Laboratory Evaluation on Performance of Recycled Asphalt Binder and Mixtures under Short-Term Aging Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Recycled Blends

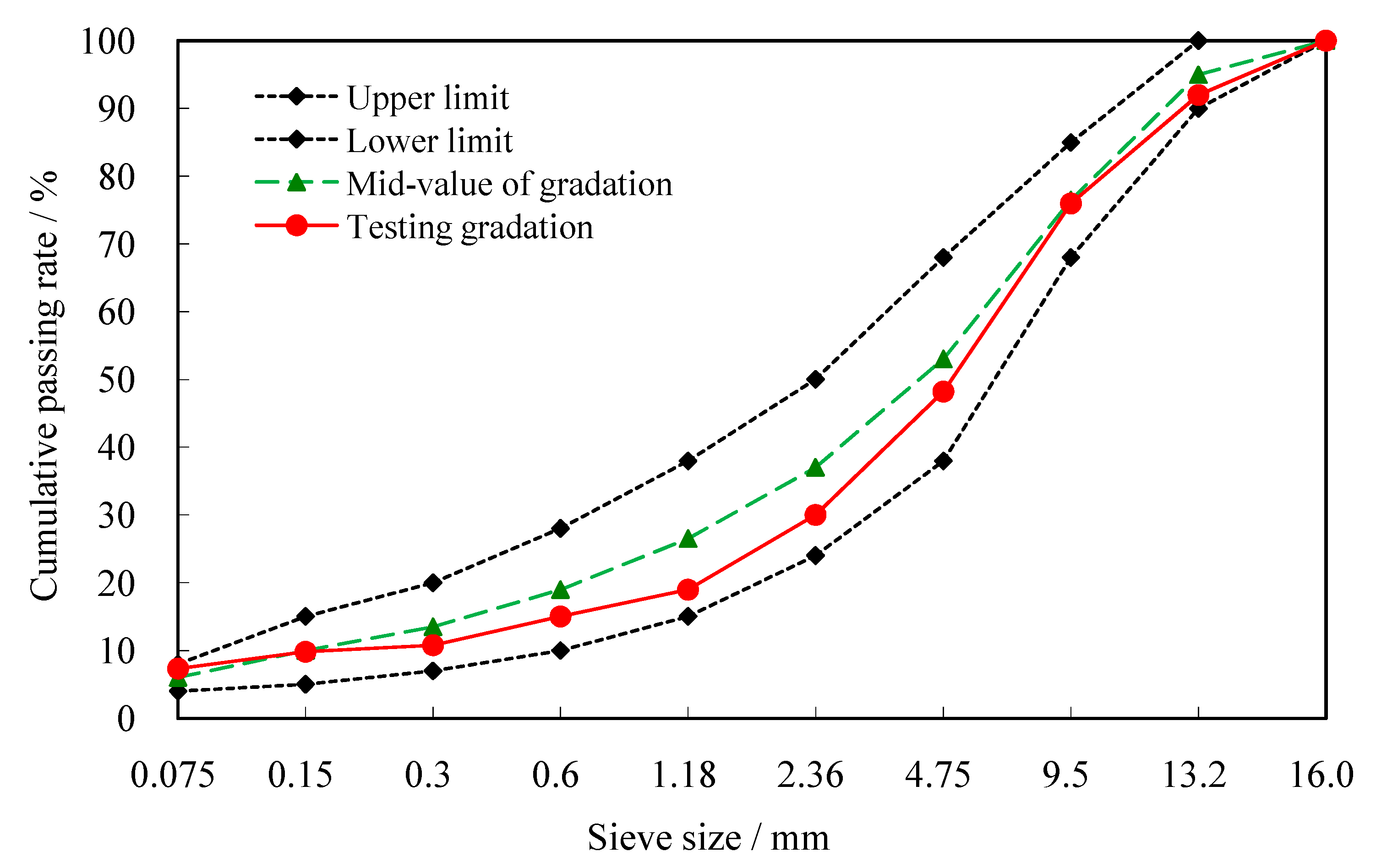

2.1.2. Mixture Gradation and Optimal Asphalt Content

2.2. Testing method

2.2.1. Binder Testing and Analysis

- 1.

- ΔTcr

- 2.

- Complex modulus master curve

- 3.

- G-R parameter

2.2.2. Mixture Testing and Analysis

- Complex modulus

- 2.

- DCT test

- 3.

- Fatigue test

3. Results and Discussion

3.1. Binder Testing

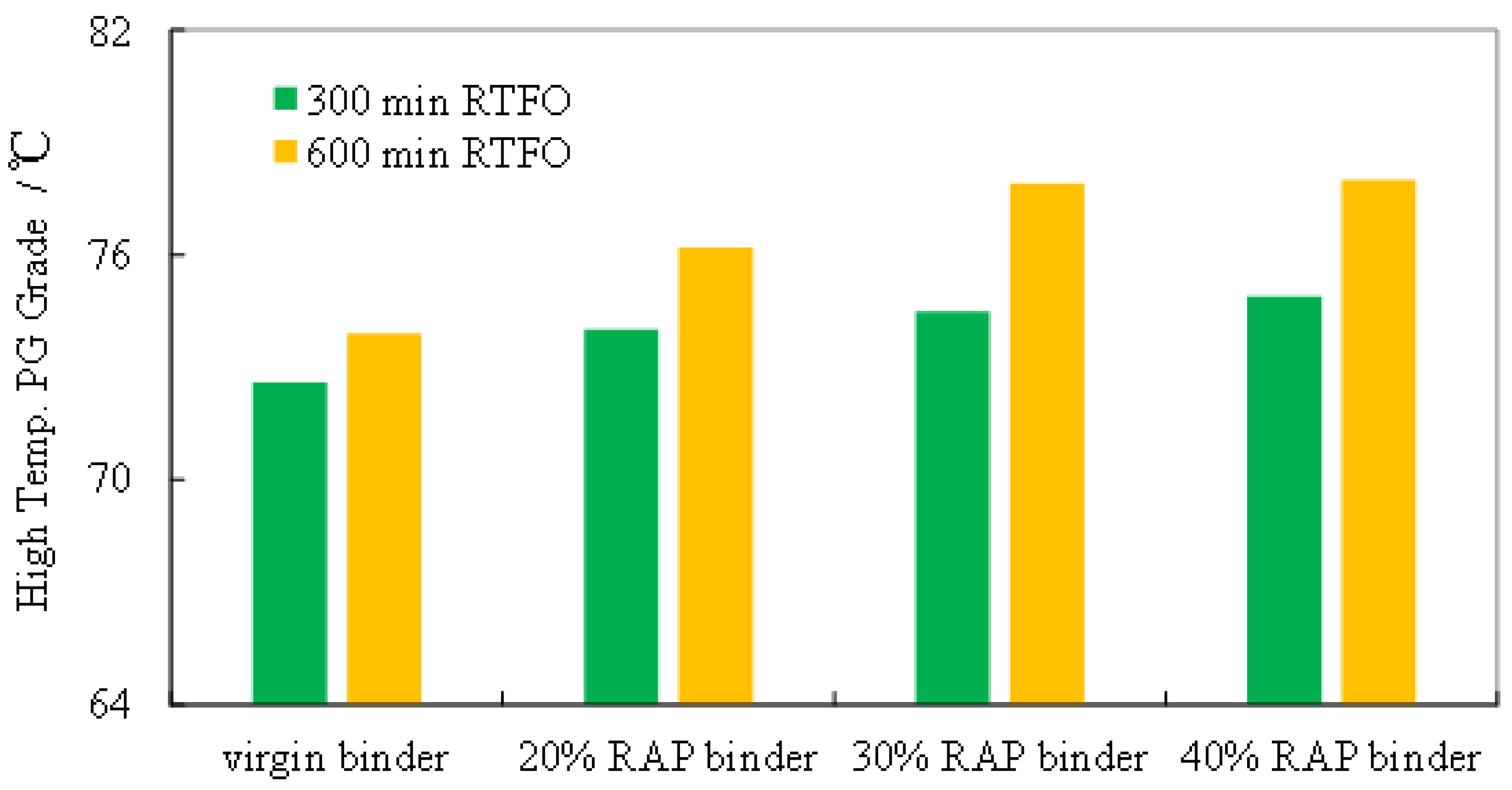

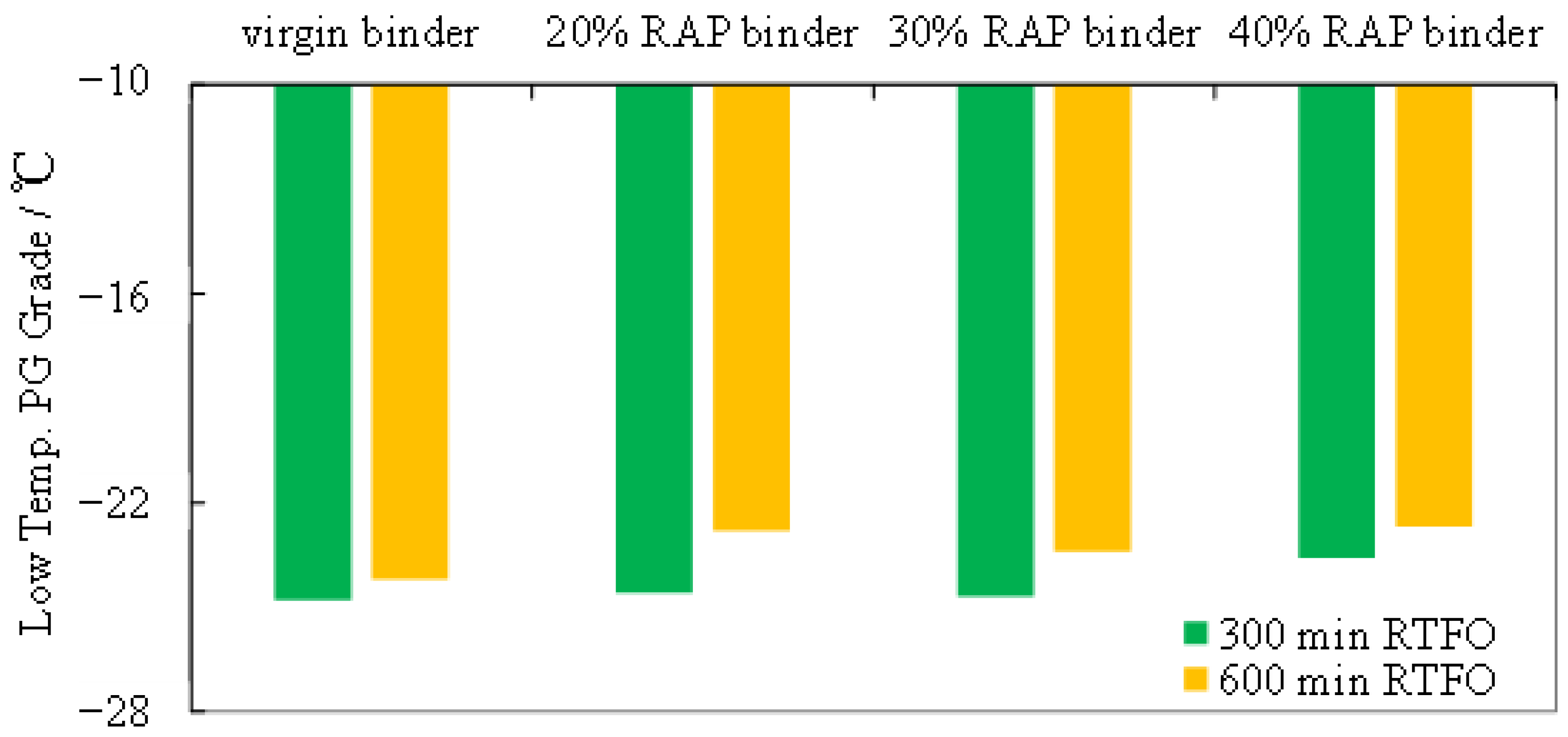

3.1.1. Performance Grading and ΔTcr

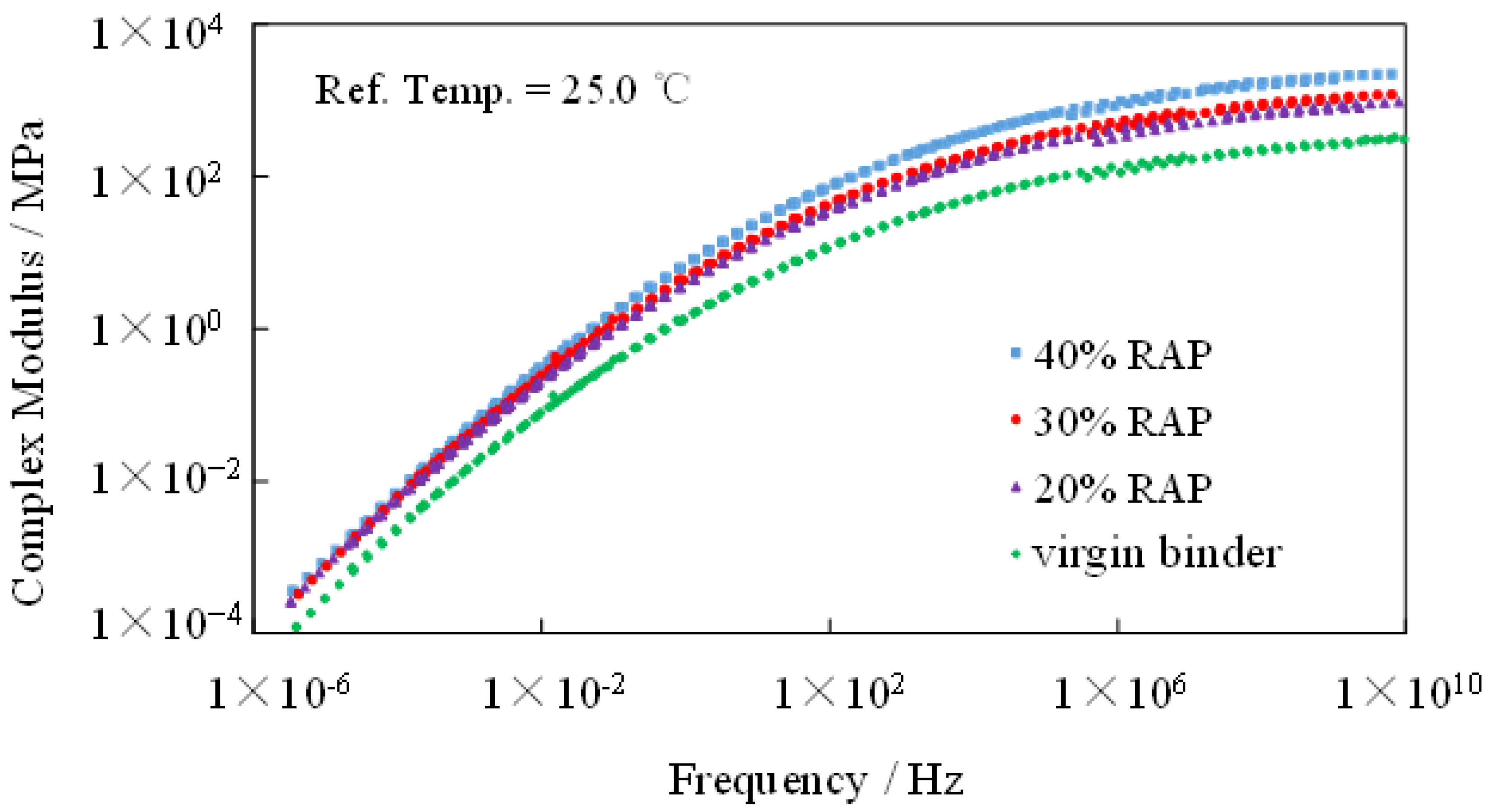

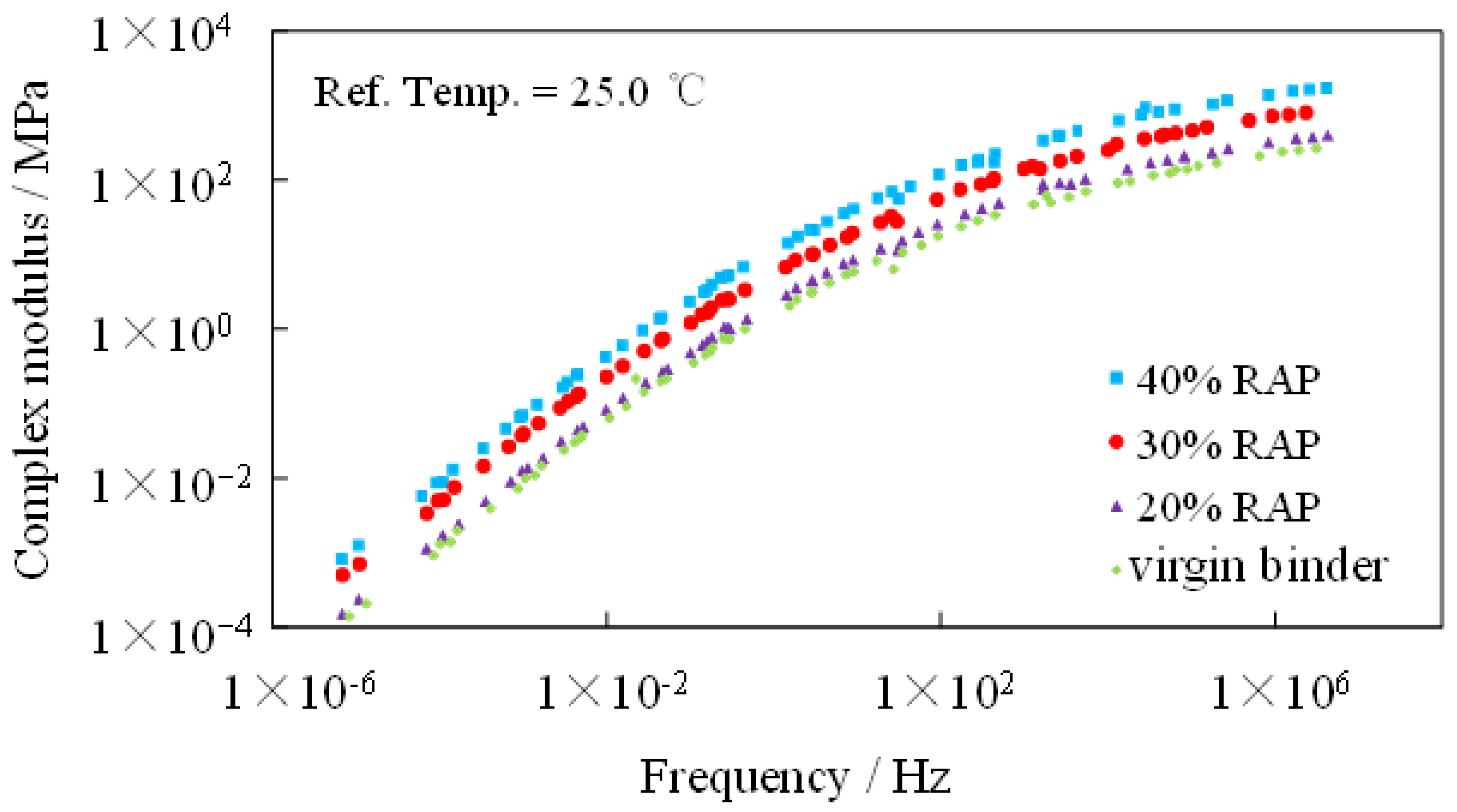

3.1.2. Complex Modulus

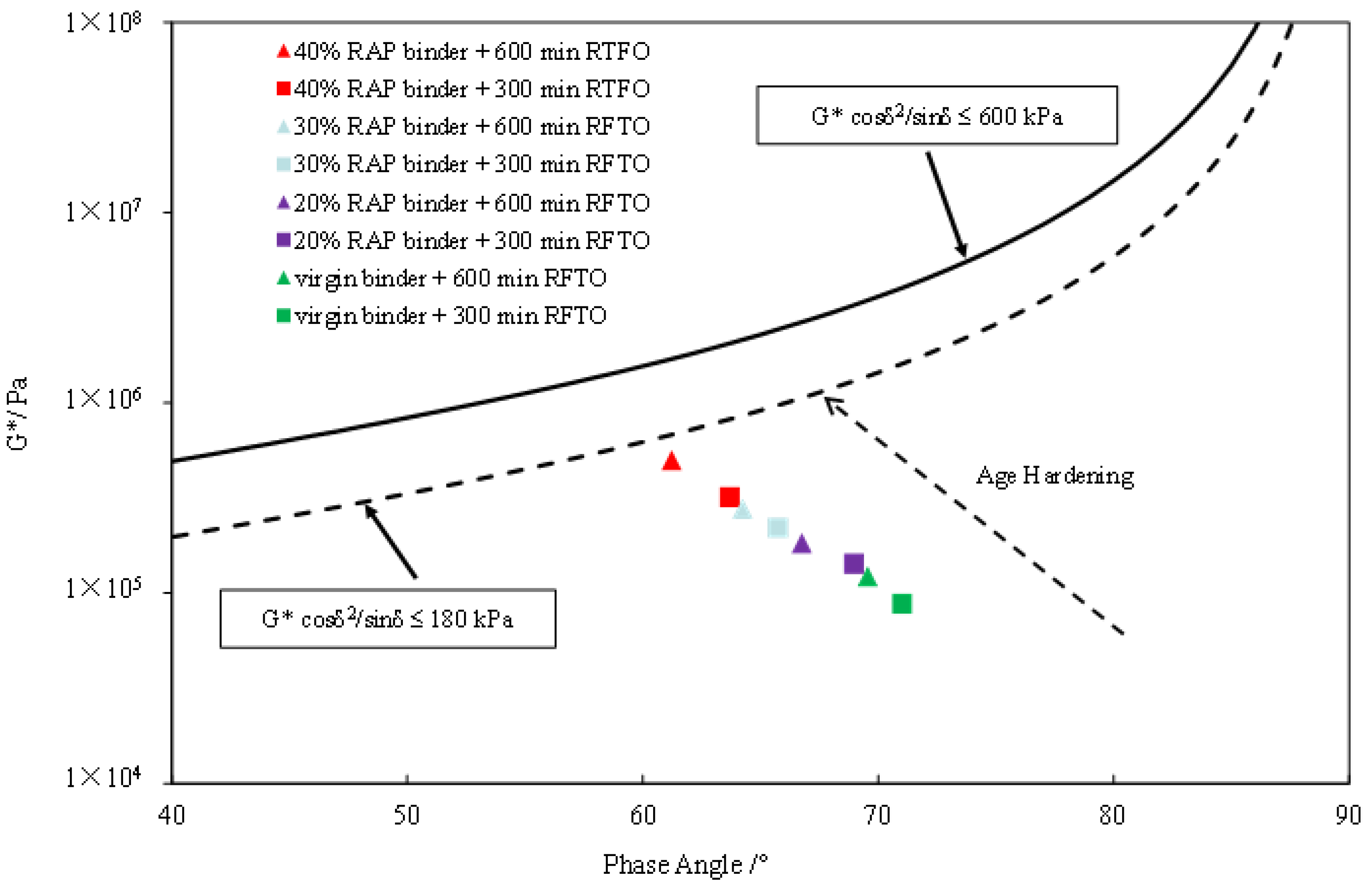

3.1.3. G-R Parameter and Rheological Indices

3.2. Mixture Testing

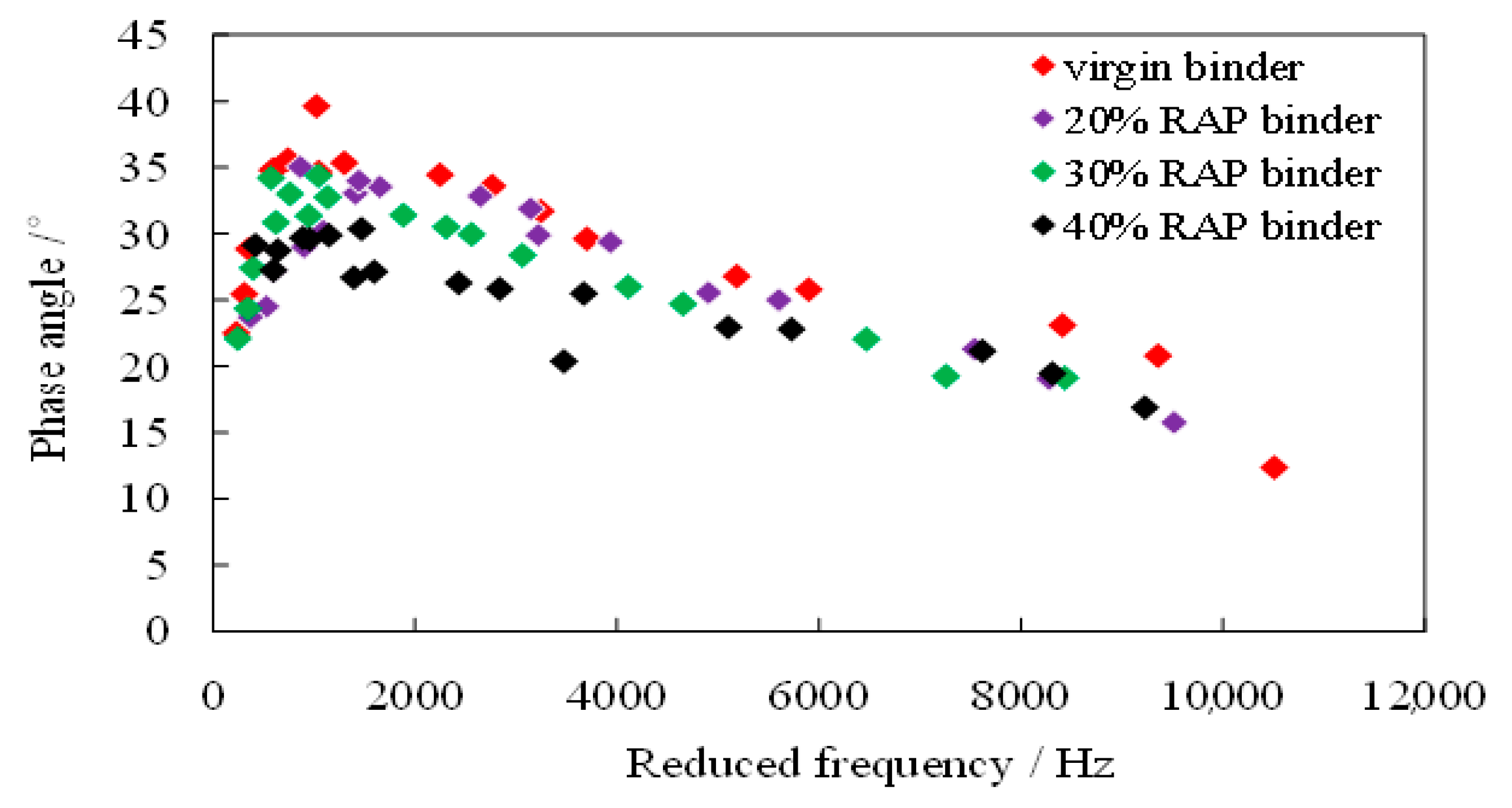

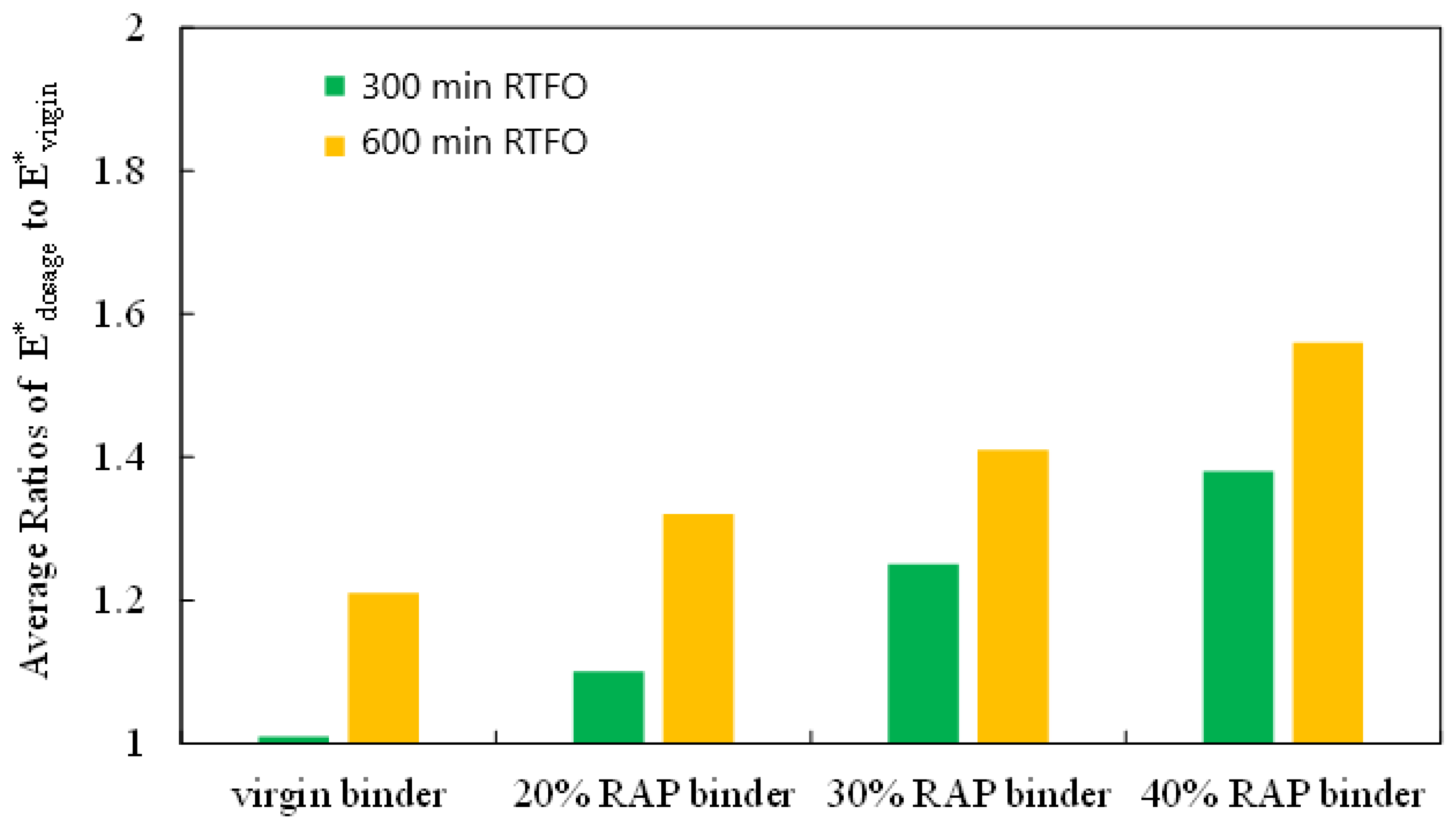

3.2.1. Dynamic Modulus and Phase Angle

3.2.2. Low Temperature Cracking

3.2.3. Fatigue Behavior

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giani, M.I.; Dotelli, G.; Brandini, N.; Zampori, L. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. [Google Scholar] [CrossRef]

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Yang, R.; Ozer, H.; Kang, S.; Al-Qadi, I.L. Environmental Impacts of Producing Asphalt Mixtures with Varying Degrees of Recycled Asphalt Materials. In Proceedings of the International Symposium on Pavement LCA, Davis, CA, USA, 14–16 October 2014. [Google Scholar]

- Del Ponte, K.; Natarajan, B.M.; Ahlman, A.P.; Baker, A.; Elliott, E.; Edil, T.B. Life-Cycle Benefits of Recycled Material in Highway Construction. Transp. Res. Rec. J. Transp. Res. Board 2017, 2628, 1–11. [Google Scholar] [CrossRef]

- Daryaee, D.; Ameri, M.; Mansourkhaki, A. Utilizing of waste polymer modified bitumen in combination with rejuvenator in high reclaimed asphalt pavement mixtures. Constr. Build. Mater. 2020, 235, 117516. [Google Scholar] [CrossRef]

- El-Shorbagy, A.M.; El-Badawy, S.M.; Gabr, A.R. Investigation of waste oils as rejuvenators of aged bitumen for sustainable pavement. Constr. Build. Mater. 2019, 220, 228–237. [Google Scholar] [CrossRef]

- Woszuk, A.; Wróbel, M.; Franus, W. Influence of Waste Engine Oil Addition on the Properties of Zeolite-Foamed Asphalt. Materials 2019, 12, 2265. [Google Scholar] [CrossRef] [PubMed]

- Dinis-Almeida, M.; Castro-Gomes, J.; Sangiorgi, C.; Zoorob, S.E.; Afonso, M.L. Performance of Warm Mix Recycled Asphalt containing up to 100% RAP. Constr. Build. Mater. 2016, 112, 1–6. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Moon, K.H.; Falchetto, A.C.; Wang, D.; Wistuba, M.P.; Tebaldi, G. Low-temperature performance of recycled asphalt mixtures under static and oscillatory loading. Road Mater. Pavement Des. 2016, 18, 297–314. [Google Scholar] [CrossRef]

- Daniel, J.S.; Gibson, N.; Tarbox, S.; Copeland, A.; Andriescu, A. Effect of long-term ageing on RAP mixtures: Laboratory evaluation of plant-produced mixtures. Road Mater. Pavement Des. 2013, 14, 173–192. [Google Scholar] [CrossRef]

- Tarbox, S.; Daniel, J.S. Effects of Long-Term Oven Aging on Reclaimed Asphalt Pavement Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2012, 2294, 1–15. [Google Scholar] [CrossRef]

- Qiao, Y.; Dave, E.; Parry, T.; Valle, O.; Mi, L.; Ni, G.; Yuan, Z.; Zhu, Y. Life Cycle Costs Analysis of Reclaimed Asphalt Pavement (RAP) Under Future Climate. Sustain. J. Rec. 2019, 11, 5414. [Google Scholar] [CrossRef]

- Kriz, P.; Grant, D.L.; Veloza, B.A.; Gale, M.J.; Blahey, A.G.; Brownie, J.H.; Shirts, R.D.; Maccarrone, S. Blending and diffusion of reclaimed asphalt pavement and virgin asphalt binders. Road Mater. Pavement Des. 2014, 15, 78–112. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M. Quantitative Characterization of Binder Blending: How Much RAP/RAS Binder is Mobilized During Mixing. Transp. Res. Rec. J. Transp. Res. Board 2015, 2506, 72–80. [Google Scholar] [CrossRef]

- Howard, I.; Baumgardner, G.; Jordan, W., III; Menapace, A.; Mogawer, W.; Hemsley, J. Haul Time Effects on Unmodified, Foamed, and Additive-Modified Binders Used in Hot-Mix Asphalt. Transp. Res. Rec. J. Transp. Res. Board 2013, 2347, 88–95. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG F40-2004 Technical Specification for Construction of Highway Asphalt Pavements; Ministry of Transport of the People’s Republic of China Press: Beijing, China, 2004.

- Anderson, M.; King, G.; Hanson, D.; Blankenship, P. Evaluation of the Relationship between Asphalt Binder Properties and Non-Load Related Cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 615–661. [Google Scholar]

- Rowe, G.M. Prepared Discussion for the AAPT paper by Anderson, King, Hanson and Blankesnship: Evaluation of the Relationship between Asphalt Binder Properties and Non-Load Related Cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 649–662. [Google Scholar]

- Glover, C.; Davison, R.; Domke, C.; Ruan, Y.; Juristyarini, P.; Knorr, D.; Jung, S. Development of a New Method for Assessing Asphalt Binder Durability with Field Evaluation; National Research Council: Washington, DC, USA, 2005.

- American Association of State Highway and Transportation Officials. Standard Method of Test for Determining the Dynamic Modulus and Flow Number for Hot-Mix Asphalt (HMA) Using the Asphalt Mixture Performance Tester (AMPT); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015. [Google Scholar]

- Al-Qadi, I.; Ozer, H.; Lambros, J.; Khatib, A.; Singhvi, P.; Khan, T.; Rivera, J.; Doll, B. Testing Protocols to Ensure Performance of High Asphalt Binder Replacement Mixes Using RAP and RAS; Report Number FHWA-ICT-15-017; Illinois Center for Transportation: Rantoul, IL, USA, 2015.

- Zhu, Y.; Dave, E.V.; Rahbar-Rastegar, R.; Daniel, J.S.; Zofka, A. Comprehensive evaluation of low-temperature fracture indices for asphalt mixtures. Road Mater. Pavement Des. 2017, 18, 467–490. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG E20-2011 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; Ministry of Transport of the People’s Republic of China Press: Beijing, China, 2011.

- Zhu, Y.; Rahbar-Rastegar, R.; Li, Y.; Qiao, Y.; Si, C. Exploring the Possibility of Using Ionic Copolymer Poly (Ethylene-co-Methacrylic) Acid as Modifier and Self-Healing Agent in Asphalt Binder and Mixture. Appl. Sci. 2020, 10, 426. [Google Scholar] [CrossRef]

- Airey, G.D. Styrene butadiene styrene polymer modification of road bitumens. J. Mater. Sci. 2004, 39, 951–959. [Google Scholar] [CrossRef]

- Rek, V.; Vranjes, N.; Barjaktarovic, Z.M. Relationship between Fractal, Viscoelastic, and Aging Properties of Linear and Radial Styrene–Butadiene–styrene polymer-modified bitumen. Mater. Res. Innov. 2005, 9, 670–691. [Google Scholar]

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

| Test Properties | Results |

|---|---|

| Viscosity (60 °C)/cSt | 320 |

| Flash point/°C | >220 |

| Saturation content/% | 14.7 |

| Aromatic content/% | 56.4 |

| Surface tension (25 °C)/10 cm−3 Nm−1 | 52.2 |

| Viscosity ratio before and after RTFO | 1.8 |

| Mass change before and after RTFO/% | 2.1 |

| Density (15 °C)/(g·cm−3) | 0.935 |

| Binder Type | High Temp. | Inter. Temp. | Low Temp. | PG Grade | ||

|---|---|---|---|---|---|---|

| Origin | RTFO | PAV (20 h) | ||||

| S/MPa | m-Slope | |||||

| SBS modified asphalt | 78.5 | 72.6 | 20.6 | −26.9 | −28.6 | 70–22 |

| RAP | 85.2 | -- | 22.8 | −21.2 | −15.8 | 82–16 |

| Binder Type | High Temp. | Inter. Temp. | Low Temp. | PG Grade | ||

|---|---|---|---|---|---|---|

| Origin | RTFO | PAV (20 h) | ||||

| S/MPa | m-Slope | |||||

| SBS modified asphalt | 78.5 | 72.6 | 20.6 | −26.9 | −28.6 | 70–22 |

| 20% RAP binder + 4% recycling agent + SBS modified asphalt | 77.6 | 74 | 20.7 | −27.9 | −26.2 | 70–22 |

| 30% RAP binder + 4% recycling agent + SBS modified asphalt | 77.8 | 74.5 | 21.3 | −26.9 | −24.6 | 70–22 |

| 40% RAP binder + 4% recycling agent + SBS modified asphalt | 76.6 | 74.3 | 24.3 | −25.3 | −22.0 | 70–22 |

| Test Properties | Results | Requirement | |

|---|---|---|---|

| Coarse aggregate | Crushed value/% | 11.8 | ≤26 |

| Los Angeles wear value/% | 10.6 | ≤28 | |

| Polished stone value/PSV | 43 | ≥42 | |

| Fine aggregate | Apparent relative density | 2.679 | ≥2.50 |

| Angularity/s | 42.7 | ≥30 | |

| Filler | Apparent density/(g·cm−3) | 2.761 | ≥2.50 |

| Water content/% | 0.4 | ≤1 | |

| Binder Type | Asphalt-Aggregate Ratio/% | Air Void/% | VFA/% | VMA/% | Stability/kN | Flow/0.1 mm |

|---|---|---|---|---|---|---|

| Virgin binder | 4.46 | 4.0 | 70.3 | 13.70 | 11.75 | 34.5 |

| 20% RAP binder | 4.68 | 4.0 | 71.3 | 13.45 | 12.11 | 32.6 |

| 30% RAP binder | 4.63 | 4.0 | 70.4 | 13.68 | 12.03 | 31.2 |

| 40% RAP binder | 4.60 | 4.0 | 71.5 | 13.53 | 12.25 | 33.7 |

| Binder Type | Stress Ratio | ||

|---|---|---|---|

| 0.2 | 0.3 | 0.4 | |

| virgin binder | 38,019 | 13,680 | 5248 |

| 20% RAP binder | 32,810 | 12,023 | 4285 |

| 30% RAP binder | 23,442 | 10,214 | 3540 |

| 40% RAP binder | 19,953 | 8810 | 3589 |

| Binder Type | Stress Ratio | ||

|---|---|---|---|

| 0.2 | 0.3 | 0.4 | |

| virgin binder | 30,200 | 12,071 | 4387 |

| 20% RAP binder | 25,119 | 10,256 | 3790 |

| 30% RAP binder | 14,125 | 6026 | 2584 |

| 40% RAP binder | 19,498 | 7586 | 3080 |

| Binder Type | Regression Equation | Aging Time/Minutes |

|---|---|---|

| virgin binder | lg Nf = 5.4354 − 4.300 σr | 300 |

| 20% RAP binder | lg Nf = 5.4020 − 4.420 σr | |

| 30% RAP binder | lg Nf = 5.2078 − 4.105 σr | |

| 40% RAP binder | lg Nf = 5.0508 − 3.725 σr | |

| virgin binder | lg Nf = 5.3241 − 4.1892 σr | 600 |

| 20% RAP binder | lg Nf = 5.2283 − 4.1068 σr | |

| 30% RAP binder | lg Nf = 4.8873 − 3.6885 σr | |

| 40% RAP binder | lg Nf = 5.0884 −4.0072 σr |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Zhang, J.; Si, C.; Yan, T.; Li, Y. Laboratory Evaluation on Performance of Recycled Asphalt Binder and Mixtures under Short-Term Aging Conditions. Sustainability 2021, 13, 3404. https://doi.org/10.3390/su13063404

Zhu Y, Zhang J, Si C, Yan T, Li Y. Laboratory Evaluation on Performance of Recycled Asphalt Binder and Mixtures under Short-Term Aging Conditions. Sustainability. 2021; 13(6):3404. https://doi.org/10.3390/su13063404

Chicago/Turabian StyleZhu, Yuefeng, Jiawei Zhang, Chundi Si, Tao Yan, and Yanwei Li. 2021. "Laboratory Evaluation on Performance of Recycled Asphalt Binder and Mixtures under Short-Term Aging Conditions" Sustainability 13, no. 6: 3404. https://doi.org/10.3390/su13063404

APA StyleZhu, Y., Zhang, J., Si, C., Yan, T., & Li, Y. (2021). Laboratory Evaluation on Performance of Recycled Asphalt Binder and Mixtures under Short-Term Aging Conditions. Sustainability, 13(6), 3404. https://doi.org/10.3390/su13063404