Sustainability of Agaricus blazei Murrill Mushrooms in Classical and Semi-Mechanized Growing System, through Economic Efficiency, Using Different Culture Substrates

Abstract

1. Introduction

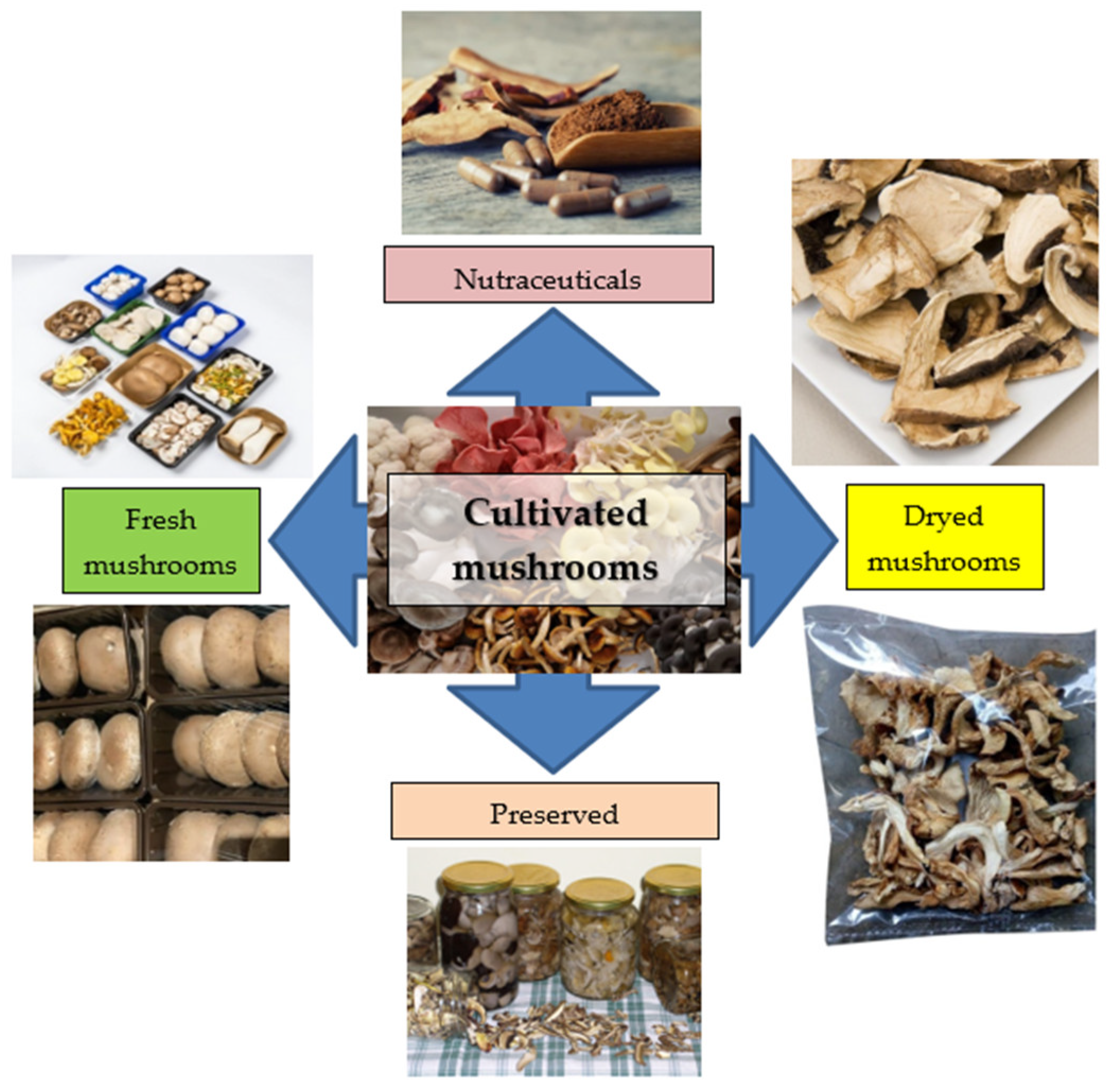

1.1. The Importance of Mushroom Growing

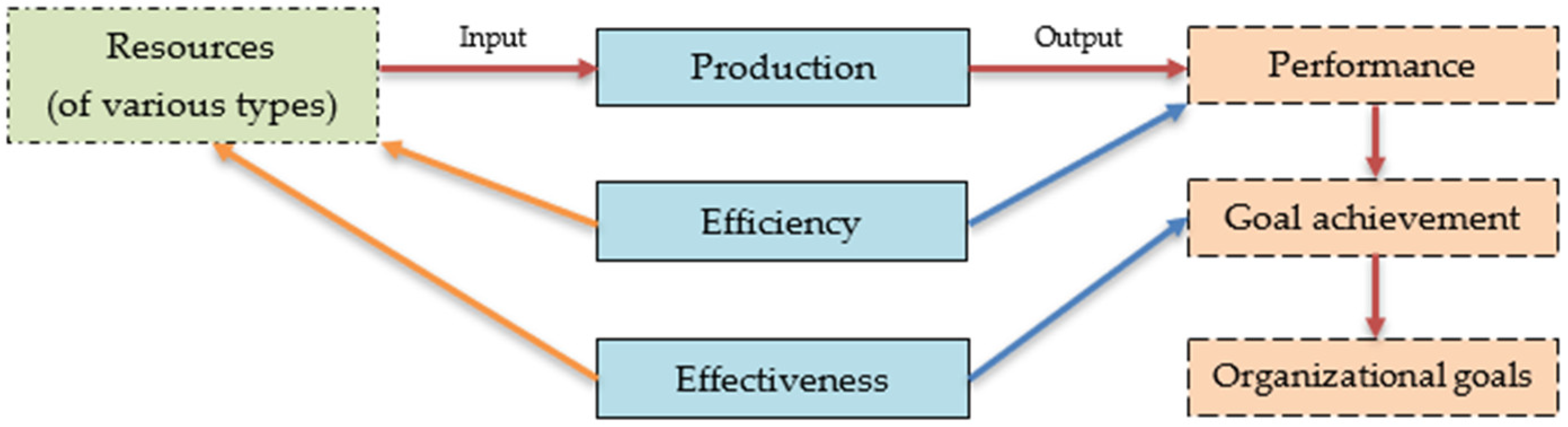

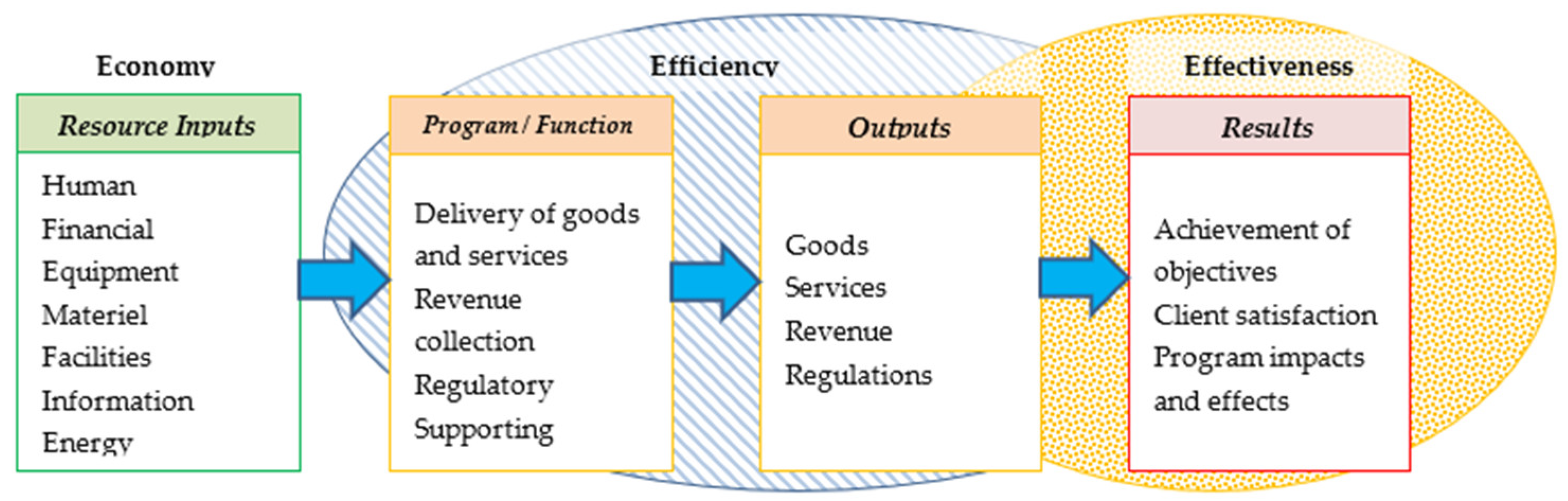

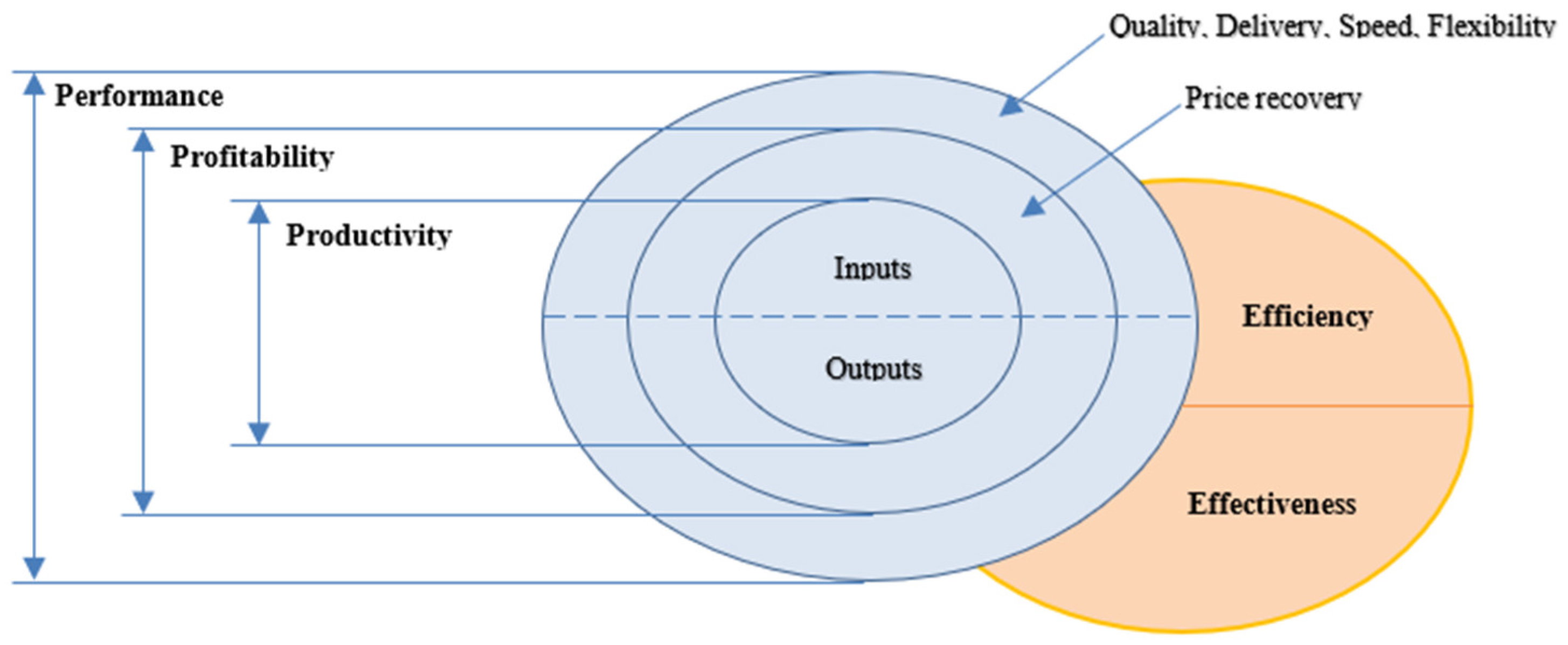

1.2. Economic Efficiency

2. Materials and Methods

2.1. Biological Material Used in the Experiment

2.2. Experimental Factors

2.3. Applied Crop Technology

2.4. Research Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Order No. | Tehnological Works in Cronological Order | Unit | Mechanical Work | Manual Work | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Volume of Work | Cost (RON/Unit) | Expenses with Mechanical Work (RON) | Volume of Work | Work Standard | The Complexity Group of the Work | Requirement of Days—Man (DM) | Expennses on Labour (RON) | |||

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 1 | Compost component | t | 1 | 100 | 100 | 0.06 | 15 | IV/2 | 0.008 | 1 |

| 2 | Pre-soak placement | t | 1 | 50 | 50 | 0.06 | 15 | IV/2 | 0.008 | 1 |

| 3 | Aerobic composting placement | t | 1.0 | 100 | 100 | 0.06 | 15 | IV/2 | 0.008 | 1 |

| 4 | Turn I, II, III, IV | t | 1 | - | - | 2 | 50 | IV/2 | 0.080 | 8 |

| 5 | Disinfection of the cultivation place | m2 | 1 | 50 | 50 | 0.06 | 15 | IV/2 | 0.008 | 1 |

| 6 | Insertion of the substrate in the cultivation chamber | m2 | 10 | - | - | 2 | 50 | III/1 | 0.040 | 3 |

| 7 | Spawning | m2 | 10 | - | - | 2 | 50 | III/3 | 0.120 | 10 |

| 8 | Casing preparation | m3 | 1 | 50 | 50 | 0.15 | 10.6 | IV/1 | 0.014 | 1 |

| 9 | Disinfection of casing mixture | m3 | 1.0 | 5 | 5 | 0.06 | 15 | IV/1 | 0.004 | 0 |

| 10 | Ruffling of casing | m2 | 10 | - | - | 0.5 | 0.12 | II/1 | 4.167 | 250 |

| 11 | Incubation culture maintenance | m2 | 10 | - | - | 0.5 | 0.12 | II/1 | 4.167 | 250 |

| 12 | The maintenance of culture in the formation of primordia | m2 | 10 | - | - | 0.5 | 0.6 | II/1 | 0.833 | 50 |

| 13 | Harvesting—3 waves | m2 | 10 | - | - | 20 | 1.1 | II/3 | 54.545 | 3273 |

| 14 | Substrate maintenance at harvest | m2 | 10 | - | - | 0.5 | 0.6 | II/1 | 0.833 | 50 |

| 15 | Disposal of used substrate | t | 1 | 50 | 50 | 0.5 | 40 | IV/2 | 0.025 | 3 |

| 16 | Cleaning the culture chambers | m2 | 10 | - | - | 0.06 | 15 | I/2 | 0.008 | 0 |

| TOTAL (RON) | 405 | 64.869 | 3901 | |||||||

| Total (euro) | 82 | 790 | ||||||||

| Order No. | Technological Works in Chronological Order | Material Consumption | ||||

|---|---|---|---|---|---|---|

| Sort of Material | UM | Normed Consumption | Price (RON) | Total (RON) | ||

| 0 | 1 | 11 | 12 | 13 | 14 | 15 |

| 1 | Compost component | Recipe components | t | 0.5 | 200 | 100 |

| 2 | Pre-soak placement | - | - | - | - | - |

| 3 | Aerobic composting placement | Amendments | kg | 14 | 10 | 140 |

| 4 | Turn I, II, III, IV | Calcium sulphate | kg | 25 | 5 | 125 |

| 5 | Disinfection of the cultivation place | Disinfectants | kg | 2 | 50 | 100 |

| 6 | Insertion of the substrate in the cultivation chamber | - | - | - | - | - |

| 7 | Spawning | Mycelium | kg | 20 | 50 | 1000 |

| 8 | Casing preparation | Black peat | t | 1 | 50 | 50 |

| 9 | Disinfection of casing mixture | Virocid Disinfectant | l | 1 | 50 | 50 |

| 10 | Ruffling of casing | - | - | - | - | - |

| 11 | Incubation culture maintenance | - | - | - | - | - |

| 12 | The maintenance of culture in the formation of primordia | - | - | - | - | - |

| 13 | Harvesting—3 waves | - | - | - | - | - |

| 14 | Substrate maintenance at harvest | - | - | - | - | - |

| 15 | Disposal of used substrate | - | - | - | - | - |

| 16 | Cleaning the culture chambers | Disinfectants | kg | 2 | 50 | 100 |

| TOTAL (RON) | 1665 | |||||

| Total (euro) | 337 | |||||

Appendix B

| Order No. | Elements of Expense | RON | % |

|---|---|---|---|

| I. Material expenses | |||

| 1. | Materials from own sources | 0 | 0.00 |

| 2. | Purchased materials | 166.5 | 23.53 |

| 3. | Supply costs (10%) | 16.65 | 2.35 |

| 4. | Expenses with mechanized works | 40.5 | 5.72 |

| 5. | The cost of watering (water) | 5 | 0.71 |

| 6. | Depreciation of fixed assets | 0 | 0.00 |

| 7. | Agricultural income tax | 0 | 0.00 |

| 8. | Electricity | 15 | 2.12 |

| 9. | Solid fuel | 10 | 1.41 |

| 10. | Other taxes and fees | 0 | 0.00 |

| 11. | Other material expenses (1%) | 3 | 0.36 |

| I. TOTAL material expenses | 256 | 36.21 | |

| II. Expenses with labour | |||

| 1. | Manual labour costs | 390 | 55.14 |

| 2. | Insurance contribution for work (2.25%) | 9 | 1.24 |

| II. TOTAL labour expenses | 399 | 56.38 | |

| III. TOTAL direct expenses (I + II) | 655 | 92.59 | |

| IV. Indirect expenses (8%) | 52 | 7.41 | |

| V. Interest on loans (IL) | 0 | 0.00 | |

| VI. TOTAL production costs (PC) | 708 | 100.00 | |

| The value of secondary production (VSP) | 0 | 0.00 | |

| VII. Main production costs (MPC) | 708 | 100.00 | |

| Economic indicators | |||

| 1. | Unit cost of production (UCP) | RON/kg | 19.93 |

| 2. | Selling price (SP) | RON/kg | 30.00 |

| 3. | Gross unit profit (GUP) | RON/kg | 10.07 |

| 4. | Profit rate (PR) | % | 50.53 |

| 5. | Work productivity (WP) | kg/DM | 5.47 |

| RON/DM | 164.2 | ||

| 6. | Production costs in product equivalent | kg/m2 | 23.58 |

References

- Kaul, T.N. Biology and Conservation of Mushrooms; Science Publishers, Inc.: Hauppauge, NY, USA, 2002. [Google Scholar]

- Stengler, M. Health Benefits of Medicinal Mushrooms; Basic Health Publications, Inc.: Laguna Beach, CA, USA, 2005. [Google Scholar]

- Chang, S.T.; Wasser, S.P. The role of culinary-medicinal mushrooms on human welfare with a pyramid model for human health. Int. J. Med. Mushrooms 2012, 14, 95–134. [Google Scholar] [CrossRef]

- Wasser, S.P. Medicinal mushroom science: History, current status, future trends, and unsolved problems. Int. J. Med. Mushrooms 2010, 12, 1–16. [Google Scholar] [CrossRef]

- Wasser, S. Medicinal mushroom science: Current perspectives, advances, evidences, and challenges. Biomed. J. 2014, 37, 345–356. [Google Scholar] [CrossRef] [PubMed]

- Singhal, S.; Rasane, P.; Kaur, S.; Garba, U.; Singh, J.; Raj, N.; Gupta, N. Mushroom cultivation, processing and value-added products: A patent-based review. Recent Pat. Food Nutr. Agric. 2019, 10, 3–19. [Google Scholar] [CrossRef] [PubMed]

- Higgins, C.; Margot, H.; Warnquist, S.; Obeysekare, E.; Mehta, K. Mushroom cultivation in the developing world: A comparison of cultivation technologies. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), San Jose, CA, USA, 19–22 October 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Rózsa, S.; Măniuțiu, D.N. Substrate Preparation Technology for Agaricus Mushroom Production; OmniScriptum Publishing Group: Saarbrücken, Germany, 2020. [Google Scholar]

- Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org/faostat/en/#home (accessed on 5 April 2022).

- Ciuperci Terapeutice. Available online: https://ciuperciterapeutice.ro/#undefined (accessed on 5 April 2022).

- Rózsa, S.; Gocan, T.M.; Lazăr, V.; Andreica, I.; Rózsa, M.; Măniuțiu, D.N.; Sima, R. The effect of processing on chemical constituents of Agaricus spp. mushrooms. Not. Bot. Horti Agrobot. Cluj-Napoca 2017, 45, 507–516. [Google Scholar] [CrossRef]

- Constantinescu, N. Dicționar de Economie Politică; Politică Publisher: Bucharest, Romania, 1974. [Google Scholar]

- Hashimzade, N.; Myles, G.; Black, J. A Dictionary of Economics, 5th ed.; Oxford University Press: Oxford, UK, 2017. [Google Scholar]

- Smith, A. The Wealth of Nations: An Inquiry into the Nature and Causes of the Wealth of Nations; Harriman House Limited: Petersfield, UK, 2010. [Google Scholar]

- Pareto, V. Manual of Political Economy: A Critical and Variorum Edition; Oxford University Press: Oxford, UK, 2014. [Google Scholar]

- Românu, I.; Vasilescu, I. Eficienţa Economică a Investiţiilor şi a Capitalului Fix; Editura Didactică şi Pedagogică: Bucharest, Romania, 1993. [Google Scholar]

- Veiss, S.D.; Abrudan, I. Experimental studies based on the model of Hofstede. Acta Tech. Napoc.-Ser. Appl. Math. Mech. Eng. 2012, 55, 939–948. [Google Scholar]

- Cistelecan, L.M. Economia, Eficiența şi Finanțarea Investițiilor; Editura Economică: Bucharest, Romania, 2002; pp. 389–419. [Google Scholar]

- Brunsson, K. The Teachings of Management: Perceptions in a Society of Organizations; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Albu, C.N.; Albu, N.; Faff, R.; Hodgson, A. Accounting competencies and the changing role of accountants in emerging economies: The case of Romania. Account. Eur. 2011, 8, 155–184. [Google Scholar] [CrossRef]

- Office of the Auditor General of Canada. Available online: https://www.oag-bvg.gc.ca/internet/English/meth_gde_e_20331.html (accessed on 5 April 2022).

- Tangen, S. Demystifying productivity and performance. Int. J. Product. Perform. Manag. 2005, 54, 34–46. [Google Scholar] [CrossRef]

- Rózsa, S.; Măniuțiu, D.N.; Poșta, G.; Gocan, T.-M.; Andreica, I.; Bogdan, I.; Rózsa, M.; Lazăr, V. Influence of the culture substrate on the Agaricus blazei murrill mushrooms vitamins content. Plants 2019, 8, 316. [Google Scholar] [CrossRef]

- Merce, E.; Andreica, I.; Arion, F.H. Managementul şi Gestiunea Unităţilor Economice cu Profil Agricol; Digital Data: Cluj-Napoca, Romania, 2010. [Google Scholar]

- NCF Noul Cod Fiscal. Available online: https://www.noulcodfiscal.ro/titlu-5/capitol-9/ (accessed on 3 March 2022).

- Stamets, P. Growing Gourmet and Medicinal Mushrooms; Ten Speed Press: Berkeley, CA, USA, 2010. [Google Scholar]

- Zaimova, D. Measuring the economic efficiency of Italian agricultural enterprises. Euricse Work. Pap. 2011, 18, 1–23. [Google Scholar] [CrossRef][Green Version]

- Garg, P. Mushroom production: Cost effective use of soyabean meal (de-oiled cake) during composting. IOSR J. Environ. Sci. Toxicol. Food Technol. 2014, 8, 113–114. [Google Scholar] [CrossRef]

- Raquel, S.F.; Ángeles, I.B. Efficiency and quality as economic dimensions of perceived value: Conceptualization, measurement, and effect on satisfaction. J. Retail. Consum. Serv. 2009, 16, 425–433. [Google Scholar] [CrossRef]

- Rácz, J.; Koronczy, I. Cum să Cultivăm Ciuperca de Bălegar; Uniunea Națională a Intreprinzătorilor Cultivatori de Ciuperci Korona: Eger, Hungary, 2009. [Google Scholar]

- Fatacean, G. Contabilitatea Managerială; Editura Alma Mater: Cluj-Napoca, Romania, 2005; p. 93. [Google Scholar]

- Butanescu-Volanin, R.C. Analiza Economica a Firmei: Resurse-Performante-Valoare; Editura Universitatii Lucian Blaga: Sibiu, Romania, 2017; p. 183. [Google Scholar]

- Khaliq, N.; Khan, N.A.; Javed, N.; Gondal, A.S. Production efficiency of different strains of Pleurotus ostreatus using various cellulosic agro-wastes. Int. J. Phytopathol. 2013, 2, 37–43. [Google Scholar] [CrossRef]

- Mahari, W.A.W.; Peng, W.; Nam, W.L.; Yang, H.; Lee, X.Y.; Lee, Y.K.; Lam, S.S. A review on valorization of oyster mushroom and waste generated in the mushroom cultivation industry. J. Hazard. Mater. 2020, 400, 123156. [Google Scholar] [CrossRef] [PubMed]

- Bandara, A.R.; Lian, C.K.; Xu, J.; Mortimer, P.E. Mushroom as a means of sustainable rural development in the Chin State, Myanmar. Circ. Agric. Syst. 2021, 1, 4. [Google Scholar] [CrossRef]

- Barmon, B.K.; Sharmin, I.; Abbasi, P.K.; Mamun, A. Economics of mushroom (Agaricus bisporus) production in a selected Upazila of Bangladesh. Agriculturists 2012, 10, 77–89. [Google Scholar] [CrossRef]

- Grimm, D.; Wösten, H.A.B. Mushroom cultivation in the circular economy. Appl. Microbiol. Biotechnol. 2018, 102, 7795–7803. [Google Scholar] [CrossRef] [PubMed]

| Experimental Variant | Type of Substrate |

|---|---|

| V1 | Classical substrate, without protein addition |

| V2 | Classical substrate, with 3% wheat bran protein addition |

| V3 | Classical substrate, with 3% corn flour protein addition |

| V4 | Synthetic substrate, without protein addition |

| V5 | Synthetic substrate, with 3% wheat bran protein addition |

| V6 | Synthetic substrate, with 3% corn flour protein addition |

| V7 | Mixed substrate, without protein addition |

| V8 | Mixed substrate, with 3% wheat bran protein addition |

| V9 | Mixed substrate, with 3% corn flour protein addition |

| V10 | Reed + horse manure substrate, without protein addition |

| V11 | Reed + horse manure substrate, with 3% wheat bran protein addition |

| V12 | Reed + horse manure substrate, with 3% corn flour protein addition |

| Job Category | Value * |

|---|---|

| I | 50 RON day−1 (10 € day−1) |

| II | 60 RON day−1 (12 € day−1) |

| III | 80 RON day−1 (16 € day−1) |

| IV | 100 RON day−1 (20 € day−1) |

| V | 130 RON day−1 (26 € day−1) |

| Stage | Related Technological Works |

|---|---|

| Stage I (Substrate preparation and seeding) | Compost component Pre-soak placement Aerobic composting placement Turn I, II, III, IV Disinfection of the cultivation place Insertion of the substrate in the cultivation chamber Spawning |

| Stage II (Preparation for fruiting) | Casing preparation Disinfection of casing mixture Ruffling of casing Incubation culture maintenance The maintenance of culture in the formation of primordia |

| Stage III (Harvesting) | Harvesting—3 flushes Substrate maintenance at harvest |

| Stage IV (Post-harvest work) | Disposal of used substrate Cleaning the culture chambers |

| Experimental Variant | Recipe Components | Amendment (V1–V3)/Urea (V4–V12) | Calcium Sulphate | Disinfectants | Mycelium | Total Material Value | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NC | UP | TV | NC | UP | TV | NC | UP | TV | NC | UP | TV | NC | UP | TV | (RON) | |

| V1 | 0.5 | 200 | 100 | 14 | 10 | 140 | 25 | 5 | 125 | 2 | 50 | 100 | 20 | 50 | 1000 | 1465 ± 6.93 b |

| V2 | 0.5 | 220 | 110 | 14 | 10 | 140 | 25 | 5 | 125 | 2 | 50 | 100 | 20 | 50 | 1000 | 1475 ± 8.08 ab |

| V3 | 0.5 | 250 | 125 | 14 | 10 | 140 | 25 | 5 | 125 | 2 | 50 | 100 | 20 | 50 | 1000 | 1490 ± 8.66 a |

| V4 | 0.5 | 200 | 100 | 7 | 10 | 70 | 20 | 5 | 100 | 2 | 50 | 100 | 20 | 50 | 1000 | 1370 ± 6.35 defg |

| V5 | 0.5 | 240 | 120 | 7 | 10 | 70 | 20 | 5 | 100 | 2 | 50 | 100 | 20 | 50 | 1000 | 1390 ± 7.51 cd |

| V6 | 0.5 | 260 | 130 | 7 | 10 | 70 | 20 | 5 | 100 | 2 | 50 | 100 | 20 | 50 | 1000 | 1400 ± 8.08 c |

| V7 | 0.5 | 255 | 128 | 2 | 10 | 20 | 24 | 5 | 120 | 2 | 50 | 100 | 20 | 50 | 1000 | 1368 ± 5.77 efg |

| V8 | 0.5 | 230 | 115 | 2 | 10 | 20 | 24 | 5 | 120 | 2 | 50 | 100 | 20 | 50 | 1000 | 1355 ± 6.93 g |

| V9 | 0.5 | 240 | 120 | 2 | 10 | 20 | 24 | 5 | 120 | 2 | 50 | 100 | 20 | 50 | 1000 | 1360 ± 7.51 fg |

| V10 | 0.5 | 270 | 135 | 2 | 10 | 20 | 24 | 5 | 120 | 2 | 50 | 100 | 20 | 50 | 1000 | 1370 ± 6.35 defg |

| V11 | 0.5 | 280 | 140 | 2 | 10 | 20 | 24 | 5 | 120 | 2 | 50 | 100 | 20 | 50 | 1000 | 1380 ± 5.77 cdef |

| V12 | 0.5 | 290 | 145 | 2 | 10 | 20 | 24 | 5 | 120 | 2 | 50 | 100 | 20 | 50 | 1000 | 1385 ± 6.93 cde |

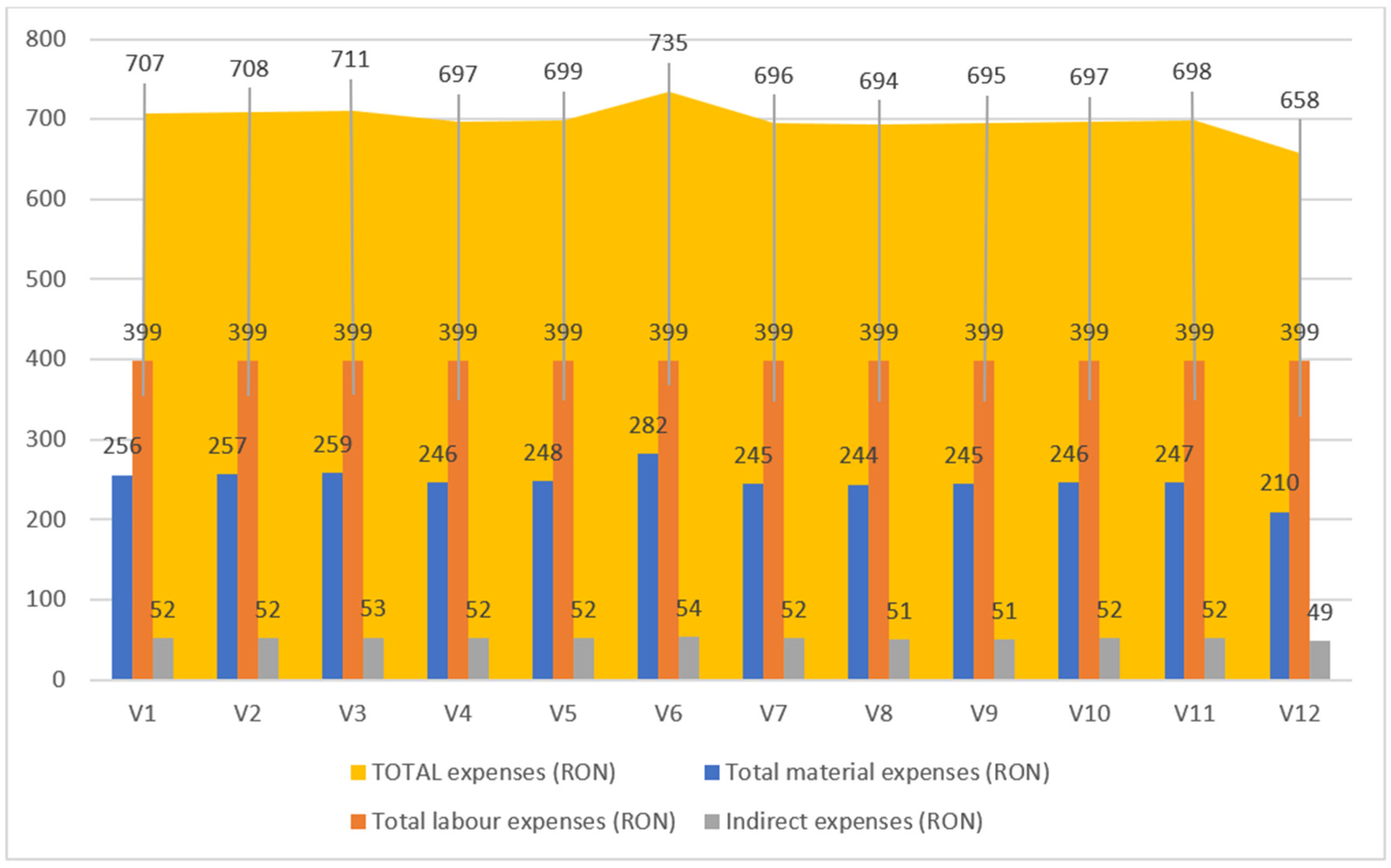

| Order No. | Elements of Expense | V1 | V2 | V3 | V4 | V5 | V6 | V7 | V8 | V9 | V10 | V11 | V12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I. Material expenses | |||||||||||||

| 1. | Materials from own sources | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2. | Purchased materials | 166.5 | 167.5 | 169 | 157 | 159 | 190 | 156.8 | 155.5 | 156 | 157.5 | 158 | 158.5 |

| 3. | Supply costs (10%) | 16.65 | 16.75 | 16.9 | 15.7 | 15.9 | 19 | 15.68 | 15.55 | 15.6 | 15.75 | 15.8 | 15.85 |

| 4. | Expenses with mechanized works | 40.5 | 40.5 | 40.5 | 40.5 | 40.5 | 40.5 | 40.5 | 40.5 | 40.5 | 40.5 | 40.5 | 4.05 |

| 5. | The cost of watering (water) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| 6. | Depreciation of fixed assets | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 7. | Agricultural income tax | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 8. | Electricity | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| 9. | Solid fuel | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| 10. | Other taxes and fees | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 11. | Other material expenses (1%) | 3 | 3 | 3 | 2 | 2 | 3 | 2 | 2 | 2 | 2 | 2 | 2 |

| I. TOTAL material expenses | 256 | 257 | 259 | 246 | 248 | 282 | 245 | 244 | 245 | 246 | 247 | 210 | |

| II. Expenses with labor | |||||||||||||

| 1. | Manual labour costs | 390 | 390 | 390 | 390 | 390 | 390 | 390 | 390 | 390 | 390 | 390 | 390 |

| 2. | Insurance contribution for work (2.25%) | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 |

| II. TOTAL labour expenses | 399 | 399 | 399 | 399 | 399 | 399 | 399 | 399 | 399 | 399 | 399 | 399 | |

| III. TOTAL direct expenses (I + II) | 655 | 656 | 658 | 645 | 647 | 681 | 644 | 643 | 643 | 645 | 646 | 609 | |

| IV. Indirect expenses (8%) | 52 | 52 | 53 | 52 | 52 | 54 | 52 | 51 | 51 | 52 | 52 | 49 | |

| V. Interest on loans (IL) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| VI. TOTAL production costs (PC) | 708 | 709 | 711 | 696 | 698 | 736 | 696 | 694 | 695 | 697 | 697 | 658 | |

| The value of secondary production (VSP) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| VII. Main production costs (MPC) | 708 ± 2.31 b | 709 ± 5.2 b | 711 ± 3.46 b | 696 ± 2.89 c | 698 ± 3.46 c | 736 ± 2.31 a | 696 ± 3.46 c | 694 ± 2.89 c | 695 ± 2.89 c | 697 ± 4.04 c | 697 ± 5.2 c | 658 ± 2.89 d | |

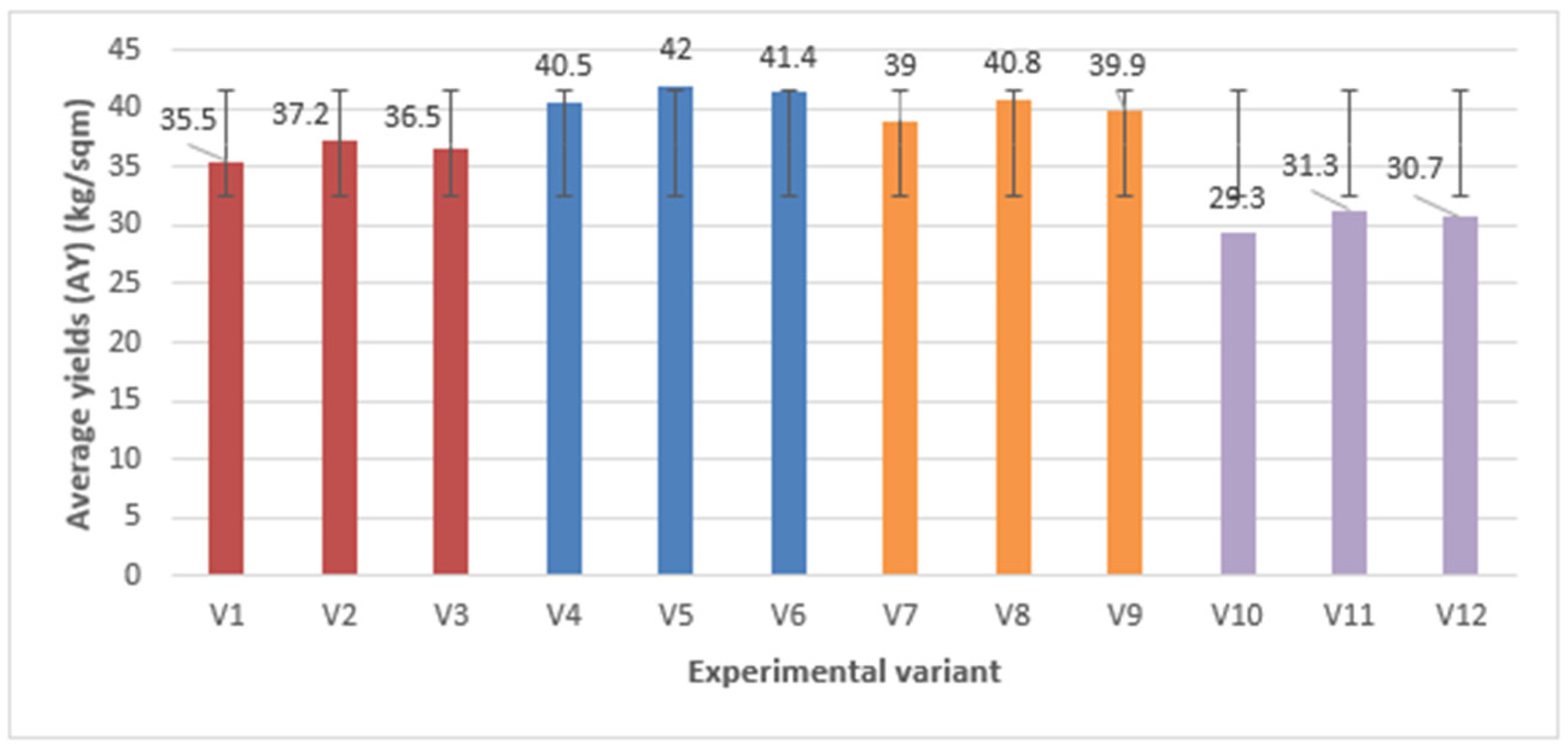

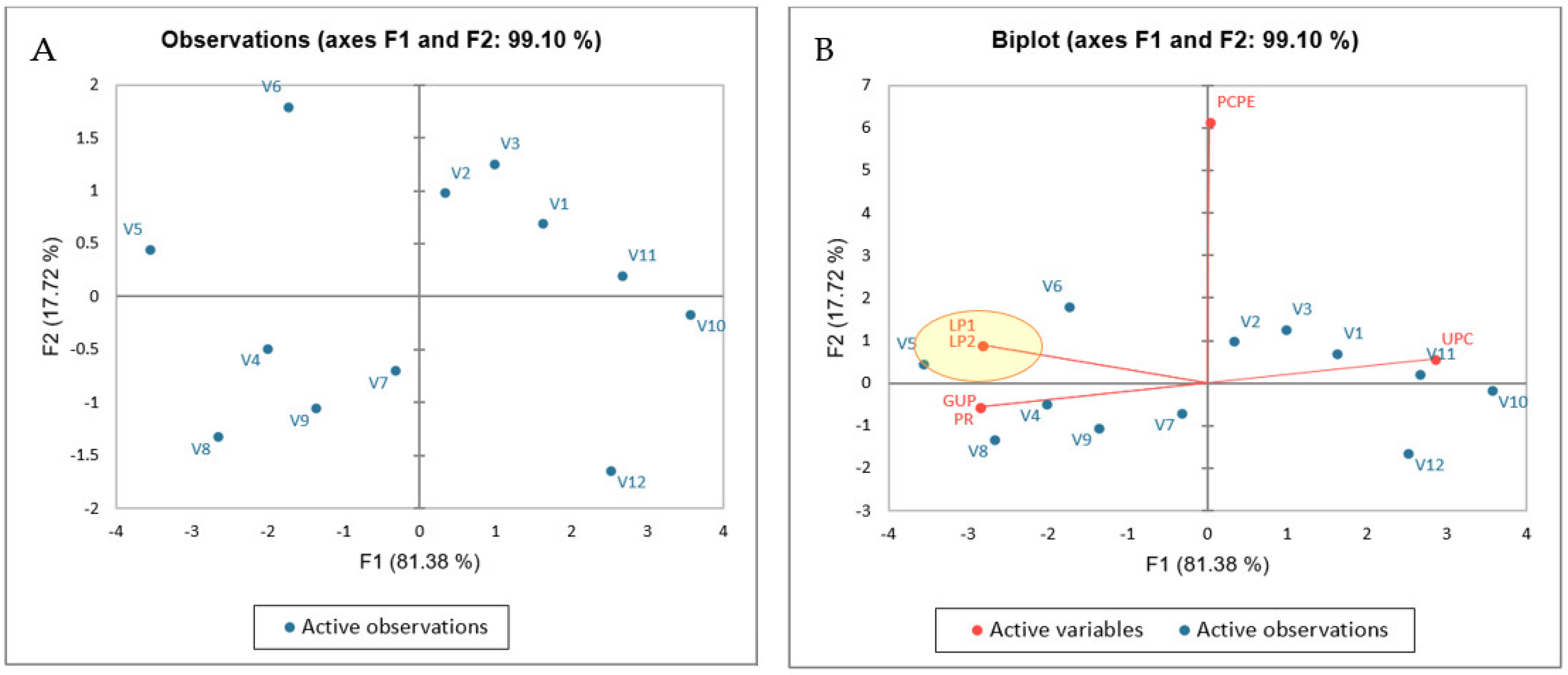

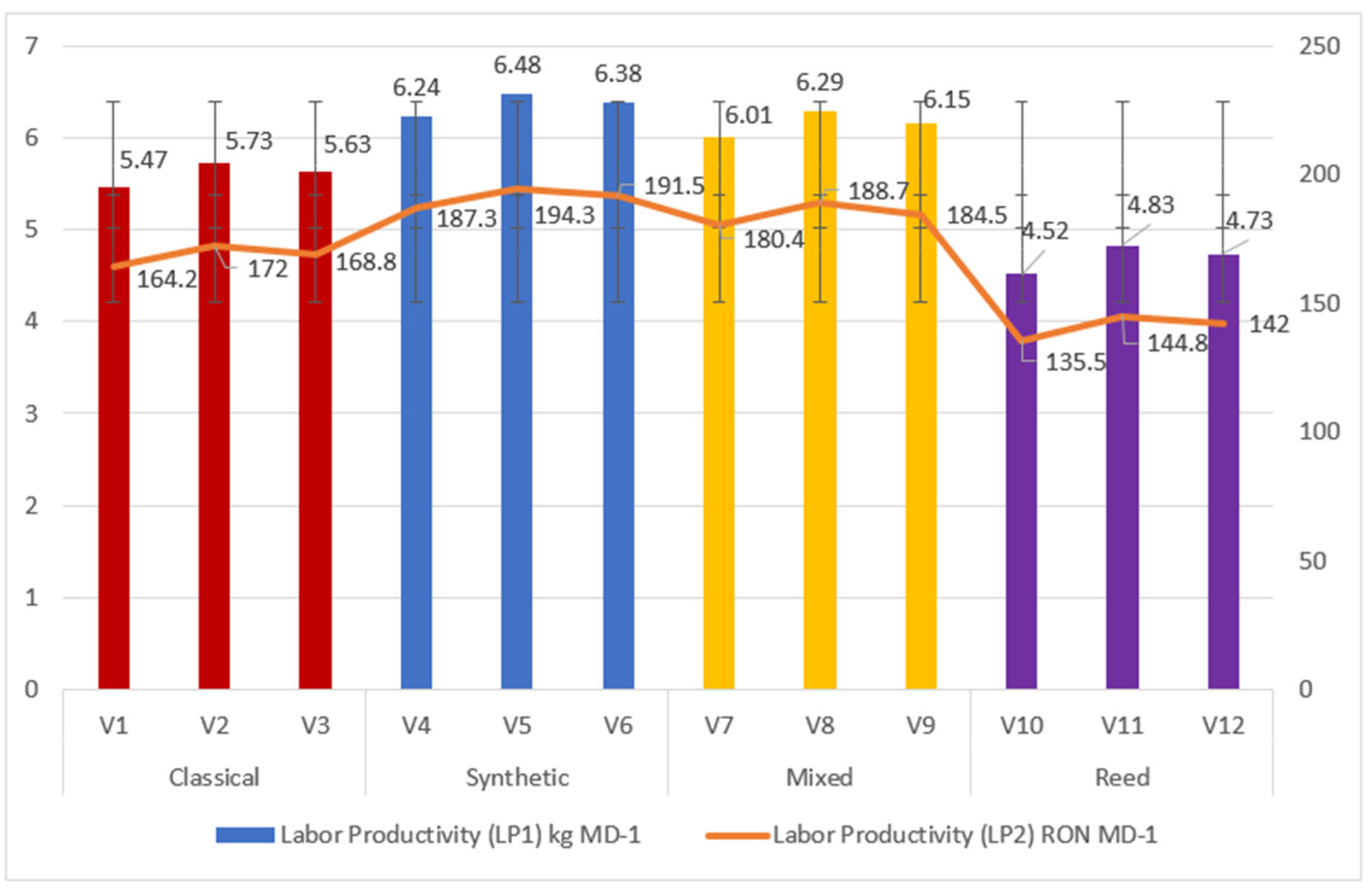

| Experimental Variant | Global Production (GP) (RON sqm−1) | Total Costs (TC) (RON sqm−1) | Unit Cost (UC) (RON kg−1) | Profit (P) (RON kg−1) | Labor Productivity (LP1) (kg md−1) | Labor Productivity (LP2) (RON md−1) | Profit Rate (PR) (%) |

|---|---|---|---|---|---|---|---|

| V1 | 1065 ± 8.66 h | 708 ± 2.31 b | 19.93 ± 0.14 d | 10.07 ± 0.14 g | 5.47 ± 0.04 h | 164.2 ± 1.33 h | 50.53 ± 1.06 g |

| V2 | 1116 ± 3.46 f | 709 ± 5.2 b | 19.05 ± 0.12 f | 10.95 ± 0.12 e | 5.73 ± 0.02 f | 172.0 ± 0.53 f | 57.47 ± 0.99 f |

| V3 | 1095 ± 5.2 g | 711 ± 3.46 b | 19.47 ± 0.16 e | 10.53 ± 0.16 f | 5.63 ± 0.03 g | 168.8 ± 0.8 g | 54.11 ± 1.28 f |

| V4 | 1215 ± 8.66 c | 696 ± 2.89 c | 17.19 ± 0.17 i | 12.81 ± 0.17 b | 6.24 ± 0.04 c | 187.3 ± 1.33 c | 74.54 ± 1.75 bc |

| V5 | 1260 ± 10.39 a | 698 ± 3.46 c | 16.63 ± 0.19 j | 13.37 ± 0.19 a | 6.48 ± 0.05 a | 194.3 ± 1.6 a | 80.42 ± 2.07 a |

| V6 | 1242 ± 6.93 b | 736 ± 2.31 a | 17.77 ± 0.14 gh | 12.23 ± 0.14 cd | 6.38 ± 0.04 b | 191.50 ± 1.07 b | 68.82 ± 1.29 de |

| V7 | 1170 ± 5.2 e | 696 ± 3.46 c | 17.84 ± 0.15 g | 12.16 ± 0.15 d | 6.01 ± 0.03 e | 180.4 ± 0.8 e | 68.15 ± 1.37 e |

| V8 | 1224 ± 6.93 c | 694 ± 2.89 c | 17.02 ± 0.15 ij | 12.98 ± 0.15 ab | 6.29 ± 0.04 c | 188.7 ± 1.07 c | 76.29 ± 1.5 b |

| V9 | 1197 ± 1.73 d | 695 ± 2.89 c | 17.42 ± 0.1 hi | 12.58 ± 0.1 bc | 6.15 ± 0.01 d | 184.5 ± 0.27 d | 72.25 ± 0.97 cd |

| V10 | 897 ± 5.2 k | 697 ± 4.04 c | 23.78 ± 0.14 a | 6.22 ± 0.14 j | 4.52 ± 0.03 k | 135.5 ± 0.8 k | 26.16 ± 0.73 j |

| V11 | 939 ± 3.46 i | 607 ± 5.2 c | 22.28 ± 0.08 b | 7.72 ± 0.08 i | 4.83 ± 0.02 i | 144.8 ± 0.53 i | 34.66 ± 0.51 i |

| V12 | 921 ± 6.93 j | 658 ± 2.89 d | 21.44 ± 0.22 c | 8.56 ± 0.22 h | 4.73 ± 0.04 j | 142.0 ± 1.07 j | 39.94 ± 1.45 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rózsa, S.; Andreica, I.; Poșta, G.; Gocan, T.-M. Sustainability of Agaricus blazei Murrill Mushrooms in Classical and Semi-Mechanized Growing System, through Economic Efficiency, Using Different Culture Substrates. Sustainability 2022, 14, 6166. https://doi.org/10.3390/su14106166

Rózsa S, Andreica I, Poșta G, Gocan T-M. Sustainability of Agaricus blazei Murrill Mushrooms in Classical and Semi-Mechanized Growing System, through Economic Efficiency, Using Different Culture Substrates. Sustainability. 2022; 14(10):6166. https://doi.org/10.3390/su14106166

Chicago/Turabian StyleRózsa, Sándor, Ileana Andreica, Gheorghe Poșta, and Tincuța-Marta Gocan. 2022. "Sustainability of Agaricus blazei Murrill Mushrooms in Classical and Semi-Mechanized Growing System, through Economic Efficiency, Using Different Culture Substrates" Sustainability 14, no. 10: 6166. https://doi.org/10.3390/su14106166

APA StyleRózsa, S., Andreica, I., Poșta, G., & Gocan, T.-M. (2022). Sustainability of Agaricus blazei Murrill Mushrooms in Classical and Semi-Mechanized Growing System, through Economic Efficiency, Using Different Culture Substrates. Sustainability, 14(10), 6166. https://doi.org/10.3390/su14106166