Future Options for Lightweight Photovoltaic Modules in Electrical Passenger Cars

Abstract

1. Introduction

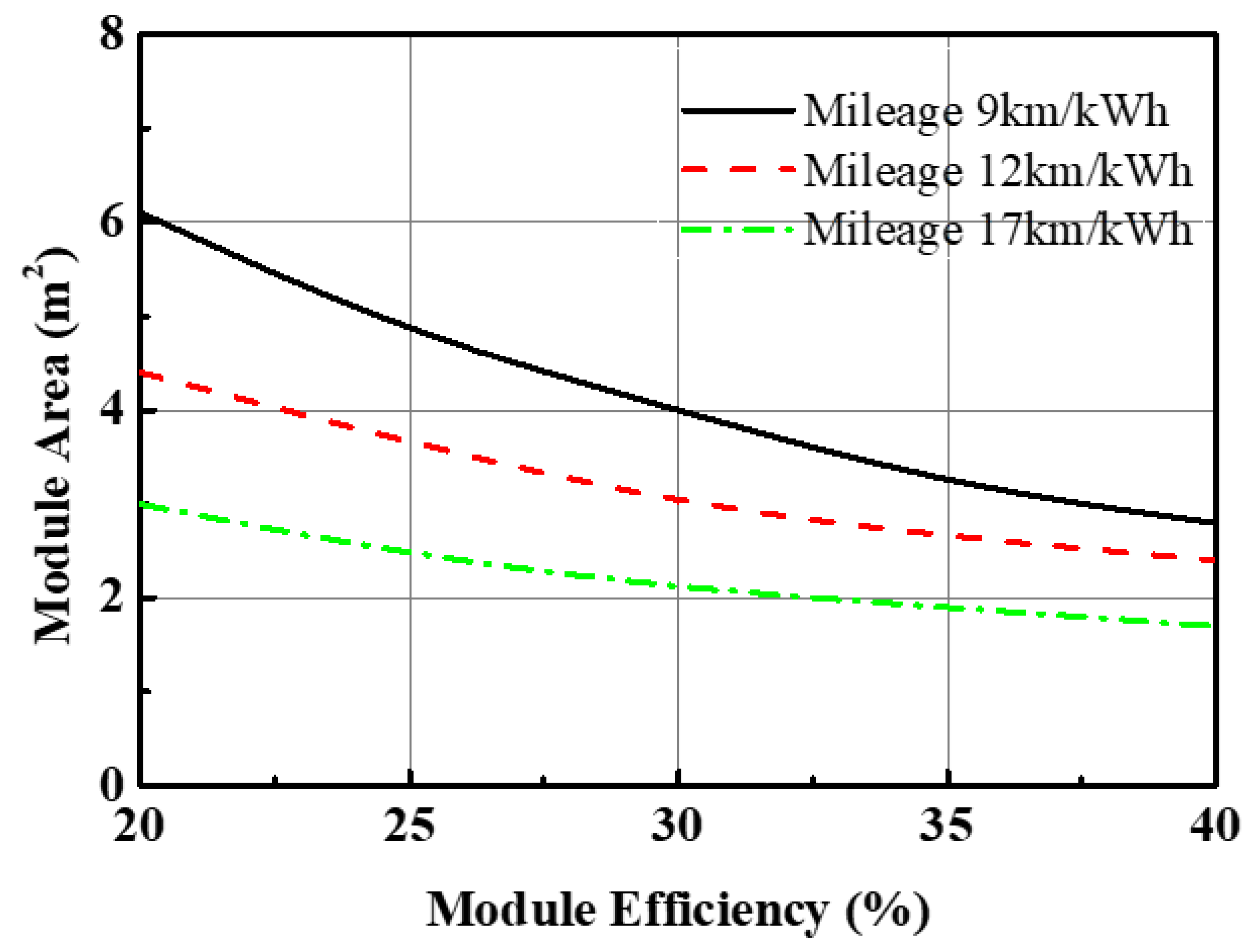

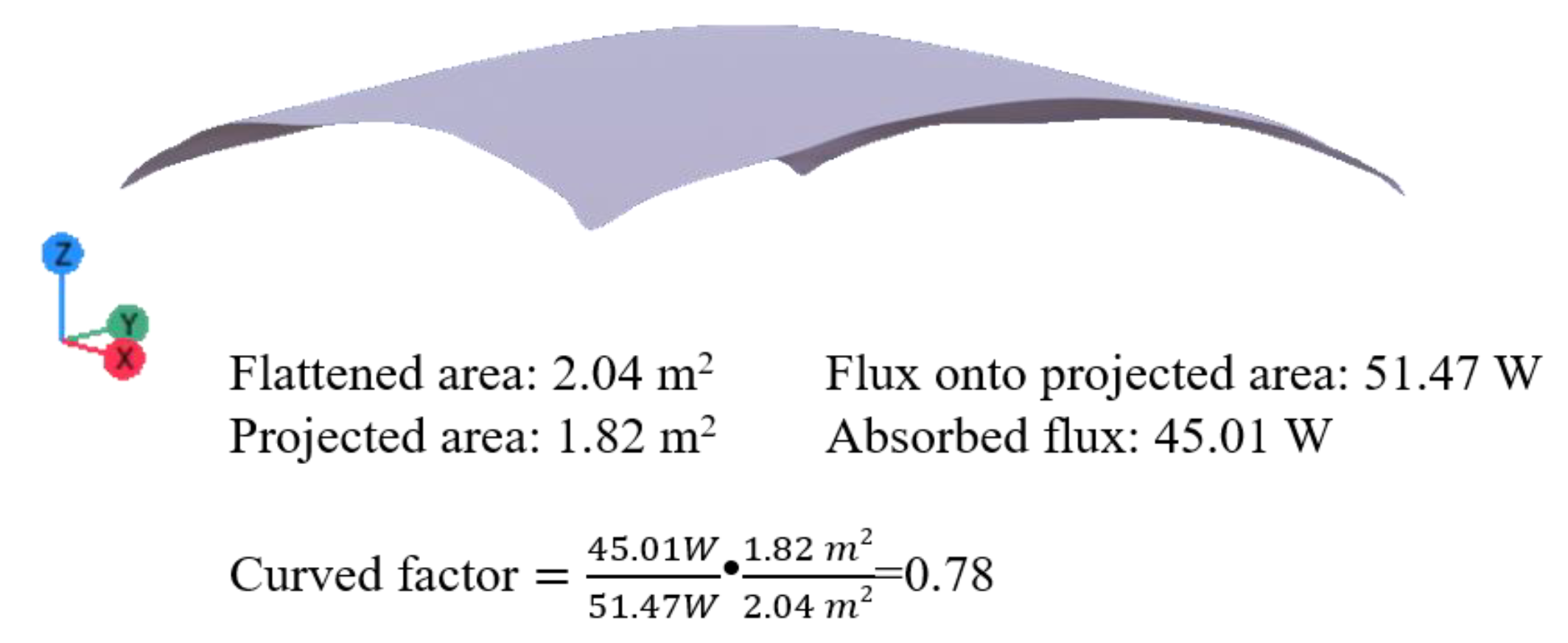

2. Effects of Applying Solar Modules to Passenger Cars

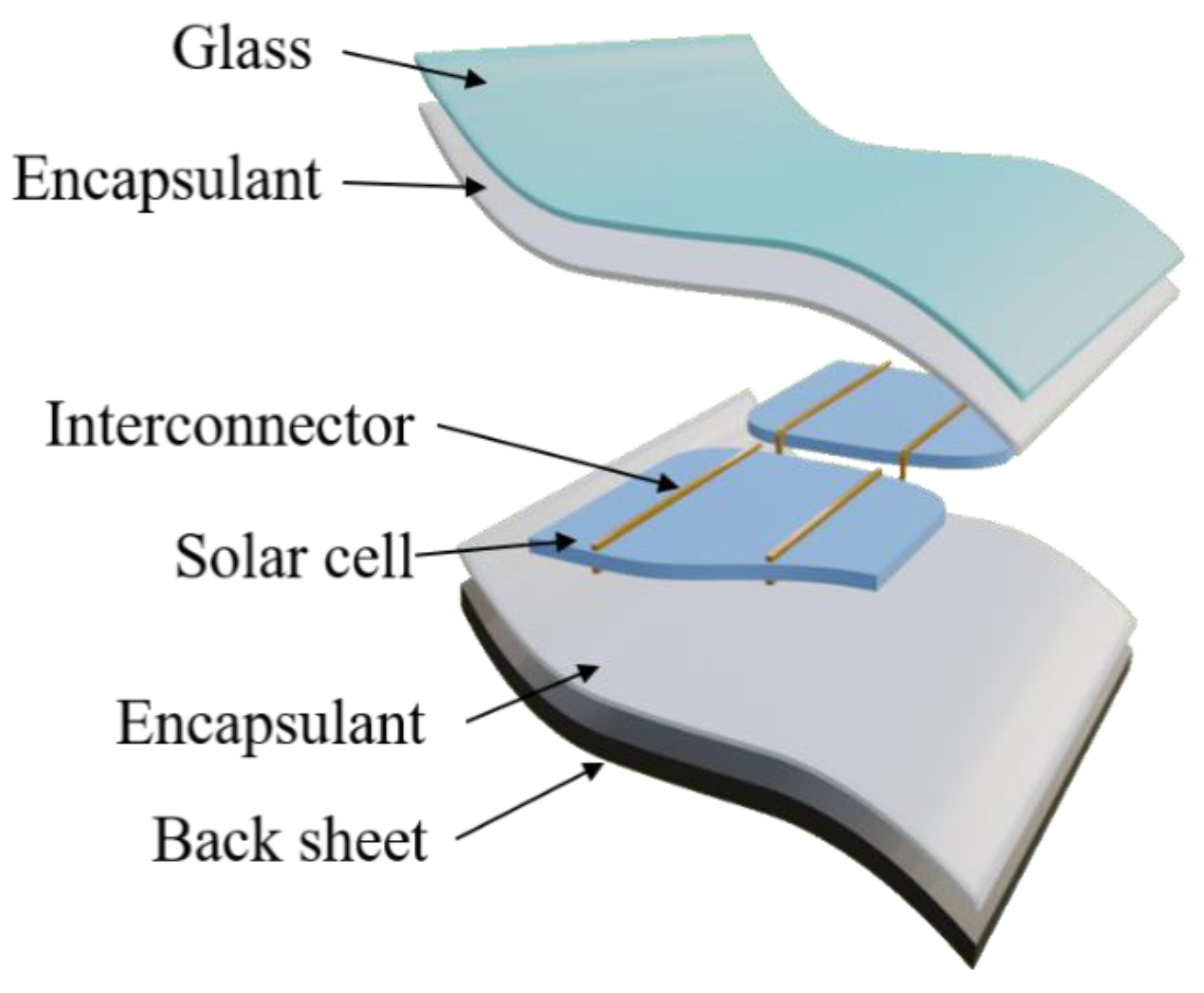

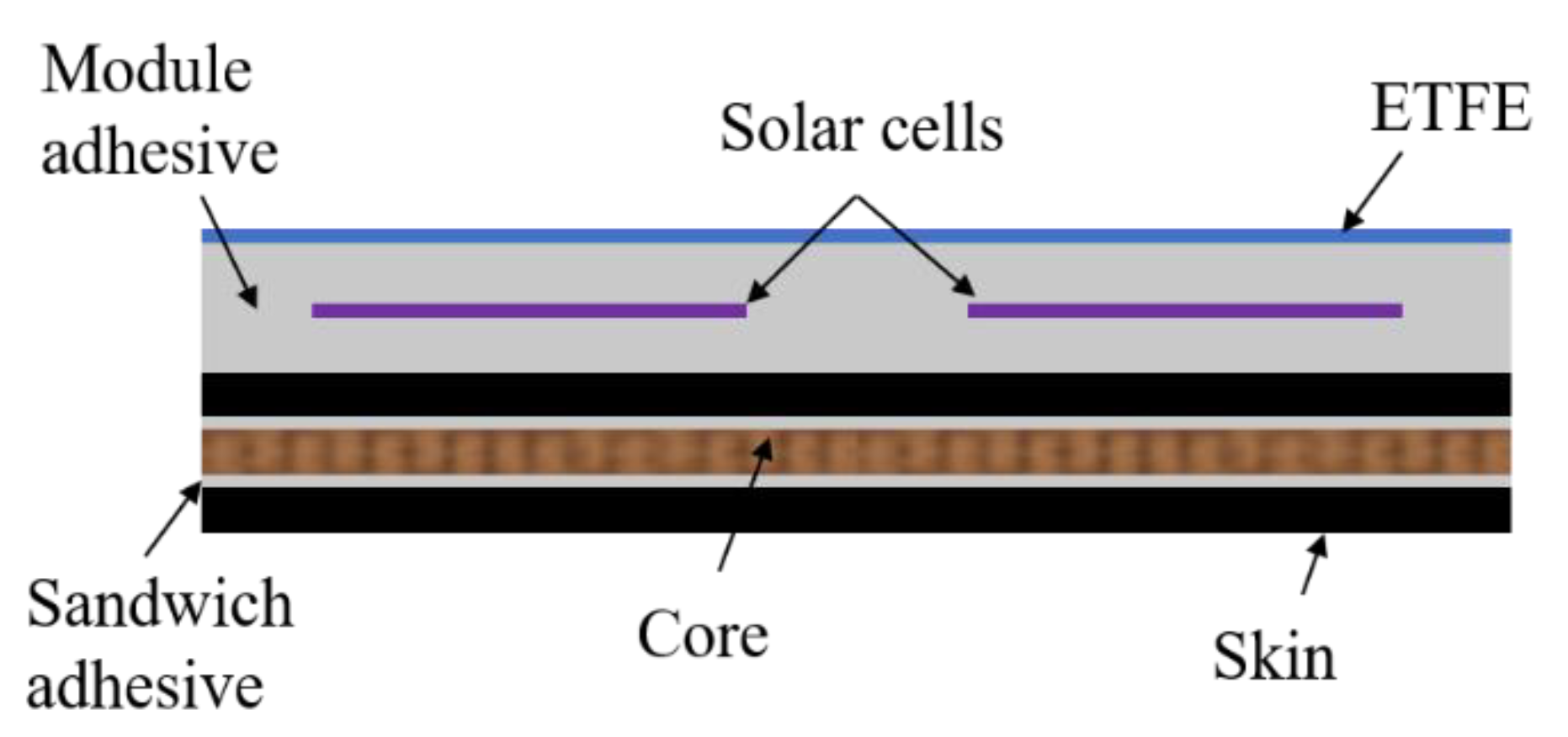

3. Methods of Reducing the Weight of Solar Modules for Passenger Cars

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Longo, M.; Yaïci, W.; Foiadelli, F. Electric vehicles charged with residential’s roof solar photovoltaic system: A case study in Ottawa. Int. Conf. Renew. Energy Res. Appl. ICRERA 2017, 2017, 121–125. [Google Scholar]

- Liu, Z.; Li, L.; Zhang, Y.J. Investigating the CO2 emission differences among China’s transport sectors and their influencing factors. Nat. Hazards 2015, 77, 1323–1343. [Google Scholar] [CrossRef]

- Lakshmanan, T.R.; Han, X. Factors underlying transportation CO2 emissions in the U.S.A.: A decomposition analysis. Transp. Res. Part D Transp. Environ. 1997, 2, 1–15. [Google Scholar] [CrossRef]

- Lee, Y.; Hur, J. A simultaneous approach implementing wind-powered electric vehicle charging stations for charging demand dispersion. Renew. Energy 2019, 144, 172–179. [Google Scholar] [CrossRef]

- Giannouli, M.; Yianoulis, P. Study on the incorporation of photovoltaic systems as an auxiliary power source for hybrid and electric vehicles. Sol. Energy 2012, 86, 441–451. [Google Scholar] [CrossRef]

- Petrović, N.T. The future of moto auto world. Int. Sci. J. Trans Motauto World 2020, 55, 54–55. [Google Scholar]

- Yamaguchi, M.; Masuda, T.; Araki, K.; Sato, D.; Lee, K.H.; Kojima, N.; Takamoto, T.; Okumura, K.; Satou, A.; Yamada, K.; et al. Development of high-efficiency and low-cost solar cells for PV-powered vehicles application. Prog. Photovolt. Res. Appl. 2020, 1–10. [Google Scholar] [CrossRef]

- Masuda, T.; Araki, K.; Okumura, K.; Urabe, S.; Kudo, Y.; Kimura, K.; Nakado, T.; Sato, A.; Yamaguchi, M. Static concentrator photovoltaics for automotive applications. Sol. Energy 2017, 146, 523–531. [Google Scholar] [CrossRef]

- Won Yang, H. Hyundai Launches First Car with Solar Roof Charging System. Available online: https://www.hyundai.news/eu/brand/hyundai-launches-first-car-with-solar-roof-charging-system/ (accessed on 15 May 2020).

- Araki, K.; Ji, L.; Kelly, G.; Yamaguchi, M. To do list for research and development and international standardization to achieve the goal of running a majority of electric vehicles on solar energy. Coatings 2018, 8, 251. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Masuda, T.; Araki, K.; Sato, D.; Lee, K.; Kojima, N.; Takamoto, T.; Okumura, K.; Satou, A.; Yamada, K.; et al. Role of PV-Powered Vehicles in Low-Carbon Society and Some Approaches of High-Efficiency Solar Cell Modules for Cars. Energy Power Eng. 2020, 12, 375–395. [Google Scholar] [CrossRef]

- Jochem, P.; Babrowski, S.; Fichtner, W. Assessing CO2 emissions of electric vehicles in Germany in 2030. Transp. Res. Part A Policy Pract. 2015, 78, 68–83. [Google Scholar] [CrossRef]

- Christensen, L.; Klauenberg, J.; Kveiborg, O.; Rudolph, C. Suitability of commercial transport for a shift to electric mobility with Denmark and Germany as use cases. Res. Transp. Econ. 2017, 64, 48–60. [Google Scholar] [CrossRef]

- Reuß, M.; Grube, T.; Robinius, M.; Stolten, D. A hydrogen supply chain with spatial resolution: Comparative analysis of infrastructure technologies in Germany. Appl. Energy 2019, 247, 438–453. [Google Scholar] [CrossRef]

- Nussbaumer, H.; Klenk, M.; Keller, N.; Turnheer, J.; Ammann, P. Record-Light Weight c-Si Modules Based on the Small Unit Compound Approach–Mechanical Load Tests and General Results. Eur. Photovolt. Sol. Energy Conf. Exhib. 2017, 146–150. [Google Scholar] [CrossRef]

- Arleth, M. Trends in Lightweight Construction of Roofs. ATZ Worldw. 2015, 4, 38–43. [Google Scholar]

- Araki, K.; Algora, C.; Siefer, G.; Nishioka, K.; Leutz, R.; Carter, S.; Wang, S.; Askins, S.; Ji, L.; Kelly, G. Standardization of the CPV and car-roof PV technology in 2018-Where are we going to go? AIP Conf. Proc. 2018, 2012, 070001. [Google Scholar]

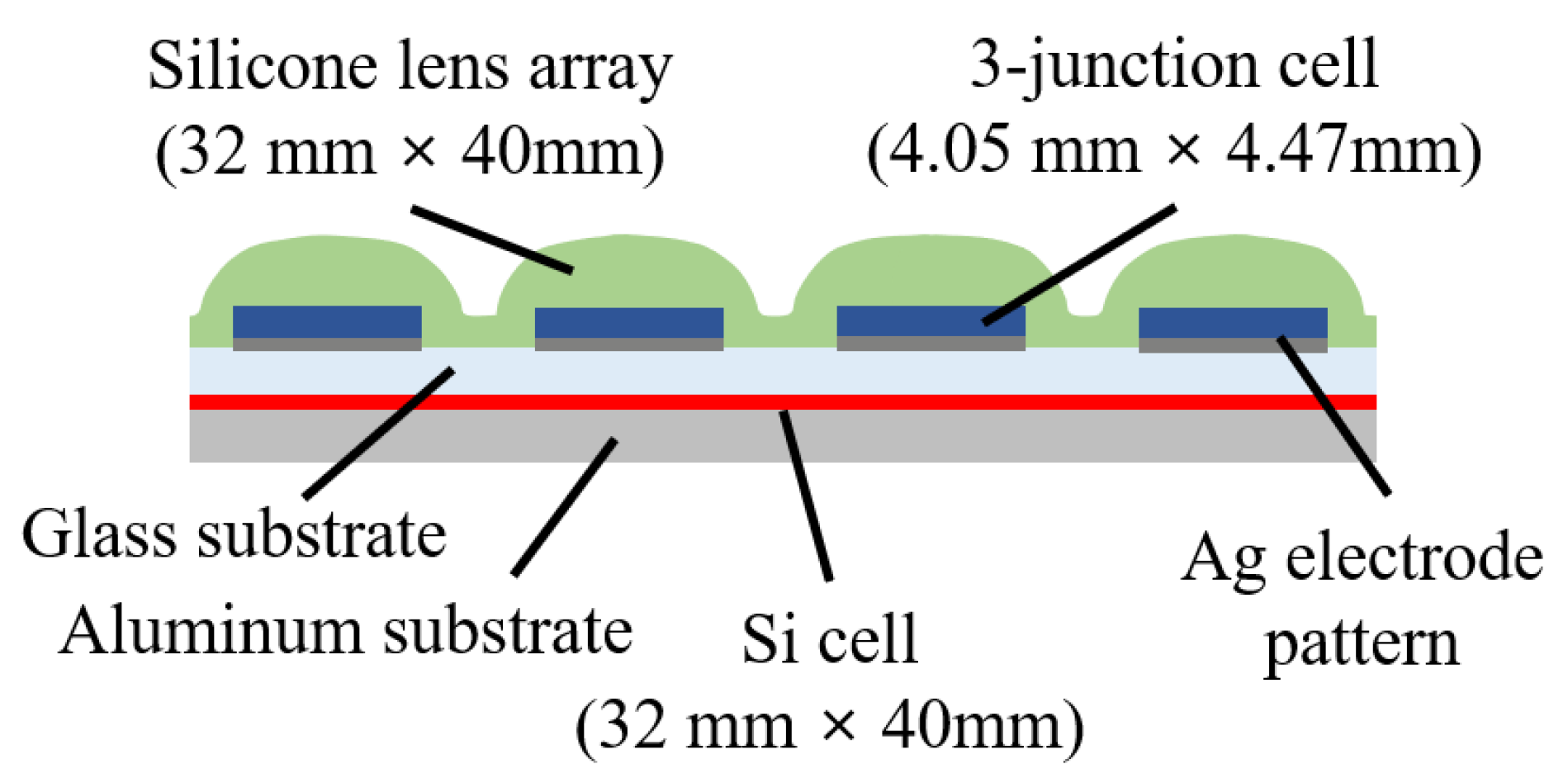

- Vu, N.H.; Pham, T.T.; Shin, S. Flat concentrator photovoltaic system for automotive applications. Sol. Energy 2019, 190, 246–254. [Google Scholar] [CrossRef]

- Korkut, T.B.; Goren, A.; Ezan, M.A. A CFD study on photovoltaic performance investigation of a solar racing car. In Green Energy and Technology; Dincer, I., Colpan, C.O., Ezan, M.A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 509–529. [Google Scholar]

- Gorter, T.; Reinders, A.H.M.E. A comparison of 15 polymers for application in photovoltaic modules in PV-powered boats. Appl. Energy 2012, 92, 286–297. [Google Scholar] [CrossRef]

- Jong, L.; Shin, R.; Gyun, W.; Hee, Y.; Kim, S.; Sung, Y. A Study on the Output and Reliability Characteristics of Ultra Barrier Film PV Module. J. Korean Sol. Energy Soc. 2019, 39, 1–10. [Google Scholar]

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Ballif, C. Robust Glass-Free Lightweight Photovoltaic Modules with Improved Resistance to Mechanical Loads and Impact. IEEE J. Photovolt. 2019, 9, 245–251. [Google Scholar] [CrossRef]

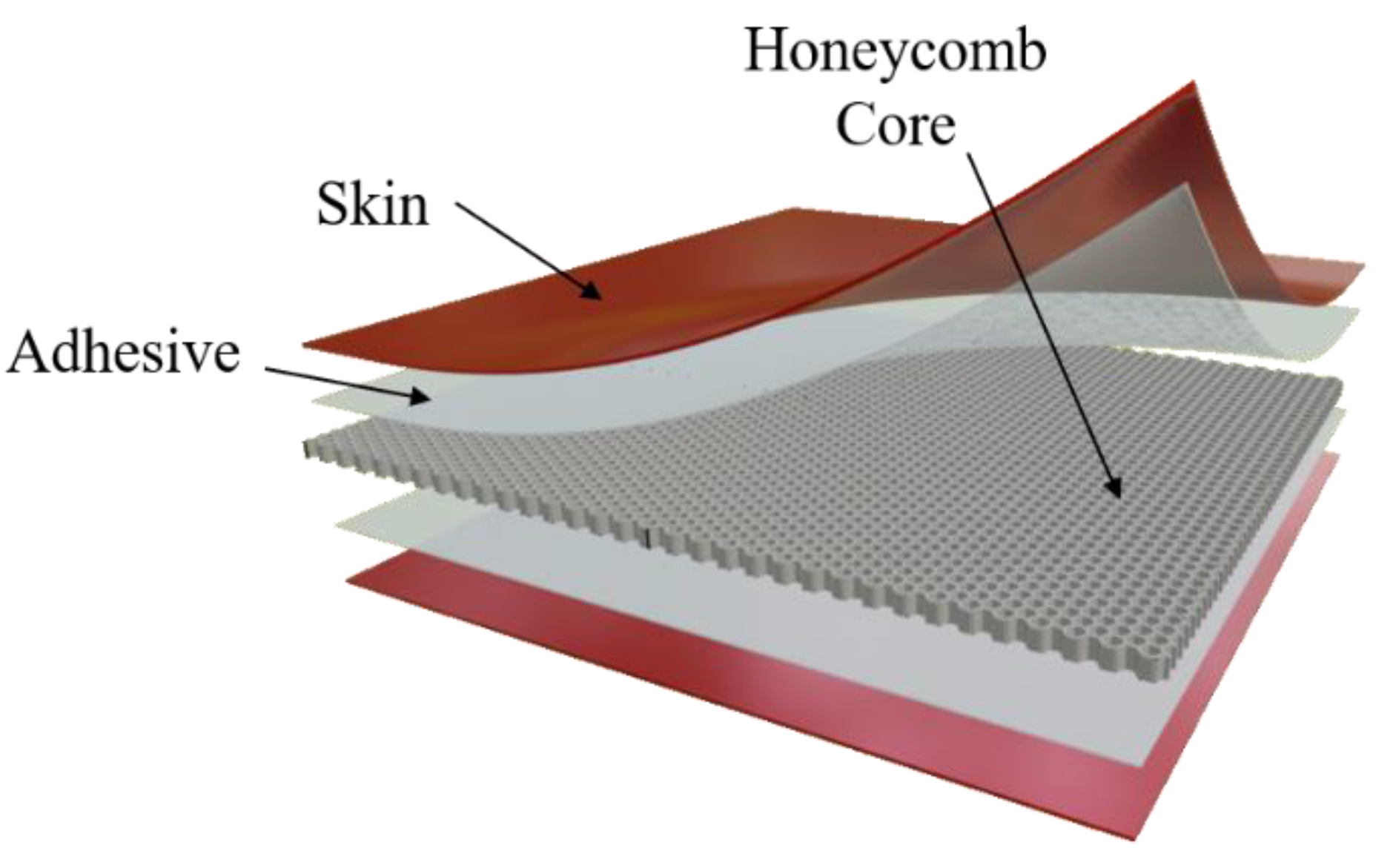

- Burton, W.S.; Noor, A.K. Structural analysis of the adhesive bond in a honeycomb core sandwich panel. Finite Elem. Anal. Des. 1997, 26, 213–227. [Google Scholar] [CrossRef]

- Kindinger, J. ASM HANDBOOK. Lightweight Structural Cores. 2001, pp. 180–183. Available online: https://dl.asminternational.org/handbooks/book/60/chapter-abstract/699237/Lightweight-Structural-Cores?redirectedFrom=fulltext (accessed on 15 May 2020).

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Ballif, C. Ultra-Lightweight PV module design for Building Integrated Photovoltaics. Photovolt. Spec. Conf. 2017, 2104–2108. [Google Scholar] [CrossRef]

- Sato, D.; Lee, K.H.; Araki, K.; Masuda, T.; Yamaguchi, M.; Yamada, N. Design and Evaluation of Low-concentration Static III-V/Si Partial CPV Module for Car-rooftop Application. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa Village, HI, USA, 10–15 June 2018; pp. 954–957. [Google Scholar]

| Materials | Density (g/cm3) | Thermal Conductivity (W/mk) |

|---|---|---|

| Glass | 2.55 | 0.8 |

| PMMA | 1.19 | 0.167–0.25 1 |

| PC | 1.2 | 0.19–0.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Holz, M.; Park, S.; Yoon, Y.; Cho, E.; Yi, J. Future Options for Lightweight Photovoltaic Modules in Electrical Passenger Cars. Sustainability 2021, 13, 2532. https://doi.org/10.3390/su13052532

Kim S, Holz M, Park S, Yoon Y, Cho E, Yi J. Future Options for Lightweight Photovoltaic Modules in Electrical Passenger Cars. Sustainability. 2021; 13(5):2532. https://doi.org/10.3390/su13052532

Chicago/Turabian StyleKim, Sehyeon, Markus Holz, Soojin Park, Yongbeum Yoon, Eunchel Cho, and Junsin Yi. 2021. "Future Options for Lightweight Photovoltaic Modules in Electrical Passenger Cars" Sustainability 13, no. 5: 2532. https://doi.org/10.3390/su13052532

APA StyleKim, S., Holz, M., Park, S., Yoon, Y., Cho, E., & Yi, J. (2021). Future Options for Lightweight Photovoltaic Modules in Electrical Passenger Cars. Sustainability, 13(5), 2532. https://doi.org/10.3390/su13052532