1. Introduction

Centralized generation is still the most common means of power generation and delivery worldwide. It is based on large facilities such as nuclear, hydro-, and thermo-electric power plants, interconnected through a network of high-voltage transmission lines that delivers power unidirectionally to distant end users in densely populated areas. By the same token, isolated, distant communities lack access to this utility due to elevated delivery cost. For these locations, distributed generation (DG) based on renewable energy sources (RES) is a better alternative, because generation takes place at or near the consumption point, lowering both generation and delivery costs [

1]. In this case, it is possible to implement autonomous interfaces, able to control whether or not to connect to the utility grid, as physical or economic conditions dictate.

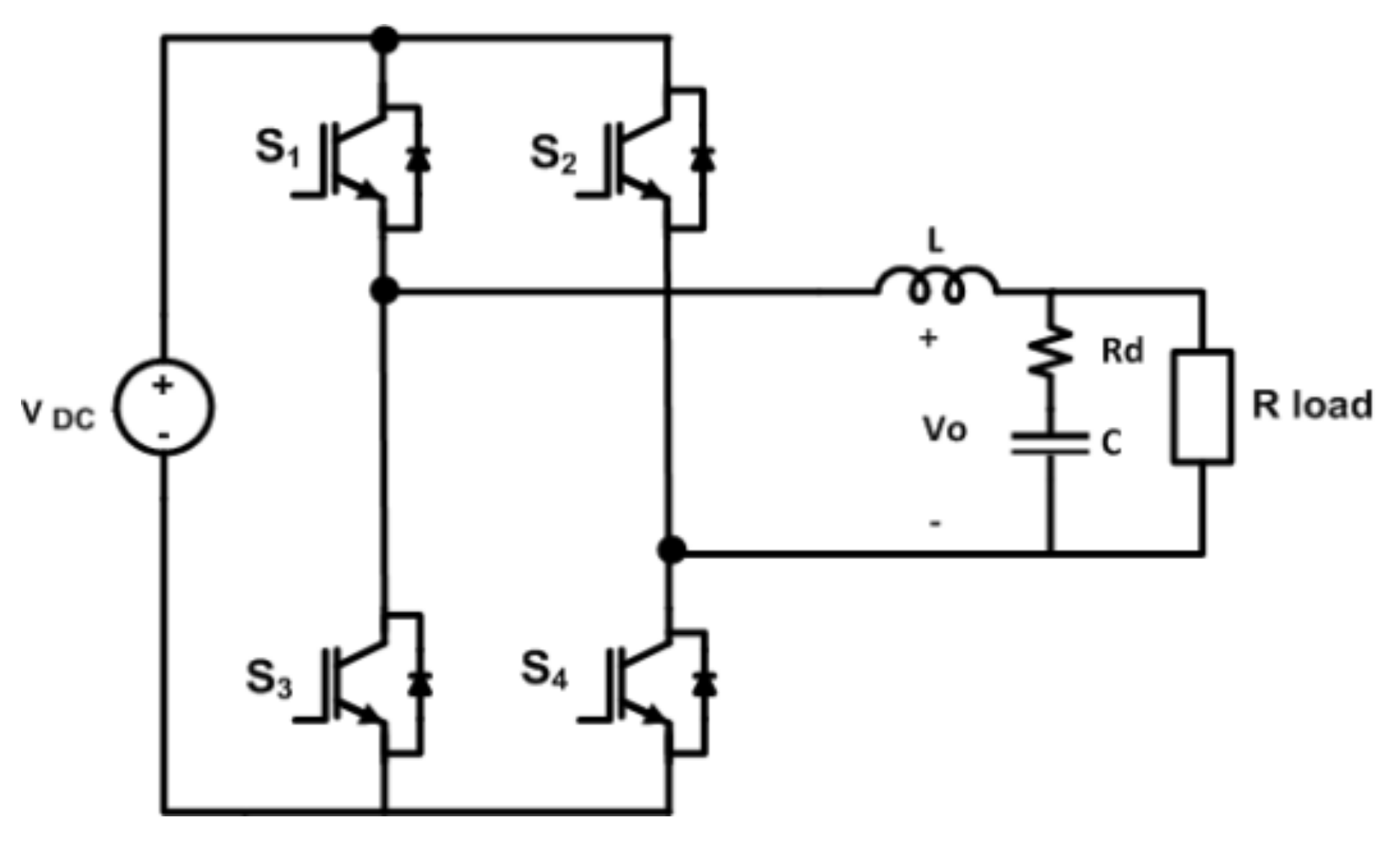

Microgrids [

2,

3,

4], as they are known, consist of power converters and storage devices powered by a combination of RES like solar panels, fuel cells, and wind micro-turbines that require the use of power inverters to condition the amplitude, frequency, and shape of the voltage signal within standard requirements for harmonic control in electric power systems, regardless of applied load [

5,

6,

7].

The diversity of RES able to mesh into microgrid power systems, as well as the need for effective and efficient management of both power generation and consumption, poses several challenges arising from the integration of electronic power converters, energy storage systems, and hierarchical control schemes. In particular, the control system must be capable of maintaining the energy balance in the microgrid, a complex task when the powers of the generation and consumption units are different [

8]. Several approaches exist to address the integration issues caused by the inherent differences in the electrical characteristics of the microgrid elements. Thus, Baek, Cho, and Yeo (2019) propose a voltage control scheme with an inner repetitive current controller to achieve lower output impedance and better disturbance rejection capability for a UPS system, for which it is important to ensure the output voltage regulation and low total harmonic distortion (THD) under non-linear loads [

9]. Jamil et al. (2020) developed a higher-order repetitive controller with phase lead compensator and applied it to the current control of a two-level three-phase grid-connected converter [

10]. Jank et al. (2017) presented a comparative analysis of the PID, resonant, and repetitive controller applied to a single-phase half-bridge pulse-width modulation (PWM) inverter, varying the switching frequency and the inductor current ripple. They concluded that both switching frequency and inductor current ripple play a key role in the controller design [

11]. Chen et al. (2020) designed a repetitive control for dual-buck full-bridge single-phase inverter to ensure the steady-state performance of the system, and adaptive PI control to speed up the system’s dynamic response process [

12]. Chen et al. (2020) presented a PID-based repetitive control strategy to achieve high control accuracy for tracking a determined periodic reference signal [

13]. Pan et al. (2018) developed a method to suppress current harmonic components caused by non-ideal factors. A new PID controller named R–2DOF PID controller was proposed and used in the control system of the permanent magnet synchronous linear motor (PMSLM) in the miniature microsecond laser cutting system, to suppress PMSLM current harmonics [

14]. Patil and More (2019) compared the performance of a Cuk converter with proportional integral controller and a proportional resonant controller [

15]. Sreekumar, Danthakani, and Veettil (2018) investigated the implementation of P-R controller in an autonomous DG unit [

16]. Torres, Roncero-Sánchez, and Batlle (2018) developed a 2DOF resonant control scheme for voltage-sag compensation in dynamic voltage restorers [

17]. Finally, Biricik and Komurcugil (2018) reported a control strategy for PUC inverters based on PI and PR controllers [

18].

Other works present control methods to carry out parallel connection of the conversion units [

19,

20,

21]. In [

19], paralleling technique with VSI inverters is implemented. The RMS Current Control technique with droop in output voltage is implemented to inverter control. The LCL filter is used at inverter output for wave shaping and output reduced noise level output. The PI compensator is used in a feedback loop to attain the system stability. In [

20], distributed generation units are connected to the microgrid through an interfacing inverter. The interfaced inverter plays the main role in the microgrid operating performance. In this paper, interfaced parallel inverter control using a droop control P-F/Q-V was investigated when the microgrid operated in island mode. In inverter islanding mode operation, droop control should maintain voltage and frequency stability. The droop control for parallel inverters is implemented and the proportional load sharing is obtained from each individual inverter. In [

21], a control strategy is proposed to improve load sharing performance in order to reduce the circulating current between inverters parallel connected in microgrids in island mode operation. The control strategy includes a filter parameter estimator, which compensates for any possible uncertainty or deviation in its value. Double loop feedback control is also adopted, with external voltage and internal current control, providing excellent performance under transient and steady state conditions.

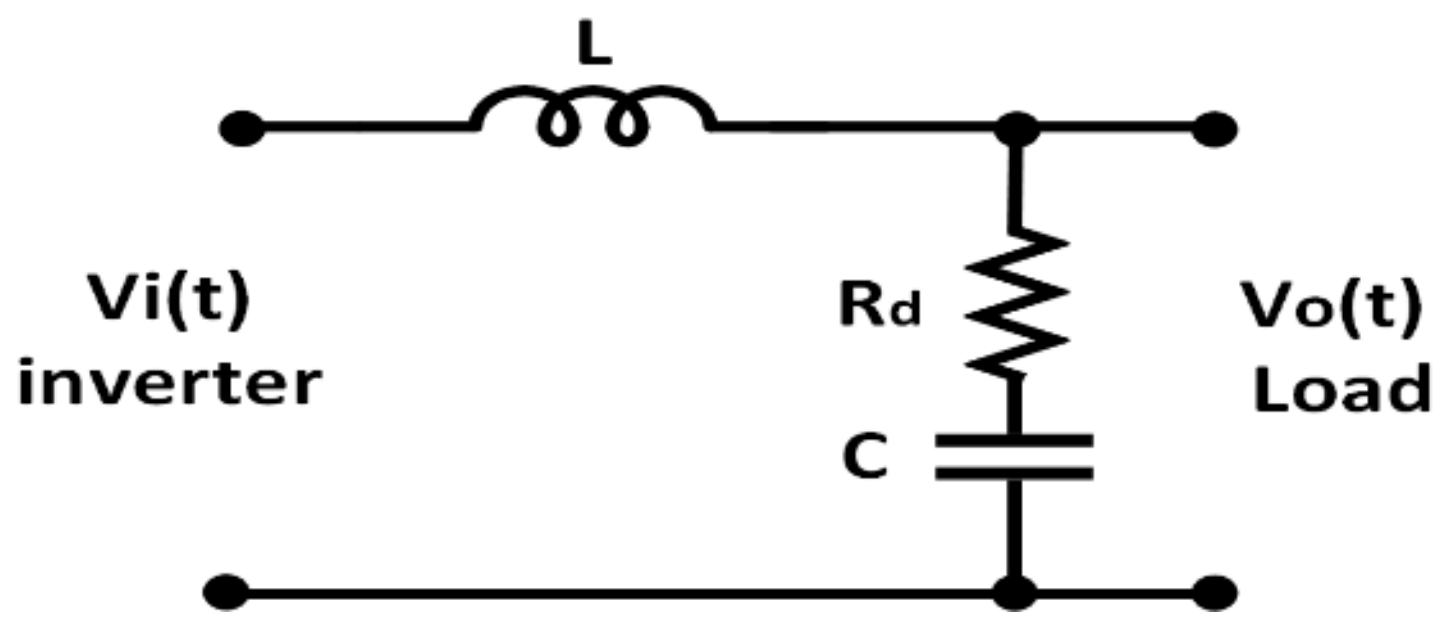

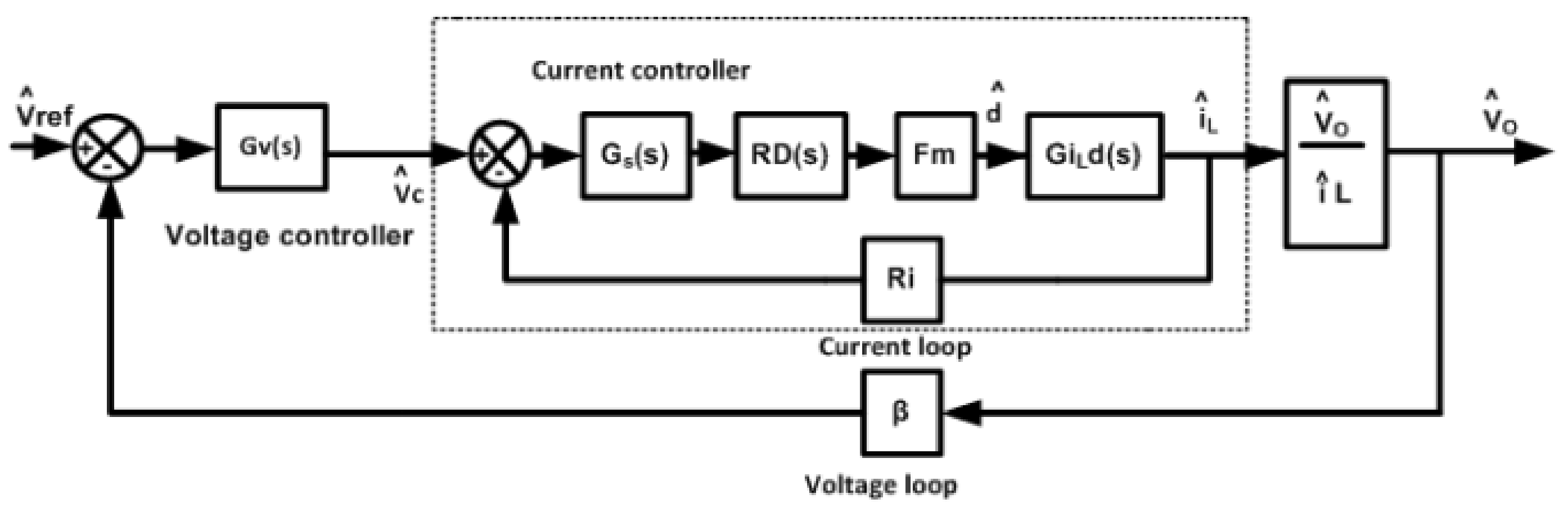

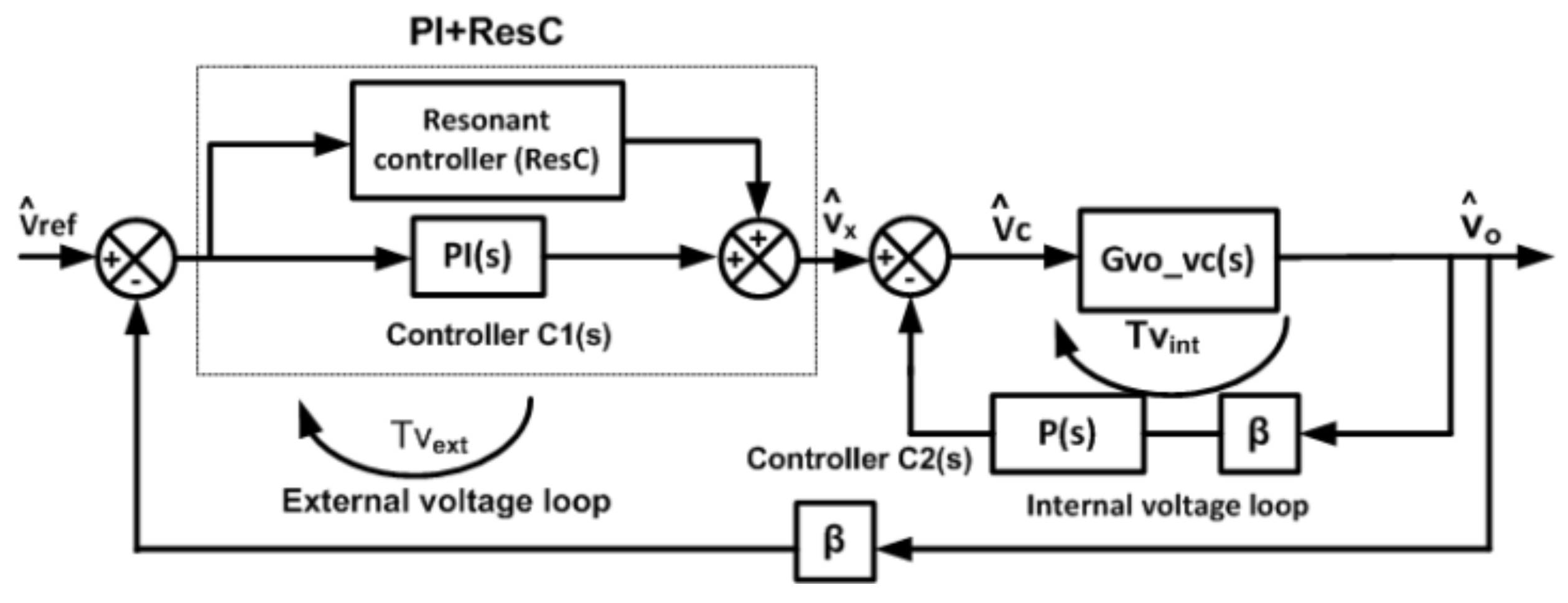

In this work, two control configurations are developed and applied: a two-degree-of-freedom control, plus a repetitive control (2DOF + RC) [

22,

23,

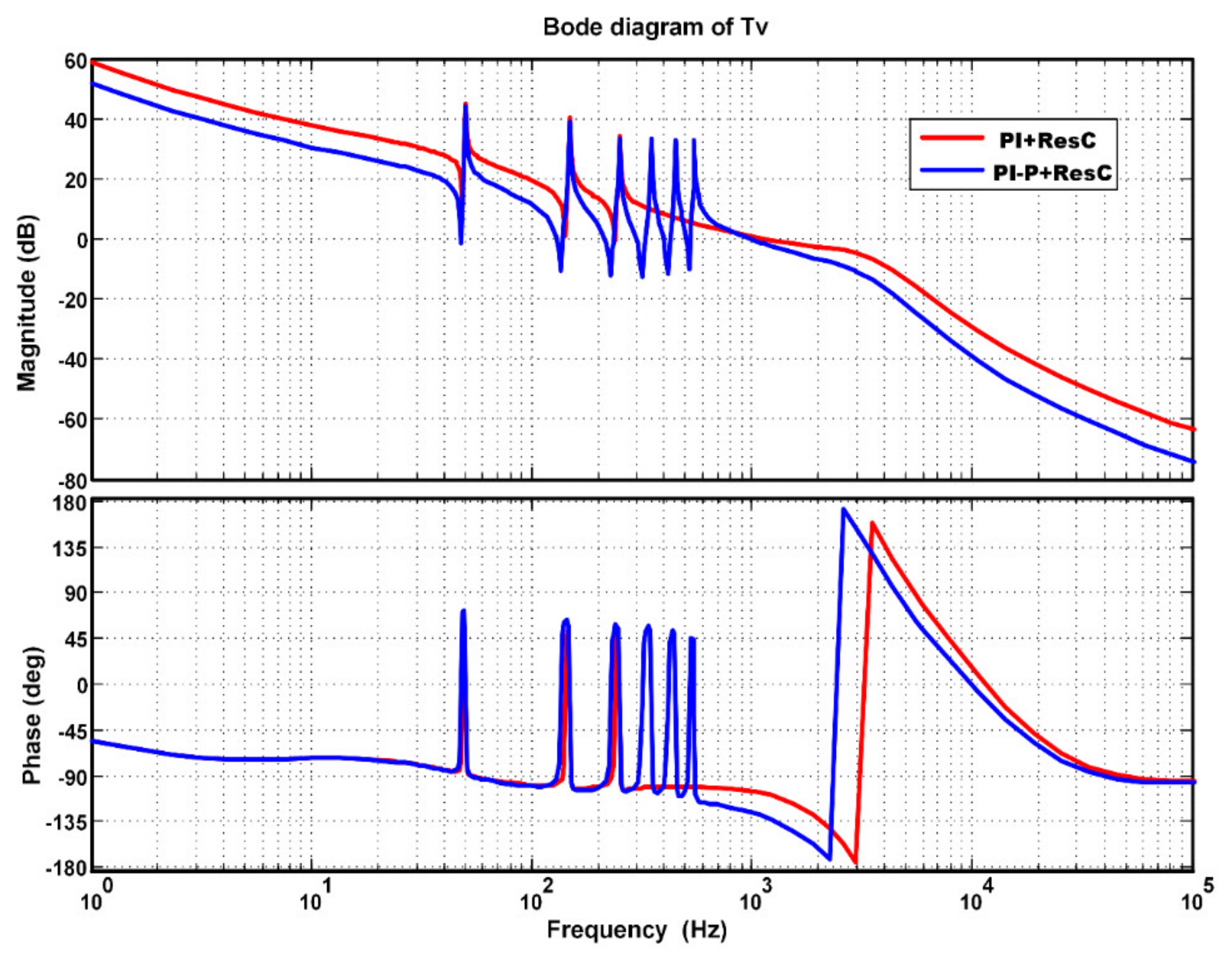

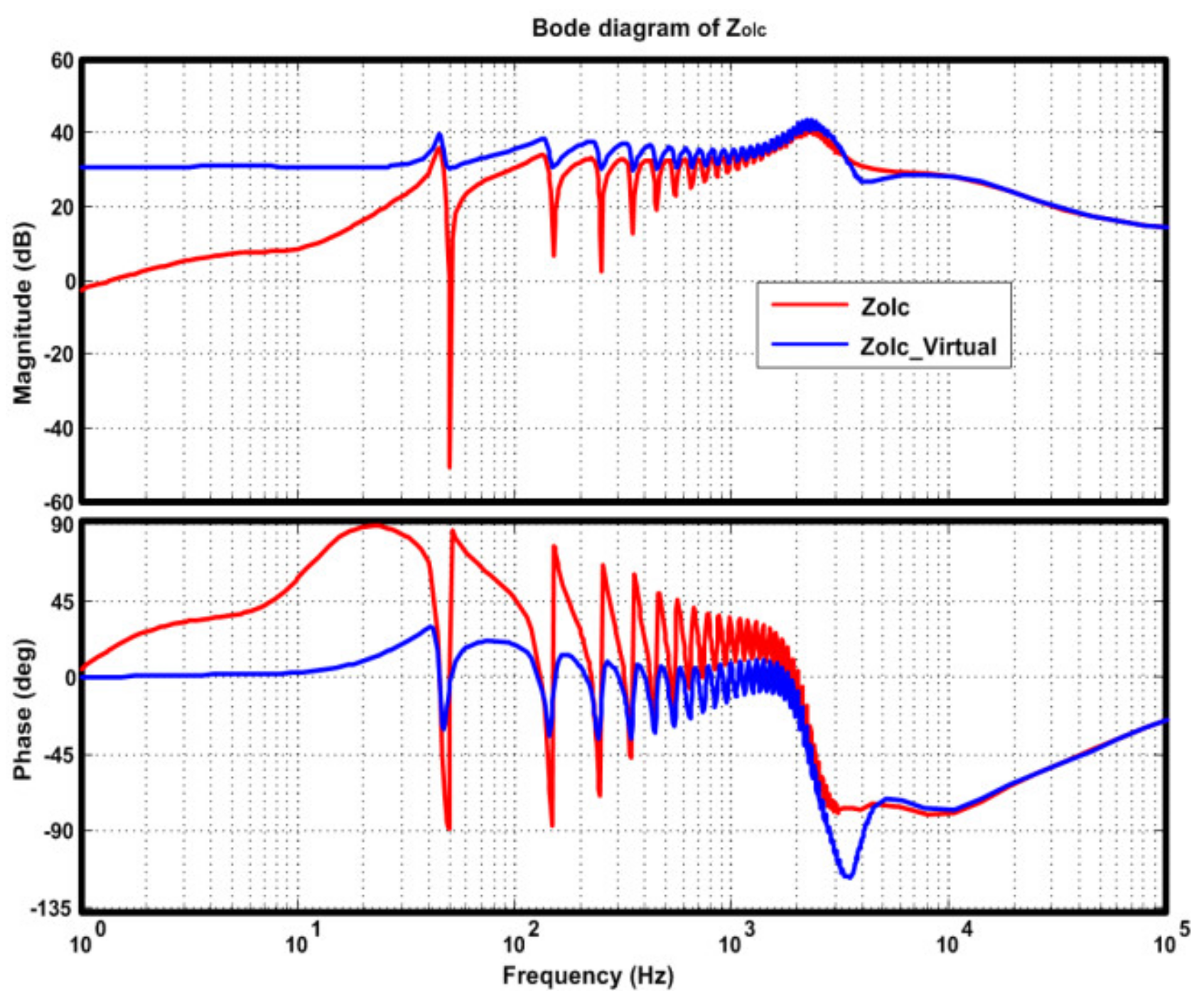

24], and a proportional–integral–proportional control plus a resonant control (PI-P + ResC) and an integral–proportional control plus a resonant control (PI-P + ResC). The 2DOF controller guarantees the overall stability of the energy conversion system, allowing, at the same time, adequate setpoint tracking and disturbance rejection. This is achieved by the first controller implemented in the direct loop, and a second controller in the feedback loop, under different configurations derived from a proportional integral derivative controller (PID); for example, a PI controller in direct loop and a derivative controller in the feedback loop, obtaining a configuration (PI-D). The design of an integral controller in the direct loop and a derivative proportional control in the feedback loop is also possible, giving rise to a configuration (I-PD). In this work, we propose the design and implementation of a control structure with the following characteristics: a PI + RC controller, implemented in the direct loop, and a P controller implemented in the feedback loop. This configuration ensures that in the direct loop, the PI controller allows good setpoint tracking, and the addition of repetitive control contributes to the disturbances rejection, adding to this task the proportional controller implemented in the feedback loop. The implementation of this control configuration causes the inverter output closed-loop impedance to have a resistive characteristic at low frequencies and an inductive characteristic at high frequencies. Therefore, it is necessary to implement a resistive virtual impedance loop and choose a droop scheme with these characteristics to allow conversion units parallel connection.

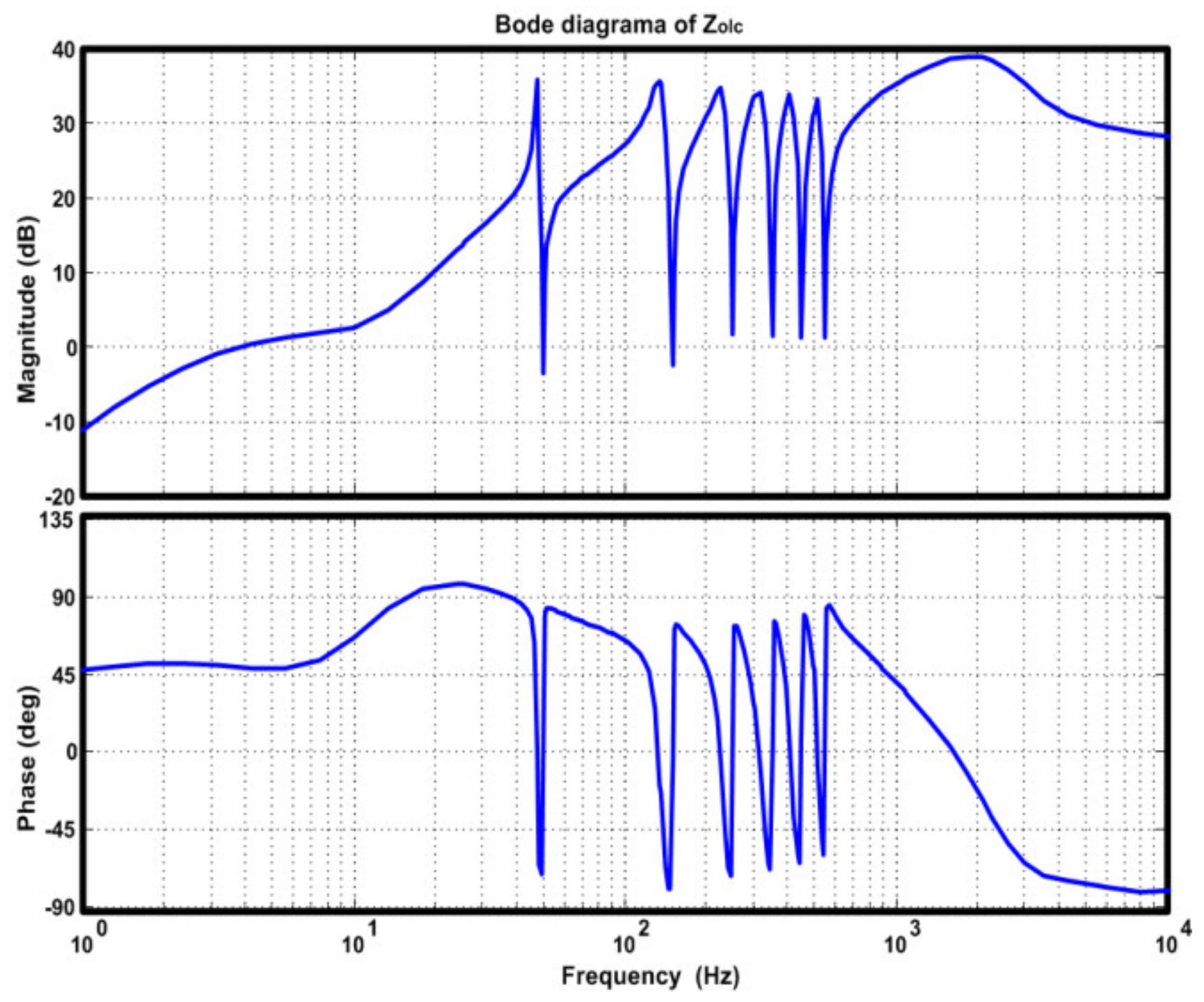

Regarding the PI-P + ResC controller, it consists of two control configurations, a proportional integral–proportional controller (PI-P) plus a resonant controller (ResC). This configuration is structured by an integral proportional control in the direct loop plus a resonant controller, and a proportional controller in the feedback loop. As the control configuration described previously, the design of the PI-P controller assures the overall stability of the conversion system, while the resonant control is designed and implemented to improve the disturbances rejection, contributing to the task of the P controller implemented in the feedback loop. This configuration achieves good setpoint tracking and good disturbances rejection, in addition to the fact that a closed-loop impedance with resistive characteristics appears at the inverter output at high frequency. Thus, it is unnecessary to implement a virtual impedance loop and, therefore, we can choose a droop scheme with a resistive character for the inverters parallel connection.

Both configurations are a new proposal to solve the problem of reduction of total harmonic distortion and for inverter connection parallel, allowing a steady state error equal to zero (eee = 0), and the disturbance rejection with linear and non-linear load in the range between 1% and 2.5%, below the 5% required by the IEEE 519-1992 standard.

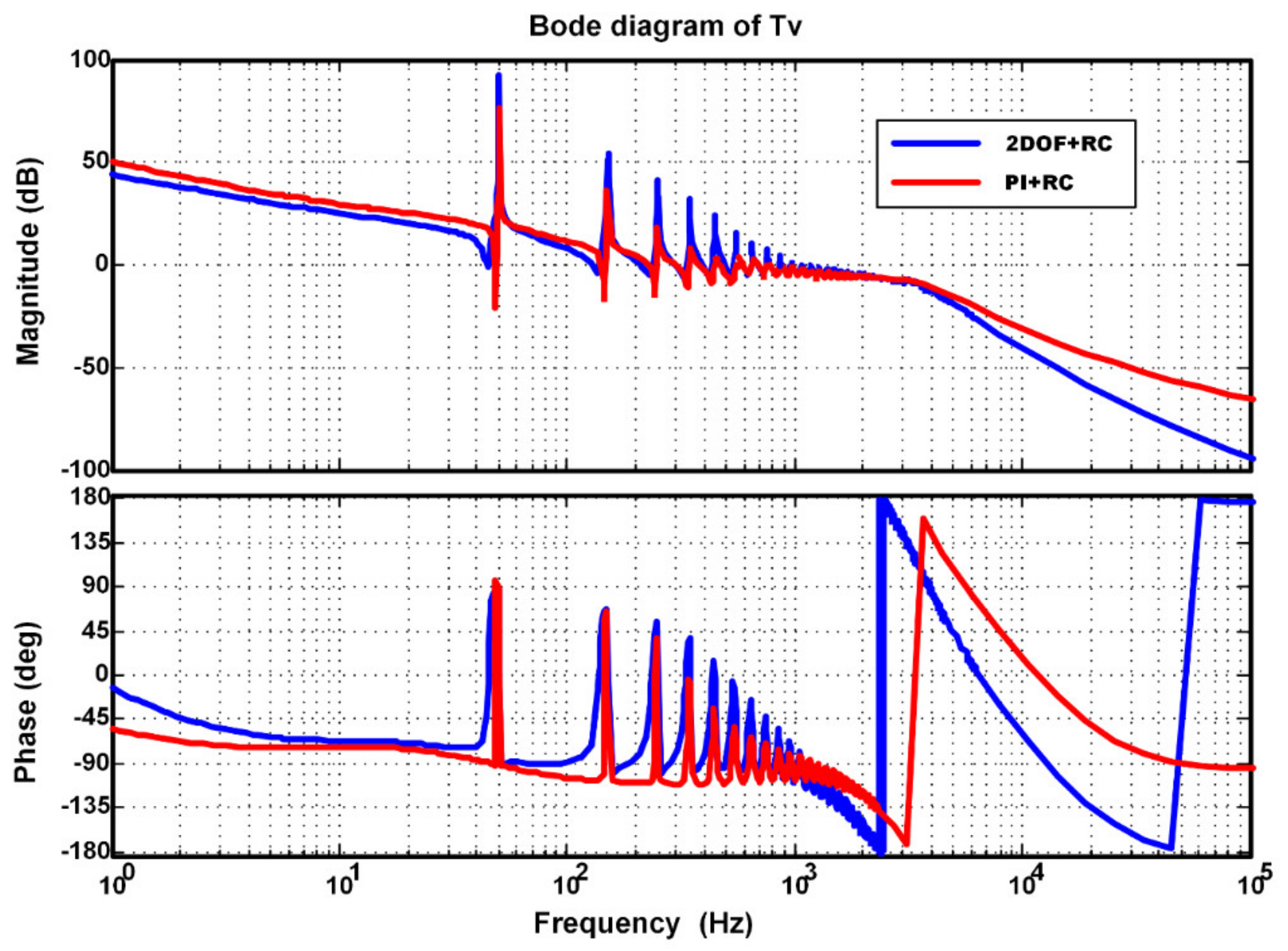

According to our simulations, good performance of the system is justified considering the following: with the implementation of these regulators, it is possible to have good setpoint tracking and good disturbance rejection, giving rise to a sinusoidal waveform of the voltage signal and maintaining the amplitude close to 230 V RMS, as well as its frequency. The reference voltage signal is obtained through droop schemes that allow the inverters connection in parallel to meet increases in load demand. For the present application, we chose a resistive droop scheme with a virtual impedance loop of the same characteristics that allows the inverters parallel connection and the homogeneous distribution of active and reactive power demanded by the load. The choice was determined considering that, with the implementation of both controllers, the inverter closed-loop impedance presents a resistive characteristic, which shows up in the Bode diagrams.

The present work is organized as follows:

Section 2 describes the energy conversion system and the small signal model used to determine the transfer functions for the design of the current and voltage loops controllers.

Section 3 describes the design of the controllers for the different control loops of the inverter.

Section 4 presents the characteristics and design of the droop scheme used in the inverter. In

Section 5, the analysis of the closed-loop impedance of the inverter with the controllers and the droop scheme employed is given. A description of the results of the simulations performed in PSIM

TM [

25] is provided in

Section 6. In

Section 7, the results obtained through experimental tests are presented. In

Section 8, the discussion of the results obtained through simulations is presented. Finally, the conclusions are delivered in

Section 9.

6. Simulation Result

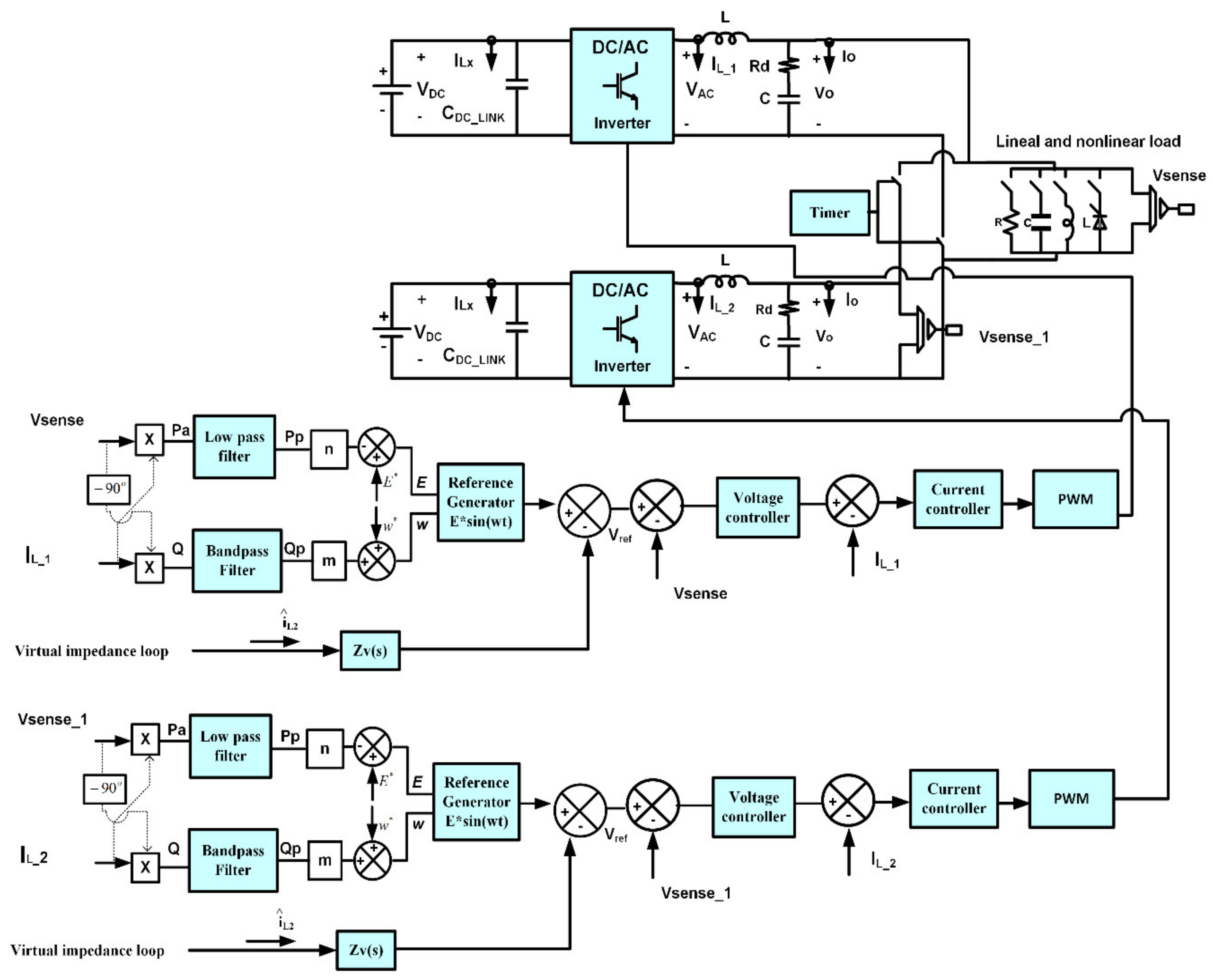

The simulations were carried on by implementing the diagram in

Figure 13, in the PSIM

TM simulator, showing the schematic of two inverters connected in parallel, with a

droop scheme and resistive virtual impedance loop.

The testing was performed using a resistive linear load of 170 Ω, and with a non-linear load consisting of a mono-phasic full-wave rectifying bridge, interconnected with a 96 μF capacitor and a 680 Ω resistance. This load presents a crest factor CF = 4.6.

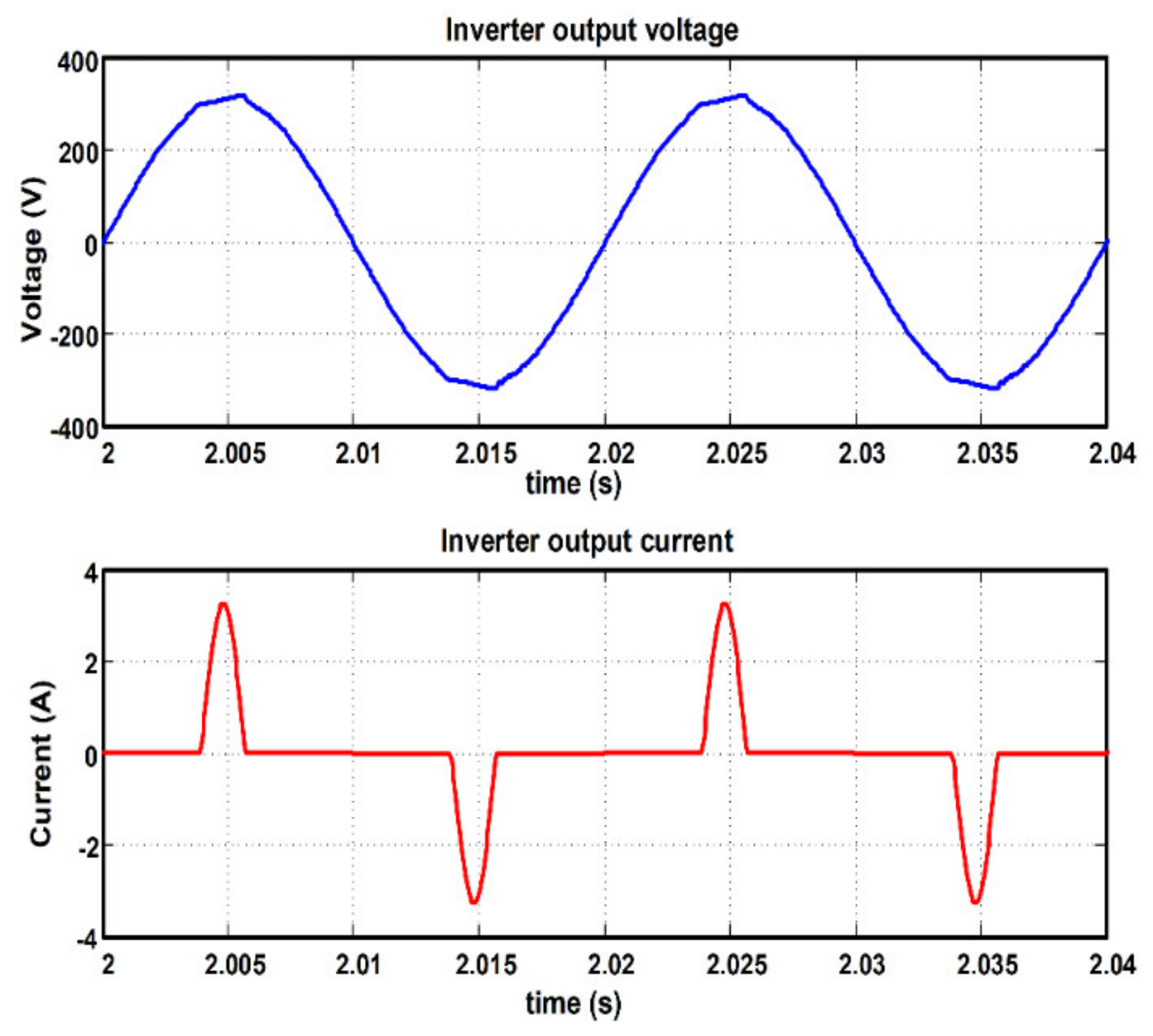

Figure 14 shows the waveforms of the output voltage and current signals of the inverter island mode operation with the implementation of the P + ResC controller in its current loop and the PI + ResC controller in its voltage loop; the simulation is done by feeding the non-linear load mentioned above. In this figure, the voltage signal presents a distortion of 4.6%, which is justified since its waveform in the maximum and minimum peaks is not sinusoidal, presenting an amplitude of 225 V RMS value that is less than the expected one that corresponds to 230 V RMS. Additionally, the current signal has a characteristics waveform of the non-linear load. The total harmonic distortion is below the 5% recommended according to IEEE 519-1992.

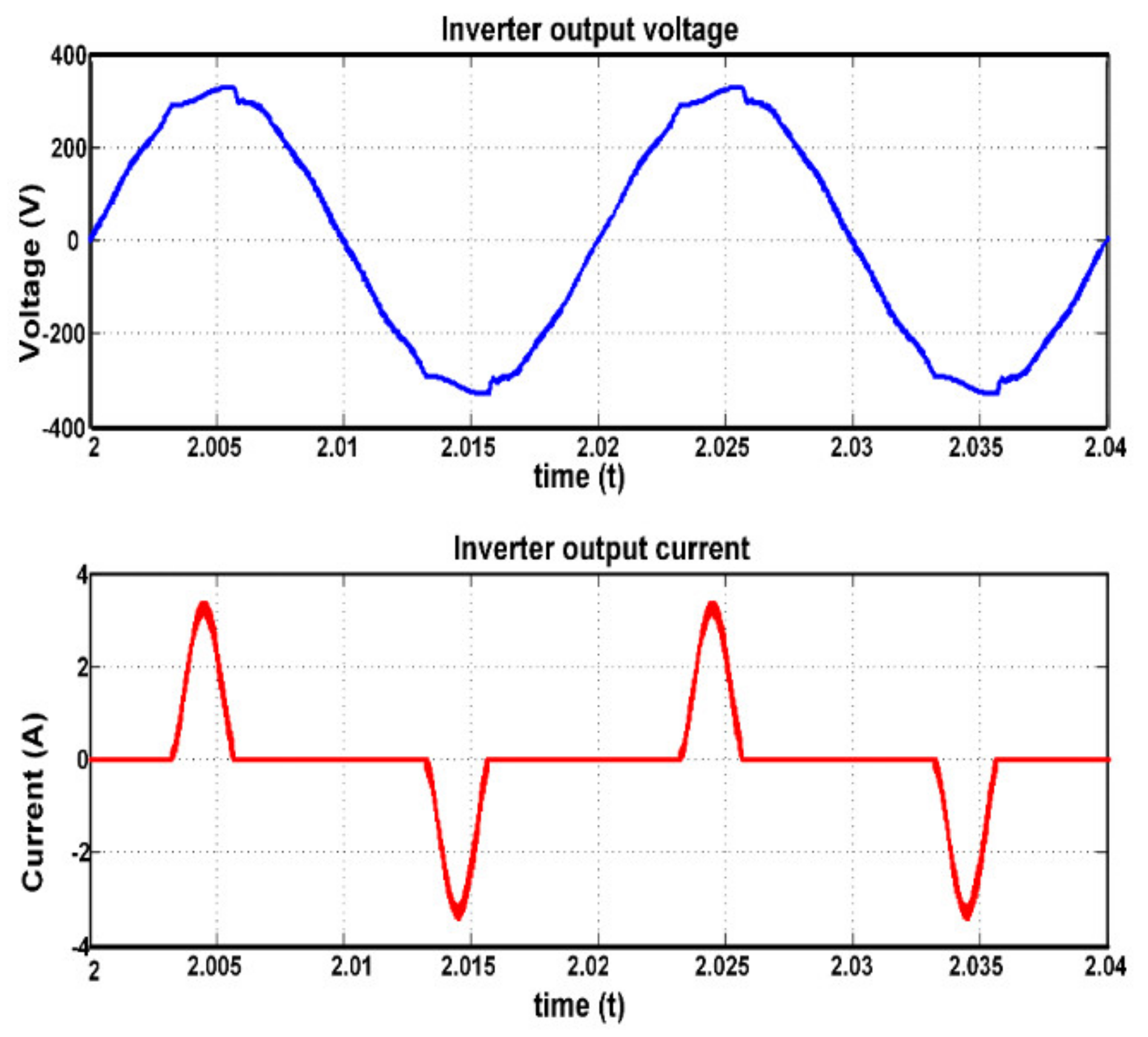

Figure 15 shows the waveforms of the output voltage and current signals of the inverter island mode operating with the implementation of the P + ResC controller in its current loop and the PI-P + ResC controller in its current loop and tension; the simulation is done by feeding the non-linear load mentioned above. In this figure, the voltage signal presents a distortion of 2.5%, which is justified since its waveform in the maximum and minimum peaks presents a more sinusoidal behavior compared to that obtained with the controller application previously presenting; being its amplitude of 229 V RMS; A value that is higher than that obtained with the previous controller implementation and is very close to the one expected, 230 V RMS. Additionally, the current presents a waveform typical of the non-linear load, being evident that the total harmonic distortion is well below the 5% that is recommended according to the IEEE 519-1992 standard.

Figure 16 shows the waveforms of the output voltage and current signals of the inverter island mode operation with the implementation of the P + ResC controller in its current loop and the PI + RC controller in its voltage loop; the simulation is done by feeding the non-linear load mentioned above. In this figure, the voltage signal presents a distortion of 4.8%, which is justified since its waveform in the maximum and minimum peaks is not sinusoidal, presenting an amplitude of 226 V RMS value that is less than the expected one that corresponds to 230 V RMS. Additionally, the current signal has a characteristics waveform of the non-linear load. The total harmonic distortion is below the 5% recommended according to IEEE 519-1992.

Figure 17 shows the waveforms of the output voltage and current signals of the inverter island mode operating with the implementation of the P + ResC controller in its current loop and the 2DOF + RC controller in its current loop and tension; the simulation is done by feeding the non-linear load mentioned above. In this figure, the voltage signal presents a distortion of 2.5%, which is justified since its waveform in the maximum and minimum peaks presents a more sinusoidal behavior compared to that obtained with the controllers application introduced earlier (PI + ResC, PI-P + ResC and PI + RC), obtaining with the 2DOF + RC controller an amplitude in the voltage signal of 230 V RMS, a value that is greater than that obtained with the controllers implementation previous, this being the expected value. Additionally, the current presents a waveform that corresponds to the non-linear load, being evident that the total harmonic distortion is well below the 5% that is recommended according to the IEEE 519-1992 standard.

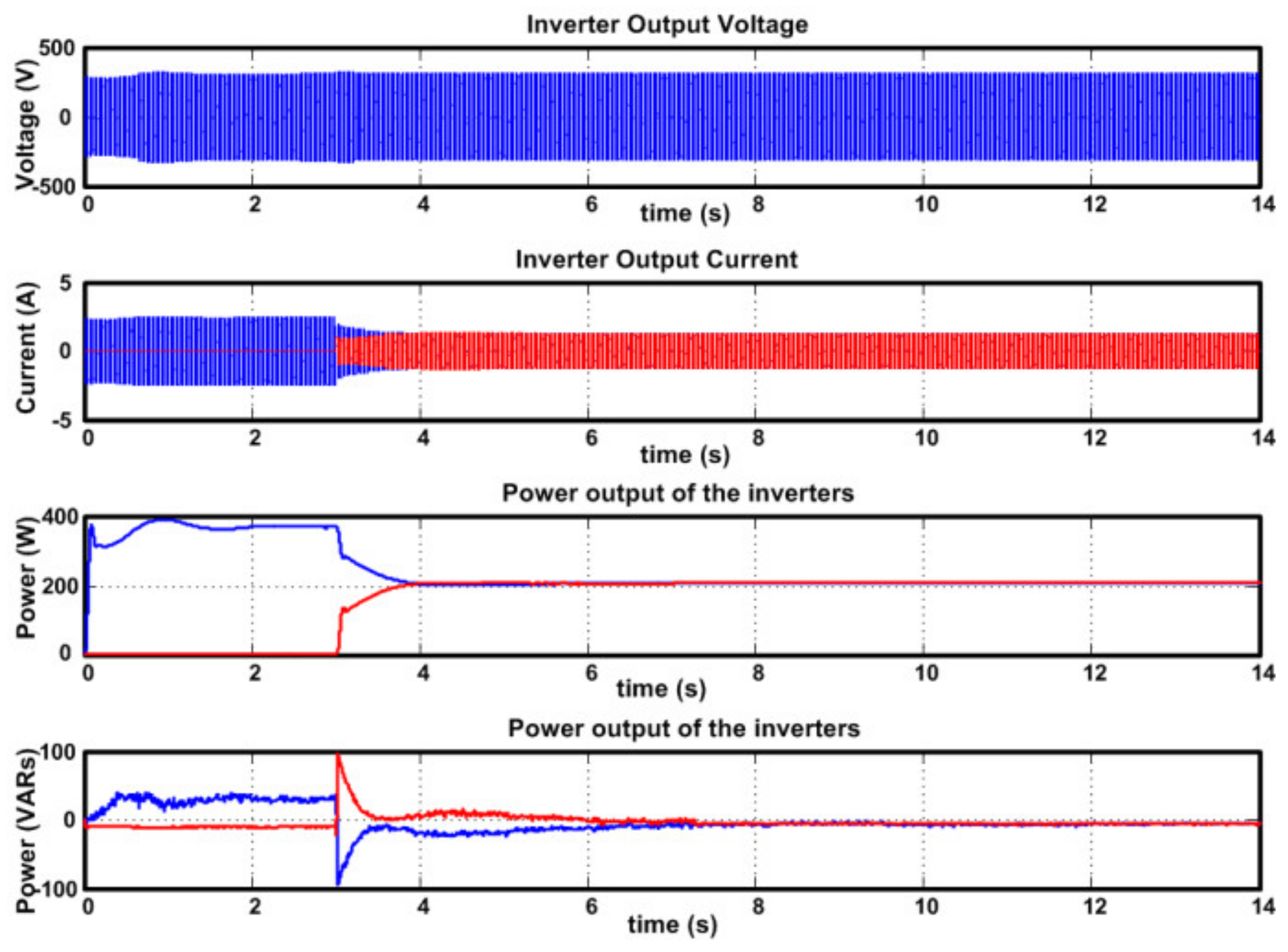

Figure 18 shows the wave shapes of voltage, current, active, and reactive power obtained with the in-parallel connection of two inverters feeding a nominal purely resistive load. The simulation was carried on with the P + ResC controller implemented in the current loop and 2DOF + RC controller implemented in the voltage loop, and a resistive virtual impedance loop. Both inverters share the load and active power, with a suitable transient response at the time of their interconnection. These results are equivalent to those obtained by applying the PI-P + ResC controllers and, therefore, are omitted.

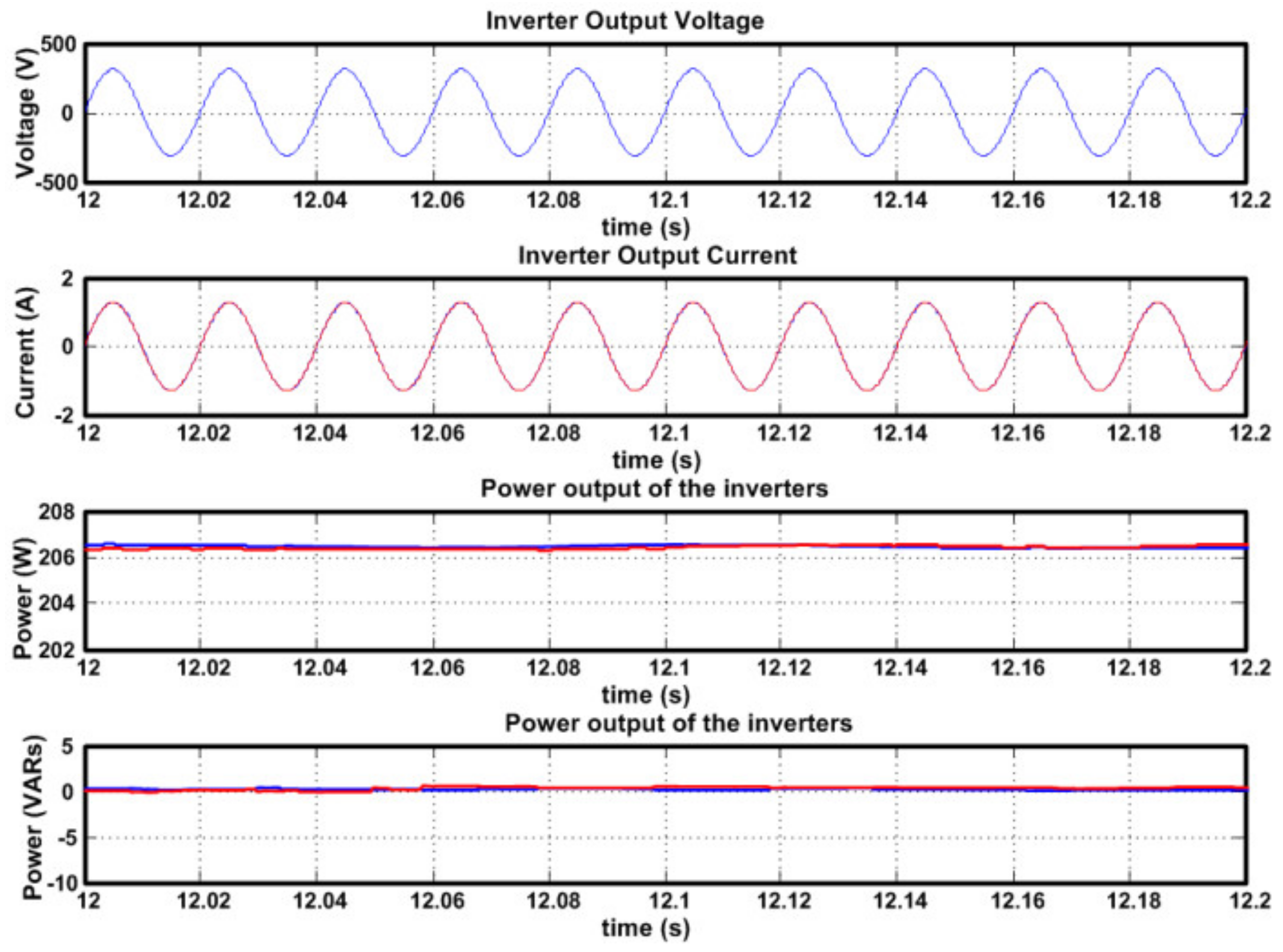

Figure 19 shows a zoom-in in the time scale (12 to 12.2) of the wave shapes of the voltage, current, and power in

Figure 18. The wave shape of the inverters’ output voltage is kept, with an adequate balance of load and reactive power between them. These results are equivalent to those obtained by applying the PI-P + ResC controller. The simulations performed are left out.

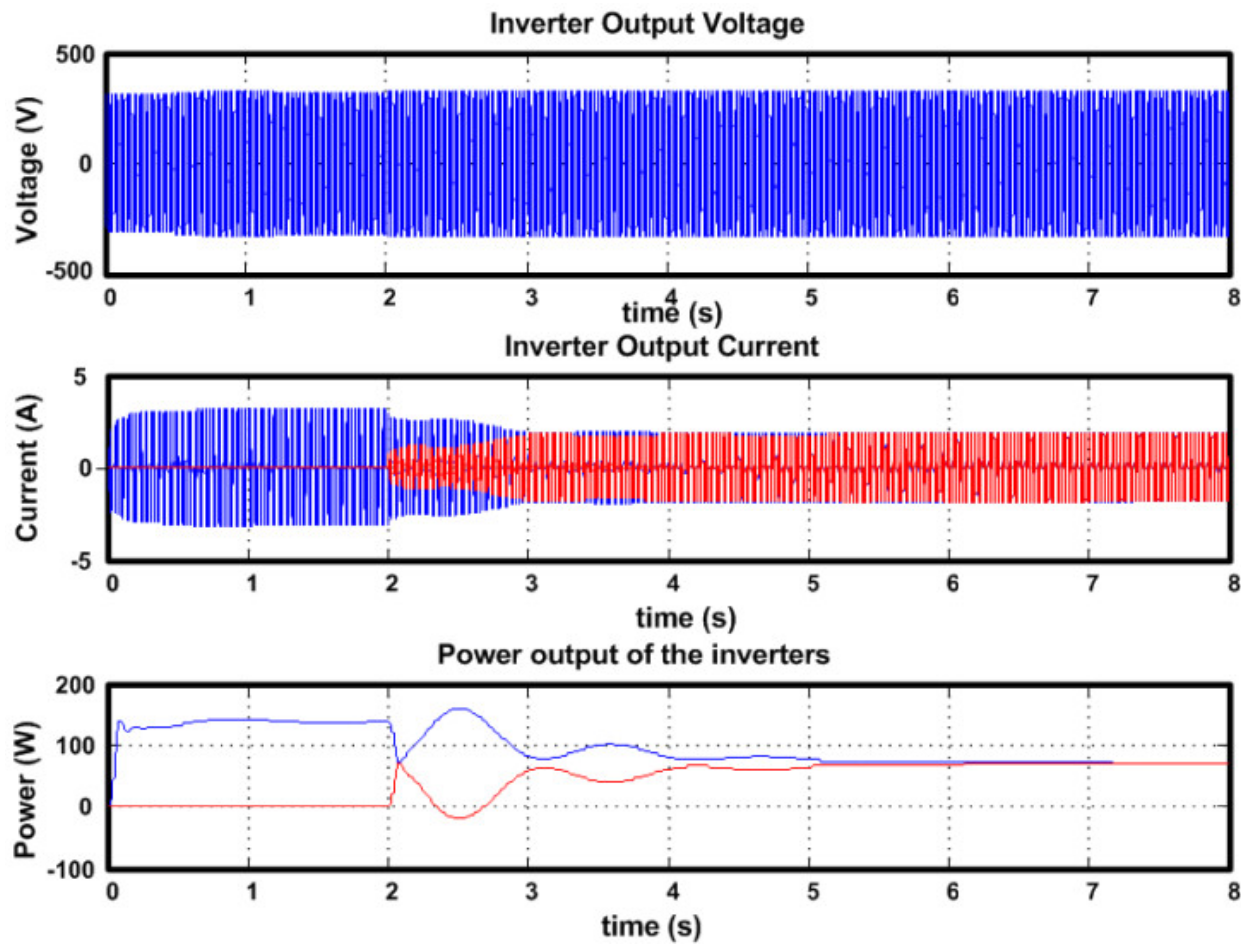

Figure 20 shows the wave shapes of current, voltage and active power, of two inverters feeding a non-linear load. The load has a nominal value equal to one third of the total inverter’s power. This simulation was carried on with the P + ResC controller implemented in the current loop, and 2DOF + RC controller, implemented in the voltage loops and a resistive virtual impedance loop. In the simulation, an appropriate transitory response at the interconnection was observed, a balanced share of load and active power between both inverters.

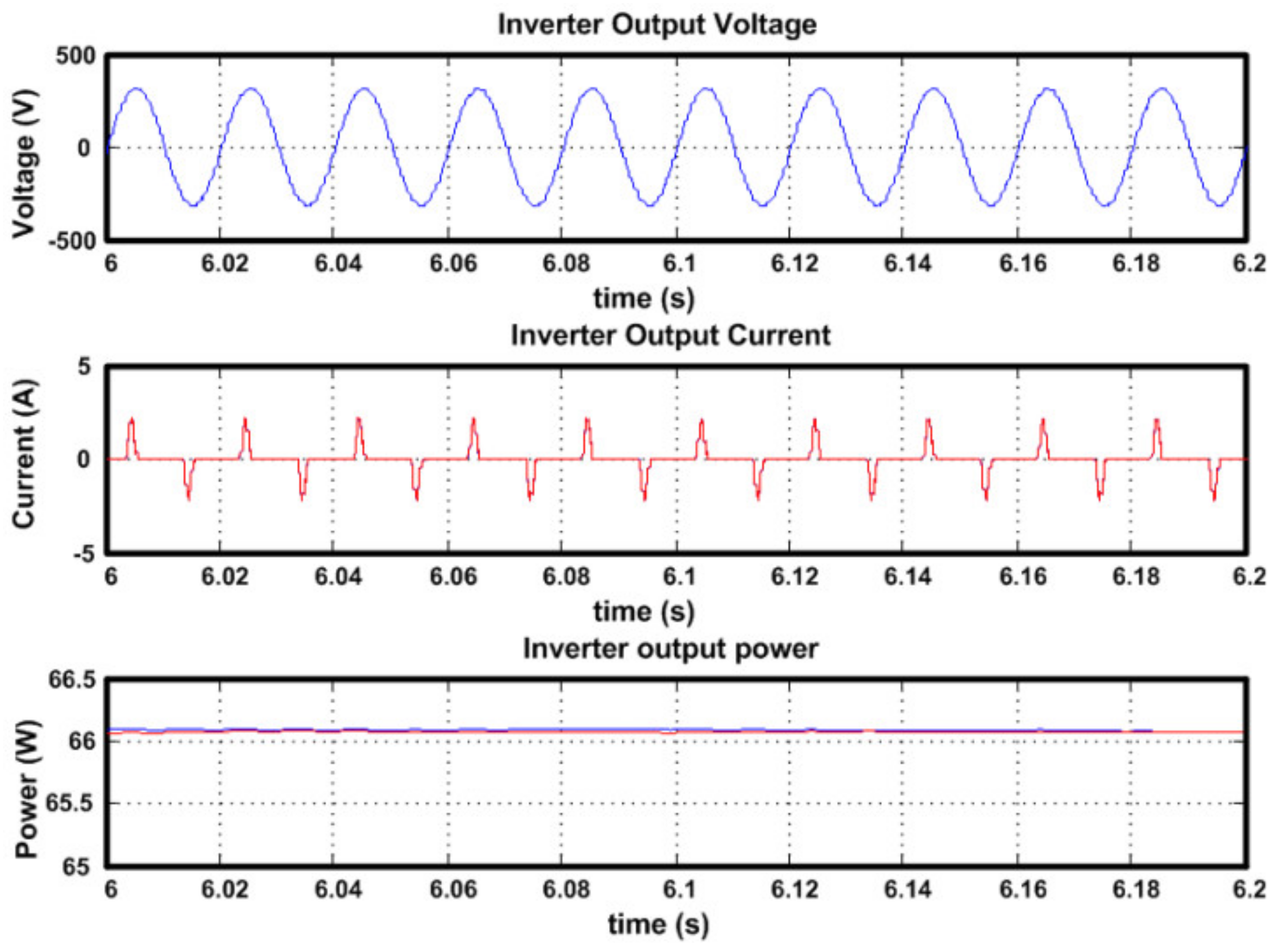

Figure 21 shows a zoom-in of

Figure 20 in the time scale (6 to 6.2) of the wave shapes of the voltage, current, and output power. In

Figure 21, the output voltage signal shows a small distortion. However, the proposed control still provides a better wave shape in the output voltage of the inverters than the previously introduced controllers. Like before, the load and active power shares appear adequately balanced between both inverters.

Figure 22 shows the waveforms obtained from the simulation of the P + ResC and PI-P + ResC controllers, with an in-parallel configuration of two inverters feeding a non-linear load equivalent to one third of the inverter’s total nominal power, without implementing a virtual impedance loop. It is possible to observe a balanced share of load and active power between inverters and an appropriate transient response when interconnected.

Figure 23 shows a zoom-in of

Figure 22 in the time scale (6 to 6.2) of the wave shapes of the voltage, current, and output power. The obtained signal is quite similar to the 2DOF + RC controller, because the output voltage signal also shows a small distortion. According to

Figure 15 and

Figure 17, which means that implementing either the 2DOF + RC or the PI-P + ResC controllers in the voltage loop, produces an appropriate voltage wave-shape at the inverters’ output, with load and active and reactive powers balanced between both inverters.

7. Experimental Results

Inverter experimental tests performance feeding a non-linear load are reported, with the 2DOF + RC and PI-P + ResC controller implementation, as well as a parallel connection test of two inverters.

Experimental measurements have been carried out on the 440 W inverter described in

Section 2. The controllers were implemented on a TMS320F28335 processor with a sampling frequency of 40 kHz. The sampling frequency is justified by applying the sampling theorem. The results obtained through simulations are like those obtained using experimental tests, so its presentation was not considered in this work.

The tests were performed with a resistive linear load of 170 Ω, and with a nonlinear load composed by a single-phase diode rectifier with a filter capacitance of Cf = 90 μF and a resistance of 680 Ω. It is worth pointing out that the rectifier has no input inductance, so that a highly nonlinear load results with a crest factor of CF = 4.2 and S = 130 VA when connected to an ideal sinusoidal mains voltage of 230 VRMS.

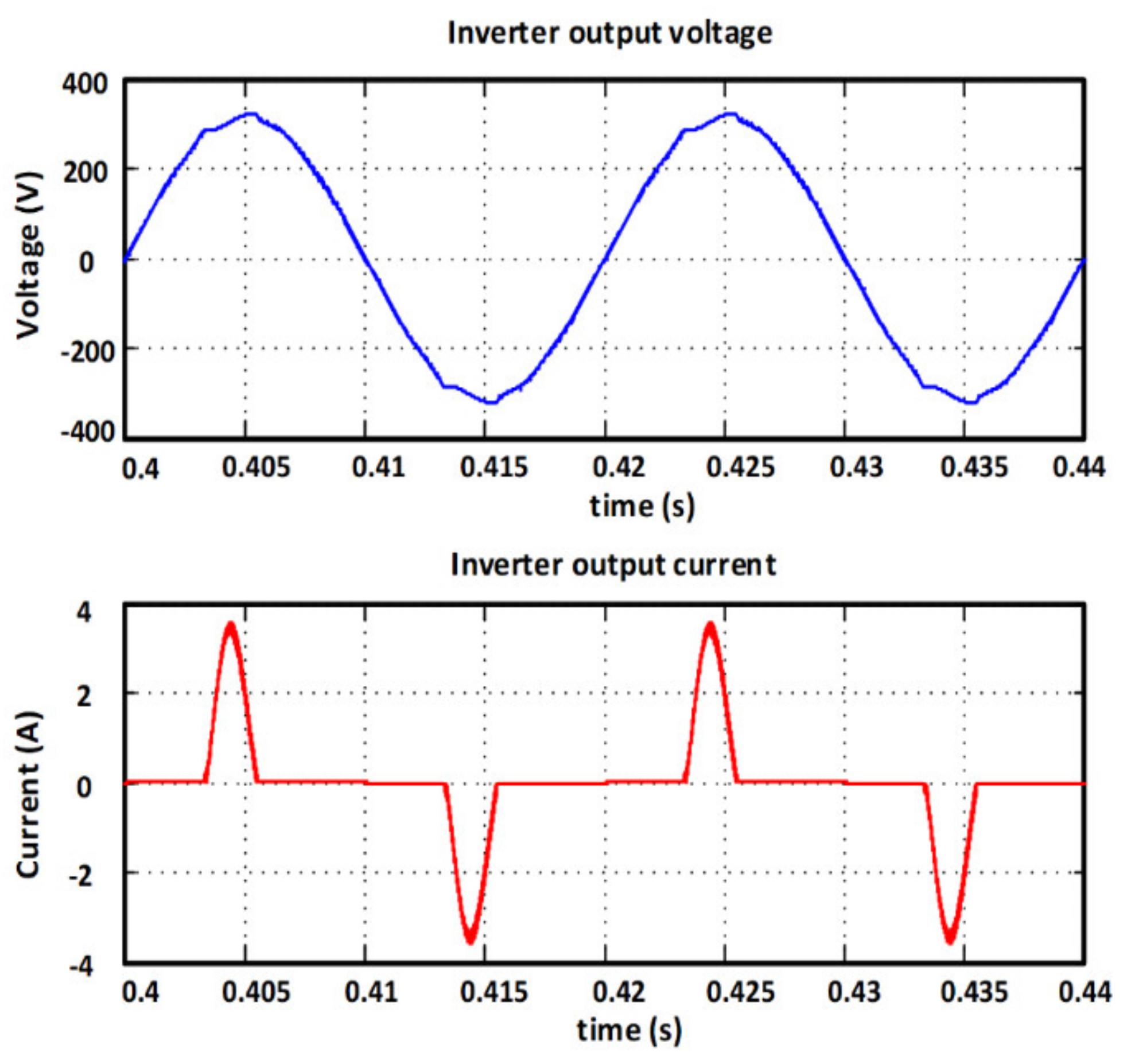

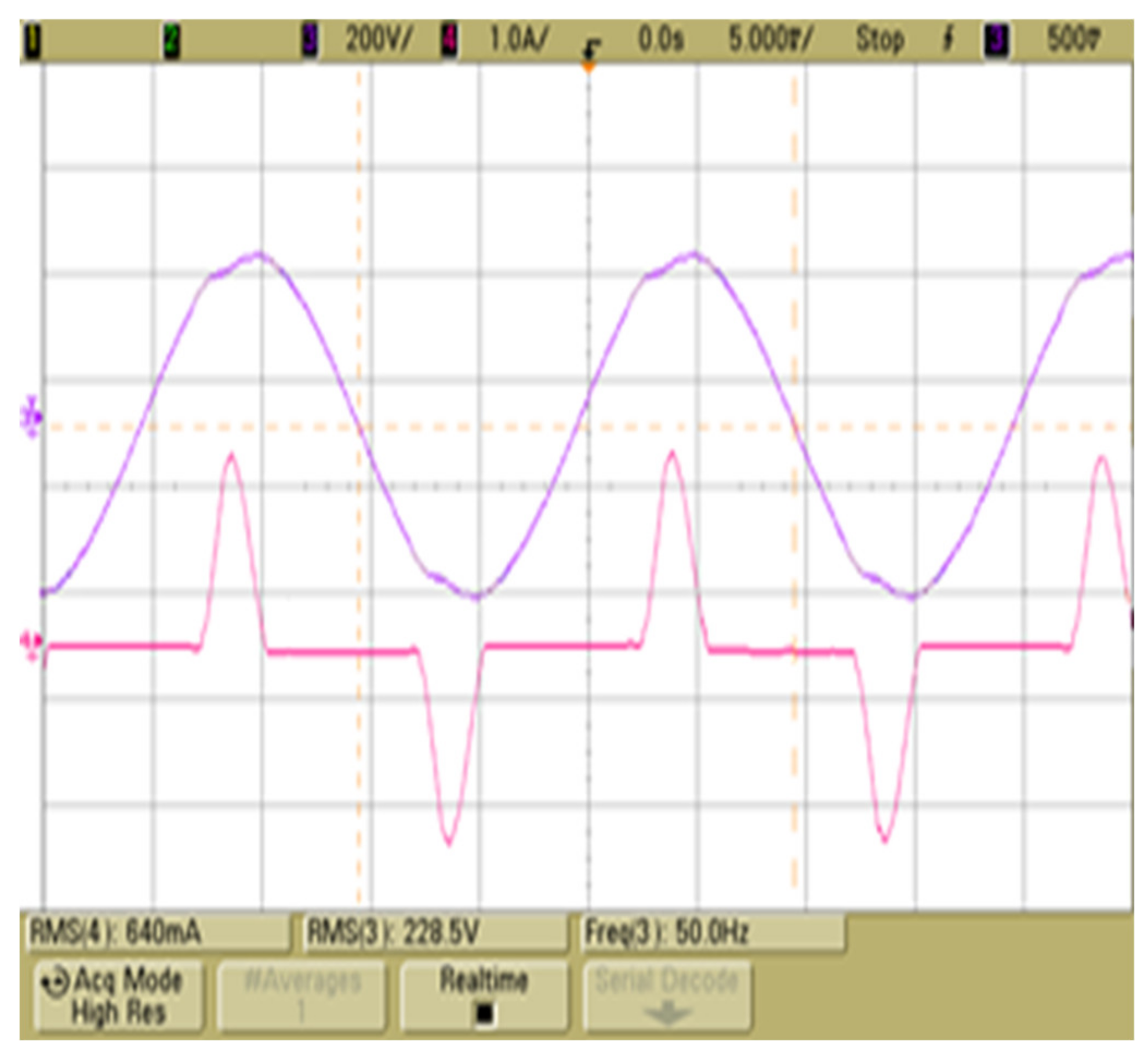

Figure 24, shows the experimental response of the output voltage and output current when the inverter powers the non-linear load using the 2DOF + RC controller. This graph shows a voltage signal with a total harmonic distortion THDv = 2.2%, a value that is below the 5% recommended by the IEEE 519-1992 standard. It is important to mention that the crest factor (CF) of this load corresponds to a value of 4.2, value that is considered high for a non-linear load. An important aspect is that the voltage signal has an amplitude of 228.5 V RMS, when the expected nominal value according to the converter operating power is 230 V RMS; which justifies the good performance of the controller. Additionally, the current signal has a characteristic form derived from the properties of the non-linear load.

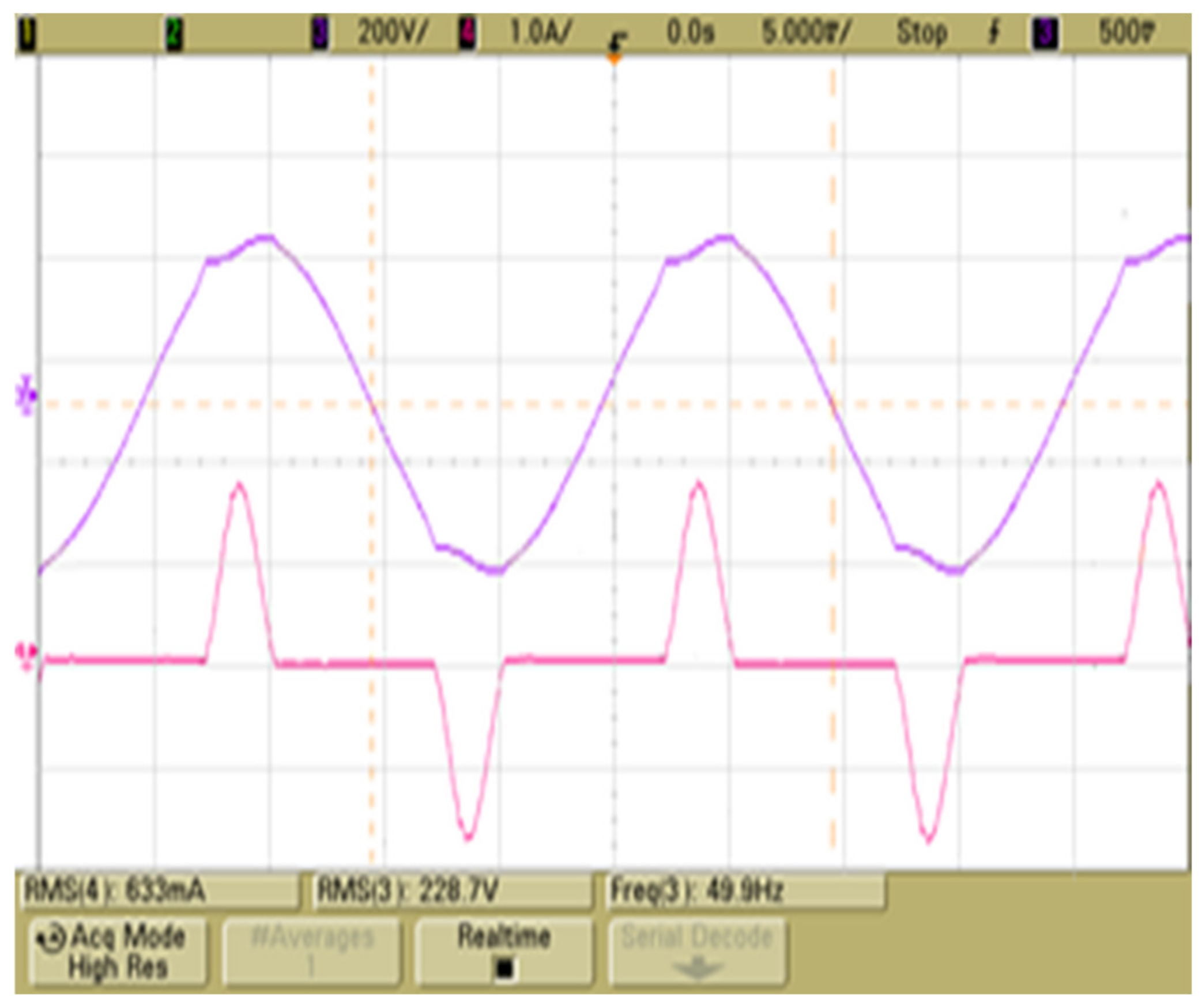

Figure 25, shows the experimental response of the output voltage and output current when the inverter powers the non-linear load using the PI-P + ResC controller. This graph shows a voltage signal with a total harmonic distortion THDv = 2.6%, a value that is below the 5% recommended by the IEEE 519-1992 standard. It is important to mention that the crest factor (CF) of this load corresponds to a value of 4.2, value that is considered high for a non-linear load. An important aspect is that the voltage signal has an amplitude of 228.7 V RMS, when the expected nominal value according to the converter operating power is 230 V RMS, which justifies the good performance of the controller. Additionally, the current signal has a characteristic form derived from the properties of the non-linear load.

Table 3 summarizes the inverter output voltage THDv using the four controllers feeding nonlinear loads. To load changes controllers, exhibit a good performance.

Figure 26, PW3198, the HIOKI network analyzer was used to display the voltage and current waveforms of two inverters connected in parallel, feeding a 170 Ω resistive load. This graph shows that the two inverters share the load in a homogeneous way, supplying currents of the same intensity with values close to 1.9 A. RMS, which justifies that both inverters are synchronized and in phase. Additionally, it is observed how the voltage signal maintains its amplitude with a value close to 230 V RMS, with a sinusoidal waveform, which proves the good performance of the designed controllers.

8. Results Discussion

This work presents the design and development of two control techniques for the grid-disconnected mode operation of an inverter. The objective of these two controllers is to provide better disturbances rejection when the converter supplies both linear and non-linear local loads. With its implementation through simulations and experimental tests, total harmonic distortion values were obtained in the voltage signal (THDv) between 1.0% and 2.5%, which represents an effective performance considering the recommendations of the IEEE 519-1992 standard, which must be less than 5%. Likewise, the parallel connection of power converters is effectively ensured. The simulations show that, at the time of interconnection and in the event of load changes, the transients present are less than 20% above the reference. Regarding the works presented in the literature, it is evident that different authors propose control strategies to reduce harmonic distortion with results close to those found in this work (THDv = 2%). Other authors propose strategies that allow the parallel connection of energy conversion units presented, with good performance. However, in this work, both strategies are proposed and implemented; that is, solutions for both the parallel connection of converters and regulators for the reduction of THDv, when the converter feeds linear and non-linear loads.

The 2DOF + RC is more robust than a repetitive controller considering that the former is designed with two controllers, one for the direct loop, and one for the feedback loop. Particularly, in the feedback loop, a controller is designed to provide larger system disturbances rejection, and the other, in the direct loop, is designed to have good setpoint tracking and contribute to the disturbance rejection task, in contrast with less robust repetitive control schemes that are normally designed in the direct loop.

The PI-P + ResC control configuration consists of two controllers: a PI + ResC controller for the direct loop and another P controller for the feedback loop. Particularly, the PI + ResC controller is designed for good setpoint tracking and the P controller for better disturbances rejection. Therefore, this control structure turns out to be more robust and presents better performance than a resonant controller, which is normally designed for direct control loop.

9. Conclusions

In the literature, control configurations have been applied to solve harmonic distortion problems for both current and voltage signals in converter applications operating in grid-connected and islanded modes. Some of these works use control configurations like resonant, repetitive, PID, control of sliding modes, and others, performing within the regulations aforementioned. In this work, two control configurations are developed and applied. The first one is configured with a control of two-degrees-of-freedom plus a repetitive control (2DOF + RC), and the second is configured with a proportional integral–proportional control plus a resonant control (PI-P + ResC). Both configurations are a new proposal in the suitable solution for problems of reduction of harmonic distortion and parallel inverter connection. These configurations combine two different control schemes in their structure to improve upon their performance. What characterizes both configurations is that a controller is implemented in the direct loop and another controller in the feedback loop, which allows to improve the performance of the converter, presenting an adequate set point tracking and, at the same time, improving the system disturbance rejection. Specifically, both control configurations allow for a steady state error equal to zero (eee = 0) and the disturbance rejection with linear and non-linear load is in the range between 1% and 2.5%, below the recommended by regulations IEEE 519-1992, which is 5%. In particular, by means of the implementation through simulations and experimental tests presented in this work, good performance of the system is justified, considering that with the implementation of these regulators, it is possible to have good set point tracking and good disturbances rejection. This causes the amplitude of the voltage signal to present values close to 230 V RMS, at 50 Hz. Additionally, inverters are successfully paralleled in response to increases in load demand. The reference voltage signal is obtained through droop schemes that allow the inverters connection in parallel to meet increases in load demand. Particularly, for this application, a resistive droop scheme was chosen with a virtual impedance loop of the same characteristics that allows the inverters parallel connection and the homogeneous distribution of active and reactive power demanded by the load. Their choice was determined considering that with the implementation of both controllers, the inverter closed-loop impedance presents a resistive characteristic.

The controller showed the capacity to reduce the Total Harmonic Distortion (THDv) of the inverter’s output below the 5% recommended by the IEEE 519-1992. THDv values of 1.2, 2.2, and 2.5% were obtained for in-parallel connected inverters feeding either a linear or non-linear load. It is worth noticing that if the PI-P + ResC controller is implemented, it is not necessary to use a virtual impedance loop.

In this work, methods are specifically described and developed so that experts in this area of knowledge can implement with certainty control strategies that allow improving the disturbances rejection in power electronic converters. Particularly, as already mentioned, for converter island mode operation. In addition, the criteria and strategies are established to effectively carry out the parallel connection of converters to meet load demands.