1. Introduction

The building sector is one of the major contributors to global climate change, producing approximately 33–39% of all global greenhouse gas emissions [

1,

2]. Due to the high percentage of global emissions stemming from the building sector and the ever-growing demand for residential and commercial buildings, much research has been conducted to investigate the environmental impacts of different building materials. Investigating the energy consumption and emissions of buildings throughout their useful life is completed using the life-cycle assessment (LCA) method [

3]. A life-cycle assessment can greatly help in increasing the sustainability of a building project by providing information on how different materials, or processes, contribute to the overall environmental impact of the building. Life-cycle energy consumption can be split broadly into two categories of embodied energy and operational energy. The embodied energy is the energy consumed during the building’s production [

4]. Operational energy is the energy used to fulfill the building’s function.

The operational phase is often greater than the building production phase over long time periods. In a study conducted by Kahhat et al. (2009), it was found that the energy consumed during the use phase of residential buildings would frequently exceed the total energy consumed during construction after 3–4 years of operation [

5]. Iyer–Raniga and Wong (2012) investigated the environmental impact of eight heritage buildings in Australia and the use phase was found to consume more than 10 times the energy consumed during the building production phase [

6]. A study conducted by Ochoa et al. (2002) similarly concluded that the use phase was the largest contributor to life-cycle environmental impact through analysis of residential buildings in the United States [

7]. Decades of research have aimed to reduce operational energy use, which has resulted in significant increases in the efficiency of building systems. As the operational energy part of building life-cycle energy becomes more efficient, the importance of the emissions associated with the embodied energy part, such as material production, transportation, construction, and end-of-life, become more important. Several studies conducted more recently, over the last decade, indicate that embodied energy can account for a large portion of total life-cycle emissions. Ramesh et al. (2010) found that 10–20% of the total energy consumed can be embodied from pre-use stages [

8]. In a study completed by Hafner (2014), it was determined that 20–55% of total CO

2 emissions came from embodied carbon in the building materials [

9]. These previous studies also show that the embodied emissions of buildings are highly influenced by the selection of construction materials and the design choices made.

In the United States, low-rise buildings are commonly constructed using light-gage framing, either wood or cold-formed steel, and mid-rise buildings are traditionally constructed using reinforced concrete and steel. However, the advancements in production and understanding of mass timber in North America coupled with the drive for more sustainable construction, has increased the desire to utilize engineered wood products in both low-rise and mid-rise buildings [

10,

11]. Numerous studies, including those conducted on timber buildings compared to reinforced concrete and steel buildings, have consistently demonstrated that timber materials have benefits in reducing global emissions. A group of studies are reviewed here that are most relevant to the study described and presented in this paper and to provide context for the results reported in

Section 3. Robertson et al. (2012) found that timber structures offer a lower environmental impact in 10 out of 11 assessment categories when compared to reinforced concrete buildings in a cradle-to-gate study [

12]. Pierobon et al. (2019) conducted a cradle-to-gate study of a hybrid mass timber and reinforced concrete alternative compared to a traditional all-concrete design and determined that the hybrid structure had an average of a 26.5% reduction in global warming potential [

11]. Gustavsson et al. (2010) investigated two archetype buildings and found that a concrete alternative embodied 129 kg C/m

2 compared to a wood alternative, which embodied 57 kg C/m

2 when coal was considered as a fossil fuel [

13]. Guggemos and Horvath (2005) found that timber framed buildings have lower CO

2 emissions when compared to steel and concrete buildings [

14]. Most of the previous work focuses on comparing timber buildings to reinforced concrete structures using a cradle-to-gate analysis boundary. Few studies have compared the environmental impact of mass timber buildings to traditional steel framed buildings from cradle to grave.

Peterson and Solberg (2002) is one of the early studies that compared mass timber to steel, using a cradle-to-gate analysis on the effect of substituting glue-laminated timber in place of steel for the main roof beams of Gardermoen airport in Norway. Peterson and Solberg (2002) found that use of glulam beams would save 0.24–0.31 tons of CO

2 equivalents per m

3 of sawn wood used in the glulam production over steel [

15]. However, the Peterson and Solberg (2002) study may not be directly applicable to full buildings located in the United States, where steel production is considerably cleaner in than other parts of the world, as noted by Pomponi and Moncaster (2018) [

16]. A detailed cradle-to-grave LCA analysis of three steel buildings located in China was more recently conducted by Su and Zhang (2016). One of the findings was that there were no significant correlations between the total area of a steel building and the embodied energy of the building (Su and Zhang, 2016). However, as the building height increased so did the embodied energy emissions per unit area, suggesting that as height increased, so too did the relative environmental burden [

4]. The Su and Zhang (2016) study may also not be directly applicable to steel buildings in the United States, where again steel production relies more heavily on recycled scrap steel and lower-emission electric arc furnaces.

There is a lack of research on the environmental impact of steel buildings built in the United States, using North American steel production quantities and average rates of recycling. Further, with the drive towards lower-carbon building construction and the increasing use of mass timber as a building material, there is a lack of understanding in how North American steel buildings would compare to all-wood mass timber alternatives at different building heights. To rectify these gaps in knowledge, this paper aims to increase the understanding of the environmental impacts of all-wood, mass timber buildings compared to a conventionally framed structural steel alternatives from cradle to grave. The LCA method was applied to two archetype buildings, both located in Seattle, Washington, with heights of 5-stories and 12-stories using the Athena Impact Estimator for Buildings (IE4B).

2. Materials and Methods

The two 5-story buildings were designed to represent a typical low-rise office building, while the two 12-story buildings were designed as a typical mid-rise residential building. Each pair of buildings were identical in footprint, floor-to-floor heights, total height, and general floor plan layout but were designed following the practical conventions for each structural material. The study results compare the environmental emission impacts of each building using six impact categories of the TRACI protocol. Analysis is conducted with respect to the overall emissions of each building for each environmental category, as well as with respect to the building components and life-cycle stage.

2.1. Low-Rise and Mid-Rise Archetype Buildings

The 5-story and 12-story mass timber buildings were adopted from Wilson et al. (2020a), which investigated the seismic performance the all-wood mass timber buildings using self-centering, cross laminated timber (CLT) shear walls [

17]. While several structural systems have been proposed at a conceptual level for mass timber buildings (i.e., Green and Karsh, 2012, [

18]; SOM, 2017, [

19]) only a few have been tested experimentally to determine their suitability for seismic applications that are prevalent in the west coast of the United States. Self-centering mass timber walls are one of the promising systems that have been experimentally and computationally investigated [

20,

21] and are especially desirable due to their resiliency, or ability to return to service after an earthquake with low damage [

22]. Further, self-centering mass timber walls are an all-wood system that does not rely on usage of reinforced concrete for lateral stability, therefore reducing the total volume of concrete and reinforcing steel needed for the building.

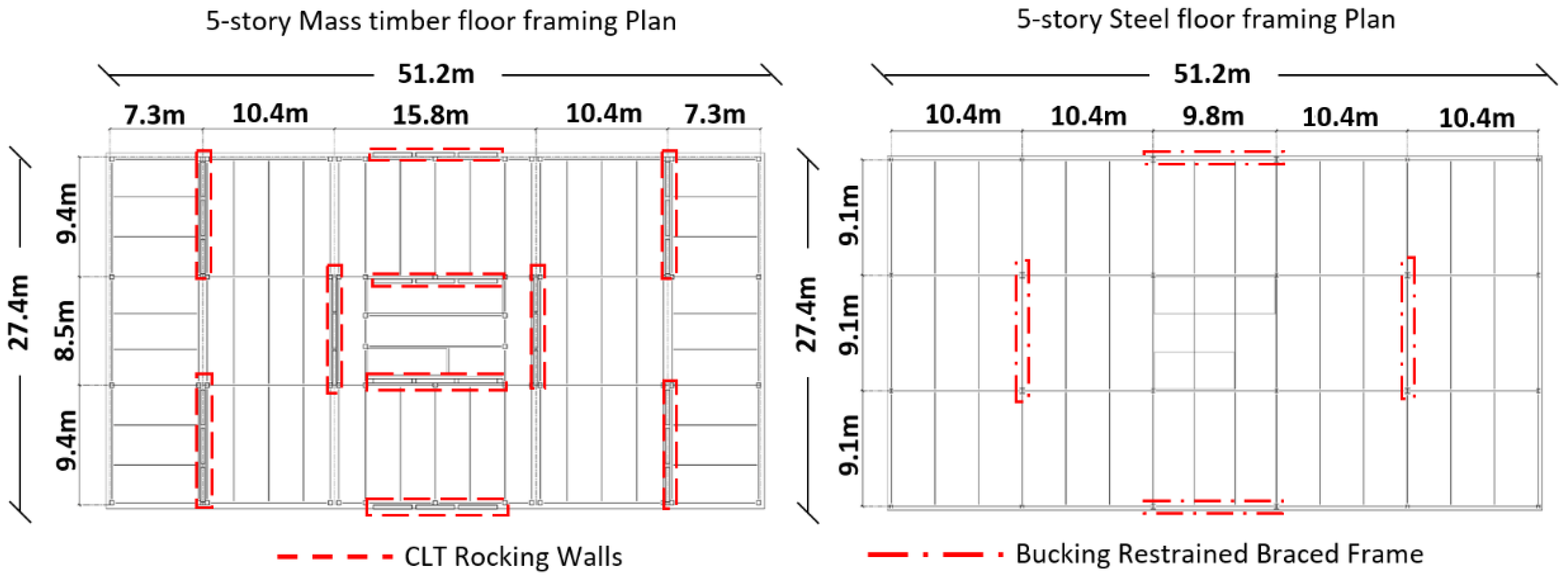

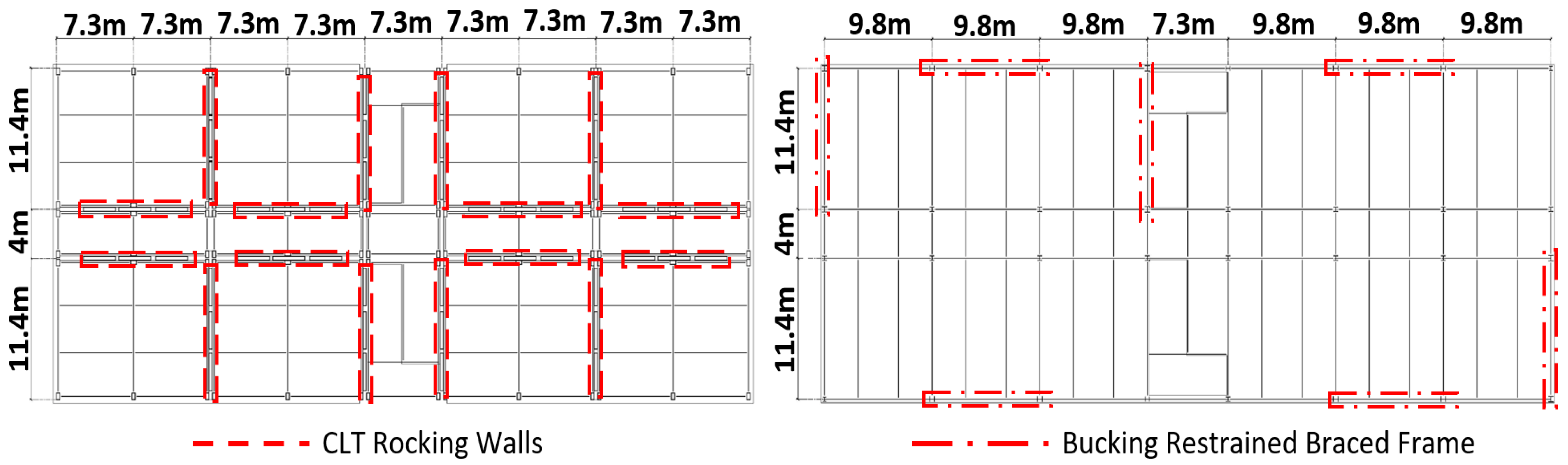

The original mass timber buildings were designed for the seismic and wind loads of an arbitrary site in Seattle, Washington. The floor plans of the 5-story and 12-story buildings are shown in

Figure 1 and

Figure 2, respectively. The gravity load system of both mass timber buildings is glue-laminated timber beams and columns with 5-ply (175 mm) CLT floors. Both mass timber buildings used an additional 51 mm of light-weight concrete topping slab on the CLT floors to satisfy fire, diaphragm, and serviceability vibration requirements. It should be noted that some practitioners hold the perception that thinner (105 mm–140 mm) CLT floor panels with closer spaced beams are preferable over 5-ply CLT floor panels to reduce costs. For the lateral force resisting system, the mass timber buildings used 9-ply (315 mm) CLT post-tensioned rocking walls, as described by Wilson (2018).

The buildings were then redesigned in this study using steel with the intent of maintaining functionally equivalent structures but using design decisions that would be representative of conventional steel design. Following Wilson (2018), the buildings were designed using the loads shown in

Table 1 [

23]. As shown by

Figure 1 and

Figure 2, the column spacing and location of lateral force resisting systems did change significantly between the mass timber and steel buildings. Specifically, due to the higher stiffness and strength of steel compared to timber, the column spacing was able to be increased and fewer columns were used. Additionally, fewer lateral force resisting frames were needed for the steel building compared to the mass timber buildings.

Both steel buildings were designed using rolled, wide-flange (W-shape) sections for the beams and columns. The floors were 76.4 mm steel deck with 50.8 mm of concrete cover. The beams were designed with varying amounts of partial-composite action with the floor slab for checking code deflection limits, but composite action was ignored during seismic drift calculations, as is standard in practice. The lateral system is composed of buckling restrained braced frames (BRBFs) of various sizes as denoted by the red dashed rectangles in the steel building plans.

In addition to the design components described by Wilson (2018), this study also included additional building materials that were deemed to have the potential of an effect on the LCA, such as the foundations, façade, and fire proofing materials. Building foundations were designed to resist structural loads and provide bearing pressures less than the allowable soil bearing capacity. The assumed allowable soil bearing pressure was 191.5 kPa for site class D soil conditions. It was assumed that differential settlement would not control foundation size. The foundation thickness was calculated to resist punching shear. The quantity of rebar in the foundation was estimated through discussions with practicing structural engineers to be 86–96 kg/m

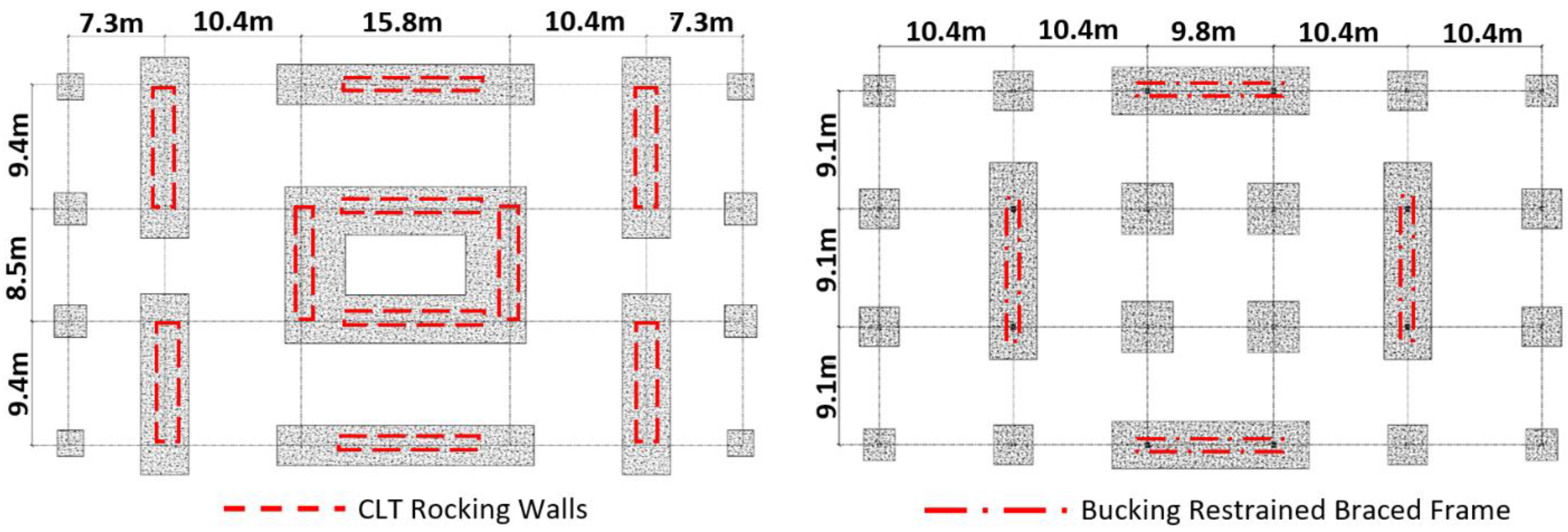

3. The foundations of the 5-story buildings were isolated spread footings under all gravity columns and combined footings under the lateral force resisting elements, as shown in

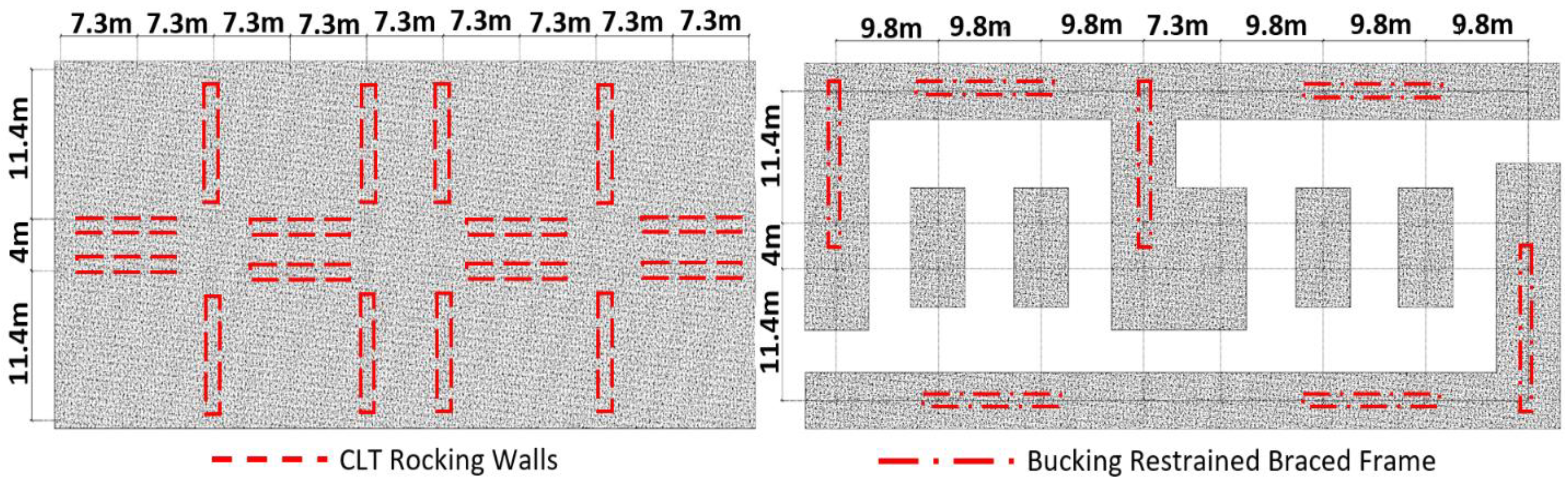

Figure 3. The difference in number of lateral force resisting elements needed between the mass timber and steel buildings is apparent in the required foundation size, with the mass timber buildings having larger foundation area. The foundation for the 12-story mass timber building was a mat foundation due to the large number of CLT rocking walls. Conversely, the foundation of the 12-story steel building was a combination of combined and isolated footings, as shown in

Figure 4.

Fire proofing was included in the study using gypsum wall board covering the required amount of mass timber for Type IV-B construction in Seattle, Washington and intumescent paint covering the steel in the steel buildings. The steel and CLT buildings were assumed to have identical facades, elevator and stair shafts, and non-structural build out (i.e., partition walls, doors, HVAC, etc.). The building façade was assumed to be 60% glass curtain wall and 40% insulated metal panels which is a common ratio for office buildings in the Pacific Northwest, as discussed by Pierobon et al. (2019). The glass curtain wall consisted of normal strength glazing panels and aluminum extrusion, the insulated metal panels consisted of galvanized steel studs, polystyrene foam insulation, a vapor barrier, a metal cladding on the exterior, and a gypsum wall board on the interior. In between the CLT decking and the lightweight concrete topping, a foam board was used as a vapor barrier and acoustic dampener. The roofing consisted of a 48 mm PVC membrane. The interior build out was not included in the scope of this study.

A comment on study limitations is that the mass timber buildings in this study likely use more timber than what a cost-competitive building in practice would use. This may be because the study buildings use 5-ply (175 mm) floor panels and thick 9-ply (315 mm) wall panels. To place the study buildings in perspective with an industry designed building, the cancelled 12-story Framework building in Portland, OR was also an all-wood, mass timber building using self-centering CLT walls and had a timber quantity of 0.28 m

3 per m

2 of building floor area [

24]. The 5-story and 12-story mass timber buildings in this study have timber quantities of 0.47 m

3 and 0.38 m

3 per m

2 of building floor area, respectively.

2.2. Building Materials Inventory

Detailed models of the prototype buildings were created in Revit to generate accurate bill of material schedules (BOMS), presented in

Table 2. When modeling the buildings in Revit, openings were created in the decks of each floor where columns/walls pass through to avoid double counting intersecting materials. For the mass timber buildings, individual columns were assumed to span between each floor level (platform construction) whereas with the steel building archetypes, columns traveled through multiple floor levels (balloon construction). For the mass timber buildings, beam lengths were determined using inside distances between girders and columns. For the steel buildings, beam lengths were determined using flange-to-flange distances on connecting columns or girders. Material quantities for all objects were calculated using cross sectional area multiplied by the aforementioned lengths. On elevated levels, edge-of-slab was assumed to extend 0.3–0.5 m beyond the centerline of the perimeter beams and columns.

2.3. LCIA Methodology and System Boundary

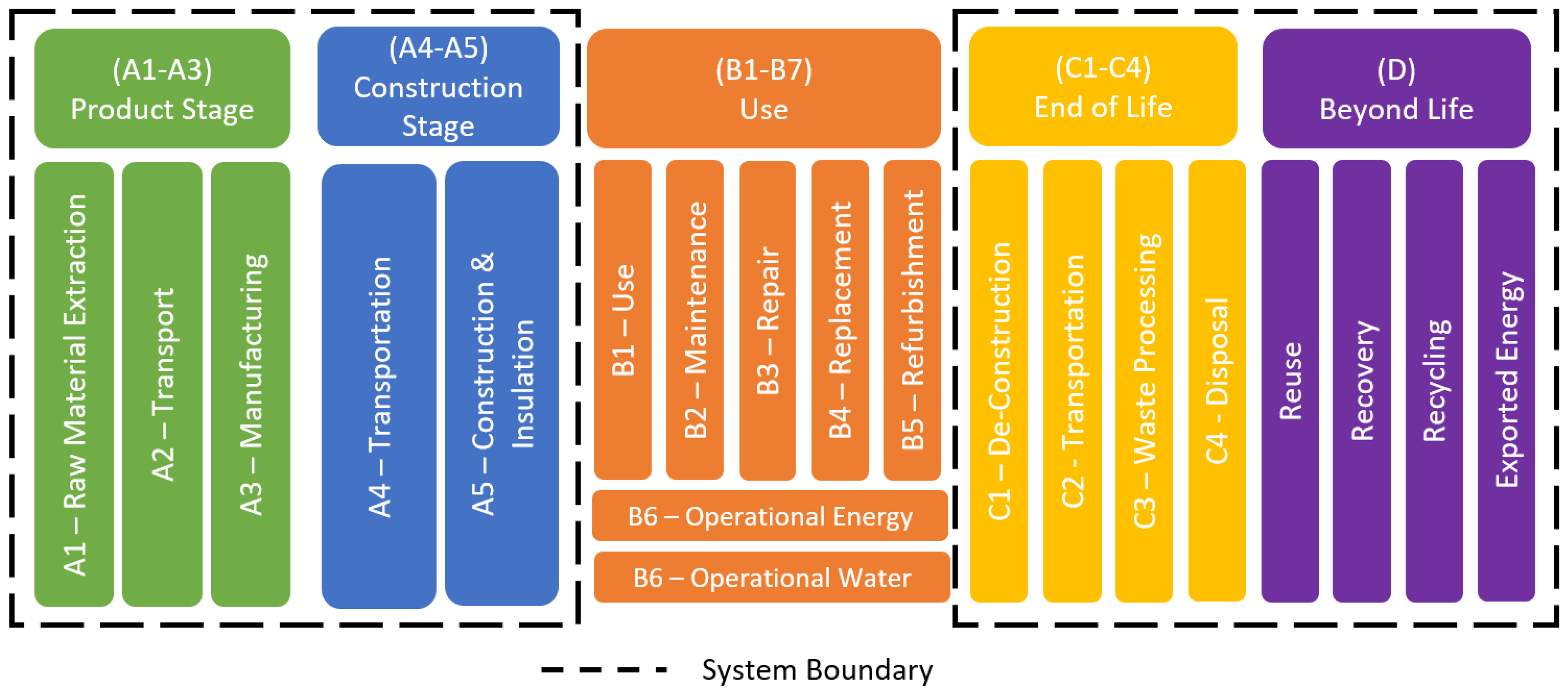

As the goal of this study was to use Athena IE4B to compare the environmental impacts from the archetype buildings over the production, construction, end-of-life, and beyond life stages for a 60-year period [

25], the system boundary was defined as “cradle-to-grave” with the exclusion of the “Use” phase (Phase B1-B7) [

26], as shown in

Figure 5. The use phase was excluded from the system boundary to compare the building materials using the embodied energy and emissions without the influence of operational energy differences that may exist and are outside the scope of this study.

Once an accurate bill of materials for each building was generated, they were imported into the IE4B LCA tool. The Athena IE4B tool has been specifically designed to model the environmental impacts of building projects in North America. The tool allows the user to input construction products rather than individual materials,

Table 2 represents the exact quantities modeled from a construction materials standpoint. Detailed schedules reporting the raw material, energy, and water inputs are able to be generated in the IE4B software if researchers would like greater control over inventory flows. The IE4B follows the EN15978 (2011) standard, which includes impacts from productions, transportation, construction, and demolition; the standard also includes impacts from energy and water use, which were excluded from this study. All default settings were using in the development of the life-cycle assessment models to allow for the results to be easily replicable and to remove potential bias of selecting environmental product declarations (EPDs) of specific materials or products. The project location was set as Seattle, Washington in IE4B for calculations involving all transportation distances and energy mixes. The 5-story buildings were designated as Office Rental Buildings and the 12-story buildings were designated as Multi-Unit Residential Rental Buildings. The IE4B tool then used the Athena LCI database, which is composed of EPDs that primarily reflect industry averages in North America, to determine the environmental impact of each structure. The environmental impact results presented across the six categories in

Section 3 exclude stage D, but stage D, and its effect on the category of global warming potential, is presented and discussed in

Section 4.2. Additional information about the IE4B methodology, as well as their list of North American LCI data, can be found in the

Athena IE4B User Manual and Transparency Document [

27].

2.4. Summary of Environmental Impact Categories

The IE4B uses the TRACI methodology [

28] to aggregate and quantify environmental impacts into the following 6 categories: (1) global warming potential, (2) acidification potential, (3) eutrophication potential, (4) HH particulate, (5) ozone depletion potential, and (6) smog potential. The categories are briefly explained here to provide context to the discussion of results. Global warming potential (GWP) is a measure of greenhouse gas emissions, which contribute to the fueling of climate change, and is measured using kilograms of carbon dioxide equivalents (kg CO

2 eq.). Acidification potential is a measure of the acids being admitted into the atmosphere, which contribute to acid rain, and is measured using kilograms of sulfur dioxide equivalents (kg SO

2 eq.). Eutrophication potential measures of the potential of pollution in water systems or aquatic ecosystems. An example is fertilizer runoff, which can cause excessive plant or algal growth. Eutrophication potential is measured using kilograms of nitrogen equivalent (kg N eq.). HH particulate is a measure of fine particulates that are emitted to the air and atmosphere that cause a danger to human health through respiratory and cardiovascular diseases and is measured in kilograms of particles under 2.5 micrometers (PM2.5) equivalent (kg PM2.5 eq). Ozone depletion potential measures the amount of hydrocarbons emitted that contribute to the depletion of Earth’s ozone layer and is measured using kilograms of Chlorofluorocarbon-11 equivalents (kg CFC-11 eq). Smog Potential is a measure of ground level ozone created by volatile organic compounds and numerous nitrogen oxides (NO

x) interacting in sunlight and creating harmful air (i.e., smog). Smog potential is measured in units of kilograms of ozone (trioxygen) equivalents (kg O

3 eq.).

3. Results

3.1. Comparison of Environmental Impact Categories

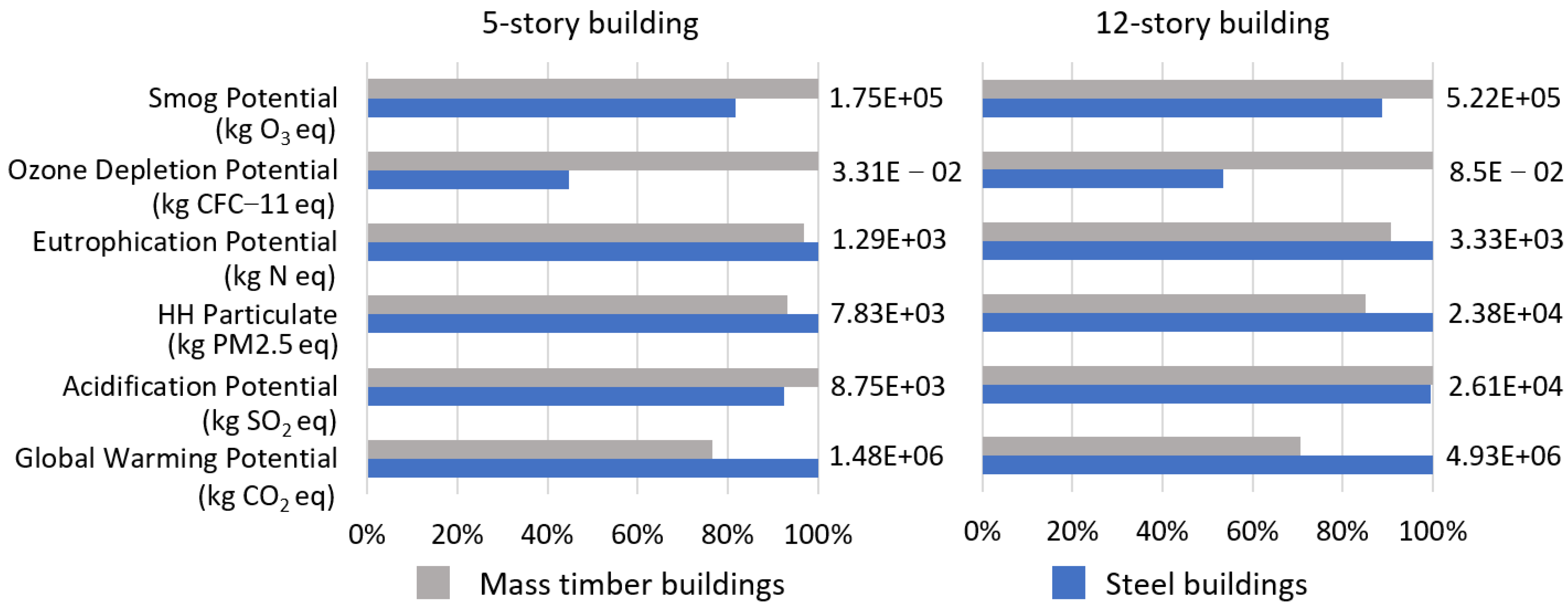

The results of the LCA for the 5-story and 12-story buildings from Stage A to Stage C are presented in

Figure 6 normalized to the larger environmental impact value for each category. The normalizing value is provided next to the larger environmental impact value so that actual quantities can be calculated, if desired. The GWP shown in

Figure 6 does not include the biogenic carbon sequestration from Stage D “beyond life”, as the considerations involved in incorporating the biogenic carbon sequestration of the timber growth is discussed further in

Section 4.2. Similar to results of previous studies, the mass timber buildings had a significantly lower GWP than the steel buildings. The GWP normalized in terms of building square footage was 160.9 kg CO

2 eq./m

2 and 164.7 kg CO

2 eq./m

2 for the 5-story and 12-story mass timber buildings, respectively. The 5-story and 12-story steel buildings had normalized GWP of 210.7 kg CO

2 eq./m

2 and 232.6 kg CO

2 eq./m

2, respectively, which is approximately 31–41% larger than their mass timber counterparts. Higher GWP density (kg CO

2 eq. per m

2) with increasing building height is consistent with the findings of Su and Zhang (2016). The correlation between increasing building height and increasing GWP discussed by Su and Zhang (2016), developed using LCA analysis of steel buildings, appears to extend to the mass timber buildings as well. This correlation is likely due to the fact that taller buildings have significantly larger foundations and gravity load members due to their larger loads.

The steel buildings had lower environmental impact in the categories of acidification potential, ozone depletion potential, and smog potential. The difference in ozone depletion potential is particularly large, where the steel buildings have between 45–55% the ozone depletion potential as the mass timber buildings. The mass timber buildings had lower human health (HH) particulate potential and eutrophication potential, though the buildings were within 15% of each other.

3.2. Comparison by Building Component Group

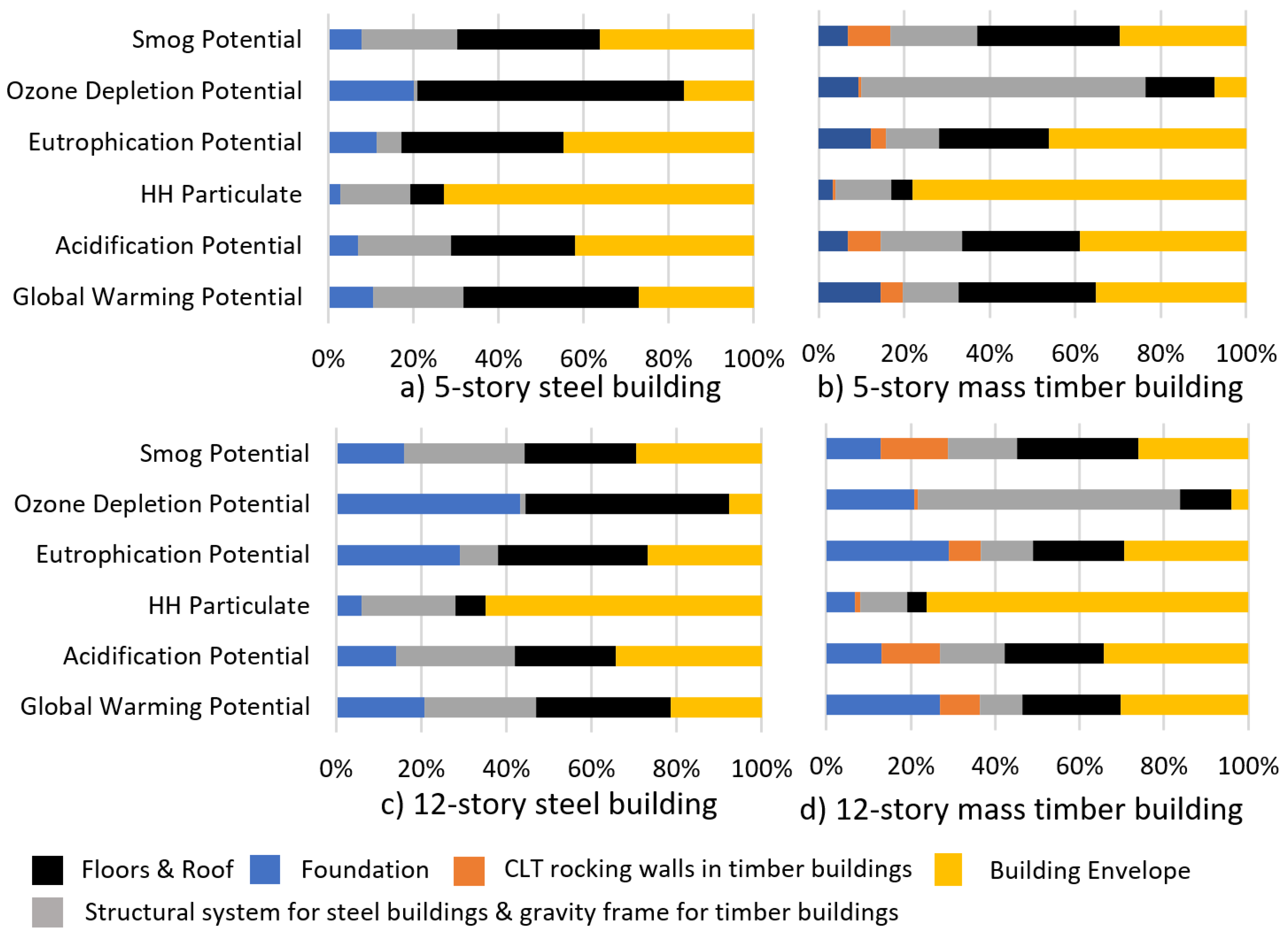

This section further analyzes the environmental emissions of the archetype buildings separated into the main building components, as shown in

Figure 7. For the steel buildings, the building was separated into the foundations, which were mostly concrete by volume, the structural system, which was all steel except for the grout inside the BRBs, the floors and roof, which were again mostly concrete and the building envelope which was assumed to be 60% structural glass glazing and 40% solid surfaces. The mass timber buildings were separated along the same lines except that the structural system was further divided into the lateral force resisting system, which is 9-ply CLT, and the gravity force resisting system, which is glulam timber. This was because the EPDs for CLT and glulam are different and the effects of those differences can be seen in the Ozone Depletion Potential and HH Particulate impact categories, where the glulam frame contributes a much higher percentage of the total emissions than the CLT walls or CLT floors.

While the effect is larger for the steel buildings, the components that are mostly concrete contribute upwards of half the total GWP emissions. The total volume of concrete required for a project is heavily related to building design decisions, and regardless of the material choice for the primary structural system, designers can take steps that reduce total concrete use by aiming for efficient design of the concrete elements. Both 12-story buildings in this study have significantly larger foundations, which required approximately 5 times more concrete and reinforcing steel per m

2 of building footprint, than their 5-story counterparts.

Figure 7 shows that the percentage of GWP impact attributed to the foundations increased approximately 10% between the 5-story and 12-story buildings. For the mass timber buildings, the foundations alone contributed 30% and 40% of the total GWP emissions for the 5-story and 12-story buildings, respectively.

Additionally, for the steel buildings, the floors contribute between one-half to two-thirds of the total concrete quantity. Therefore, environmental emissions could be improved in steel buildings by advocating for a design approach that uses mass timber floor panels over the traditional cast-in-place concrete floors. An imprecise analysis of the effect of using mass timber floors for the steel buildings in this study could be estimated by replacing the emissions associated with the steel building concrete floors with the emissions associated with the mass timber buildings CLT floors. Under that scenario, the GWP of the 5-story and 12-story steel buildings would be reduced by approximately 10% to 15%. Compared to the 5-story and 12-story mass timber buildings, the theoretical wood-floored steel buildings would have GWP 15% to 20% greater than their timber counterparts.

Lastly, the building envelope, which was structural glass glazing, light-frame steel studs, and aluminum for this study, contributed more than 20% of total emissions to all impact categories except ozone depletion potential. Therefore, if the goal of a designer is to reduce the embodied emissions of a building, the impact of the envelope cannot be ignored as a major source of emissions. Further, most building envelopes use different materials than the primary structural materials of steel, concrete, or timber and therefore are not directly tied to structural system design choices. The impact of different envelope alternatives on life-cycle emissions should be studied further. Additionally, the building envelope design is also highly tied to the energy performance of the building during the use phase. Therefore, LCA studies on the performance of envelope alternatives probably should not omit the use phase, as picking envelope materials that minimizing the embodied energy but result in much higher operational energy may not be a net positive.

5. Conclusions

The results of this study show that mass timber buildings have advantages over conventionally framed steel buildings with respect to several environmental impact categories, especially global warming potential. For a system boundary of cradle-to-grave, excluding the operation phase, the mass timber archetype buildings had GWP that were 31% to 41% lower than that of the steel building alternatives. Further, if the carbon sequestration effects of the buildings (Stage D) were included in the analysis, the mass timber buildings became close to carbon neutral (excluding operational energy) while the steel buildings remained relatively unchanged.

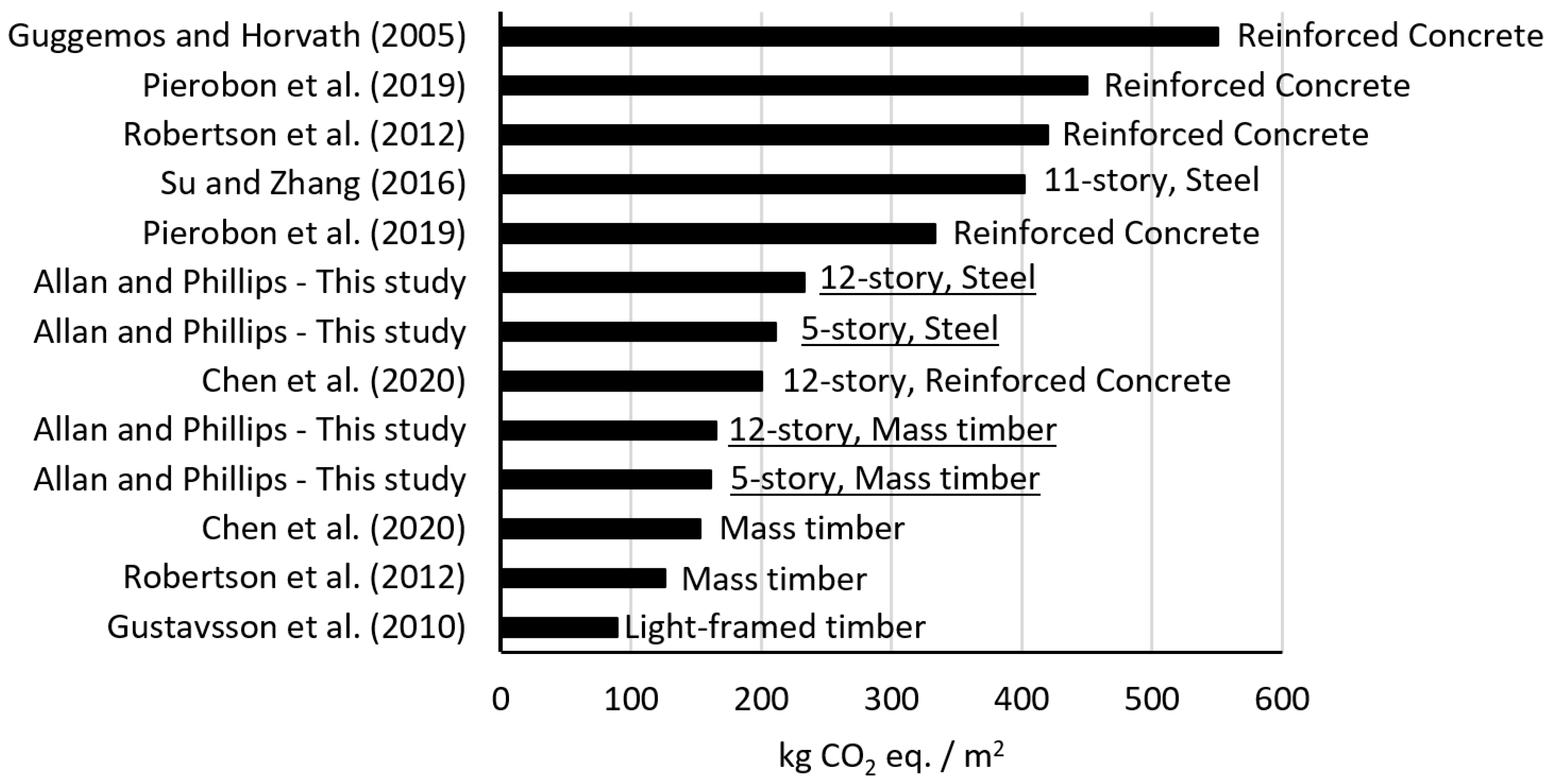

However, the steel buildings had lower environmental impact in the categories of acidification potential, ozone depletion potential, and smog potential compared to the mass timber buildings. The steel buildings had ozone depletion potential emissions that were 45% to 55% lower than that of the mass timber building alternatives. For broader context with respect to other structural system, mainly reinforced concrete, the GWP calculated in this study was compared to previous studies on North American buildings. The steel buildings had GWP emissions in between that of mass timber buildings and the reinforced concrete buildings. Further, the GWP of the steel buildings located in the United States, as calculated in this study, was significantly lower than the GWP of steel buildings located in China, calculated by Su and Zhang (2016). This is likely due to the North American steel, which is produced using cleaner processes that mostly utilize recycled scrap steel.

Further, a large portion of the emissions across all six impact categories for both buildings were from the concrete components and the building envelope components. For the steel buildings, this was especially pronounced because the foundations and floors were concrete, resulting in more than 50% of the total GWP being attributed to the concrete components. This finding suggests that there is likely a significant environmental benefit to using mass timber floors in steel buildings to reduce their environmental impact. The building envelope components contributed more than 20% of the total emissions in the impact categories of GWP and smog potential. The envelope contributed more than 40% of the total emissions for the categories of HH particulate, eutrophication potential, and acidification potential. This demonstrates that holistic design is best suited for reducing environmental impact of buildings, as all four archetypes buildings would have benefited from a lower emission building envelope.

Lastly, future research may focus on the exploration of how different design decisions, including variation in column spacing, beam spacing, and building height may affect material quantity and therefore life-cycle environmental impact. Variations in design configuration that can make use of thinner mass timber panels, smaller foundations, and less concrete for flooring should further reduce the total environmental impact. Lastly, future work should focus on incorporating the use phase scenarios to further study the effect of the building envelope design on both embodied and operational energy and the interaction between the two.