Multi-Criteria Selection of Additives in Porous Asphalt Mixtures Using Mechanical, Hydraulic, Economic, and Environmental Indicators

Abstract

1. Introduction

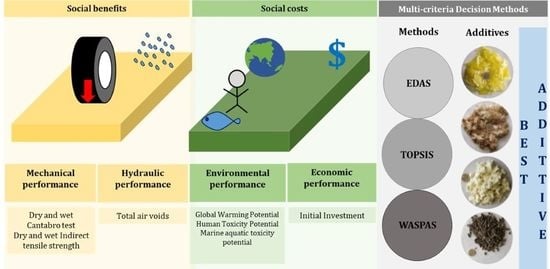

2. Methodology

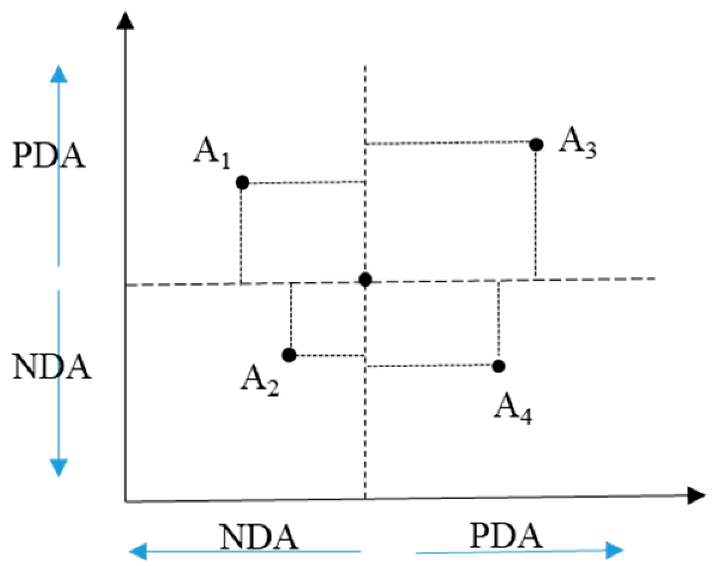

2.1. Multi-Criteria Decision-Making Methods (MCDMs)

2.2. Materials and Alternatives

2.3. Selection of Indicator

2.3.1. Mechanical Indicators

2.3.2. Hydraulic Indicators

2.3.3. Economic Indicators

2.3.4. Environmental Indicator

- CELLU fibers contain 90% cellulose fiber and 10% bitumen. According to the provider, cellulose fibers contain recycled waste paper, its percentage varying depending on its quality. For the analysis, waste paper fibers were used as the main raw material.

- ARA-POL is composed of 13% aramid fiber and 87% polyolefin fiber. As no information regarding the type of polyolefin used was found, polystyrene was assumed for this work.

- The production process for aramid fiber (ARA) is available in GaBi, but for aramid pulp (PULP) it is not available. As the manufacturer published the manufacturing process and the GWP impact of both materials, the difference among them was solely due to an increase in electricity consumption while manufacturing PULP.

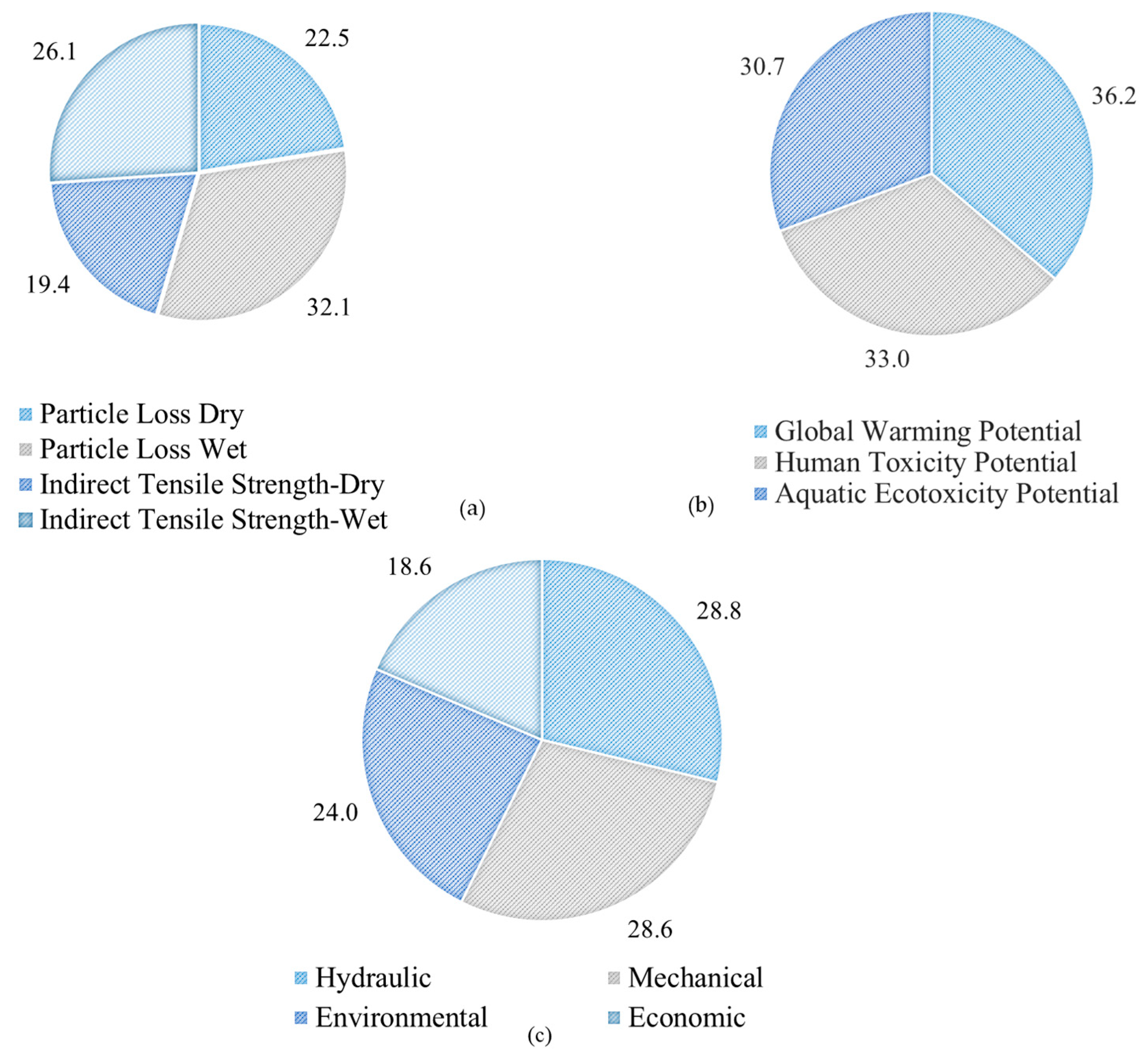

2.4. Computation of Relative Weights

2.4.1. The Relative Weight of Mechanical Indicators

2.4.2. Relative Weights of Environmental Indicators

2.4.3. Comparison of Indicators

3. Results and Discussion

3.1. Mechanical Indicators

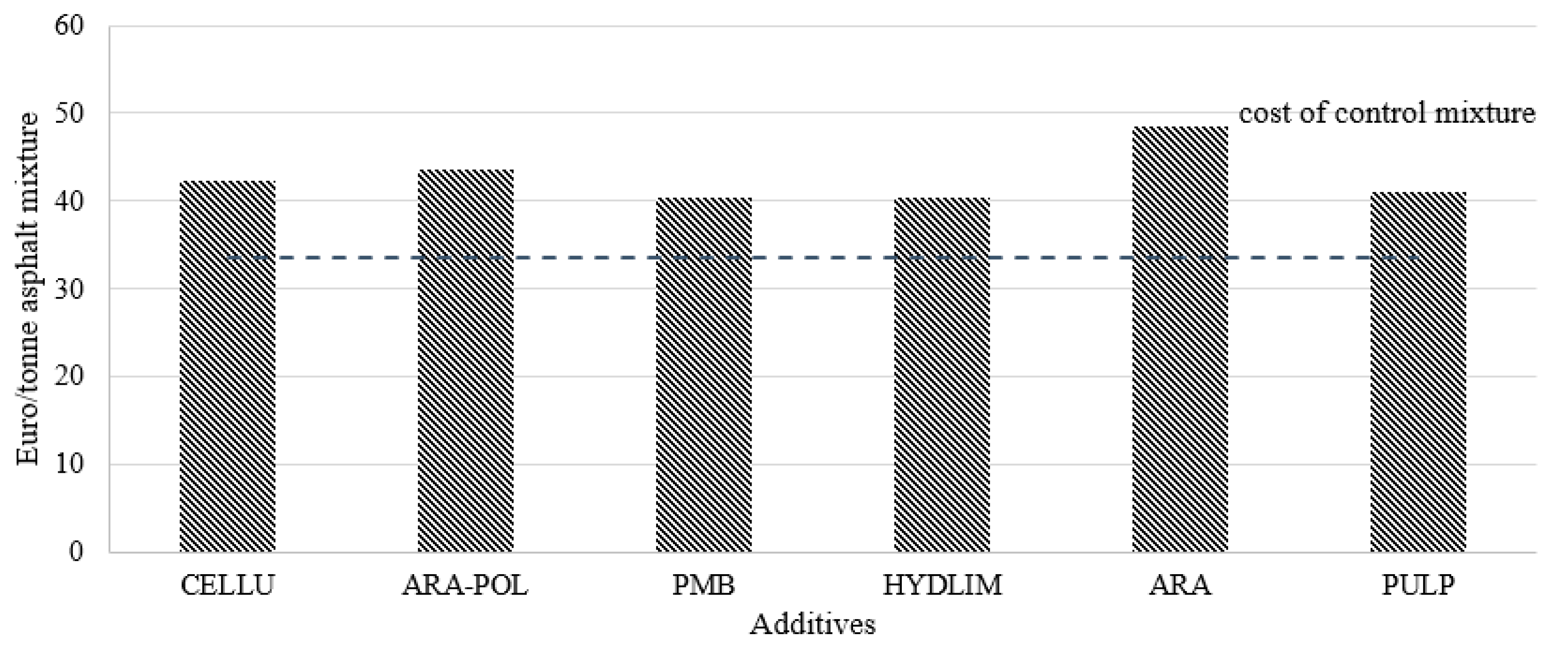

3.2. Hydraulic and Economic Indicators

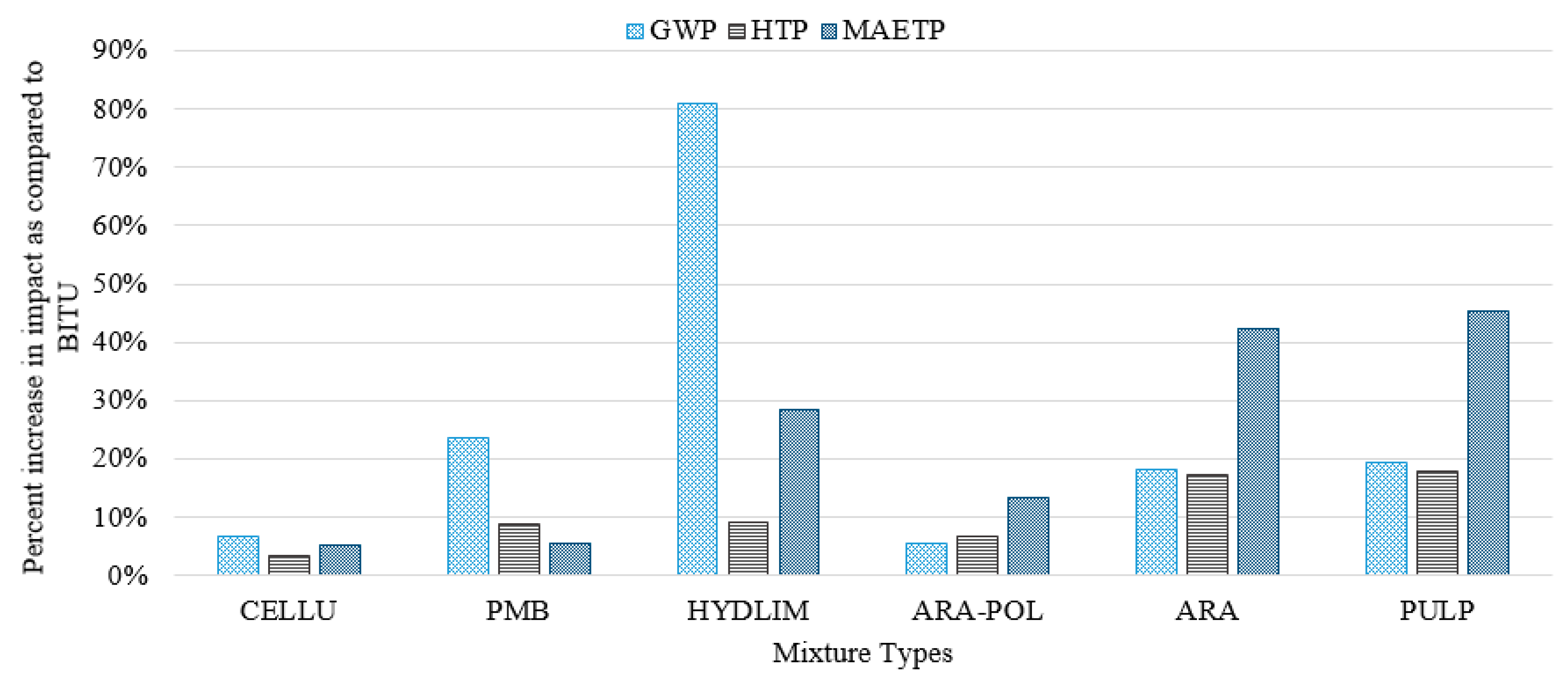

3.3. Environmental Indicators

3.4. Ranking of Indicators

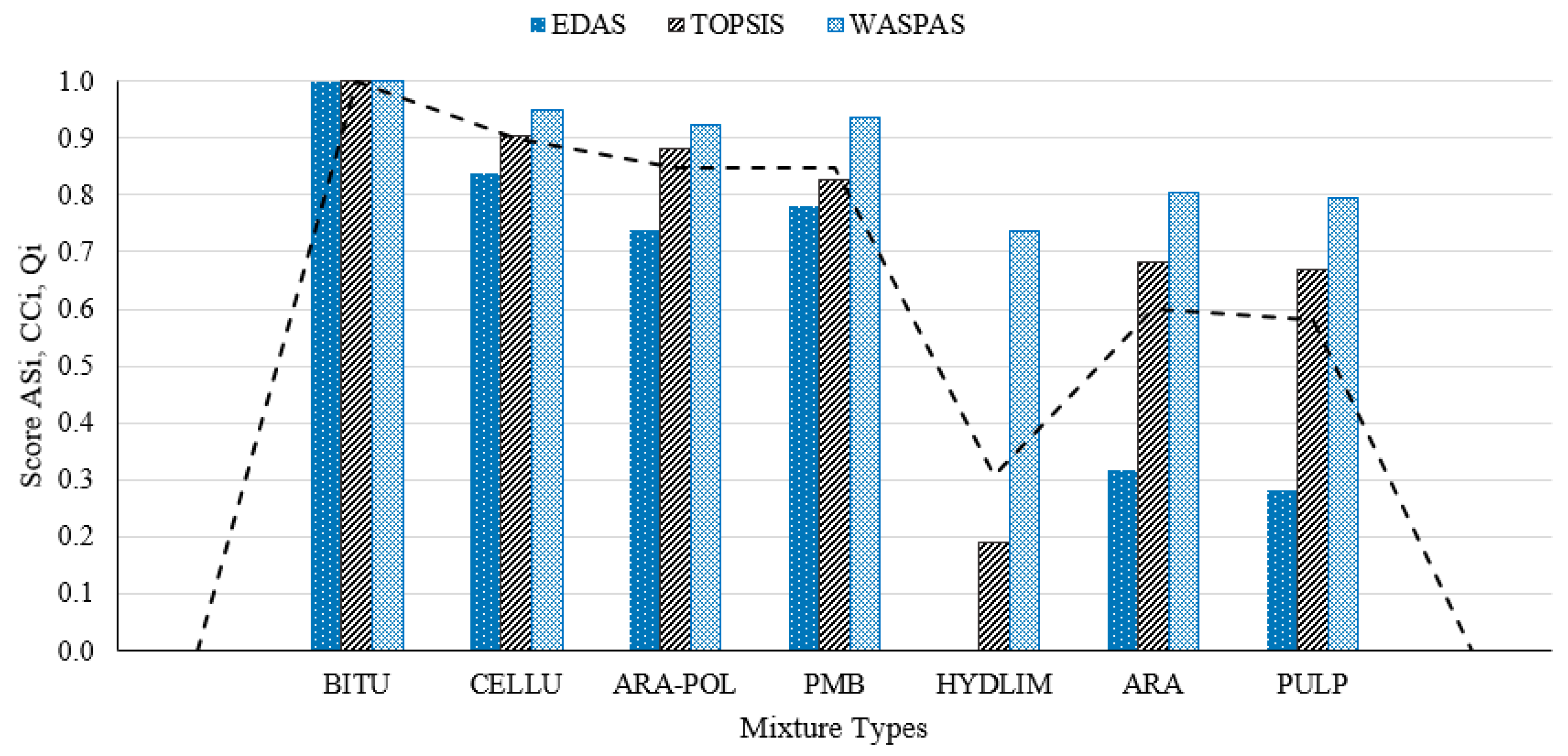

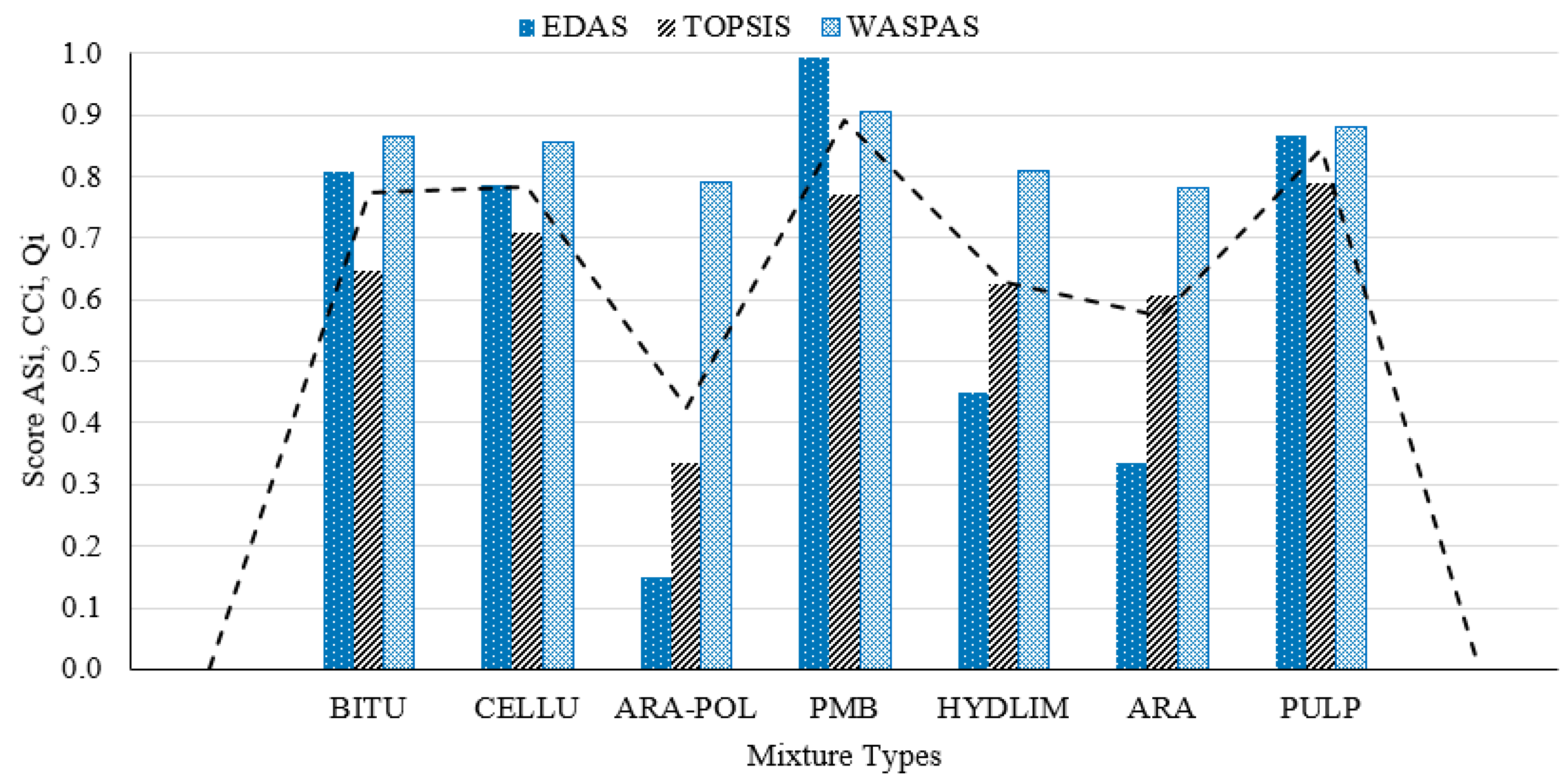

3.5. Discussion of Multi-Criteria Decision-Making Methods

4. Conclusions

- According to the Delphi method, experts gave the highest relative weights to abrasion loss in wet conditions in mechanical resistance as it poses a serious concern for porous asphalt mixtures due to their open-graded structure. Meanwhile, for the environmental indicator, the highest relative weight was allotted to global warming potential.

- The additives improved the mechanical performance of the PA mixtures. The highest scores were observed for the porous asphalt mixtures with PULP fibers according to all three methods. Additionally, mixtures with aramid pulp exhibited highest abrasion resistance, whereas with aramid-polyolefin fibers showed the lowest abrasion resistance.

- The additives did not compromise the hydraulic characteristics of the PA mixtures severely. The scores were given in the order (best to worst): ARA > HYDLIM > PMB > ARA-POL > PULP > CELLU. Although cellulose fiber displayed the lowest air voids content, no significant reduction was observed compared to the reference mixture.

- Concerning the economic indicator, the highest score was given to mixtures with hydrated lime. This was closely followed by the aramid pulp, which was a waste product during the manufacturing of the aramid fibers, requiring the least initial investment among all the fibers included in the study.

- The environmental indicator suggested that the additives had a higher impact on the environment. However, the addition of cellulose fiber (the only natural fiber tested) had the least impact on the environment, whereas the hydrated lime had the highest impact on global warming potential.

- The three multi-criteria decision-making methods used (EDAS, TOPSIS, and WASPAS) have shown very good agreement, especially for the mechanical indicators. EDAS and WASPAS have shown higher agreement compared to EDAS and TOPSIS or TOPSIS and WASPAS.

- Overall, the use of aramid pulp and cellulose fibers is recommended in PA mixtures based on mechanical, hydraulic, economic, and environmental indicators. On the one hand, aramid pulp (a waste product) had been shown to have enhanced the mechanical characteristics considerably, while on the other hand, cellulose fibers had the lowest impact on the environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Pouranian, M.R.; Shishehbor, M. Sustainability assessment of green asphalt mixtures: A review. Environments 2019, 6, 73. [Google Scholar] [CrossRef]

- Landi, D.; Marconi, M.; Bocci, E.; Germani, M. Comparative life cycle assessment of standard, cellulose-reinforced and end of life tires fiber-reinforced hot mix asphalt mixtures. J. Clean. Prod. 2020, 248, 119295. [Google Scholar] [CrossRef]

- David, K.H. Structural and Hydrological Design of Permeable Pavements. In Proceedings of the Annual Conference of Transport Association Canada Halifax, Halifax, NS, Canada, 26–29 September 2010. [Google Scholar]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Calzada-Pérez, M.A.; Castro-Fresno, D. Effect of synthetic fibers and hydrated lime in porous asphalt mixture using multi-criteria decision-making techniques. Materials 2020, 13, 675. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.; Jian, L. The Effect of Fiber on the Performance of Open Graded Friction Course (An Environmental Survey). Ekoloji 2019, 28, 4891–4895. [Google Scholar]

- Tanzadeh, R.; Tanzadeh, J.; Amid, S. Experimental study on the effect of basalt and glass fibers on behavior of open-graded friction course asphalt modified with nano-silica. Constr. Build. Mater. 2019, 212, 467–475. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D. Laboratory assessment of porous asphalt mixtures reinforced with synthetic fibers. Constr. Build. Mater. 2020, 234, 117224. [Google Scholar] [CrossRef]

- Norgbey, E.; Huang, J.; Hirsch, V.; Liu, W.J.; Wang, M.; Ripke, O.; Li, Y.; Annan, G.E.T.; Ewusi-Mensah, D.; Wang, X.; et al. Unravelling the efficient use of waste lignin as a bitumen modifier for sustainable roads. Constr. Build. Mater. 2020, 230, 116957. [Google Scholar] [CrossRef]

- Wurst, J.E.; Putman, B.J. Laboratory Evaluation of Warm-Mix Open Graded Friction Course Mixtures. J. Mater. Civ. Eng. 2013, 25, 403–410. [Google Scholar] [CrossRef][Green Version]

- Senior-Arrieta, V.; Córdoba-Maquilón, J.E. Mechanical characterization of porous asphalt mixes modified with fatty acid amides -FAA-[Caracterización mecánica de mezclas asfálticas porosas modificadas con amidas de ácidos grasos]. Ing. Investig. 2017, 37, 43–48. [Google Scholar]

- Renken, L.; Li, T.; Lu, G.; Oeser, M.; Wang, D.; Li, H. Experimental study on the polyurethane-bound pervious mixtures in the application of permeable pavements. Constr. Build. Mater. 2019, 202, 838–850. [Google Scholar] [CrossRef]

- Chen, J.-S.; Lin, K.-Y. Mechanism and Behavior of Bitumen Strength Reinforcement Using Fibers. J. Mater. Sci. 2005, 40, 87–95. [Google Scholar] [CrossRef]

- Enieb, M.; Diab, A.; Yang, X. Short- and long-term properties of glass fiber reinforced asphalt mixtures. Int. J. Pavement Eng. 2019, 22, 64–76. [Google Scholar] [CrossRef]

- Lastra-González, P.; Indacoechea-Vega, I.; Calzada-Pérez, M.A.; Castro-Fresno, D. Recyclability potential of induction-healable porous asphalt mixtures. Sustainability 2020, 12, 9962. [Google Scholar] [CrossRef]

- Luo, D.; Khater, A.; Yue, Y.; Abdelsalam, M.; Zhang, Z.; Li, Y.; Li, J.; Iseley, D.T. The performance of asphalt mixtures modified with lignin fiber and glass fiber: A review. Constr. Build. Mater. 2019, 209, 377–387. [Google Scholar] [CrossRef]

- Shukry, N.A.M.; Hassan, N.A.; Abdullah, M.E.; Hainin, M.R.; Yusoff, N.I.M.; Jaya, R.P.; Mohamed, A. Effect of various filler types on the properties of porous asphalt mixture. IOP Conf. Ser. Mater. Sci. Eng. 2018, 342, 012036. [Google Scholar] [CrossRef]

- Ma, X.; Li, Q.; Cui, Y.C.; Ni, A.Q. Performance of porous asphalt mixture with various additives. Int. J. Pavement Eng. 2018, 19, 355–361. [Google Scholar] [CrossRef]

- Hu, X.; Dai, K.; Pan, P. Investigation of engineering properties and filtration characteristics of porous asphalt concrete containing activated carbon. J. Clean. Prod. 2019, 209, 1484–1493. [Google Scholar] [CrossRef]

- Chen, J.S.; Sun, Y.C.; Liao, M.C.; Huang, C.C.; Tsou, K.W. Evaluation of permeable friction course mixes with various binders and additives. J. Mater. Civ. Eng. 2013, 25, 573–579. [Google Scholar] [CrossRef]

- Andrés-Valeri, V.C.; Marchioni, M.; Sañudo-Fontaneda, L.A.; Giustozzi, F.; Becciu, G. Laboratory assessment of the infiltration capacity reduction in clogged porous mixture surfaces. Sustainability 2016, 8, 751. [Google Scholar] [CrossRef]

- Marzouk, M.; Elzayat, M.; Aboushady, A. Assessing environmental impact indicators in road construction projects in developing countries. Sustainability 2017, 9, 843. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Lizasoain-Arteaga, E.; Lastra-González, P.; Castro-Fresno, D. Mechanical, environmental and economic feasibility of highly sustainable porous asphalt mixtures. Constr. Build. Mater. 2020, 251. [Google Scholar] [CrossRef]

- Eghtesadifard, M.; Afkhami, P.; Bazyar, A. An integrated approach to the selection of municipal solid waste landfills through GIS, K-Means and multi-criteria decision analysis. Environ. Res. 2020, 185, 109348. [Google Scholar] [CrossRef]

- Cao, W.; Wang, A.; Yu, D.; Liu, S.; Hou, W. Establishment and implementation of an asphalt pavement recycling decision system based on the analytic hierarchy process. Resour. Conserv. Recycl. 2019, 149, 738–749. [Google Scholar] [CrossRef]

- Torres-Machi, C.; Nasir, F.; Achebe, J.; Saari, R.; Tighe, S.L. Sustainability Evaluation of Pavement Technologies through Multicriteria Decision Techniques. J. Infrastruct. Syst. 2019, 25, 1–10. [Google Scholar] [CrossRef]

- Loc, H.H.; Duyen, P.M.; Ballatore, T.J.; Lan, N.H.M.; Gupta, A.D. Applicability of sustainable urban drainage systems: An evaluation by multi-criteria analysis. Environ. Syst. Decis. 2017, 37, 332–343. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Yiwo, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J.C. Design and application of a Sustainable Urban Surface Rating System (SURSIST). Ecol. Indic. 2018, 93, 1253–1263. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Indacoechea-Vega, I.; Gáspár, L.; Castro-Fresno, D. Decision Support Model for the Selection of Asphalt Wearing Courses in Highly Trafficked Roads. Soft Comput. 2018, 22, 7407–7421. [Google Scholar] [CrossRef]

- Saaty, R.W. The analytic hierarchy process-what it is and how it is used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Shrestha, K.K.; Shrestha, P.P. Change Orders on Road Maintenance Contracts: Causes and Preventive Measures. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2019, 11, 1–11. [Google Scholar] [CrossRef]

- Jiménez Ariza, S.L.; Martínez, J.A.; Muñoz, A.F.; Quijano, J.P.; Rodríguez, J.P.; Camacho, L.A.; Díaz-Granados, M. A multicriteria planning framework to locate and select sustainable urban drainage systems (SUDS) in consolidated urban areas. Sustainability 2019, 11, 2312. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Pascual-Muñoz, P.; Lastra-González, P.; Castro-Fresno, D. A multi-criteria decision-making analysis for the selection of fibres aimed at reinforcing asphalt concrete mixtures. Int. J. Pavement Eng. 2019, 1–17. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J.; Zakarevicius, A. Optimization of Weighted Aggregated Sum Product Assessment. Elektron. Elektrotech. 2012, 122, 3–6. [Google Scholar] [CrossRef]

- Badalpur, M.; Nurbakhsh, E. An application of WASPAS method in risk qualitative analysis: A case study of a road construction project in Iran. Int. J. Constr. Manag. 2019, 1–9. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications; Springer: Berlin/Heidelberg, Germany, 1981; Available online: https://www.springer.com/gp/book/9783540105589 (accessed on 14 August 2020).

- Zavadskas, E.K.; Kalibatas, D.; Kalibatiene, D. A multi-attribute assessment using WASPAS for choosing an optimal indoor environment. Arch. Civ. Mech. Eng. 2016, 16, 76–85. [Google Scholar] [CrossRef]

- Toosi, E.S.; Tousi, S.G.; Ghassemi, A.; Cheshomi, A.; Alaghmand, S. A multi-criteria decision analysis approach towards efficient rainwater harvesting. J. Hydrol. 2020, 582, 124501. [Google Scholar] [CrossRef]

- Vilutienė, T.; Zavadskas, E.K. The application of multi-criteria analysis to decision support for the facility management of a residential district. J. Civ. Eng. Manag. 2003, 9, 241–252. [Google Scholar] [CrossRef]

- Ghorabaee, M.K.; Zavadskas, E.K.; Olfat, L.; Turskis, Z. Multi-Criteria Inventory Classification Using a New Method of Evaluation Based on Distance from Average Solution (EDAS). Inf. Neth. 2015, 26, 435–451. [Google Scholar] [CrossRef]

- Wu, S.P.; Gang, L.I.; Mo, L.T.; Zheng, C.H.; Ye, Q.S. Influence of Fiber Types on Relevant Properties of Porous Asphalt. Wuhan Ligong Daxue Xuebao J. Wuhan Univ. Technol. 2006, 28, 50–52. [Google Scholar] [CrossRef]

- Afonso, M.L.; Dinis-Almeida, M.; Fael, C.S. Study of the porous asphalt performance with cellulosic fibres. Constr. Build. Mater. 2017, 135, 104–111. [Google Scholar] [CrossRef]

- Lyons, K.R.; Putman, B.J. Laboratory evaluation of stabilizing methods for porous asphalt mixtures. Constr. Build. Mater. 2013, 49, 772–780. [Google Scholar] [CrossRef]

- Chen, M.J.; Wong, Y.D. Porous Asphalt Mixture with a Combination of Solid Waste Aggregates. J. Mater. Civ. Eng. 2014, 27, 04014194. [Google Scholar] [CrossRef]

- Chen, J.-S.; Sun, Y.-C.; Liao, M.-C.; Huang, C.-C. Effect of Binder Types on Engineering Properties and Performance of Porous Asphalt Concrete. Transp. Res. Rec. 2012, 2293, 55–62. [Google Scholar] [CrossRef]

- Zhen, L.; Xiong, Y. Multiscale Chemico-Thermo-Hydro-Mechanical Modeling of Early-Stage Hydration and Shrinkage of Cement Compounds. J. Mater. Civ. Eng. 2013, 25, 1239–1247. [Google Scholar] [CrossRef]

- Massahi, H.A.; Koohifar, F.; Baqersad, M. Investigation of pavement raveling performance using smartphone. Int. J. Pavement Res. Technol. 2018, 11, 553–563. [Google Scholar] [CrossRef]

- Arrieta, V.S.; Maquilón, J.E.C. Resistance to Degradation or Cohesion Loss in Cantabro Test on Specimens of Porous Asphalt Friction Courses. Procedia Soc. Behav. Sci. 2014, 162, 290–299. [Google Scholar] [CrossRef]

- Frigio, F.; Stimilli, A.; Virgili, A.; Canestrari, F. Performance Assessment of Plant-Produced Warm Recycled Mixtures for Open-Graded Wearing Courses. Transp. Res. Rec. 2017, 2633, 16–24. [Google Scholar] [CrossRef]

- Liu, Q.; Yu, W.; Schlangen, E.; van Bochove, G. Unravelling porous asphalt concrete with induction heating. Constr. Build. Mater. 2014, 71, 152–157. [Google Scholar] [CrossRef]

- Mahmud, M.Z.H.; Hassan, N.A.; Hainin, M.R.; Ismail, C.R. Microstructural Investigation on Air Void Properties of Porous Asphalt Using Virtual Cut Section. Constr. Build. Mater. 2017, 155, 485–494. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, H.; Wang, Y. Interaction of asphalt and water between porous asphalt pavement voids with different aging stage and its significance to drainage. Constr. Build. Mater. 2020, 252, 119085. [Google Scholar] [CrossRef]

- Rasool, R.t.; Hongru, Y.; Hassan, A.; Wang, S.; Zhang, H. In-field aging process of high content SBS modified asphalt in porous pavement. Polym. Degrad. Stab. 2018, 155, 220–229. [Google Scholar] [CrossRef]

- Lizasoain-Arteaga, E.; Indacoechea-Vega, I.; Pascual-Muñoz, P.; Castro-Fresno, D. Environmental impact assessment of induction-healed asphalt mixtures. J. Clean. Prod. 2019, 208, 1546–1556. [Google Scholar] [CrossRef]

- Abbe, O.; Hamilton, L. BRE Global Environmental Weighting for Construction Products Using Selected Parameters from EN 15804; BRE Global Ltd.: Hertfordshire, UK, 2017. [Google Scholar]

- Huppes, G.; van Oers, L. Evaluation of Weighting Methods for Measuring the EU-27 Overall Environmental Impact; Institute for Environment and Sustainability: Luxembourg, 2011. [Google Scholar]

- Lizasoain-Arteaga, E.; Castro-Fresno, D.; Flintsch, G.W. Effect of durability on fiber-reinforced asphalt mixtures sustainability. In Pavement, Roadway, and Bridge Life Cycle Assessment 2020, Proceedings of the International Symposium on Pavement. Roadway, and Bridge Life Cycle Assessment 2020 (LCA 2020), Sacramento, CA, USA, 3–6 June 2020; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar] [CrossRef]

- Rodriguez-Hernandez, J.; Andrés-Valeri, V.C.; Calzada-Pérez, M.A.; Vega-Zamanillo, Á.; Castro-Fresno, D. Study of the Raveling Resistance of Porous Asphalt Pavements Used in Sustainable Drainage Systems Affected by Hydrocarbon Spills. Sustainability 2015, 7, 16226–16236. [Google Scholar] [CrossRef]

- Opara, K.R.; Skakuj, M.; Stöckner, M. Factors affecting raveling of motorway pavements—A field experiment with new additives to the deicing brine. Constr. Build. Mater. 2016, 113, 174–187. [Google Scholar] [CrossRef]

- Tang, G.; Gao, L.; Ji, T.; Xie, J. Study on the Resistance of Raveling for Porous Asphalt Pavement. In Proceedings of the 2018 International Conference on Transportation Infrastructure and Materials (ICTIM 2017), Tianjin, China, 1–4 June 2018; ISBN 978-1-60595-442-4. Available online: https://www.mdpi.com/2071-1050/7/12/15812 (accessed on 8 May 2019).

- Gupta, A.; Castro-Fresno, D.; Lastra-Gonzalez, P.; Rodriguez-Hernandez, J. Selection of fibers to improve porous asphalt mixtures using multi-criteria analysis. Constr. Build. Mater. 2020, 266, 121198. [Google Scholar] [CrossRef]

- Gupta, A.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Incorporation of additives and fibers in porous asphalt mixtures: A review. Materials 2019, 12, 3156. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Rodriguez-Hernandez, J.; Slebi, C.; Castro-Fresno, D. Improving porous asphalt mixes by incorporation of additives. Transp. Res. Arena 2020. [Google Scholar] [CrossRef]

- Tholibon, D.A.; Ariffin, J.; Abdullah, J.; Idrus, J. Experimental Evaluation of Anti-Stripping Additives on Porous Asphalt Mixtures. J. Teknol. 2016, 3, 1–6. Available online: https://journals.utm.my/index.php/jurnalteknologi/article/view/9502 (accessed on 15 May 2019).

| EDAS | TOPSIS | WASPAS |

|---|---|---|

| Full form | ||

| Evaluation Distance from Average Solution | Technique for Order Preference by Similarity to Ideal Solution | Weighted aggregated sum product assessment |

| 1. Construct the decision-making matrix | ||

| X = [xij]mxn = (i = 1, 2, 3, …, m and j = 1, 2, 3, …, n) Xij gives the performance of the ith alternative with respect to the jth criterion | ||

| 2. PDA and NDA | 2. Normalize the decision matrix | |

| Beneficial criteria The positive distance from average (PDAij) and negative distance from average (NDAij) is calculated as: , | ij = | Beneficial criteria ij |

| Non-beneficial criteria , is the average solution according to all criteria j.  | Non-beneficial criteria ij = | |

| 3. Weighted normalized decision matrix | ||

| = Where refers to the weight of jth criterion. | WASPAS is a combination of two methods Weighted Sum Model (WSM) and Weighted Product Model (WPM) | |

| 4. Normalize the Matrix | 4. Positive and negative ideal solutions | |

NSNi = 1 − | Positive ideal solutions (Q+) , J)} Negative ideal solutions (Q−) , J)} Where I relates to beneficial criteria; I = 1, 2, 3, …, m and J related to non-beneficial criteria j = 1, 2, 3, …, n. Positive solutions () and negative solutions distance = = | |

| 5. Calculate the relative scores | ||

| Appraisal score (ASi) (NSPi + NSNi) Where 0 ≤ ASi ≥ | Relative closeness (CCi) | Joint Performance score (Qi) Where, |

| Scheme 22. | 22 | 16 | 8 | 4 | 2 | 1 | 0.5 | 0.25 | 0.063 |

|---|---|---|---|---|---|---|---|---|---|

| Passing (%) | 100 | 100 | 54.5 | 19.0 | 14.1 | 10.3 | 7.8 | 6.3 | 5.0 |

| Fiber | Aramid-Polyolefin Fiber | Aramid Pulp | Aramid Fiber | Cellulose | |

|---|---|---|---|---|---|

| Aramid | Polyolefin | ||||

| Form | Monofilament | Serrated | |||

| Color | Yellow | Yellow | Yellow | Yellow | Brown |

| Density (g/cm3) | 1.44 | 0.91 | 1.44 | 1.39 | 0.48 |

| Length (mm) | 19 | 19 | 1–1.5 | 6 | 1.1 |

| Tensile Strength (MPa) | 2758 | 483 | 3200 | ||

| Decomposition temperature (°C) | >450 | 157 | >450 | 500 | |

| Acid/Alkali Resistance | Inert | Inert | |||

| Properties | Standards | Value | Specification | |

|---|---|---|---|---|

| Bitumen | ||||

| Virgin bitumen | PMB | |||

| Penetration (0.1 mm) | EN-1426 | 57 | 55 | 50–70 |

| Softening Point (°C) | EN-1427 | 51.6 | 74.1 | 46–54 |

| Frass Point (°C) | EN-12593 | −13 | ≤−8 | |

| Specific Weight (g/cc) | EN-15326 | 1.035 | 1.028 | |

| Coarse aggregates | ||||

| Specific Weight (g/cm3) | EN 1097-6 | 2.787 | 8/4 | |

| Los Angeles (%) | EN 1097-2 | 15 | 14/10 | ≤15% |

| Flakiness Index (%) | EN 933-3 | 12 | 12/6 | ≤20% |

| Flakiness Index (%) | EN 933-4 | 20 | 18/12 | |

| Fine aggregates | ||||

| Specific Weight (g./cm3) | EN 1097-6 | 2.705 | ||

| Sand equivalent (%) | EN 933-8 | 78 | >55 | |

| Hydrated Lime | ||||

| Density (g/cm3) | 1.959 | |||

| CaO content (%) | ≥90 | |||

| MgO content (%) | ≤5 | |||

| CO2 content (%) | ≤4 | |||

| Remained on sieve 0.2 mm (%) | ≤2 | |||

| Mixture types | BITU | PMB | HYDLIM | ARA-POL | PULP | ARA | CELLU |

|---|---|---|---|---|---|---|---|

| Type of Bitumen; Bitumen Content (%) | Virgin bitumen; 4.5% | PMB bitumen; 4.5% | Virgin bitumen; 4.5% | Virgin bitumen; 4.5% | Virgin bitumen; 4.5% | Virgin bitumen; 4.5% | Virgin bitumen; 5% |

| Fiber; fiber Content (%) | None | None | None | Aramid-Polyolefin fiber; 0.05% | Aramid Pulp; 0.05% | Aramid fiber; 0.05% | Cellulose fiber; 0.5% |

| Filler | Limestone | Limestone | Hydrated lime | Limestone | Limestone | Limestone | Limestone |

| Mixtures/Criteria | CELLU | ARA-POL | PMB | HYDLIM | ARA | PULP |

|---|---|---|---|---|---|---|

| PL—dry (% reduction) | ➚18.73 | ➚10.65 | ➚24.56 | ➘6.46 | ➚0.69 | ➚58.82 |

| PL—wet (% reduction) | ➚38.05 | ➘94.68 | ➚47.17 | ➚30.21 | ➚24.84 | ➚55.04 |

| ITS—dry (% rise) | ➚6.58 | ➚10.52 | ➚8.27 | ➚18.98 | ➚10.32 | ➚0.87 |

| ITS—wet (% rise) | ➚27.32 | ➚21.71 | ➚27.03 | ➚11.41 | ➘7.27 | ➚13.39 |

| Mixtures/Criteria | CELLU | ARA-POL | PMB | HYDLIM | ARA | PULP |

|---|---|---|---|---|---|---|

| Percentage variation (%) | ➘8.19 | ➘1.64 | ➘0.09 | ➚0.16 | ➚0.51 | ➘4.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, A.; Slebi-Acevedo, C.J.; Lizasoain-Arteaga, E.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Multi-Criteria Selection of Additives in Porous Asphalt Mixtures Using Mechanical, Hydraulic, Economic, and Environmental Indicators. Sustainability 2021, 13, 2146. https://doi.org/10.3390/su13042146

Gupta A, Slebi-Acevedo CJ, Lizasoain-Arteaga E, Rodriguez-Hernandez J, Castro-Fresno D. Multi-Criteria Selection of Additives in Porous Asphalt Mixtures Using Mechanical, Hydraulic, Economic, and Environmental Indicators. Sustainability. 2021; 13(4):2146. https://doi.org/10.3390/su13042146

Chicago/Turabian StyleGupta, Anik, Carlos J. Slebi-Acevedo, Esther Lizasoain-Arteaga, Jorge Rodriguez-Hernandez, and Daniel Castro-Fresno. 2021. "Multi-Criteria Selection of Additives in Porous Asphalt Mixtures Using Mechanical, Hydraulic, Economic, and Environmental Indicators" Sustainability 13, no. 4: 2146. https://doi.org/10.3390/su13042146

APA StyleGupta, A., Slebi-Acevedo, C. J., Lizasoain-Arteaga, E., Rodriguez-Hernandez, J., & Castro-Fresno, D. (2021). Multi-Criteria Selection of Additives in Porous Asphalt Mixtures Using Mechanical, Hydraulic, Economic, and Environmental Indicators. Sustainability, 13(4), 2146. https://doi.org/10.3390/su13042146