Development of Material Combination Model Considering Economics and Construction Efficiency for G-SEED Certification

Abstract

1. Introduction

1.1. Background and Purpose

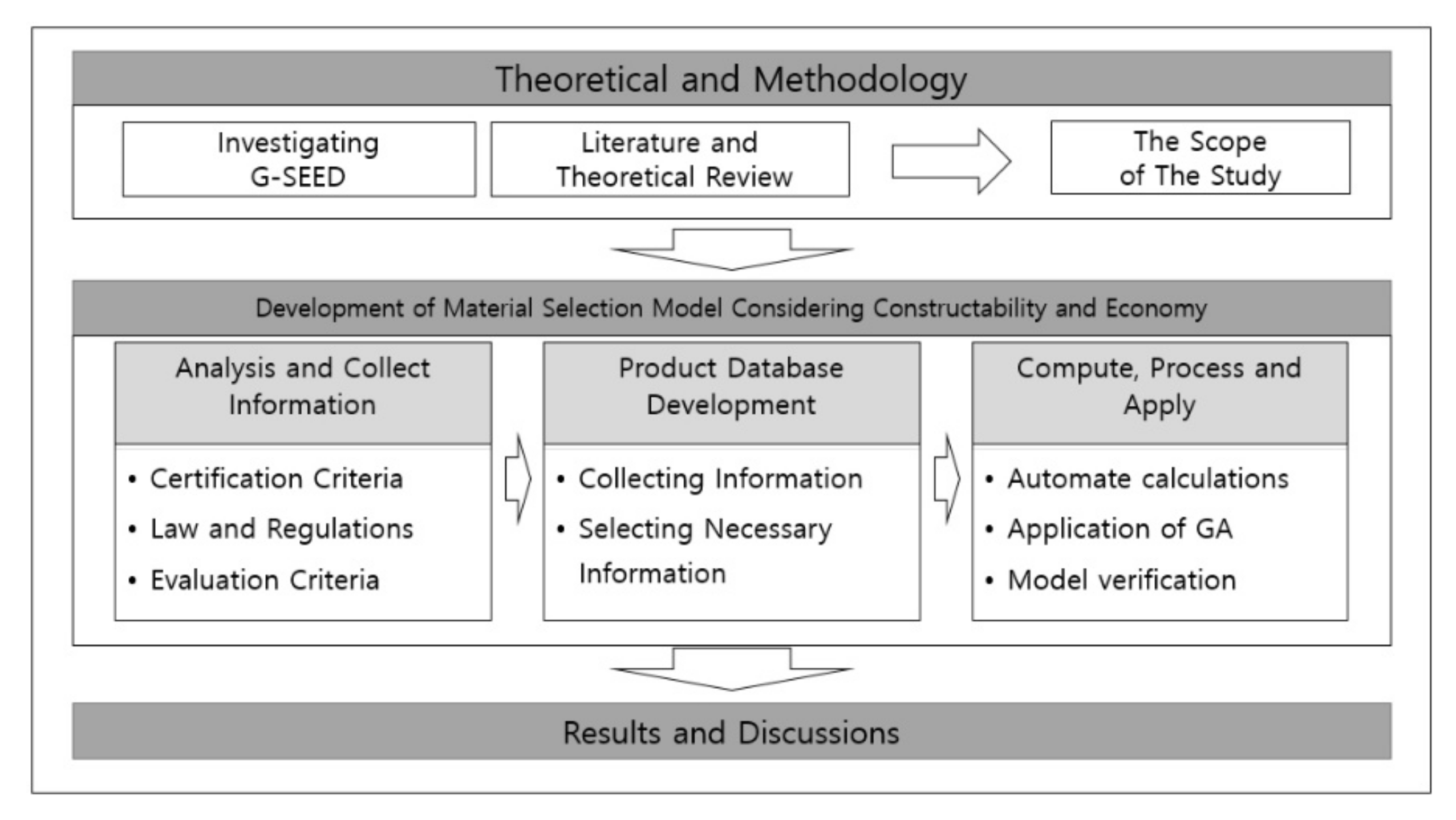

1.2. Research Scope and Method

1.3. Existing Research Review

1.4. Research Significance

2. Theoretical Review

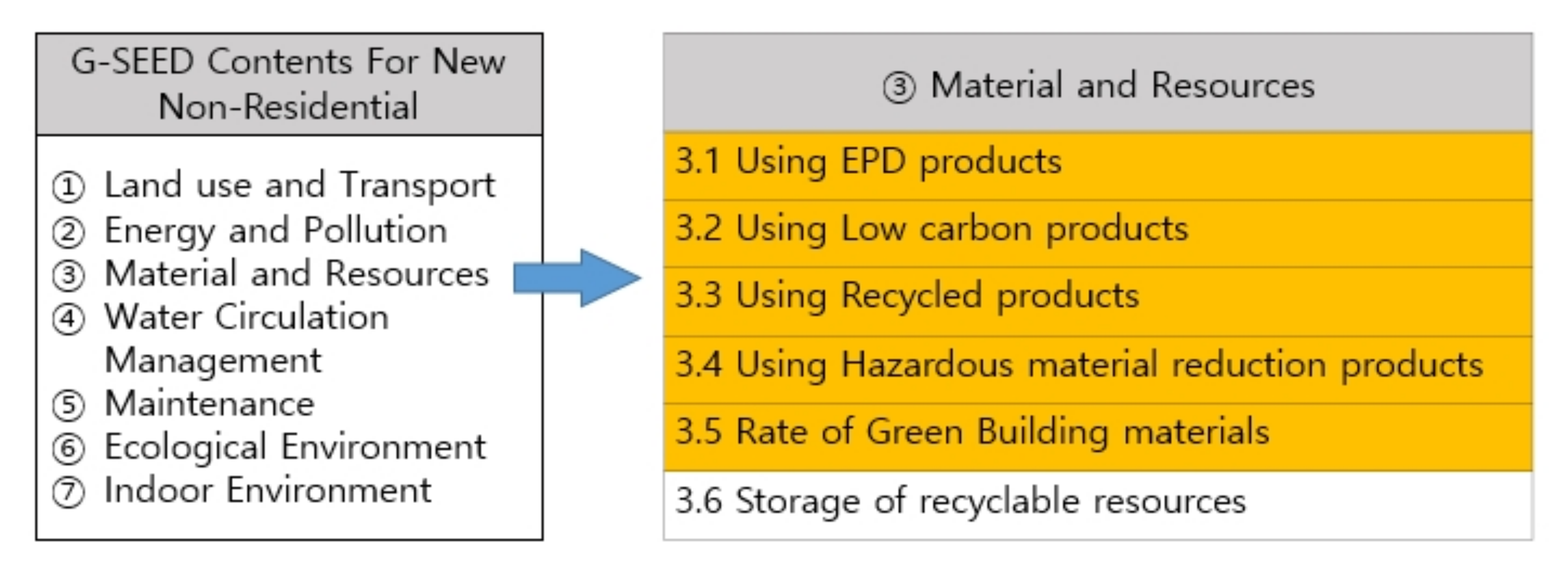

2.1. Green Standard for Energy and Environmental Design: G-SEED

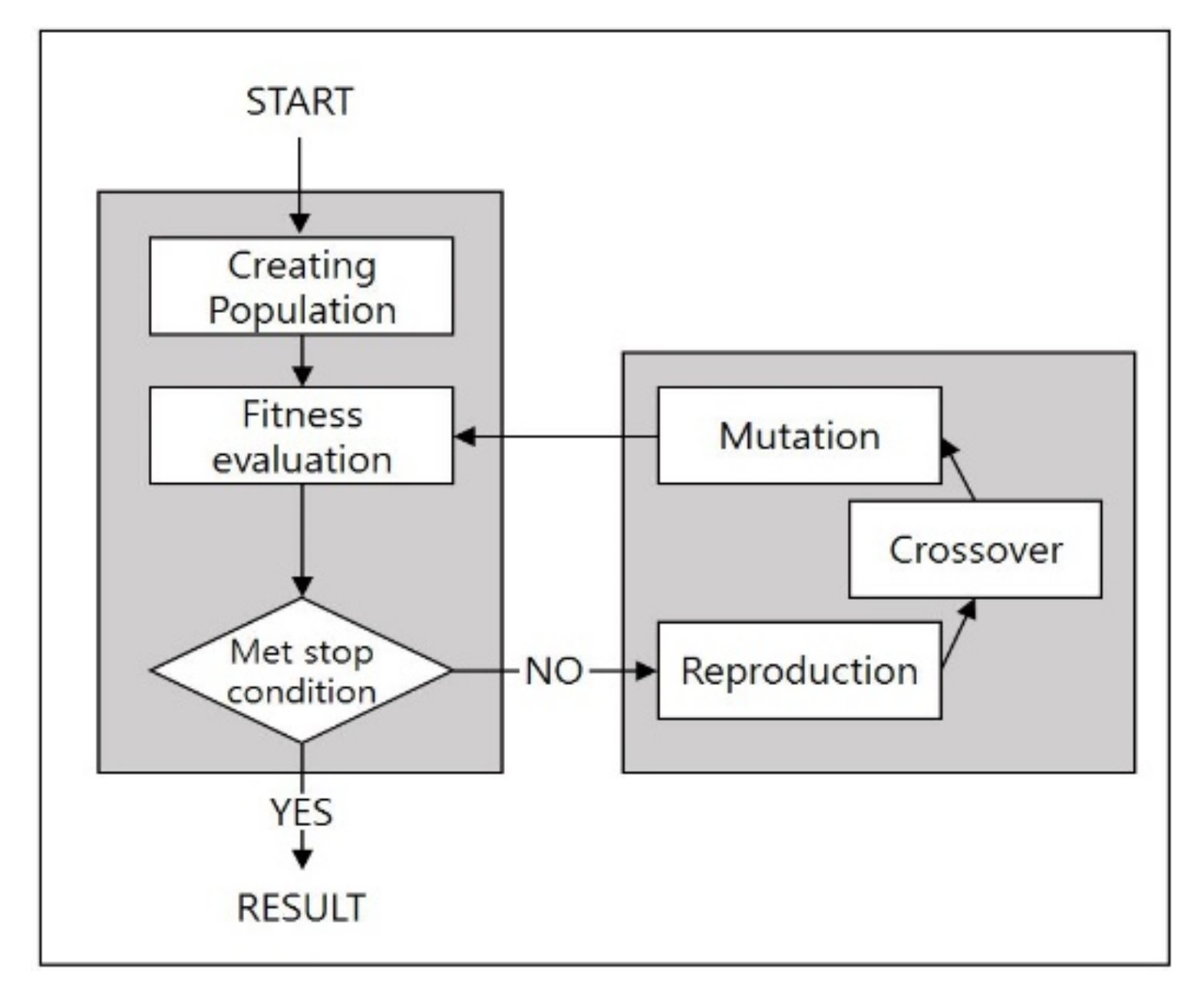

2.2. GA

3. Development of the Material Selection Model

3.1. Analysis of the Certification Criteria and Material Information Collection

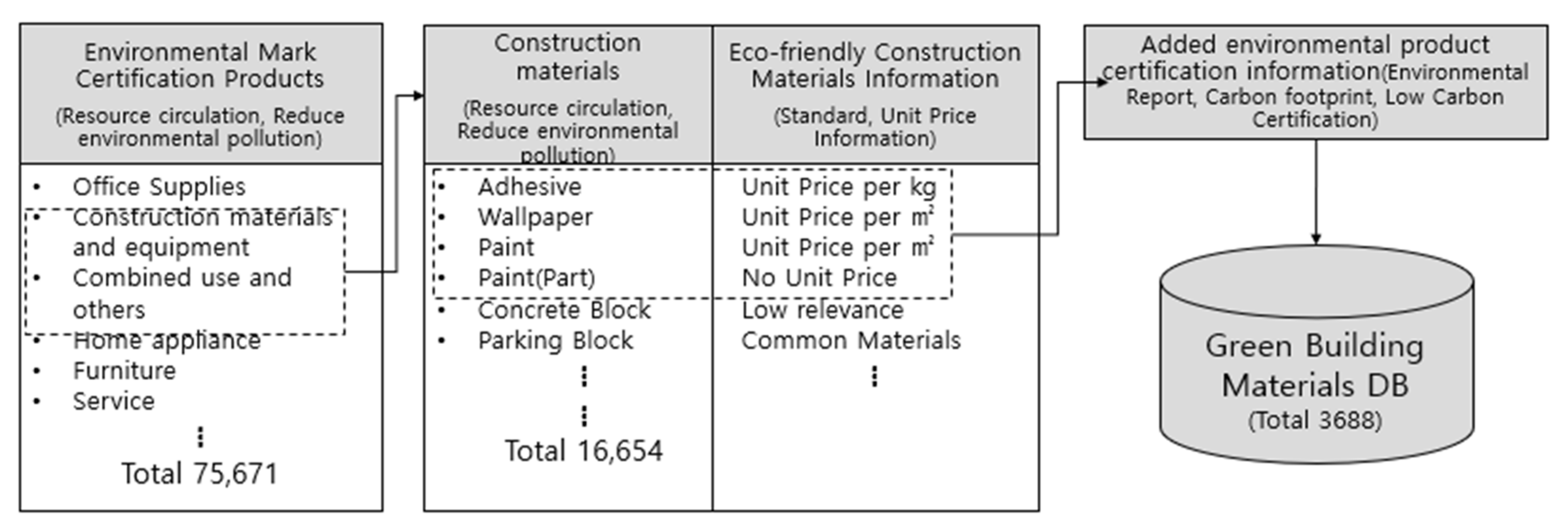

3.2. Building Material Database

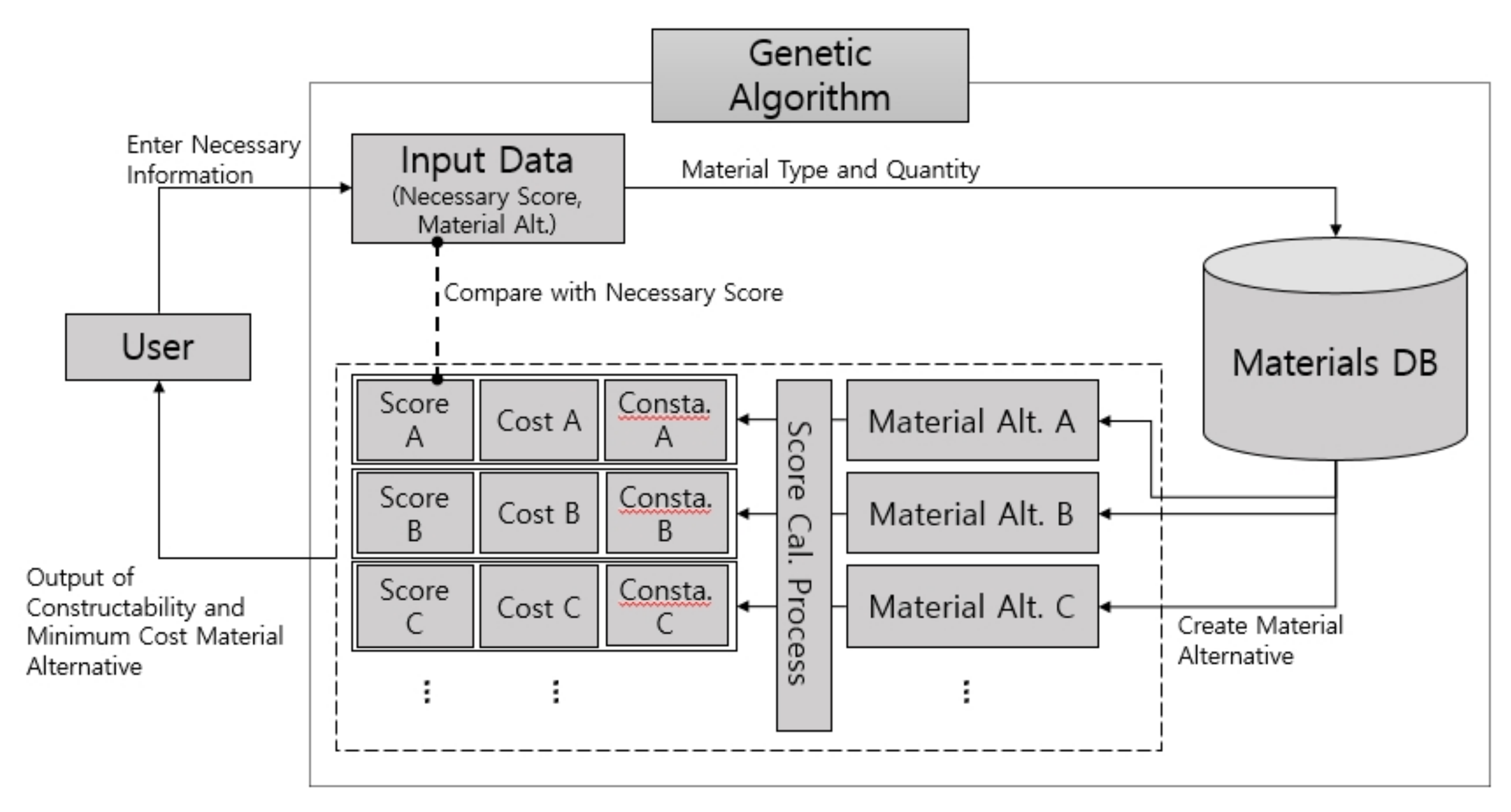

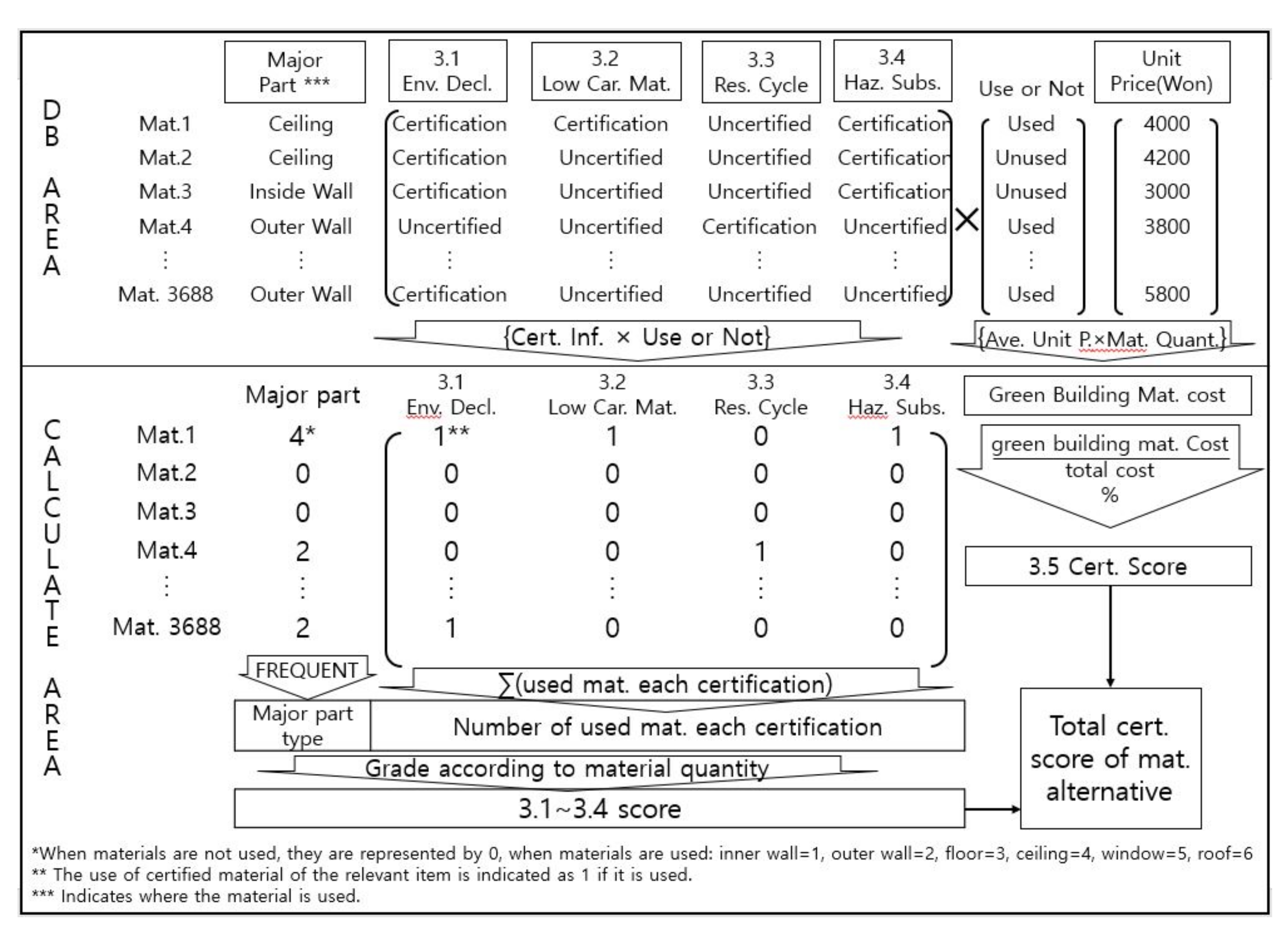

3.3. Class Estimation Process and Material Selection

3.3.1. Class Estimation Process

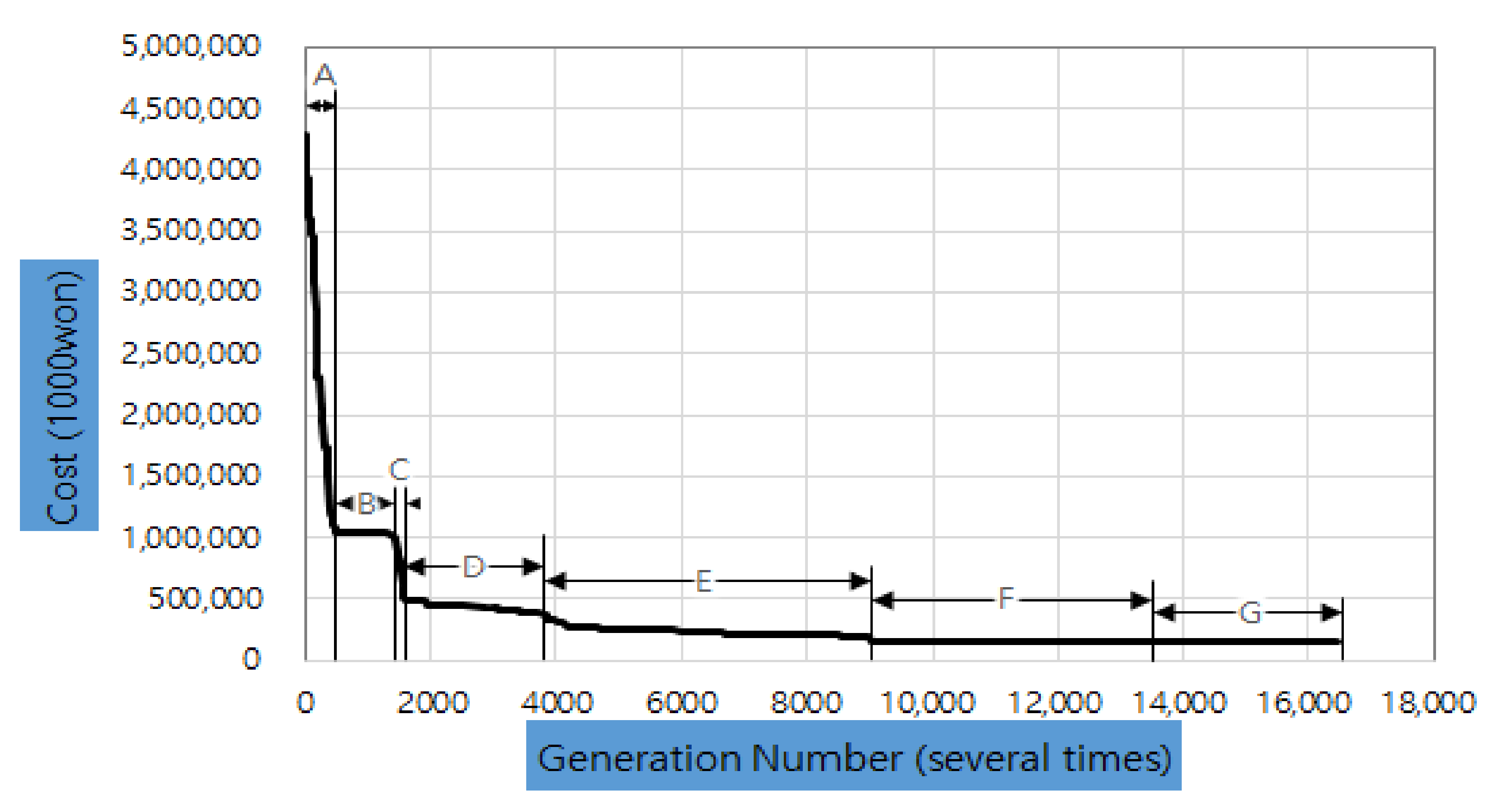

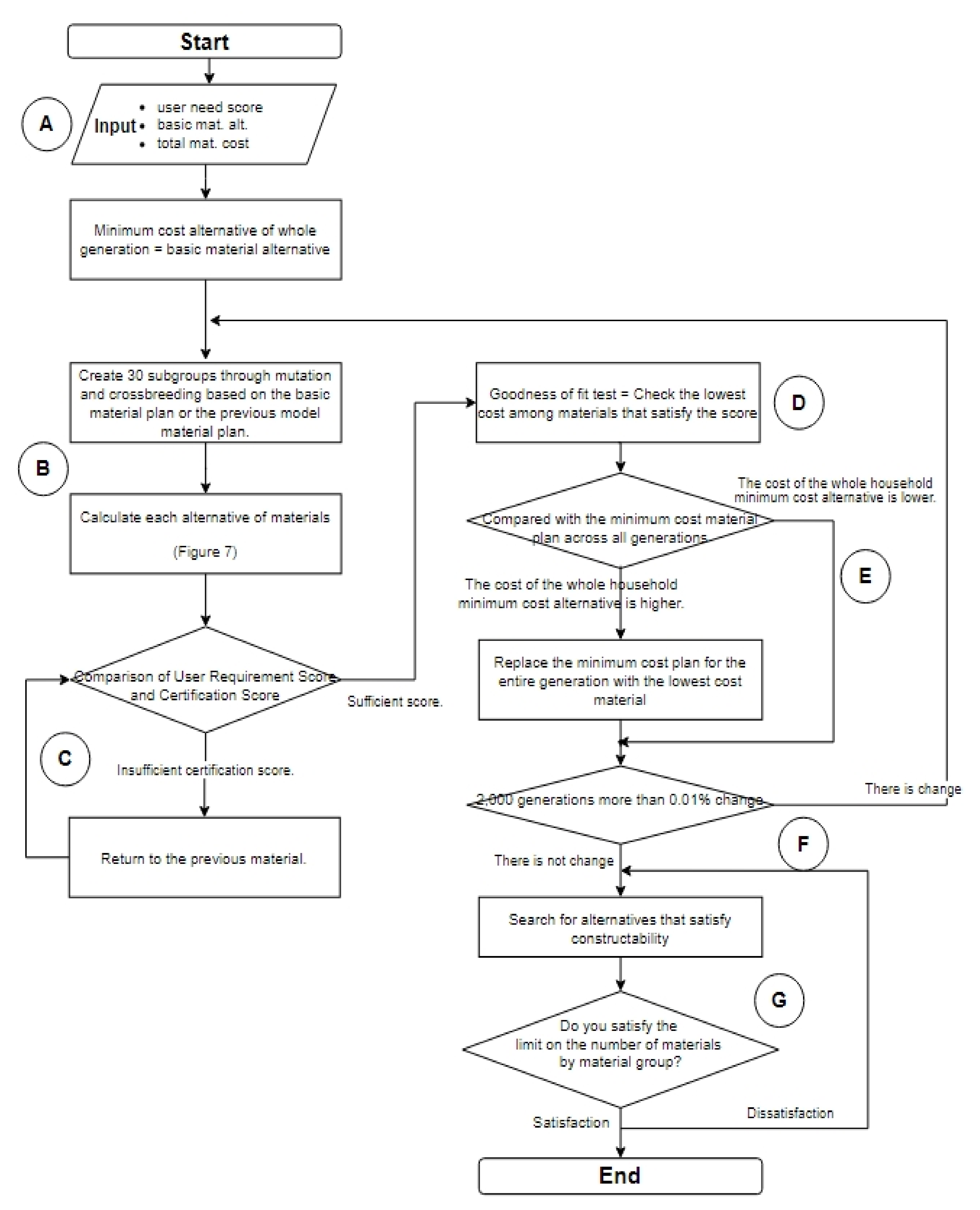

3.3.2. Designing the GA

3.4. Material Selection Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cho, S.H.; Seo, S.M.; Chae, C.W. A Study on the Improvement of G-SEED considering Life Cycle Assessment. Korean Soc. Life Cycle Assess. 2016, 17, 47–57. [Google Scholar]

- Cho, S.W.; Lee, J.H. A Research on the Certification Characteristics according to the Change of G-SEED Certification Criteria. J. Reg. Assoc. Archit. Inst. Korea 2017, 19, 103–112. [Google Scholar]

- Cho, D.W.; Kim, S.A.; Yang, K.S.; Chae, C.U.; Hwang, U.K.; Yoon, Y.S.; Rhyu, K.H.; Kim, S.S.; Chang, D.H.; Kim, D.H.; et al. A Study on Improving Green Building Certification Program and Activate Certification System; Korea Institute of Technology: Seoul, Korea, 2009. [Google Scholar]

- Choi, H.M. A Study on Performance Comparison of Various Genetic Algorithms to Solve the Graph Coloring Problem. Master’s Thesis, Hanlim University, Chuncheon, Korea, 1997. [Google Scholar]

- Ji, H.G.; Hong, S.J.; Kim, Y.R. Consideration for Improvement of G-SEED Existing Building Certification by LEED Certification. J. Archit. Inst. Korea 2018, 38, 723–725. [Google Scholar]

- Jung, D.H.; Jung, C.W. A Comparative Study on Domestic and International Evaluation Criteria of Commissioning for Sustainable Building Certification. Korean J. Constr. Eng. Manag. 2017, 18, 27–36. [Google Scholar]

- Jang, H.S.; Lee, S.W. A Comparison Study on the Importance and Problems of Assessment Items of the G-SEED System. Korea Inst. Ecol. Archit. Environ. 2012, 14, 113–120. [Google Scholar]

- Lee, T.K. A Study on the Improvement of the Green Building Certification System in Korea. Master’s Thesis, Andong University, Andong, Korea, 2013. [Google Scholar]

- Hyun, E.M.; Lee, J.E.; Ahn, K.H. A Study on Improvement Direction of G-SEED for Existing Buildings. J. Archit. Inst. Korea Struct. Constr. 2011, 34, 59–67. [Google Scholar]

- Lee, S.H. Apartment G-SEED after Authentication Comparative Study on the Acquisition Rate by Evaluation Items. Master’s Thesis, University of Seoul, Seoul, Korea, 2017. [Google Scholar]

- Kim, Y.K. An Analysis on the Life Cycle Cost for Design Alternatives for Green Structural Elements, Focusing on Apartments. Master’s Thesis, University of Seoul, Seoul, Korea, 2011. [Google Scholar]

- Kim, M.Y.; Kim, H.G. Analysis of Construction Cost of Energy Performance by Apartment Size according to Seoul Green Building Design Guide and G-SEED. Korean Inst. Arch. Sustain. Environ. Build. Syst. J. 2018, 12, 1–14. [Google Scholar]

- Rho, M.S. A Study on the Development of Design Support System Prototype for the Evaluation of G-SEED (Green Standard for Energy and Environmental Design) Based on BIM. Master’s Thesis, Hanyang University, Seoul, Korea, 2013. [Google Scholar]

- Suzer, O. Analyzing the compliance and correlation of LEED and BREEAM by conducting a criteria-based comparative analysis and evaluating dual-certified projects. Build. Environ. 2019, 147, 158–170. [Google Scholar] [CrossRef]

- Akcay, E.C.; Arditi, D. Desired points at minimum cost in the “Optimize Energy Performance” credit of leed certification. J. Civ. Eng. Manag. 2017, 23, 796–805. [Google Scholar] [CrossRef]

- Azhara, S.; Carlton, W.A.; Olsen, D.; Ahmad, I. Building information modeling for sustainable design and LEED® rating analysis. Autom. Constr. 2011, 20, 217–224. [Google Scholar] [CrossRef]

- Ansah, M.K.; Chen, X.; Yang, H.; Lu, L.; Lam, P.T.I. A review and outlook for integrated BIM application in green building assessment. Sustain. Cities Soc. 2019, 48, 101576. [Google Scholar] [CrossRef]

- Scofield, J.H. Efficacy of LEED-certification in reducing energy consumption and greenhouse gas emission for large New York City office buildings. Energy Build. 2013, 67, 517–524. [Google Scholar] [CrossRef]

- Matisoff, D.C.; Noonan, D.S.; Mazzolini, A.M. Performance or marketing benefits? The case of LEED certification. Environ. Sci. Technol. 2014, 48, 2001–2007. [Google Scholar] [CrossRef] [PubMed]

- Taemthong, W.; Chaisaard, N. An analysis of green building costs using a minimum cost concept. J. Green Build. 2019, 14, 53–78. [Google Scholar] [CrossRef]

- Uğur, L.O.; Leblebici, N. An examination of the LEED green building certification system in terms of construction costs. Renew. Sustain. Energy Rev. 2018, 81, 1476–1483. [Google Scholar] [CrossRef]

- Pham, A.D.; Nguyen, Q.T.; Luong, D.L.; Truong, Q.C. The Development of a Decision Support Model for Eco-Friendly Material Selection in Vietnam. Sustainability 2020, 12, 2769. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelhamid, M.; Elsheikh, M. Selecting sustainable building materials using system dynamics and ant colony optimization. J. Environ. Eng. Landsc. Manag. 2013, 21, 237–247. [Google Scholar] [CrossRef]

- Castro-Lacouture, D.; Sefair, J.A.; Flórez, L.; Medagila, A.L. Optimization model for the selection of materials using a LEED-based green building rating system in Colombia. Build. Environ. 2009, 44, 1162–1170. [Google Scholar] [CrossRef]

- Korea Institute of Civil Engineering and Technology (KICT). G-SEED Interpretation v1.0; Korea Research Institute of Eco-Environmental Architecture: Seoul, Korea, 2016. [Google Scholar]

| Division | Best | Excellent | Super | Normal | |

|---|---|---|---|---|---|

| New Building | Residential | Over 74 points | Over 66 points | Over 58 points | Over 50 points |

| Detached House | Over 74 points | Over 66 points | Over 58 points | Over 50 points | |

| Non-Residential | Over 80 points | Over 70 points | Over 60 points | Over 50 points | |

| Existing | Residential | Over 69 points | Over 61 points | Over 53 points | Over 45 points |

| Non-Residential | Over 75 points | Over 65 points | Over 55 points | Over 45 points | |

| Green Remodeling | Residential | Over 69 points | Over 61 points | Over 53 points | Over 45 points |

| Non-Residential | Over 75 points | Over 65 points | Over 55 points | Over 45 points | |

| Certification Article | Evaluation Criteria | Points |

|---|---|---|

| 3.1 Using Environmental Product Declaration (EPD) Products | When using more than six kinds of environmental declaration products from more than four kinds of main building members | 4 |

| 3.2 Using Low-Carbon Products | Seven or more low-carbon materials | 2 |

| 3.3 Using Recycling Products | 20 or more resource recycling materials | 2 |

| 3.4 Using Hazardous Material Reduction Products | 20 or more hazardous substance reduction materials | 2 |

| 3.5 Rate of Green Building Materials | When the rate of applying green building materials is more than 7% of the construction cost | 4 |

| Data Name | Certification Content | Issuer |

|---|---|---|

| Environmental Mark Certification Products | Global Environmental Pollution Reduction, Local Environmental Pollution Reduction, Hazardous Substance Reduction, Recycling Effective Resources, Improving Resource Circulation | Environmental Industry and Technology Institute |

| Eco-friendly Construction Material Information | Material Unit Cost | Environmental Industry and Technology Institute |

| Environmental Declaration Production Information | Environmental Label, Water Footprint, Carbon Footprint, Low-Carbon Products | Ministry of Environment |

| Product Category | Material No. |

|---|---|

| Paint (kg) | 726 |

| Wallpaper (m2) | 78 |

| Insulation board (m2) | 218 |

| Waterproofing material (m2) | 67 |

| Flooring (m2) | 337 |

| Floor panels for heating (m2) | 11 |

| Finishing material for wall and ceiling (m2) | 66 |

| Finishing material for the wall (m2) | 201 |

| Finishing material for the ceiling (m2) | 12 |

| Windows (kg) | 882 |

| Windows (m2) | 415 |

| Glue (kg) | 25 |

| OA Floor (m2) | 38 |

| Sealant (L) | 41 |

| Toilet partition (m2) | 287 |

| Deck (m2) | 52 |

| Copper alloy (kg) | 7 |

| Clay tile (EA) | 40 |

| Clay brick (EA) | 185 |

| Total | 3688 |

| Division | Evaluation Criteria | Points |

|---|---|---|

| 1st Grade | When using more than nine kinds of environmental declaration products from more than four kinds of main building member * | 4 |

| 2nd Grade | When using more than seven kinds of environmental declaration products from more than three kinds of main building member | 3.2 |

| 3rd Grade | When using more than five kinds of environmental declaration products from more than two kinds of main building member | 2.4 |

| 4th Grade | When using more than three kinds of environmental declaration products from more than one kind of main building member | 1.6 |

| Generation Number | 9000 | 10,000 | 11,000 | 12,000 | 13,000 | 13,545 |

| Initial Cost (1000 Won) | 158,225 | 153,763 | 150,024 | 147,643 | 147,550 | 147,549 |

| Reduce Amount (1000 Won) | - | 4462 | 3739 | 2381 | 93 | 1 |

| Reduction Rate (%) | - | 2.8% | 2.4% | 1.6% | 0.06% | 0.001% |

| Division | Case A | Case B | Case C | Case D | ||||

|---|---|---|---|---|---|---|---|---|

| Reduction Rate * (%) | Material No. | Reduction Rate * (%) | Material No. | Reduction Rate * (%) | Material No. | Reduction Rate * (%) | Material No. | |

| Restrict the number of materials per certification item | 84 | 693 | 22 | 1021 | 1 | 330 | 41 | 1,041 |

| Division | Certification Contents | |||

|---|---|---|---|---|

| 3.1 Using Environmental Product Declaration Products | 3.2 Using Low-Carbon Products | 3.3 Using Recycling Products | 3.4 Using Hazardous Material Reduction Products | |

| Minimum material numbers | 9 | 9 | 25 | 25 |

| Type of material by material group | Insulation board, waterproofing material, wall finishing material, wallpaper flooring, paint, toilet divider, sealing material, glue | |||

| Division | Case A | Case B | Case C | Case D | |||||

|---|---|---|---|---|---|---|---|---|---|

| Reduce Rate * (%) | Material No. | Reduce Rate * (%) | Material No. | Reduce Rate * (%) | Material No. | Reduce Rate * (%) | Material No. | ||

| (1) | Restrict the number of materials per certification item | −39 | 33 | −9 | 38 | −1 | 47 | 17 | 49 |

| (2) | Restrict the number of materials by material group | 82 | 49 | 22 | 40 | 1 | 40 | 41 | 50 |

| (3) | Restrict the total number of materials | 82 | 40 | 22 | 70 | 1 | 80 | 41 | 60 |

| Case | Real Data | Unrestricted Model | Restricted Model by Material Group | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material Cost (1000 won) (A) | Required Point | Material Cost (1000 won) (B) | Reduction Rate (A − B)/A × 100 | Earned Point | Using Material Number | Material Cost (1000 won) (C) | Reduction Rate (A − C)/A × 100 | Earned Point | Using Material Number | |

| A | 780,223 | 8 | 124,217 | 84% | 8.4 | 693 | 141,093 | 82% | 8 | 49 |

| B | 879,497 | 12 | 686,053 | 22% | 12.4 | 1021 | 686,040 | 22% | 12.4 | 40 |

| C | 676,078 | 10.4 | 671,047 | 1% | 10.4 | 330 | 671,155 | 1% | 10.4 | 40 |

| D | 1,230,458 | 14 | 731,825 | 41% | 14 | 1041 | 731,837 | 41% | 14 | 50 |

| Total | 3,566,256 | 2,230,125 | 37.5% | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, B.-J.; Kim, B.-S. Development of Material Combination Model Considering Economics and Construction Efficiency for G-SEED Certification. Sustainability 2021, 13, 3535. https://doi.org/10.3390/su13063535

Jeon B-J, Kim B-S. Development of Material Combination Model Considering Economics and Construction Efficiency for G-SEED Certification. Sustainability. 2021; 13(6):3535. https://doi.org/10.3390/su13063535

Chicago/Turabian StyleJeon, Byung-Ju, and Byung-Soo Kim. 2021. "Development of Material Combination Model Considering Economics and Construction Efficiency for G-SEED Certification" Sustainability 13, no. 6: 3535. https://doi.org/10.3390/su13063535

APA StyleJeon, B.-J., & Kim, B.-S. (2021). Development of Material Combination Model Considering Economics and Construction Efficiency for G-SEED Certification. Sustainability, 13(6), 3535. https://doi.org/10.3390/su13063535