Sustainable Management of Autoclaved Aerated Concrete Wastes in Gypsum Composites

Abstract

1. Introduction

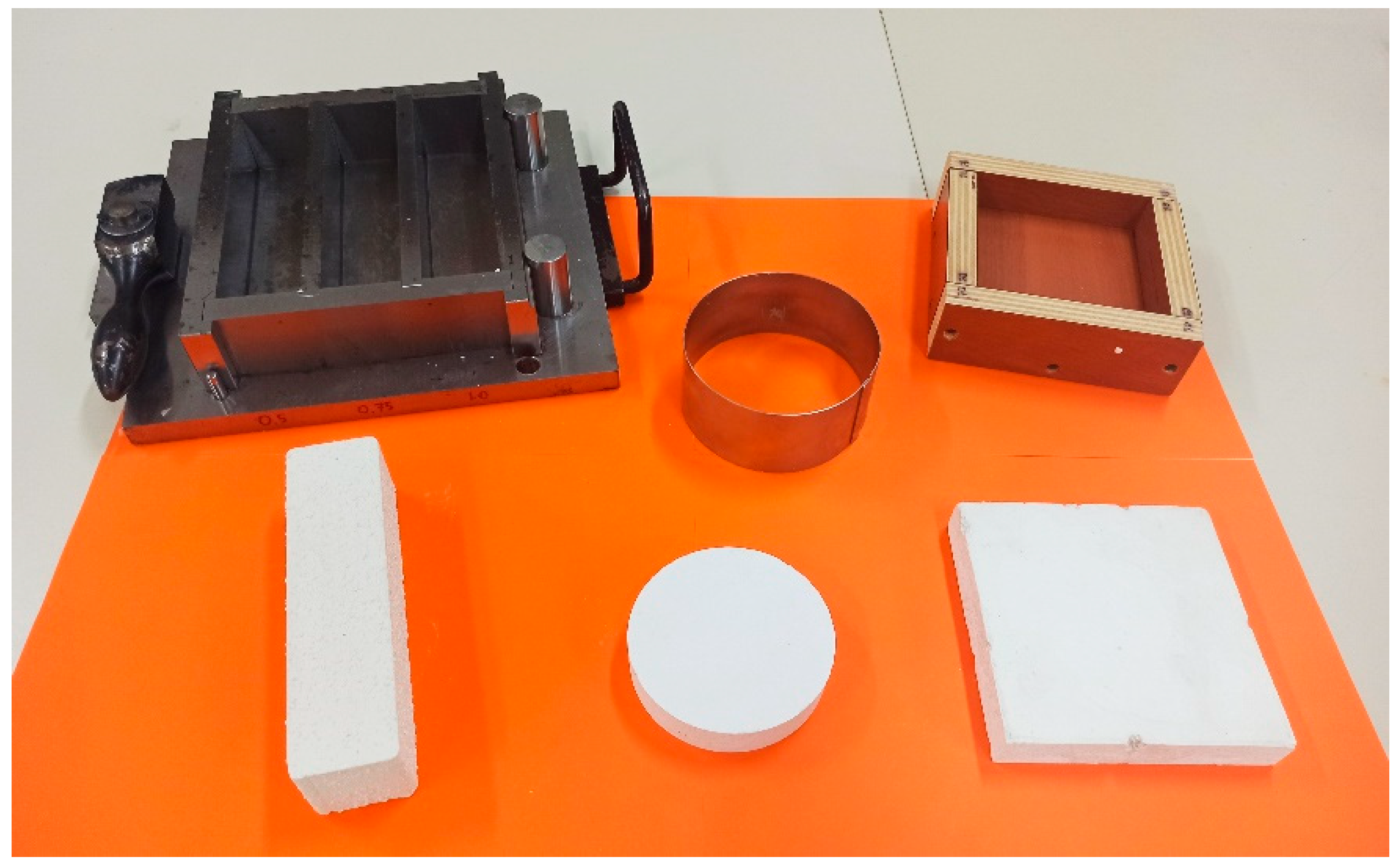

2. Materials and Methods

2.1. Materials

2.2. AAC–Gypsum Composites Preparation and Characterization

3. Results and Discussion

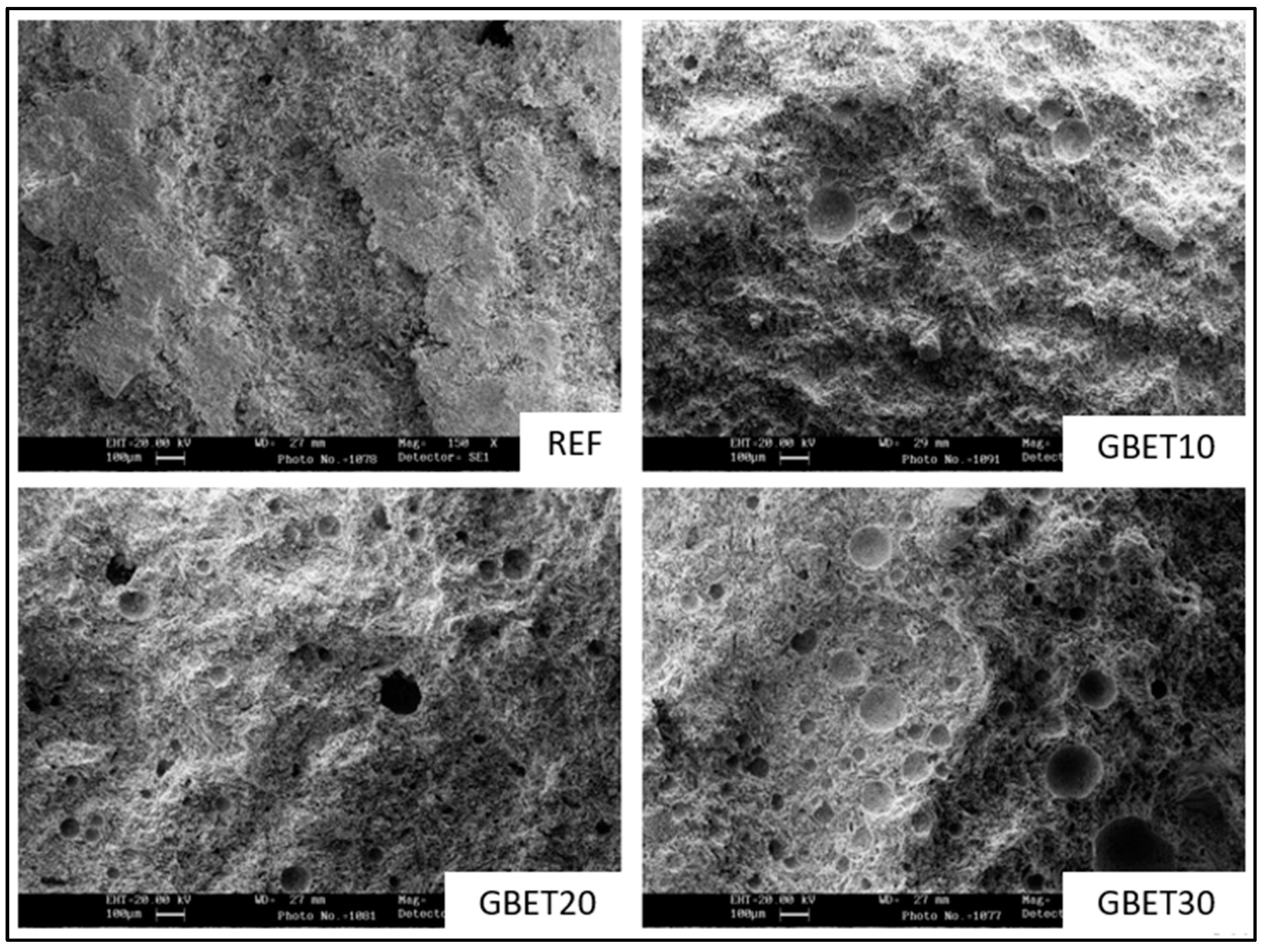

3.1. Evaluation of the AAC Granulates Waste

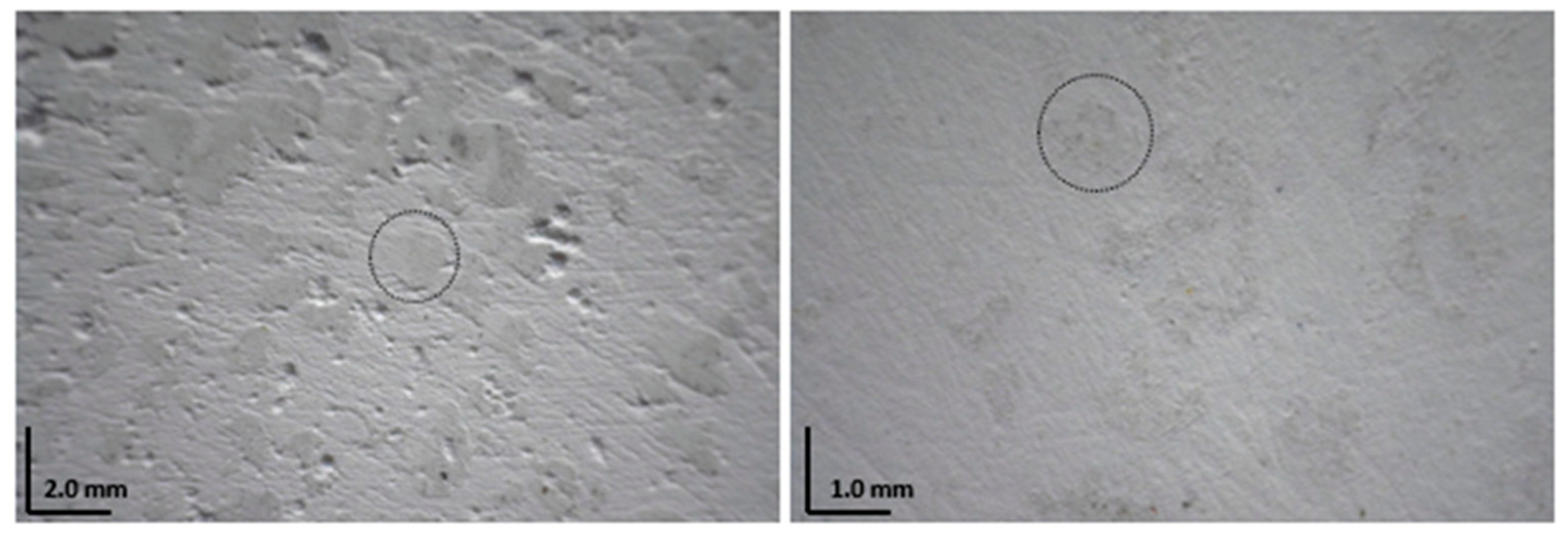

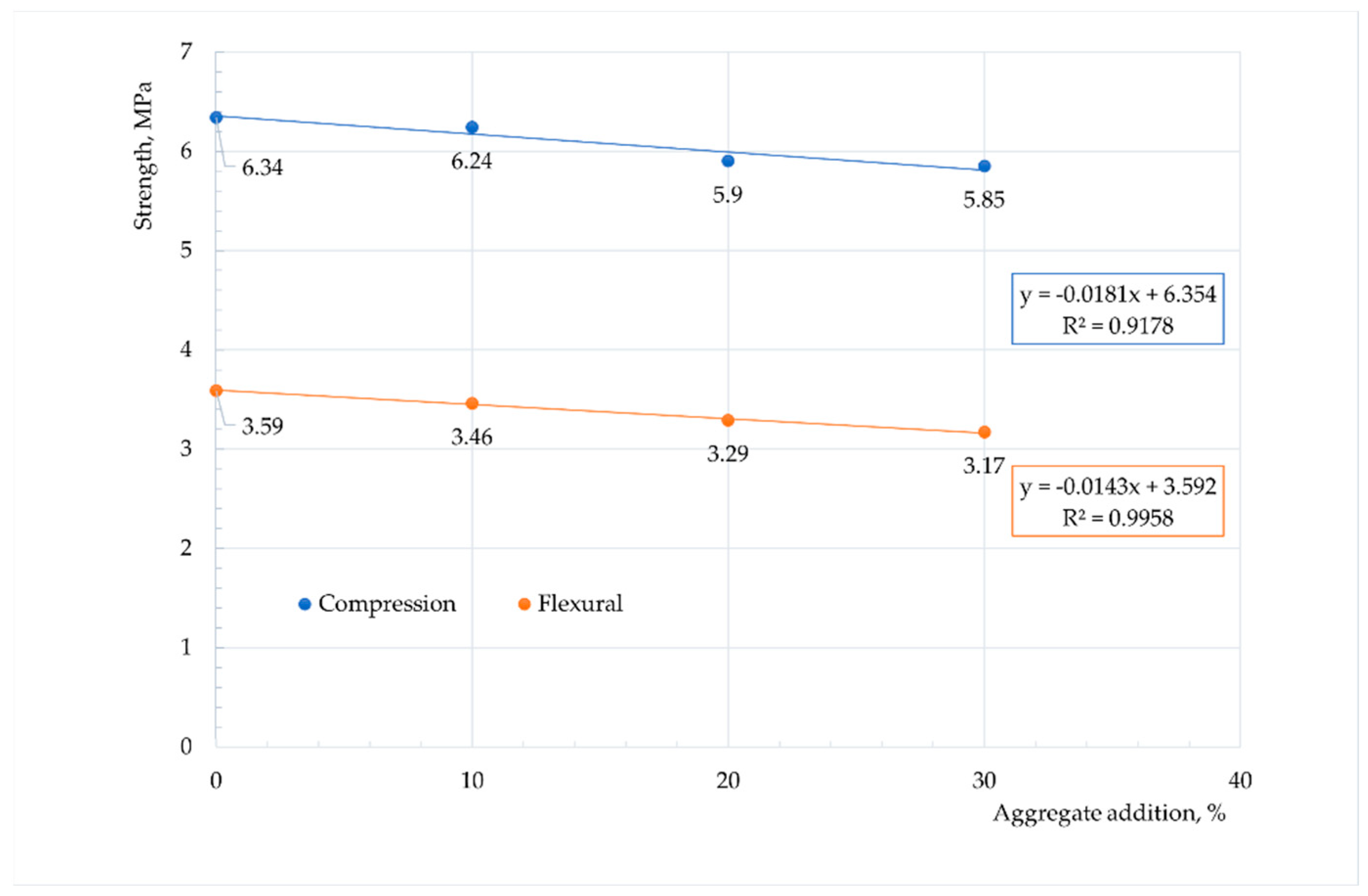

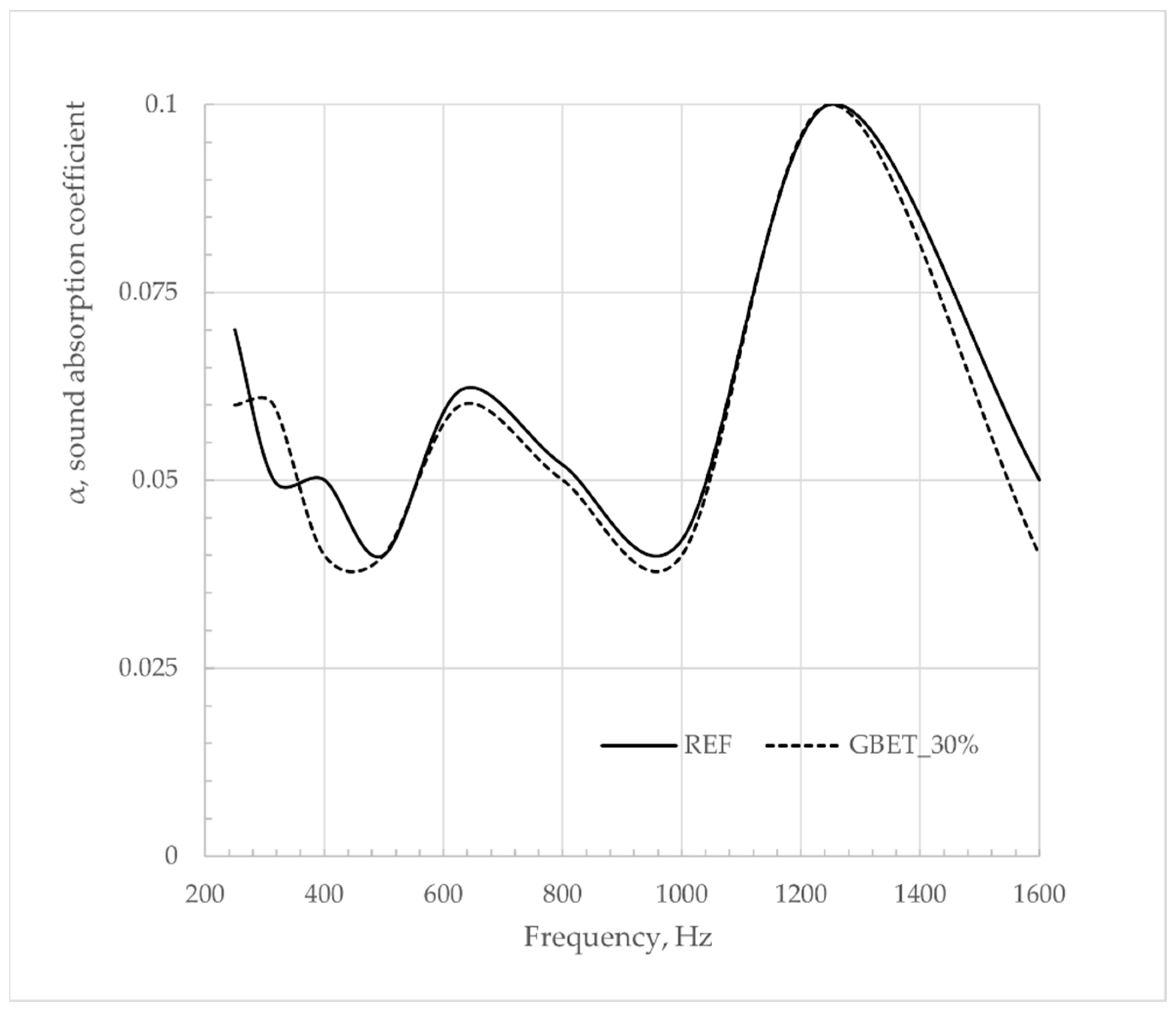

3.2. AAC–Gypsum Composites Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiménez-Rivero, A.; García-Navarro, J. Indicators to Measure the Management Performance of End-of-Life Gypsum: From Deconstruction to Production of Recycled Gypsum. Waste Biomass Valorization 2016, 7, 913–927. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Pini, C.; Penazzi, S. On the design of closed-loop networks for product life cycle management: Economic, environmental and geography considerations. J. Transp. Geogr. 2015, 48, 121–134. [Google Scholar] [CrossRef]

- Ahmari, S.; Ren, X.; Toufigh, V.; Zhang, L. Production of geopolymeric binder from blended waste concrete powder and fly ash. Constr. Build. Mater. 2012, 35, 718–729. [Google Scholar] [CrossRef]

- Fudge, C.; Fouad, F.; Klingner, R. Autoclaved aerated concrete. In Developments in the Formulation and Reinforcement of Concrete; Elsevier BV: Vancouver, BC, Canada, 2019; pp. 345–363. [Google Scholar]

- Bergmans, J.; Nielsen, P.; Snellings, R.; Broos, K. Recycling of autoclaved aerated concrete in floor screeds: Sulfate leaching reduction by ettringite formation. Constr. Build. Mater. 2016, 111, 9–14. [Google Scholar] [CrossRef][Green Version]

- Schreiner, J.; Jansen, D.; Ectors, D.; Goetz-Neunhoeffer, F.; Neubauer, J.; Volkmann, S. New analytical possibilities for monitoring the phase development during the production of autoclaved aerated concrete. Cem. Concr. Res. 2018, 107, 247–252. [Google Scholar] [CrossRef]

- Gyurkó, Z.; Jankus, B.; Fenyvesi, O.; Nemes, R. Sustainable applications for utilization the construction waste of aerated concrete. J. Clean. Prod. 2019, 230, 430–444. [Google Scholar] [CrossRef]

- Hlawatsch, F.; Aycil, H.; Kropp, J. Autoclaved aerated concrete (AAC) rubble for new recycling building products: In dry premixed mortars for masonry, in masonry blocks, and in lightweight blocks. ce/papers 2018, 2, 457–464. [Google Scholar] [CrossRef]

- Schoon, J.; De Buysser, K.; Van Driessche, I.; De Belie, N. Feasibility study on the use of cellular concrete as alternative raw material for Portland clinker production. Constr. Build. Mater. 2013, 48, 725–733. [Google Scholar] [CrossRef]

- Lam, N.N. Recycling of AAC Waste in the Manufacture of Autoclaved Aerated Concrete in Vietnam. Int. J. GEOMATE 2021, 20, 128–134. [Google Scholar] [CrossRef]

- Lushnikova, N.; Dvorkin, L. Sustainability of gypsum products as a construction material. Sustain. Constr. Mater. 2016. [Google Scholar] [CrossRef]

- Raghavendra, T.; Udayashankar, B. Engineering properties of controlled low strength materials using flyash and waste gypsum wall boards. Constr. Build. Mater. 2015, 101, 548–557. [Google Scholar] [CrossRef]

- Guerra, B.C.; Bakchan, A.; Leite, F.; Faust, K.M. BIM-based automated construction waste estimation algorithms: The case of concrete and drywall waste streams. Waste Manag. 2019, 87, 825–832. [Google Scholar] [CrossRef] [PubMed]

- Hansen, S.; Sadeghian, P. Recycled gypsum powder from waste drywalls combined with fly ash for partial cement replacement in concrete. J. Clean. Prod. 2020, 274, 122785. [Google Scholar] [CrossRef]

- Vimmrová, A.; Keppert, M.; Svoboda, L.; Černý, R. Lightweight gypsum composites: Design strategies for multi-functionality. Cem. Concr. Compos. 2011, 33, 84–89. [Google Scholar] [CrossRef]

- Fort, J.; Černý, R. Carbon footprint analysis of calcined gypsum production in the Czech Republic. J. Clean. Prod. 2018, 177, 795–802. [Google Scholar] [CrossRef]

- Capasso, I.; Iucolano, F. Production of lightweight gypsum using a vegetal protein as foaming agent. Mater. Struct. 2020, 53, 1–13. [Google Scholar] [CrossRef]

- Tounchuen, K.; Buggakupta, W.; Panpa, W. Characteristics of Automotive Glass Waste-Containing Gypsum Bodies Made from Used Plaster Mould. Key Eng. Mater. 2014, 608, 91–96. [Google Scholar] [CrossRef]

- Alameda, L.; Calderón, V.; Junco, C.; Rodríguez, A.; Gadea, J.; Gutiérrez-González, S. Characterization of gypsum plasterboard with polyurethane foam waste reinforced with polypropylene fibers. Mater. Constr. 2016, 66, e100. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Rodríguez-Liñán, C.; Flores-Colen, I.; de Brito, J. Use of polycarbonate waste as aggregate in recycled gypsum plasters. Materials 2020, 13, 3042. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.; Morales-Conde, M.; Pérez-Gálvez, F.; Rubio-De-Hita, P. Influence of polycarbonate waste on gypsum composites: Mechanical and environmental study. J. Clean. Prod. 2019, 218, 21–37. [Google Scholar] [CrossRef]

- Yi, S.-Y.; Fan, L.-W.; Fu, J.-H.; Xu, X.; Yu, Z.-T. Experimental determination of the water vapor diffusion coefficient of autoclaved aerated concrete (AAC) via a transient method: Effects of the porosity and temperature. Int. J. Heat Mass Transf. 2016, 103, 607–610. [Google Scholar] [CrossRef]

- Kang, Y.; Chang, S.J.; Kim, S. Hygrothermal behavior evaluation of walls improving heat and moisture performance on gypsum boards by adding porous materials. Energy Build. 2018, 165, 431–439. [Google Scholar] [CrossRef]

- Bouzit, S.; Laasri, S.; Taha, M.; Laghzizil, A.; Hajjaji, A.; Merli, F.; Buratti, C. Characterization of Natural Gypsum Materials and Their Composites for Building Applications. Appl. Sci. 2019, 9, 2443. [Google Scholar] [CrossRef]

- De Oliveira, K.A.; Barbosa, J.C.; Christoforo, A.L.; Molina, J.C.; Oliveira, C.A.B.; Bertolini, M.S.; Gava, M.; Ventorim, G. Sound absorption of recycled gypsum matrix composites with residual cellulosic pulp and expanded polystyrene. BioResources 2019, 14, 4806–4813. [Google Scholar]

| Sample | Real Density [g/mL] | Open Porosity [%] | Compressive Strength [MPa] | Flexural Strength [MPa] |

|---|---|---|---|---|

| REF | 2.23 0.01 | 51.12 0.13 | 6.34 0.24 | 3.59 0.03 |

| GBET10 | 2.15 0.01 | 51.57 0.17 | 6.24 0.16 | 3.46 0.18 |

| GBET20 | 2.09 0.02 | 52.14 0.16 | 5.90 0.22 | 3.29 0.13 |

| GBET30 | 2.07 0.01 | 52.35 0.18 | 5.85 0.28 | 3.17 0.04 |

| Type | Flexural Strength [N/mm2] | Compressive Strength [N/mm2] |

|---|---|---|

| B1-Gypsum for construction a | 1 | 2 |

| B2-Gypsum mortar b | 1 | 2 |

| B3-Gypsum mortar with lime c | 1 | 2 |

| B4-Lightweight gypsum a | 1 | 2 |

| B5-Lightweight gypsum mortar b | 1 | 2 |

| B6-Lightweight gypsum mortar with lime c | 1 | 2 |

| B7-Lightweight gypsum for construction a |

| Sample | |||

|---|---|---|---|

| REF | 7.31 0.28 | 0.16 0.02 | 28.42 0.99 |

| GBET30 | 7.84 0.19 | 0.17 0.02 | 26.34 1.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iucolano, F.; Campanile, A.; Caputo, D.; Liguori, B. Sustainable Management of Autoclaved Aerated Concrete Wastes in Gypsum Composites. Sustainability 2021, 13, 3961. https://doi.org/10.3390/su13073961

Iucolano F, Campanile A, Caputo D, Liguori B. Sustainable Management of Autoclaved Aerated Concrete Wastes in Gypsum Composites. Sustainability. 2021; 13(7):3961. https://doi.org/10.3390/su13073961

Chicago/Turabian StyleIucolano, Fabio, Assunta Campanile, Domenico Caputo, and Barbara Liguori. 2021. "Sustainable Management of Autoclaved Aerated Concrete Wastes in Gypsum Composites" Sustainability 13, no. 7: 3961. https://doi.org/10.3390/su13073961

APA StyleIucolano, F., Campanile, A., Caputo, D., & Liguori, B. (2021). Sustainable Management of Autoclaved Aerated Concrete Wastes in Gypsum Composites. Sustainability, 13(7), 3961. https://doi.org/10.3390/su13073961