Testing Biodegradable Films as Alternatives to Plastic-Film Mulching for Enhancing the Yield and Economic Benefits of Processed Tomato in Xinjiang Region

Abstract

1. Introduction

2. Test Materials and Methods

2.1. General Situation of the Research Area

2.2. Materials and Methods

2.2.1. Test Materials

2.2.2. Experimental Design

2.3. Observation Index and Method

2.3.1. Strength Performance of Plastic Film

2.3.2. Temperature Increasing Performance

2.3.3. Soil Moisture Conservation Performance

2.3.4. Observation on Degradation of Biodegradable Film

2.3.5. Determination of Yield and Quality of Processed Tomato

2.4. Data Analysis

3. Results and Analysis

3.1. Machine Performance of Biodegradable Film

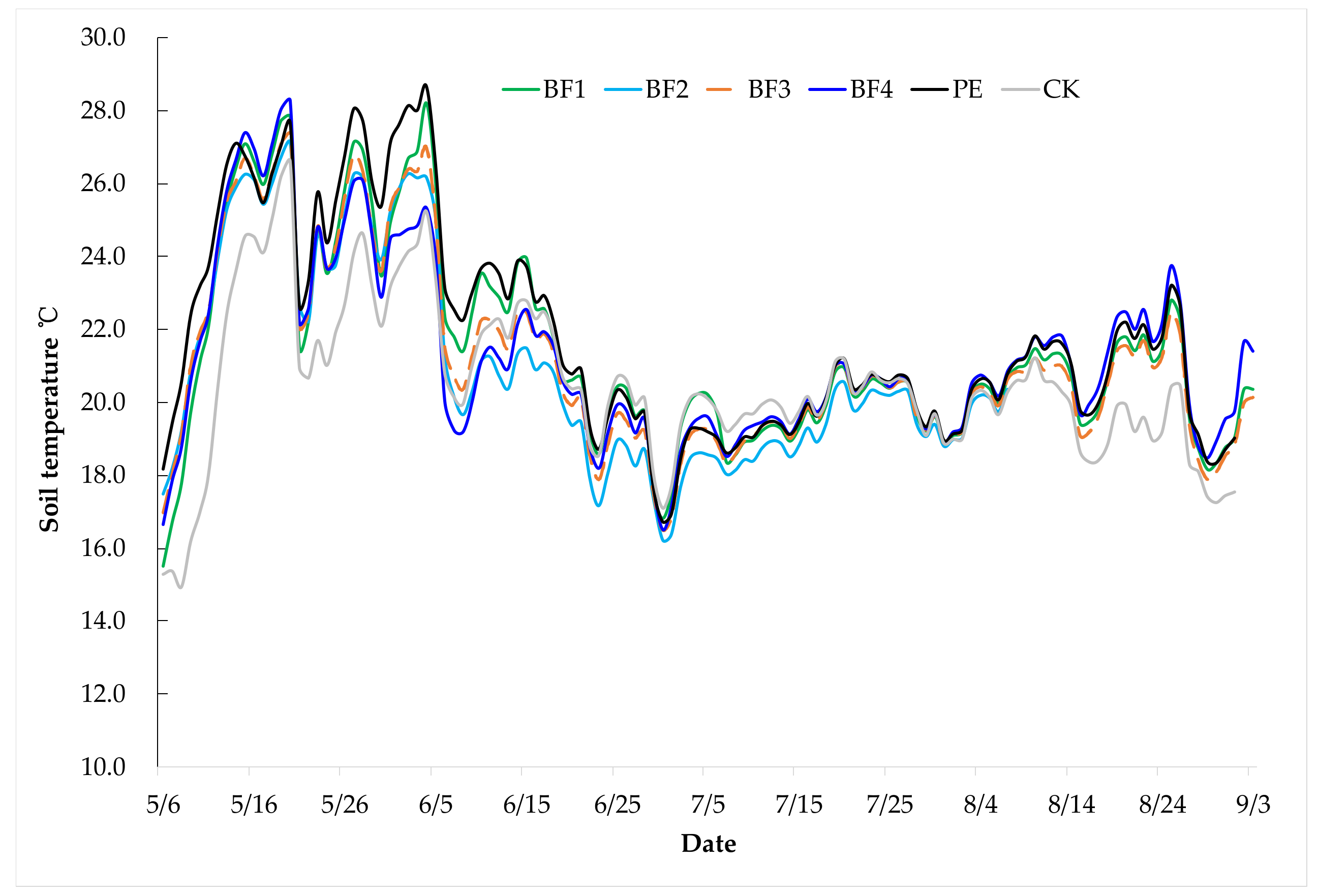

3.2. Effect of Biodegradable Film on Ground Temperature

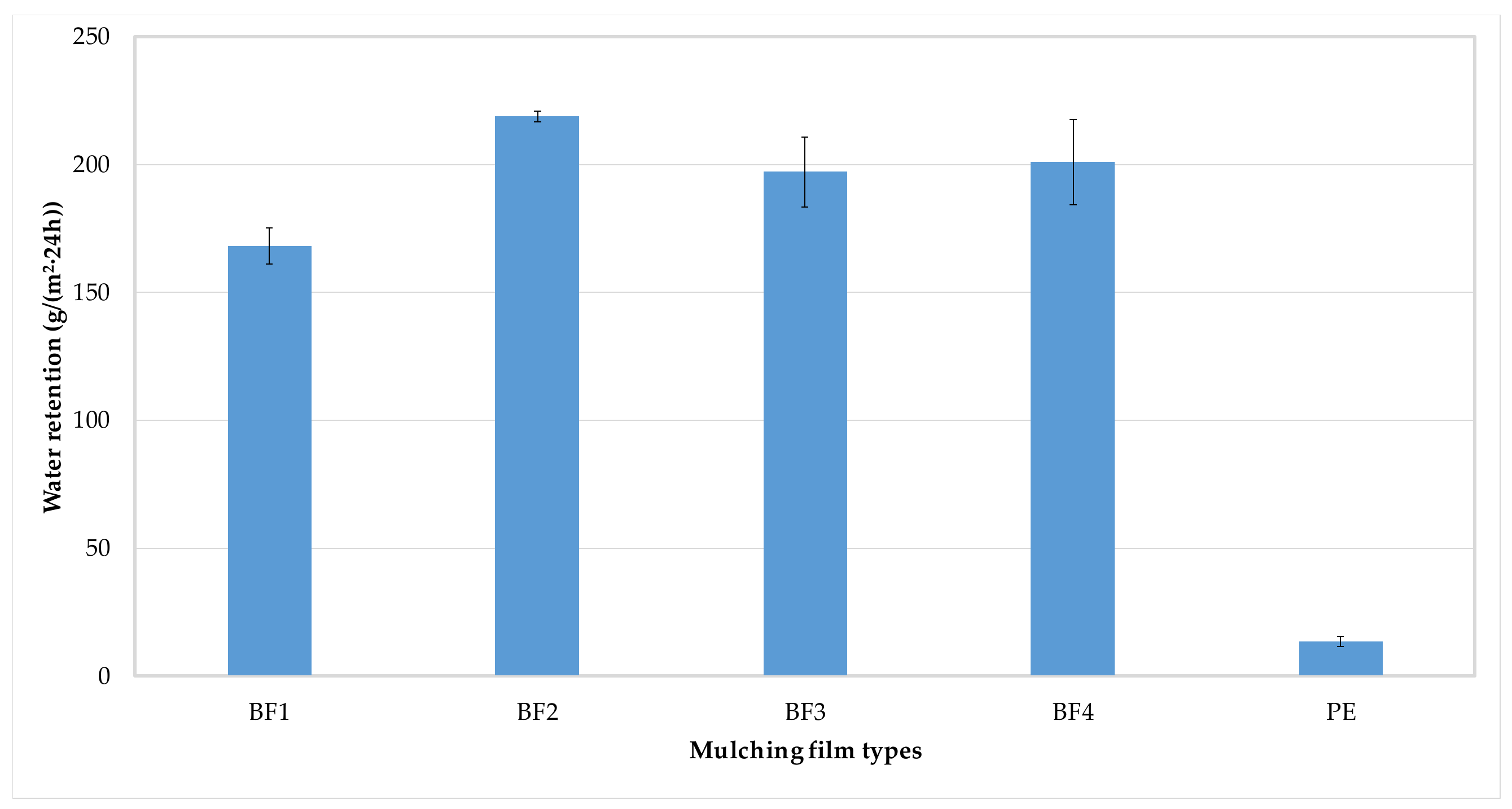

3.3. Soil Moisture Conservation Characteristics of Biodegradable Film

3.4. Degradation of Biodegradable Film

3.5. Effects of Film Mulching on Yield and Quality of Processed Tomato

3.6. Economic Feasibility Analysis of Biodegradable Film

4. Discussion

5. Conclusions

- Biodegradable mulch film with a thickness of about 8 μm can meet the mechanical operation requirements, and the effect of biodegradable mulching film was completely consistent with that of PE film. There were no problems such as fracture and tearing of biodegradable film in the process of operation.

- In addition, although the four kinds of biodegradable mulch film in this experiment were slightly different from PE film in increasing temperature and water retention, they basically meet the requirements of processed-tomato growth and development. Nearly 50%–70% of the biodegradable film was ruptured and degraded during processed-tomato harvesting, which avoids the occurrence of the winch of the plastic-film winding harvester and improves the efficiency and commodity rate of the processed tomato harvest operation.

- Plastic-film planting can ensure a net profit of 1.14–1.64 ten thousand CNY per hectare under the current production conditions and mode of Changji in Xinjiang. In addition, the yield, output value, and net profit of processed tomato covered with three kinds of BF1, BF2, and BF4 were the same as those of PE film. This indicated that the application of biodegradable film in the production of processed tomato in Xinjiang is economical and feasible.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, C.; He, W.; Liu, S. Application of Mulch Film and Prevention of its Residual Pollution in CHINA; China Science Press: Beijing, China, 2015. [Google Scholar]

- Gao, H.; Yan, C.; Liu, Q.; Ding, W.; Chen, B.; Li, Z. Effects of plastic mulching and plastic residue on agricultural production: A meta-analysis. Sci. Total Environ. 2018, 651, 484–492. [Google Scholar] [CrossRef] [PubMed]

- Lobell, D.B.; Field, C.B. Global scale climate–Crop yield relationships and the impacts of recent warming. Environ. Res. Lett. 2007, 2, 4002. [Google Scholar] [CrossRef]

- Wei, Q.; Chi, B.; Oene, O.; Gordon, L.E. Long-Term Monitoring of Rainfed Wheat Yield and Soil Water at the Loess Plateau Reveals Low Water Use Efficiency. PLoS ONE 2013, 8, 8828. [Google Scholar]

- Abouziena, H.F.; Hafez, O.M.; Metwally, E.I.M.; Sharma, S.D.; Singh, M. Comparison of Weed Suppression and Mandarin Fruit Yield and Quality Obtained with Organic Mulches, Synthetic Mulches, Cultivation, and Glyphosate. Hortscience 2008, 43, 795–799. [Google Scholar] [CrossRef]

- Rao, F.; Abudikeranmu, A.; Shi, X.; Heerink, N.; Ma, X. Impact of participatory irrigation management on mulched drip irrigation technology adoption in rural Xinjiang, China. Water Resour. Econ. 2021, 33, 170. [Google Scholar] [CrossRef]

- Dong, H.; Liu, T.; Li, Y.; Liu, H.; Wang, D. Effects of plastic film residue on cotton yield and soil physical and chemical properties in Xinjiang. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2013, 29, 91–99. [Google Scholar]

- National Bureau of Statistics of China. China Statistical Yearbook; China Statistics Press: Beijing, China, 2019.

- Brodhagen, M.; Goldberger, J.R.; Hayes, D.G.; Inglis, D.A.; Marsh, T.L.; Miles, C. Policy considerations for limiting unintended residual plastic in agricultural soils. Environ. Sci. Policy 2017, 69, 81–84. [Google Scholar] [CrossRef]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Tröger, J.; Muñoz, K.; Frör, O.; Schaumann, G.E. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Ohtake, Y.; Kobayashi, T.; Asabe, H.; Murakami, N. Studies on biodegradation of LDPE—observation of LDPE films scattered in agricultural fields or in garden soil. Polym. Degrad. Stab. 1998, 60, 79–84. [Google Scholar] [CrossRef]

- Ohtake, Y.; Kobayashi, T.; Asabe, H.; Murakami, N.; Ono, K. Oxidative degradation and molecular weight change of LDPE buried under bioactive soil for 32–37 years. J. Appl. Polym. Sci. 1998, 70, 1643–1648. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Bandopadhyay, S.; English, M.E.; Bary, A.I.; De Bruyn, J.M.; Schaeffer, S.M.; Miles, C.A.; Reganold, J.P.; Flury, M. Impacts of biodegradable plastic mulches on soil health. Agric. Ecosyst. Environ. 2019, 273, 36–49. [Google Scholar] [CrossRef]

- Yan, C.; Liu, E.; Shu, F.; Liu, Q.; Liu, S.; He, W. Review of agricultural plastic mulching and its residual pollution and prevention measures In China. J. Agric. Resour. Environ. 2014, 31, 95–102. [Google Scholar]

- Xia, Z.; Jiang, H.; Li, Q.; Zhao, F. Effect of mulch on soil temperature and moisture and analysis of water saving benefit. J. Hohai Univ. 1997, 25, 39–45. [Google Scholar]

- Zhang, J.; Jiang, P.; Shen, Y.; Wang, W.; Su, H. Present conditions and control measures of plastic film residue in agricultural fields in Xinjiang. Xinjiang Agric. Sci. 2010, 47, 1656–1659. [Google Scholar]

- Liang, M.; Bu, Y.; Li, W.; Zhou, Q.; Shi, X.; Ma, R. Effect of different mulching materials on soil moisture and temperature and crop yield. Chin. Agric. Sci. Bull. 2011, 27, 328–335. [Google Scholar]

- Fu, X.; Du, Q. Uptake of di-(2-ethylhexyl) phthalate of vegetables from plastic film greenhouses. J. Agric. Food Chem. 2011, 59, 11585–11588. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Q.; Jia, W.; Yan, C.; Wang, J. Agricultural plastic mulching as a source of microplastics in the terrestrial environment. Environ. Pollut. 2020, 260, 4096. [Google Scholar] [CrossRef]

- Ng, E.; Lwanga, E.H.; Eldridge, S.M.; Johnston, P.; Hu, H.; Geissen, V.; Chen, D. An overview of microplastic and nanoplastic pollution in agroecosystems. Sci. Total Environ. 2018, 627, 1377–1388. [Google Scholar] [CrossRef]

- Qi, R.; Davey, L.J.; Li, Z.; Liu, Q.; Yan, C. Behavior of microplastics and plastic film residues in the soil environment: A critical review. Sci. Total Environ. 2019, 703, 134722. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Ossowicki, A.; Yang, X.; Lwanga, E.H.; Dini-Andreote, F.; Geissen, V.; Garbeva, P. Effects of plastic mulch film residues on wheat rhizosphere and soil properties. J. Hazard. Mater. 2019, 387, 1711. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; He, W.; Xue, Y.; Liu, E.; Liu, Q. Application of biodegradable plastic film to reduce plastic film residual pollution in Chinese agriculture. Chin. J. Biotechnol. 2016, 32, 748–760. [Google Scholar]

- Wu, J.; Xie, B. Study of Starch/PCL thermoplastic full-biodegradable film. China Plast. Ind. 2002, 30, 22–24. [Google Scholar]

- Weng, Y.; Jin, Y.; Meng, Q.; Wang, L.; Zhang, M.; Wang, Y. Biodegradation behavior of poly (butylene adipate-co-terephthalate) (PBAT), poly (lactic acid) (PLA), and their blend under soil conditions. Polym. Test. 2013, 32, 918–926. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Morreale, M.; La Mantia, F.P. The Effects of Nanoclay on the Mechanical Properties, Carvacrol Release and Degradation of a PLA/PBAT Blend. Materials 2020, 13, 983. [Google Scholar] [CrossRef]

- Cabrera, F.; Torres, A.; Campos, J.L.; Jeison, D. Effect of Operational Conditions on the Behaviour and Associated Costs of Mixed Microbial Cultures for PHA Production. Polymers 2019, 11, 191. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly(lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef]

- Sridewi, N.; Bhubalan, K.; Sudesh, K. Degradation of commercially important olyhydroxyalkanoates in tropical mangrove ecosystem. Polym. Degrad. Stab. 2006, 91, 2931–2940. [Google Scholar] [CrossRef]

- Schlebrowski, T.; Ouali, R.; Hahn, B.; Wehner, S.; Fischer, C.B. Comparing the Influence of Residual Stress on Composite Materials Made of Polyhydroxybutyrate (PHB) and Amorphous Hydrogenated Carbon (a-C:H) Layers: Differences Caused by Single Side and Full Substrate Film Attachment during Plasma Coating. Polymers 2021, 13, 184. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Chen, B.; Fan, J.; Feng, J. Exploring the Application of Sustainable Poly (propylene carbonate) Copolymer in Toughening Epoxy Thermosets. ACS Sustain. Chem. Eng. 2015, 3, 2077–2083. [Google Scholar] [CrossRef]

- Kapanen, A.; Schettini, E.; Vox, G.; Itävaara, M. Performance and Environmental Impact of Biodegradable Films in Agriculture: A Field Study on Protected Cultivation. J. Polym. Environ. 2008, 16, 109–122. [Google Scholar] [CrossRef]

- Caruso, G.; Stoleru, V.; De Pascale, S.; Cozzolino, E.; Pannico, A.; Giordano, M.; Teliban, G.; Cuciniello, A.; Rouphael, Y. Production, Leaf Quality and Antioxidants of Perennial Wall Rocket as Affected by Crop Cycle and Mulching Type. Agronomy 2019, 9, 194. [Google Scholar] [CrossRef]

- Sekara, A.; Pokluda, R.; Cozzolino, E.; del Piano, L.; Cuciniello, A.; Caruso, G. Plant growth, yield, and fruit quality of tomato affected by biodegradable and non-degradable mulches. Hortic. Sci. 2019, 46, 138–145. [Google Scholar] [CrossRef]

- Duan, Y.; Zhang, X. Influence of biodegradable membrane on soil fertility and photo yield. Crop Res. 2018, 32, 25–29. [Google Scholar]

- Li, H.; Zhou, Y.; Jin, T.; Wang, Y.; Ruan, G.; Li, Y. Degradation characteristics of different mulch and the effect on potato yield. Chin. Agric. Sci. Bull. 2017, 33, 36–40. [Google Scholar]

- Caruso, G.; Carputo, D.; Conti, S.; Borrelli, C.; Maddaluno, P.; Frusciante, L. Effect of mulching and plant density on out-of-season organic potato growth, yield and quality. Adv. Hortic. Sci. 2013, 27, 115–121. [Google Scholar]

- Sun, T.; Li, G.; Ning, T.Y.; Zhang, Z.M.; Mi, Q.H.; Lal, R. Suitability of mulching with biodegradable film to moderate soil temperature and moisture and to increase photosynthesis and yield in peanut. Agric. Water Manag. 2018, 208, 214–223. [Google Scholar] [CrossRef]

- Zhang, N.; Li, Q.; Hou, W.; Ye, J. Effect of polylactic acid-degradable film mulch on soil temperature and cotton yield. J. Agric. Resour. Environ. 2016, 33, 114–119. [Google Scholar]

- Wang, Z.; Wu, Q.; Fan, B.; Zhang, J.; Li, W.; Zheng, X.; Lin, H.; Guo, L. Testing biodegradable films as alternatives to plastic films in enhancing cotton (Gossypium hirsutum L.) yield under mulched drip irrigation. Soil Tillage Res. 2019, 192, 196–205. [Google Scholar] [CrossRef]

- Deng, L.; Yu, Y.; Zhang, H.; Wang, Q.; Yu, R. The Effects of Biodegradable Mulch Film on the Growth, Yield, and Water Use Efficiency of Cotton and Maize in an Arid Region. Sustainability 2019, 11, 7039. [Google Scholar] [CrossRef]

- Shen, L.; Wang, P.; Zhang, L. Degradation property of degradable film and its effect on soil temperature and moisture and maize growth. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2012, 28, 111–116. [Google Scholar]

- Yin, M.; Li, Y.; Fang, H.; Chen, P. Biodegradable mulching film with an optimum degradation rate improves soil environment and enhances maize growth. Agric. Water Manag. 2019, 216, 127–137. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Z.; Zhang, J.; Li, W. Combined Effect of Different Amounts of Irrigation and Mulch Films on Physiological Indexes and Yield of Drip-Irrigated Maize (Zea mays L.). Water 2019, 11, 472. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, M.; Dannenmann, M.; Tao, Y.; Yao, Z.; Jing, R.; Zheng, X.; Bahl, B.K.; Lin, S. Benefit of using biodegradable film on rice grain yield and N use efficiency in ground cover rice production system. Field Crop. Res. 2017, 201, 52–59. [Google Scholar] [CrossRef]

- Lv, S.H.; Dong, Y.J.; Jiang, Y.; Padilla, H.; Li, J.; Uphoff, N. An Opportunity for Regenerative Rice Production: Combining Plastic Film Cover and Plant Biomass Mulch with No-Till Soil Management to Build Soil Carbon, Curb Nitrogen Pollution, and Maintain High-Stable Yield. Agronomy 2019, 9, 600. [Google Scholar] [CrossRef]

- Zhao, G.; Fan, T.; Dang, Y.; Zhang, J.; Li, S.; Wang, S.; Cheng, W.; Lei, W. Effects of biodegradable plstic film mulching on the growth winter wheat on the Loess Plateau Dryland. Arid Zone Res. 2019, 36, 339–347. [Google Scholar]

- Bai, Y.; Jia, S.; Huang, C.; Luo, T. Effect of biodegradable film on soil temperature, moisture and yield of spring wheat in dryland. J. Triticease Crops 2015, 35, 1558–1563. [Google Scholar]

- Hu, W.; Sun, J.; Shan, N.; Yan, J.; Wang, X. Effect of COPO degradable membrance on soil temperature and crop yield and analysis of its degrandable characteristics. Xinjiang Agric. Sci. 2015, 52, 317–320. [Google Scholar]

- He, W.; Yan, C.; Zhao, C.; Chang, R.; Liu, Q.; Liu, S. Study on the pollution by plastic mulch film and its countermeasures in China. J. Agro-Environ. Sci. 2009, 28, 533–538. [Google Scholar]

- Rhim, J.; Hong, S.; Ha, C. Tensile, water vapor barrier and antimicrobial properties of PLA/nanoclay composite films. LWT Food Sci. Technol. 2009, 42, 612–617. [Google Scholar] [CrossRef]

- Liu, E.; He, W.; Yan, C. ‘White revolution’ to ‘white pollution’—Agricultural plastic film mulch in China. Environ. Res. Lett. 2014, 9, 1001. [Google Scholar] [CrossRef]

- Li, F.; Wang, J.; Xu, J. Plastic Film Mulch Effect on Spring Wheat in a Semiarid Region. J. Sustain. Agric. 2005, 25, 5–17. [Google Scholar] [CrossRef]

- Liu, Q.; Mu, X.; Yuan, Z.; Gao, H.; Zhang, R. Degradation of biodegradable mulch film and its effect on growth and yield of maize. Bull. Soil Water Conserv. 2011, 31, 126–129. [Google Scholar]

- Ibarra, L.; Zermeño, A.; Munguía, J.; Rosario, M.A.; De, M. Photosynthesis, soil temperature and yield of cucumber as affected by colored plastic mulch. Acta Agric. Scand. Sect. B Plant Soil Sci. 2008, 58, 372–378. [Google Scholar]

- Hou, H.; Lv, J.; Guo, T.; Zhang, G.; Zhang, P.; Zhang, X. Effects of whole field soil-plastic mulching on soil thermal-moisture status and wheat yield in semiarid region on Northwest Loess Plateau. Acta Ecol. Sin. 2014, 34, 5503–5513. [Google Scholar]

- He, W.; Zhao, C.; Liu, S.; Yan, C.; Chang, R.; Cao, S. Study on the degradation of biodegradable plastic mulch filmand its effect on the yield of cotton. J. China Agric. Univ. 2011, 16, 21–27. [Google Scholar]

- Hayes, D.G.; Anunciado, M.B.; Debruyn, J.M.; Bandopadhyay, S.; Sintim, H.Y. Biodegradable Plastic Mulch Films for Sustainable Specialty Crop Production. In Polymers for Agri-Food Applications; Springer: Cham, Switzerland, 2019; pp. 183–213. [Google Scholar]

| Mulch Film Types | Color | Thickness (μm) | Width (cm) | Maximum Load (N, Vertical/Horizontal) |

|---|---|---|---|---|

| Baishan Xifeng (BF1) | Black | 9.6 | 125 | 4.1/1.7 (>1.5) |

| Shandong Qingtian (BF2) | Black | 9.8 | 125 | 4.2/1.6 (>1.5) |

| Shanghai Hongrui (BF3) | Black | 9.8 | 125 | 3.2/1.6 (>1.5) |

| Lanshan Tunhe (BF4) | Black | 9.7 | 125 | 4.2/1.7 (>1.5) |

| PE | Black | 10 | 125 | - (1.6) |

| Treatments | Fruit Number per Hill | Fruit Weight per Hill (kg) | Single Fruit Weight (g) | Yield (t/ha) |

|---|---|---|---|---|

| BF1 | 62.2 b | 3.54 ab | 56.3 a | 125.7 a |

| BF2 | 64.8 ab | 3.72 a | 57.1 a | 132.0 a |

| BF3 | 61.7 b | 3.38 b | 55.1 ab | 119.8 b |

| BF4 | 66.7 a | 3.62 a | 54.3 ab | 127.5 a |

| PE | 67.1 a | 3.39 b | 50.5 b | 124.1 a |

| CK | 55.8 c | 2.91 c | 52.2 b | 104.3 c |

| Treatments | Total Acid (%) | VC (%) | Sugar–Acid Ratio (%) | Sugar–Acid Ratio |

|---|---|---|---|---|

| BF1 | 0.40 ab | 24.32 b | 5.08 a | 12.7 |

| BF2 | 0.39 b | 26.65 ab | 5.37 a | 13.8 |

| BF3 | 0.36 b | 26.11 ab | 5.16 a | 12.9 |

| BF4 | 0.37 b | 22.23 b | 4.79 a | 12.8 |

| PE | 0.41 ab | 25.75 b | 5.68 a | 13.8 |

| CK | 0.46 a | 32.11 a | 4.69 a | 10.2 |

| Treatments | Agricultural Material Inputs | Leasehold and Labor Cost | Harvesting and Plastic Recycling Cost | Total Inputs | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fertilizer | Plastic Film | Germchit | Pesticides | Water and Electricity | Labor Cost | Leasehold Cost | Harvesting Cost | Plastic Recycling Cost | ||

| BF1 | 0.36 | 0.25 | 0.48 | 0.08 | 0.27 | 0.45 | 0.60 | 1.05 | 3.54 a | |

| BF2 | 0.36 | 0.25 | 0.48 | 0.08 | 0.27 | 0.45 | 0.60 | 1.05 | 3.54 a | |

| BF3 | 0.36 | 0.25 | 0.48 | 0.08 | 0.27 | 0.45 | 0.60 | 1.05 | 3.54 a | |

| BF4 | 0.36 | 0.25 | 0.48 | 0.08 | 0.27 | 0.45 | 0.60 | 1.05 | 3.54 a | |

| PE | 0.36 | 0.10 | 0.48 | 0.08 | 0.27 | 0.45 | 0.60 | 1.05 | 0.05 | 3.43 a |

| CK | 0.36 | 0.00 | 0.48 | 0.08 | 0.33 | 0.60 | 0.60 | 1.05 | 3.50 a | |

| Treatments | Total Inputs | Yield (t/hm2) | Total Output | Profit | Profit Rate (%) |

|---|---|---|---|---|---|

| BF1 | 3.54 a | 125.7 a | 4.96 a | 1.42 b | 12.8 |

| BF2 | 3.54 a | 132.0 a | 5.18 a | 1.64 a | 30.2 |

| BF3 | 3.54 a | 119.8 b | 4.67 b | 1.14 c | −9.7 |

| BF4 | 3.54 a | 127.5 a | 4.97 a | 1.41 b | 14.1 |

| PE | 3.43 a | 124.1 a | 4.84 a | 1.26 c | 11.9 |

| CK | 3.50 a | 104.3 c | 4.07 c | 0.57 d | −54.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abduwaiti, A.; Liu, X.; Yan, C.; Xue, Y.; Jin, T.; Wu, H.; He, P.; Bao, Z.; Liu, Q. Testing Biodegradable Films as Alternatives to Plastic-Film Mulching for Enhancing the Yield and Economic Benefits of Processed Tomato in Xinjiang Region. Sustainability 2021, 13, 3093. https://doi.org/10.3390/su13063093

Abduwaiti A, Liu X, Yan C, Xue Y, Jin T, Wu H, He P, Bao Z, Liu Q. Testing Biodegradable Films as Alternatives to Plastic-Film Mulching for Enhancing the Yield and Economic Benefits of Processed Tomato in Xinjiang Region. Sustainability. 2021; 13(6):3093. https://doi.org/10.3390/su13063093

Chicago/Turabian StyleAbduwaiti, Anwar, Xiaowei Liu, Changrong Yan, Yinghao Xue, Tuo Jin, Hongqi Wu, Pengcheng He, Zhe Bao, and Qin Liu. 2021. "Testing Biodegradable Films as Alternatives to Plastic-Film Mulching for Enhancing the Yield and Economic Benefits of Processed Tomato in Xinjiang Region" Sustainability 13, no. 6: 3093. https://doi.org/10.3390/su13063093

APA StyleAbduwaiti, A., Liu, X., Yan, C., Xue, Y., Jin, T., Wu, H., He, P., Bao, Z., & Liu, Q. (2021). Testing Biodegradable Films as Alternatives to Plastic-Film Mulching for Enhancing the Yield and Economic Benefits of Processed Tomato in Xinjiang Region. Sustainability, 13(6), 3093. https://doi.org/10.3390/su13063093