How Corporate Social Responsibility and External Stakeholder Concerns Affect Green Supply Chain Cooperation among Manufacturers: An Interpretive Structural Modeling Analysis

Abstract

1. Introduction

2. Literature Review

2.1. Going Green in Supply Chain

2.2. Green Supply Chain Cooperation

2.3. Influencing Factors for Green Supply Chain Cooperation: CSR and External Stakeholders

3. Research Methodology

3.1. Interpretive Structural Modeling (ISM)

- Step 1.

- Variables (factors, elements or criteria) of the system under consideration are listed.

- Step 2.

- A contextual relationship is established with the variables identified in the first step to determine which pairs of variables should be examined.

- Step 3.

- A structural self-interaction matrix (SSIM) is constructed, indicating pairwise relationships among variables of the system under consideration.

- Step 4.

- A reachability matrix (RM) is developed from the SSIM to be checked for transitivity. The transitivity is a basic assumption declaring that if a variable A is related to B and B is related to C, then A is necessarily related to C.

- Step 5.

- The RM developed in the previous step is partitioned into different levels.

- Step 6.

- A direct graph is drawn based on the relationships given in the RM and the transitive links are removed.

- Step 7.

- The resultant digraph is converted into an ISM with the replacement of variable nodes with statements.

- Step 8.

- The ISM model is then checked for conceptual inconsistency and necessary modifications as well as commentary is made.

3.2. Data Collection

3.3. Building Structural Self-Interaction Matrix (SSIM)

- V: Factor i will help achieve factor j;

- A: Factor j will help achieve factor i;

- X: Factors i and j will help achieve each other; and

- O: Factors i and j are independent.

3.4. Building the Reachability Matrix (RM)

- (1)

- The cell (i, j) of the SSIM containing a “V” should be filled with 1 and the corresponding cell (j, i) should be filled with 0.

- (2)

- The cell (i, j) of the SSIM containing a “A” should be filled with 0 and the corresponding cell (j, i) should be filled with 1.

- (3)

- The cell (i, j) of the SSIM containing a “X” should be filled with 1 and the corresponding cell (j, i) should be filled with 1.

- (4)

- The cell (i, j) of the SSIM containing a “O” should be filled with 0 and the corresponding cell (j, i) should be filled with 0.

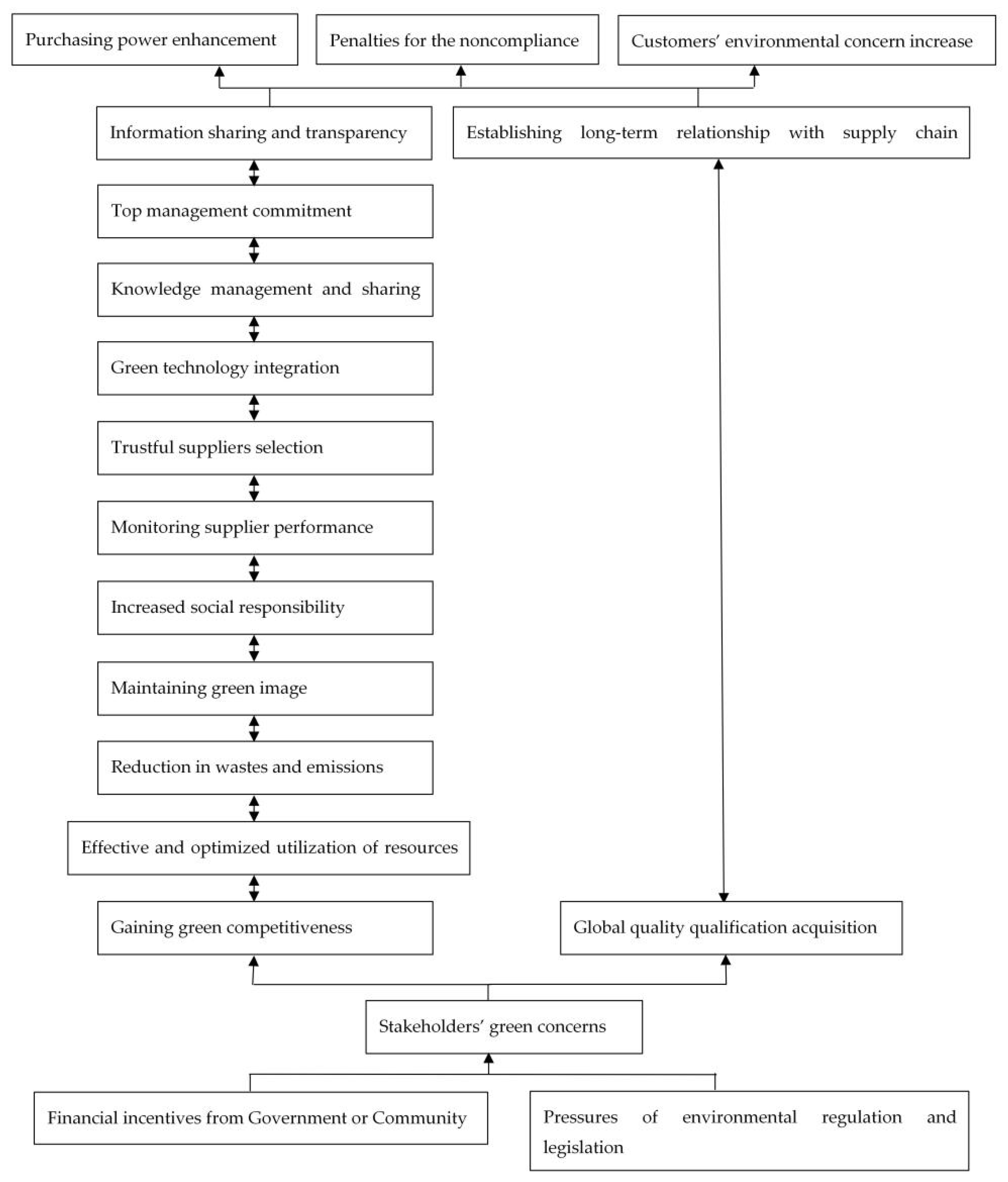

3.5. Levels Partitioning and Development of ISM-Based Model

3.6. MICMAC Analysis

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MEEC (Ministry of Ecology and Environment of China). China’s Ecological and Environmental Statements 2018; MEEC: Beijing, China, 2019.

- Ramanathan, U.; Bentley, Y.; Pang, G. The role of collaboration in the UK green supply chains: An exploratory study of the perspectives of suppliers, logistics and retailers. J. Clean. Prod. 2014, 70, 231–241. [Google Scholar] [CrossRef]

- Swami, S.; Shah, J. Channel coordination in green supply chain management. J. Oper. Res. Soc. 2013, 64, 336–351. [Google Scholar] [CrossRef]

- Mentzer, J.T.; Dewitt, W.; Keebler, J.S. Defining supply chain management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y. Drivers and barriers of extended supply chain practices for energy saving and emission reduction among Chinese manufacturers. J. Clean. Prod. 2013, 40, 6–12. [Google Scholar] [CrossRef]

- Singh, A.K.; Jha, S.K.; Prakash, A. Green Manufacturing (GM) performance measures: An empirical investigation from Indian MSMEs. Int. J. Res. Advent Technol. 2014, 2, 51–65. [Google Scholar]

- Thurner, T.W.; Roud, V. Greening strategies in Russia’s manufacturing—From compliance to opportunity. J. Clean. Prod. 2016, 162, 1607–1616. [Google Scholar] [CrossRef]

- Rao, P. Greening of the supply chain: An empirical study for SMEs in the Philippine context. J. Asia Bus. Stud. 2007, 1, 55–66. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Carroll, A.B.; Shabana, K.M. The business case for corporate social responsibility: A review of concepts, research and practice. Int. J. Manag. Rev. 2010, 12, 85–105. [Google Scholar] [CrossRef]

- Seuring, S. Sustainability management beyond corporate boundaries. J. Clean. Prod. 2010, 18, 1118–1119. [Google Scholar] [CrossRef]

- Lozano, R. Developing collaborative and sustainable organisations. J. Clean. Prod. 2008, 16, 499–509. [Google Scholar] [CrossRef]

- Govindan, K.; Seuring, S.; Zhu, Q.; Garrido, A.S. Accelerating the transition towards sustainability dynamics into supply chain relationship management and governance structures. J. Clean. Prod. 2016, 112, 1813–1823. [Google Scholar] [CrossRef]

- Subramanian, R.; Gupta, S.; Talbot, B. Product design and supply chain coordination under extended producer responsibility. Prod. Oper. Manag. 2009, 18, 259–277. [Google Scholar] [CrossRef]

- Xu, J.; Chen, Y.; Bai, Q. A two-echelon sustainable supply chain coordination under cap-and-trade regulation. J. Clean. Prod. 2016, 135, 42–56. [Google Scholar] [CrossRef]

- Govindan, K.; Popiuc, M.N. Reverse supply chain coordination by revenue sharing contract: A case for the personal computers industry. Eur. J. Oper. Res. 2014, 233, 326–336. [Google Scholar] [CrossRef]

- Oglethorpe, D. Optimising economic, environmental, and social objectives: A goal-programming approach in the food sector. Environ. Plan. A 2010, 42, 1239–1254. [Google Scholar] [CrossRef]

- Guo, Y.; Yen, D.A.; Geng, R.; Azar, G. Drivers of green cooperation between Chinese manufacturers and their customers: An empirical analysis. Ind. Mark. Manage. 2021, 93, 137–146. [Google Scholar] [CrossRef]

- Zhang, J.; Gou, Q.; Liang, L.; Huang, Z. Supply chain coordination through cooperative advertising with reference price effect. Omega 2013, 41, 345–353. [Google Scholar] [CrossRef]

- Dai, R.; Zhang, J.; Tang, W. Cartelization or cost-sharing? Comparison of cooperation modes in a green supply chain. J. Clean. Prod. 2017, 156, 159–173. [Google Scholar] [CrossRef]

- Burr, C.; Knauff, M.; Stepanova, A. On the prisoner’s dilemma in R&D with input spillovers and incentives for R&D cooperation. Math. Soc. Sci. 2013, 66, 254–261. [Google Scholar]

- Marini, M.A.; Petit, M.L.; Sestini, R. Strategic timing in R&D agreements. Econ. Innov. New Technol. 2014, 23, 274–303. [Google Scholar]

- Riedel, R.; Mueller, E. Production management and supply chain management in a global context. Int. J. Manuf. Technol. Manag. 2009, 16, 300. [Google Scholar] [CrossRef]

- Berry, D.; Towill, D.R.; Wadsley, N. Supply chain management in the electronics products industry. Int. J. Phys. Distrib. Logist. Manag. 1994, 24, 20–32. [Google Scholar] [CrossRef]

- Welford, R. Globalisation, corporate social responsibility and human rights. Corp. Soc. Responsib. Environ. Manag. 2002, 9, 1–8. [Google Scholar] [CrossRef]

- González-Benito, J.; González-Benito, Ó. The role of stakeholder pressure and managerial values in the implementation of environmental logistics practices. Int. J. Prod. Res. 2006, 44, 1353–1373. [Google Scholar] [CrossRef]

- Locke, R.; Romis, M. Improving work conditions in a global supply chain. MIT Sloan Manag. Rev. 2007, 48, 54–62. [Google Scholar]

- Collins, C.M.; Steg, L.; Koning, M.A.S. Customers’ values, beliefs on sustainable corporate performance, and buying behavior. Psychol. Mark. 2010, 24, 555–577. [Google Scholar] [CrossRef]

- Hong, Z.; Guo, X. Green product supply chain contracts considering environmental responsibilities. Omega 2018, 83, 155–166. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2013, 25, 898–916. [Google Scholar] [CrossRef]

- Hoek, V.; Remko, I. From reversed logistics to green supply chains. Supply Chain Manag. Int. J. 1999, 4, 129–135. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Walton, S.V.; Handfield, R.B.; Melnyk, S.A. The green supply chain: Integrating suppliers into environmental management processes. J. Supply Chain Manag. 2010, 34, 2–11. [Google Scholar] [CrossRef]

- Barratt, M. Understanding the meaning of collaboration in the supply chain. Supply Chain Manag. Int. J. 2004, 9, 30–42. [Google Scholar] [CrossRef]

- Danese, P. Designing CPFR collaborations: Insights from seven case studies. Int. J. Oper. Prod. Manag. 2007, 27, 181–204. [Google Scholar] [CrossRef]

- Ramanathan, R.; He, Q.; Black, A.; Ghobadian, A.; Gallear, D. Environmental regulations, innovation and firm performance: A revisit of the Porter hypothesis. J. Clean. Prod. 2016, 155, 79–92. [Google Scholar] [CrossRef]

- Khan, O.; Christopher, M.; Creazza, A. Aligning product design with the supply chain: A case study. Supply Chain Manag. Int. J. 2012, 17, 323–336. [Google Scholar] [CrossRef]

- Hart, S.L.; Dowell, G.I. A natural-resource-based view of the firm: Fifteen years after. J. Manag. 2011, 37, 1464–1479. [Google Scholar]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Melville, N.P. Information systems innovation for environmental sustainability. Mis Q. 2010, 34, 1–21. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Wallin, C.; Allred, C.; Fawcett, A.M.; Magnan, G.M. Information technology as an enabler of supply chain collaboration: A dynamic-capabilities perspective. J. Supply Chain Manag. 2011, 47, 38–59. [Google Scholar] [CrossRef]

- Cai, Z.; Huang, Q.; Liu, H.; Liang, L. The moderating role of information technology capability in the relationship between supply chain collaboration and organizational responsiveness. Int. J. Oper. Prod. Manag. 2016, 36, 1247–1271. [Google Scholar] [CrossRef]

- Handfield, R.; Sroufe, R.; Walton, S. Integrating environmental management and supply chain strategies. Bus. Strategy Environ. 2010, 14, 1–19. [Google Scholar] [CrossRef]

- Large, R.O.; Thomsen, C.G. Drivers of green supply management performance: Evidence from Germany. J. Purch. Supply Manag. 2011, 17, 176–184. [Google Scholar] [CrossRef]

- Walker, H.; Jones, N. Sustainable supply chain management across the UK private sector. Supply Chain Manag. Int. J. 2012, 17, 15–28. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Pujari, D.; Peattie, K.; Wright, G. Organizational antecedents of environmental responsiveness in industrial new product development. Ind. Mark. Manag. 2004, 33, 381–391. [Google Scholar] [CrossRef]

- Pagell, M.; Wu, Z. Building a more complete theory of sustainable supply chain management using case studies of 10 exemplars. J. Supply Chain Manag. 2010, 45, 37–56. [Google Scholar] [CrossRef]

- Hofer, C.; Cantor, D.E.; Dai, J. The competitive determinants of a firm’s environmental management activities: Evidence from US manufacturing industries. J. Oper. Manag. 2012, 30, 69–84. [Google Scholar] [CrossRef]

- Rehman, M.A.; Seth, D.; Shrivastava, R.L. Impact of green manufacturing practices on organisational performance in Indian context: An empirical study. J. Clean. Prod. 2016, 137, 427–448. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2004, 23, 449–468. [Google Scholar] [CrossRef]

- Cheng, J.; Yeh, C.; Tu, C. Trust and knowledge sharing in green supply chains. Supply Chain Manag. Int. J. 2008, 13, 283–295. [Google Scholar] [CrossRef]

- Gmelin, H.; Seuring, S. Determinants of a sustainable new product development. J. Clean. Prod. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Lee, S.Y. The effects of green supply chain management on the supplier’s performance through social capital accumulation. Supply Chain Manag. 2015, 20, 42–55. [Google Scholar] [CrossRef]

- Hoejmose, S.; Brammer, S.; Millington, A. “Green” supply chain management: The role of trust and top management in B2B and B2C markets. Ind. Mark. Manag. 2012, 41, 609–620. [Google Scholar] [CrossRef]

- Hartmann, J.; Germain, R. Understanding the relationships of integration capabilities, ecological product design, and manufacturing performance. J. Clean. Prod. 2015, 92, 196–205. [Google Scholar] [CrossRef]

- Sharma, S. Managerial interpretations and organizational context as predictors of corporate choice of environmental strategy. Acad. Manag. J. 2000, 43, 681–697. [Google Scholar]

- Seuring, S. Integrated chain management and supply chain management comparative analysis and illustrative cases. J. Clean. Prod. 2004, 12, 1059–1071. [Google Scholar] [CrossRef]

- Mudgal, R.K.; Shankar, R.; Talib, P.; Raj, T. Modelling the barriers of green supply chain practices: An Indian perspective. Int. J. Logist. Syst. Manag. 2010, 7, 81. [Google Scholar] [CrossRef]

- Claver, E.; López, M.D.; Molina, J.F.; Tari, A.A. Environmental management and firm performance: A case study. J. Environ. Manag. 2007, 84, 606–619. [Google Scholar] [CrossRef] [PubMed]

- Shang, K.C.; Lu, C.S.; Li, S.R. A taxonomy of green supply chain management capability among electronics-related manufacturing firms in Taiwan. J. Environ. Manag. 2010, 91, 1218–1226. [Google Scholar] [CrossRef] [PubMed]

- Gunasekaran, A.; Spalanzani, A. Sustainability of manufacturing and services: Investigations for research and applications. Int. J. Prod. Econ. 2012, 140, 35–47. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.S.F. Evaluating firm’s green supply chain management in linguistic preferences. J. Clean. Prod. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Scur, G.; Barbosa, M.E. Green supply chain management practices: Multiple case studies in the Brazilian home appliance industry. J. Clean. Prod. 2017, 141, 1293–1302. [Google Scholar] [CrossRef]

- Figge, F.; Hahn, T. Is green and profitable sustainable? Assessing the trade-off between economic and environmental aspects. Int. J. Prod. Econ. 2012, 140, 92–102. [Google Scholar] [CrossRef]

- Thollander, P.; Backlund, S.; Trianni, A.; Cagno, E. Beyond barriers—A case study on driving forces for improved energy efficiency in the foundry industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 2013, 111, 636–643. [Google Scholar] [CrossRef]

- Liu, P.; Zhou, Y.; Zhou, D.K.; Xue, L. Energy Performance Contract models for the diffusion of green-manufacturing technologies in China: A stakeholder analysis from SMEs’ perspective. Energy Policy 2017, 106, 59–67. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S.; Herrmann, C.; Egede, P.; Wulbusch, C. Drivers and Barriers of Environmentally Conscious Manufacturing: A Comparative Study of Indian and German Organizaionts; Leveraging Technology for a Sustainable World; Springer: Berlin/Heidelberg, Germany, 2012; pp. 97–102. [Google Scholar]

- Henriques, J.; Catarino, J. Motivating towards energy efficiency in small and medium enterprises. J. Clean. Prod. 2016, 139, 42–50. [Google Scholar] [CrossRef]

- Parker, C.M.; Redmond, J.; Simpson, M. A review of interventions to encourage SMEs to make environmental improvements. Environ. Plan. C Gov. Policy 2009, 27, 279–301. [Google Scholar] [CrossRef]

- Lee, K.E.; Mokhtar, M.; Goh, C.T.; Singh, H.; Chan, P.W. Initiatives and challenges of a chemical industries council in a developing country: The case of Malaysia. J. Clean. Prod. 2015, 86, 417–423. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Wong, C.W.; Lai, K.H. Relational stability and alliance performance in supply chain. Omega 2008, 36, 600–608. [Google Scholar] [CrossRef]

- Govindan, K.; Diabat, A.; Shankar, K.M. Analyzing the drivers of green manufacturing with fuzzy approach. J. Clean. Prod. 2015, 96, 182–193. [Google Scholar] [CrossRef]

- Zheng, D.; Shi, M. Multiple environmental policies and pollution haven hypothesis: Evidence from China’s polluting industries. J. Clean. Prod. 2017, 141, 295–304. [Google Scholar] [CrossRef]

- Neto, G.C.O.; Leite, R.R.; Shibao, F.Y.; Lucato, W.C. Framework to overcome barriers in the implementation of cleaner production in small and medium-sized enterprises: Multiple case studies in Brazil. J. Clean. Prod. 2016, 142, 50–62. [Google Scholar] [CrossRef]

- Darnall, N.; Jolley, G.J.; Handfield, R. Environmental management systems and green supply chain management: Complements for sustainability? Bus. Strategy Environ. 2008, 17, 30–45. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.; Jabbour, C.J.; Latan, H.; Teixeira, A.A.; de Oliveira, J.H. Quality management, environmental management maturity, green supply chain practices and green performance of Brazilian companies with ISO 14001 certification: Direct and indirect effects. Transp. Res. Part E 2015, 74, 139–151. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Farris, D.R.; Sage, A.P. On the use of interpretive structural modeling to obtain models for worth assessment. Comput. Electr. Eng. 1975, 2, 149–174. [Google Scholar] [CrossRef]

- Warfield, J.N. Societal Systems: Planning, Policy, and Complexity; Wiley: New York, NY, USA, 1976. [Google Scholar]

- Sage, A. Interpretive Structural Modeling: Methodology for Large Scale Systems; McGraw-Hill: New York, NY, USA, 1977. [Google Scholar]

- Govindan, K.; Pokharel, S.; Kumar, P.S. A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 2011, 55, 493–494. [Google Scholar] [CrossRef]

- Lai, K.H.; Bao, Y.; Li, X. Channel relationship and business uncertainty: Evidence from the Hong Kong market. Ind. Mark. Manag. 2008, 37, 713–724. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Freeman, E.R. Strategic Management: A Stakeholder Approach; Pitman: Boston, MA, USA, 1984. [Google Scholar]

- Reinhardt, F.L. Bringing the environment down to earth. Harv. Bus. Rev. 1999, 77, 149–157. [Google Scholar] [PubMed]

- Lee, S.Y.; Klassen, R.D. Drivers and enablers that foster environmental management capabilities in small- and medium-sized suppliers in supply chains. Prod. Oper. Manag. Soc. 2008, 17, 573–586. [Google Scholar] [CrossRef]

- Delmas, M.A.; Montiel, I. The Adoption of Iso 14001 within the Supply Chain: When Are Customer Pressures Effective? ISBER Publications, Paper 10; Institute for Social, Behavioral, and Economic Research: Santa Barbara, CA, USA, 2007; Available online: http://repositories.cdlib.org/isber/publications/10 (accessed on 23 February 2021).

- Handfield, R.; Walton, S.V.; Seegers, L.K.; Melnyk, S.A. Green value chain practices in the furniture industry. J. Oper. Manag. 1997, 15, 293–315. [Google Scholar] [CrossRef]

- Backer, L. Engaging stakeholders in corporate environmental governance. Bus. Soc. Rev. 2007, 112, 29–54. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- Darnall, N.; Henriques, I.; Sadorsky, P. Do environmental management systems improve business performance in an international setting? J. Int. Manag. 2008, 14, 364–376. [Google Scholar] [CrossRef]

- Hoffman, A. Competitive Environmental Strategy: A Guide to the Changing Business Landscape. Island Press: Washington, DC, USA, 2000. [Google Scholar]

| Influencing Factors | Description | Source | |

|---|---|---|---|

| 1 | Information sharing and transparency | Information sharing through the communication systems along the supply chain can be seen as the enabling resources for the development of green capacities within the enterprise as well as across the partners with information exchange and transparency and the cooperation up and down the supply chain. | Hervani et al., 2005; Melville, 2010; Fawcett et al., 2011; Cai et al., 2016 [42,43,44,45] |

| 2 | Purchasing power enhancement | The purchasing strategy of environmental issues’ involvement enables the enterprises to define an action plan towards suppliers for green purchases. | Handfield et al., 2010; Large and Thomsen, 2011; Walker and Jones, 2012 [46,47,48] |

| 3 | Top management commitment | The commitment from the top management of an enterprise allows for the devotion of the necessary resources for green cooperation through the supply chain. | Bowen et al., 2001; Pujari et al., 2004; Pagell and Wu, 2009; Hofer et al., 2012; Rehman et al., 2016 [49,50,51,52,53] |

| 4 | Knowledge management and sharing | Knowledge management encourages learning, sharing and spreading environmental knowledge and technical green initials between enterprises across the chain. | Zhu et al., 2004; Cheng et al., 2008; Gmelin and Seuring, 2014; Lee, 2015 [54,55,56,57] |

| 5 | Green technology integration | Technological integration with primary suppliers and major customers is believed to be positively linked to environmental performance and cooperation. | Vachon and Klassen, 2006; Gmelin and Seuring, 2014 [34,56] |

| 6 | Trustful suppliers’ selection | Trust is vital in the cooperation between supply chain partners and the trustful suppliers will enhance their commitment and investment for environmental issues, which is the major consideration for enterprises to select their suppliers. | Zhu and Sakis, 2004; Cheng et al., 2008; Hoejmose et al., 2012; Hartmann and Germain, 2015 [11,55,58,59] |

| 7 | Monitoring supplier performance | Evaluating and monitoring the performance of suppliers on the basis of environmental criteria is positively linked with the participation of suppliers in during the cooperation across the chain. | Zhu and Sarkis, 2004; Cheng et al., 2008; Walker and Jones, 2012, Hartmann and Germain, 2015 [11,55,48,59] |

| 8 | Increased social awareness | Social awareness suggests that an enterprise is willing not to take simple compliance but also take the public and partners into consideration in terms of environmental issues. | Sharma, 2000; Seuring, 2004; Mudgal et al., 2010 [60,61,62] |

| 9 | Maintaining green image | Green image of an enterprises is believed as a driver for implementation and cooperation of green supply chain practices. | Claver et al., 2007; Shang et al., 2010; Gunasekaran and Spalanzani, 2012 [63,64,65] |

| 10 | Reduction in wastes and emissions | Wastes and emissions reduction will be directly achieved through green supply chain cooperation. | Tseng and Chiu, 2013; Scur and Barbosa, 2017 [66,67] |

| 11 | Effective and optimized utilization of resources and energy | Improved energy and resources efficiency measures across the supply chain can lead to reduction of environmental impacts. | Figge and Hahn, 2012; Thollander et al., 2013; Liu et al., 2017 [68,69,70] |

| 12 | Gaining green competitiveness | Green supply chain cooperation should help enterprises to enhance their competitive advantages with pollution reduction, cost saving and productivity increase. | Mittal et al., 2012; Henriques and Catarino, 2016 [71,72] |

| 13 | Financial incentives from government or community | Financial incentives are the important drivers for enterprises to apply green supply chain practices as well as cooperate with their supply chain partners. | Parker et al., 2009; Liu et al., 2017 [70,73] |

| 14 | Stakeholders’ green concerns | Pressures and impetus from stakeholders about environmental issues help enhance the implementation of green supply chain practices and cooperation. | Claver et al., 2007; Zhu and Geng, 2013; Lee et al., 2015 [7,63,74] |

| 15 | Establishing long-term relationship with supply chain partners | Effective green supply chain cooperation can be achieved through long-term relationship with supply chain partners. | Mentzer et al., 2001; Yang et al., 2008; Lee, 2015 [4,57,75] |

| 16 | Pressures of environmental regulation and legislation | Implementation of legal mechanisms like regulations, legislations and laws are effective to prevent polluting industries from relocation and promote cooperation with supply chain partners. | Govindan et al., 2015; Zheng and Shi, 2017 [76,77] |

| 17 | Penalties for the noncompliance | Severe penalties are putting pressures on enterprises for not performing green and to seek help and cooperation with their supply chain partners. | Tseng and Chiu, 2013; Neto et al., 2016 [66,78] |

| 18 | Customers’ environmental concern increase | The increasing green awareness of customers is valued by the supplier chain partners and promotes their cooperation. | Zhang et al., 2013; Hong and Guo, 2018 [21,31] |

| 19 | Global quality qualification acquisition | Acquiring and applying the environmental qualifications such as ISO 9001 and ISO 140,001 is believed to facilitate the extension of green actions to other supply chain partners. | Handfield et al., 2010; Darnall et al., 2008; de Sousa et al., 2014; Dubey et al., 2015 [46,79,80,81] |

| Influencing Factors | 19 | 18 | 17 | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | V | V | O | A | A | A | A | A | X | O | X | A | O | A | X | X | A | O | X |

| 2 | O | O | O | O | O | O | O | A | O | O | A | O | A | O | O | O | O | X | |

| 3 | V | V | O | A | V | A | A | V | V | V | V | X | O | O | V | V | X | ||

| 4 | V | V | O | A | X | A | A | V | V | V | X | X | V | A | X | X | |||

| 5 | V | V | O | A | V | A | A | V | V | V | V | X | A | X | X | ||||

| 6 | V | V | O | A | X | A | A | V | V | V | V | V | V | X | |||||

| 7 | V | V | O | A | V | A | A | V | V | V | V | V | V | ||||||

| 8 | X | V | O | A | O | A | A | V | X | V | V | X | |||||||

| 9 | X | V | O | A | O | A | A | V | A | A | X | ||||||||

| 10 | V | V | O | A | O | A | A | V | A | X | |||||||||

| 11 | V | V | O | A | X | A | A | V | X | ||||||||||

| 12 | X | V | O | A | V | A | A | X | |||||||||||

| 13 | V | O | O | O | O | V | X | ||||||||||||

| 14 | V | O | O | A | O | X | |||||||||||||

| 15 | X | O | O | A | X | ||||||||||||||

| 16 | V | V | O | X | |||||||||||||||

| 17 | O | O | X | ||||||||||||||||

| 18 | A | X | |||||||||||||||||

| 19 | X |

| Influencing Factors | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| 2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 3 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| 4 | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| 5 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| 6 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| 7 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| 8 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| 9 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| 10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| 11 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| 12 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| 13 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 |

| 14 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 |

| 15 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 |

| 16 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 |

| 17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| 18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| 19 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 |

| Influencing Factors | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | Driving Power |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 5 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 6 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 7 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 9 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 10 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 11 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 12 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 13 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 17 |

| 14 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 1 | 16 |

| 15 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| 16 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 17 |

| 17 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 |

| 18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 |

| 19 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 1 | 15 |

| Dependent power | 16 | 17 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 1 | 3 | 16 | 1 | 1 | 17 | 16 |

| Influencing Factors | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| 1 | 1,2,3,4,5,6,7,8,9,10,11,12,15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 2 | 2 | 1,2,3,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 2 | 1 |

| 3 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 4 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 5 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 6 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 7 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 8 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 9 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 10 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 11 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 12 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 13 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,18,19 | 13 | 13 | 4 |

| 14 | 1,2,3,4,5,6,7,8,9,10,11,12,14,15,18,19 | 13,14,16 | 14 | 3 |

| 15 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

| 16 | 1,2,3,4,5,6,7,8,9,10,11,12,14,15,16,18,19 | 16 | 16 | 4 |

| 17 | 17 | 17 | 17 | 1 |

| 18 | 18 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,18,19 | 18 | 1 |

| 19 | 1,2,3,4,5,6,7,8,9,10,11,12, 15,18,19 | 1,3,4,5,6,7,8,9,10,11,12,13,14,15,16,19 | 1,3,4,5,6,7,8,9,10,11,12,15,19 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Yang, S.; Shi, X. How Corporate Social Responsibility and External Stakeholder Concerns Affect Green Supply Chain Cooperation among Manufacturers: An Interpretive Structural Modeling Analysis. Sustainability 2021, 13, 2518. https://doi.org/10.3390/su13052518

Huang X, Yang S, Shi X. How Corporate Social Responsibility and External Stakeholder Concerns Affect Green Supply Chain Cooperation among Manufacturers: An Interpretive Structural Modeling Analysis. Sustainability. 2021; 13(5):2518. https://doi.org/10.3390/su13052518

Chicago/Turabian StyleHuang, Xiangmeng, Shuai Yang, and Xiaolan Shi. 2021. "How Corporate Social Responsibility and External Stakeholder Concerns Affect Green Supply Chain Cooperation among Manufacturers: An Interpretive Structural Modeling Analysis" Sustainability 13, no. 5: 2518. https://doi.org/10.3390/su13052518

APA StyleHuang, X., Yang, S., & Shi, X. (2021). How Corporate Social Responsibility and External Stakeholder Concerns Affect Green Supply Chain Cooperation among Manufacturers: An Interpretive Structural Modeling Analysis. Sustainability, 13(5), 2518. https://doi.org/10.3390/su13052518