Factors Allowing Users to Influence the Environmental Performance of Their T-Shirt

Abstract

1. Introduction

2. Materials and Methods

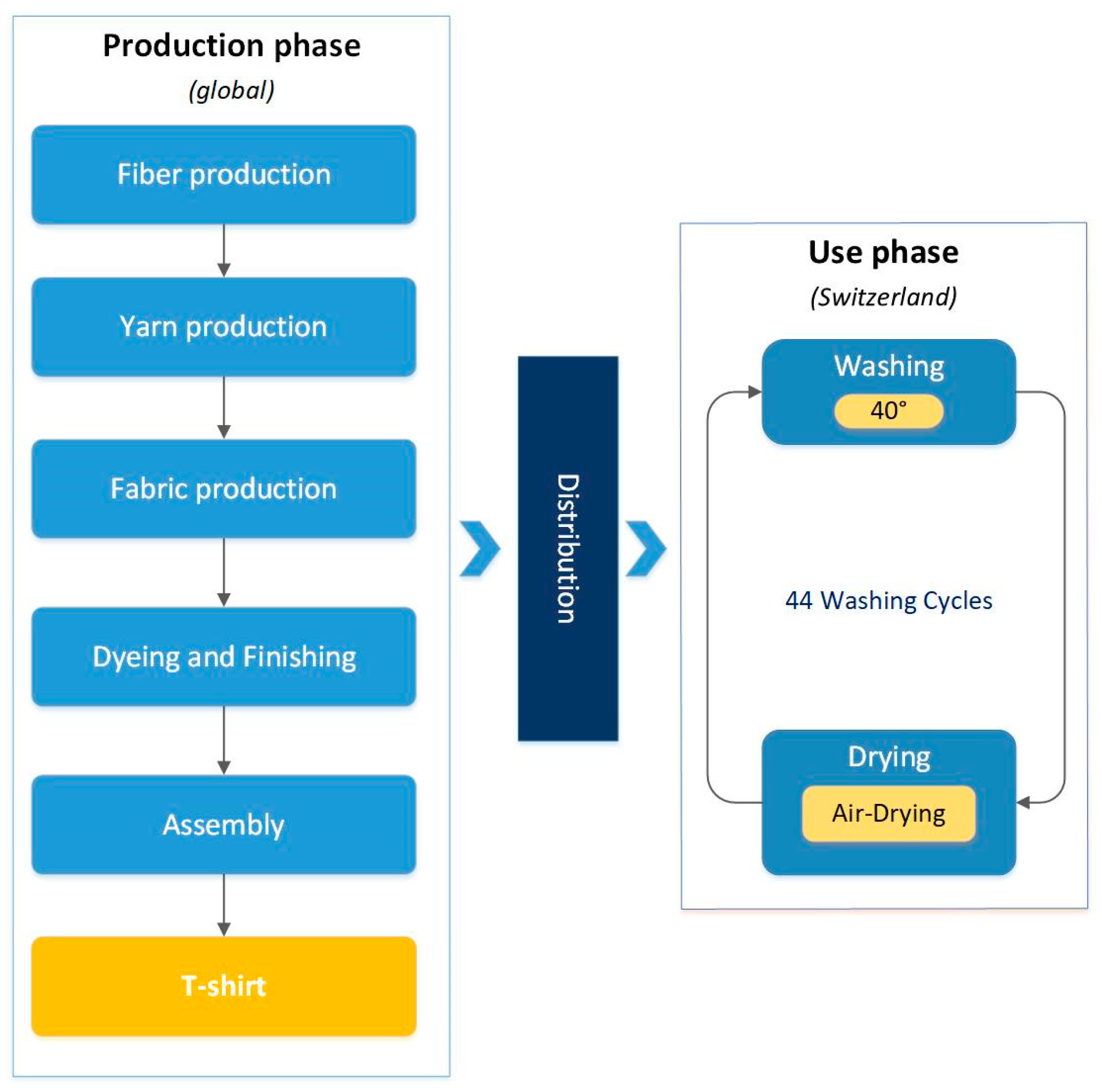

2.1. System Boundaries

2.2. Sensitivity Analyses

2.2.1. Different Types of Fiber

2.2.2. Different User Behavior

3. Results

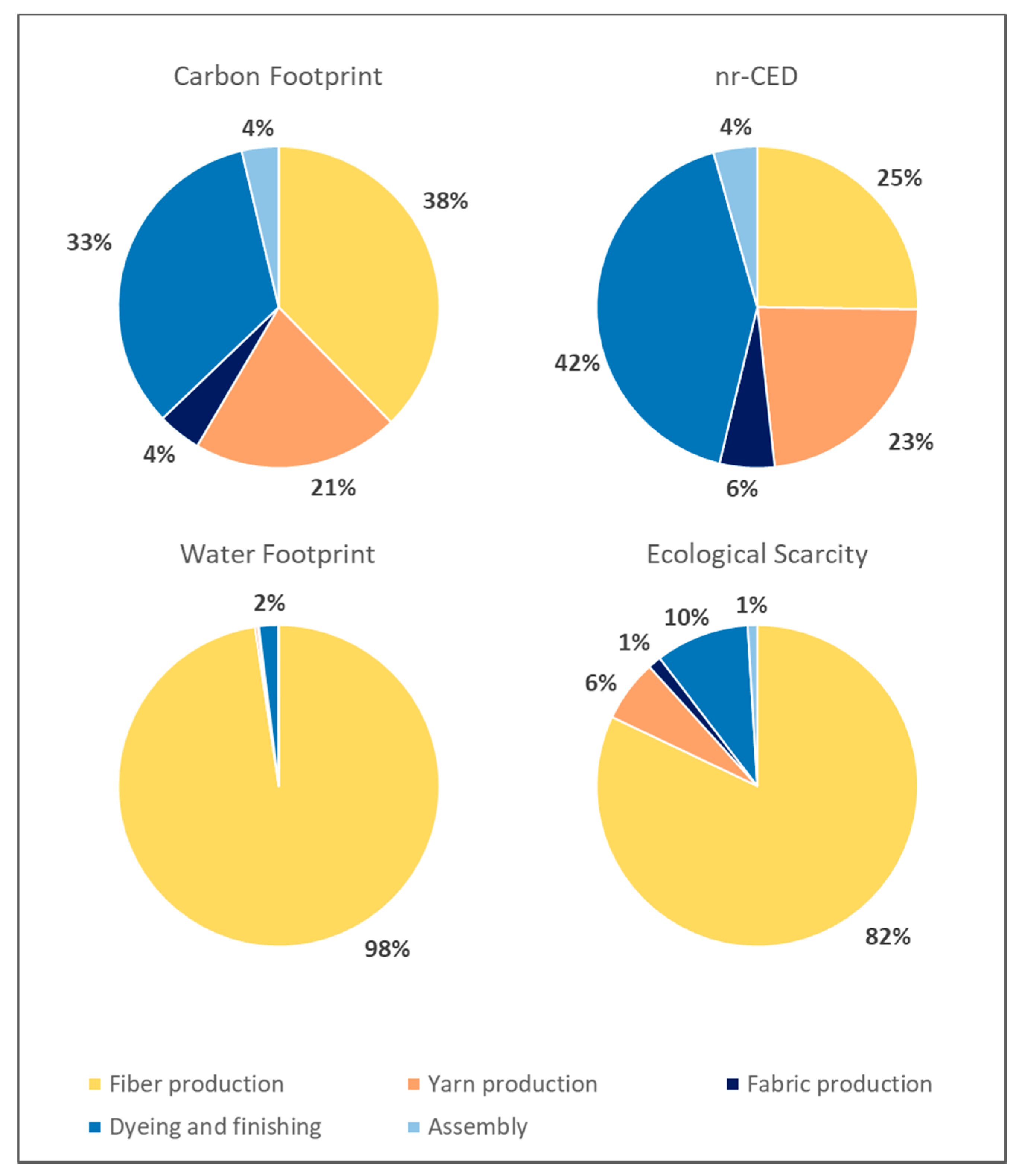

3.1. Overall Environmental Impact of the T-Shirt’s Life Cycle

3.2. Means for the Consumer to Influence the Impact of Their T-Shirt

3.2.1. Influence of the Raw Material Choice

- Regarding the carbon footprint (Figure 4A), silk (36.0 kg CO2-eq) had the highest impact, followed by wool (9.7 kg CO2-eq), nylon (2.7 kg CO2-eq), cotton (1.2 kg CO2-eq), polyester (1.1 kg CO2-eq), polyacryl (1.1 kg CO2-eq), viscose (0.9 kg CO2-eq), and finally flax (0.4 kg CO2-eq).

- The fiber with the highest nr-CED was also silk with 298.7 MJ-eq (Figure 4B). This was followed by nylon (36.7 MJ-eq), polyacryl (26.0 MJ-eq), polyester (24.5 MJ-eq), wool (17.5 MJ-eq), viscose (12.0 MJ-eq), cotton (9.1 MJ-eq), and flax (3.2 MJ-eq). The three fibers with the highest impact after silk were the three synthetic fibers.

- For the water footprint (Figure 4C), silk again had the highest impact with 360.2 m3 water-eq, followed by cotton (50 m3 water-eq), flax (5.6 m3 water-eq), and wool (2.5 m3 water-eq). The three synthetic fibers had a very low impact (<1 m3 water-eq).

- Finally, the ecological scarcity (Figure 4D) also showed that silk had the highest impact of all fibers (188,236 ecopoints). The second highest impact was from wool (24,005 ecopoints) and the third from cotton (10,783 ecopoints). The other fibers were in a similar range (between 1287 ecopoints and 2257 ecopoints).

3.2.2. Influence of the Washing Behavior and of Decreasing the T-Shirt’s Lifetime

4. Discussion

4.1. Influence of the Consumer while Buying a T-Shirt

- Carbon footprint: flax < viscose < polyacryl = polyester < cotton < nylon << wool <<< silk

- nr-CED: flax < cotton < viscose < wool < polyester < polyacryl < nylon <<< silk

- Water footprint: polyester < polyacryl < nylon < viscose < wool < flax << cotton <<< silk

4.2. Influence of the Consumer While Using a T-Shirt

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ellen MacArthur Foundation. A new Textiles Economy: Redesigning Fashion’s Future. 2017. Available online: http://www.ellenmacarthurfoundation.org/publications (accessed on 12 October 2020).

- Ness, B.; Urbel-Piirsalu, E.; Anderberg, S.; Olsson, L. Categorising tools for sustainability assessment. Ecol. Econ. 2007, 60, 498–508. [Google Scholar] [CrossRef]

- ISO. Environmental Management—Life Cycle Assessment—Principles and Framework; Eur. Stand. EN ISO 14’440; International Standardization Organization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- ISO. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; Eur. Stand. EN ISO 14’044; International Standardization Organisation (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Astudillo, M.F.; Thalwitz, G.; Vollrath, F. Life cycle assessment of Indian silk. J. Clean. Prod. 2014, 81, 158–167. [Google Scholar] [CrossRef]

- Bamonti, S.; Spinelli, R.; Bonoli, A. Environmental Footprint in the Production of Recycled Wool. Environ. Eng. Manag. J. 2018, 15, 1923–1931. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Simmons, A.; Watson, K.J.L.; Biggs, L. Effect of methodological choice on the estimated impacts of wool production and the significance for LCA-based rating systems. Int. J. Life Cycle Assess 2019, 24, 848–855. [Google Scholar] [CrossRef]

- Yacout, D.M.M.; Abd El-Kawi, M.A.; Hassouna, M.S. Cradle to gate environmental impact assessment of acrylic fiber manufacturing. Int. J. Life Cycle Assess 2016, 21, 326–336. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, L.; Zhang, C.; Ren, F.; Huang, H.; Liu, Z. Life cycle assessment of melange yarns from the manufacturer perspective. Int. J. Life Cycle Assess 2020, 25, 588–599. [Google Scholar] [CrossRef]

- Allison, A.L.; Ambrose-Dempster, E.; Aparsi, T.D.; Bawn, M.; Miguel Casas Arredondo, C.C.; Chandler, K.; Dobrijevic, D.; Hailes, H.; Lettieri, P.; Liu, C.; et al. The environmental dangers of employing single-use face masks as part of a COVID-19 exit strategy. UCL Open Environ. 2020, 53, 1689–1699. [Google Scholar] [CrossRef]

- La Rosa1, A.D.; Grammatikos, S.A. Comparative life cycle assessment of cotton and other natural fibers for textile applications. Fibers 2019, 7, 101. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I.G.; Henry, B. Use phase of wool apparel: A literature review for improving LCA. Prod. Lifetimes Environ. 2017, 202–207. [Google Scholar] [CrossRef]

- Oelerich, J.; Bijleveld, M.; Bouwhuis, G.H.; Brinks, G.J. The life cycle assessment of cellulose pulp from waste cotton via the SaXcellTM process. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 192012. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M.; Svanström, M. Moving down the cause-effect chain of water and land use impacts: An LCA case study of textile fibres. Resour. Conserv. Recycl. 2013, 73, 104–113. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Environmental impact assessment of man-made cellulose fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Esteve-Turrillas, F.A.; de la Guardia, M. Environmental impact of Recover cotton in textile industry. Resour. Conserv. Recycl. 2017, 116, 107–115. [Google Scholar] [CrossRef]

- Van Der Velden, N.M.; Patel, M.K.; Vogtländer, J.G. LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane. Int. J. Life Cycle Assess. 2014, 19, 331–356. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Turunen, L. The environmental impacts of the production of hemp and flax textile yarn. Ind. Crops Prod. 2008, 27, 1–10. [Google Scholar] [CrossRef]

- Chico, D.; Aldaya, M.M.; Garrido, A. A water footprint assessment of a pair of jeans: The influence of agricultural policies on the sustainability of consumer products. J. Clean. Prod. 2013, 57, 238–248. [Google Scholar] [CrossRef]

- Morita, A.M.; Moore, C.C.S.; Nogueira, A.R.; Kulay, L.; Ravagnani, M.A.D.S.S. Assessment of potential alternatives for improving environmental trouser jeans manufacturing performance in Brazil. J. Clean. Prod. 2020, 247. [Google Scholar] [CrossRef]

- Lenzo, P.; Traverso, M.; Mondello, G.; Salomone, R.; Ioppolo, G. Sustainability Performance of an Italian Textile Product. Economies 2018, 6, 17. [Google Scholar] [CrossRef]

- Wiedemann, S.G.; Biggs, L.; Nebel, B.; Bauch, K.; Laitala, K.; Klepp, I.G.; Swan, P.G.; Watson, K. Environmental impacts associated with the production, use, and end-of-life of a woollen garment. Int. J. Life Cycle Assess. 2020, 25, 1486–1499. [Google Scholar] [CrossRef]

- Kazan, H.; Akgul, D.; Kerc, A. Life cycle assessment of cotton woven shirts and alternative manufacturing techniques. Clean Technol. Environ. Policy 2020, 22, 849–864. [Google Scholar] [CrossRef]

- Yang, Y.; He, W.; Chen, F.; Wang, L. Water footprint assessment of silk apparel in China. J. Clean. Prod. 2020, 260, 121050. [Google Scholar] [CrossRef]

- Baydar, G.; Ciliz, N.; Mammadov, A. Life cycle assessment of cotton textile products in Turkey. Resour. Conserv. Recycl. 2015, 104, 213–223. [Google Scholar] [CrossRef]

- Bech, N.M.; Birkved, M.; Charnley, F.; Kjaer, L.L.; Pigosso, D.C.A.; Hauschild, M.Z.; McAloone, T.C.; Moreno, M. Evaluating the environmental performance of a product/service-system business model for Merino Wool Next-to-Skin Garments: The case of Armadillo Merino®. Sustainability 2019, 11, 5854. [Google Scholar] [CrossRef]

- Zamani, B.; Sandin, G.; Peters, G.M. Life cycle assessment of clothing libraries: Can collaborative consumption reduce the environmental impact of fast fashion? J. Clean. Prod. 2017, 162, 1368–1375. [Google Scholar] [CrossRef]

- Farrant, L.; Olsen, S.I.; Wangel, A. Environmental benefits from reusing clothes. Int. J. Life Cycle Assess. 2010, 15, 726–736. [Google Scholar] [CrossRef]

- Roos, S.; Peters, G.M. Three methods for strategic product toxicity assessment—The case of the cotton T-shirt. Int. J. Life Cycle Assess. 2015, 20, 903–912. [Google Scholar] [CrossRef]

- Steinberger, J.K.; Friot, D.; Jolliet, O.; Erkman, S. A spatially explicit life cycle inventory of the global textile chain. Int. J. Life Cycle Assess. 2009, 14, 443–455. [Google Scholar] [CrossRef]

- van der Velden, N.M.; Vogtländer, J.G. Monetisation of external socio-economic costs of industrial production: A social-LCA-based case of clothing production. J. Clean. Prod. 2017, 153, 320–330. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Xiao, R.; Yuan, Z. Life cycle assessment of cotton T-shirts in China. Int. J. Life Cycle Assess. 2015, 20, 994–1004. [Google Scholar] [CrossRef]

- Manda, B.M.K.; Worrell, E.; Patel, M.K. Prospective life cycle assessment of an antibacterial T-shirt and supporting business decisions to create value. Resour. Conserv. Recycl. 2015, 103, 47–57. [Google Scholar] [CrossRef]

- Walser, T.; Demou, E.; Lang, D.J.; Hellweg, S. Prospective environmental life cycle assessment of nanosilver T-shirts. Environ. Sci. Technol. 2011, 45, 4570–4578. [Google Scholar] [CrossRef] [PubMed]

- Lehmann, A.; Roffeis, M.; Finkbeiner, M. Ökobilanzielle Bewertung des Lebensweges eines handelsüblichen weißen Baumwolle T-Shirts in Deutschland. Fachgebiet Sustainable Engineering (FG SEE) der TU Berlin: Berlin, Germany, 2019. [Google Scholar]

- Sandin, G.; Roos, S.; Peters, G. Environmental Assessment of Swedish Clothing Consumption—Six Garments, Sustainable Futures. RISE AB: Göteborg, Sweden, 2019; ISBN 9789189049055. [Google Scholar]

- Laitala, K.; Klepp, I.G.; Henry, B. Does use matter? Comparison of environmental impacts of clothing based on fiber type. Sustainability 2018, 10, 2524. [Google Scholar] [CrossRef]

- Laitala, K.; Boks, C.; Klepp, I.G. Potential for environmental improvements in laundering. Int. J. Consum. Stud. 2011, 35, 254–264. [Google Scholar] [CrossRef]

- Rana, S.; Pichandi, S.; Moorthy, S.; Bhattacharyya, A. Carbon Footprint of Textile and Clothing Products. Handb. Sustain. Appar. Prod. 2015, 128–155. [Google Scholar] [CrossRef]

- Yasin, S.; Behary, N.; Rovero, G.; Kumar, V. Statistical analysis of use-phase energy consumption of textile products. Int. J. Life Cycle Assess. 2016, 21, 1776–1788. [Google Scholar] [CrossRef]

- Centre, E. Ecoinvent Data v3.6—Recycled-Content System Model; Ecoinvent Association: Zürich, Switzerland; Available online: www.ecoinvent.org (accessed on 10 August 2020).

- IPCC. Climate Change 2013: The Physical Science Basis Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013. [Google Scholar]

- Hischier, R.; Weidema, B.; Althaus, H.-J.; Bauer, C.; Doka, G.; Dones, R.; Frischknecht, R.; Hellweg, S.; Humbert, S.; Jungbluth, N.; et al. Implementation of Life Cycle Impact Assessment Methods; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2010. [Google Scholar]

- Boulay, A.M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA consensus characterization model for water scarcity footprints: Assessing impacts of water consumption based on available water remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [Google Scholar] [CrossRef]

- Frischknecht, R.; Büsser Knöpfel, S. Ökofaktoren Schweiz 2013 gemäss der Methode der ökologischen Knappheit. Methodische Grundlagen und Anwendung auf die Schweiz; BAFU: Bern, Switzerland, 2013. [Google Scholar]

- Hischier, R. Car vs. Packaging—A First, Simple (Environmental) Sustainability Assessment of Our Changing Shopping Behaviour. Sustainability 2018, 10, 3061. [Google Scholar] [CrossRef]

- PEFCR Product Environmental Footprint Category Rules (PEFCR)—T-Shirts. 2019, pp. 1–130. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_tshirt.pdf (accessed on 9 August 2020).

- Stamminger, R.; Schmitz, A. Washing machines in Europe–detailed assessment of consumption and performance. Tenside Surfactants Deterg. 2016, 70–86. [Google Scholar] [CrossRef]

- Schmitz, A.; Stamminger, R. Usage behaviour and related energy consumption of European consumers for washing and drying. Energy Effic. 2014, 7, 937–954. [Google Scholar] [CrossRef]

- Golsteijn, L.; Menkveld, R.; King, H.; Schneider, C.; Schowanek, D.; Nissen, S. A compilation of life cycle studies for six household detergent product categories in Europe: The basis for product-specific A.I.S.E. Charter Advanced Sustainability Profiles. Environ. Sci. Eur. 2015. [Google Scholar] [CrossRef] [PubMed]

- Kooistra, K.; Termorshuizen, A. The Sustainability of Cotton Consequences for Man and Environment; Science Shop Wageningen UR: Wageningen, The Netherlands, 2006. [Google Scholar]

- Babu, K.M. Natural Textile Fibres: Animal and Silk Fibres; Woodhead Publishing Limited: Cambridge, UK, 2015; ISBN 9780857095619. [Google Scholar]

- Sandin, G.; Roos, S.; Johansson, M. Environmental Impact of Textile Fibers–What We Know and What We Don’t know the Fiber Bible Part 2. 2019. Available online: https://www.researchgate.net/publication/331980907_Environmental_impact_of_textile_fibres_-_what_we_know_and_what_we_don’t_know_Fiber_Bible_part_2 (accessed on 4 January 2021).

- Pérez, J.J.B.; Queiruga-Dios, A.; Martínez, V.G.; del Rey, Á.M. Traceability of ready-to-wear clothing through blockchain technology. Sustainability 2020, 12, 7491. [Google Scholar] [CrossRef]

- GOTS Global Organic Textile Standard—Key Features. Available online: https://www.global-standard.org/the-standard/gots-key-features (accessed on 4 January 2021).

- Oeko-Tex Made in Green by Oeko-Tex. Available online: https://www.oeko-tex.com/en/our-standards/made-in-green-by-oeko-tex (accessed on 4 January 2021).

- Good on You Rating Brands on the Issues that Matter. Available online: https://goodonyou.eco/how-we-rate/ (accessed on 4 January 2021).

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Vadicherla, T.; Saravanan, D.; Muthu Ram, M.; Suganya, K. Fashion Renovation via Upcycling. In Textiles and Clothing Sustainability; Textile Science and Clothing Technology; Muthu, S., Ed.; Springer: Singapore, 2016. [Google Scholar]

- Yasin, S.; Sun, D. Propelling textile waste to ascend the ladder of sustainability: EOL study on probing environmental parity in technical textiles. J. Clean. Prod. 2019, 233, 1451–1464. [Google Scholar] [CrossRef]

| Scenarios | Washing Temperature | Drying | Fullness of Washing Machine | Lifetime |

|---|---|---|---|---|

| Basic scenario | 40 °C | Air-drying | Half-full | 44 washing cycles |

| Lower Washing Temperature | 30 °C | Air-drying | Half-full | 44 washing cycles |

| Higher Washing Temperature | 60 °C | Air-drying | Half-full | 44 washing cycles |

| Tumbler | 40 °C | Tumbler | Half-full | 44 washing cycles |

| Full Washing Machine | 40 °C | Air-drying | Full | 44 washing cycles |

| T-shirt Washed Alone | 40 °C | Air-drying | T-Shirt washed alone | 44 washing cycles |

| Lower Lifetime | 40 °C | Air-drying | Half-full | 11 washing cycles |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmutz, M.; Hischier, R.; Som, C. Factors Allowing Users to Influence the Environmental Performance of Their T-Shirt. Sustainability 2021, 13, 2498. https://doi.org/10.3390/su13052498

Schmutz M, Hischier R, Som C. Factors Allowing Users to Influence the Environmental Performance of Their T-Shirt. Sustainability. 2021; 13(5):2498. https://doi.org/10.3390/su13052498

Chicago/Turabian StyleSchmutz, Mélanie, Roland Hischier, and Claudia Som. 2021. "Factors Allowing Users to Influence the Environmental Performance of Their T-Shirt" Sustainability 13, no. 5: 2498. https://doi.org/10.3390/su13052498

APA StyleSchmutz, M., Hischier, R., & Som, C. (2021). Factors Allowing Users to Influence the Environmental Performance of Their T-Shirt. Sustainability, 13(5), 2498. https://doi.org/10.3390/su13052498