation tests of cement paste, with different contents of cement and flotation tailings, it was concluded that cement paste with a cement content of 5%, a flotation tailing content of 71%, and a water content of 24% best meets all of the necessary requirements. This backfill, in addition to all of its physically mechanical characteristics, also satisfies the economic aspect, which was crucial for further consideration of this material.

To check the adequacy of the use of cement paste in groundwater protection, an experiment was improvised to fill the rock with cement paste, in order to check the chemical reaction between the groundwater sample and the cement paste. This was to prove that there was no formation of wastewater that would affect the environment. The chemical composition of water with characteristic anions, before and after passing through the backfill, is shown in Table 7. The presence of heavy metals was traced after the simulation passage of groundwater through the cement paste.

Table 7.

Chemical content for water before (W1) and after (W2) going through CPB.

From the aspect of sustainable development [1,5,6], environmental protection [13,20], and groundwater, after the passage of the groundwater through the cement paste, the new synthesized material proved to be very efficient because there was no significant chemical change in the groundwater. The increased content of SO4−2 can be attributed to the chemical reaction of the simulated groundwater and rock mass. The increased content of SO4−2 (Table 7) can be attributed to the chemical reaction of the groundwater and rock mass. Krstić (2021), Krstić and Pešovski (2021), and Krstić et al. (2018) [49,50,51] emphasized the danger of toxic elements to human health and described some of the methods for wastewater treatment from copper mines.

The mining industry generates waste that seriously endangers the environment. Innovative technologies that reduce their existence are becoming increasingly advanced [52]. One of the useful solutions for the reduction of tailings as waste in mining is the use of tailings for the preparation of cement paste. Jiang et al. [22] found that the optimal solid content in the suspension is approximately 70–85% and the binder content is around 3–5%, in order to achieve higher strength. Based on the synthesis of the paste that we tested (a cement content of 5%, flotation tailing content of 71%, and water content of 24%), it can be concluded that our paste is within the stated optimal limits.

Belem et al. [46] and Hefni et al. [36] in their work provided results of UCS testing on traps after different maturing times (curing) (7, 14, 28, and 90 days) and the application of different binders. Belem et al. [46] concluded that UCS increases from 1000 to 2500 kPa after 56 days of maturation if the content of a particular binder increases from 3% to 6%. Hefni et al. [36] came to a similar conclusion because in their case, after 28 days, UCS increased from 200 to 1200 kPa with only a change in the content of the applied binder. We reached a similar conclusion in the experiment described in this paper, since by changing the content of cement as a binder (from 3% to 9%), without changing the water content, we observed an increase in UCS from 925 to 2497 kPa after 28 days of maturation.

Yang et al. [53] focused their research on the triaxial mechanical properties of CTBs with different binder–tailing ratios at a curing time of 28 days. Xu et al. [54] indicated that the triaxial pressure behavior of CTB is strongly influenced by the cement content, age of hardening, and limiting pressure. A model of CPB strength parameters under the coupled influence of granulometric tailing composition and limiting pressure was constructed by Wu et al. [55]. Moreover, Wu et al. [56] tested triaxial compression and ultrasonic detection to determine the relationship between ultrasonic wave velocity (UPV) and CPB strength parameters. Wang et al. [57] studied the relationship between layered CPB strength and limiting pressure under triaxial cyclic loading conditions.

Based on the data in the literature, it is noted that the abovementioned researchers conducted triaxial testing of paste using the standard for triaxial testing of coherent soil, ASTM D4767-11 [58]. Since UCS pastes were tested in our experiment, triaxial tests on our synthesized materials could be performed in further research works, according to the conditions mentioned by the researchers in their works. In this way, the obtained results would be comparable and more information about the material itself would be obtained.

5. Conclusions and Future Perspectives

Mining activities must be linked to the goals of sustainable development to provide current and future generations with a healthy environment and quality drinking water. Maintaining the quality of the environment, human safety, and economic growth are the basic requirements for the sustainable operation of mining companies. Utilization of the waste generated by mining operations, primarily tailings, can make a significant contribution to achieving the goals of sustainable development. In this paper, flotation tailings as a basic material for the synthesis of cement paste obtained by using different ratios of three basic elements: flotation tailings, cement, and water. To better understand the properties of CPB, physicochemical and mechanical tests were considered in this paper.

Flotation tailings have a filtration coefficient value of kf = 2.8 × 10−5 m/s, which classifies them as a material with a high filtration coefficient. After combining the flotation tailings with cement and water, the filtration coefficient of the paste thus obtained received a value of 8.3 × 10−6 m/s, i.e., we obtained a material with an average filtration coefficient. The passage of groundwater through the cement paste did not lead to a significant change in its chemical composition, nor did it show the presence of heavy metals, which confirmed that the obtained paste can be used in groundwater protection and further mining. In order to obtain a paste with even better filtration characteristics (i.e., more waterproof), it is necessary to use a certain type of additive, which would improve this characteristic.

Based on the analyzed results, the synthesized sample of flotation tailings with 5% cement and 71% flotation tailings proved to be the best. The main criterion was UCS. The compressive strength of the synthesized cement paste after 28 days was 1.123 MPa, which satisfies the initial condition of the required compressive strength of 1.0–1.5 MPa. The obtained results showed excellent physical and chemical characteristics and mechanical properties and future research should continue in the synthesis of paste with the addition of natural additives to improve the quality and application of newly synthesized materials in mining and groundwater protection.

Author Contributions

Conceptualization, L.Đ.I. and V.K.; methodology, L.Đ.I. and V.K.; software, n/a.; validation, V.R., M.M. and D.I.; formal analysis, V.Đ.; investigation, L.Đ.I. and V.K.; resources, D.I.; data curation, V.R. and M.M.; writing—original draft preparation, V.K. and L.Đ.I.; writing—review and editing, L.Đ.I. and V.K.; visualization, V.R.; supervision, V.J.; project administration, L.Đ.I. and V.K.; funding acquisition, L.Đ.I. All authors have read and agreed to the published version of the manuscript.

Funding

Financial support for this study was provided by the Ministry of Education, Science and Technological Development of the Republic of Serbia (Contract No. 451-03-68/2022-14/200052).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Famiyeh, S.; Opoku, R.A.; Kwarteng, A.; Asante-Darko, D. Driving forces of sustainability in the mining industry: Evidence from a developing country. Resour. Policy 2021, 70, 101910. [Google Scholar] [CrossRef]

- Kurakova, K.N.; Ponomarenko, T.V. Impact of mining industry growth on sustainable development indicators. In Proceedings of the E3S Web of Conferences, Agadir, Morocco, 22–24 July 2021; Volume 266, p. 06007. [Google Scholar]

- Huang, Y.; Raza, S.M.F.; Hanif, I.; Alharthi, M.; Abbas, Q.; Zain-ul-Abidin, S. The role of forest resources, mineral resources, and oil extraction in economic progress of developing Asian economies. Resour. Policy 2020, 69, 10187. [Google Scholar] [CrossRef]

- Jahanmiri, S.; Asadizadeh, M.; Alipour, A.; Nowak, S.; Sherizadeh, T. Predicting the Contribution of Mining Sector to the Gross Domestic Product (GDP) Index Utilizing Heuristic Approaches. Appl. Artif. Intell. 2021, 35, 1990–2012. [Google Scholar] [CrossRef]

- Jahanger, A.; Usman, M.; Murshed, M.; Mahmood, H.; Balsalobre-Lorente, D. The linkages between natural resources, human capital, globalization, economic growth, financial development, and ecological footprint: The moderating role of technological innovations. Resour. Policy 2022, 76, 102569. [Google Scholar] [CrossRef]

- Pons, A.; Vintrò, C.; Rius, J.; Vilaplana, J. Impact of Corporate Social Responsibility in mining industries. Resour. Policy 2021, 72, 102117. [Google Scholar] [CrossRef]

- Szabo, A.; Shriver, T.E.; Longo, S. Environmental threats and activism against extractive industries: The case of gold mining in Rosia Montană, Romania. J. Rural. Stud. 2022, 92, 26–34. [Google Scholar] [CrossRef]

- Fu, L.; Jiang, X.; He, L. How Natural Resource-Based Industry Affect Sustainable Development? An Evolutionary Study of China. Sustainability 2020, 12, 291. [Google Scholar] [CrossRef] [Green Version]

- Singhal, D.; Poonia, H. Sustainable Development and Mining Comparative Analysis with Reference of Environmental Law. Sustain. Dev. 2021, 14, 1–9. [Google Scholar]

- Carvalho, F.P. Mining industry and sustainable development: Time for change. Food Energy Secur. 2017, 62, 61–77. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, P.; Gojenko, B.; Yu, J.; Wei, L.; Luo, D.; Xiao, T. A review of water pollution arising from agriculture and mining activities in Central Asia: Facts, causes and effects. Environ. Pollut. 2021, 291, 118209. [Google Scholar] [CrossRef]

- Lončar, D.; Paunković, J.; Jovanović, V.; Krstić, V. Environmental and social responsibility of companies cross EU countries–Panel data analysis. Sci. Total Environ. 2019, 657, 287–296. [Google Scholar] [CrossRef] [PubMed]

- Doulati Ardejani, F.; Maghsoudy, S.; Shahhosseini, M.; Jodeiri Shokri, B.; Doulati Ardejani, S.; Shafaei, F.; Amirkhani Shiraz, F.; Rajaee, A. Developing a Conceptual Framework of Green Mining Strategy in Coal Mines: Integrating socio-economic, health and environmental factors. J. Min. Environ. 2022, 13, 101–115. [Google Scholar]

- Aron, A.S.; Molina, O. Green innovation in natural resource industries: The case of local suppliers in the Peruvian mining industry. Extr. Ind. Soc. 2020, 7, 353–365. [Google Scholar] [CrossRef] [Green Version]

- Gedam, V.V.; Raut, R.D.; de Sousa Jabbour, A.B.L.; Agrawal, N. Moving the circular economy forward in the mining industry: Challenges to closed-loop in an emerging economy. Resour. Policy 2021, 74, 102279. [Google Scholar] [CrossRef]

- Upadhyay, A.; Laing, T.; Kumar, V.; Dora, M. Exploring barriers and drivers to the implementation of circular economy practices in the mining industry. Resour. Policy 2021, 72, 102037. [Google Scholar] [CrossRef]

- Bull, A.J.; Fall, M. Curing temperature dependency of the release of arsenic from cemented paste backfill made with Portland cement. J. Environ. Manag. 2020, 269, 110772. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Gardić, V.; Petrović, J.; Đurđevac-Ignjatovic, L.; Kolaković, S.; Vujović, S. Procena uticaja rudničkih drenažnih i komunalnih otpadnih voda na kvalitet površinskih voda u Boru i okolini. Chem. Ind. 2015, 69, 165–174. [Google Scholar]

- Ma, D.; Duan, H.; Liu, J.; Li, X.; Zhou, Z. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci. Total Environ. 2019, 664, 636–1448. [Google Scholar] [CrossRef]

- Xiu, Z.; Wang, S.; Ji, Y.; Wang, F.; Ren, F. Experimental study on the triaxial mechanical behaviors of the Cemented Paste Backfill: Effect of curing time, drainage conditions and curing temperature. J. Environ. Manag. 2022, 301, 113828. [Google Scholar] [CrossRef]

- Jiang, H.; Yi, H.; Yilmaz, E.; Liu, S.; Qiu, J. Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature. Ultrasonics 2020, 100, 105983. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Chen, W.; Tian, M.; Guo, L. Effect of temperature on time-dependent rheological and compressive strength of fresh cemented paste backfill containing flocculants. Construct. Build. Mater. 2021, 267, 121038. [Google Scholar] [CrossRef]

- Fang, K.; Cui, L.; Fall, M. A coupled chemo-elastic cohesive zone model for backfill-rock interface. Comput. Geotech. 2020, 125, 103666. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, D.; Tian, Y.; Liu, X. Numerical simulation of stress-strain behaviour of cemented paste backfill in triaxial compression. Eng. Geol. 2017, 231, 165–175. [Google Scholar] [CrossRef]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress–strain behaviour of cemented paste backfill in compression. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Rybak, J.; Gorbatyuk, S.M.; Kongar-Syuryun, C.; Khayrutdinov, A.M.; Tyulyaeva, Y.; Makarov, P.S. Utilization of Mineral Waste: A Method for Expanding the Mineral Resource Base of a Mining and Smelting Company. Metallurgist 2021, 64, 851–861. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Ubysz, A.; Faradzhov, V. Models and algorithms of choice of development technology of deposits when selecting the composition of the backfilling mixture. IOP Conf. Ser. Earth Environ. Sci. 2021, 684, 012008. [Google Scholar] [CrossRef]

- Khairutdinov, A.; Ubysz, A.; Adigamov, A. The concept of geotechnology with a backfill is the path of integrated development of the subsoil. IOP Conf. Ser. Earth Environ. Sci. 2021, 684, 012007. [Google Scholar]

- Ponomarenko, T.; Nevskaya, M.; Jonek-Kowalska, I. Mineral Resource Depletion Assessment: Alternatives. Problems, Results. Sustainability 2021, 13, 862. [Google Scholar] [CrossRef]

- Resniova, E.; Ponomarenko, T. Sustainable Development of the Energy Sector in a Country Deficient in Mineral Resources: The Case of the Republic of Moldova. Sustainability 2021, 13, 3261. [Google Scholar] [CrossRef]

- Niemiec, D.; Duraj, M.; Cheng, X.; Marschalko, M.; Kubac, J. Selected black-coal mine waste dumps in the Ostrava Karvina region: An analysis of their potential use. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042061. [Google Scholar] [CrossRef]

- Zglinicki, K.; Szamałek, K.; Wołkowicz, S. Critical Minerals from Post-Processing Tailing. A Case Study from Bangka Island, Indonesia. Minerals 2021, 11, 352. [Google Scholar] [CrossRef]

- Zglinicki, K.; Małek, R.; Szamałek, K.; Wołkowicz, S. Mining Waste as a Potential Additional Source of HREE and U for the European Green Deal: A Case Study of Bangka Island (Indonesia). Minerals 2022, 12, 44. [Google Scholar] [CrossRef]

- Han, G.; Zhang, J.; Sun, H.; Shen, D.; Wu, Z.; An, X.; Meye, S.M.; Huang, Y. Application of Iron Ore Tailings and Phosphogypsum to Create Artificial Rockfills Used in Rock-Filled Concrete. Buildings 2022, 12, 555. [Google Scholar] [CrossRef]

- Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The potential re-use of Saudi mine tailings in mine backfill: A path towards sustainable mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

- Šajn, R.; Ristović, I.; Čeplak, B. Mining and Metallurgical Waste as Potential Secondary Sources of Metals—A Case Study for the West Balkan Region. Minerals 2022, 12, 547. [Google Scholar] [CrossRef]

- ISO 17892-4:16; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. ISO: Geneva, Switzerland, 2016.

- Kolaković, S.; Trajković, S. Hidrotehničke Melioracije—Odvodnjavanje; FTN Novi Sad, GAF Niš: Novi Sad, Serbia, 2006; ISBN 86-7892-002-5. [Google Scholar]

- EN 12390-3:19; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. 2019. Available online: https://iss.rs/sr_Cyrl/project/show/iss:proj:62276 (accessed on 19 April 2022).

- Construction Standard CS3: 2013; Aggregates for Concrete. CEDD: Hong Kong, China, 2013.

- Đurđevac Ignjatović, L.; Ignjatović, D.; Ljubojev, M.; Zlatanović, D. Basic requirements of backfilling with flotation tailings in the Bor River underground mine. Min. Metall. Eng. Bor 2015, 3, 29–32. [Google Scholar] [CrossRef] [Green Version]

- Đurđevac Ignjatović, L.; Ignjatović, D.; Ljubojev, M.; Mitrović, M. Change the uniaxial compressive strength of paste backfill depending on change the parameters. Min. Metall. Eng. Bor 2016, 1, 17–24. [Google Scholar] [CrossRef]

- Mitchell, R.J. Stability of cemented tailings backfill. In Computer and Physical Modelling in Geotechnical Engineering; Balkema: Rotterdam, The Netherlands, 1989; pp. 501–507. [Google Scholar]

- Li, L.; Aubertin, M.; Simon, R.; Bussiere, B.; Belem, T. Modeling Arching Effects in Narrow Backfilled Stopes with FLAC. In Proceedings of the 3rd International FLAC Symposium, Sudbury, ON, Canada, 31 May 2003; Balkema: Rotterdam, The Netherlands, 2003; pp. 211–218. [Google Scholar]

- Belem, T.; Benzaazoua, M.; Bussiere, B. Mechanical Behaviour of Cemented Paste Backfill, Materials Science, Montreal. 2000. Corpus ID: 56076620. Available online: https://www.semanticscholar.org/paper/MECHANICAL-BEHAVIOUR-OF-CEMENTED-PASTE-BACKFILL-Belem-Benzaazoua/0618219d2edc0e8b73a96f8abd9d8b1369c0cf0d (accessed on 19 April 2022).

- ASTM C 143:21; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- Magalhäes Gomes, A.; Costa, J.O.; Albertini, H.; Aguiar, J.E. Permeability of Concrete: A Study Intended for the “In Situ” Valuation Using Portable Instruments and Traditional Techniques. In Proceedings of the International Symposium (Non-Destructive Testing in Civil Engineering 2003), Berlin, Germany, 16–19 September 2003. [Google Scholar]

- Krstić, V. Chapter 12: Some Effective Methods for Treatment of Wastewater from Cu Production. In Water Pollution and Remediation: Heavy Metals. Environmental Chemistry for a Sustainable World; Inamuddin, Ahamed, M.I., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2021; Volume 53, pp. 313–440. [Google Scholar]

- Krstić, V.; Pešovski, B. Novel multifunctional two layer catalytic activated titanium electrodes for various technological and environmental processes. Arab. J. Chem. 2021, 14, 103101. [Google Scholar] [CrossRef]

- Krstić, V.; Urošević, T.; Pešovski, B. A review on adsorbents for treatment of water and wastewaters containing copper ions. Chem. Eng. Sci. 2018, 192, 273–287. [Google Scholar] [CrossRef]

- Rybak, J.; Kongar-Syuryun, C.; Tyulyaeva, Y.; Khayrutdinov, A.M. Creation of Backfill Materials Based on Industrial Waste. Minerals 2021, 11, 739. [Google Scholar] [CrossRef]

- Yang, L.; Xu, W.; Yilmaz, E.; Wang, Q.; Qiu, J. A combined experimental and numerical study on the triaxial and dynamic compression behavior of cemented tailings backfill. Eng. Struct. 2020, 219, 110957. [Google Scholar] [CrossRef]

- Xu, W.; Liu, B.; Wu, W. Strength and deformation behaviors of cemented tailings backfill under triaxial compression. J. Cent. South Univ. 2020, 27, 3531–3543. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Chen, Z.; Mao, X.; Han, G.; Wang, Y. Particle size distribution effects on the strength characteristic of cemented paste backfill. Minerals 2018, 8, 322. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Jing, H.; Yin, Q.; Meng, B.; Han, G. Strength and ultrasonic properties of cemented waste rock backfill considering confining pressure, dosage and particle size effects. Construct. Build. Mater. 2020, 242, 118132. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W. Mechanical properties and microstructure of layered cemented paste backfill under triaxial cyclic loading and unloading. Construct. Build. Mater. 2020, 257, 119540. [Google Scholar] [CrossRef]

- ASTM D4767-11; Standard Test Method for Consolidated Undrained Triaxial Compression Test for Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2011.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).