Potential of Renewable Energy in Jamaica’s Power Sector: Feasibility Analysis of Biogas Production for Electricity Generation

Abstract

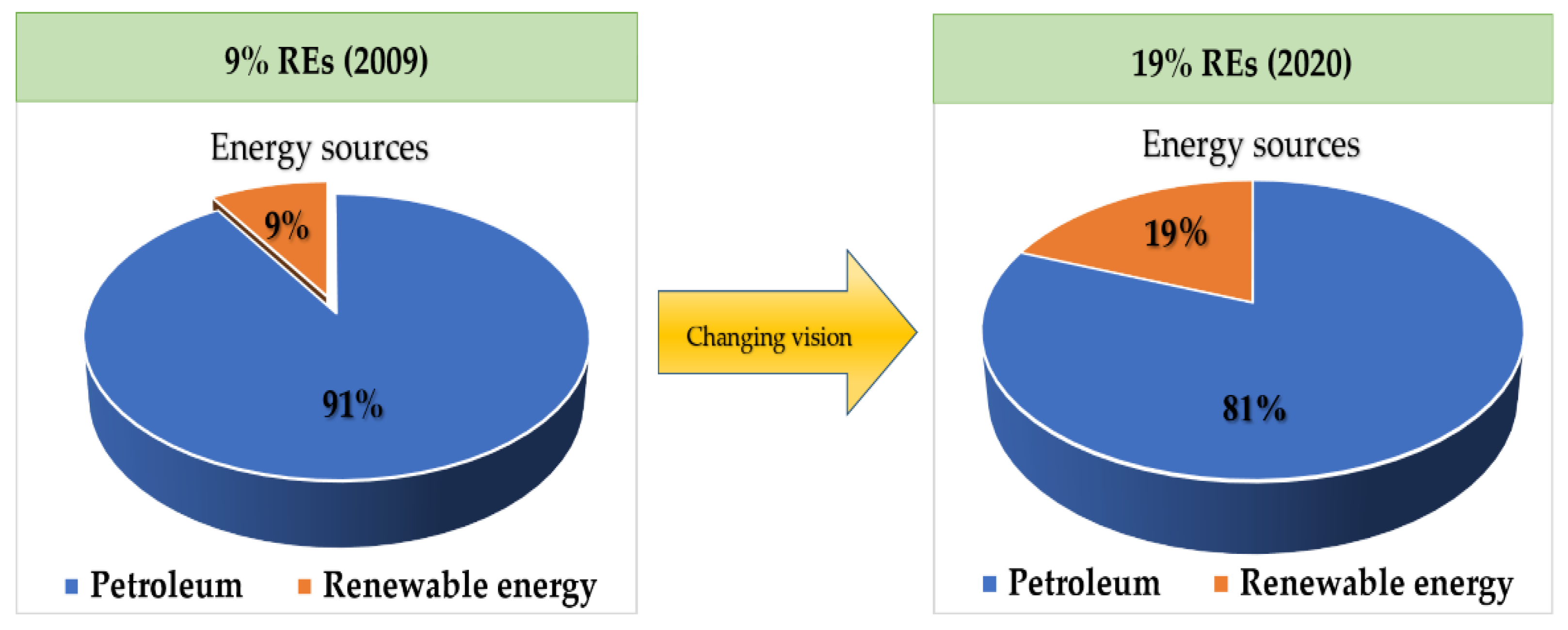

1. Introduction

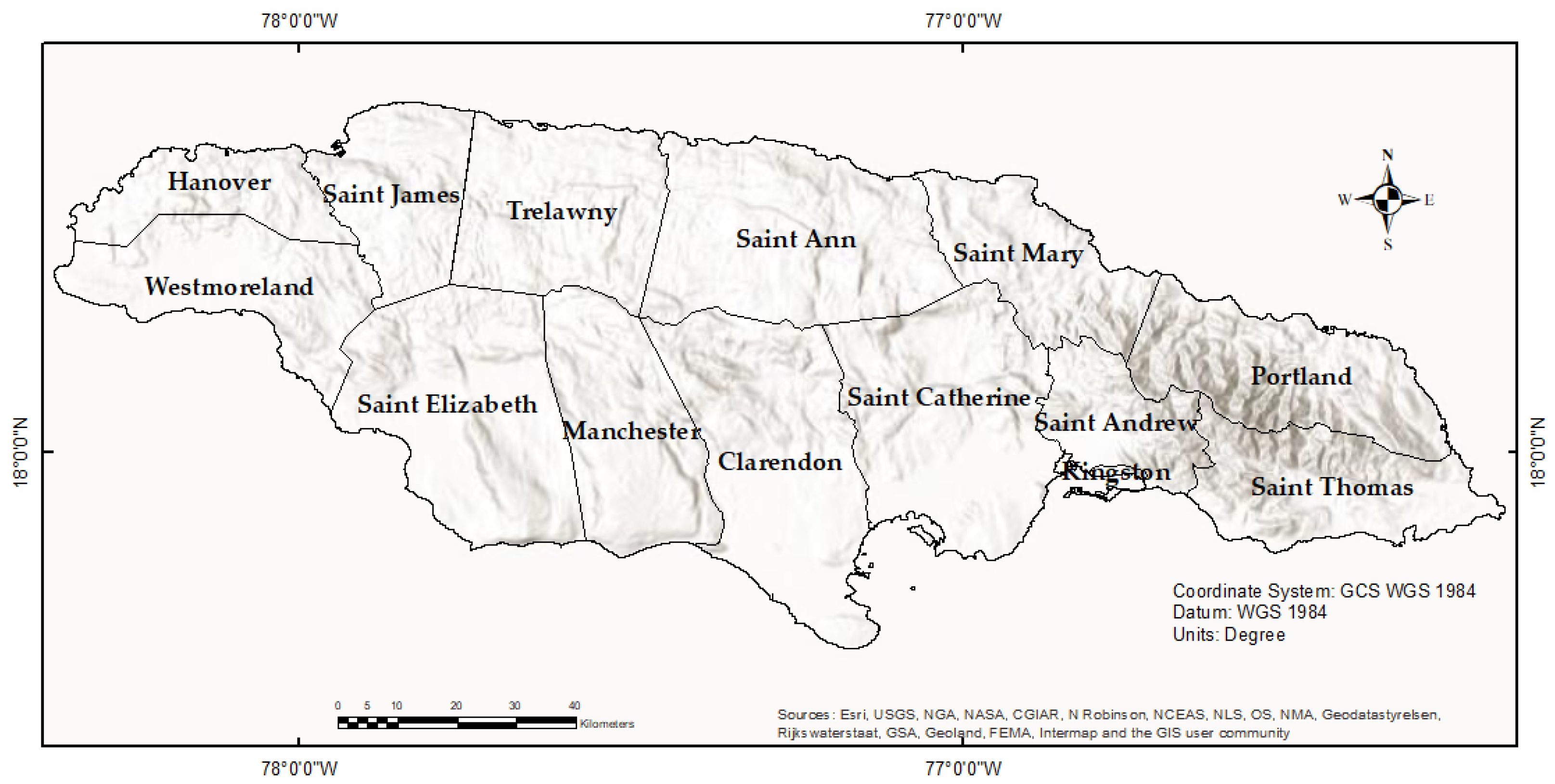

2. Study Area and Data

2.1. Study Area

2.2. Bioenergy Utilization in Jamaica

| Renewable Energy Source | Proven RE Potential (MW) | Potential Being Utilized (%) | Estimated Installed Capacity (MW) (Up to 2020) |

|---|---|---|---|

| Solar | 650–1876 | 5 | 93 |

| Biomass | 192 | 0 | 32 |

| Waste-to-Energy | 65–127 | 5 | 5 (3.25% from bagasse) |

| Hydro | 33.4–56.1 | 57 | 31.92 |

| Wind | 112–1313 | 7.78 | 99 |

| Geothermal | Minimal potential | 0 | 0 |

| Total | - | - | 260.92 |

| Renewable energy as % installed power capacity = approximately 19% | |||

2.3. Anaerobic Digestion and Biogas

3. Materials and Methods

- Secondary data collection of available residues from agricultural and livestock manures was collated to assess the appropriate feedstock for analysis.

- A comprehensive literature review looked at similar studies and an array of relevant country policy papers.

- Quantification of the agricultural and livestock residues was performed through data assimilation. The works applied are listed in this section.

- The data was computed in Microsoft Excel software, with findings centered on specific distinguishing factors from residue types.

- Finally, a brief conclusion was drawn to estimate available bioresources for energy application.

3.1. Assumptions

3.2. Data Collection

3.3. Quantitative Assessment of Agricultural and Livestock Residues’ Energy-from-Waste Potential

| Agricultural Residue | Collection Factor | Surplus Availability Factor | Residue Dryness Factor | Ratio of Volatile Solid | Biogas Generation Rate | References |

|---|---|---|---|---|---|---|

| Unit | 0–1 | 0–1 | 0–1 | 0–1 | m3/kgVS | |

| Rice straws | 0.60 | 0.50 | 0.83 | 0.54 | 0.34 | [30,38,44,45] |

| Rice husk | 0.80 | 0.46 | 0.876 | 0.69 | 0.69 | [30,35,44,45,46] |

| Rice bran | 1.00 | 0.68 | 0.91 | 0.69 | 0.50 | [30,35,45,47,48] |

| Jute stalks | 0.35 | 0.50 | 0.905 | 0.50 | 0.30 | [30,45] |

| Sugarcane tops | 0.70 | 1.00 | 0.50 | 0.50 | 0.37 | [30,38,45] |

| Wheat straws | 0.35 | 0.20 | 0.925 | 0.94 | 0.36 | [30,35,45,46] |

| Sugarcane bagasse | 1.00 | 0.21 | 0.51 | 0.74 | 0.37 | [30,35,45,46] |

| Livestock Type | Collection Factor | Ratio of Volatile Solid to Dry Matter | Biogas Generation Rate | References |

|---|---|---|---|---|

| Unit | 0–1 | 0–1 | m3/kgVS | |

| Poultry | 0.50 | 0.46 | 0.18 | [25,35,45] |

| Sheep | 0.60 | 0.91 | 0.31 | [25,33,45] |

| Goat | 0.60 | 0.59 | 0.31 | [25,38,45] |

| Swine | 0.50 | 0.89 | 0.65 | [40] |

| Dairy cow | 0.50 | 0.93 | 0.66 | [25,26,38,45] |

| Livestock Type | Residue Generation Rate | Collection Factor | Ratio of Volatile Solid to Dry Matter | Biogas Generation Rate | References |

|---|---|---|---|---|---|

| Unit | kg dry matter/day | - | - | m3/kgVS | |

| Sugarcane bagasse and Swine | - | 0.90 | 0.71 | 0.89 | [20,25,40] |

| Sugarcane bagasse and dairy cow | - | 0.75 | 0.80 | 0.92 | [26,41] |

4. Findings and Discussion

4.1. Sugarcane Bagasse Availability in Jamaica

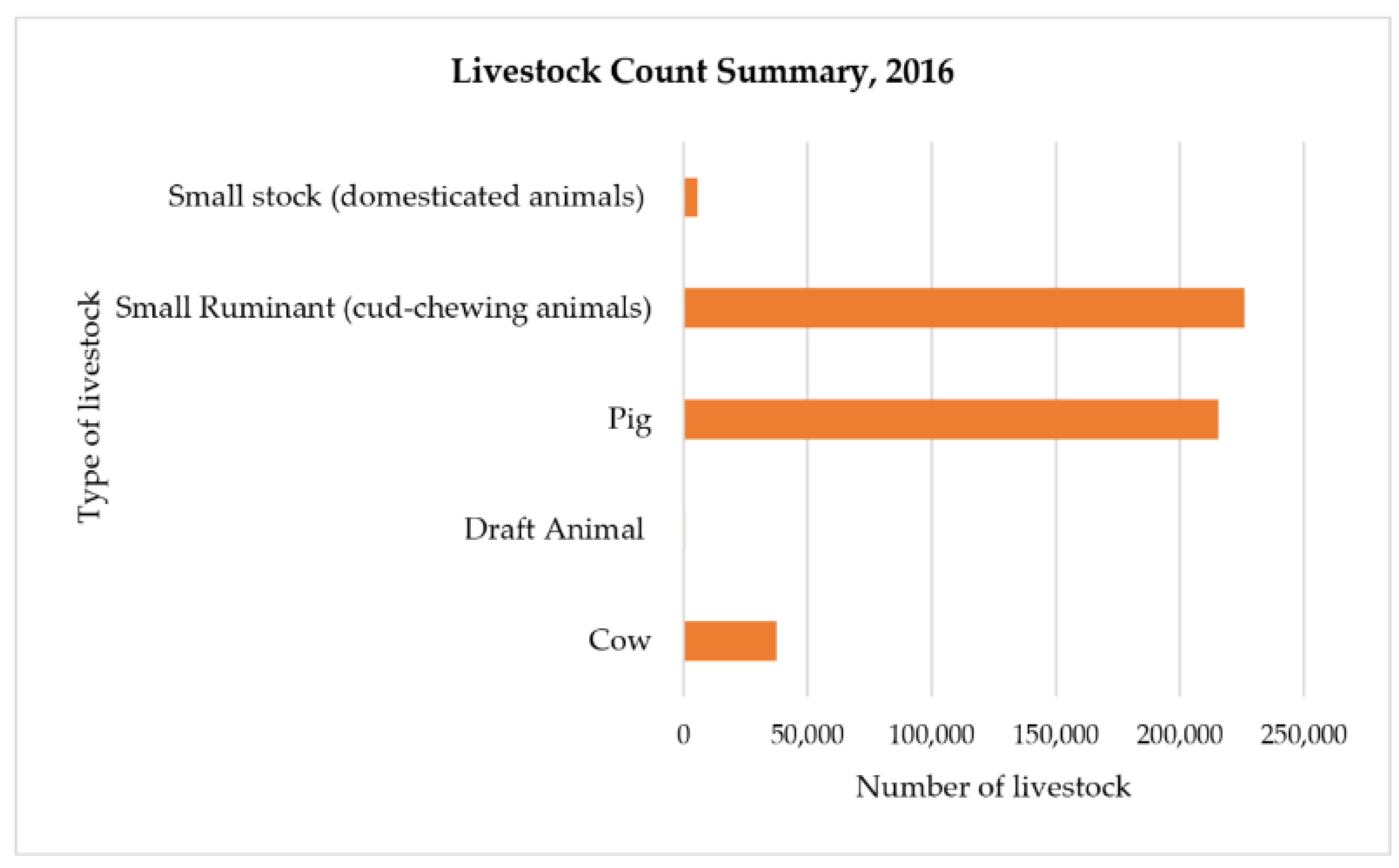

4.2. Livestock Production and Availability in Jamaica

4.3. Potential Biogas Yield and Electrical Energy Generation

4.4. Biogas Functionality

4.5. Potential for Improved Manure Management

- (1)

- The above systems should include resource and recovery mechanisms using efficient technology, for example, BIMA digesters.

- (2)

- Upgrade current systems in Jamaica as some of the BTS up-flow models were installed during the 1980s.

- (3)

- Biogas projects need to be promoted by the government and other stakeholders in rural areas and large-scale factories.

- (4)

- Rural, family-owned farms have limited capital for investment in new, applicable, sustainable, and ecology-based high technology. Therefore, the government should subsidize such businesses to aid in sustainable manure management.

- (5)

- Technical support and consultation regarding environmental initiatives are needed for all farmers in Jamaica, not just livestock farmers. However, crop farmers might also value resource recovery since the waste types yielded contribute to industries’ circular economy models and synergies.

- (6)

- The success of sustainable agriculture requires proper planning with an emphasis on economic viability as such, a system with several industries combined is necessary to generate profit.

- (7)

- Government support is necessary for the success of agri-waste treatment by fermentation in Jamaica since the technology required can be expensive for low-earning farms. Jamaican farms’ adaptable and amenable technologies are also considered the available natural resources.

4.6. Biogas for Sustainable Development in Communities

- The amelioration of quality of livestock and agricultural wastes.

- The provision of support for local businesses and rural community members with increased investments.

- Increases in energy recovery rate from bioresources, regenerating natural capital. In this case, namely agricultural and manure wastes.

- Sustainable energy production in communities, especially those outside urban centers, where remoteness hampers easy transfer of on-grid electricity. Moreover, where heating demand is high, alternative renewable energy sources such as wind, solar, and hydropower cannot fill the market demand.

- Contributes to sustainable social development by accentuating symbiotic relationships between private and governmental entities in exchanging goods. This structure improves circularity, a core element in energy recovery from recycling, as highlighted in sustainable development goal (SDG) number 11, Sustainable Cities and Communities, promoting a reduction in city resources and environmental impacts. Moreover, other connected SDGs to a circular economy include 7 Affordable Clean Energy, 12 Responsible Consumption and Production, 13 Climate Action, and 15 Life on Land.

- Improved coordination of industries, namely agriculture, with solid waste management.

- Improved waste management system, boasting a design within which wastes (feedstock) will be easily transferable to utilization zones.

- The promotion of family-sized or community-based methods will encounter fewer barriers, such as social acceptability, high startup input costs, and formal policies for streamlining development in the renewable energy market.

- Effective planning and market application to locate viable organic feedstock.

- Biomass residues collected on a large scale are appropriate for improving the current electric power generation. However, small-scale ones are applicable to meet household cooking needs in remote regions where natural gas and electricity are unreachable or too costly.

5. Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Supplementary Data Explaining Crop Types in Jamaica

| Legend for Crops Represented in Figure 2 | |

|---|---|

| Legumes | broad beans, sugar beans, cowpeas, gungo peas, red peas, peanuts |

| Vegetables | beetroot, broccoli, cabbage, calaloo, carrot, cauliflower, celery, chow-chow, cucumber, eggplant, iceberg lettuce, other lettuce, okra, pak choy, pumpkin, squash, string beans, tomato, turnip, other vegetables |

| Condiments | scallion, ginger, onion, hot pepper, sweet pepper, thyme |

| Fruits | cantaloupe, pawpaw, pineapple, watermelon |

| Cereals | hybrid corn, ordinary corn, sweet corn, rice |

| Plantain | horse plantain, other plantains |

| Potatoes | sweet potato, irish potato |

| Yams | lucea, negro, renta, St. Vincent, sweet, tau, yellow, other |

| Other tubers | bitter cassava, sweet cassava, coco, dasheen |

| Category | Year | Total Production (metric tons/yr.) | Factories (No.) | Bagasse (% pol) | Bagasse (moisture %) | Total Production Area (ha.) |

|---|---|---|---|---|---|---|

| Sugarcane | 2009 | 1,334,579 | 6 | 3.59 | 51.76 | No available data (NAD) |

| 2010 | 1,390,084 | 6 | 3.03 | 51.47 | NAD | |

| 2011 | 1,518,340 | 5 | 3.44 | 51.37 | NAD | |

| 2012 | 1,475,225 | 6 | 3.45 | 51.29 | NAD | |

| 2013 | 1,402,564 | 6 | 3.47 | 51.23 | NAD | |

| 2014 | 1,779,258 | 6 | 3.39 | 51.20 | 29,197 | |

| 2015 | 1,585,543 | 6 | 3.25 | 51.37 | 21,135 | |

| 2016 | 1,127,751 | 5 | 2.59 | 51.27 | 25 | |

| 2017 | 1,133,353 | 5 | 2.9 | 51.01 | 21 | |

| 2018 | 1,028,400 | 6 | NAD | NAD | 18,558 | |

| Total | 10 years | 13,775,097 | 6 | 3.234 | 51.33 | Inadequate data |

References

- Planning Institute of Jamaica. Vision 2030 Jamaica: National Development Plan; PIOJ: Kingston, Jamaica, 2009. [Google Scholar]

- Ministry of Science, Energy, and Technology, Total Petroleum Imports. 2018. Available online: https://www.mset.gov.jm/sites/default/files/pdf/Petroleum%20Imports%202013-2017.pdf/ (accessed on 16 November 2018).

- Killeen, P. Jamaica and How Renewables Are Changing Island Energy Economics. 2015. Available online: https://www.greenbiz.com/article/Jamaica-and-how-renewables-are-changing-island-energy-economics/ (accessed on 27 August 2018).

- Ministry of Energy and Mining, National Energy from Waste Policy 2010–2030. 2010. Available online: https://www.mset.gov.jm/wp-content/uploads/2019/07/Draft-Waste-to-Energy-Policy_0.pdf/ (accessed on 22 October 2018).

- Jamaica Information Service, Office of the Prime Minister, Jamaica to Increase Renewables Target to 50%—PM Holness. 2018. Available online: https://jis.gov.jm/jamaica-to-increase-renewables-target-to-50-pm-holness/ (accessed on 13 November 2018).

- International Renewable Energy Agency (IRENA). ENERGY PROFILE Jamaica. 2021. Available online: https://www.irena.org/IRENADocuments/Statistical_Profiles/Central%20America%20and%20the%20Caribbean/Jamaica_Central%20America%20and%20the%20Caribbean_RE_SP.pdf (accessed on 6 February 2022).

- Contreras-Lisperguer, R.; Batuecas, E.; Mayo, C.; Díaz, R.; Pérez, F.J.; Springer, C. Sustainability assessment of electricity cogeneration from sugarcane bagasse in Jamaica. J. Clean. Prod. 2018, 200, 390–401. [Google Scholar] [CrossRef]

- Grant, S.; Marshalleck, A. Energy production and Pollution mitigation from broilers houses on poultry farms in Jamaica and Pennsylvania. Int. J. Serv. Learn. Eng. Humanit. Eng. Soc. Entrep. 2008, 3, 41–52. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Liu, G.; Chen, C.; He, Y.; Liu, X. Comparison of methane production potential, biodegradability, and kinetics of different organic substrates. Bioresour. Technol. 2013, 149, 565–569. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Energy and Mining. National Renewable Energy Policy (2009–2030). 2010. Available online: https://www.mset.gov.jm/sites/default/files/pdf/Draft%20Renewable%20Energy%20Policy.pdf (accessed on 9 March 2019).

- Agricultural Marketing Information Division, Ministry of Industry, Commerce, Agriculture & Fisheries. 2017. Available online: https://moa.gov.jm/content/agricultural-marketing-information-division/ (accessed on 29 October 2018).

- National Solid Waste Management Authority, Waste Characterization and Per Capita Generation Rate Report 2013: The Metropolitan Wasteshed. 2013. Available online: http://www.nswma.gov.jm/WASTEGENERATIONANDCOMPOSITIONSURVEYREPORT2013.pdf/ (accessed on 12 July 2019).

- GEOFABRIK. 2020. Available online: http://www.geofabrik.de/ (accessed on 11 March 2017).

- Bandy, B.; Lindo, G. Global Bioenergy Partnership Bioenergy Week, Ministry of Science, Technology, Energy, and Mining. 2013. Available online: http://www.globalbioenergy.org/fileadmin/user_upload/gbep/docs/2013_events/GBEP_Bioenergy_Week_Brasilia_18-23_March_2013/3.12_BANDY_LINDO.pdf/ (accessed on 6 July 2019).

- Ministry of Energy and Mining, National Renewable Energy Policy (2009–2030). 2010. Available online: https://www.mset.gov.jm/wp-content/uploads/2019/07/National-Energy-Policy_0.pdf/ (accessed on 29 October 2018).

- Ministry of Energy and Mining, National Biofuels Policy 2010–2030. 2010. Available online: https://www.mset.gov.jm/wp-content/uploads/2019/07/Draft-Biofuels-Policy_0.pdf/ (accessed on 22 October 2018).

- United Nations Development Programme; Legros, G.; Havet, I.; Bruce, N.; Bonjour, S.; Rijal, K.; Dora, C. The Energy Access Situation in Developing Countries. Available online: https://www.undp.org/publications/energy-access-developing-countries (accessed on 5 June 2020).

- Ahmed, A. Jamaica’s Electricity Mix in 2030: The Role of Renewables and Natural Gas. 2017. Available online: http://www.worldwatch.org/jamaica%E2%80%99s-electricity-mix-2030-role-renewables-and-natural-gas/ (accessed on 6 May 2019).

- Hydro Review, Jamaica Adds 7.2 MW in First Hydropower Expansion in 30 Years, Issue 5 and Volume 36. 2019. Available online: https://www.hydroreview.com/2017/06/01/jamaica-adds-7-2-mw-in-first-hydropower-expansion-in-30-years/#gref/ (accessed on 2 May 2019).

- Surendra, K.C.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Khanal, S.K.; Nindhia, T.G.T.; Nitayavardhana, S. Biogas from wastes: Processes and applications. In Sustainable Resource Recovery and Zero Waste Approaches; Elsevier: St. Louis, MO, USA, 2019; pp. 165–174. [Google Scholar]

- Radhakrishnan, M.V.; Sugumaran, E. Efficacy of sugarcane bagasse to produce bacterial biofilm in water for fish culture. J. Ecobiotechnol. 2010, 2. Available online: https://www.researchgate.net/profile/Sugumaran-Ezhilovian/publication/216326429_Efficacy_of_Sugarcane_Bagasse_to_produce_bacterial_biofilm_in_water_for_fish_culture/links/0912f504223dd7fd8e000000/Efficacy-of-Sugarcane-Bagasse-to-produce-bacterial-biofilm-in-water-for-fish-culture.pdf (accessed on 22 April 2019).

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T. Biotechnological potential of agro-industrial residues. I: Sugarcane Bagasse. Bioresour. Technol. 2000, 74, 69–80. [Google Scholar] [CrossRef]

- Okot-Okumu, J.; Nyenje, R. Municipal solid waste management under decentralisation in Uganda. Habitat Int. 2011, 35, 537–543. [Google Scholar] [CrossRef]

- Bhattacharya, S.C.; Thomas, J.M.; Salam, P.A. Greenhouse gas emissions and the mitigation potential of using animal wastes in Asia. Energy 1997, 22, 1079–1085. [Google Scholar] [CrossRef]

- Afrizal, F.; Muhammad, I.; Satria, P. Kinetics on anaerobic co-digestion of bagasse and digested cow manure with short hydraulic retention time. Res. Agric. Eng. 2017, 63, 121–127. [Google Scholar]

- Mashi, B.H. Comparative study of biogas production from sugarcane bagasse and cow dung. UMYU J. Microbiol. Res. 2018, 3, 127–131. [Google Scholar]

- Alves, M.; Ponce, G.H.; Silva, M.A.; Ensinas, A.V. Surplus electricity production in sugarcane mills using residual bagasse and straw as fuel. Energy 2015, 91, 751–757. [Google Scholar] [CrossRef]

- Carrère, H.; Sialve, B.; Bernet, N. Improving pig manure conversion into biogas by thermal and thermo-chemical pretreatments. Bioresour. Technol. 2009, 100, 3690–3694. [Google Scholar] [CrossRef] [PubMed]

- Hossain, A.K.; Badr, O. Prospects of renewable energy utilisation for electricity generation in Bangladesh. Renew. Sustain. Energy Rev. 2007, 11, 1617–1649. [Google Scholar] [CrossRef]

- Bandy, B. Bioenergy Development in Jamaica: Challenge and Barriers, Ministry of Science, Energy, and Technology. 2016. Available online: http://ledslac.org/wp-content/uploads/2016/10/biofuels_development_in_jamaica-23-09-2016.pdf/ (accessed on 3 May 2019).

- Hopwood, L. Farm-Scale Anaerobic Digestion Plant Efficiency NNFCC 11-015. 2011. Available online: https://web.archive.org/web/20110514144653/http://www.nnfcc.co.uk/tools/farm-scale-anaerobic-digestion-plant-efficiency-nnfcc-11-015/ (accessed on 20 July 2019).

- Banks, C. Optimising Anaerobic Digestion: Evaluating the Potential for Anaerobic Digestion to Provide Energy and Soil Amendment; University of Reading: Reading, UK, 2009. [Google Scholar]

- Qiu, H.; Sun, L.; Xu, X.; Cai, Y.; Bai, J. Potentials of crop residues for commercial energy production in China: A geographic and economic analysis. Biomass Bioenergy 2014, 64, 110–123. [Google Scholar] [CrossRef]

- Suhartini, S.; Lestari, Y.P.; Nurika, I. Estimation of methane and electricity potential from canteen food waste. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2019; p. 012075. [Google Scholar]

- Rahman, M.M.; Paatero, J.V. A methodological approach for assessing potential of sustainable agricultural residues for electricity generation: South Asian perspective. Biomass Bioenergy 2012, 47, 153–163. [Google Scholar] [CrossRef]

- Smyth, B.M.; Murphy, J.D.; O’Brien, C.M. What is the energy balance of grass biomethane in Ireland and other temperate northern European climates? Renew. Sustain. Energy Rev. 2009, 13, 2349–2360. [Google Scholar] [CrossRef]

- Perera, K.K.C.K.; Rathnasiri, P.G.; Senarath, S.A.S.; Sugathapala, A.G.T.; Bhattacharya, S.C.; Salam, P.A. Assessment of sustainable energy potential of non-plantation biomass resources in Sri Lanka. Biomass Bioenergy 2005, 29, 199–213. [Google Scholar] [CrossRef]

- Armah, E.K.; Chetty, M.; Deenadayalu, N. Biogas production from sugarcane bagasse with South African industrial wastewater and novel kinetic study using response surface methodology. Sci. Afr. 2020, 10, e00556. [Google Scholar] [CrossRef]

- Tuesorn, S.; Wongwilaiwalin, S.; Champreda, V.; Leethochawalit, M.; Nopharatana, A.; Techkarnjanaruk, S.; Chaiprasert, P. Enhancement of biogas production from swine manure by a lignocellulolytic microbial consortium. Bioresour. Technol. 2013, 144, 579–586. [Google Scholar] [CrossRef]

- Sthembiso, M.; Makarfi, I.Y. Production of biogas from bagasse: Effect of cow dung to bagasse feed ratio, media solution pH and digester’s moisture content on biogas volume and methane yield. Int. J. 2020, 8, 7. [Google Scholar] [CrossRef]

- Rangkuti, C.; Ahmad, S.; Permatasari, R. Effect of Mixture Ratio of Cow Faces with Water on Biogas Production. 2006. Available online: https://www.researchgate.net/publication/310507273_Effect_of_mixture_ratio_of_cow_faeces_with_water_on_biogas_production (accessed on 12 December 2021).

- Lansing, S.; Martin, J.F.; Botero, R.B.; Da Silva, T.N.; Da Silva, E.D. Methane production in low-cost, unheated, plug-flow digesters treating swine manure and used cooking grease. Bioresour. Technol. 2010, 101, 4362–4370. [Google Scholar] [CrossRef] [PubMed]

- Karellas, S.; Boukis, I.; Kontopoulos, G. Development of an investment decision tool for biogas production from agricultural waste. Renew. Sustain. Energy Rev. 2010, 14, 1273–1282. [Google Scholar] [CrossRef]

- Baky, M.A.H.; Rahman, M.M.; Islam, A.S. Development of renewable energy sector in Bangladesh: Current status and future potentials. Renew. Sustain. Energy Rev. 2017, 73, 1184–1197. [Google Scholar] [CrossRef]

- Prasertsan, S.; Sajjakulnukit, B. Biomass and biogas energy in Thailand: Potential, opportunity and barriers. Renew. Energy 2006, 31, 599–610. [Google Scholar] [CrossRef]

- Singh, J.; Panesar, B.S.; Sharma, S.K. Energy potential through agricultural biomass using geographical information system—A case study of Punjab. Biomass Bioenergy 2008, 32, 301–307. [Google Scholar] [CrossRef]

- Kellogg, R.L. Profile of Farms with Livestock in the United States: A Statistical Summary, Natural Resources Conservation Service, United States Department of Agriculture. 2002. Available online: https://www.nrcs.usda.gov/wps/portal/nrcs/detail/national/home/?cid=nrcs143_014121/ (accessed on 20 June 2019).

- Venier, F.; Yabar, H. Renewable energy recovery potential towards sustainable cattle manure management in Buenos Aires Province: Site selection based on GIS spatial analysis and statistics. J. Clean. Prod. 2017, 162, 1317–1333. [Google Scholar] [CrossRef]

- Ministry of Science, Energy, and Technology, Petroleum Imports. 2019. Available online: https://www.mset.gov.jm/documents/petroleum-imports/ (accessed on 22 January 2019).

- Bennet, D. Diagnosis of Generation in Latin America & the Caribbean: Jamaica. Canadian Cooperation under the Project on Sustainable Energy for Latin America and the Caribbean 2012–2017. 2013. Available online: http://www.olade.org/sites/default/files/CIDA/OLADE%20Generation%20Diagnosis%20Jamaica.pdf/ (accessed on 5 July 2019).

- Singh, J. Identifying an economic power production system based on agricultural straw on regional basis in India. Renew. Sustain. Energy Rev. 2016, 60, 1140–1155.57. [Google Scholar] [CrossRef]

- Sugar Industry Authority. Cane and Sugar Production in Jamaica: 1957–2017. 2019. Available online: https://www.jamaicasugar.org/sugar-cane-production.html/ (accessed on 16 September 2019).

- U.S. Department of Agriculture (USDA). Global Agricultural Information Network Report: Jamaica Annual Sugar Report 2018; GAIN Report Number: JM1801; Global Agricultural Information Network: Washington, DC, USA, 2018.

- De Paoli, F.; Bauer, A.; Leonhartsberger, C.; Amon, B.; Amon, T. Utilization of by-products from ethanol production as substrate for biogas production. Bioresour. Technol. 2011, 102, 6621–6624. [Google Scholar] [CrossRef]

- Jewell, W.J.; Cummings, R.J.; Richards, B.K. Methane fermentation of energy crops: Maximum conversion kinetics and in situ biogas purification. Biomass Bioenergy 1993, 5, 261–278. [Google Scholar] [CrossRef]

- Ramjeawon, T. Life cycle assessment of electricity generation from bagasse in Mauritius. J. Clean. Prod. 2008, 16, 1727–1734. [Google Scholar] [CrossRef]

- Richards, B.K.; Cummings, R.J.; Jewell, W.J. High-rate low solids methane fermentation of sorghum, corn and cellulose. Biomass Bioenergy 1991, 1, 249–260. [Google Scholar] [CrossRef]

- To, L.S.; Seebaluck, V.; Leach, M. Future energy transitions for bagasse cogeneration: Lessons from multi-level and policy innovations in Mauritius. Energy Res. Soc. Sci. 2018, 35, 68–77. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Livestock Statistics—Concepts, Definitions and Classifications. 2021. Available online: https://www.fao.org/economic/the-statistics-division-ess/methodology/methodology-systems/livestock-statistics-concepts-definitions-and-classifications/en/ (accessed on 2 November 2019).

- Food and Agriculture Organization of the United Nations. Africa Sustainable Livestock 2050: Livestock Production Systems Spotlight Kenya Cattle and Poultry Sectors. 2018. Available online: http://www.fao.org/3/i8270en/I8270EN.pdf/ (accessed on 20 June 2019).

- WorldData.info. Energy consumption in Jamaica. Available online: https://www.worlddata.info/america/jamaica/energy-consumption.php (accessed on 26 March 2022).

- United States Department of Energy. Energy Transitions Initiatives: Jamaica Energy Snapshot. 2020. Available online: Energy.gov/sites/default/files/2020/09/f79/ETI-Energy-Snapshot-Jamaica_FY20.pdf (accessed on 18 November 2021).

- Savci, S. An agricultural pollutant: Chemical fertilizer. Int. J. Environ. Sci. Dev. 2012, 3, 73. [Google Scholar] [CrossRef]

- Lal, R. Restoring soil quality to mitigate soil degradation. Sustainability 2015, 7, 5875–5895. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Fisheries (MoAF). 2020. Available online: https://www.moa.gov.jm/search/content/livestock (accessed on 12 February 2022).

- Global Forum for Rural Advisory Services. Jamaica. 2022. Available online: https://www.g-fras.org/en/world-wide-extension-study/central-america-and-the-caribbean/caribbean/jamaica.html (accessed on 10 February 2022).

- Uddin, M.; Siddiki, S.; Arafat, Y.; Ahmed, S.F.; Rony, Z.I.; Chowdhury, M.A.K.; Mofijur, M. Estimation of sustainable bioenergy production from olive mill solid waste. Energies 2021, 14, 7654. [Google Scholar] [CrossRef]

- Mishima, S.I.; Leon, A.; Eguchi, S.; Shirato, Y. Livestock waste, potential manure production and its use in Japan in 1980 and 2010. Compost. Sci. Util. 2017, 25 (Suppl. 1), S43–S52. [Google Scholar] [CrossRef]

- Loy, D.; Coviello, M. Renewable Energies Potential in Jamaica. 2005. Available online: https://repositorio.cepal.org/handle/11362/4138/ (accessed on 22 October 2021).

- United States Agency for International Development (USAID), LAND LINKS, Jamaica. 2021. Available online: https://www.land-links.org/country-profile/jamaica/#:~:text=Jamaica%E2%80%99s%20forest%20land%20currently%20includes%20339%2C000%20hectares%20of,and%20is%20largely%20comprised%20of%20tropical%20montane%20forest/ (accessed on 22 October 2021).

- Zidago, A.P.; Wang, Z. Charcoal and Fuelwood consumption and its impacts on environment in cote d’Ivoire (case study of Yopougon area). Environ. Nat. Resour. Res. 2016, 6, 2016. [Google Scholar] [CrossRef]

| Scenarios | Residue Type | Total Residue (kg/day) | Total Available Residue (kg/day) | Residue Mix (ratio) | Potential Biogas (300 days) (m3/year) | Total Electricity Potential (MWh/year) |

|---|---|---|---|---|---|---|

| CASE 1 | Dairy cow dung | 106,887 | 53,443 | - | 4,920,495 | 3,187,742 |

| CASE 2 | Swine dung | 215,393 | 10,769,650 | - | 934,536,378 | 6,859,029 |

| CASE 3 | Sugarcane bagasse | 399,478 | 42,784 | - | 3,514,281 | 2,213,997 |

| CASE 4 | Sugarcane bagasse and dairy cow dung | 399,478 and 1,068,867 | 42,784 and 42,784 | 1:1 | 18,893,400 | 12,240,089 |

| CASE 5 | Sugarcane bagasse and swine dung | 399,478 and 407,093 | 42,784 and 1,426,133 | 3:1 | 10,814,083 | 7,721,255 |

| Animal Dung | Biogas Generation (liters biogas/kg manure) |

|---|---|

| Chicken | 70 |

| Cattle | 40 |

| Pig | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richards, D.; Yabar, H. Potential of Renewable Energy in Jamaica’s Power Sector: Feasibility Analysis of Biogas Production for Electricity Generation. Sustainability 2022, 14, 6457. https://doi.org/10.3390/su14116457

Richards D, Yabar H. Potential of Renewable Energy in Jamaica’s Power Sector: Feasibility Analysis of Biogas Production for Electricity Generation. Sustainability. 2022; 14(11):6457. https://doi.org/10.3390/su14116457

Chicago/Turabian StyleRichards, Delmaria, and Helmut Yabar. 2022. "Potential of Renewable Energy in Jamaica’s Power Sector: Feasibility Analysis of Biogas Production for Electricity Generation" Sustainability 14, no. 11: 6457. https://doi.org/10.3390/su14116457

APA StyleRichards, D., & Yabar, H. (2022). Potential of Renewable Energy in Jamaica’s Power Sector: Feasibility Analysis of Biogas Production for Electricity Generation. Sustainability, 14(11), 6457. https://doi.org/10.3390/su14116457