Non-Revenue Water in Malaysia: Influence of Water Distribution Pipe Types

Abstract

1. Introduction

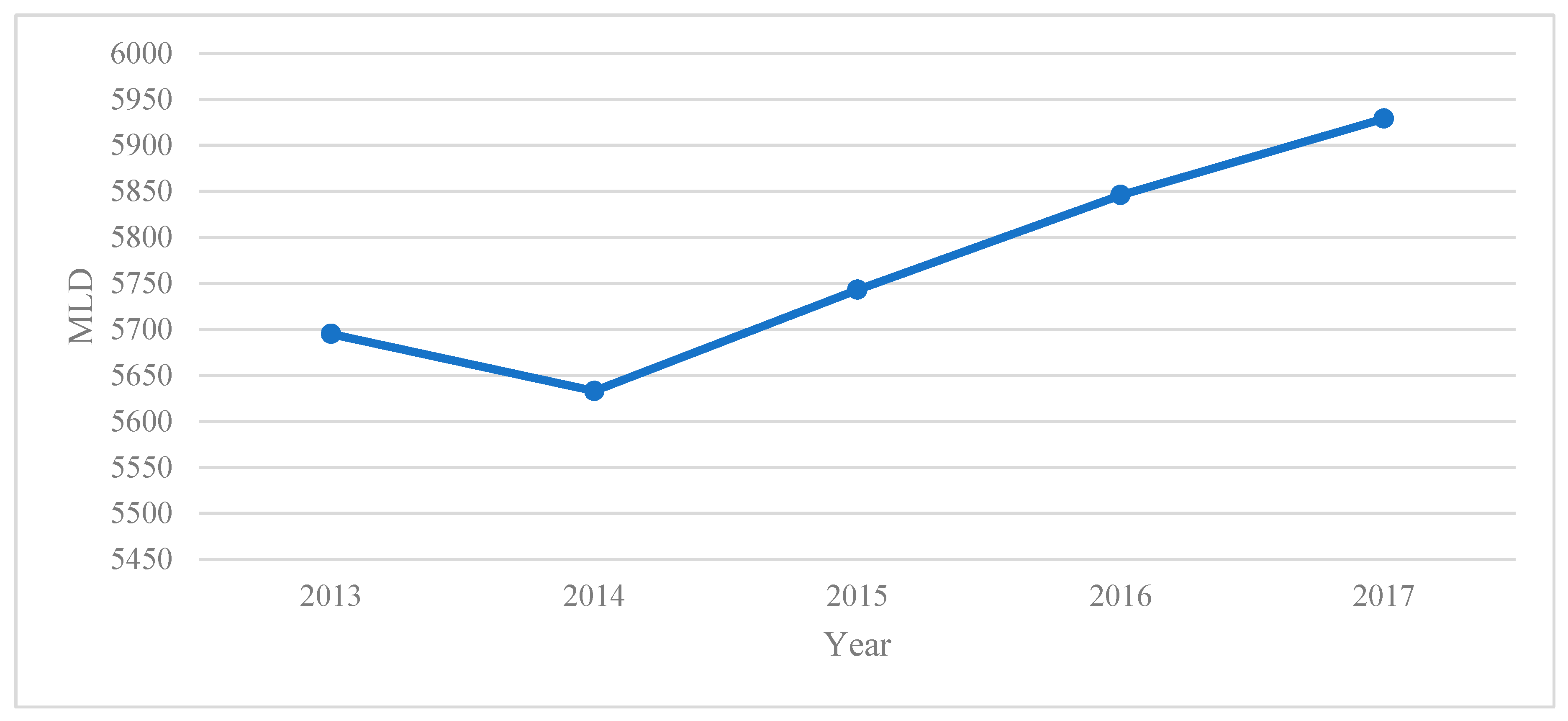

NRW in Malaysia

2. Literature Review

2.1. Non-Revenue Water (NRW)

2.2. Types of Water Pipes

2.2.1. Ductile Iron Pipes

2.2.2. Mild Steel Pipes

2.2.3. Polyethylene Pipes

3. Research Methodologies

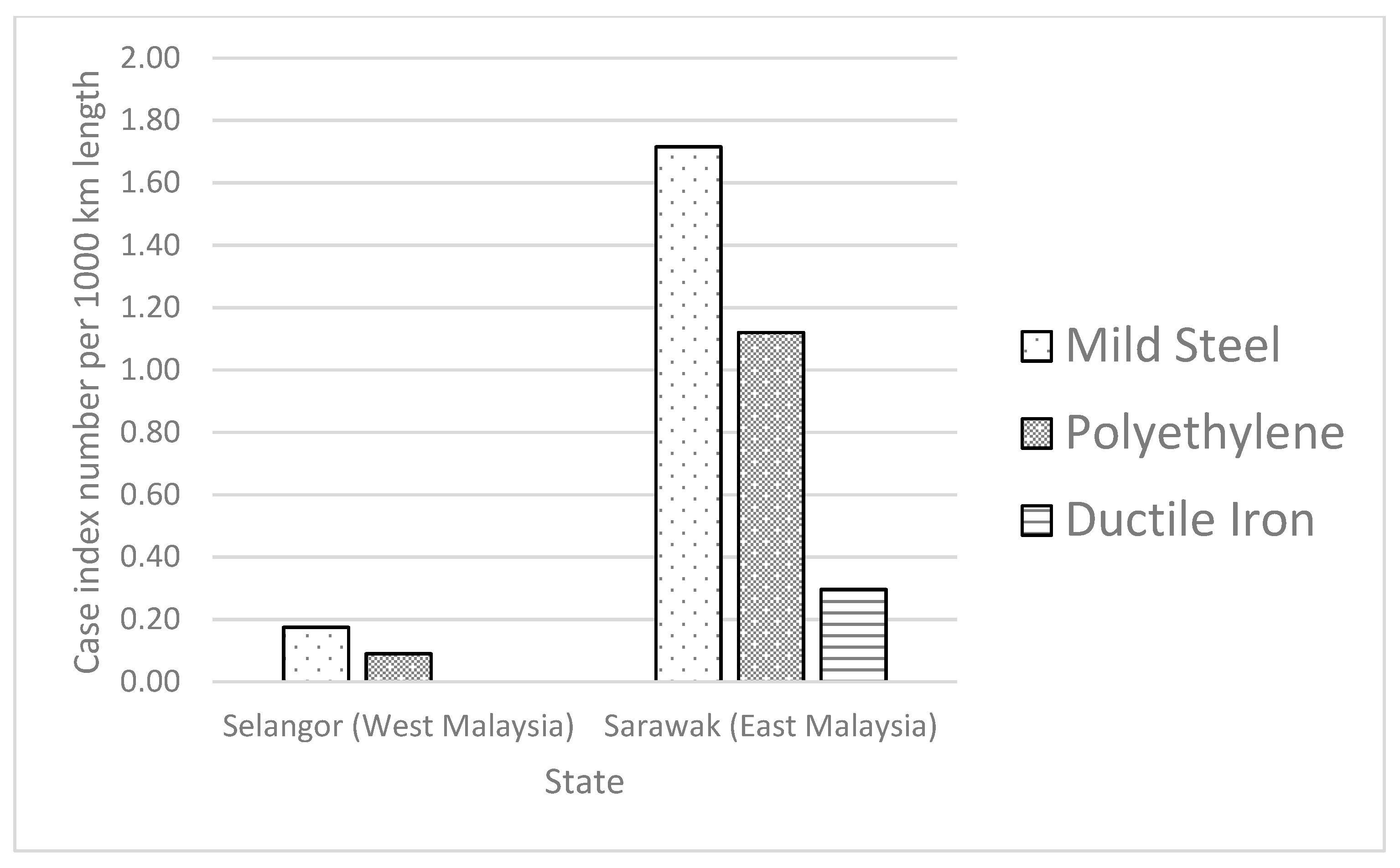

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Variables | Variables Definition |

|---|---|

| Dependent | |

| NRWi,t | Non-Revenue Water Loss in million liters per day; |

| Experimental | |

| LMSi,t | Length of Mild Steel pipes in kilometer; |

| LDIi,t | Length of Ductile Iron pipes in kilometer; |

| LPEi, t | Length of Polyethylene pipes in kilometer; |

| LOPi, t | Length of Other pipes in kilometer (inclusive of galvanized iron (GI) and acrylonitrile butadiene (ABS); |

| Control | |

| DVCi,t | Domestic Volume of Water Consumption in million liters per day; |

| NDVCi,t | Non-Domestic Volume of Water Consumption in million liters per day; |

| WSISi,t | Number of Water Services Interruption Scheduled. |

| WSIUSi,t | Number of Water Services Interruption Unscheduled. |

| WSCi,t | Number of Water Services Complaints of Pipe Burst, Breakages and Leak |

| POPSERi,t | Population served by state. |

| Year | Year dummy. |

Appendix B

Appendix C

References

- Frauendorfer, R.; Liemberger, R. The Issues and Challenges of Reducing Non-Revenue Water; Asian Development Bank: Mandaluyong, Philippines, 2010; ISBN 978-92-9092-398-5. [Google Scholar]

- Lambert, A.; Charalambous, B.; Fantozzi, M.; Kovac, J.; Rizzo, A.; Galea St John, S. 14 Years Experience of Using IWA Best Practice Water Balance and Water Loss Performance Indicators in Europe. In Proceedings of the IWA Specialized Conference, Water Loss, Vienna, Austria, 30 March–2 April 2014; pp. 1–31. [Google Scholar]

- Consolidated Utility District of Rutherford County Water Theft Policy. Available online: https://www.cudrc.com/water-theft/ (accessed on 30 September 2020).

- Bernama SPAN: Water Tariff Review Long Overdue; Malay Mail; Bernama: Kuala Lumpur, Malaysia, 2019.

- González-Gómez, F.; García-Rubio, M.A.; Guardiola, J. Why Is Non-Revenue Water So High in So Many Cities? Int. J. Water Resour. Dev. 2011, 27, 345–360. [Google Scholar] [CrossRef]

- Kingdom, B.; Liemberger, R.; Marin, P. The Challenge of Reducing Non-Revenue Rate (NRW) in Developing Countries- How the Private Sector Can Help: A Look at Performance-Based Service Contracting; Water Supply And Sanitation Sector Board Discussion Paper Series; The World Bank Group: Washington, DC, USA, 2006. [Google Scholar]

- Coles, C. “Teen Pregnancy and” Internal Poverty. Futurist 2005, 39, 9. [Google Scholar]

- Chelliapan, S.; Kamaruddin, S.; Zaini, N.; Othman, N.; Mohammad, R.; Nasri, N.; Yazid, N. Economic and Efficiency Indicators in Non-Revenue Water (NRW) Performance. Int. J. Civ. Eng. Technol. 2017, 8, 1419–1431. [Google Scholar]

- Lahlou, Z.M. Leak Detection and Water Loss Control. In Water Encyclopedia; Lehr, J.H., Keeley, J., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; p. mv1817. ISBN 978-0-471-47844-7. [Google Scholar]

- The Malaysian Water Association (MWA). Malaysia Water Industry Guide 2018; The Malaysian Water Association (MWA): Kuala Lumpur, Malaysia, 2018. [Google Scholar]

- Abu-Bakar, M.S.; Ku-Mahamud, K.R.; Wan-Ishak, W.H. Identifying The Location And Magnitude of Non-Revenue Water: A Case Study at FELDA Chuping, Perlis. In Proceedings of the International Conference on Engineering & ICT (ICEI), Tunggal, Malaysia, 27–28 November 2007; Volume 2. [Google Scholar]

- Tan, V. Selangor Plans to Reduce Wasted Treated Water. TheStar, 12 January 2017. [Google Scholar]

- The Malaysian Water Association (MWA) Malaysia Water Industry Guide 2015; The Malaysian Water Association (MWA): Kuala Lumpur, Malaysia, 2015.

- The Malaysian Water Association (MWA) Malaysia Water Industry Guide 2016; The Malaysian Water Association (MWA): Kuala Lumpur, Malaysia, 2016.

- The Malaysian Water Association (MWA) Malaysia Water Industry Guide 2017; The Malaysian Water Association (MWA): Kuala Lumpur, Malaysia, 2017.

- Jabari, S.J. Non-Revenue Water Management In Palestine. Int. J. Urban Civ. Eng. 2017, 11, 953–959. [Google Scholar] [CrossRef]

- Murugan, S.S.; Chandran, S. Assessment of Non-Revenue Water in a Water Distribution System and Strategies to Manage the Water Supply. Int. Res. J. Eng. Technol. 2019, 6, 3488–3492. [Google Scholar]

- Kangangi, I.M. The Determinants of Non-Revenue Water in Water Services Provision in Kirinyaga Country in Kenya: A Case of Kirinyaga Water and Sanitation Company. Master’s Thesis, University of Nairobi, Nairobi, Kenya, 2015. [Google Scholar]

- Lambert, A.; Hirner, W. Losses from Water Supply Systems: Standard Terminology and Recommended Performance Measures; International Water Association: London, UK, 2000. [Google Scholar]

- Safework NSW Work near Underground Assets-Guide 2007; Safework: Wollongong, Australia, 2007.

- Criminisi, A.; Fontanazza, C.M.; Freni, G.; Loggia, G.L. Evaluation of the Apparent Losses Caused by Water Meter Under-Registration in Intermittent Water Supply. Water Sci. Technol. 2009, 60, 2373–2382. [Google Scholar] [CrossRef] [PubMed]

- Chan, N.; Lai, C.; Roy, R. Understanding Public Perception of and Participation in Non-Revenue Water Management in Malaysia to Support Urban Water Policy. Water 2017, 9, 26. [Google Scholar] [CrossRef]

- Lee, C. Water Tariff and Development: The Case of Malaysia; Working paper series; University of Manchester: Manchester, UK, 2005; ISBN 978-1-905381-16-6. [Google Scholar]

- Chan, N.W.; Lai, C.H.; Tan, D.T.; Roy, R.; Zakaria, N.A. Systems Thinking Approach for Analysing Non-Revenue Water Management Reform in Malaysia. Water Policy 2020, 22, 237–251. [Google Scholar] [CrossRef]

- Skipworth, P.J.; Saul, A.J.; Machell, J. The Effect of Regional Factors on Leakage Levels and the Role of Performance Indicators. Water Environ. J. 1999, 13, 184–188. [Google Scholar] [CrossRef]

- Farley, M.; Liemberger, R. Developing a Non-Revenue Water Reduction Strategy: Planning and Implementing the Strategy. Water Supply 2005, 5, 41–50. [Google Scholar] [CrossRef]

- van den Berg, C. Drivers of Non-Revenue Water: A Cross-National Analysis. Util. Policy 2015, 36, 71–78. [Google Scholar] [CrossRef]

- Tabesh, M.; Roozbahani, A.; Roghani, B.; Faghihi, N.R.; Heydarzadeh, R. Risk Assessment of Factors Influencing Non-Revenue Water Using Bayesian Networks and Fuzzy Logic. Water Resour Manag. 2018, 32, 3647–3670. [Google Scholar] [CrossRef]

- Hunaidi, O. Detecting Leaks in Water-Distribution Pipes. Constr. Technol. Update 2000, 40, 1–6. [Google Scholar]

- Georgia Environmental Protection Division (EPD). Water Leak Detection and Repair Program. In EPD Guidance Document 2007; Georgia Environmental Protection Division (EPD): Hong Kong, China, 2007. [Google Scholar]

- Wengstöm, T. Comparative Analysis of Pipe Break Rates: A Literature Review; Chalmers University of Technology: Göteborg, Sweden, 1993. [Google Scholar]

- Rutledge, M. Water-Treating Chemical Causing Early Failure in Hamilton Pipes. Journal-News, 2 December 2019. [Google Scholar]

- Rishyakaran, R. Selangor Should Prepare to Aggressively Replace Old Pipes; Malaysiakini: Petaling Jaya, Malaysia, 2016. [Google Scholar]

- Kaur, G. Selangor to Leverage on RM11bil Water Pipes Stockpile. TheStar, 24 February 2014. [Google Scholar]

- Lai, A.; Selva, M.N.T. RM125mil for New Pipes. TheStar, 4 November 2016. [Google Scholar]

- Bernama. Salcon to Replace Pipes for Air Selangor. TheStar, 18 September 2017.

- Toft, P.; Wigle, D.; Meranger, J.C.; Mao, Y. Asbestos and Drinking Water in Canada. Stud. Environ. Sci. 1981, 12, 77–89. [Google Scholar] [CrossRef]

- Luus, K. Asbestos: Mining Exposure, Health Effects and Policy Implications. Mcgill. J. Med. 2007, 10, 121–126. [Google Scholar] [PubMed]

- Safitri Zen, I.; Ahamad, R.; Gopal Rampal, K.; Omar, W. Use of Asbestos Building Materials in Malaysia: Legislative Measures, the Management, and Recommendations for a Ban on Use. Int. J. Occup. Environ. Health 2013, 19, 169–178. [Google Scholar] [CrossRef] [PubMed]

- Ab Razak, N.H.; Praveena, S.M.; Aris, A.Z.; Hashim, Z. Drinking Water Studies: A Review on Heavy Metal, Application of Biomarker and Health Risk Assessment (a Special Focus in Malaysia). J. Epidemiol. Glob. Health 2015, 5, 297–310. [Google Scholar] [CrossRef] [PubMed]

- Paradkar, A.B. An Evaluation of Failure Modes for Cast Iron and Ductile Iron Water Pipes. Master’s Thesis, University of Texas, Arlington, TX, USA, 2012. [Google Scholar]

- Rajani, B.; Kleiner, Y. Comprehensive Review of Structural Deterioration of Water Mains: Physically Based Models. Urban Water 2001, 3, 151–164. [Google Scholar] [CrossRef]

- Kirmeyer, G.J.; Richards, W.; Smith, C.D. An Assessment of Water Distribution Systems and Associated Research Needs; American Water Works Association Research Foundation: Denver, CO, USA, 1994. [Google Scholar]

- Walski, T.M. A History of Water Distribution. J.-Am. Water Work. Assoc. 2006, 98, 110–121. [Google Scholar] [CrossRef]

- Makar, J.M.; Desnoyers, R.; McDonald, S.E. Failure Modes and Mechanisms in Gray Cast Iron Pipe; NRC: Waterloo, ON, Canada, 2001; pp. 1–10. [Google Scholar]

- Gould, S.J.F.; Davis, P.; Marlow, D.R. Importance of Installation Practices for Corrosion Protection of Ductile Iron Pipe. Urban Water J. 2016, 13, 198–211. [Google Scholar] [CrossRef]

- Installation Guide for Ductile Iron Pipe 2016; DIPRA: Birmingham, Alabama, 2016.

- USEPA. Deteriorating Buried Infrastructure Management Challenges and Strategies; Office Of Ground Water And Drinking Water Distribution System Working Paper; USEPA: Washington, DC, USA, 2002. [Google Scholar]

- Folkman, S. Water Main Break Rates in the USA and Canada: A Comprehensive Study; Utah State University: Logan, UT, USA, 2018. [Google Scholar]

- Wang, W. Failure Analysis of Underground Pipeline Subjected to Corrosion. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2018. [Google Scholar]

- Ruchti, G.F. (Ed.) Water Pipeline Condition Assessment; ASCE Manuals and Reports on Engineering Practice; The American Society of Civil Engineers: Reston, VA, USA, 2017; ISBN 978-0-7844-1475-0. [Google Scholar]

- Barton, N.A.; Farewell, T.S.; Hallett, S.H.; Acland, T.F. Improving Pipe Failure Predictions: Factors Affecting Pipe Failure in Drinking Water Networks. Water Res. 2019, 164, 114926. [Google Scholar] [CrossRef]

- Keil, B.; Devletian, J. Comparison of the Mechanical Properties of Steel and Ductile Iron Pipe Materials. In Proceedings of the Pipelines 2011 American Society of Civil Engineers, Washington, DC, USA, 23–27 July 2011; pp. 1301–1312. [Google Scholar]

- Ramesh, S.; Rajeswari, S.; Maruthamuthu, S. Effect of Inhibitors and Biocide on Corrosion Control of Mild Steel in Natural Aqueous Environment. Mater. Lett. 2003, 57, 4547–4554. [Google Scholar] [CrossRef]

- Twort, A.C.; Ratnayaka, D.D.; Brandt, M.J. Water Supply, 5th ed.; Arnold/IWA Pub: London, UK, 2000; ISBN 978-0-340-72018-9. [Google Scholar]

- Romano, M. Near Real-Time Detection and Approximate Location of Pipe Bursts and Other Events in Water Distribution Systems. Ph.D. Thesis, University of Exeter, Exeter, UK, 2012. [Google Scholar]

- Hou, Y.; Lei, D.; Li, S.; Yang, W.; Li, C.-Q. Experimental Investigation on Corrosion Effect on Mechanical Properties of Buried Metal Pipes. Int. J. Corros. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- SPAN Specification for Steel Pipes, Fittings and Joints for Water and Sewage—Part 1: Technical Delivery Requirements 2013; SPAN: Cyberjaya, Malaysia, 2013.

- Ellison, D.; Spencer, D. The True Causes of AC Pipe Failures—According to the Data. In Proceedings of the Pipelines 2016 American Society of Civil Engineers, Kansas City, MI, USA, 17–20 July 2016; pp. 637–647. [Google Scholar]

- Mitul, M. EN 10224 Grade L355 Carbon Steel Seamless Tubes—Ferropipe. Available online: https://www.ferropipe.com/en-10224-grade-l355-carbon-steel-seamless-tubes/ (accessed on 16 February 2020).

- Bonds, R.W. Material Comparisons: Ductile Iron Pipe vs. PVC-O Pipe 2017; DIPRA: Birmingham, Alabama, 2017. [Google Scholar]

- PE100+ Association PE & HDPE Pipe: Properties and Types of PE100 Pipe. Available online: https://www.pe100plus.com/PE-Pipes/Technical-guidance/Trenchless/Methods/PE-Pipe-i1341.html (accessed on 16 February 2020).

- Kowalska, B.; Klepka, T.; Kowalski, D. Influence of Chlorinated Water on Mechanical Properties of Polyethylene and Polyvinyl Chloride Pipes. In Proceedings of the 3rd International Conference on Design, Construction, Maintenance, Monitoring and Control of Urban Water Systems, Venice, Italy, 27–29 June 2016; pp. 63–74. [Google Scholar]

- Holder, S.L.; Hedenqvist, M.S.; Nilsson, F. Understanding and Modelling the Diffusion Process of Low Molecular Weight Substances in Polyethylene Pipes. Water Res. 2019, 157, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Colin, X.; Audouin, L.; Verdu, J.; Rozental-Evesque, M.; Rabaud, B.; Martin, F.; Bourgine, F. Aging of Polyethylene Pipes Transporting Drinking Water Disinfected by Chlorine Dioxide. I. Chemical Aspects. Polym. Eng. Sci. 2009, 49, 1429–1437. [Google Scholar] [CrossRef]

- Ghabeche, W.; Alimi, L.; Chaoui, K. Degradation of Plastic Pipe Surfaces in Contact with an Aggressive Acidic Environment. Energy Procedia 2015, 74, 351–364. [Google Scholar] [CrossRef]

- White, H. A Heteroskedasticity-Consistent Covariance Matrix Estimator and a Direct Test for Heteroskedasticity. Econometrica 1980, 48, 817–838. [Google Scholar] [CrossRef]

- Joshi, T. An Evaluation of Large Diameter Steel Water Pipelines; University of Texas: Arlington, TX, USA, 2012. [Google Scholar]

- DIPRA, S. Ductile Iron Versus Steel. Available online: https://www.dipra.org/ductile-iron-pipe/dipra-facts-and-figures/ductile-iron-vs-steel (accessed on 1 January 2021).

- DIPRA Frequently Asked Questions—Corrosion Control. Available online: https://www.dipra.org/ductile-iron-pipe-resources/frequently-asked-questions/corrosion-control#:~:text=A%3A%20Properly%20designed%20and%20installed,do%20not%20change%20with%20age (accessed on 3 January 2020).

- DIPRA Charleston Water System: Flow Test of 97-Year-Old Cement-Mortar Lined Pipe. Available online: https://www.dipra.org/ductile-iron-pipe/pipeline/flow-test-of-97-year-old-cement-mortar-lined-pipe (accessed on 3 January 2020).

- Crippen, K.; Lever, E. The Impact of Heavy Hydrocarbon Permeation on PE Pipe. 2014. Available online: https://www.pe100plus.com/PPCA/The-Impact-of-Heavy-Hydrocarbon-Permeation-on-PE-Pipe-p1391.html (accessed on 16 February 2020).

| States | 2013 | 2014 | 2015 | 2016 | 2017 | Total (MLD) | |

|---|---|---|---|---|---|---|---|

| Johor * | NRW(MLD) | 417 | 426 | 436 | 450 | 433 | 2162 |

| NRW (%) | 26.4 | 25.9 | 25.6 | 25.9 | 24.7 | ||

| Kelantan * | NRW(MLD) | 228 | 220 | 222 | 232 | 234 | 1136 |

| NRW (%) | 53.1 | 49.4 | 49.0 | 49.4 | 49.3 | ||

| Malacca * | NRW(MLD) | 107 | 102 | 93 | 95 | 101 | 498 |

| NRW (%) | 22.1 | 21.4 | 19.3 | 19.0 | 19.6 | ||

| Negeri Sembilan | NRW(MLD) | 267 | 267 | 264 | 253 | 245 | 1296 |

| NRW (%) | 36.3 | 35.9 | 34.8 | 32.7 | 32.6 | ||

| Penang * | NRW(MLD) | 180 | 182 | 202 | 227 | 231 | 1022 |

| NRW (%) | 18.2 | 18.3 | 19.9 | 21.5 | 21.9 | ||

| Pahang | NRW(MLD) | 561 | 588 | 596 | 532 | 528 | 2,805 |

| NRW (%) | 52.7 | 53.1 | 52.8 | 47.9 | 47.5 | ||

| Perak * | NRW(MLD) | 365 | 379 | 382 | 402 | 406 | 1934 |

| NRW (%) | 30.4 | 30.6 | 30.3 | 30.5 | 30.9 | ||

| Perlis * | NRW(MLD) | 132 | 121 | 124 | 148 | 152 | 677 |

| NRW (%) | 62.4 | 55.8 | 56.3 | 60.7 | 63.1 | ||

| Sabah * | NRW(MLD) | 602 | 618 | 677 | 634 | 679 | 3210 |

| NRW (%) | 53.2 | 51.7 | 55.1 | 52.0 | 53.8 | ||

| Sarawak * | NRW(MLD) | 359 | 381 | 423 | 479 | 529 | 2171 |

| NRW (%) | 31.3 | 32.0 | 33.3 | 36.0 | 37.8 | ||

| Selangor | NRW(MLD) | 1575 | 1545 | 1497 | 1547 | 1526 | 7672 |

| NRW (%) | 34.5 | 33.6 | 32.0 | 32.2 | 31.5 | ||

| Terengganu | NRW(MLD) | 210 | 188 | 192 | 189 | 186 | 965 |

| NRW (%) | 33.8 | 31.0 | 31.0 | 30.0 | 30.4 | ||

| Kedah * | NRW(MLD) | 675 | 596 | 614 | 637 | 651 | 3173 |

| NRW (%) | 50.9 | 46.1 | 46.7 | 46.7 | 47.5 | ||

| Labuan * | NRW(MLD) | 16 | 20 | 22 | 22 | 23 | 103 |

| NRW (%) | 25.9 | 29.5 | 30.9 | 30.5 | 32.0 |

| States | 2013 | 2014 | 2015 | 2016 | 2017 | Total |

|---|---|---|---|---|---|---|

| Johor | 57,627 | 61,525 | 62,697 | 63,551 | 58,306 | 303,706 |

| Kelantan | 11,179 | 16,257 | 16,062 | 25,870 | 41,191 | 110,559 |

| Malacca | 33,948 | 24,712 | 22,897 | 30,923 | 33,514 | 145,994 |

| Negeri Sembilan | 27,945 | 29,180 | 28,740 | 32,026 | 30,215 | 148,106 |

| Penang | 47,959 | 43,517 | 42,947 | 47,977 | 39,809 | 222,209 |

| Pahang | 4081 | 2471 | 5018 | 6917 | 7039 | 25,526 |

| Perak | 32,987 | 39,322 | 24,332 | 13,362 | 13,131 | 123,134 |

| Perlis | 7295 | 7456 | 6381 | 5523 | 1413 | 28,068 |

| Sabah | 15,276 | 18,050 | 18,231 | 17,996 | 14,096 | 83,649 |

| Sarawak | 15,239 | 16,769 | 21,629 | 16,325 | 14,786 | 84,748 |

| Selangor | 125,114 | 136,163 | 123,673 | 123,930 | 164,199 | 673,079 |

| Terengganu | 21,252 | 20,282 | 23,496 | 22,336 | 21,048 | 108,414 |

| Kedah | 44,825 | 40,357 | 40,295 | 37,212 | 38,312 | 201,001 |

| Labuan | 1151 | 893 | 354 | 564 | 1643 | 4605 |

| Variable | Mean | Std. Dev | Quartile 1 | Median | Quartile 3 |

|---|---|---|---|---|---|

| NRWi,t | 412.03 | 368.92 | 186.5 | 313.00 | 553.8 |

| LMSi,t | 2959.50 | 3701.53 | 901.5 | 1587.00 | 3139.8 |

| LDIi,t | 826.03 | 931.39 | 96.5 | 541.00 | 1123.8 |

| LPEi,t | 1839.84 | 1693.08 | 687.5 | 944.00 | 2234.5 |

| LOPi,t | 4775.06 | 3718.73 | 2166 | 4508 | 5164 |

| DVCi,t | 45.65 | 437.28 | 203.0 | 319.00 | 510.8 |

| NDVCi,t | 290.54 | 308.81 | 176.0 | 217.00 | 329.8 |

| WSISi,t | 339.43 | 470.38 | 18.75 | 185.50 | 452.00 |

| WSIUSi,t | 9201.73 | 18,503.05 | 404 | 3948.50 | 6566 |

| WSCi,t | 32,325.69 | 33,210.19 | 13,546 | 23,196.50 | 40,174 |

| POPSERi,t | 2099.15 | 1569.18 | 1091.4 | 1720.55 | 2692.1 |

| Variables | NRW | LDI | LMS | LPE | LOP | DVC | NDVC | WSIS | WSIUS | POPSER | WCS |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NRW | 1 | ||||||||||

| (0.000) | |||||||||||

| LDI | 0.471 | 1 | |||||||||

| (0.000) | (0.000) | ||||||||||

| LMS | 0.872 | 0.316 | 1 | ||||||||

| (0.000) | 0.008 | (0.000) | |||||||||

| LPE | 0.214 | 0.483 | −0.122 | 1 | |||||||

| 0.074 | (0.000) | 0.315 | (0.000) | ||||||||

| LOP | 0.579 | 0.374 | 0.533 | −0.007 | 1 | ||||||

| (0.000) | 0.001 | (0.000) | 0.954 | (0.000) | |||||||

| DVC | 0.891 | 0.546 | 0.786 | 0.197 | 0.671 | 1 | |||||

| (0.000) | (0.000) | (0.000) | 0.101 | (0.000) | (0.000) | ||||||

| NDVC | 0.881 | 0.565 | 0.829 | 0.139 | 0.576 | 0.867 | 1 | ||||

| (0.000) | (0.000) | (0.000) | 0.252 | (0.000) | (0.000) | (0.000) | |||||

| WSIS | 0.805 | 0.495 | 0.777 | 0.126 | 0.579 | 0.794 | 0.795 | 1 | |||

| (0.000) | (0.000) | (0.000) | 0.300 | (0.000) | (0.000) | (0.000) | (0.000) | ||||

| WSIUS | 0.712 | 0.222 | 0.617 | 0.208 | 0.386 | 0.767 | 0.729 | 0.781 | 1 | ||

| (0.000) | 0.065 | (0.000) | 0.084 | 0.065 | (0.000) | (0.000) | (0.000) | (0.000) | |||

| POPSER | 0.900 | 0.613 | 0.867 | 0.222 | 0.668 | 0.897 | 0.874 | 0.840 | 0.640 | 1 | |

| (0.000) | (0.000) | (0.000) | 0.081 | (0.000) | (0.000) | (0.000) | (0.000) | (0.000) | (0.000) | ||

| WCS | 0.782 | 0.423 | 0.745 | −0.046 | 0.655 | 0.826 | 0.818 | 0.697 | 0.662 | 0.785 | 1 |

| (0.000) | (0.000) | (0.000) | 0.701 | (0.000) | (0.000) | (0.000) | (0.000) | (0.000) | (0.000) | (0.000) |

| NRW | Model (1) | Model (2) |

|---|---|---|

| LDI | 0.0207 | −0.0058 |

| 0.089 | (−0.126) | |

| LMS | 0.0842 ** | 0.0849 ** |

| 6.019 | 3.347 | |

| LPE | 0.071 ** | 0.0687 * |

| 4.395 | 4.699 | |

| LOP | 0.013 | −0.0037 |

| 0.997 | (−0.594) | |

| DVC | 0.7567 | |

| 1.627 | ||

| NDVC | −0.5648 | |

| (−0.668) | ||

| WSIS | 0.1329 | |

| 1.228 | ||

| WSIUS | −0.0032 | |

| (−1.236) | ||

| POPSER | −0.0857 | |

| (−1.251) | ||

| WSC | 0.0009 | |

| 0.304 | ||

| Year fixed-effect | Included | Included |

| R-Squared | 0.8821 | 0.9179 |

| Adjusted R2 | 0.8666 | 0.8970 |

| N observations | 70 | 70 |

| F-Statistics | 57.05 | 43.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jones, L.J.N.; Kong, D.; Tan, B.T.; Rassiah, P. Non-Revenue Water in Malaysia: Influence of Water Distribution Pipe Types. Sustainability 2021, 13, 2310. https://doi.org/10.3390/su13042310

Jones LJN, Kong D, Tan BT, Rassiah P. Non-Revenue Water in Malaysia: Influence of Water Distribution Pipe Types. Sustainability. 2021; 13(4):2310. https://doi.org/10.3390/su13042310

Chicago/Turabian StyleJones, Lim Jen Nee, Daniel Kong, Boon Thong Tan, and Puspavathy Rassiah. 2021. "Non-Revenue Water in Malaysia: Influence of Water Distribution Pipe Types" Sustainability 13, no. 4: 2310. https://doi.org/10.3390/su13042310

APA StyleJones, L. J. N., Kong, D., Tan, B. T., & Rassiah, P. (2021). Non-Revenue Water in Malaysia: Influence of Water Distribution Pipe Types. Sustainability, 13(4), 2310. https://doi.org/10.3390/su13042310